Patents

Literature

39results about How to "Guaranteed cooling uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chamfered crystallizer with taper continuous casting plate blank

InactiveCN102328037AIncrease temperatureAdapt to solidification shrinkage characteristicsSteelmakingCopper

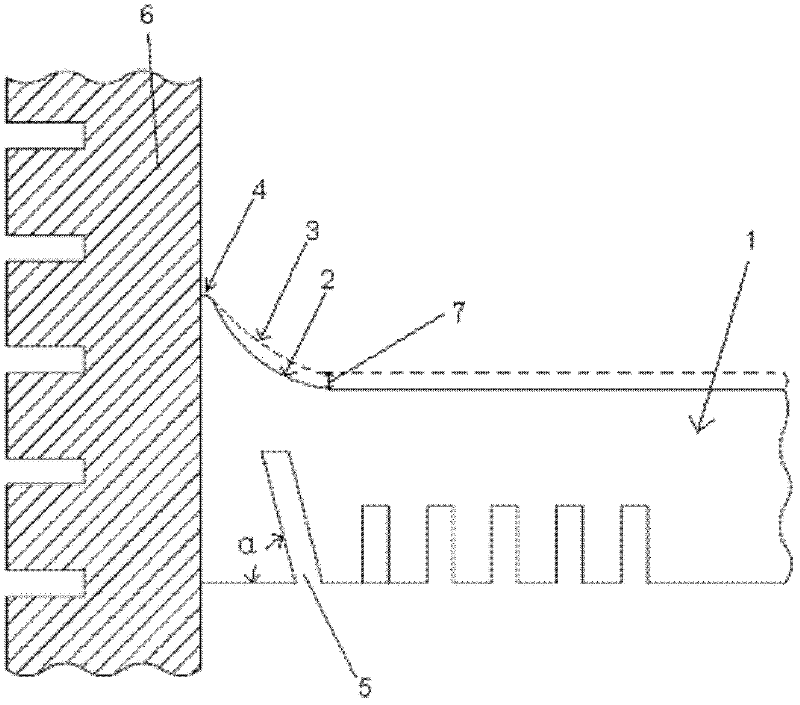

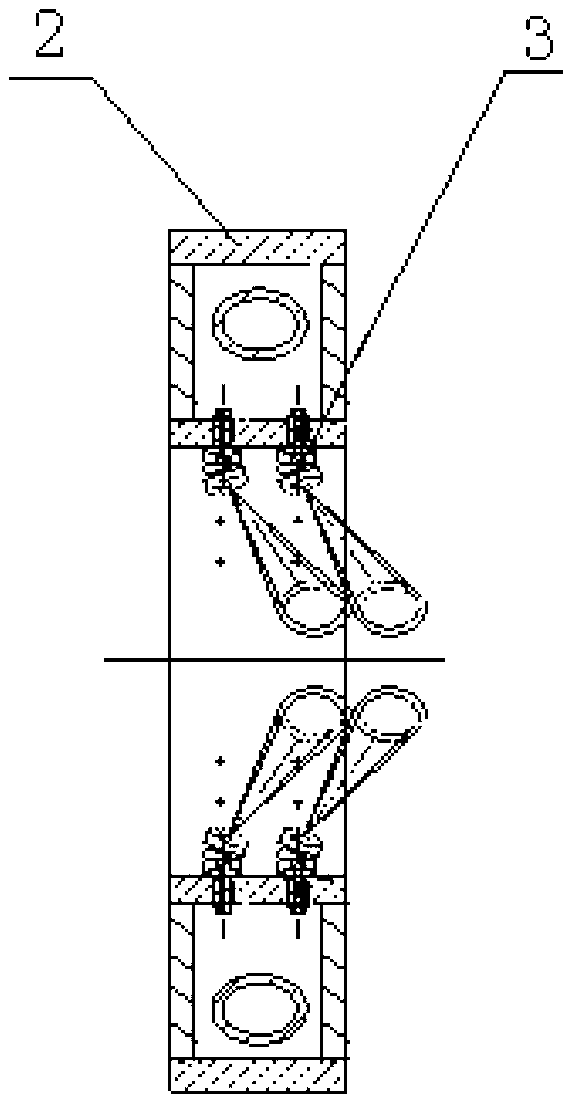

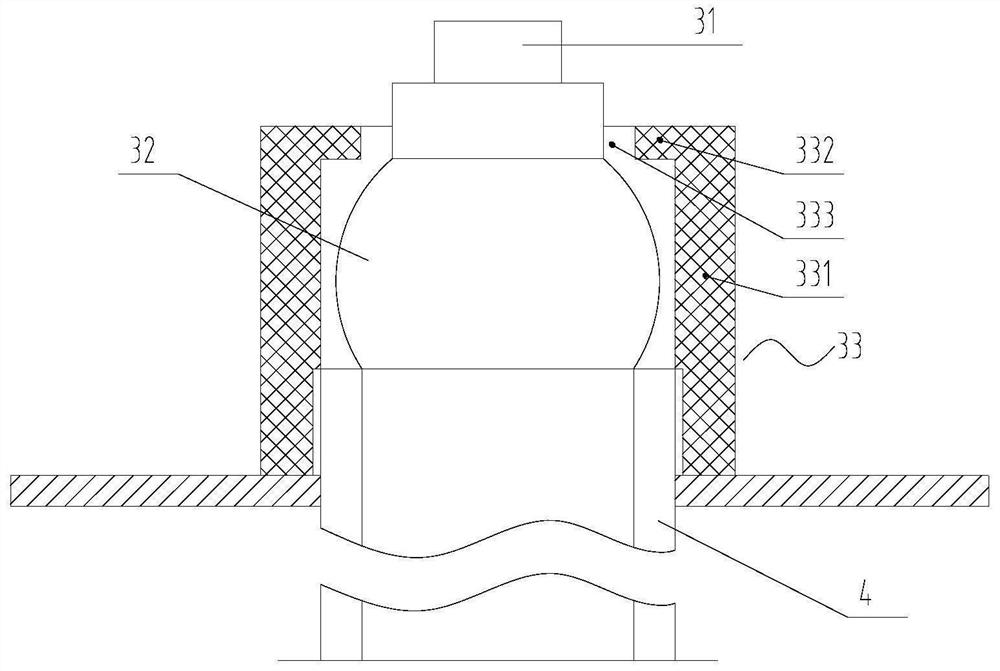

The invention discloses a chamfered crystallizer with a taper continuous casting plate blank, and belongs to the technical field of steel-making-casting. The chamfered crystallizer comprises relatively wide copper plates and relatively narrow copper plates and is characterized in that the chamfered crystallizer is composed of two relative wide copper plates and two relative narrow copper plates; a chamfer surface transitioned from an inner surface of the narrow copper plate to the inner surface of the wide copper plate is a circular arc curved surface or plane, the chamber surface has a natural inverted taper from an upper opening to a lower opening of the crystallizer; an included angle of two ends of the narrow copper plate and the wide copper plate is 90 degrees, the platform width of the chamfer surfaces at two ends is 0-6 mm; and the chamfer surface has a taper. A multi-variety and multi-specification mature industrial application is realized, the transverse corner crack of the continuous casting plate blank is eliminated, and the longitudinal corner crack defect is avoided. The thickness specification range of the proper continuous casting plate blank is 130-420 mm, and the width specification ranges from 1000 to 3000 mm. The matched casting process is reliable and stable. The structure is relative simple and the popularization is strong.

Owner:SHOUGANG CORPORATION

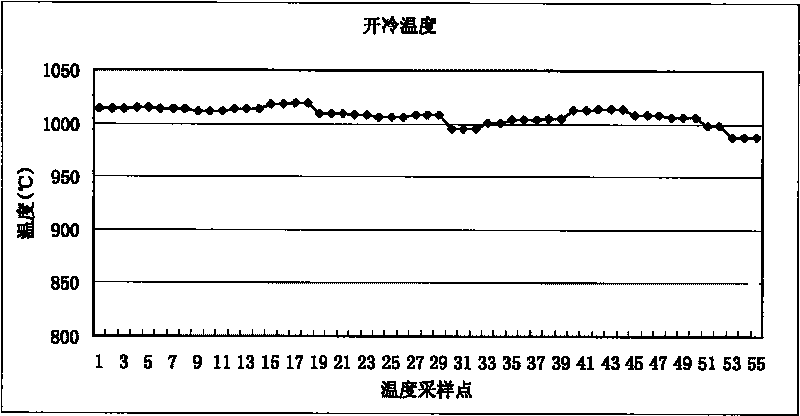

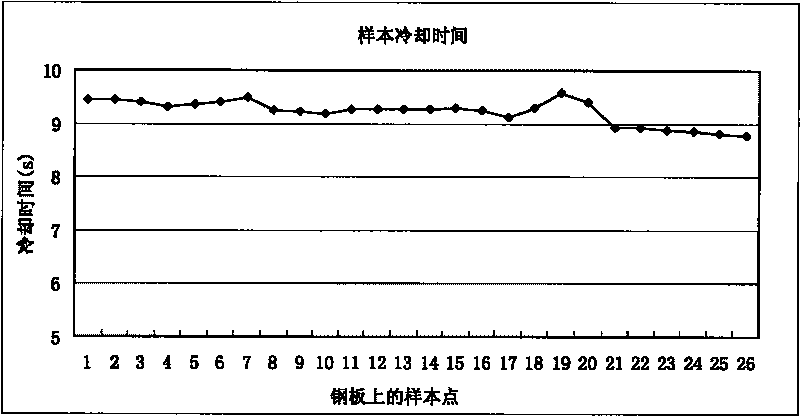

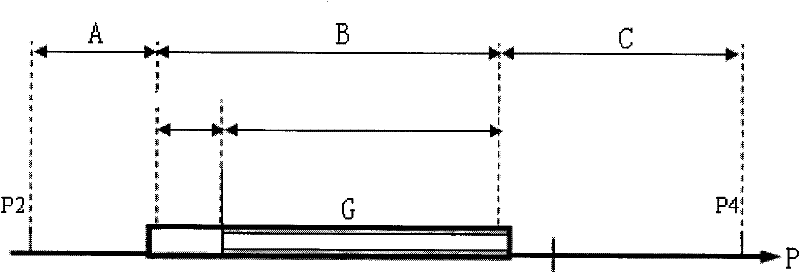

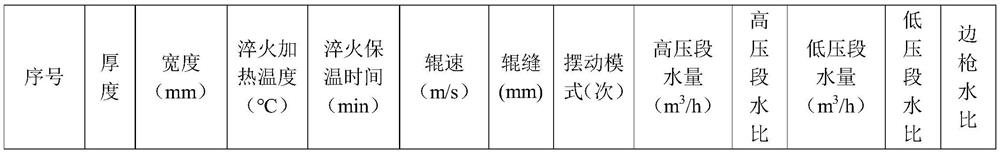

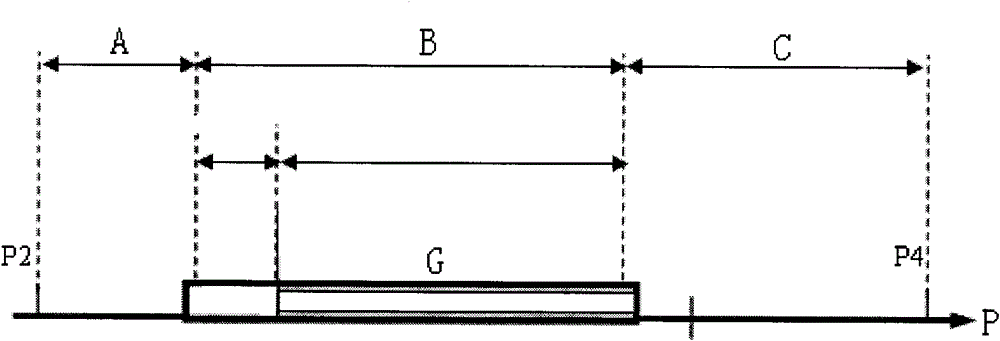

Method for controlling speed of cooling roller bed after rolling medium plate

InactiveCN101733291AGuaranteed cooling uniformityAvoid uneven tissue performanceTemperature control deviceAutomatic controlSheet steel

