Patents

Literature

69results about "Electric arc spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

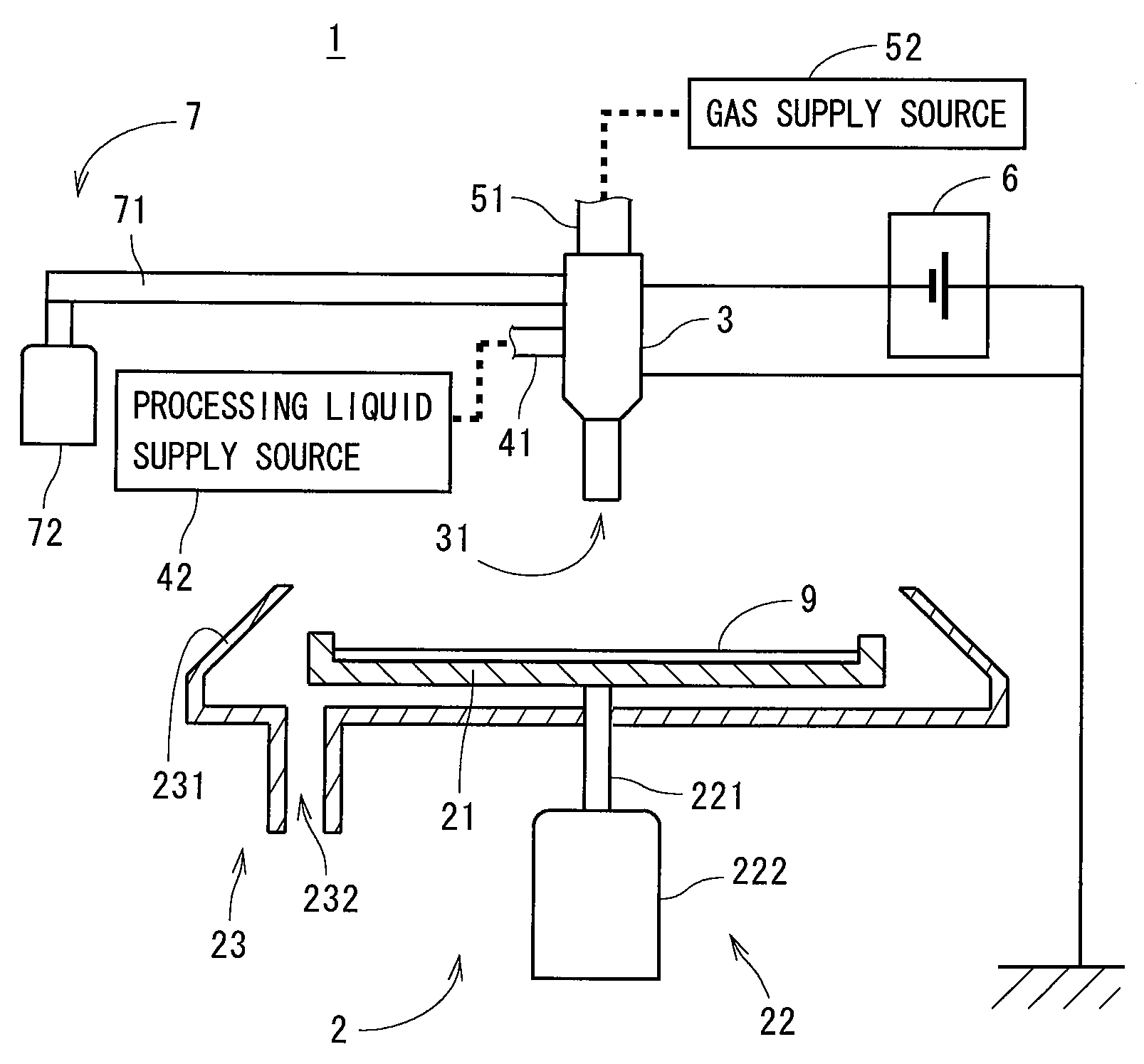

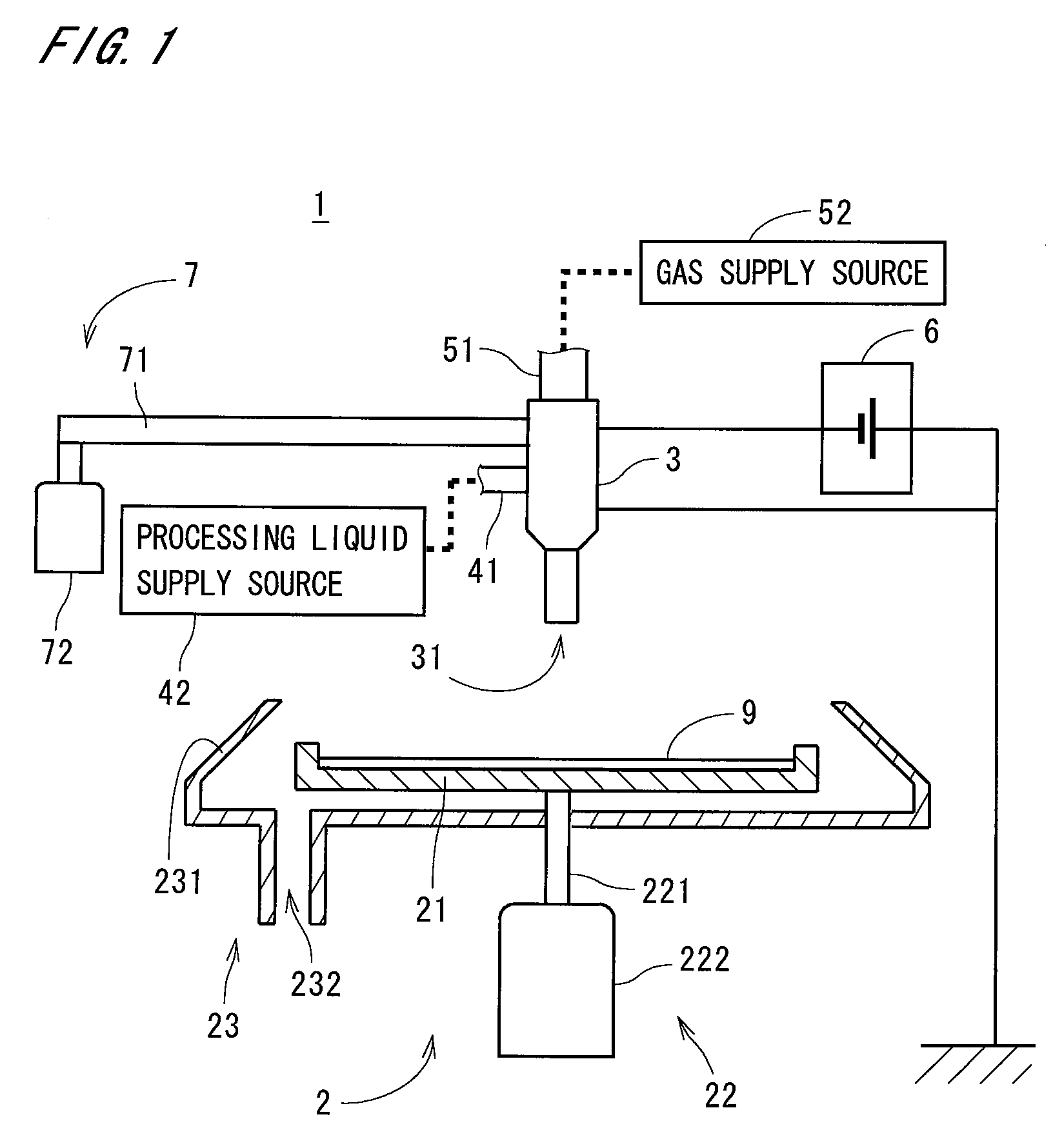

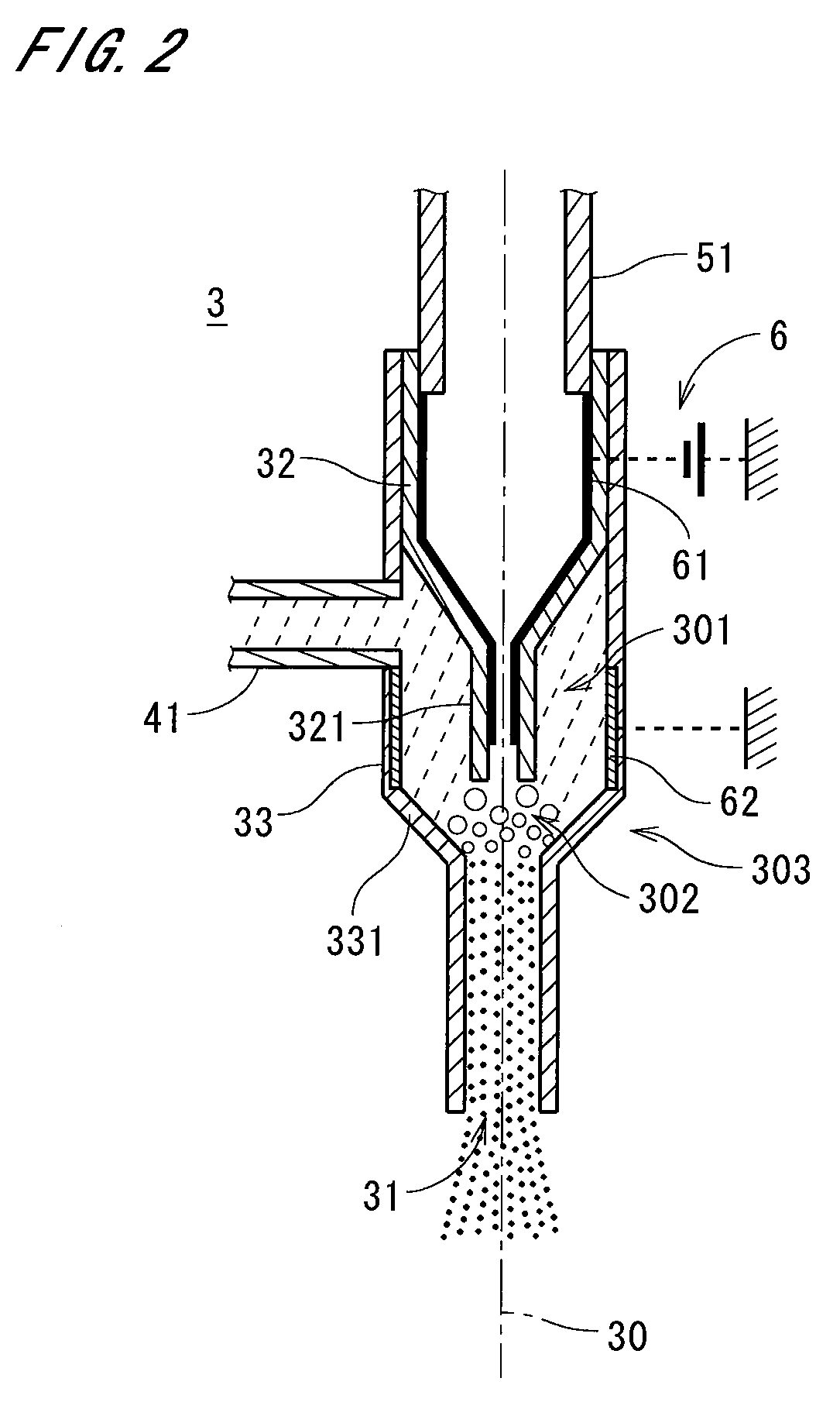

Two-fluid nozzle, substrate processing apparatus, and substrate processing method

InactiveUS20080173327A1Efficiently charge dropletEasy constructionBurnersSludge treatmentEngineeringMechanical engineering

A substrate processing apparatus has a two-fluid nozzle having an inner cylindrical member and an outer cylindrical member. Gas flows in the inner cylindrical member which is a gas passage and the processing liquid downwardly flows in a processing liquid passage constituted of the inner and outer cylindrical members. The gas and the processing liquid are mixed in a mixing area below the inner cylindrical member to generate fine droplets, and the droplets are ejected from an outlet of a lower end of the outer cylindrical member onto a substrate. Charge is induced on the processing liquid by generating an electric potential difference between a first electrode provided in the gas passage and a second electrode provided in the processing liquid passage, to generate charged droplets. In the nozzle, the first electrode is isolated from the processing liquid with a simple construction, and the droplets can be charged efficiently.

Owner:DAINIPPON SCREEN MTG CO LTD

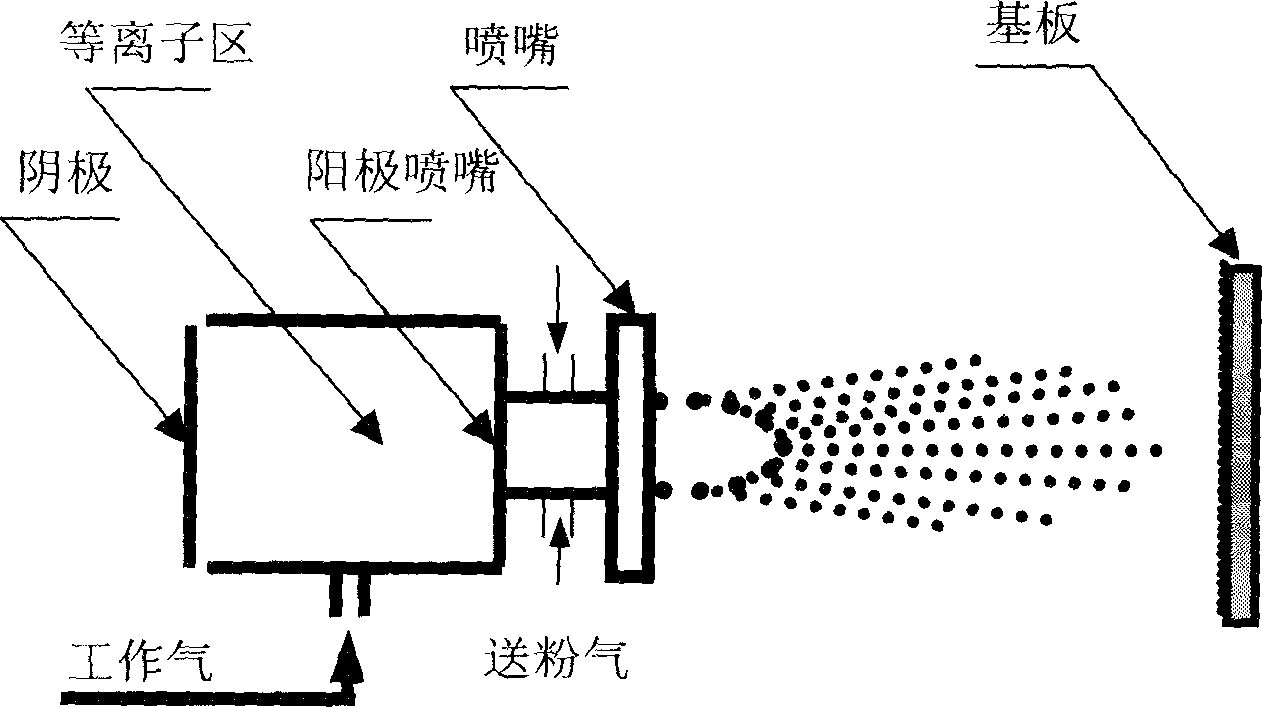

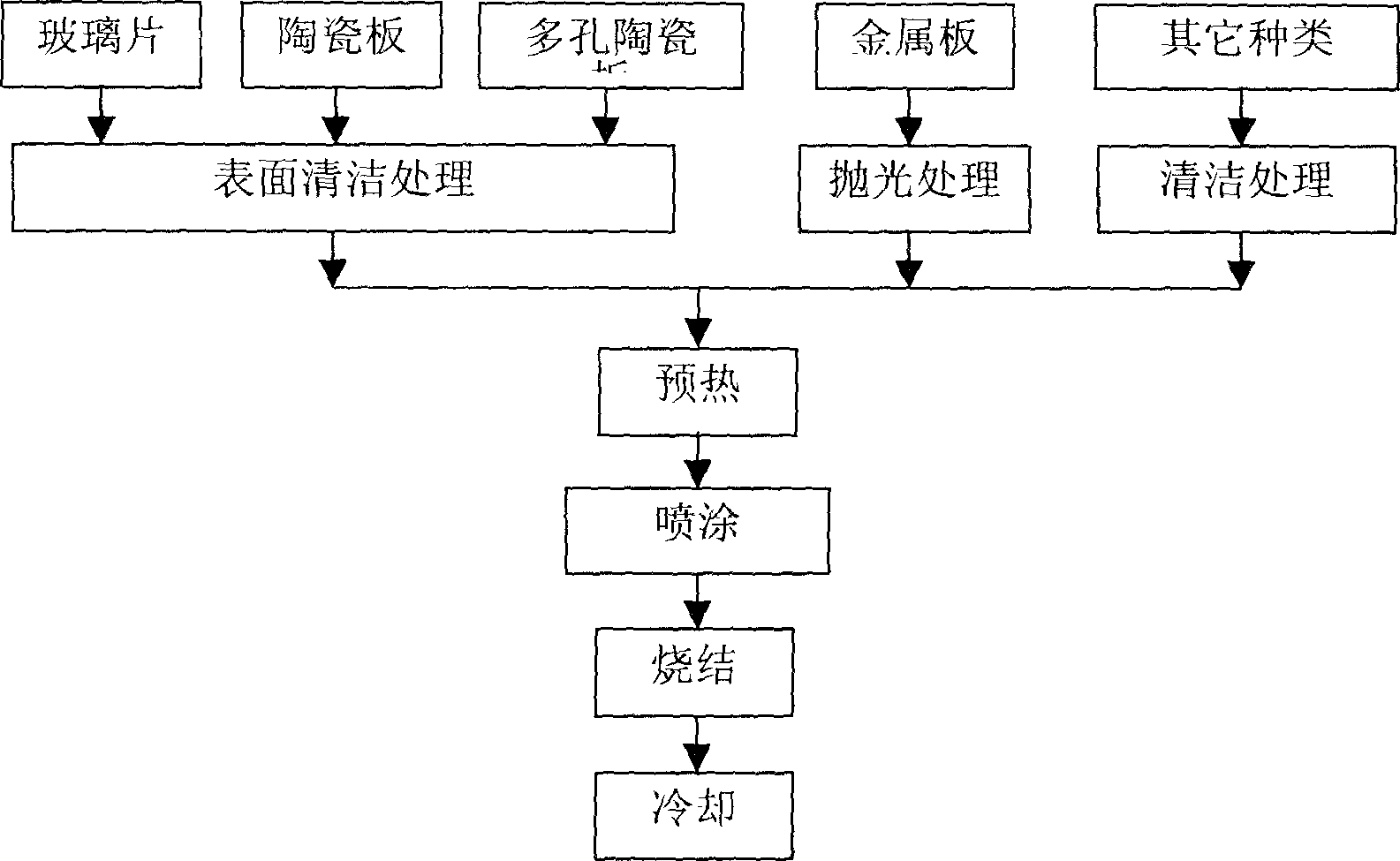

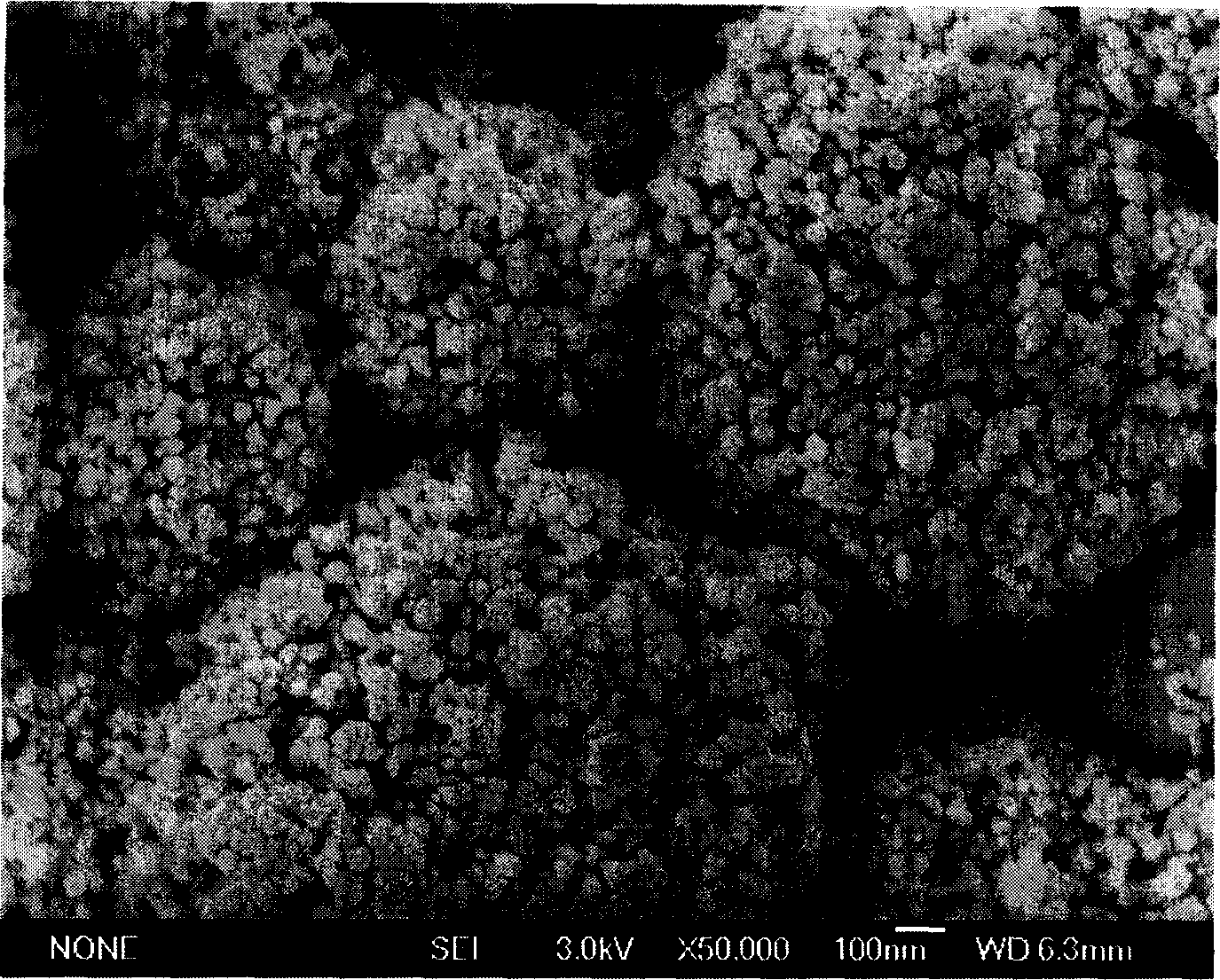

Method for forming nano TiO2 light catalystic active agenbt coating on substrate

InactiveCN1491753AImprove photocatalytic activityThe method is simpleLiquid surface applicatorsMolten spray coatingHydrogenNitrogen

The present invention belongs to the field of coating technology, and is especially plasma spray process of forming nano TiO2 photocatalytic activator coating on substrate. The process includes utilizing the mixed gas of nitrogen or argon and hydrogen as work gas and nitrogen as powder feeding gas; cleaning the substrate, preheating at 200-600 deg.c, spraying nano TiO2 powder onto the surface of the substrate in a plasma spraying equipment to form nano TiO2 film; and sintering at 500-600 deg.c to cure the nano TiO2 film completely and obtain the nano TiO2 photocatalytic activator coating. The coating is firm, stable and high in photocatalytic activity. The present invention may be used widely in the carrying of photocatalyst and heat spraying of nano powder.

