Self-protection core welding stick used for underwater wet welding

A flux-cored wire and wet welding technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as foreign technical constraints, and achieve good re-starting, excellent mechanical properties, and arc combustion. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below.

[0019] In order to better embody the present invention, the following examples are used to illustrate, but not to limit the present invention.

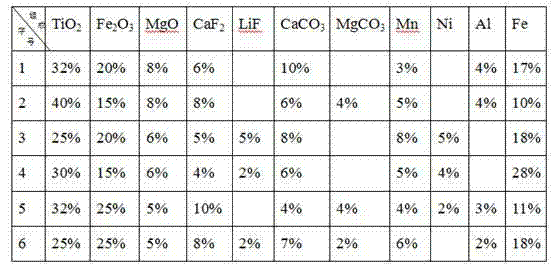

[0020] Prepare the powder according to the above ratio, balance it with iron powder, adjust the composition and content of the core powder, as shown in Table 1, prepare 6 different flux cored wires, and the particle size of the core powder is 80 mesh.

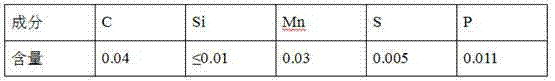

[0021] The preparation method of the self-shielding flux-cored welding wire of the present invention is as follows: an ordinary low-carbon steel strip is selected, the chemical composition is shown in Table 2, and the specification of the steel strip is: 0.3mm×8mm. On the ordinary flux-cored wire production line, the flux-cored wire with cross-section "O" is prepared, the diameter of the wire is Φ1.6mm, and the filling rate of the flux core is 25%-33%.

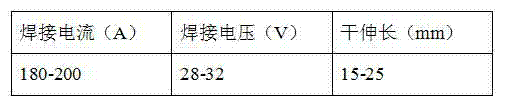

[0022] The welding base material used in the embodiment of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com