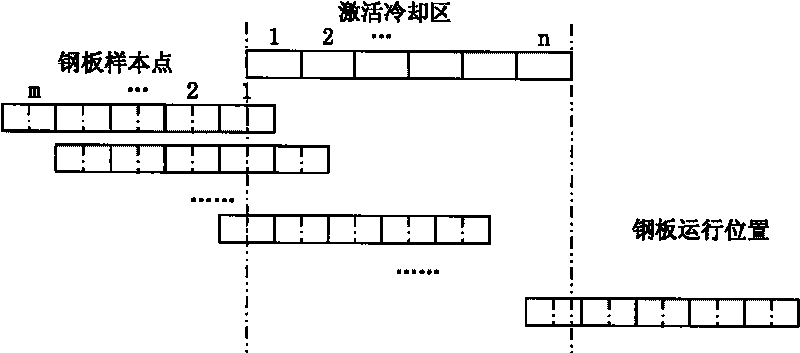

The invention discloses a method for controlling the speed of a cooling roller bed after rolling a medium plate, which belongs to the technical field of steel rolling automatic control, is mainly used in the process of cooling the medium plate after rolling, and realizes the control of the cooling uniformity of a steel plate in the length direction by controlling the speed of the roller bed. The invention provides the method for controlling the speed of the cooling roller bed after rolling the medium plate, which can ensure the cooling uniformity of the steel plate in the length direction. The method adopts a cooling control system after rolling and comprises the following steps: firstly, performing sample division on the steel plate in the length direction; secondly, before the steel plate enters an activation cooling zone, acquiring the actual temperature value of the steel plate in the length direction through a thermo-detector before cooling, and determining the speed of each sample of the steel plate to pass through the activation cooling zone; and thirdly, transmitting the speed, determined in the second step, of each sample of the steel plate to pass through the activation cooling zone to a basic automation unit of the cooling control system after cooling, and controlling the speed of the cooling roller bed by the basic automation unit of the cooling control system after cooling.