Owner:INST OF CHEM CHINESE ACAD OF SCI

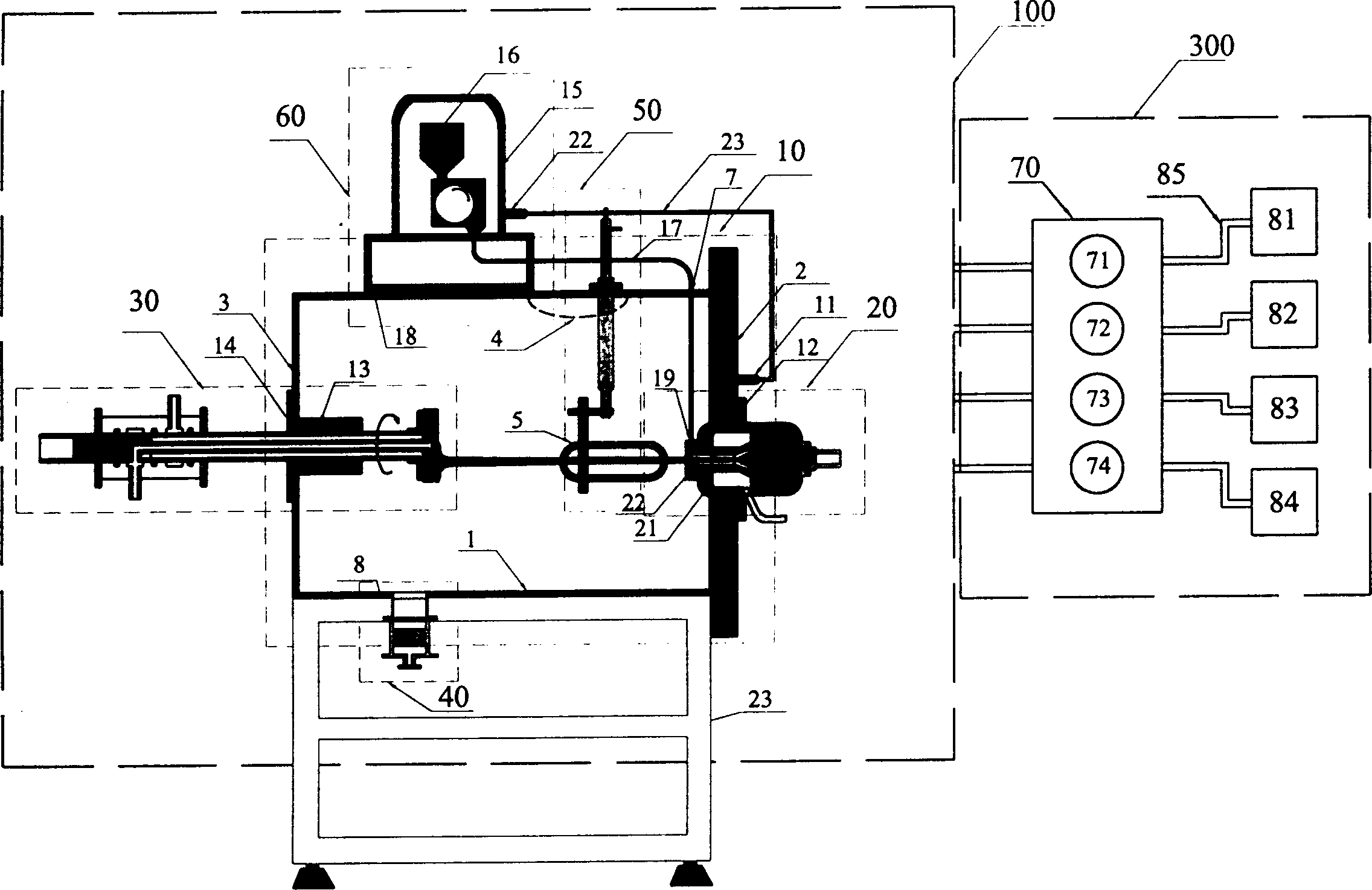

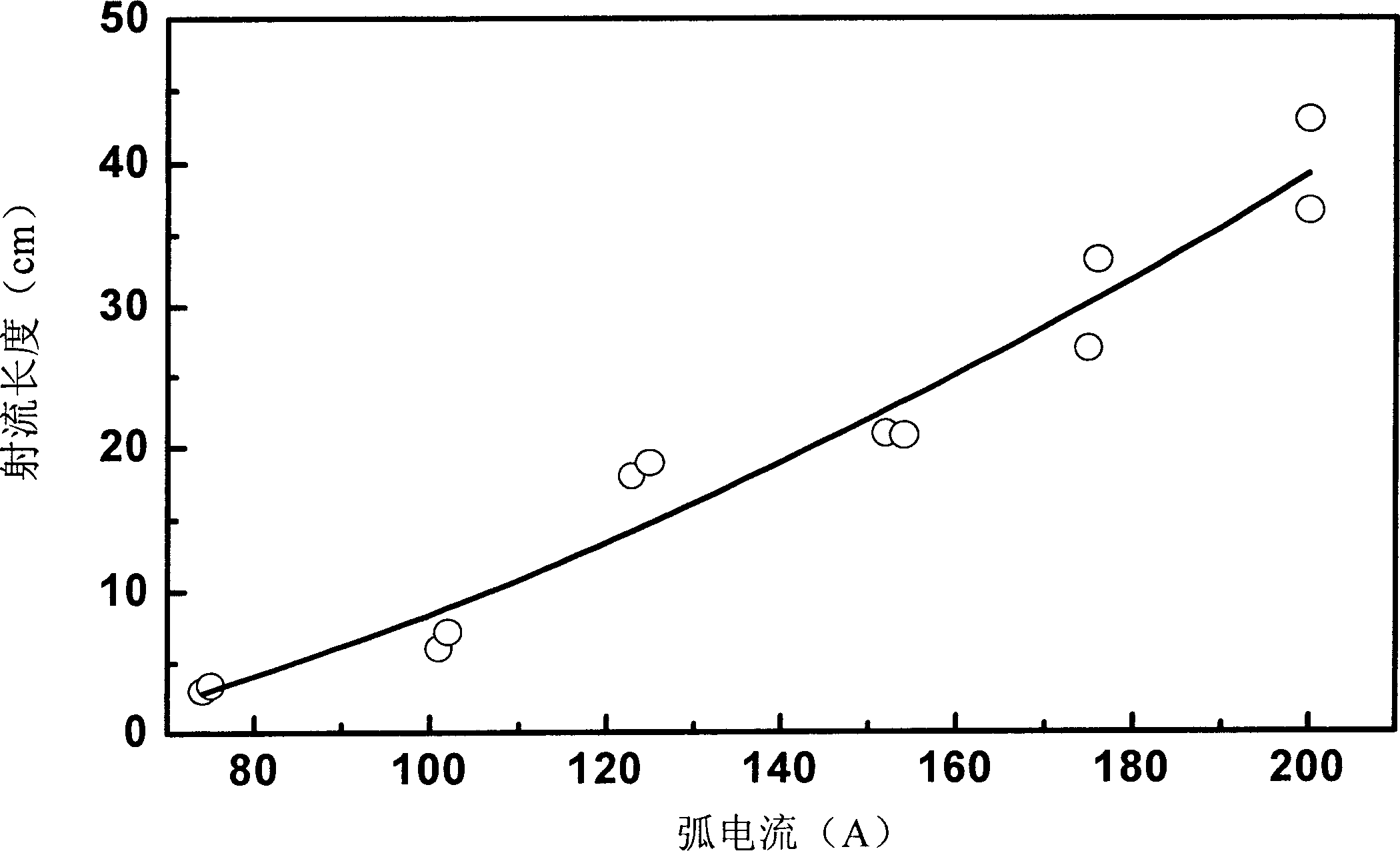

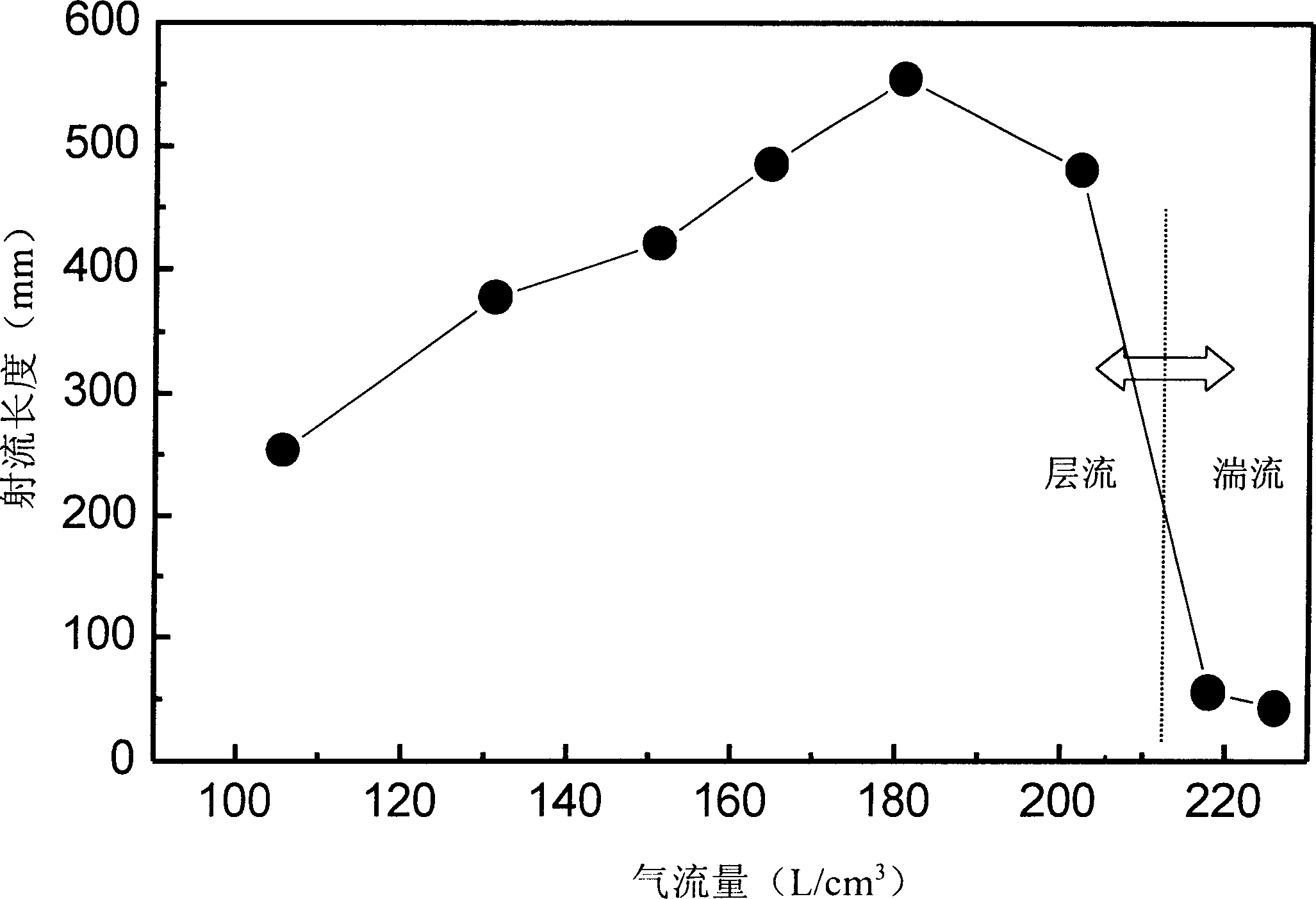

Laminar flow plasma spraying equipment and method

InactiveCN1421278AEffective meltingImprove interfacial adhesionLiquid spraying plantsLiquid surface applicatorsPlasma jetPlasma generator

The present invention is laminar flow plasma spraying equipment and method. A laminator flow plasma generator with different powder feeding modes, inside the gun or outside the gun and single port ormultiple ports, is used. While maintaining the laminar flow plasma jetting state in small power, air flow rate is increased to raise the heat efficiency of the jet. According to powder sort, materialproperty and particle size, proper jet energy and distribution and carrying air flow rate are selected to obtain high-quality coating. The present invention has les sintroduced impurity, high jet energy utilization, capacity of spraying high-smelting point coating at relatively low power condition, less oxidation of non-oxide coating and full heating of the powder material.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Plasma spraying gun

InactiveCN1404925ACompact and beautiful structureGuaranteed shaft alignmentElectric arc sprayingArc welding apparatusInternal pressureEngineering

The plasma spraying gun mainly comprises gun body, insulator, gas spiral-flow ring, flow divider, anode nozzle, front pressure cap, cathode body, inner pressure cap, insulating cover and outer pressure cap, in which the anode nozzle is connected with gun body by means of inner pressure cap, the flow divider is fixed in the interior of gun body by means of tight fit, the gas sprial-flow ring and insulator are connected with gun body by means of inner pressure cap,and the cathode body is fixed in the interior of gun body by means of insualting cover, outer pressure cap and in sulator. Said invention adopts integrated structure design, its structure is compact and beautiful.

Owner:SHANGHAI JIAO TONG UNIV

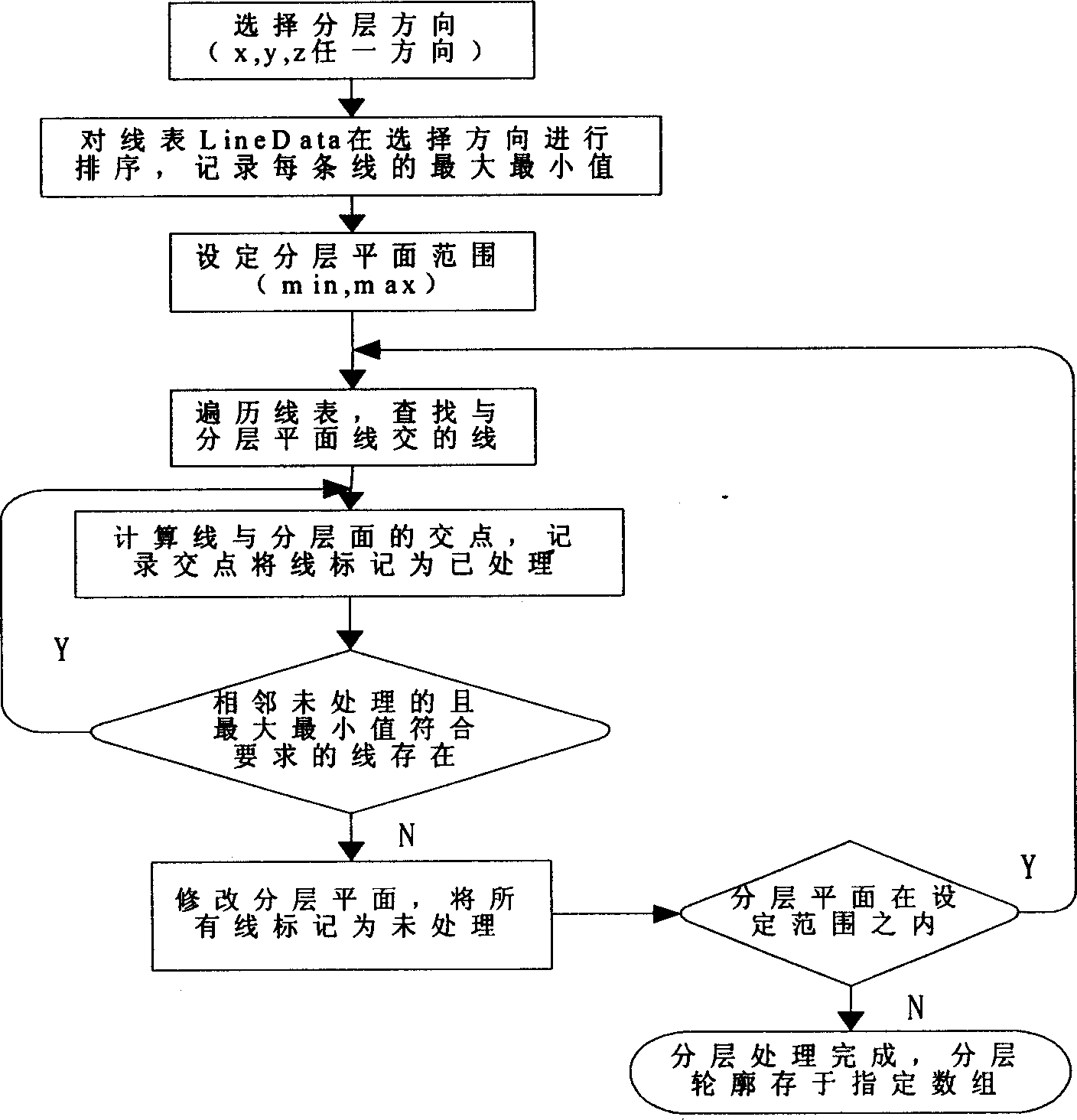

Special robot motion method with three-dimensional CAD data driving directly

InactiveCN1583373AEasy motion track controlReliable trajectory controlProgramme-controlled manipulatorShaping toolsSpatial positioningControl system

A method for using 3D CAD data to directly drive the dedicated robot used to metal arc spray on the punch die of the covering part for car includes such steps as generating the 3D CAD data of said punch die, hierarchica process of data model, slicing layer by layer, coordinate transform between the coordinate systems of computer and die-making equipment, and movement, control.

Owner:TONGJI UNIV

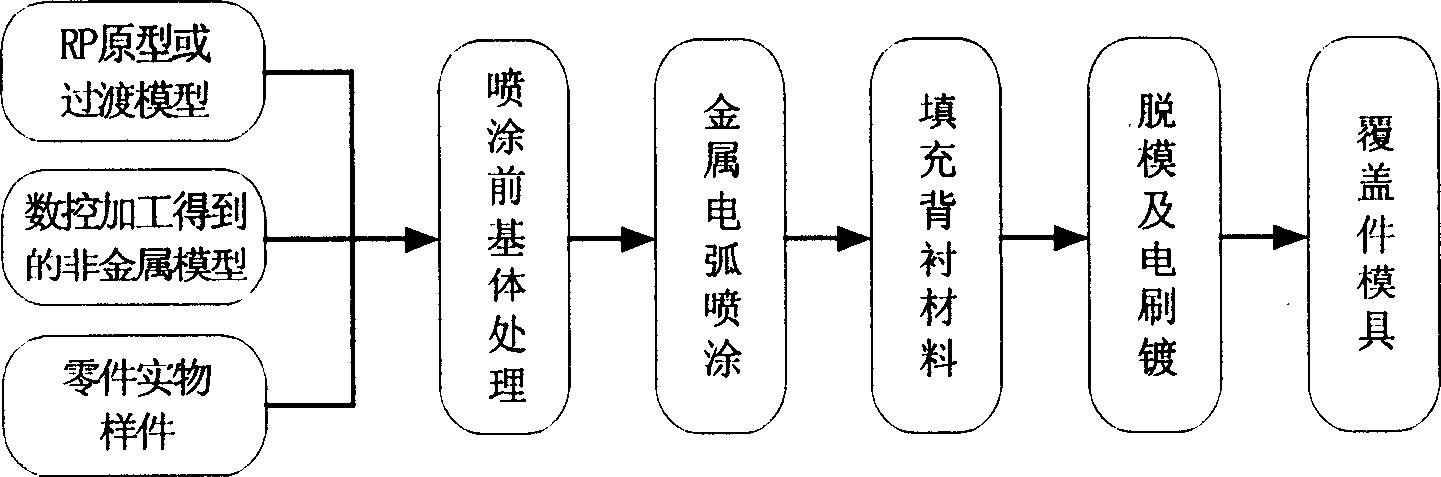

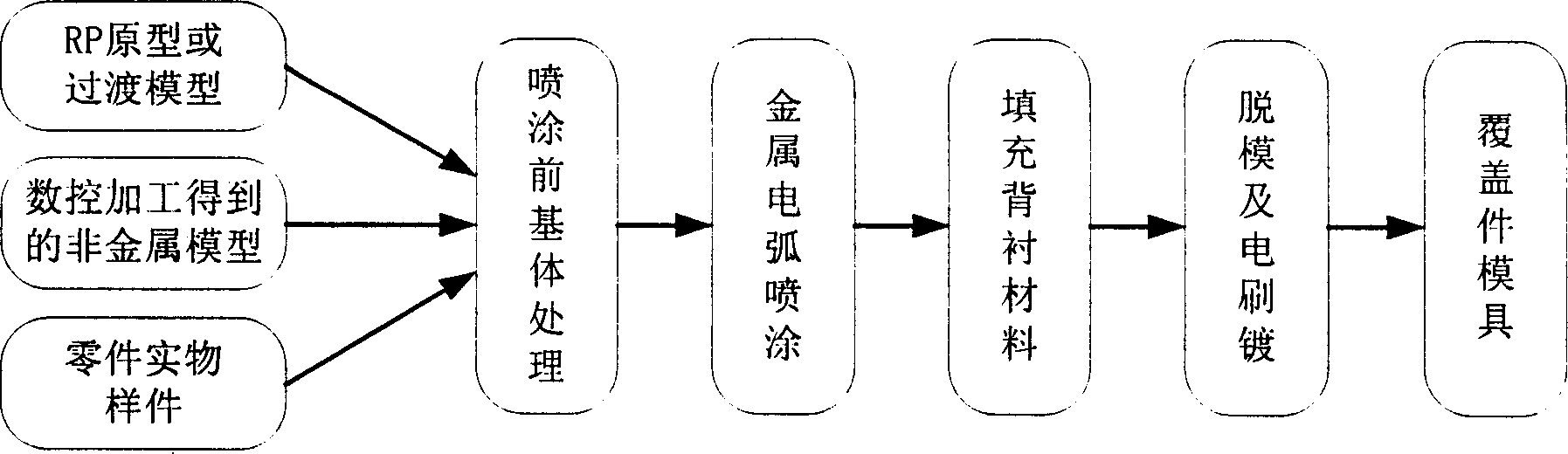

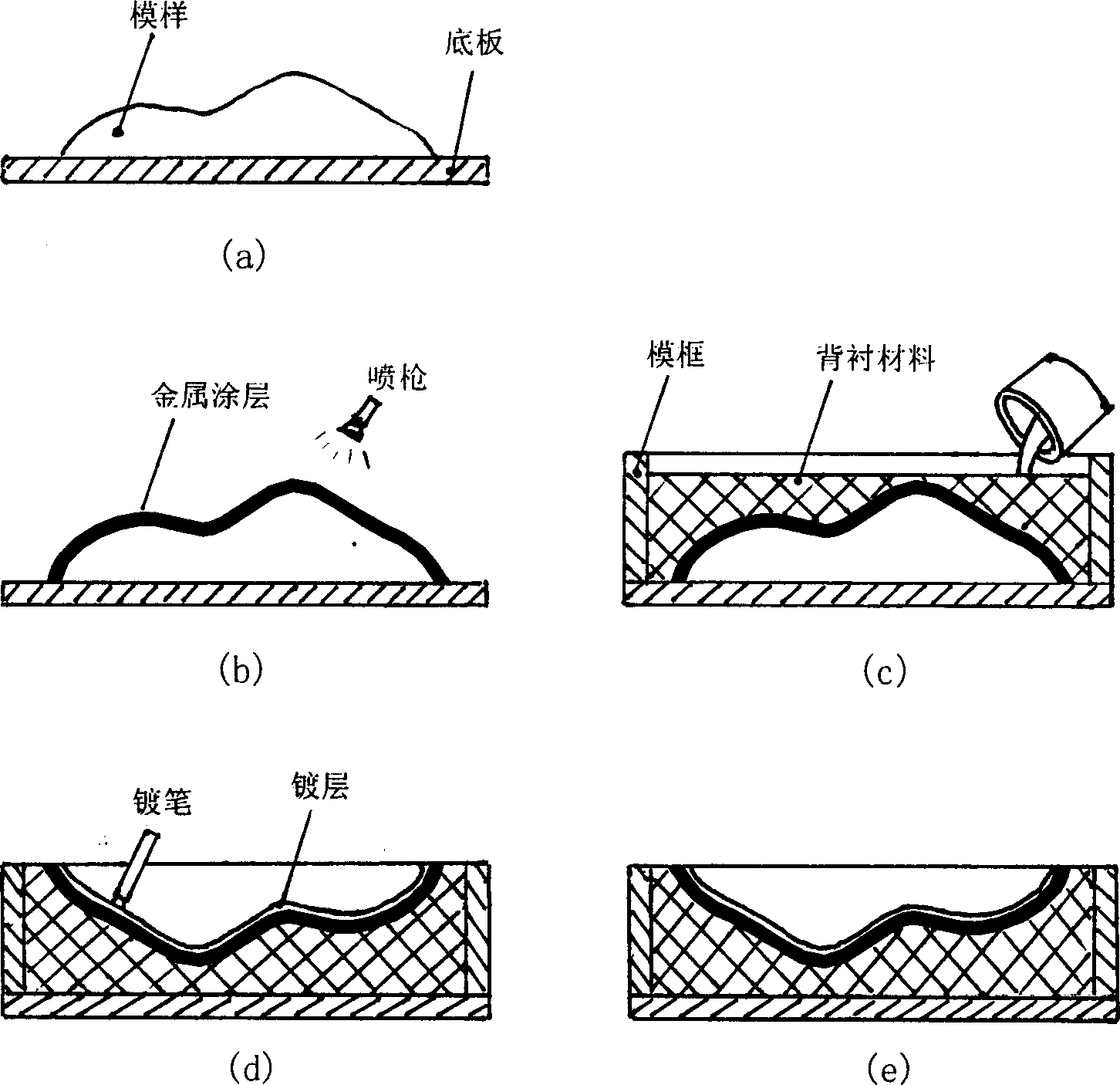

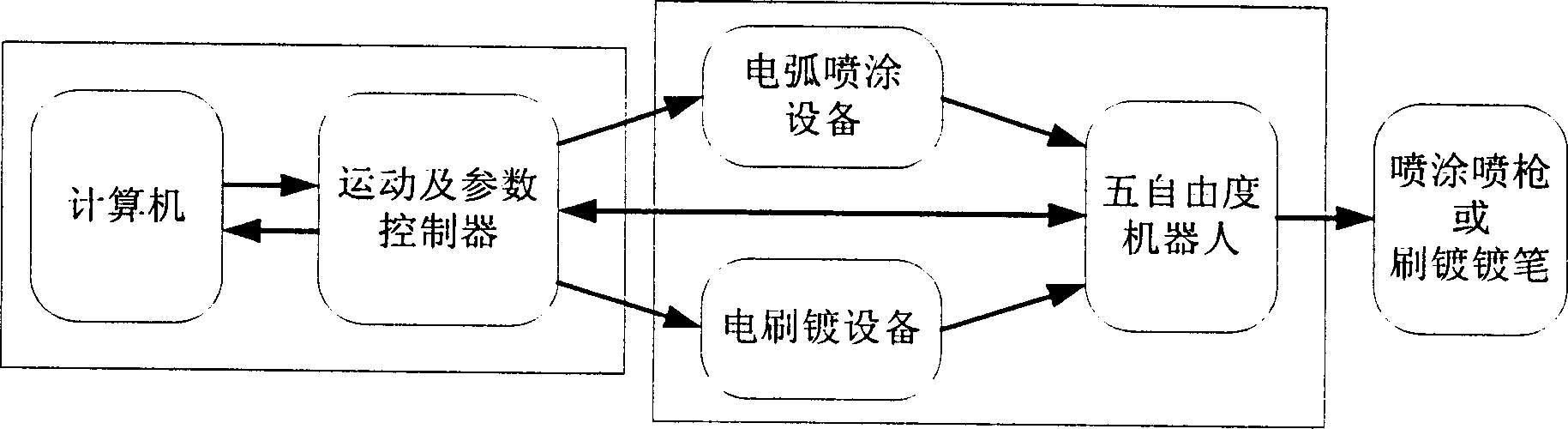

Manufacture method of intelligence integral dies of arc spraying and brush plating

InactiveCN1413800AEfficient preparationFast preparationElectric arc sprayingLiquid spraying apparatusAutomatic controlManufactured apparatus

A technology for manufacturing the intelligent arc-spraying and electric brush plating integrated die, which can automatically perform both arc spraying and electric brush plating under the direct drive of CAD data, features that its manufacture apparatus is composed of computer, moving and technological parameter controller, arc spraying unit, electric brush plating unit and 5-freedom robot. Its advantages are low cost and high efficiency.

