Plasma spraying gun

A spraying gun and plasma technology, applied in the field of spraying guns and ion spraying guns, can solve the problems of not being able to have both internal powder feeding and external powder feeding at the same time, not being able to realize subsonic and supersonic speeds at the same time, and limiting the industrial application range of spraying guns, etc. , to achieve the effect of expanding the spraying range, ensuring the uniformity of heat dissipation and cooling, and reducing the spraying power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

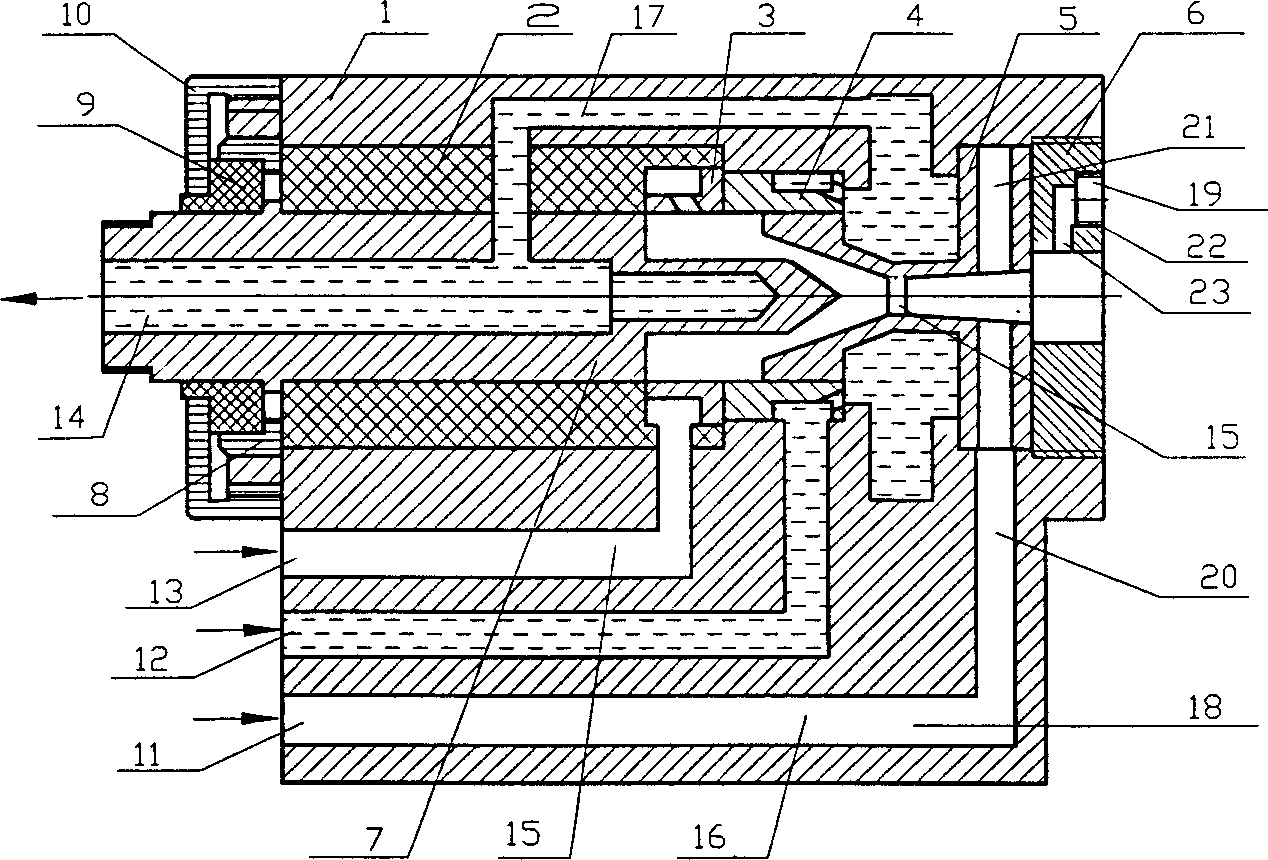

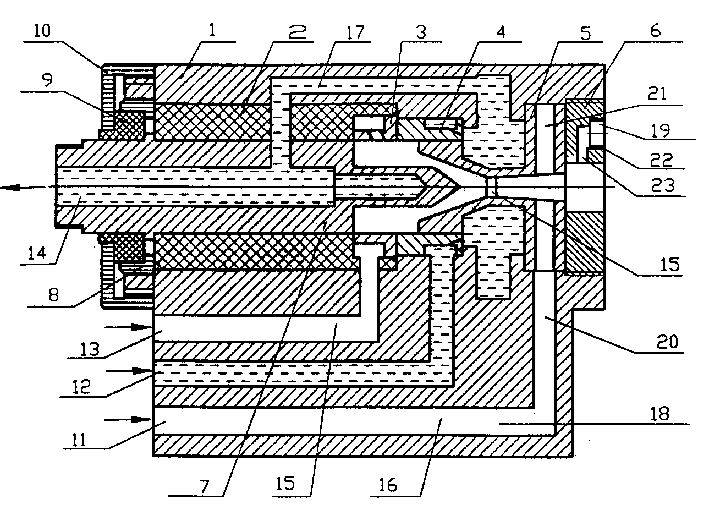

[0012] Such as figure 1 As shown, the present invention mainly includes: gun body 1, insulator 2, gas swirl ring 3, flow divider 4, nozzle 5, front pressure cap 6, cathode body 7, internal pressure cap 8, insulating sleeve 9, external pressure cap 10 , the connection method is: the anode nozzle 5 is connected to the gun body 1 through the internal pressure cap 6, the flow divider 4 is fixed inside the gun body 1 through tight fit, the gas swirl ring 3 and the insulator 2 are connected to the gun body through the internal pressure cap 8 The cathode body 7 is fixed inside the gun body 1 through the insulating sleeve 9, the external pressure cap 10 and the insulator 2.

[0013] The rear part of the gun body 1 is provided with a powder feeding gas inlet 11, a water inlet cable interface 12 and an ion gas inlet 13, and the rear part of the cathode body is provided with a water outlet cable interface 14.

[0014] The gun body 1 and the anode nozzle 5 belong to the same anode, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com