Owner:NORTHEASTERN UNIV LIAONING

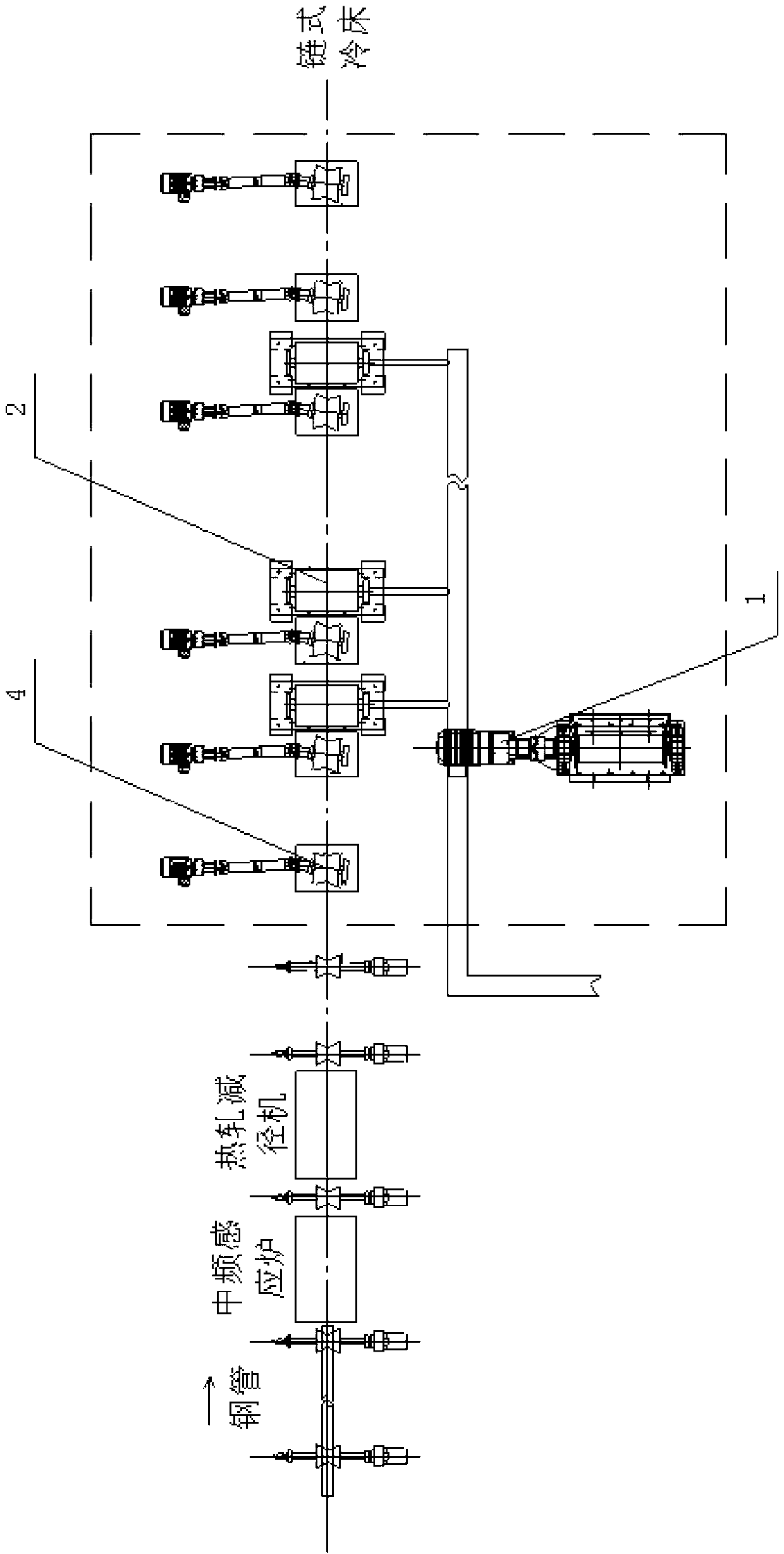

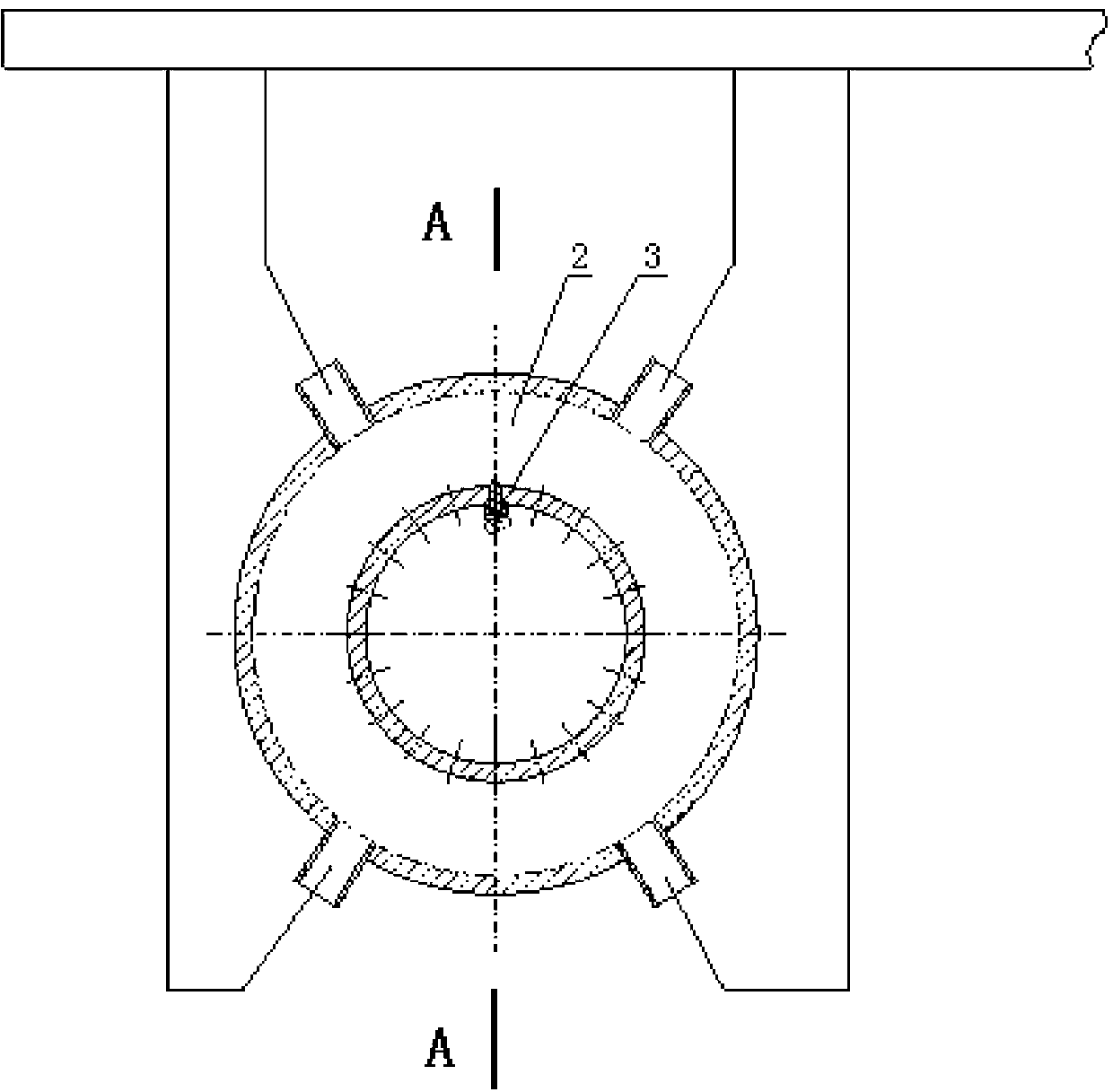

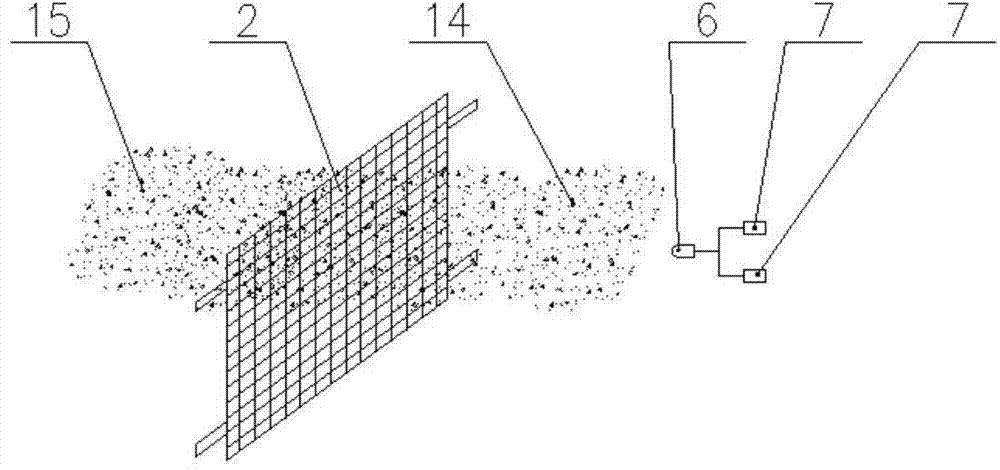

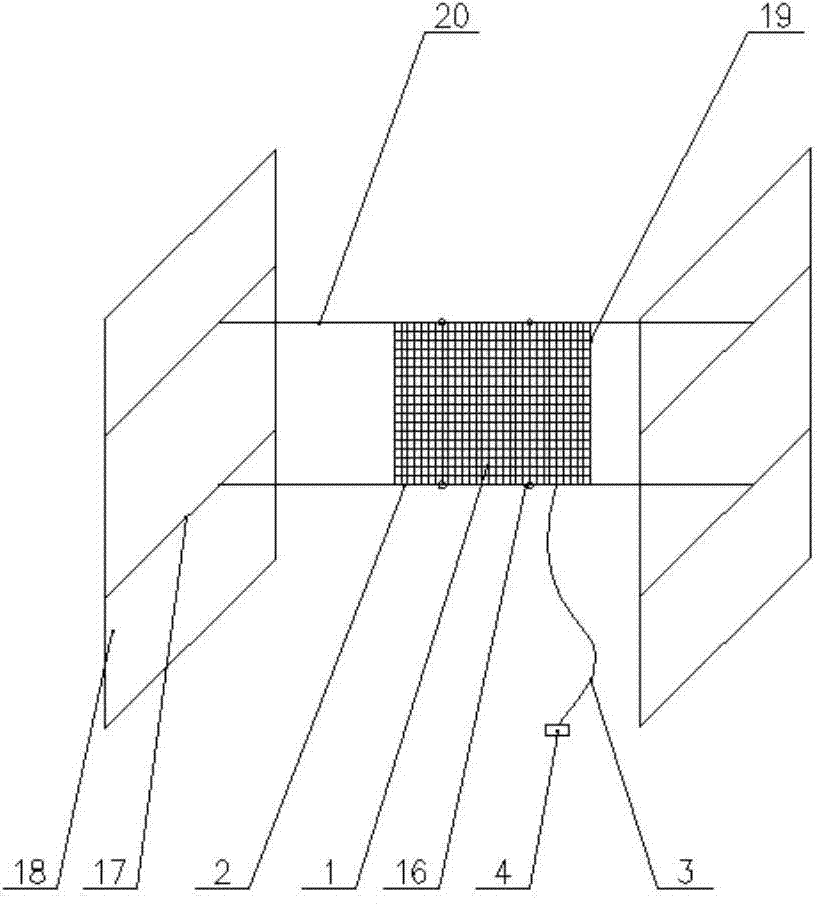

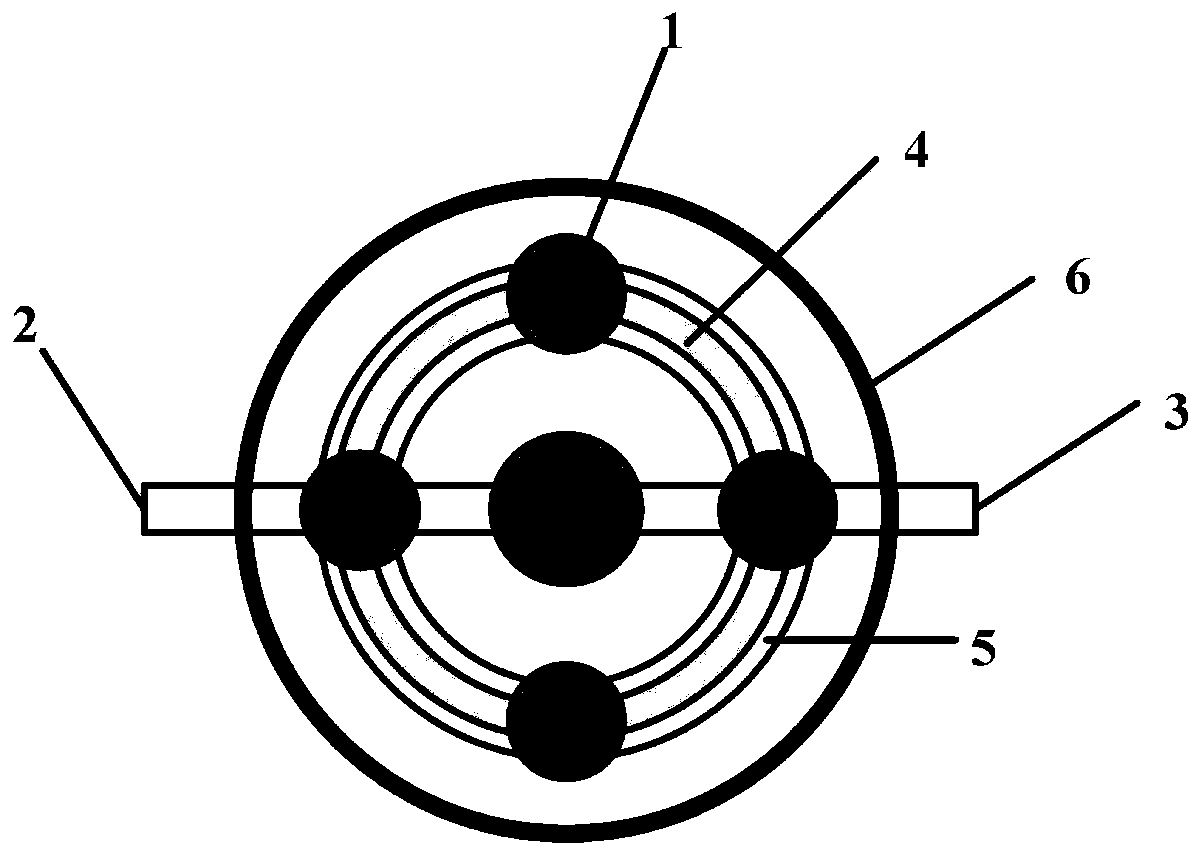

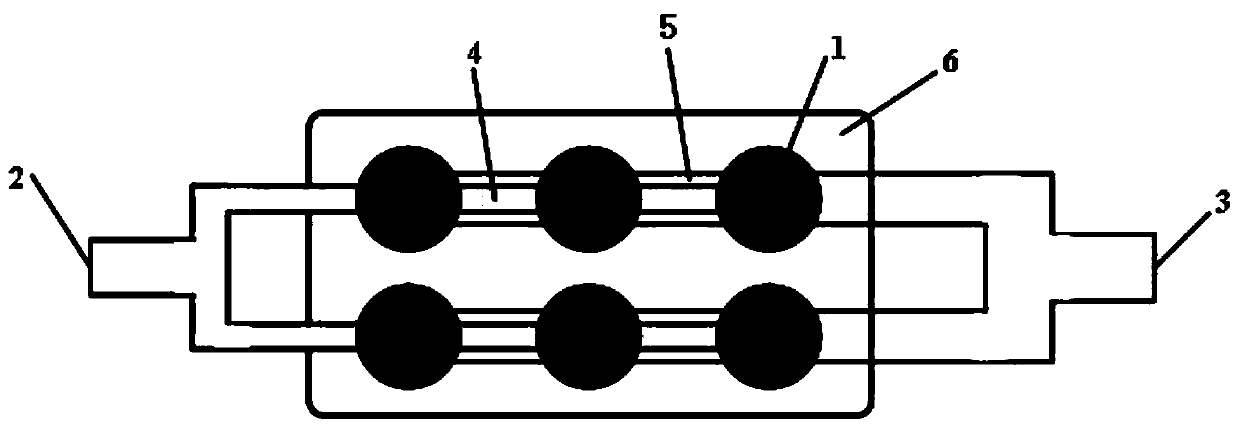

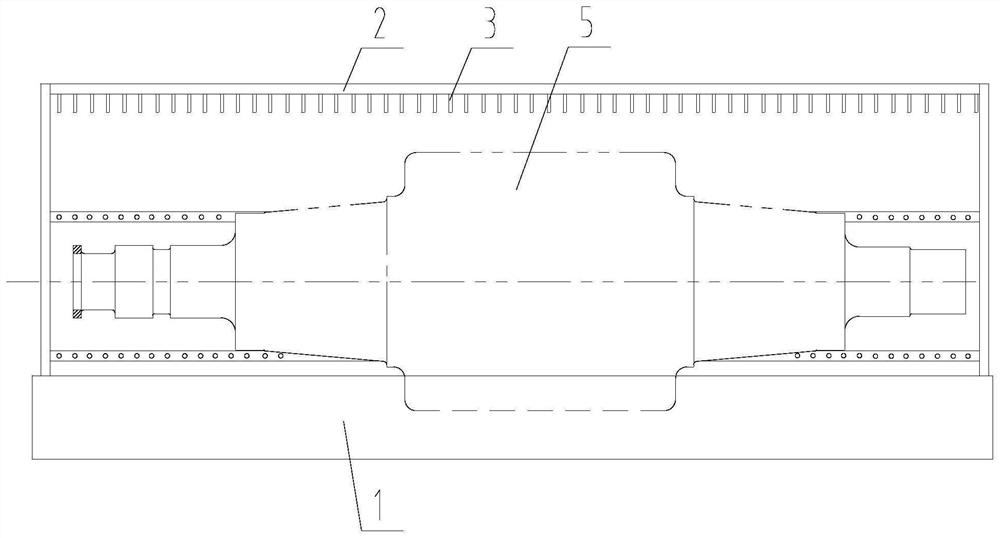

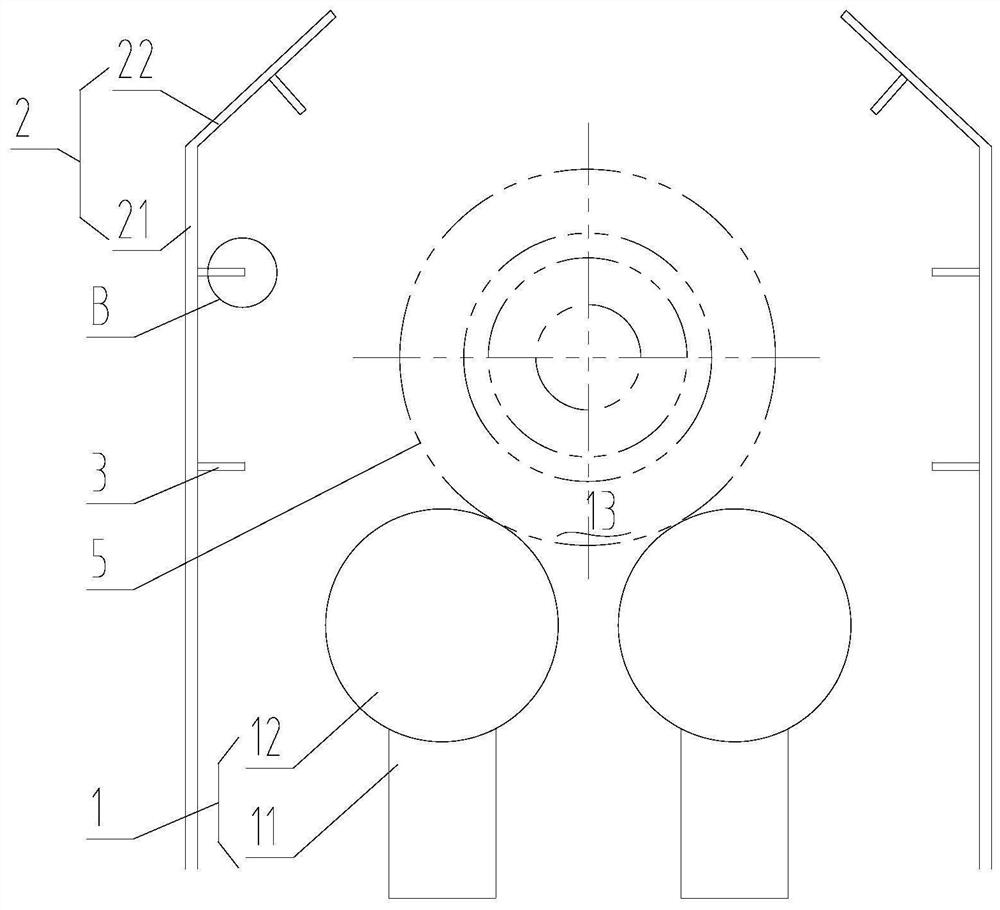

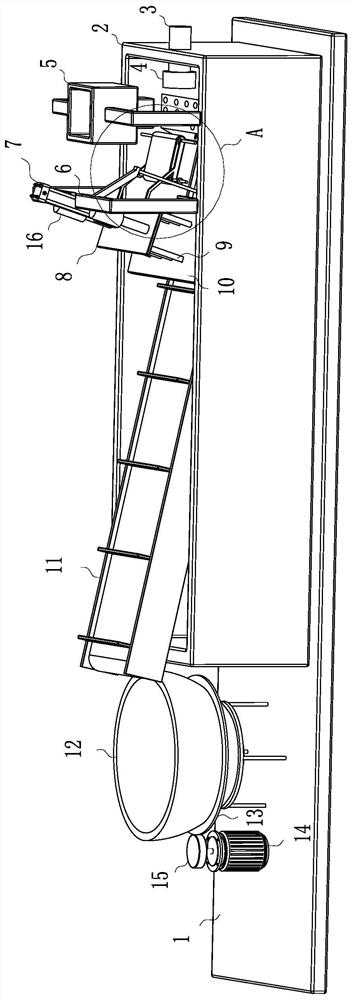

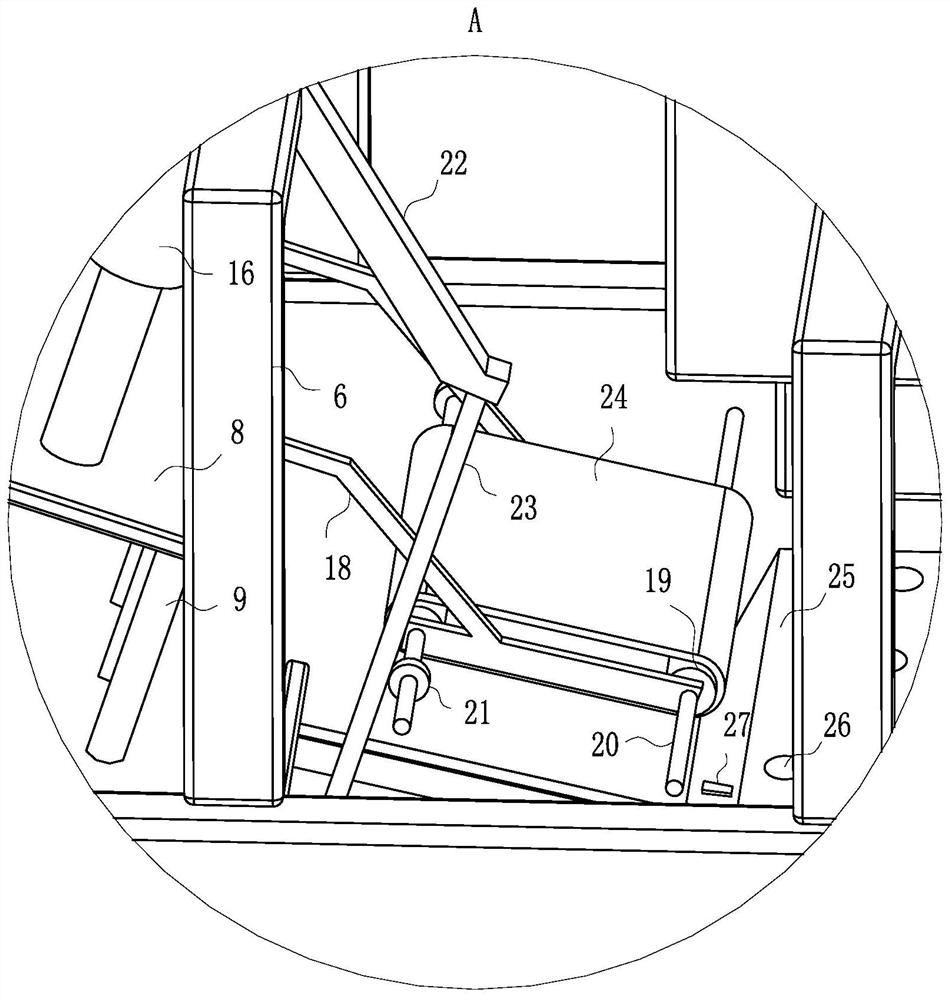

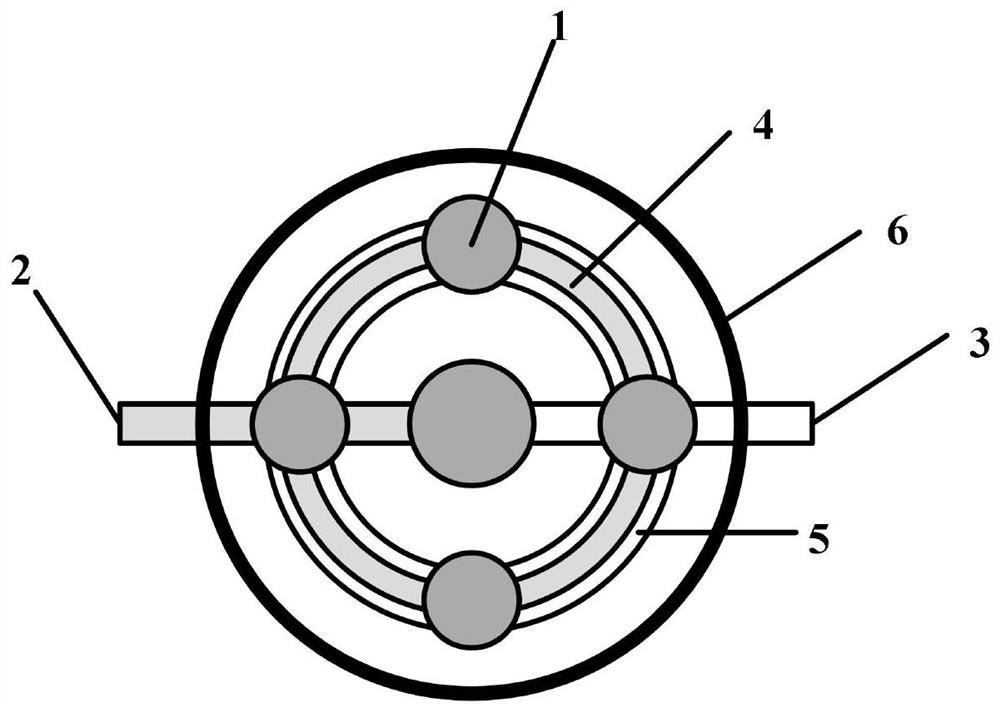

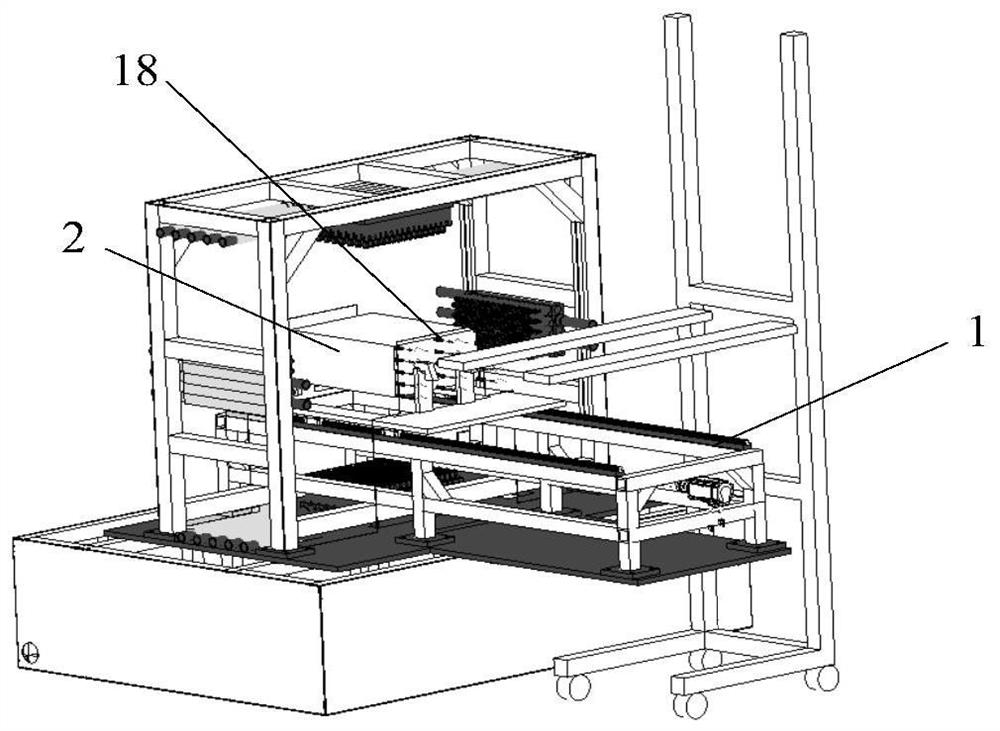

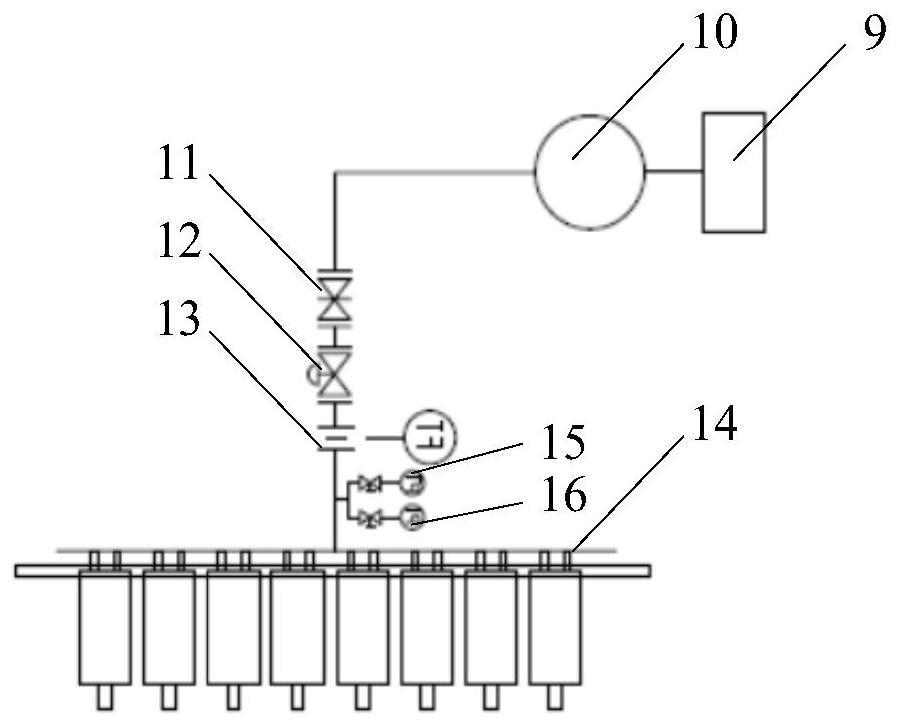

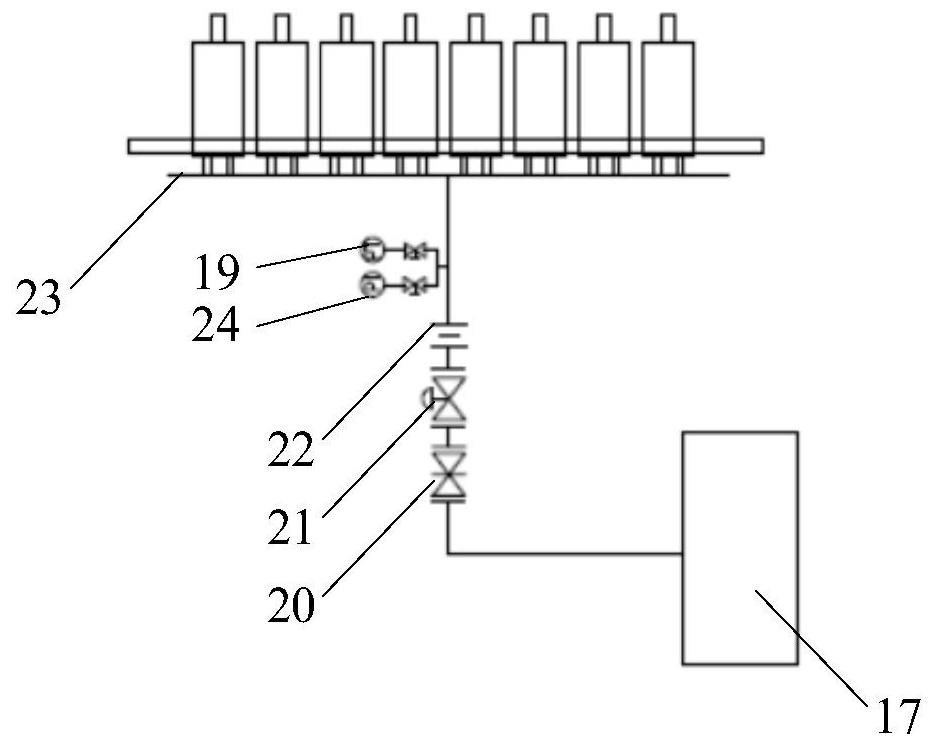

On-line cooling control method and device for improving strength and tenacity of high-frequency-welding (HFW) welded pipe after being hot rolled

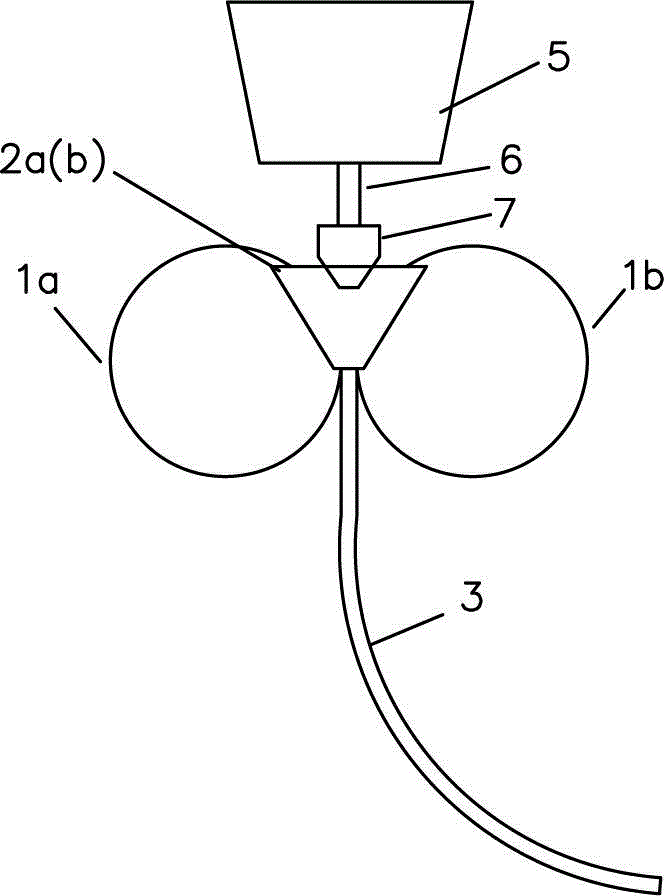

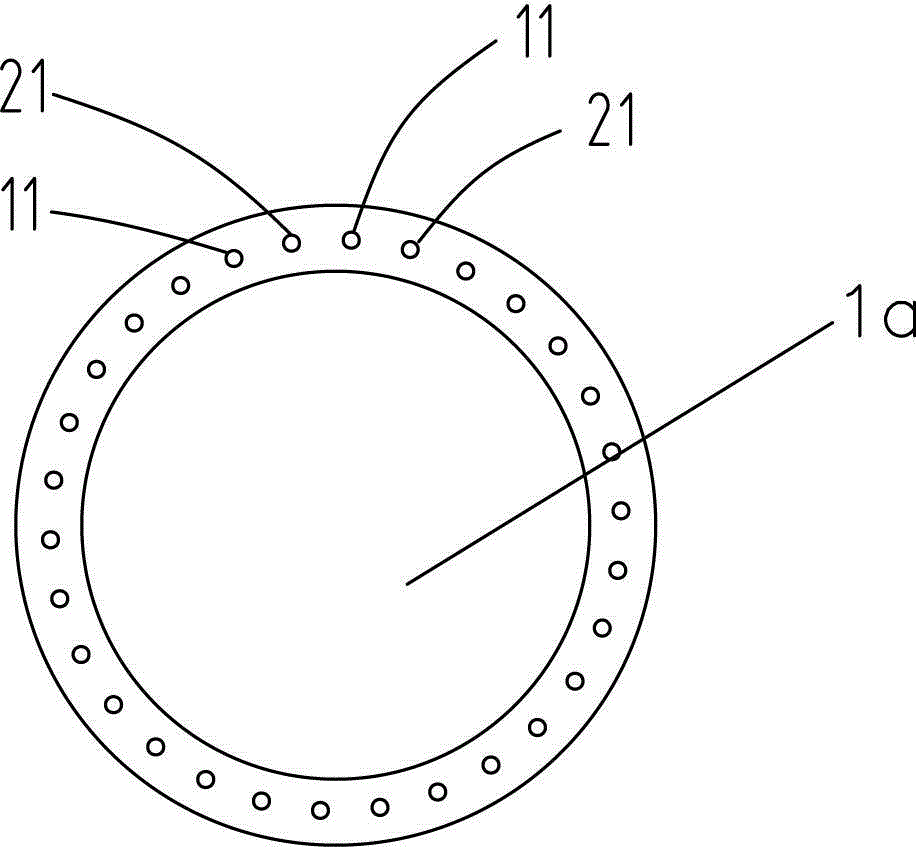

ActiveCN103128108AImprove toughnessHeating fastTemperature control deviceWork treatment devicesResource consumptionSpray nozzle