Owner:SUZHOU BC TECH

Method fr preparing electric arc spraying fiber material containing core of nano material

InactiveCN1562555AHigh bonding strengthImprove wear resistanceElectric arc sprayingWelding/cutting media/materialsFiberMechanical components

An arc-spraying wire with the core containing nano material features that its core is a composite powder containing nano material and its jacket layer is chosen from carbon steel band, chromium steel band, stainless steel band, nickel band and aluminium band. Its sprayed layer has high adhesion and resistance to abrasion, crossion and oxidization.

Owner:ZHEJIANG UNIV +1

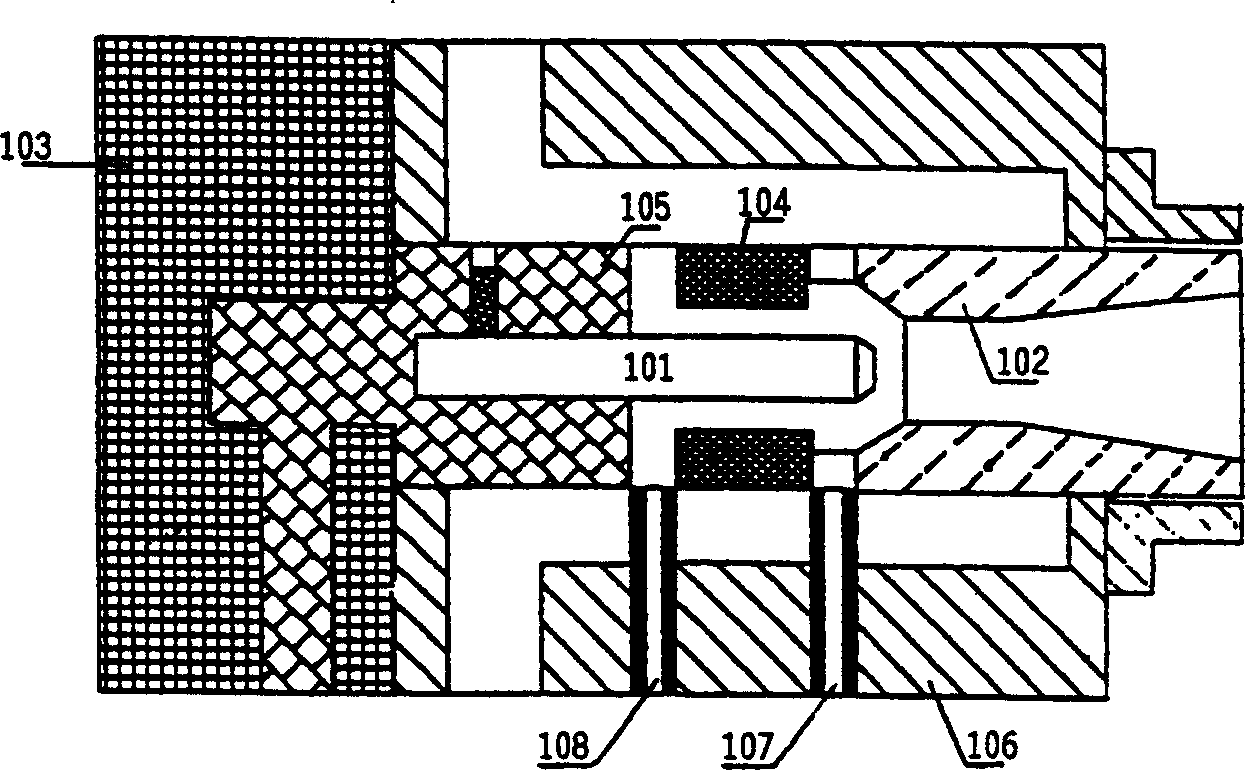

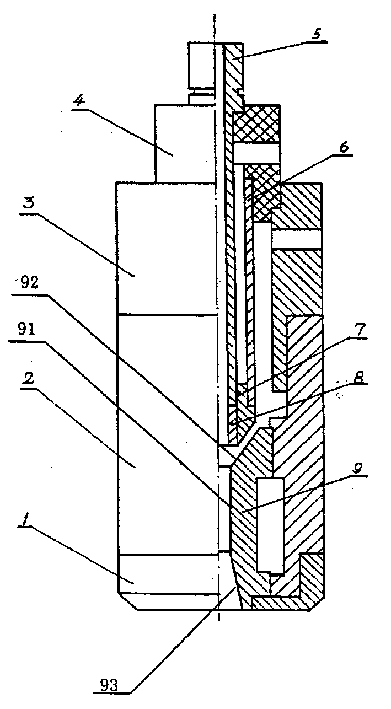

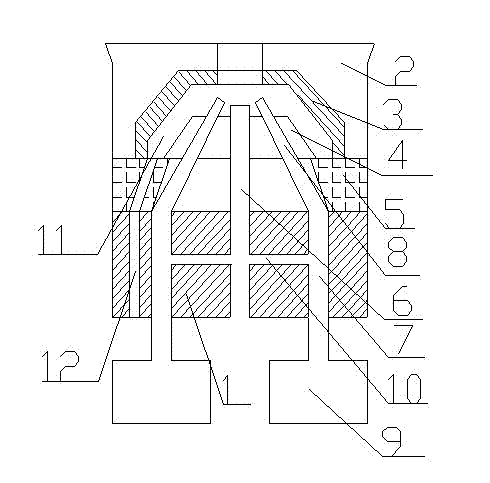

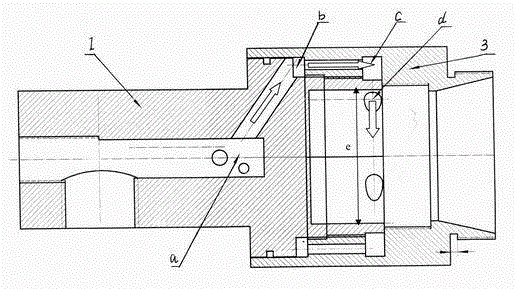

Hollow cathode central axial powder-feeding plasma spraying gun

InactiveCN1448223AImprove stabilityReduce interferenceElectric arc sprayingLiquid spraying apparatusPlasma jetPlasma sprayed

The present invention is one plasma spray gun with hollow cathode and powder feeding in central axle direction. The hollow cathode is made of concentric inner tube and outer tungsten tube, and the anode has nozzle cavity with trapezoidal cross section. The plasma spray gun in such a structure can control effectively the flying locus of powder inside the plasma jet and feed powder to the center of the plasma jet to heat and accelerate sprayed particles effectively, and has stable arc burning, less adhesion of powder and long service life of the electrodes.

Owner:XI AN JIAOTONG UNIV

Electrode nozzle of electric arc spraying coater in supersonic speed and manufacturing method

InactiveCN1562498AImprove wear resistanceReasonable structureElectric arc sprayingSpray nozzlesTitanium carbideCobalt

An electric conducting tip for the supersonic arc-spraying machine is composed of the cylindrical front half made of cermat prepared from tungsten carbide, titanium carbide, tatalum carbide, niobium carbide and chromium (or cobalt or nickel) of carbide for high antiwear performance, and the cylindrical back half made of Cu alloy prepared from Cu, Cr, Zr, Mg and Ce or Y alloy.

Owner:ZHEJIANG UNIV +1

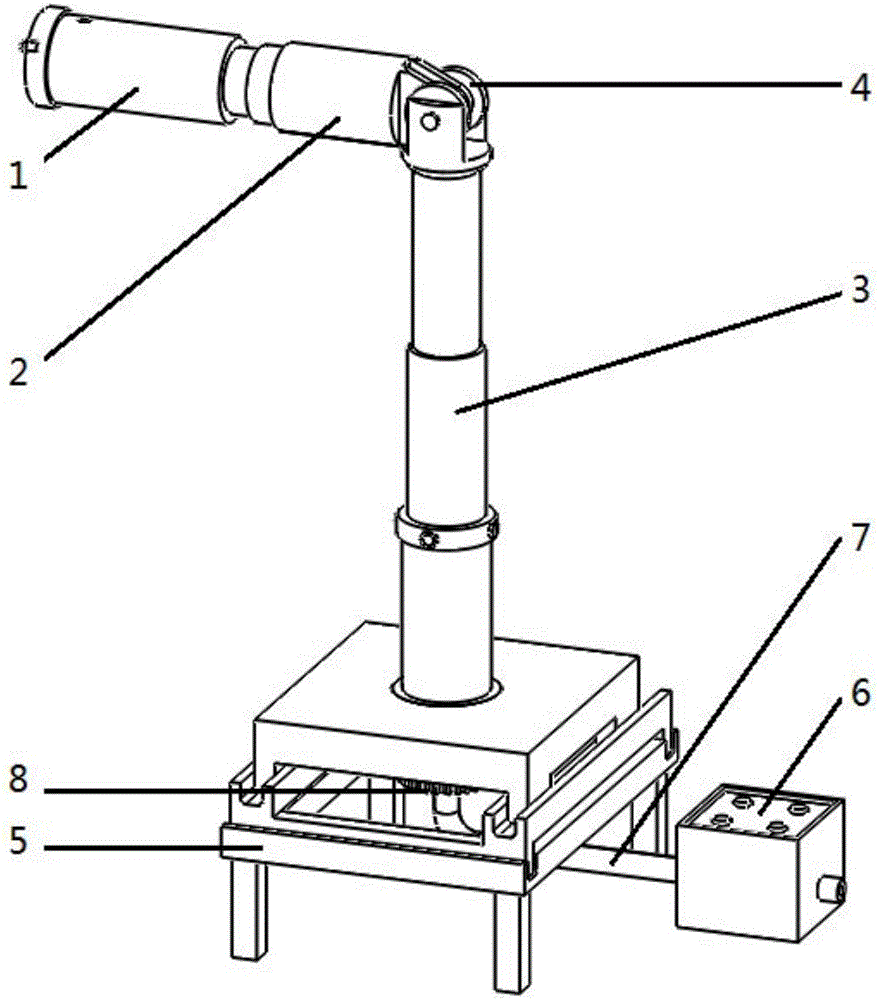

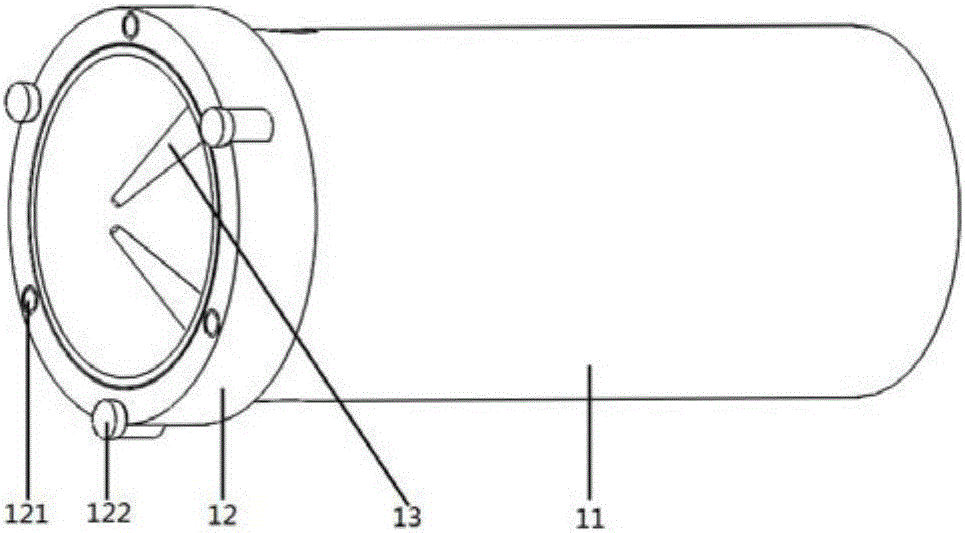

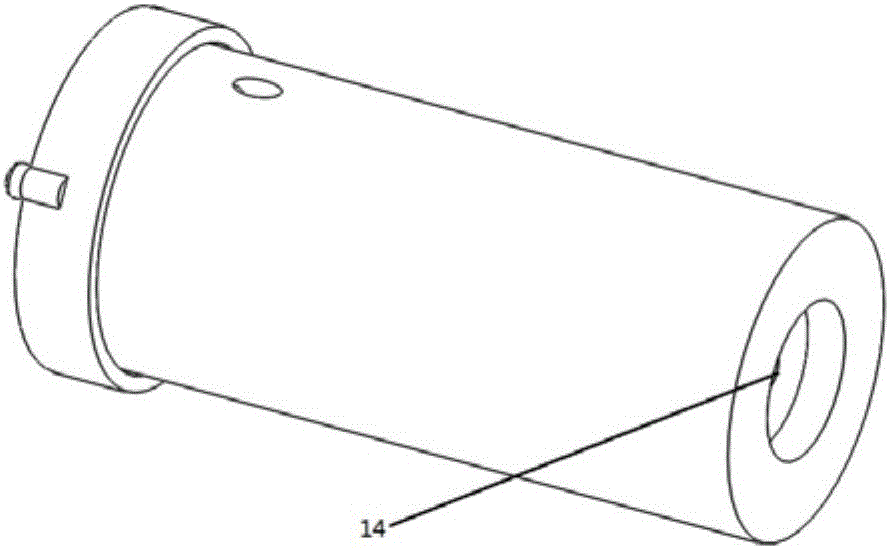

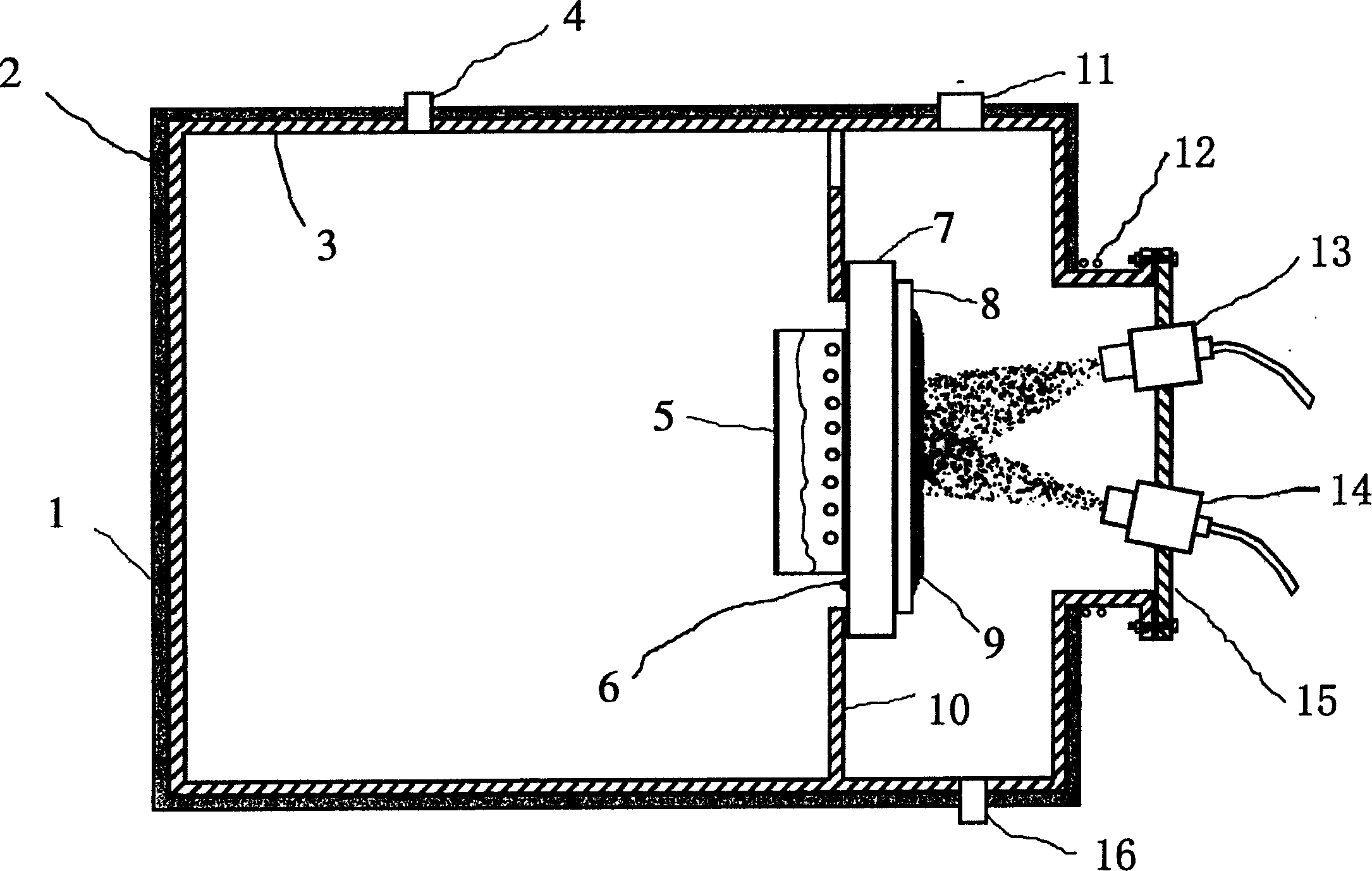

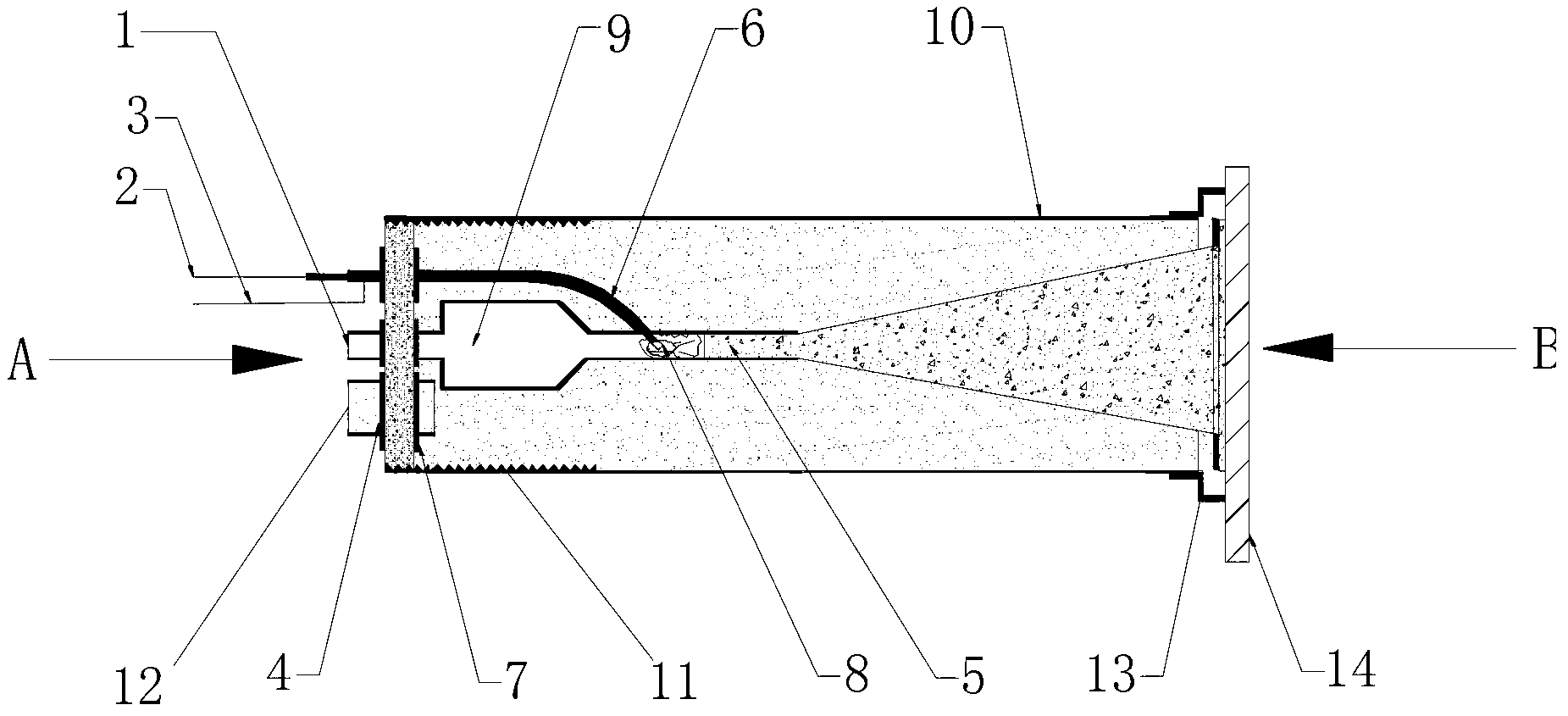

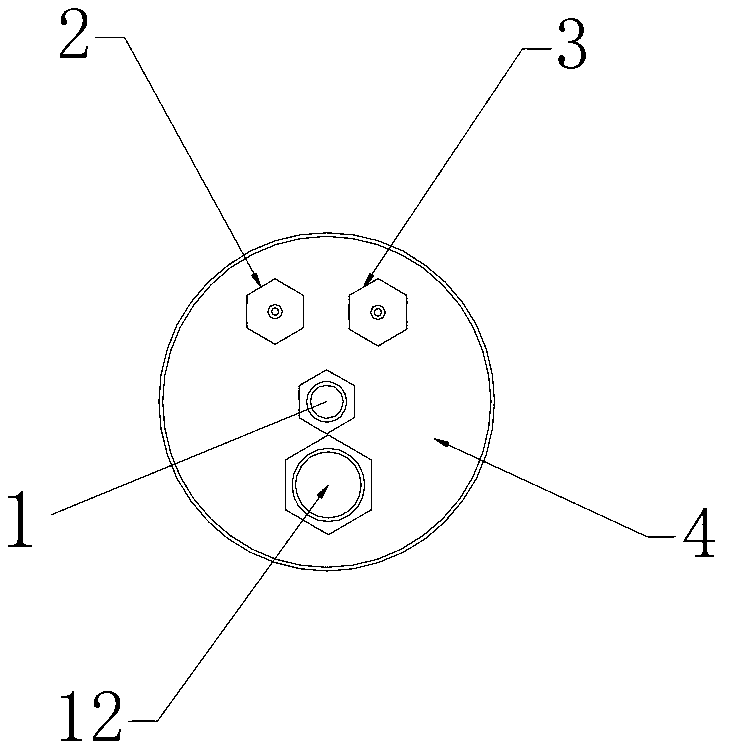

Electric arc spraying device suitable for inner wall of pressure vessel

ActiveCN105709978AImprove corrosion resistancePrecise thickness controlLiquid surface applicatorsElectric arc sprayingDrive shaftEngineering

The invention belongs to the field of electric arc spraying and coating systems, and particularly relates to an electric arc spraying device suitable for the inner wall of a pressure vessel. The electric arc spraying device suitable for the inner wall of the pressure vessel comprises a spraying gun, a swing telescopic shaft, a rotary telescopic shaft, a rotary connecting mechanism, a sliding positioning base, a control cabinet, a wire and compressed air conveying pipe and a transmission mechanism. The swing telescopic shaft and the rotary telescopic shaft are connected through the rotary connecting mechanism. The rotary telescopic shaft is installed on a platform of the sliding positioning base. The wire and compressed air conveying pipe penetrates through the rotary telescopic shaft and the swing telescopic shaft and is connected with the spraying gun and the control cabinet. The transmission mechanism is assembled on a transmission shaft at the bottom of the rotary telescopic shaft. The electric arc spraying device can be used for conducting electric arc spraying operation on the inner wall of the welded pressure vessel and conducting repairing spraying operation on a weld zone of the inner wall of the pressure vessel, and thus the corrosion resistance of the inner wall of the pressure vessel is improved. The spraying process can be observed in real time and adjusted anytime, and operation steps are simple.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

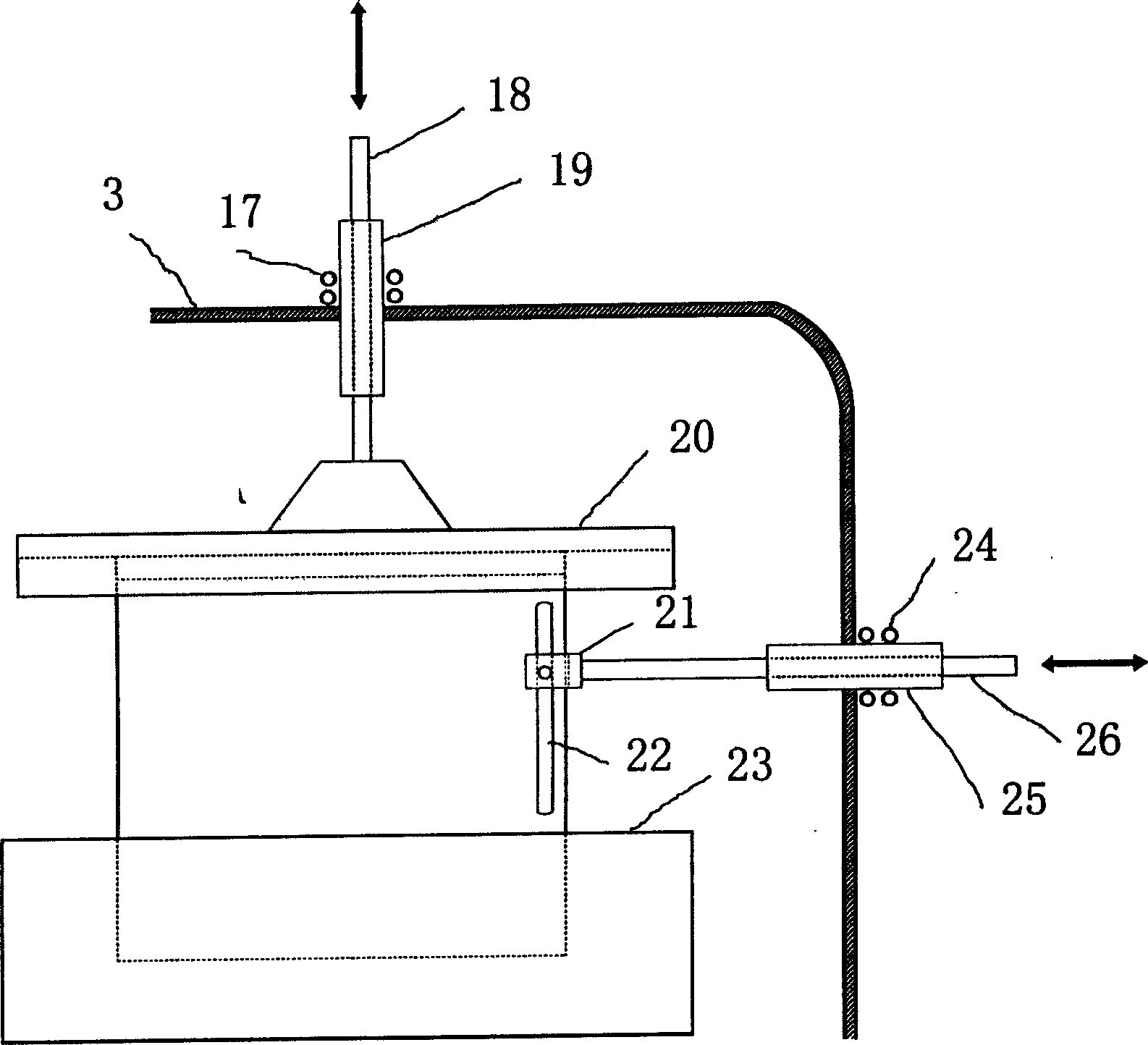

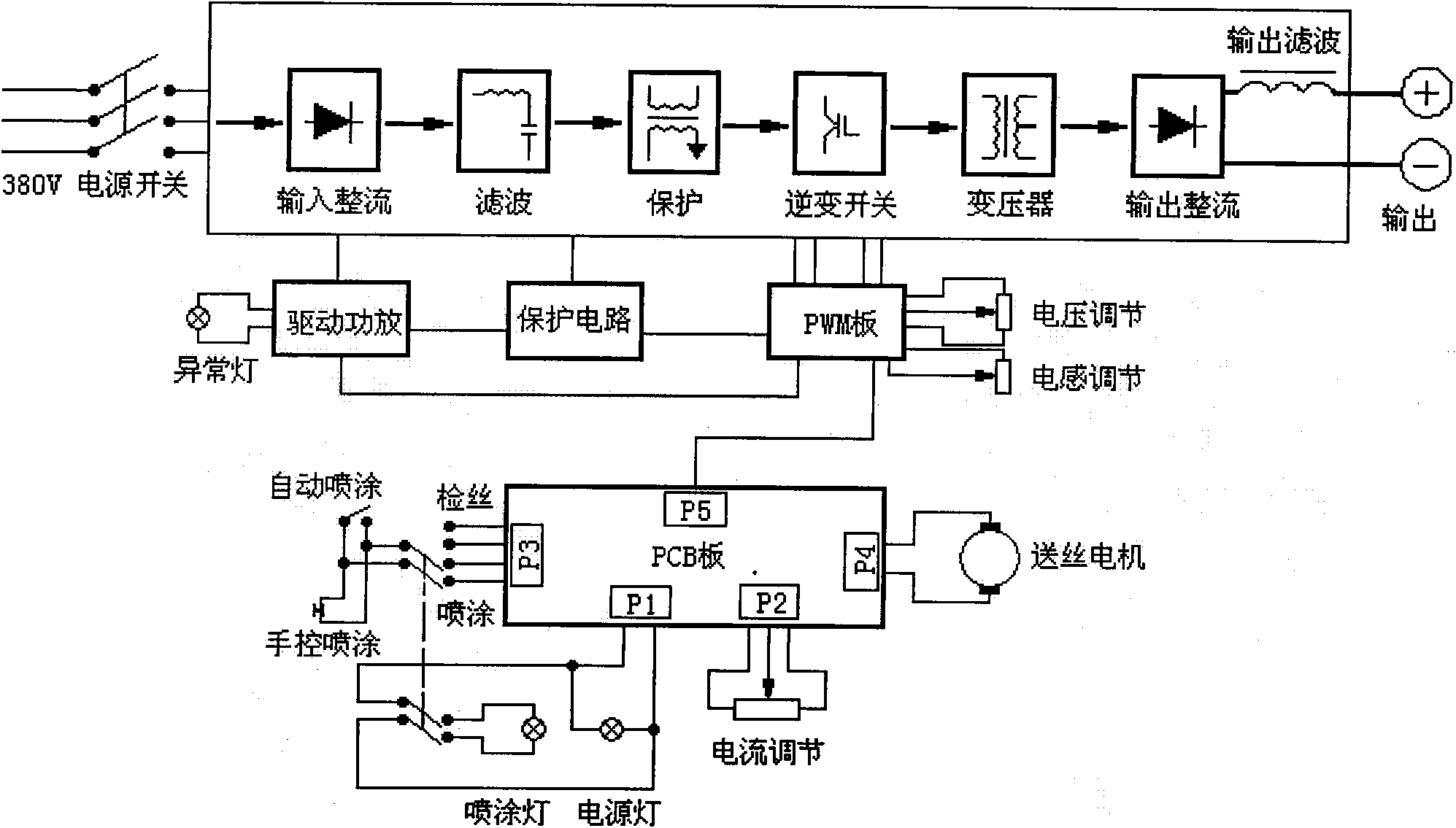

Simultaneous online zinc spraying and dust removal device for multiple microchannel aluminium flat pipes

ActiveCN103938146ADoes not affect setpointImprove anti-interference abilityCombination devicesMolten spray coatingPower flowEngineering

The invention discloses a simultaneous online zinc spraying and dust removal device for multiple microchannel aluminium flat pipes. The simultaneous online zinc spraying and dust removal device comprises spraying equipment, a spraying cabinet and a dust removal device, wherein the spraying equipment is arranged in the spraying cabinet, and an air outlet of the spraying cabinet is connected to the dust removal device; the multiple microchannel aluminium flat pipes enter into the spraying cabinet from one side of the spraying cabinet in parallel and exit out of the spraying cabinet from the other side of the spraying cabinet; the spraying equipment comprises a spraying main machine and a plurality of melting injection spray guns, the electric current parts of the plurality of melting injection spray guns are connected to the electric current output end of the spraying main machine, each melting injection spray gun is used for carrying out zinc spraying operation on each microchannel aluminium flat pipe, and the spraying main machine is provided with a power source part which comprises an input rectifying circuit, an input filter circuit, a power switch circuit, a voltage conversion and isolation circuit, an output rectifying circuit, an output filter circuit, an electric arc zone temperature detection sensor, a comparison circuit and a control circuit. The simultaneous online zinc spraying and dust removal device has a good spraying effect and low pollution to environments.

Owner:SHANGHAI LIANGSHI BLASTING & COATING EQUIP

Core strip used for preparation of antiskid anticorrosion coating

InactiveCN1880498AHigh bonding strengthReduce porosityMolten spray coatingElectric arc sprayingYarnRare earth

The invention discloses a powder-core yarn material of anti-skid anti-erosion coater, which consists of powder-core and envelope, wherein the powder-core is composed of aluminum powder, chrome oxide powder and hybrid rare earth powder; the envelop is aluminum band with 99.9 percent purity; the filling rate of powder-core is between 24 and 26 percent. The invention provides anti-skid anti-erosion coater through arc spraying on the steel structure of marine platform deck, ship deck and port, which lengthens anti-skid anti-erosion lifetime under marine climate environment.

Owner:天津市旭航广告有限公司

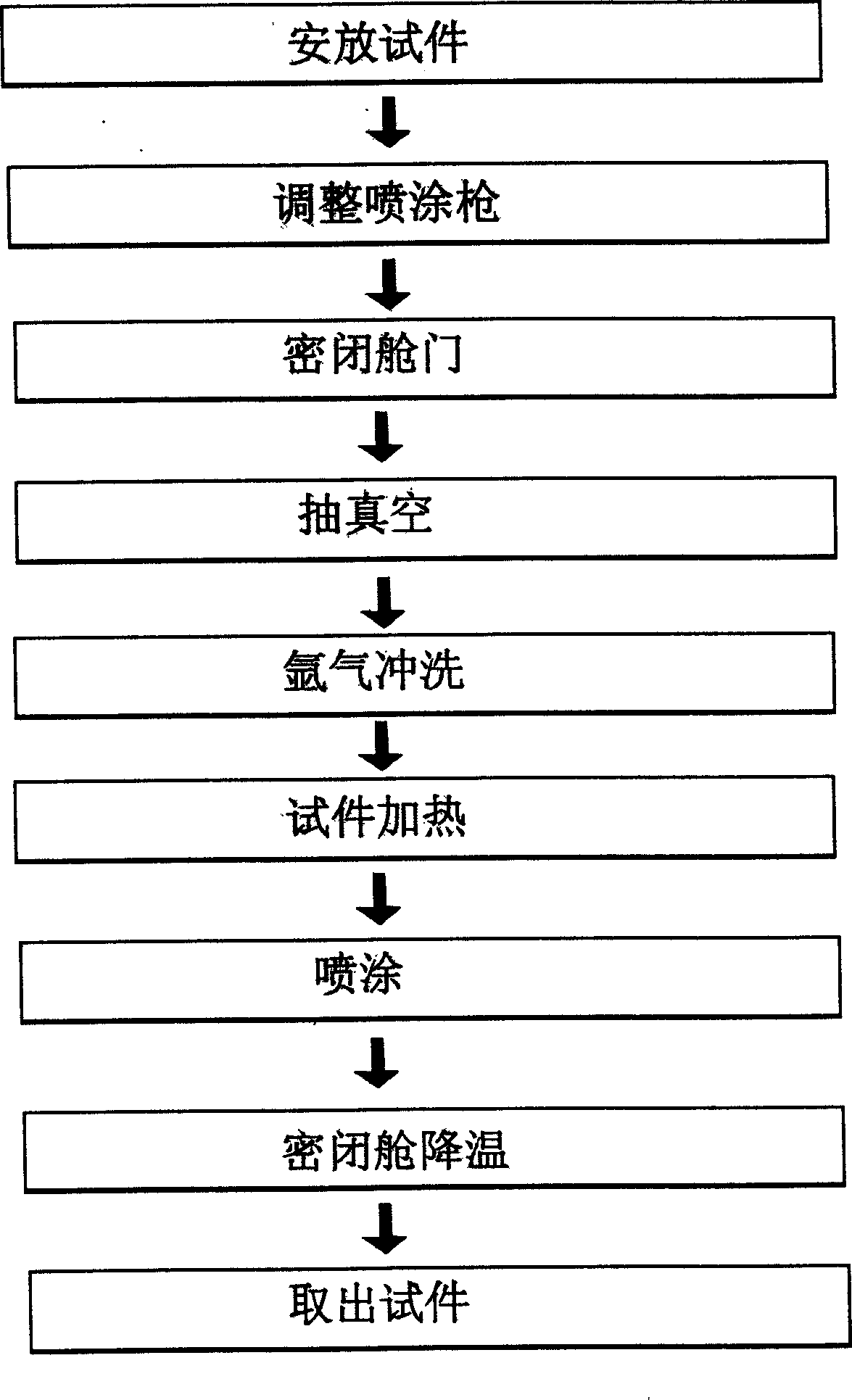

Multicomponent atmosphere controllable spraying method and apparatus

InactiveCN1583283AHigh bonding strength between layersNo porosityLiquid spraying plantsElectric arc sprayingEngineeringPlasma sprayed

A multi-element atmosphere controllable spray method includes such steps as installing a sample on carrier table, regulating spray distance, sealing door, vacuumizing, filling inertial gas, heating sample, using arc and plasma guns for spaying, holding its temp, and cooling. Its apparatus is composed of case, supporting plate, movable carrier table, heating plate and arc and plasma guns.

Owner:SHENYANG POLYTECHNIC UNIV

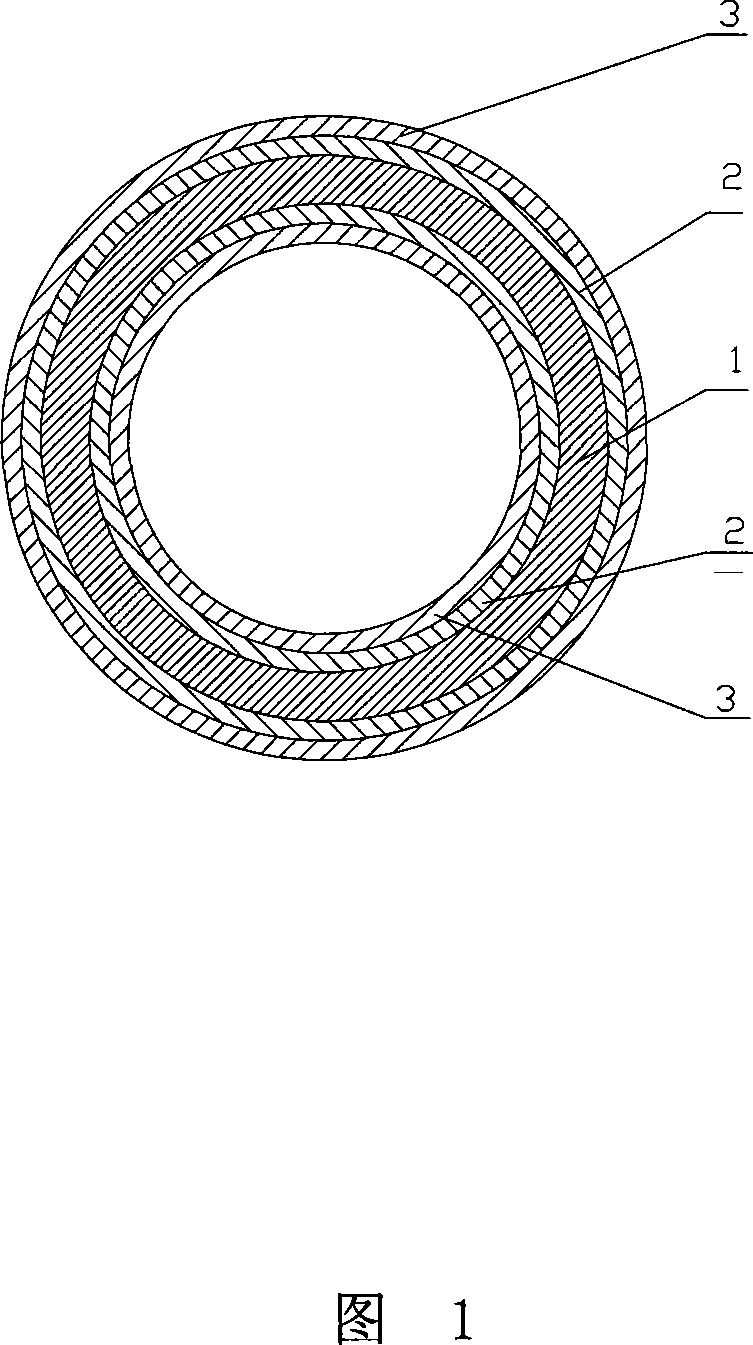

Stainless steel anti-corrosion pipe used for oil gas field and manufacturing method thereof

InactiveCN101215716AHas stainless steel propertiesSolve the problem of anti-corrosionElectric arc sprayingAlloyWater cooling

The invention relates to a stainless steel anti-corrosion pipe which is used in oil-gas field and a manufacturing method. The manufacturing technology of the stainless steel anti-corrosion pipe comprises the following steps: first, carrying out impact cleaning on an oil pipe or a sleeve pipe, then immersing in NaOH liquid for 3-5 seconds to remove oily soil on the surface of the oil pipe or the sleeve pipe, washing away residual oily soil by water, then washing in hydrochloric acid 15% for 5-7 seconds to remove oil on the pipe, washing away residual acid by water, assistant plating in plating auxiliary for 2 seconds, drying in a groove type drying pool for 2 seconds under the temperature of 120 DEG C, immersing the pipe in aluminum multicomponent alloy liquid, smelting the pipe for 3-5 seconds under the temperature of 700-750 DEG C, leading the surface of the pipe body into stainless steel, then air cooling and water cooling, and obtaining stainless steel anti-corrosion oil pipe and sleeve pipe through electric arc hot spraying on a screw thread. An oil pipe or a sleeve pipe which is prepared by the method has the advantages of good corrosion resistance, large binding force, good mechanical property, ageing resistance and strong antiscaling paraffin-controlling property.

Owner:DAQING GASOLINEEUM INST +1

Aqueous fire board marble simulation paint, preparation method and construction method thereof

InactiveCN104974627AReduce load-bearing pressureEasy constructionElectric arc sprayingMovable spraying apparatusChemistryEmulsion

The invention provides to an aqueous fire board marble simulation paint, a preparation method and a construction method thereof, and relates to a coating material and a use method thereof. The aqueous fire board marble simulation paint is prepared from water, an emulsion, a film-forming additive, a wetting agent, a defoamer, propylene glycol, a preservative, a multifunctional additive, a thickener aqueous solution, rock sheet and color sand. The preparation method comprises three steps such as dispersion preparation, base paint preparation and aqueous fire board marble simulation paint preparation. The construction method comprises five steps such as base layer treatment, prime coat brushing, middle coating spraying, aqueous fire board marble simulation paint spraying, and top coat brushing. According to the present invention, the process is simple, the product system is system, the construction is simple and quick, the aqueous fire board marble simulation paint has the granite effect, and the limitations of cumbersome color blending, complex process, instable product system and high construction difficulty of the water-in-water multi-color coating material; the difficult problems of high cost, low safety factor and the like of the granite and the marble are overcome; and the disadvantages of easy pollution, color blur, low simulation and the like of the stone paint are solved.

Owner:DALIAN ZHONGKAI COATING MAKING CO LTD

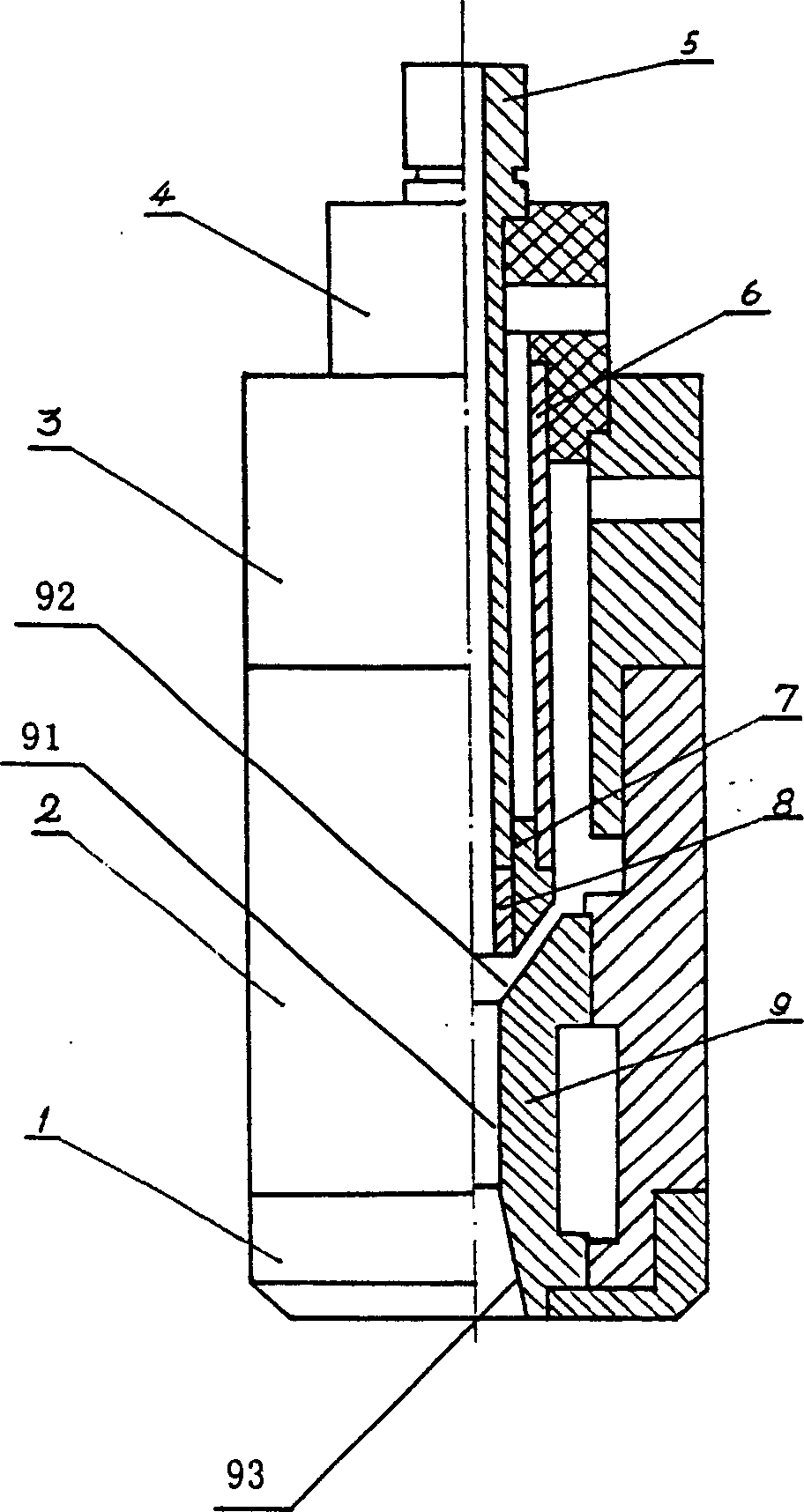

Fistular cathodic axial powder feeding plasma painting gun

InactiveCN1481939AHeating evenlyImprove energy utilizationElectric arc sprayingLiquid spraying apparatusMolten stateMetallurgy

The present invention relates to one kind of axially powder-feeding plasma spray gun for improved plasma spraying technological process. The spray gun consists of water-cooled hollow cathode and tubular anode. The sprayed powder material is fed through the hollow cathode and heated in the high temperature area inside the spray gun to reach melt state gradually before leaving from the spray gun and being sprayed at high speed to the surface of the workpiece to be sprayed to form plasma coating with specific performance.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Electric conduction plastic wire material for electrical arc spray coating, and preparation method thereof

InactiveCN104372281AExtended service lifeMolten spray coatingElectric arc sprayingElectrically conductiveElectric arc

The invention relates to an electric conduction plastic wire material for electrical arc spray coating, and a preparation method thereof. The electric conduction plastic wire material comprises a plastic substrate and a carbon material electric conduction substance, wherein the carbon material electric conduction substance is continuously distributed in the plastic substrate along the axial direction. The preparation method comprises: (1) completely mixing the molten-state or powder-state plastic substrate and the carbon material electric conduction substance powder to obtain a mixture; and (2) carrying out wire production on the mixture on a wire production device to obtain the electric conduction plastic wire material for electrical arc spray coating. The electric conduction plastic wire material of the present invention is suitable for electrical arc spray coating, and can be used for the anti-corrosion anti-wear coating of the metal equipment so as to substantially improve the service life of the metal equipment.

Owner:BEIJING ZHONGKE JINTENG TECH

High intensity abrasion resistant arc spraying filament material for circulating fluidized bed boiler

InactiveCN1730713AExtend your lifeGood anti-wear effectMolten spray coatingElectric arc sprayingRare-earth elementMetallurgy

The invention discloses a high intensity abrasion resistant arc spraying filament material for circulating fluidized bed boiler, wherein low-carbon steel or stainless steel band is used as the shell of the material, the core is added by 25-48 wt% of mixture powder of CrB2 and B4C, the content of CrB2 in the mixture is 70-95 wt%. The core comprises 0-5 wt% of powder of any one selected from Ni and / or Al and / or Mo and / or rare-earth element.