The invention discloses an on-line cooling control method and a device for improving strength and tenacity of a high-frequency-welding (HFW) welded pipe after being hot rolled. According to the on-line cooling control method and the device for improving the strength and the tenacity of the HFW welded pipe after being hot rolled, firstly, the HFW welded pipe is heated to a temperature 80-200 DEG C higher than the austenitizing phase-transition temperature, and then pipe blank with needed specification is obtained after hot rolling reducing, and then the pipe blank at a temperature still higher than the phase-transition temperature is enabled to rotate and is fast cooled to a needed temperature through the on-line cooling control device. The on-line cooling control device comprises a variable frequency pump, sprayers, nozzles and transmission devices. Each sprayer is of an annular structure. A water inlet pipe of each sprayer is connected with a water outlet of each variable frequency pump. The nozzles are evenly distributed in the inner walls of the sprayers along the circumferential direction. Each transmission devices are arranged between two sprayers and is used for driving the HFW welded pipe to move at a certain speed in a rotary mode. According to the on-line cooling control method and the device for improving the strength and the tenacity of the HFW welded pipe after being hot rolled, cooling uniformity of steel pipes in the circumferential direction, the axial direction, and the wall thickness direction is achieved, the microstructure of welded pipe is refined, the strength and the tenacity of the whole pipe body are improved, good overall performance is achieved, cost is saved at the same time, and resource consumption and energy consumption are reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