Owner:JIANGXI HENGDA HI TECH CO LTD

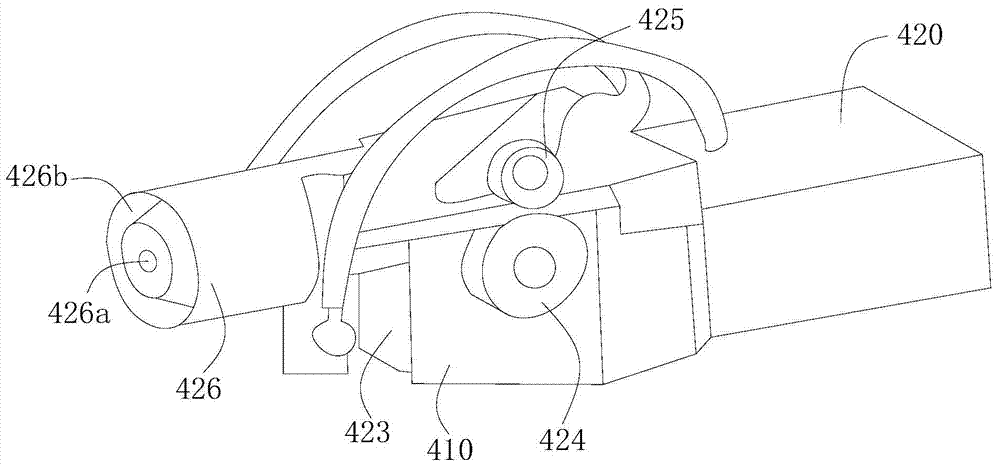

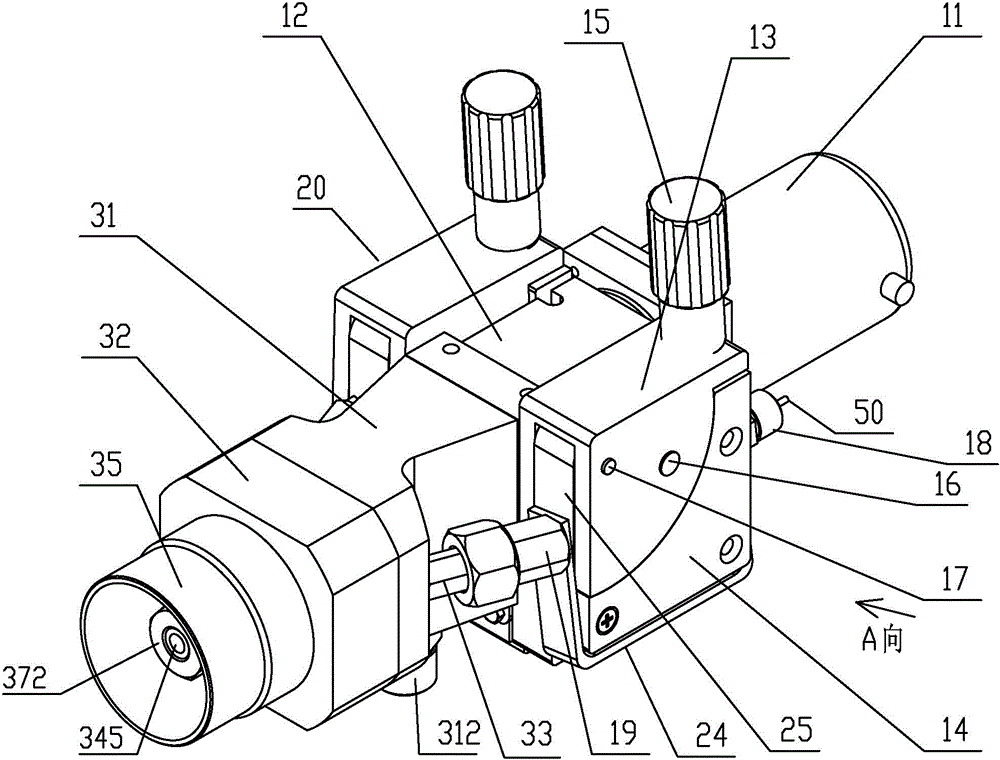

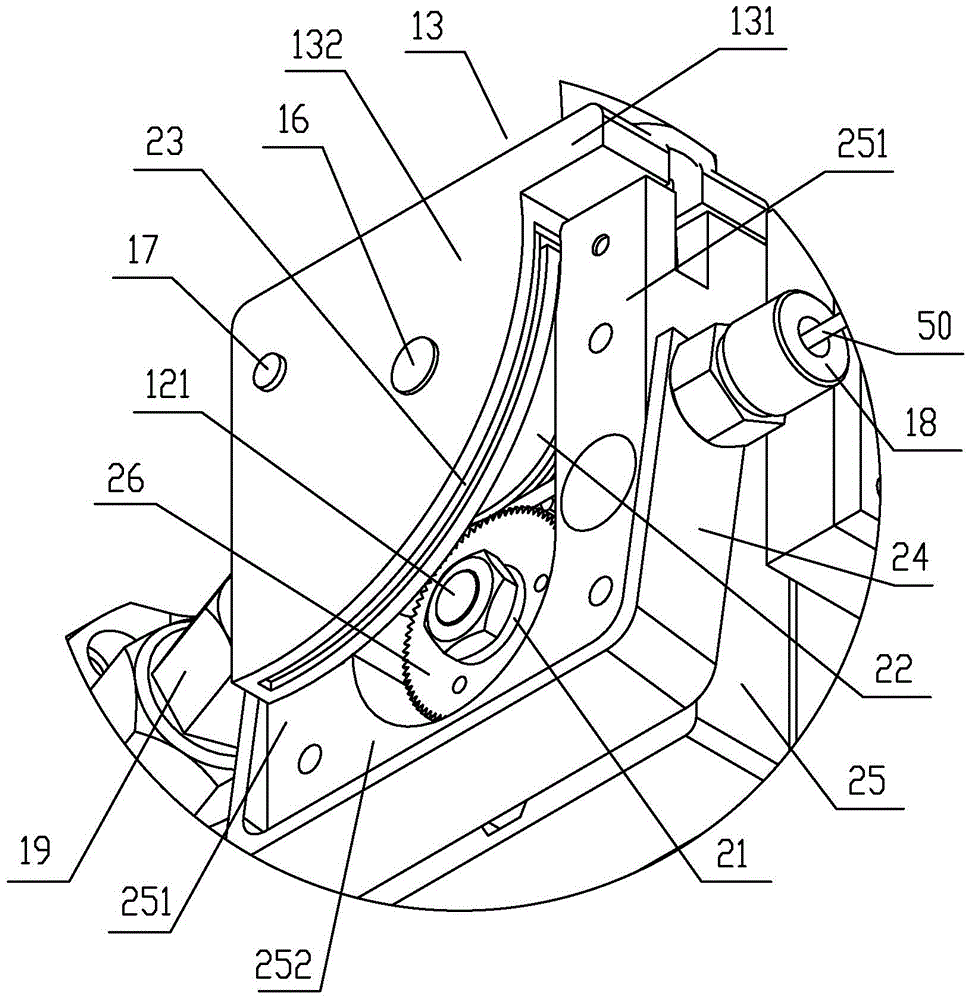

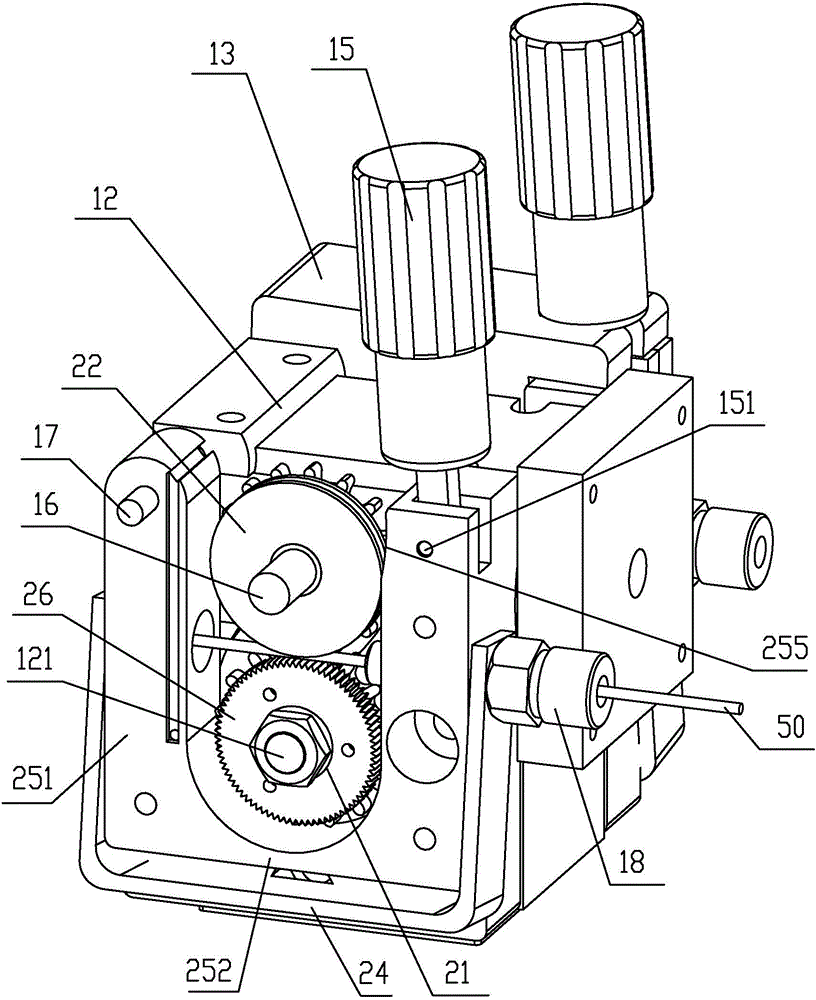

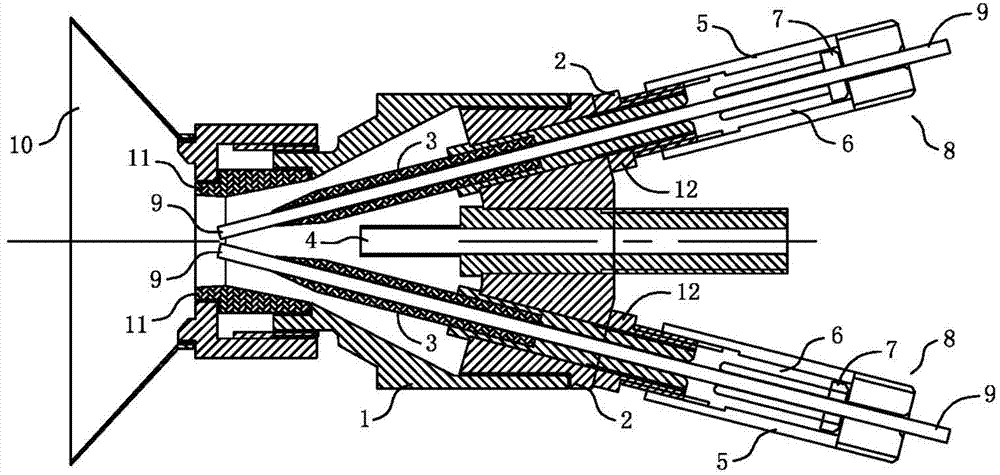

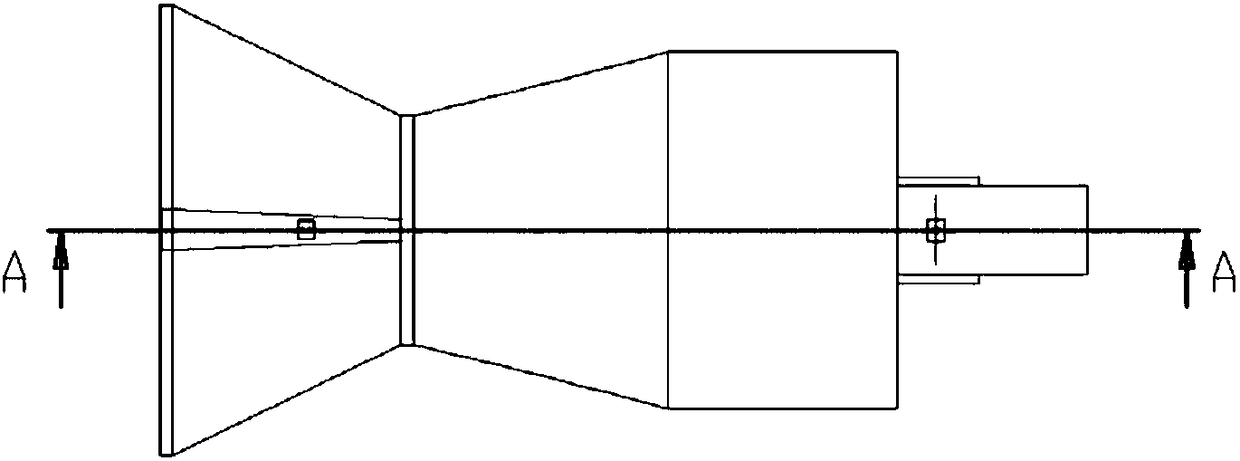

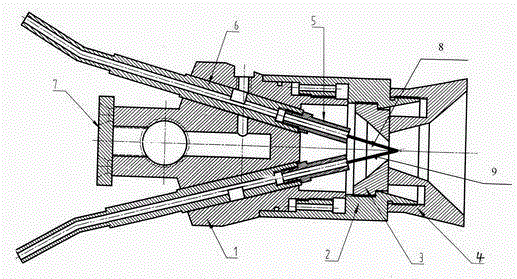

Wiredrawing type high-speed electric arc spraying gun

ActiveCN104874497ARealize the atomization effectUniform atomizationElectric arc sprayingElectric machineryEngineering

The invention discloses a wiredrawing type high-speed electric arc spraying gun. The wiredrawing type high-speed electric arc spraying gun comprises a wire feeding motor, a speed reducing mechanism, wire feeding mechanisms and a spraying gun head, wherein an output shaft of the wire feeding motor is connected with the speed reducing mechanism; two ends of an output shaft of the speed reducing mechanism are connected with the wire feeding mechanisms respectively; wire inlet and outlet pipes are arranged on each wire feeding mechanism; the spraying gun head comprises a rear gun body; a front gun body is mounted at the front end of the rear gun body; a spray nozzle is fixed on the rear gun body through a support seat and extends out of an inner cavity of the front gun body; an airflow flow channel is formed in the rear gun body and penetrates through a converging-diverging flow channel of the spray nozzle; an outer cover is arranged on the outer wall of the spray nozzle, and an annular flow channel communicated with the converging-diverging flow channel is formed between the outer cover and the spray nozzle; the rear gun body is equipped with two current contact nozzles, the current contact nozzles correspond to corresponding wire guiding inclined holes in the spray nozzle, and two wires conveyed from the wire guiding inclined holes are converged nearby the converging-diverging flow channel. According to the wiredrawing type high-speed electric arc spraying gun, the particle spray speed can be increased, so that the atomizing jet is more uniformly concentrated, wire feeding parts in the wire feeding mechanisms are prevented from being contacted with wires and dust, and the service life is effectively prolonged.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

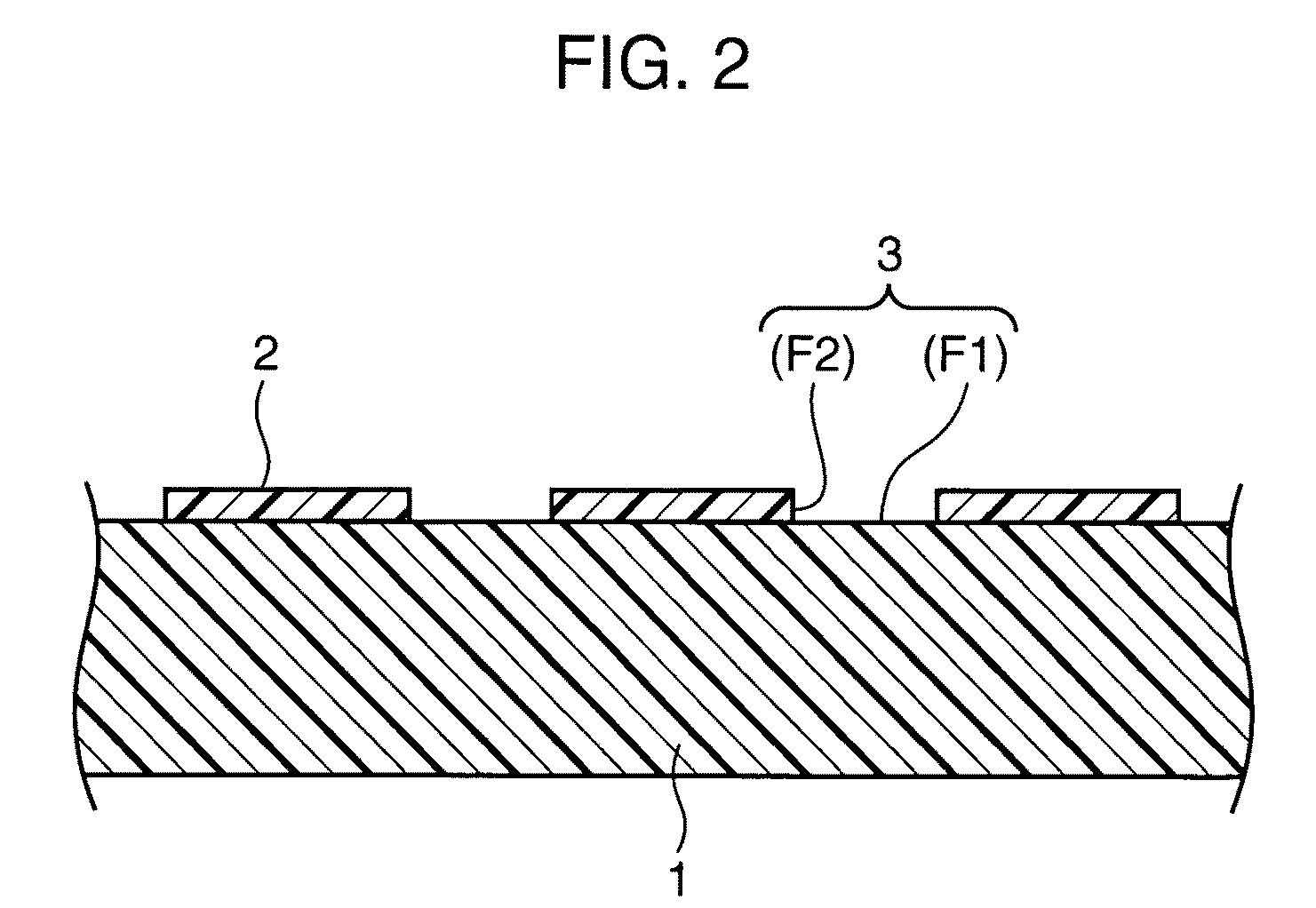

Method for coating metal on the surface of integrated circuit structure

InactiveCN1449004AThickness reachesEasy to mass produceElectric arc sprayingSemiconductor/solid-state device detailsMetal coatingElectromagnetic shielding

The present invention is the method of coating metal onto the surface of IC structure. The IC structure includes one substrate, one or more IC chips coupled to the substrate via gold wire, polycrystal or other material, and one coating covering at least the chips and near parts on the substrate. Through metal spraying, one metal coating is formed on partial non-conducting surface of the IC structure and before metal spraying some protecting film may be formed optionally. The sprayed metal coating, with required thickness altered via control, can reach excellent heat dissipating effect and electromagnetic shielding effect for the normal operation of the IC chips.

Owner:VIA TECH INC

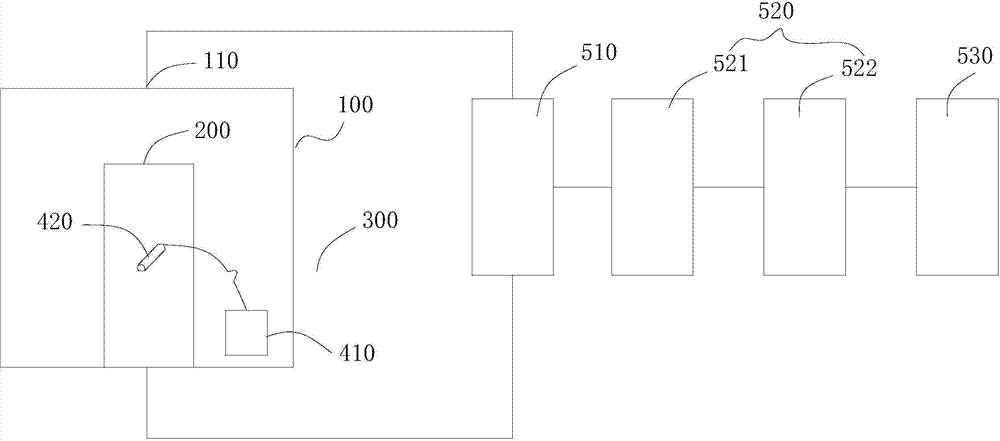

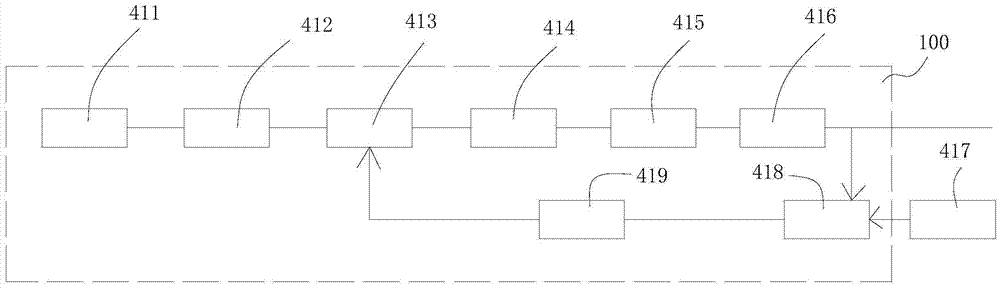

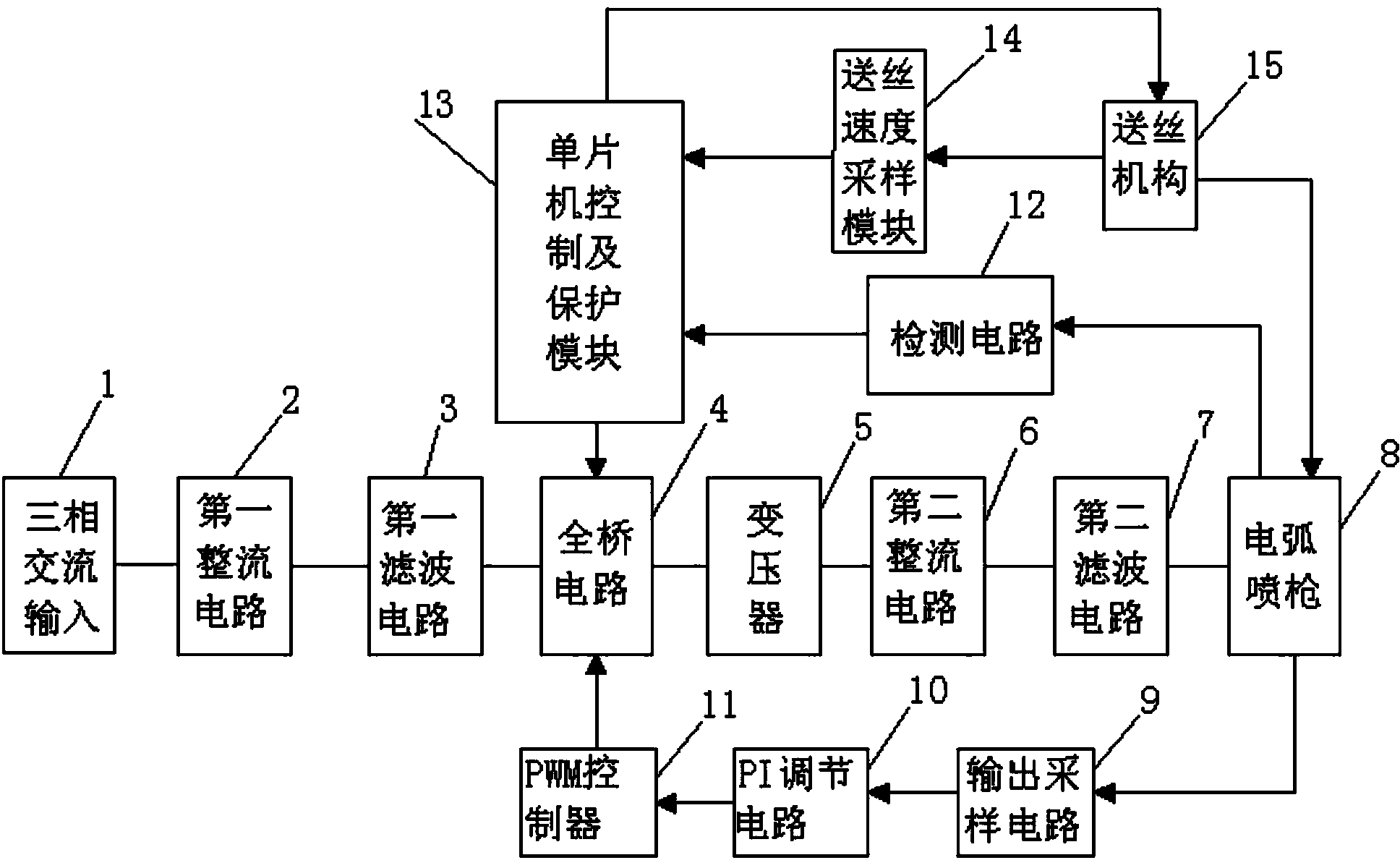

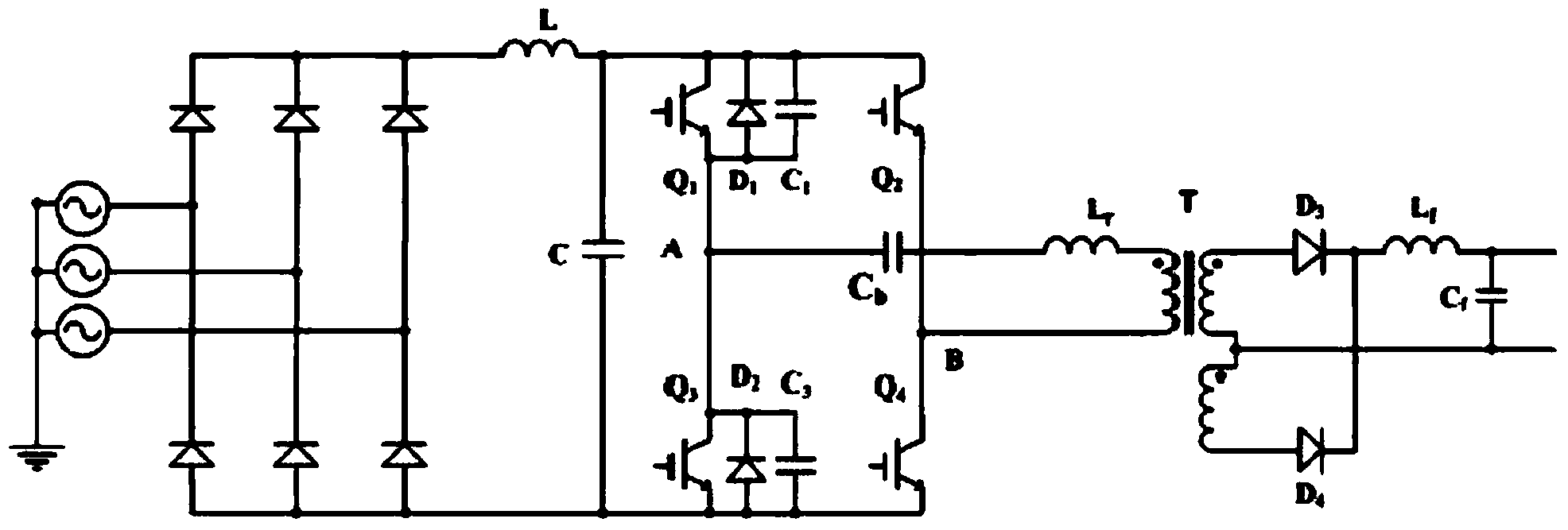

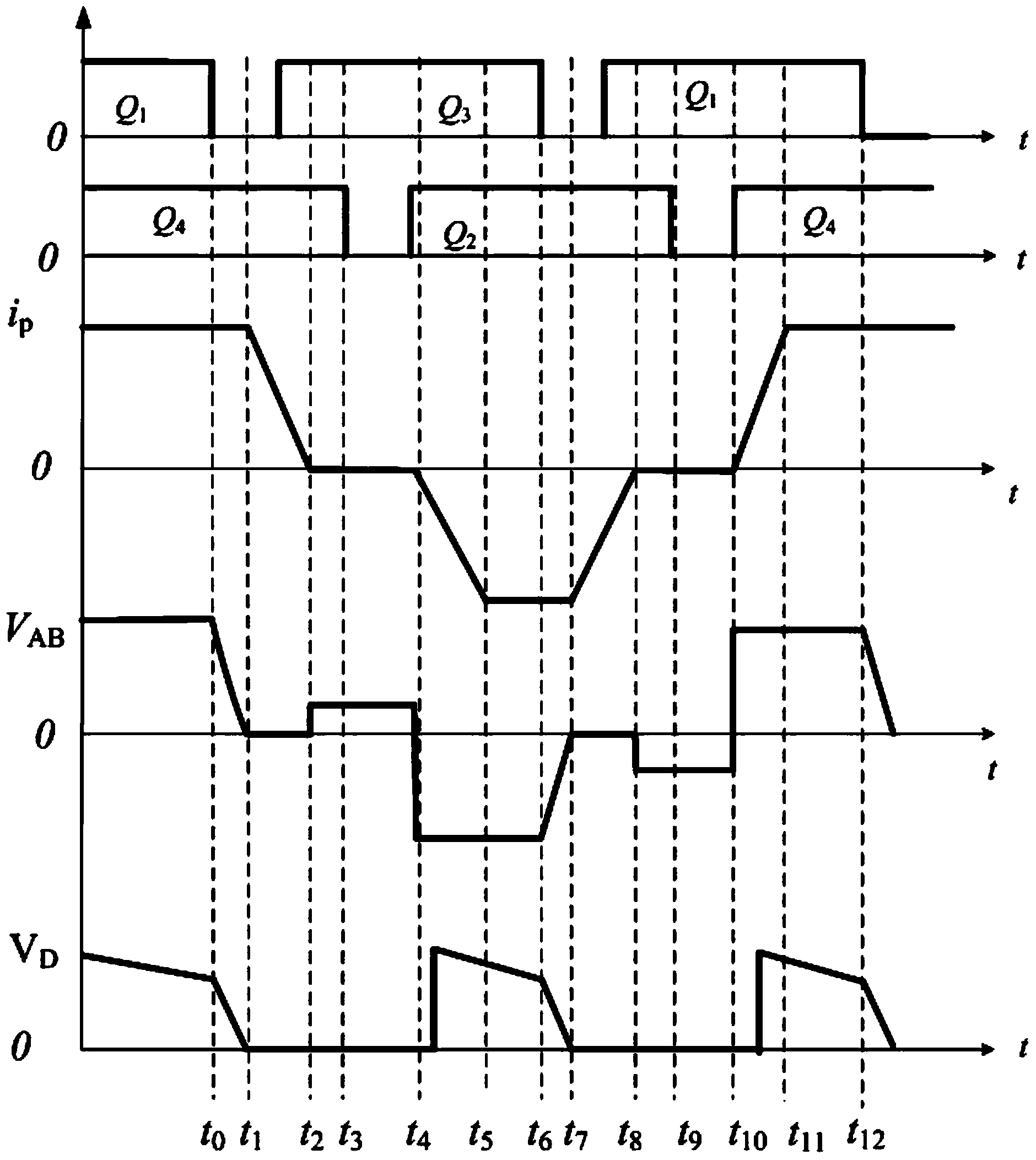

Inverter type electric arc spraying power source based on phase-shifted full-bridge

InactiveCN104038071AReduce switching lossesReduce volumeEfficient power electronics conversionElectric arc sprayingPhase shiftedFull bridge

The invention relates to an inverter type electric arc spraying power source based on a phase-shifted full-bridge. The inverter type electric arc spraying power source comprises a first rectifier circuit, a first filter circuit, a full-bridge circuit, a high-frequency transformer T, a second rectifier circuit and a second filter circuit, all of which are orderly connected to one another, wherein the first rectifier circuit is connected to a three-phase alternating current input; the second rectifier circuit is connected to an arc pistol. The inverter type electric arc spraying power source further comprises an auxiliary control module which is used for controlling the full-bridge circuit to work. The inverter type electric arc spraying power source has the advantages that soft switching of a switching tube is realized by use of the phase-shifted full-bridge, the switching loss of the power source is greatly reduced due to the use of the soft switching technology, the overall efficiency is improved and the electric energy is saved.

Owner:SUZHOU NUCLEAR POWER RES INST

Electric arc spray nozzle

ActiveCN103657909ARealize automatic cleaningPrecise tool changeMolten spray coatingElectric arc sprayingSpray nozzleFront cover

The invention discloses an electric arc spray nozzle. The electric arc spray nozzle comprises a support, an air cap, a nozzle cap, a front cover plate, an air nozzle, nozzle bases, nozzle tips and feeding mechanisms, wherein the air nozzle is fixed to the front end of the support, the nozzle bases are fixed to the support, and are arranged on the two sides of the air nozzle respectively, the nozzle tips are arranged at the front ends of the nozzle bases, the feeding mechanisms are connected with the rear ends of the nozzle bases, the front cover plate is arranged at the front end of the support, the nozzle cap is arranged at the front end of the front cover plate, and the air cap is connected with the front portion of the nozzle cap in a sleeved mode. According to the mode, the electric arc spray nozzle has the advantages of being high in reliability and good in electrical conductivity, having the clean surface, being low in requirement for the diameter tolerance of materials and capable of achieving two times of atomization and automatic cleaning of metal wires, and having wide market prospect in the surface spraying market.