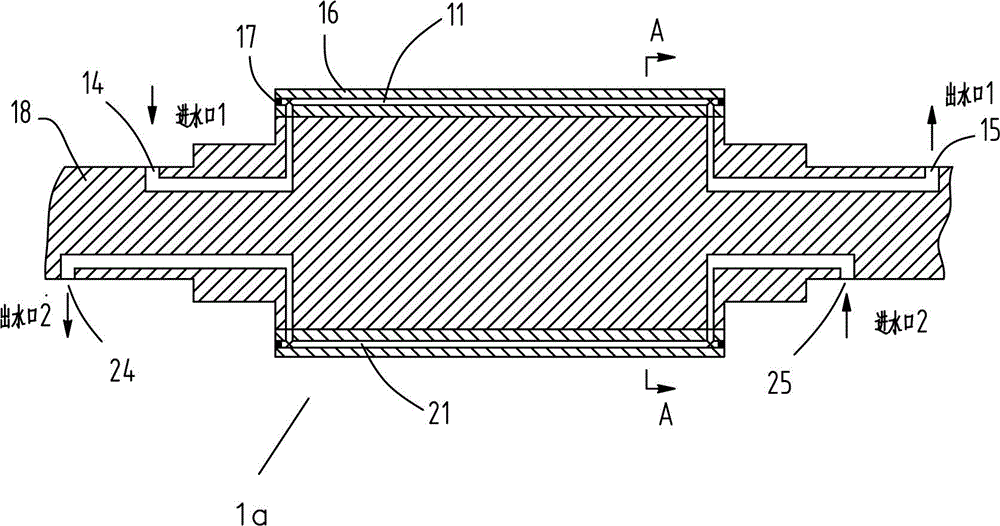

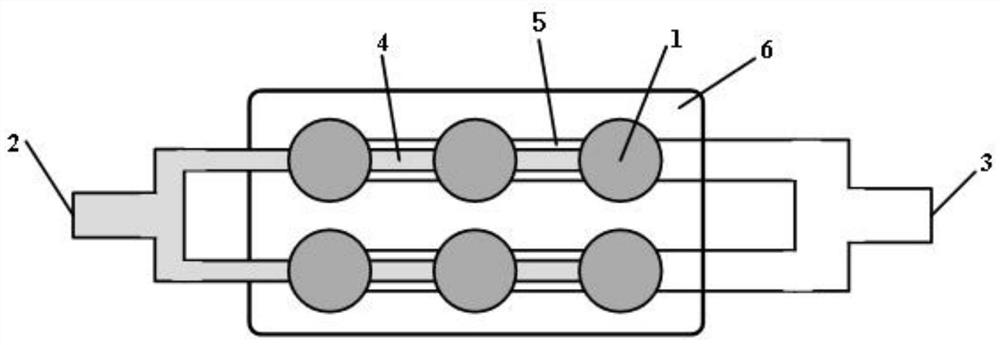

Method for controlling cooling water flow of double-roll strip casting rolls

The invention discloses a method for controlling cooling water flow of double-roll strip casting rolls. Each casting roll is provided with one or more water inlets and corresponding water outlets. Correspondingly, one or more independent cooling water channels are formed in each casting roll. A water outlet of each cooling water channel is provided with a flow adjusting valve which can adjust the flow of cooling water passing through the cooling water channel. A water pump which can adjust the flow is used for providing cooling water for the two casting rolls. Meanwhile, a flow controller monitors the flow qn of cooling water in each cooling water channel of each casting roll and adjusts the corresponding flow adjusting valve to change the flow of cooling water in the corresponding cooling water channel according to the deviation of the flow qn and the cooling water flow average value in the cooling water channels, finally, the flow in all the cooling water channels in each casting roll is consistent, and therefore the cooling strength in the casting rolls can be even. The method has the beneficial effects that the cooling water flow control precision is high, and the responding speed is high.

Owner:BAOSHAN IRON & STEEL CO LTD +1

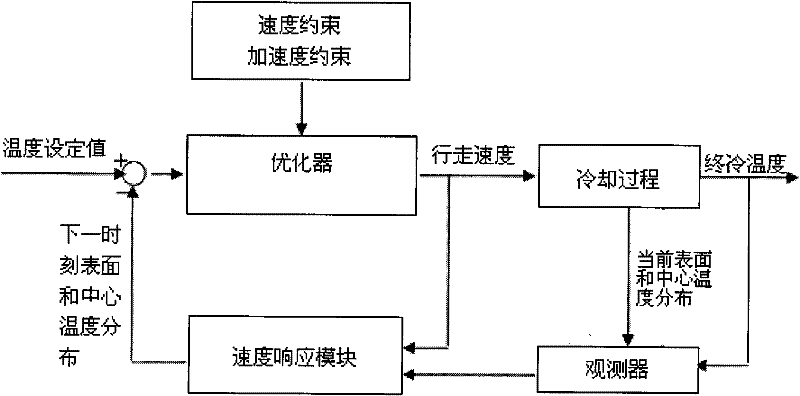

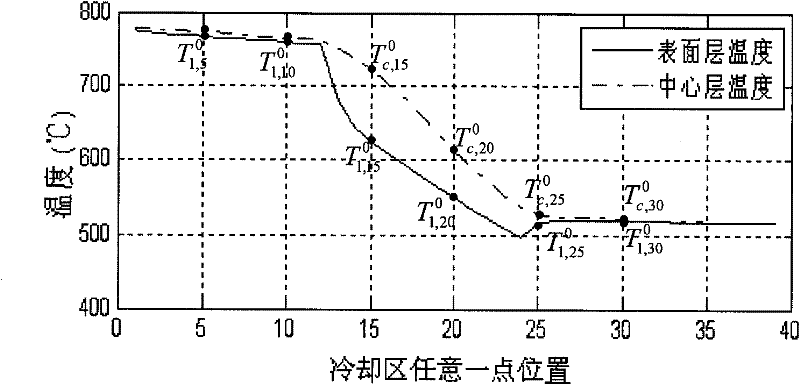

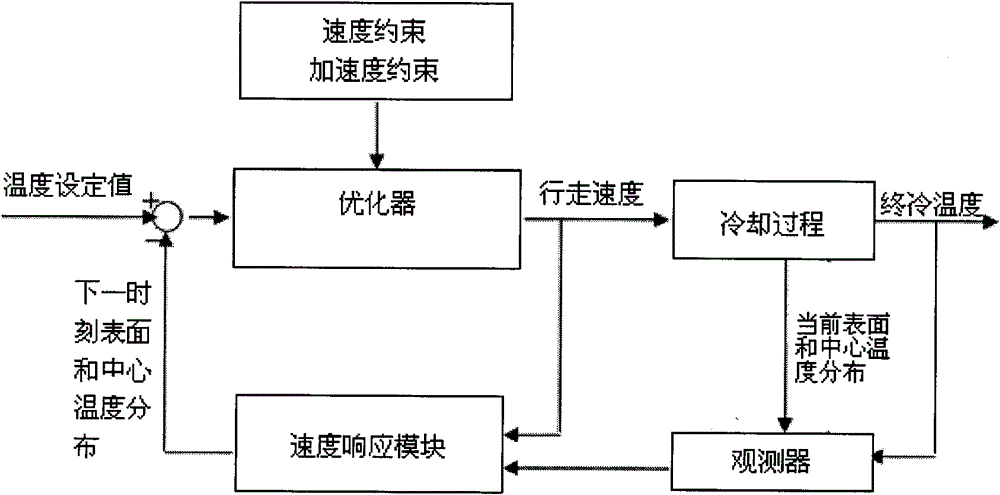

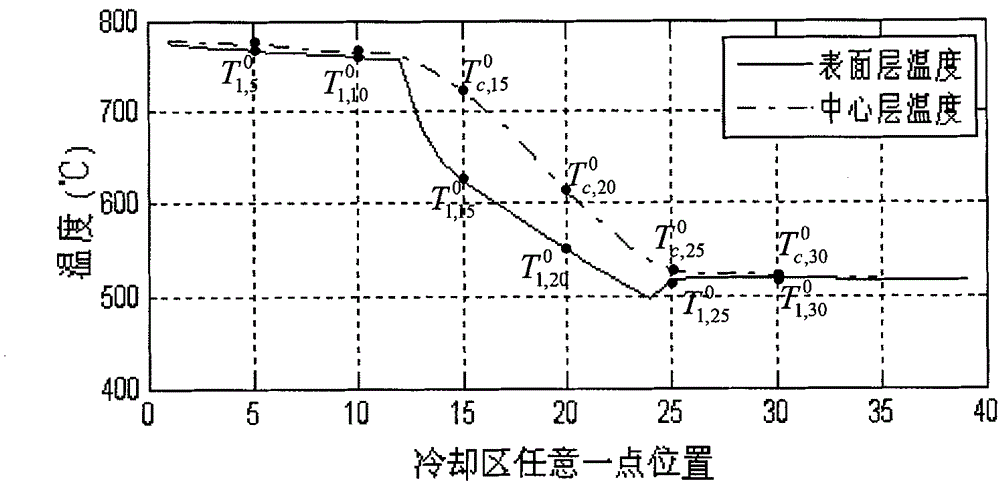

Dynamic control method of on-line cooling control system for medium and thick steel plates

ActiveCN102294366AOvercome the effects of uneven temperature distributionHigh control precisionTemperature control deviceSheet steelControl system

The invention discloses a dynamic control method for an online cooling control system of a medium-thickness steel plate. The method comprises the following steps of: setting a surface temperature set value and a central temperature set value of a medium-thickness steel plate at any position in a cooling area, and storing the set value in an optimizer; measuring the surface temperature value and central temperature value of the medium-thickness steel plate at any position at a k moment in real time by using an observer, transmitting the surface temperature value and the central temperature value to a speed responding module which is connected with an observer, calculating by using the speed responding module to obtain the surface temperature value and the central temperature value of the medium-thickness steel plate at any position at a k+1 moment, comparing the obtained surface temperature value and the central temperature value with the surface temperature set value and the central temperature set value, and calculating the optimized walking speed and optimized walking acceleration of the medium-thickness steel plate from the k moment to the k+1 moment; and obtaining the optimized walking speed and the optimized walking acceleration by using the online cooling control system of the medium-thickness steel plate and applying the optimized walking speed and the optimized walkingacceleration to the medium-thickness steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

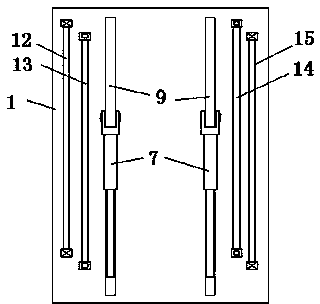

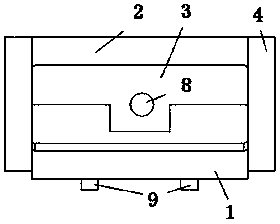

Ingot mold for preparing steel ingot with large single weight and pouring method

The invention discloses an ingot mold for preparing a steel ingot with a large single weight and a pouring method, belonging to the technical fields of steel ingot pouring equipment and pouring methods. The ingot mold is designed to be dynamically opened and closed, the steel ingot is dynamically pressed down in a steel ingot cooling process through the force of a hydraulic ejector rod, so that looseness in the steel ingot is eliminated; accelerated cooling of the steel ingot is implemented by the cooling water in the ingot mold through a heat conduction effect of the ingot mold, and a square ingot with a good interior tissue is finally prepared. According to the ingot mold for preparing the steel ingot with the large single weight and the pouring method, improvement of the interior tissue of the steel ingot can be promoted, the cooling uniformity of the steel ingot is improved, the feeding deficiency of a heart part of the steel ingot is reduced, the horizontal restraint of the surface of the steel ingot is increased, and the probability of cracks on the surface of the steel ingot is reduced. The pouring problem of the steel ingot with the large thickness, which troubles iron and steel enterprises for a long time, is solved, the pouring quality of the steel ingot with the large thickness is greatly improved, a bottleneck for restricting production of a steel plate with a large-thickness specification is broken, the production efficiency is greatly improved, and the economic benefit and the social benefit are remarkable.

Owner:WUYANG IRON & STEEL

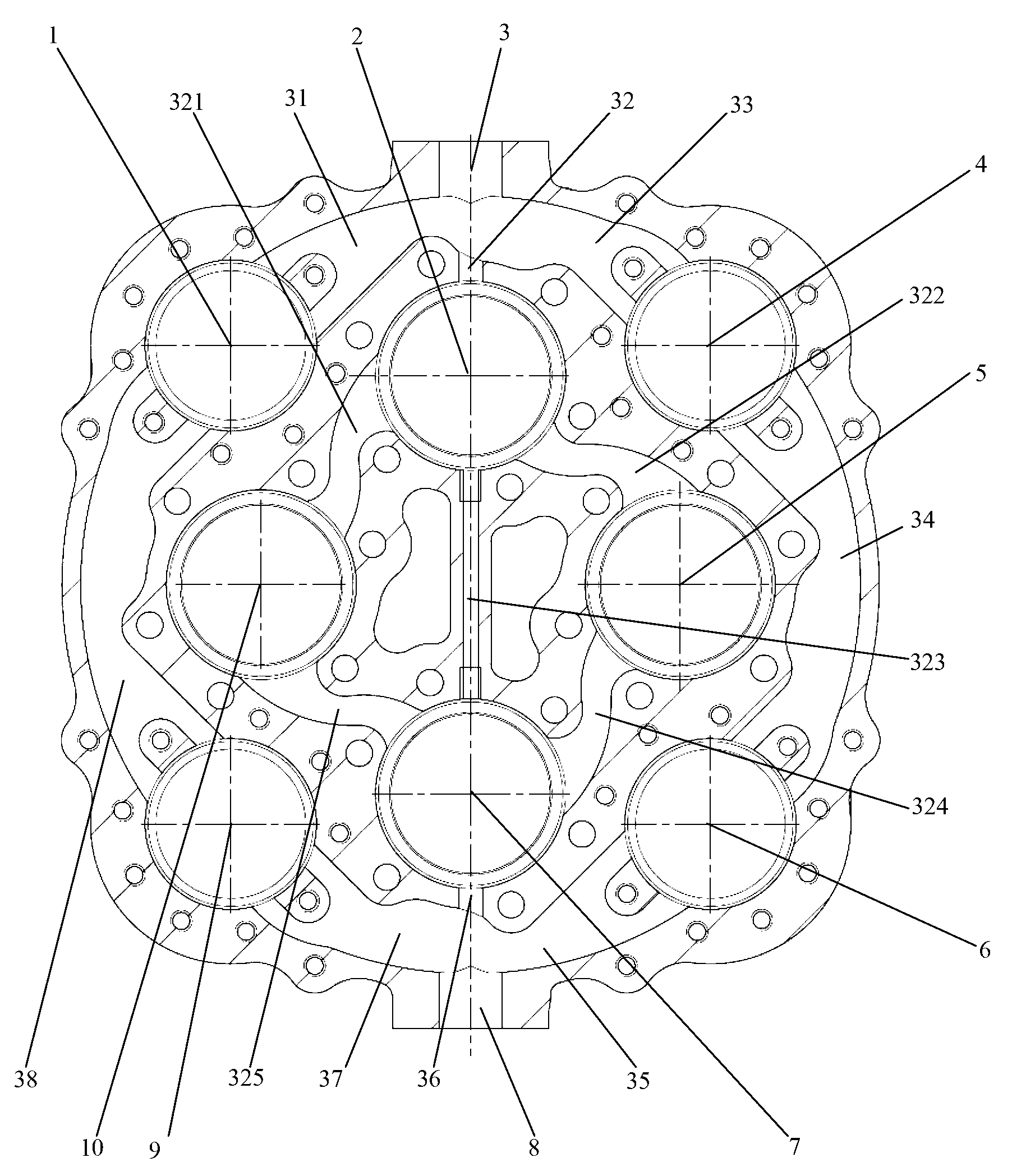

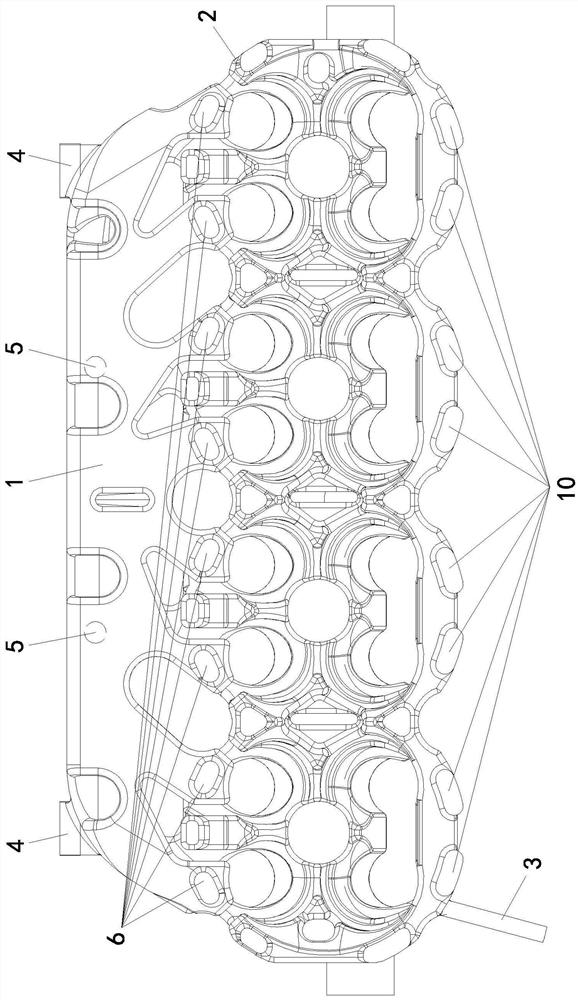

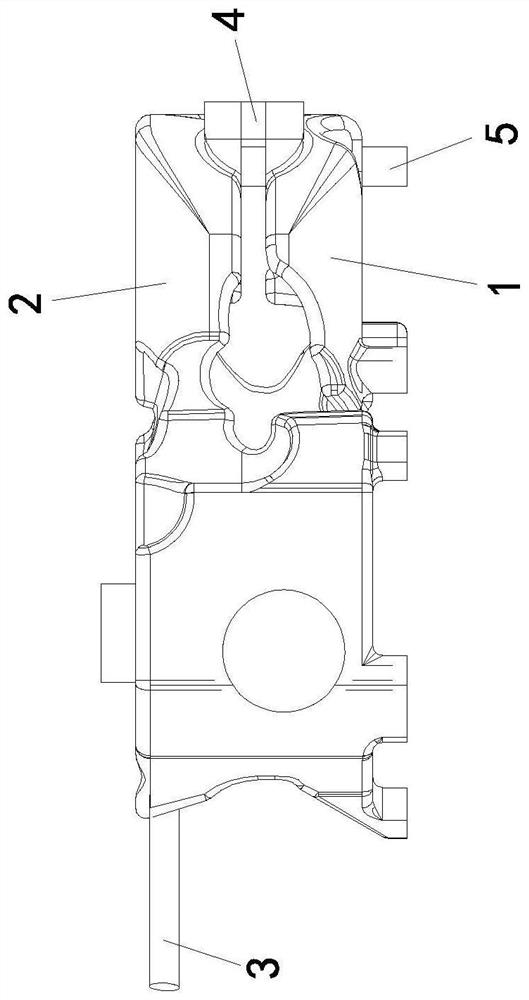

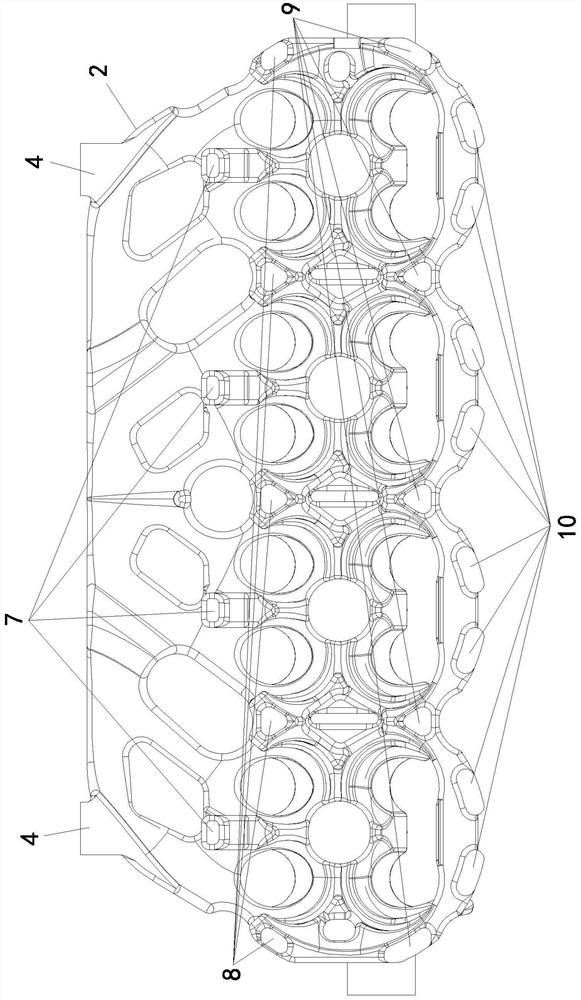

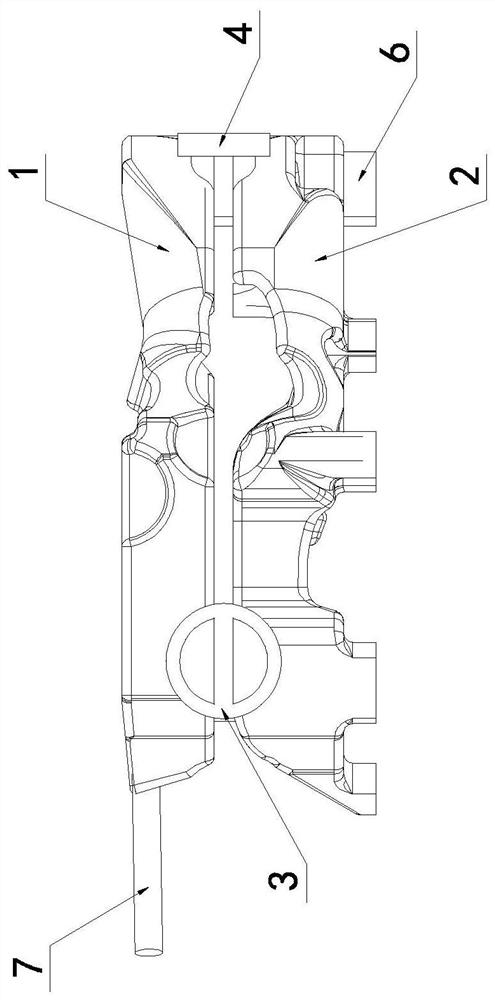

Engine body for hot air engine

ActiveCN103016203AGuaranteed cooling uniformityThe temperature difference of working fluid is reducedHot gas positive displacement engine plantsCooling effectWater flow