Owner:SHIJIAZHUANG XINRI ZINC IND

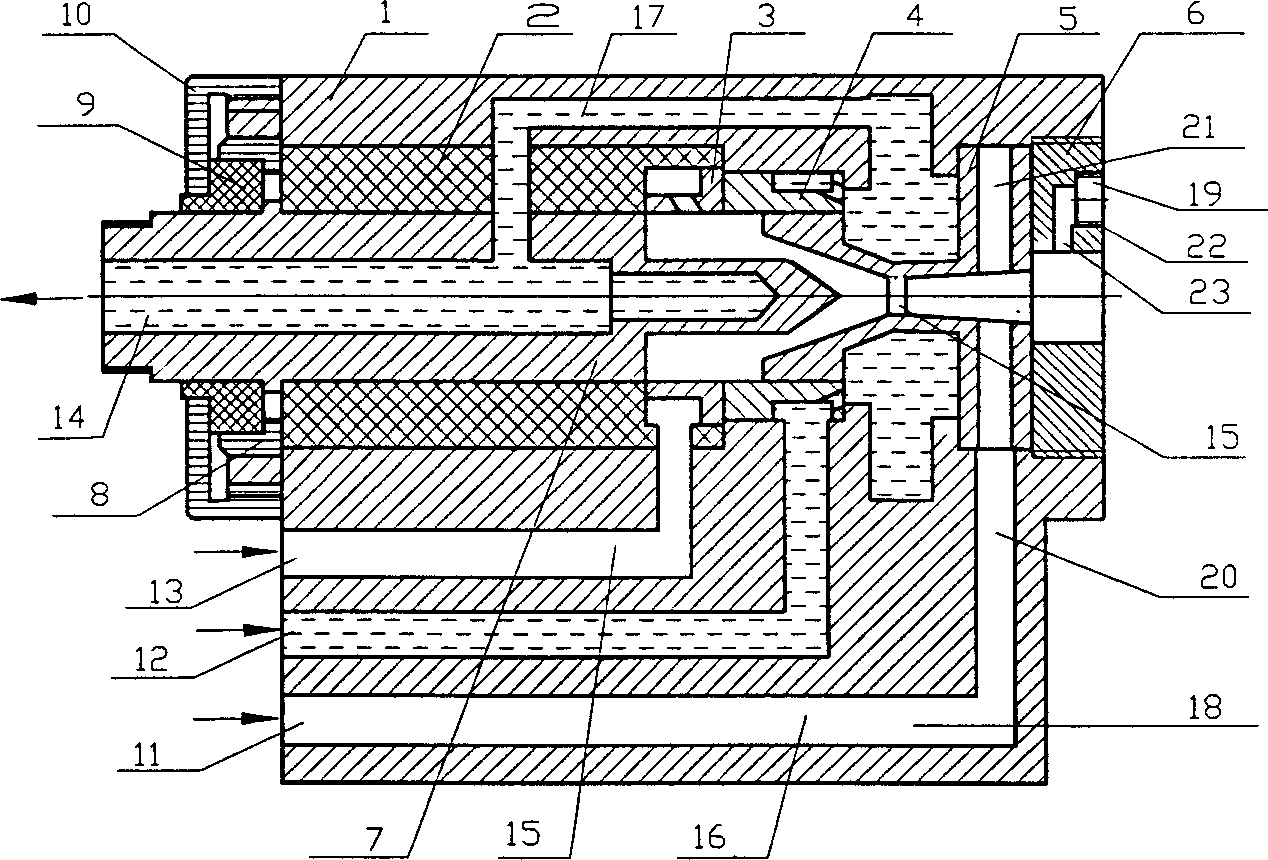

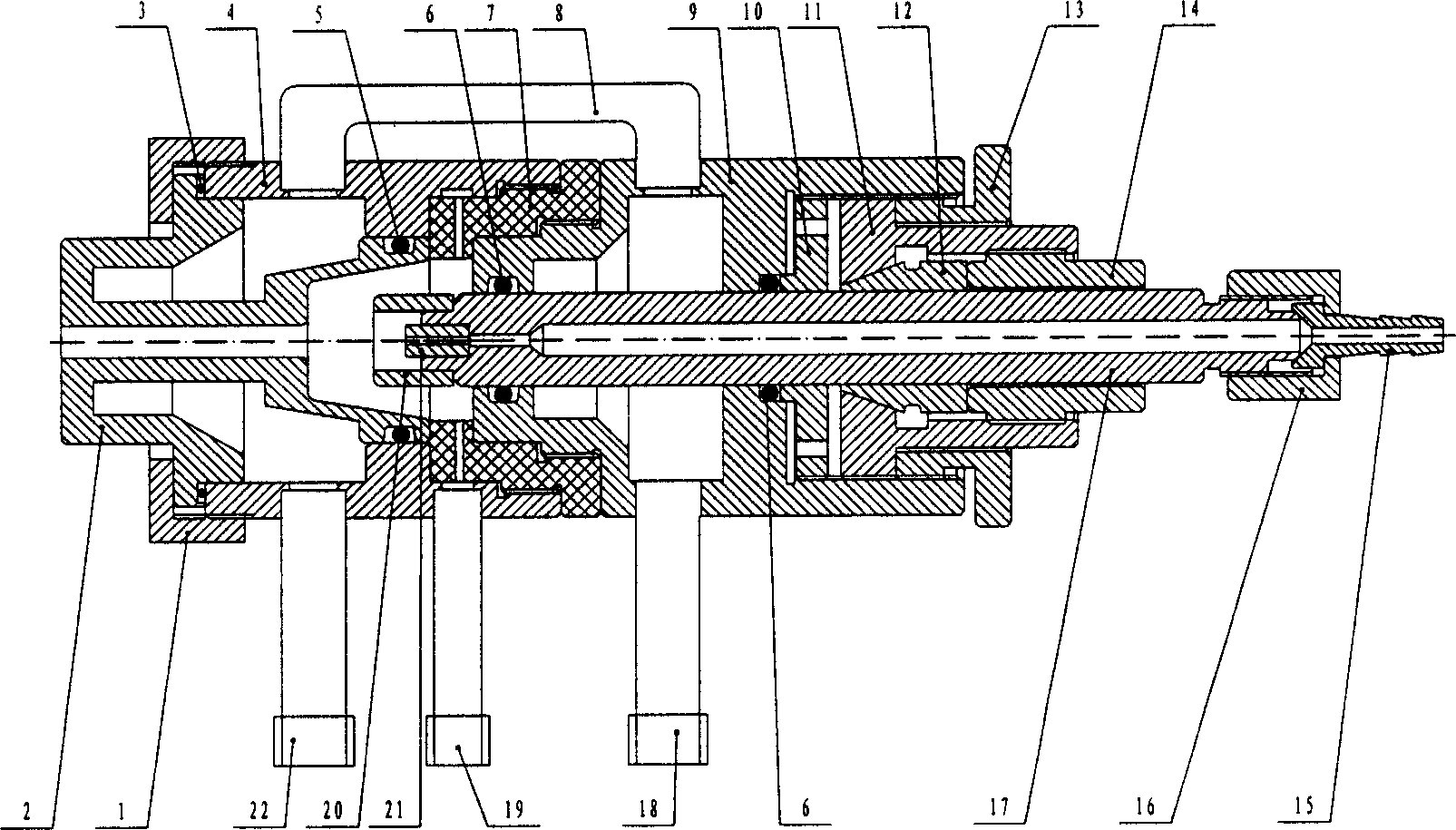

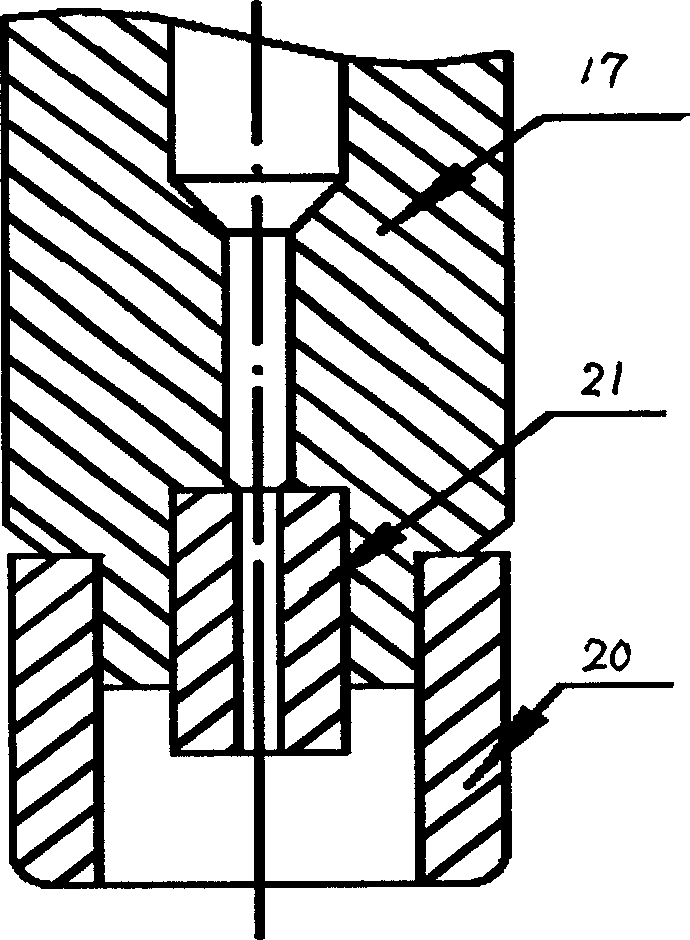

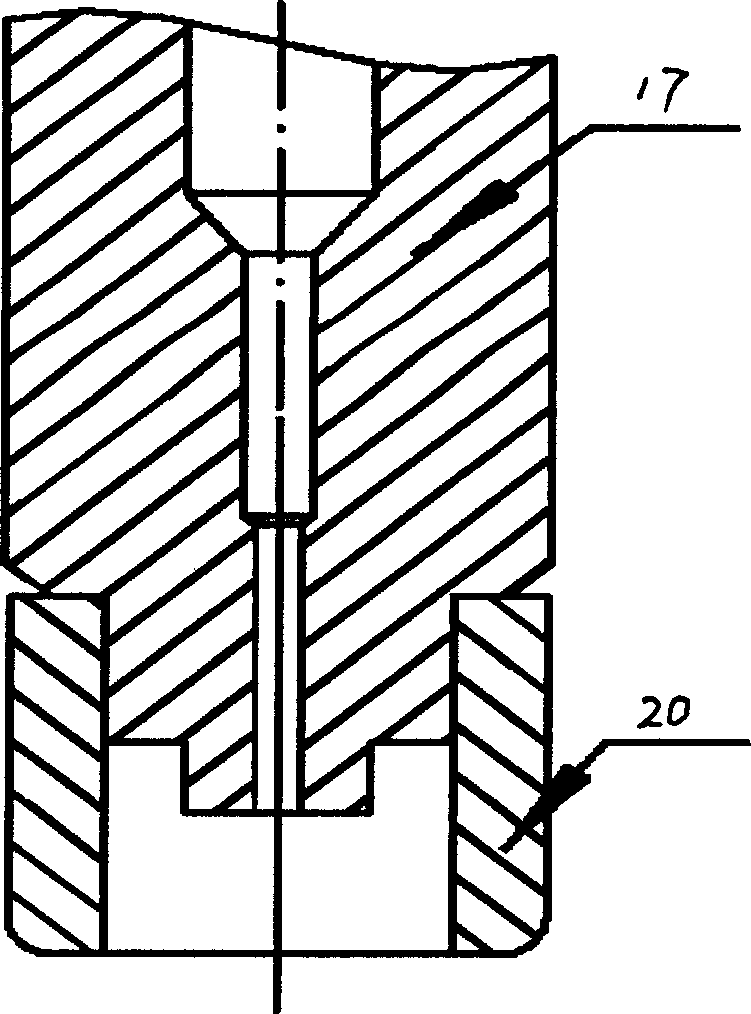

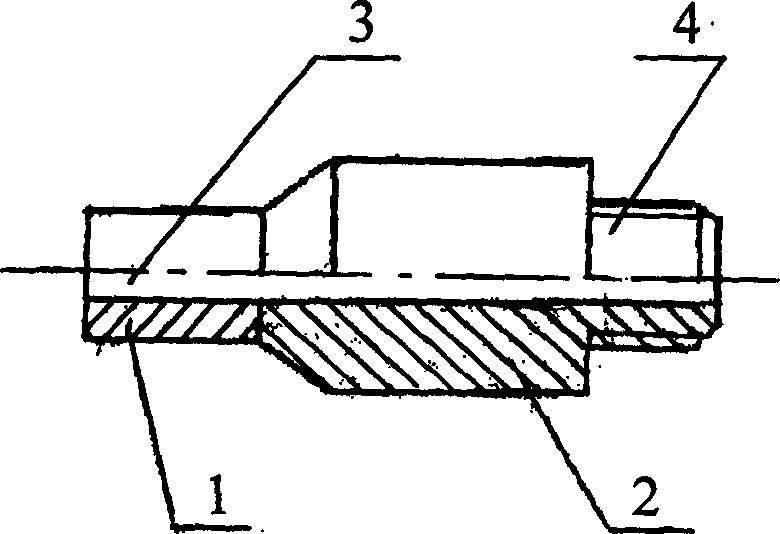

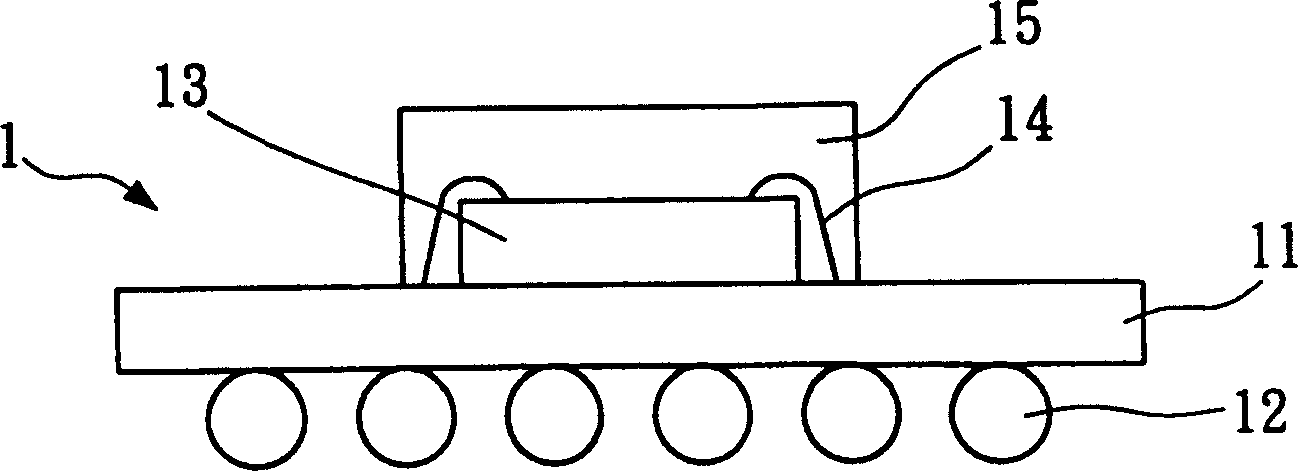

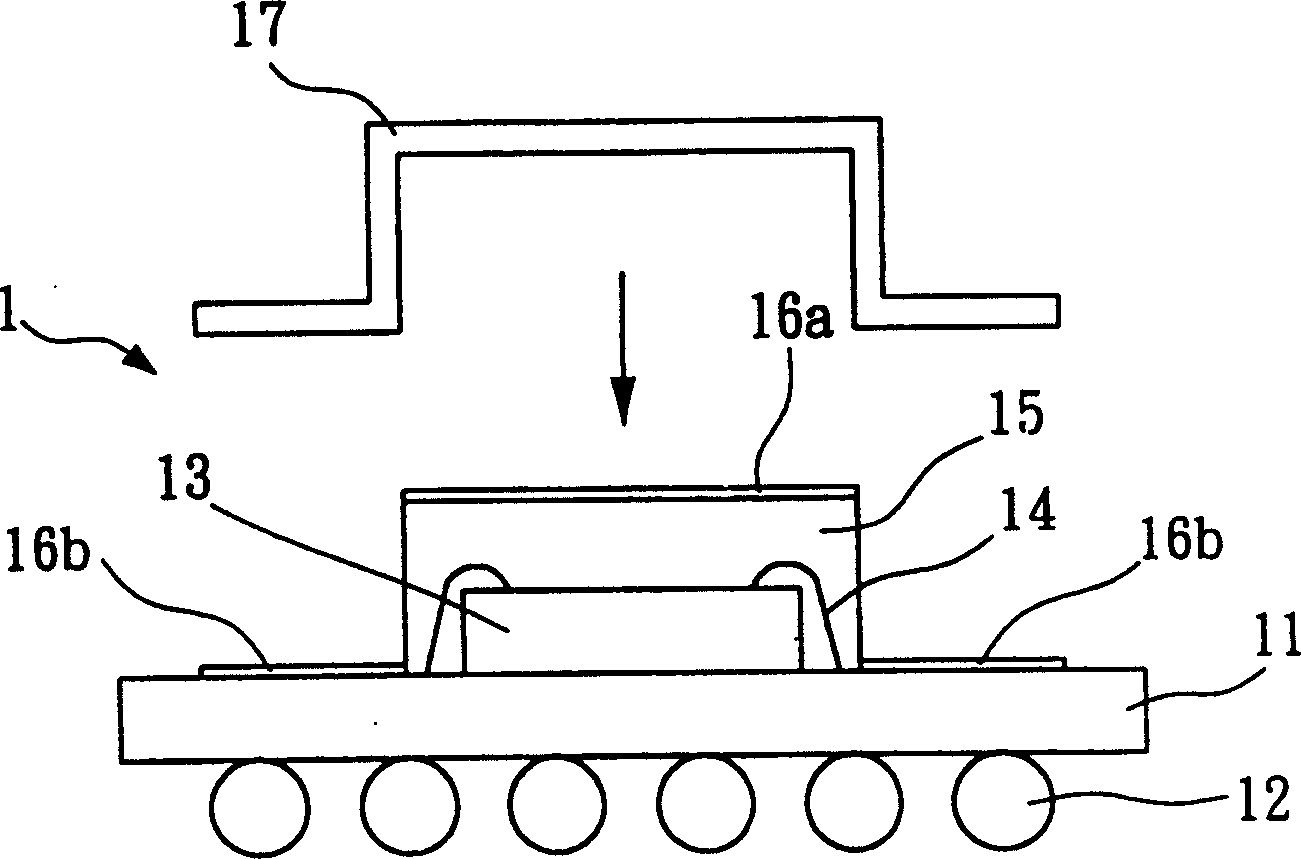

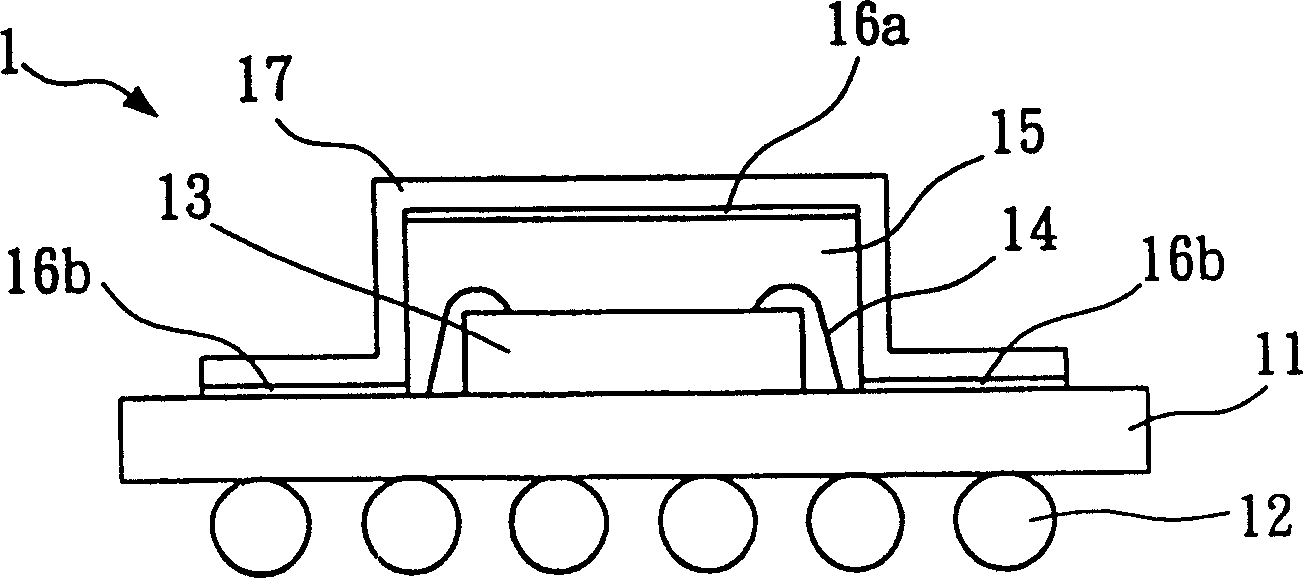

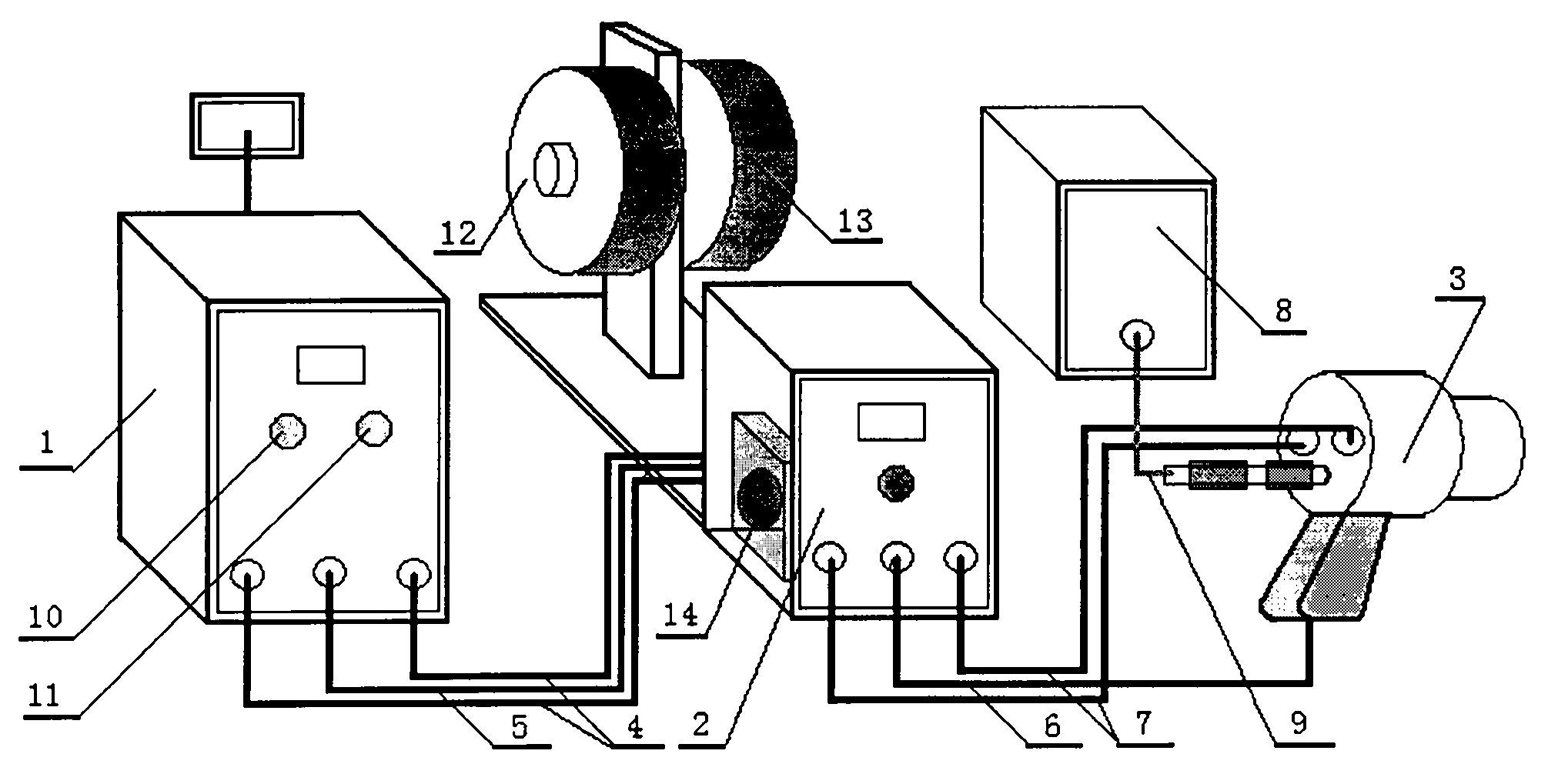

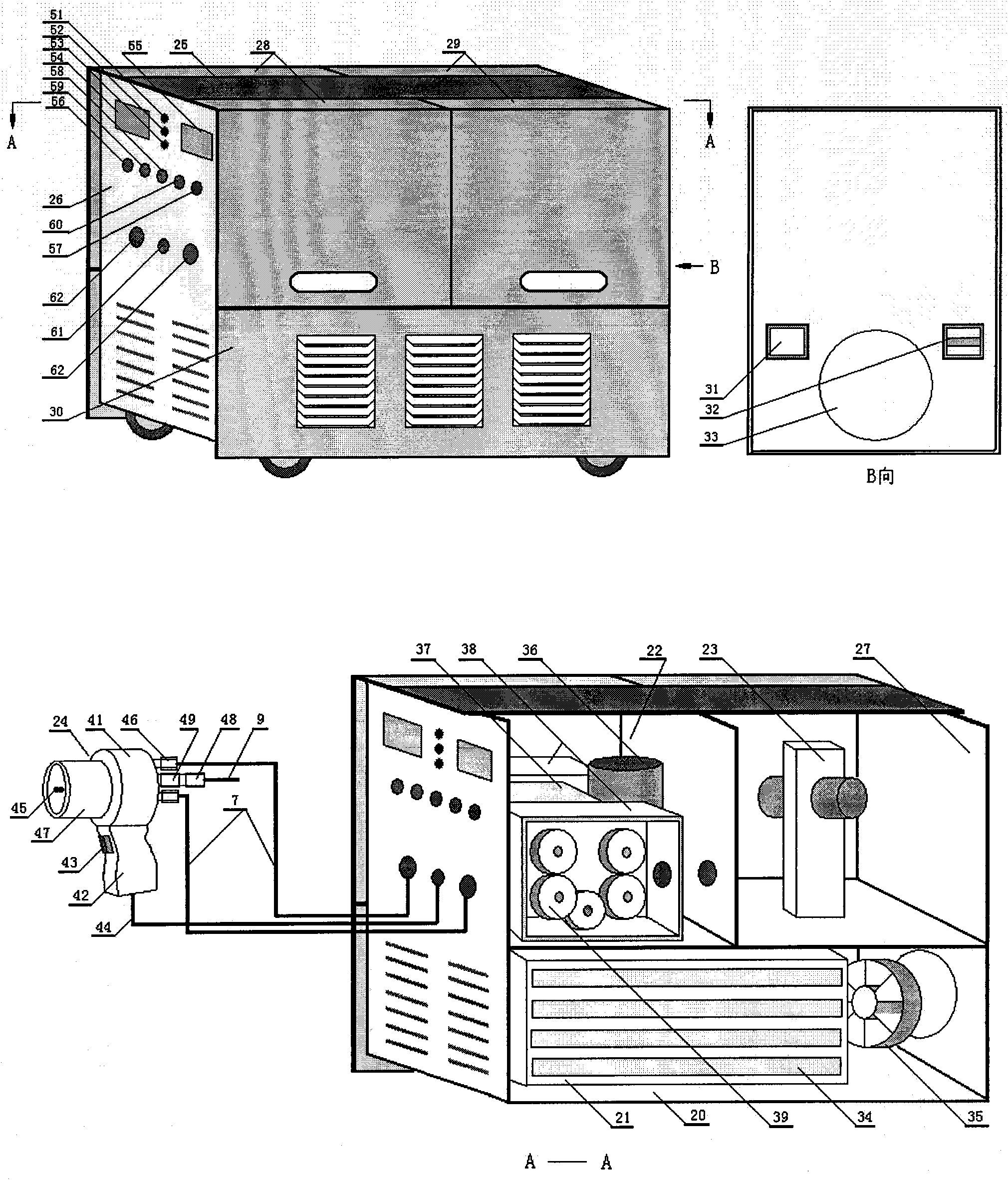

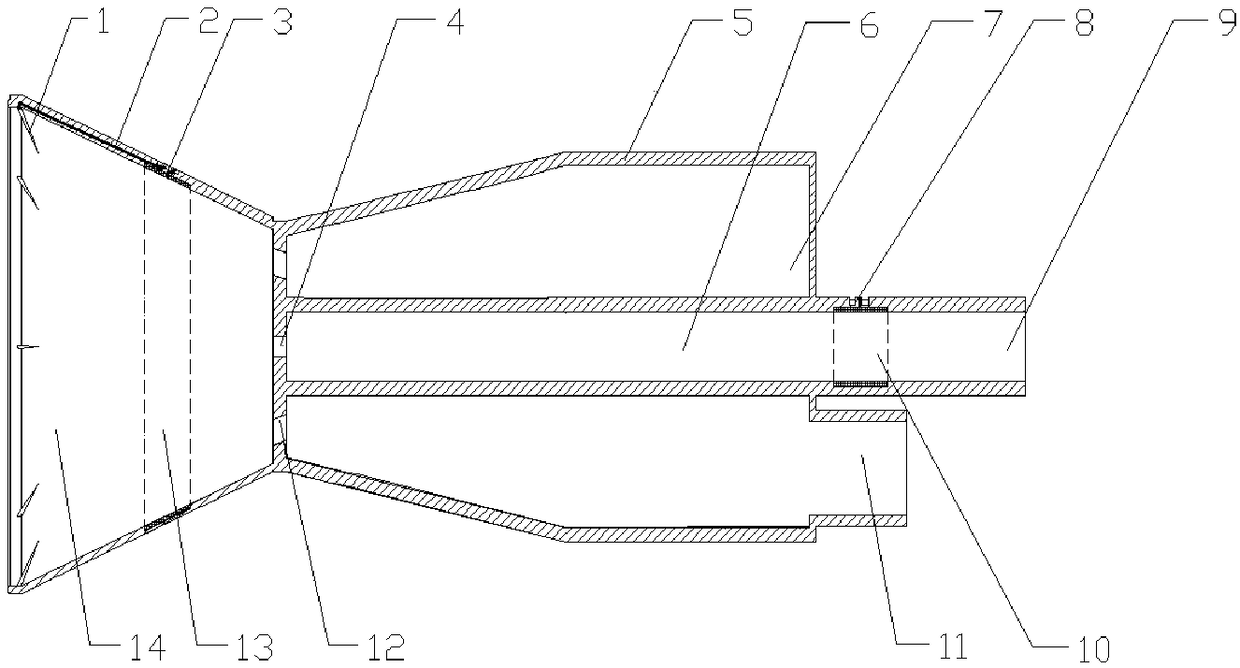

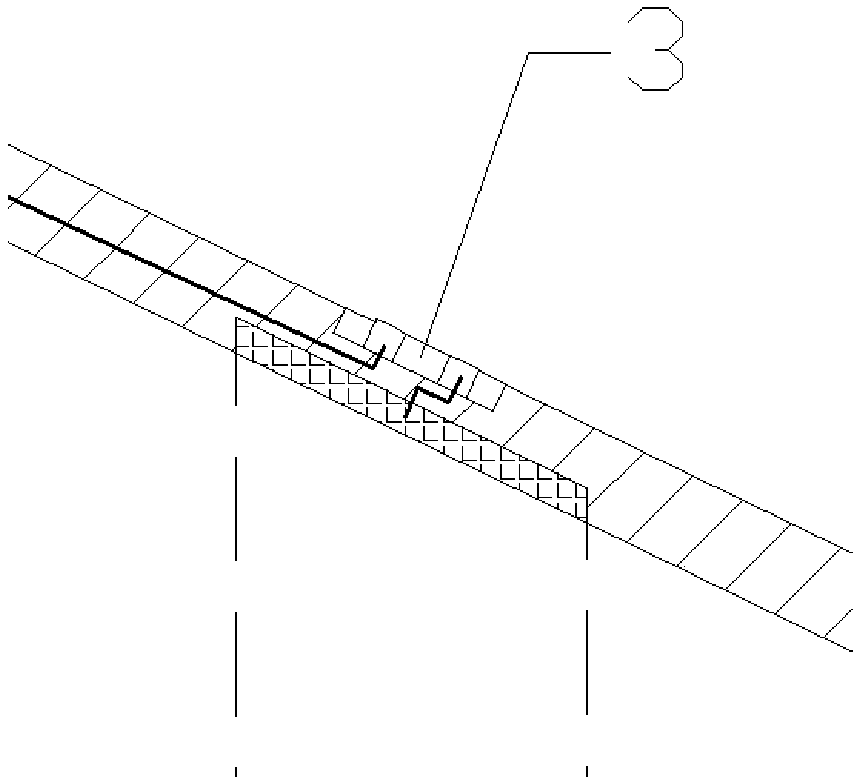

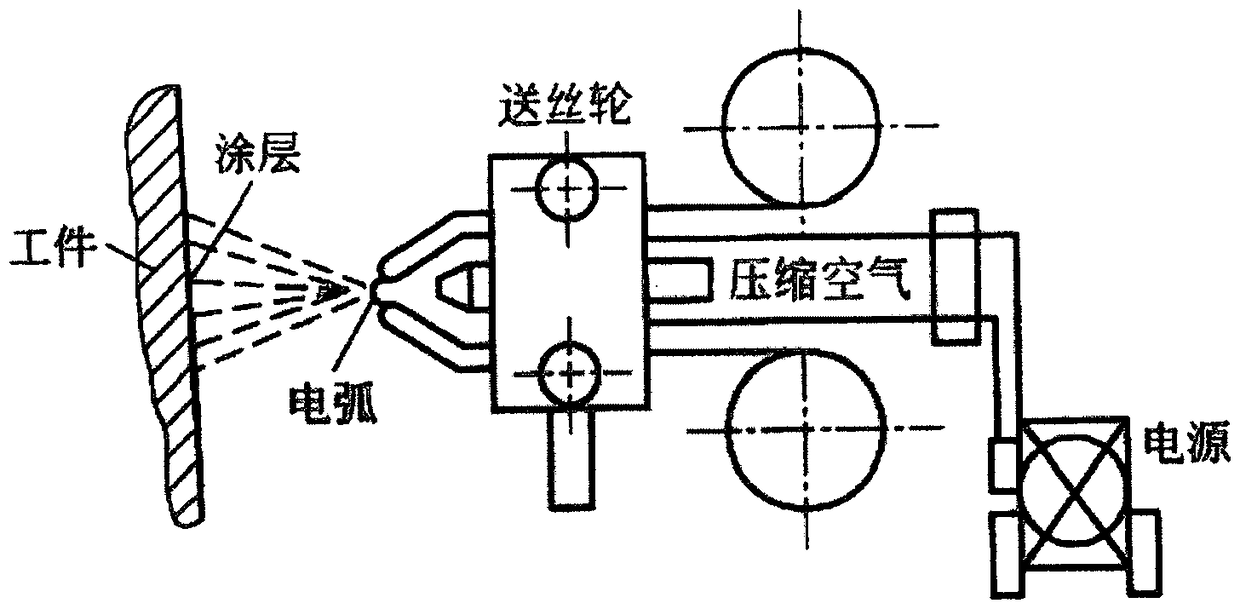

Integral push-wire-type electric arc spraying equipment

InactiveCN101864550AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingWhole body

The invention relates to an integral push-wire-type electric arc spraying equipment used for thermal spraying, which can be seen in an attached figure of the abstract. The equipment adopt an inverter-type spraying power supply, has the technical scheme of combining and closing the spraying power supply, a wire feed device and a wire reel bracket (including a wire reel) into a whole body, and is matched with a home-made electric arc spray gun. The integral push-wire-type electric arc spraying equipment solve the problems of heavy weight, large volume, dispersed devices, more externally connected cables and the like of the push-wire-type electric arc spraying equipment. The equipment have the function of stepless regulation for output voltage within the range of 10-50V, and can freely adjust the parameters without stopping a machine in the spraying process; the equipment is provided with a manual / automatic spraying and wire detection / spraying switch, thus being convenient for the selection of operation way and preventing electric arc from hurting people and damaging equipment when in the process of installing, adjusting and checking spraying wires; and due to the full-closed structure, the blockage phenomenon of a wire guide pipe is avoided. The equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like.

Owner:慈溪光华金属复合材料有限公司

Anti-power-failure arc spraying gun

InactiveCN103480519AFreedom of movementSimple structureElectric arc sprayingElectrode supporting devicesElectricityGuide tube

The invention discloses an anti-power-failure arc spraying gun, and belongs to an arc spraying or spray welding device. The anti-power-failure arc spraying gun comprises a spraying gun body and a spraying gun seat, the spraying gun body is mounted on the spraying gun seat, at least one guide wire tube and a compressed air tube are arranged inside the spraying gun seat, and an opening at the front end of the spraying gun body is corresponding to an opening of each guide wire tube; shells are fixed at the positions, corresponding to inlets of the guide wire tubes, at the rear end of the spraying gun seat; the other end of each shell is connected with a terminal pad, and an electrode bundle corresponding to the inlet of each guide wire tube is mounted on each terminal pad. Electroconductive assemblies are adopted to conduct electricity in a mode of axially wrapping metal wires, the spraying gun is ensured to form continuous electricity conduction in use by a mode of electrode wire contact, and accordingly arc breaking caused by power failure is avoided; besides, the metal wires can freely move between the electrode bundles by the axial wrapping mode; in addition, through the vertically-symmetrical guide tubes and electroconductive assemblies, spraying arc breakage can be further prevented.

Owner:张志宇

Induction charging and corona charging combined two-stage charging atomizing nozzle

PendingCN108080166AReduce charging voltage requirementsImprove securityElectric arc sprayingInduction-charging sprayingElectricityCorona ring

The invention relates to an induction charging and corona charging combined two-stage charging atomizing nozzle. The induction charging and corona charging combined two-stage charging atomizing nozzlecomprises a pesticide solution spray pipe, an airflow spray pipe and a conical charging cavity; the middle of the pesticide solution spray pipe is embedded with a ring-shaped pesticide solution electrode, the rear of the pesticide solution spray pipe is provided with a pesticide solution inlet, and the front portion of the pesticide solution spray pipe is a conical spray nozzle; the airflow spraypipe wraps the pesticide solution spray pipe, the front of the airflow spray pipe is provided with a ring-shaped air outlet, and the air outlet angle of the airflow spray pipe is identical to the opening angle of the conical charging cavity; the conical charging cavity is connected with the front portions of the pesticide solution spray pipe and the airflow spray pipe, the middle of the inner wall of the conical charging cavity is embedded with a ring-shaped induction electrode, and the front opening of the conical charging cavity is provided with a corona electrode with 8 corona needles; thepesticide solution electrode and the corona electrode are connected with the negative electrode of a power supply, the induction electrode is connected with the positive electrode of the power supply, pesticide solution is sprayed and atomized via the conical spray nozzle and meanwhile induces negative charges to complete a primary charging process; the 8 corona needles of the corona electrode discharge under action of corona voltage, negative charge ions encounter with and are combined with charged droplets when moving towards the induction electrode to complete a secondary charging process.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

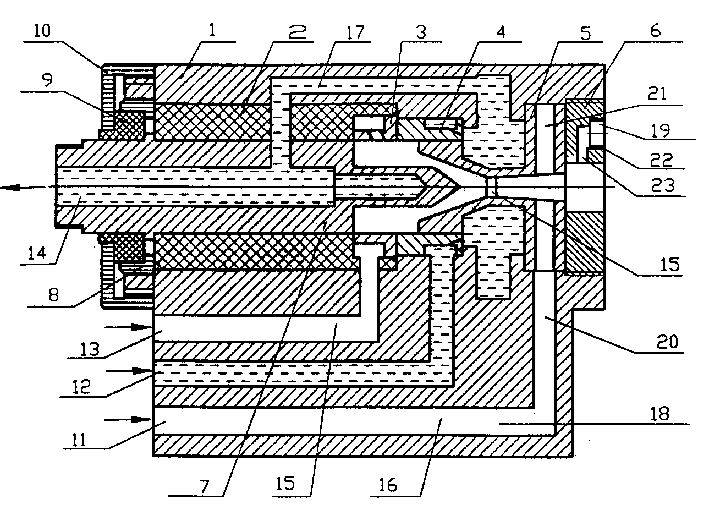

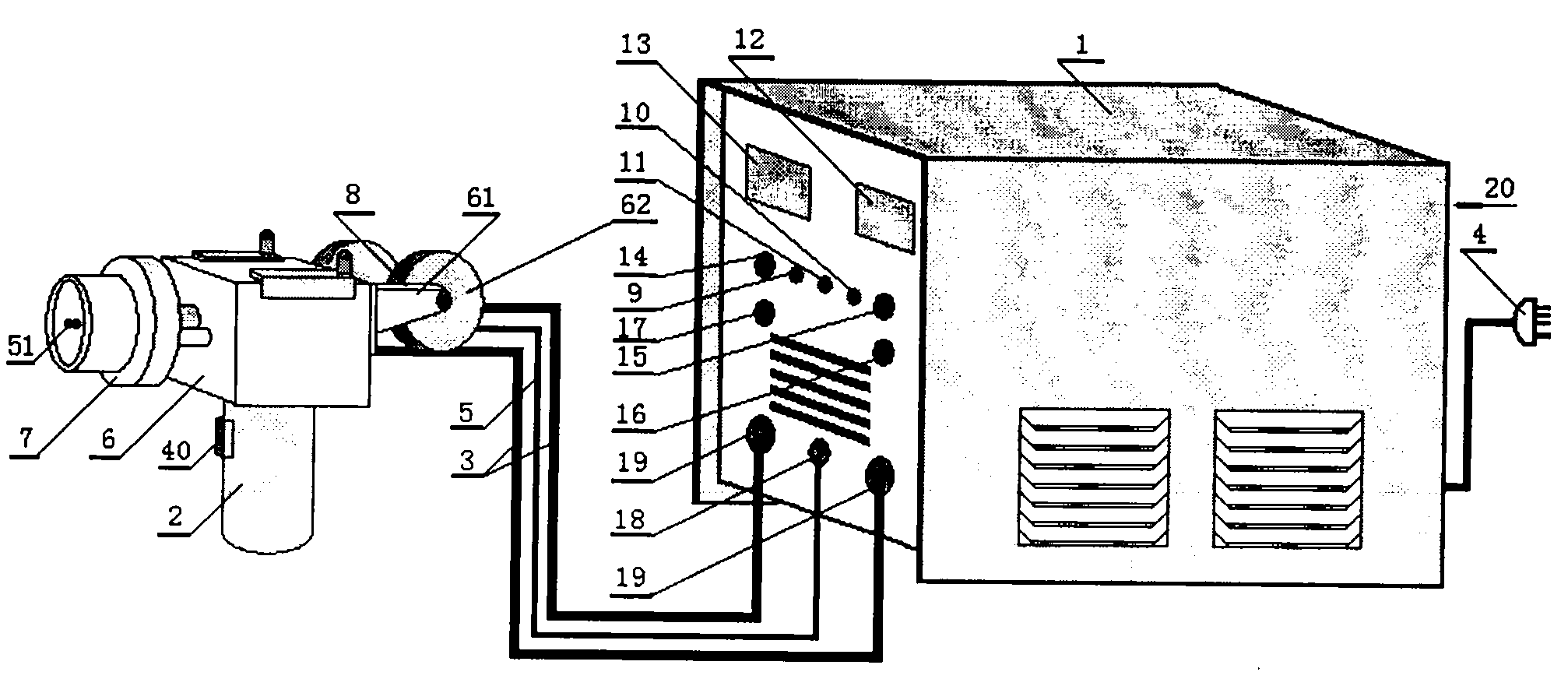

Small-sized wire drawing type electric arc spraying equipment

ActiveCN101864549AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingPower flow

The invention relates to small-sized wire drawing type electric arc spraying equipment used for hot spraying, which is shown in the attached drawing of the abstract. The equipment adopts the technical scheme of an inversion type spraying power supply and a wire drawing type spraying gun, the output voltage of 10 to 40V is regulated in a stepless way, and the voltage can be regulated in the spraying process without stop; a manual / automatic spraying and wire inspection / spraying switch is arranged, which is convenient to select an operation mode and avoid the occurrence of the condition that electric arcs injure people and damage equipment because of the short circuit of a wire material when the spraying wire material is installed, regulated and inspected; the spraying wire material is limited to be phi 1.0 to phi 1.6mm, the maximum spraying current is 250A, the load duration rate is 100 percent, and continuous spraying is permitted; the weight of the spraying power supply is 15kg, and the weight of the spraying gun is 1.5kg; and the equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like, is suitable for the field operation and the use in an occasion with small spraying space and is suitable for spraying a component with a fine and small structure and a product with a fine coating.

Owner:慈溪光华金属复合材料有限公司

Spiral-flow type supersonic speed electric arc spraying gun

InactiveCN102974486AGood effectImprove stabilityMolten spray coatingElectric arc sprayingSpray coatingSpray nozzle

The invention discloses a spiral-flow type supersonic speed electric arc spraying gun, which comprises a gun body, wherein a contact tip is connected onto a conducting wire; airflow holes are uniformly distributed on a radial airflow channel arranged in the gun body; a spiral-flow ring is connected with the gun body through screw threads; spiral-flow holes are uniformly distributed on the periphery of the spiral-flow ring; an air gathering hood is fixed with the spiral-flow ring through screw threads; a ceramic nozzle is pressed in the spiral-flow ring through the air gathering hood; and an inner cavity of the ceramic nozzle and an inner cavity of the air gathering hood are combined to form a Laval nozzle. According to the technical scheme, spiral-flow atomization and supersonic speed atomization are combined, the effect and the stability of jet flow atomization are enhanced through a spiral-flow structure and a Laval spray pipe, secondary acceleration of jet flow is realized, and the speed of jet flow is further improved, so that the spray coating particle hole atomization effect is stronger, nanometer refinement is achieved, flying speed achieves supersonic speed, and the prepared coating layer is obviously improved. The spiral-flow type supersonic speed electric arc spraying gun is not only suitable for coating equipment for precision parts, but also suitable for large-area coating preparation.

Owner:新乡市布瑞林特机械再制造有限责任公司

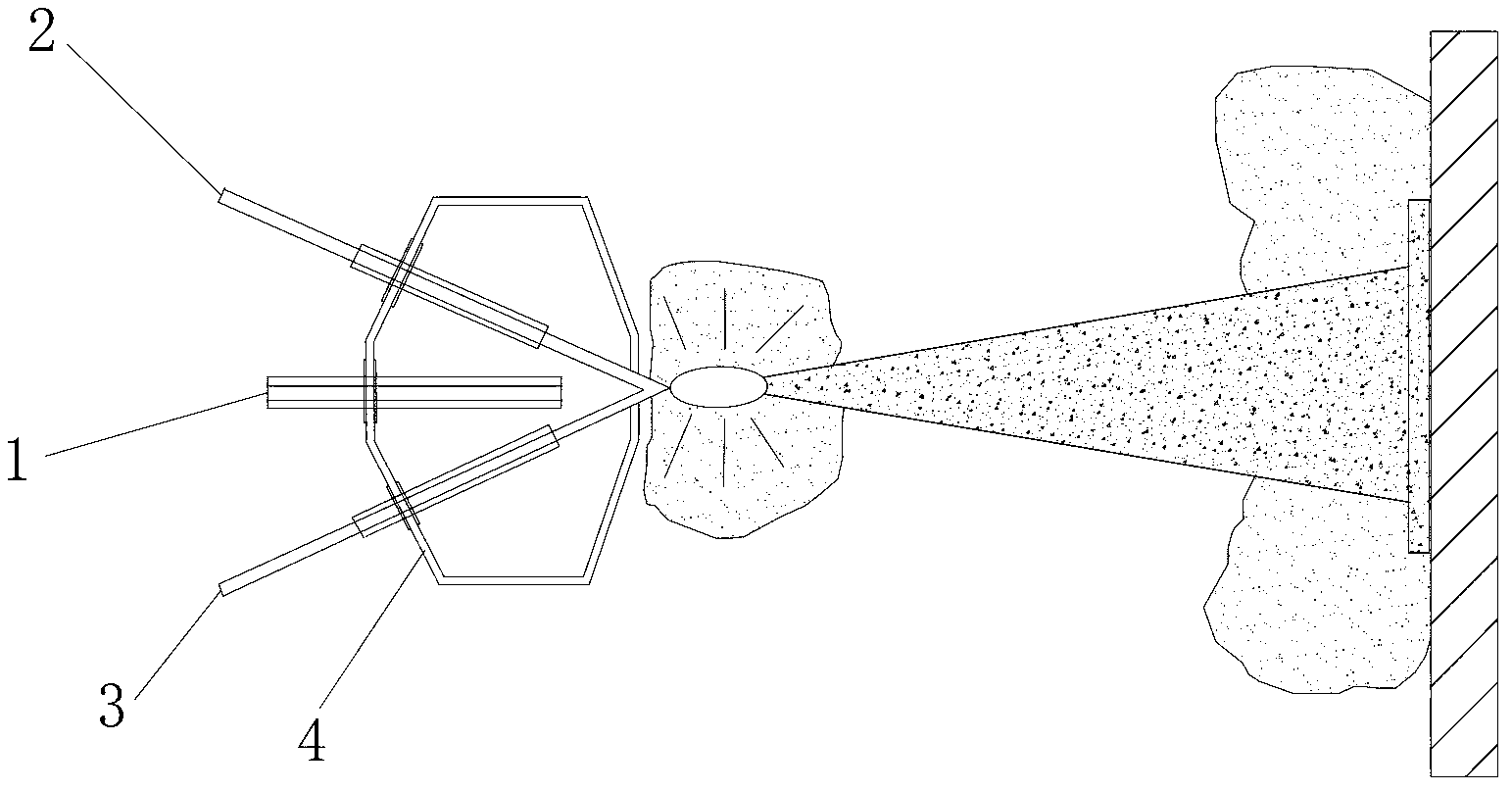

Supersonic-speed electric arc spraying gun

InactiveCN103263989AImprove surface deposition rateImprove Thermal Spray QualityElectric arc sprayingPower flowThermal spraying

The invention provides a light and zero-pollution supersonic-speed electric arc spraying gun for opening up the technical field of micro-spraying thermal spraying. The supersonic-speed electric arc spraying gun comprises a compressed air delivering pipe, a positive pole wire feeding pipe, a negative pole wire feeding pipe and an insulating plate, wherein the positive pole wire feeding pipe and the negative pole wire feeding pipe are insulated mutually and carry current, the tail end of the compressed air delivering pipe is connected with a powder-gathering accelerating pipe, the tail ends of the positive pole wire feeding pipe and the negative pole wire feeding pipe are connected with conducting nozzles, the compressed air delivering pipe, the positive pole wire feeding pipe and the negative pole wire feeding pipe penetrate the insulating plate, and the positive pole wire feeding pipe and the negative pole wire feeding pipe are arranged on one side of an air delivering pipe and are arranged in the compressed air delivering pipe at an included angle of 45-75 degrees. The supersonic-speed electric arc spraying gun opens up the technical field of micro-spraying thermal spraying, is light and zero-pollution and improves the thermal spraying quality.

Owner:东方翼能(北京)科技发展有限公司

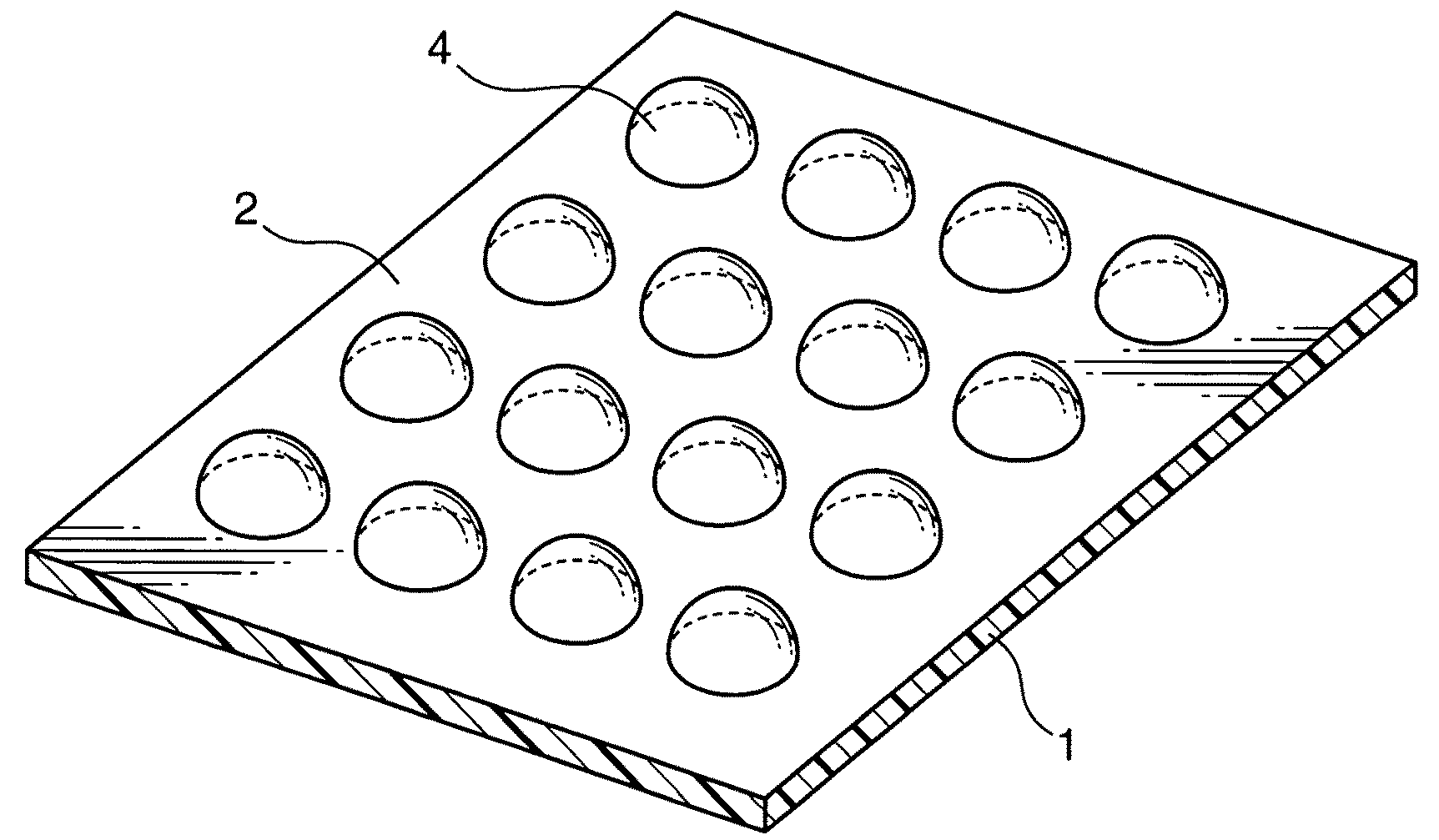

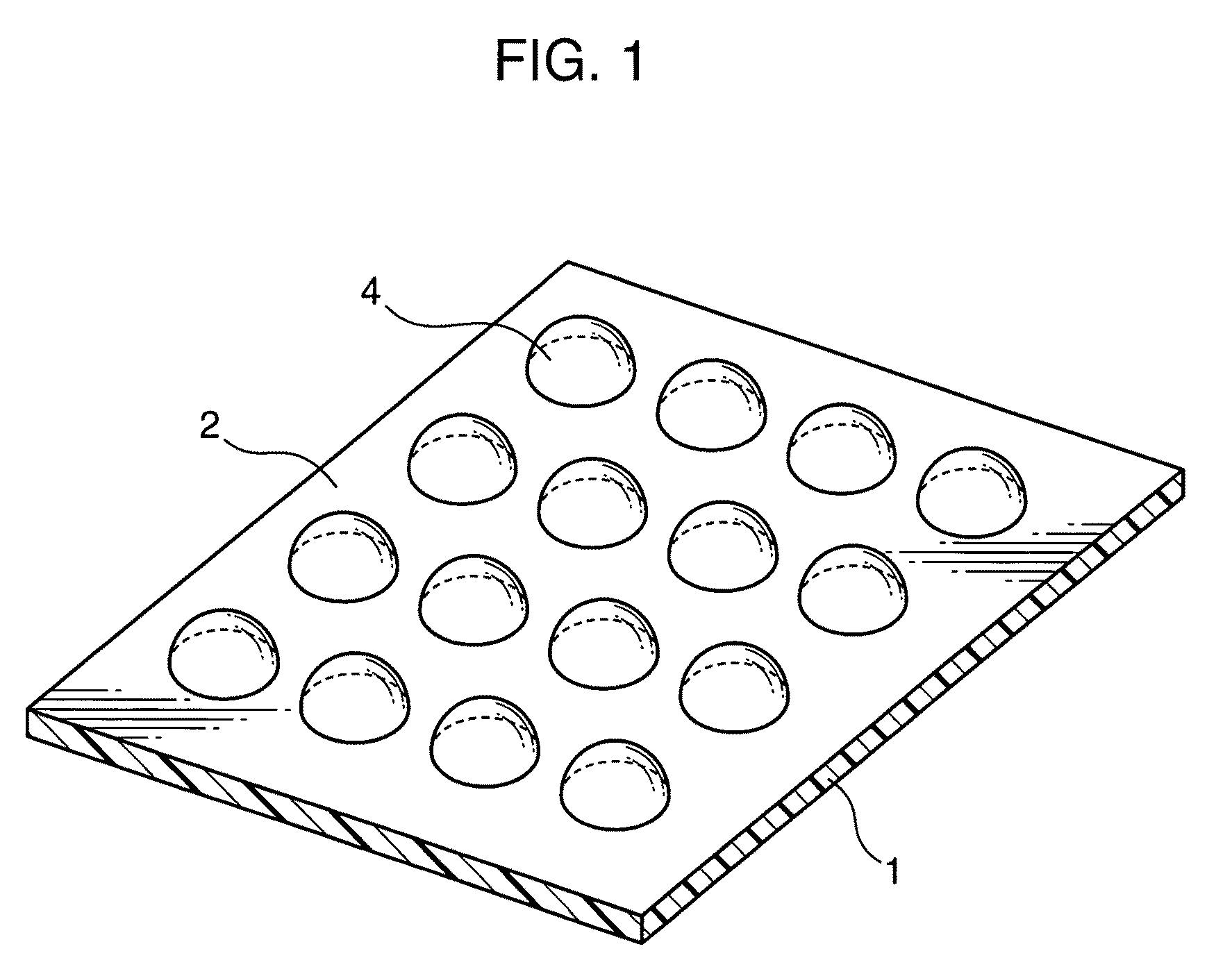

Micro lens, micro lens array, and method of manufacturing the same

InactiveUS7532405B2Excellent resistance to separationShorten the optical path lengthElectric arc sprayingSolid-state devicesOptoelectronicsMicro lens array

A micro lens includes a base material and a lens formed on the base material, wherein the lens is disposed at an opening on the base material, and the opening is formed by covering a surface of the base material with a first monolayer; and the first monolayer has critical surface energy of 22 mN / m or lower and shows non-affinity for a lens material in comparison with a region within the opening, and is fixed to the surface of the base material via a covalent bind.

Owner:PANASONIC CORP

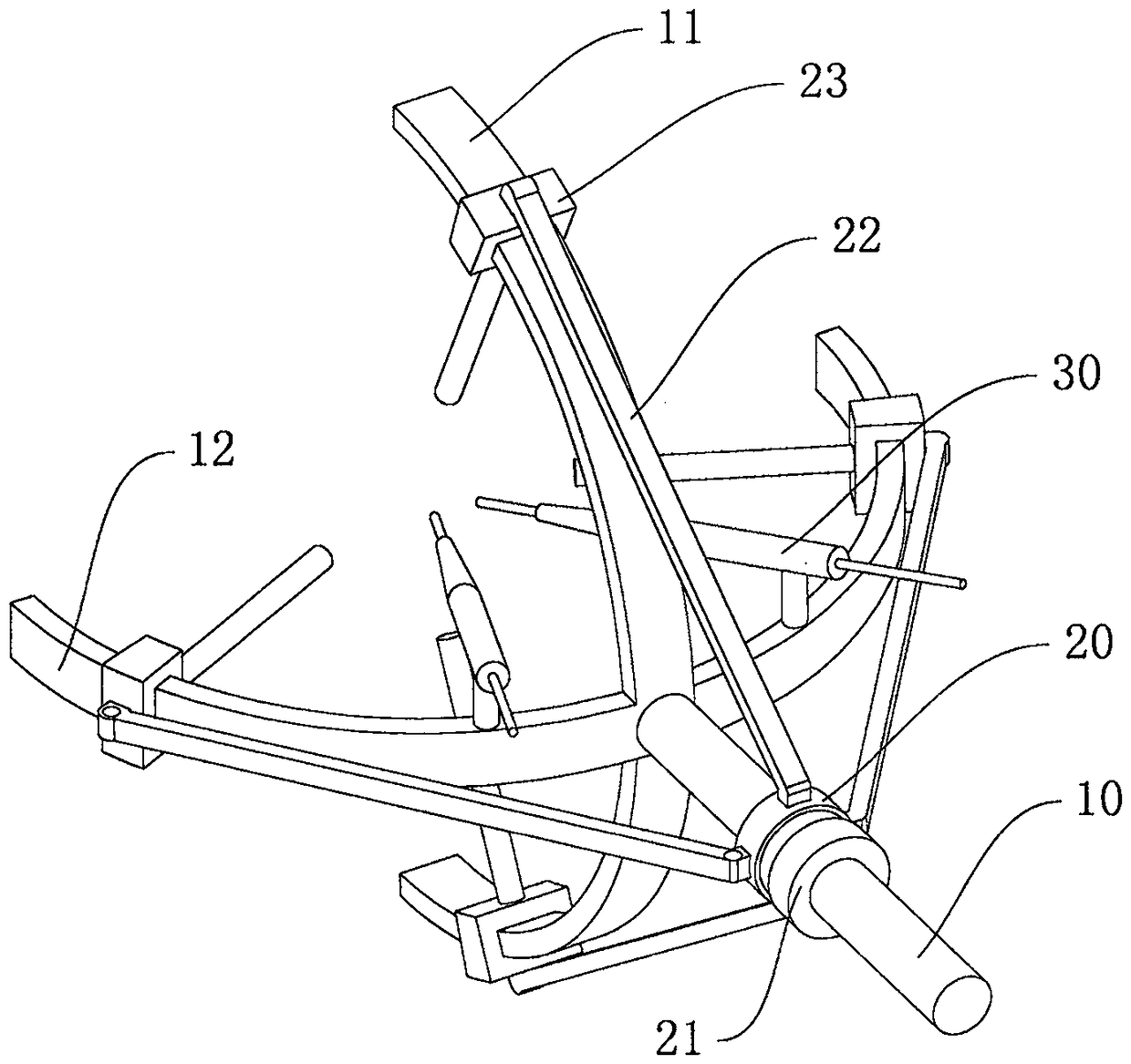

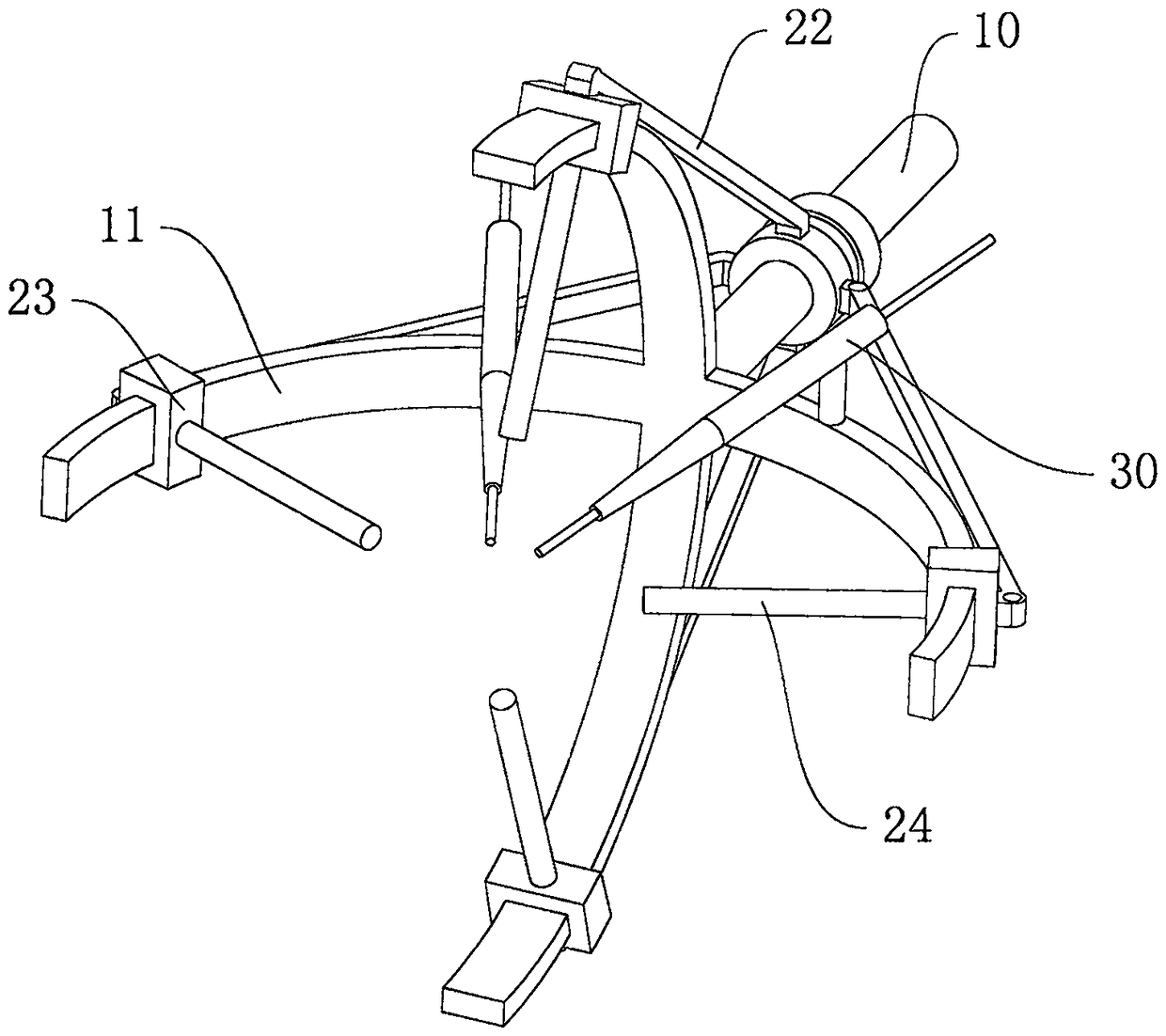

Electric arc spraying device

The invention discloses an electric arc spraying device, and belongs to the technical field of electric arc spraying. The electric arc spraying device comprises a wire feeding device and a gas sourceand further comprises a guide frame, wherein the guide frame comprises first arc-shaped sliding rods, second arc-shaped sliding rods and a supporting screw rod. The electric arc spraying device further comprises an adjusting device which comprises a connecting ring, a screw sleeve, connecting rods, guide blocks corresponding to the connecting rods in a one-to-one mode, the screw sleeve is matchedwith the supporting screw rod and is rotatably connected to the connecting ring, the connecting ring is connected to the supporting screw rod in a sleeve mode, one end of each connecting rod is hingedto the corresponding guide block, and the other ends of the connecting rods is hinged to the connecting ring, and the guide blocks are slidably arranged on the first arc-shaped sliding rods and the second arc-shaped sliding rods; the wire feeding device is used for conveying wires and enabling arc striking points of the wires to be located in an arc center of the first arc-shaped sliding rods andthe second arc-shaped sliding rods. According to the electric arc spraying device, a spraying range can be adjusted when a distance between air nozzles and a workpiece is fixed; and molten wires canbe fully atomized and an influence of arc position deviation, caused by deformation of the wires, on spraying effect is reduced.

Owner:SHENYANG INST OF ENG

Popular searches

Electrostatic separators Dewatering/demulsification with electric/magnetic means Semiconductor/solid-state device manufacturing Refining by electric/magnetic means Liquid separation Cleaning using liquids Fatty/oily/floating substances removal devices Electrostatic cleaning Centrifuges Filtration separation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com