The invention discloses an engine body for a hot air engine. Four cylinder sleeve installing holes and cooler installing holes as well as a cooling water inlet, a cooling water outlet and a cooler flow passage are arranged in the integral engine body, the cylinder sleeve installing holes and the cooler installing holes are in square arrangement in a separated way, the cooler installing holes are arranged near the adjacent cylinder sleeve installing holes, the number of the cooling water inlet and the number of the cooling water outlet are respectively one, cooling water flow passages are divided into an outer flow passage and an inner flow passage, cooling water of the outer flow passage is communicated with the cooler installing holes and is used for cooling a cooler, cooling water of the inner flow passage is communicated with the cylinder sleeve installing holes and is used for cooling a cylinder sleeve, and a cooling water supplementing flow passage is also arranged between the No.1 cylinder sleeve installing hole and the No.3 cylinder installing hole at the far end and is used for enhancing the cooling effect of the No.3 cylinder installing hole at the far end. The engine body has the characteristics of simple structure and good cooling effect and is suitable for being used by a Stirling engine.

Owner:SHANGHAI MICROPOWERS

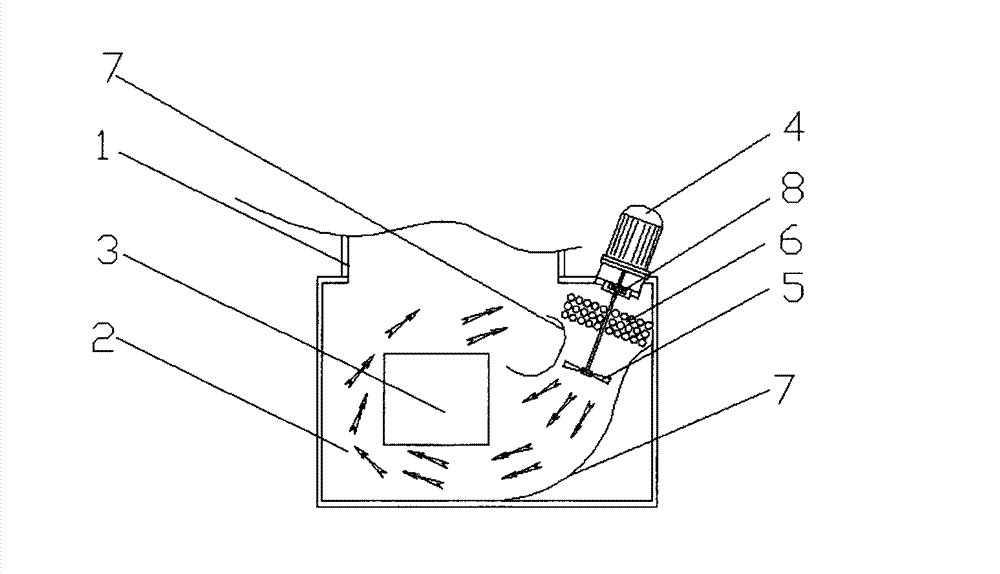

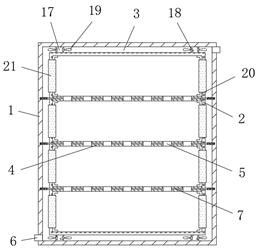

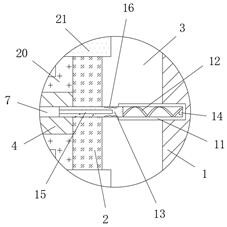

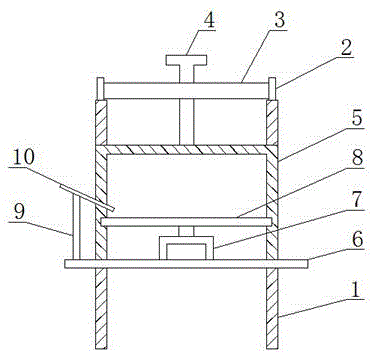

Oil cooling system for double-chamber vacuum oil quenching furnace

InactiveCN102808071AGuaranteed cooling uniformitySolve the inconvenienceQuenching devicesAutomatic controlQuenching

The invention discloses an oil cooling system for a double-chamber vacuum oil quenching furnace. The oil cooling system comprises a furnace body and an oil tank, wherein a quenching oil cooling device is arranged on the oil tank; the quenching oil cooling device comprises a stirring motor, an impeller and a heat exchanger, wherein the heat exchanger is arranged on the transmission shaft of the stirring motor; and the impeller is arranged at the tail end of the transmission shaft of the stirring motor. The oil cooling system is characterized in that the stirring motor is arranged above the oil tank in an inclined way; annular flow guide plates are arranged on both two sides of the impeller in the oil tank; the two side surfaces of each annular flow guide plate are respectively welded with the two side surfaces of the oil tank; a thermocouple oil temperature detection device is arranged on the heat exchanger; and the signal feedback end of the thermocouple oil temperature detection device is connected with a water supply system of the heat exchanger and automatically controls the water supply system of the heat exchanger. The stirring motor is arranged above the oil tank in an inclined way, so that the problem of inconvenience in maintenance after the oil tank leaks is solved; and the control over the oil temperature is realized by controlling the flow rate of water supply by sending the feedback information to an automatic control valve in the water supply system of the heat exchanger by the thermocouple oil temperature detection device.

Owner:SUZHOU INDAL PARK JIESHITONG VACUUM TECH

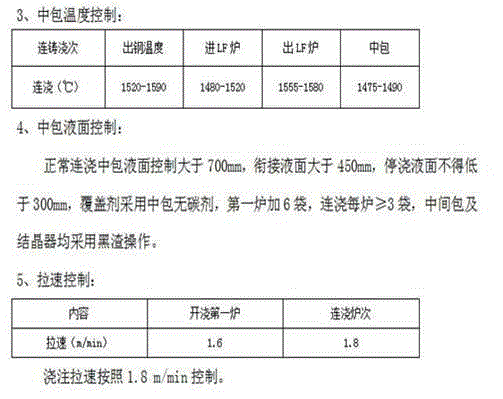

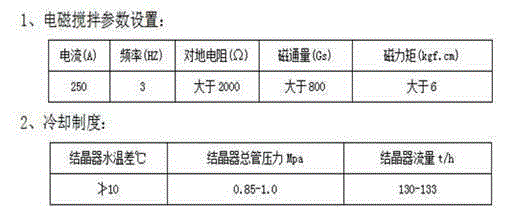

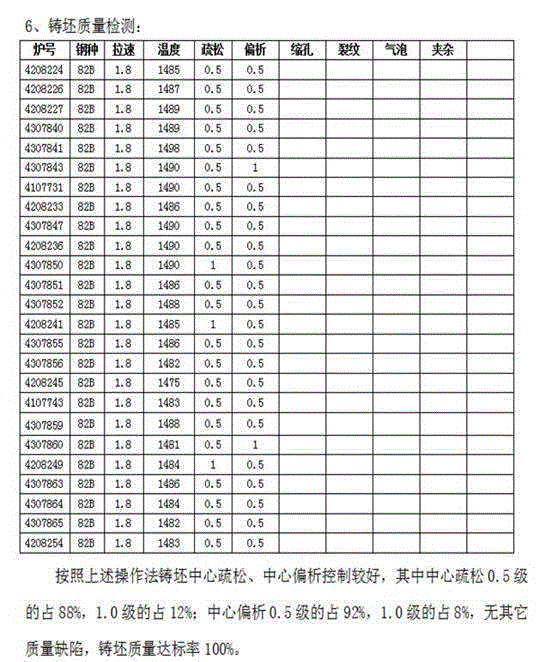

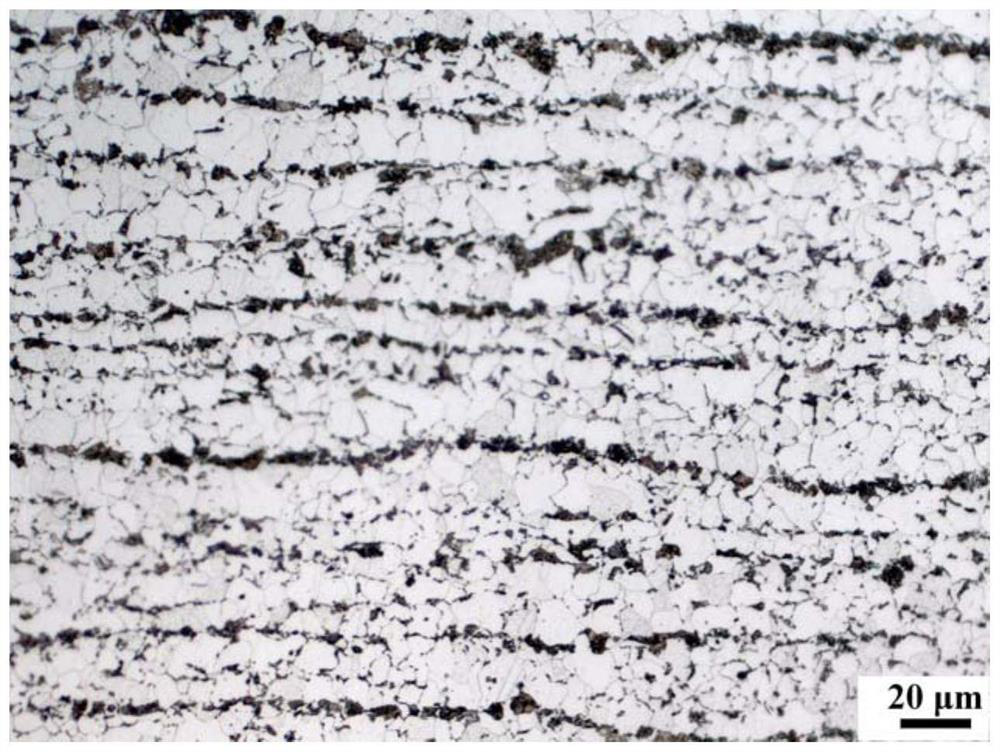

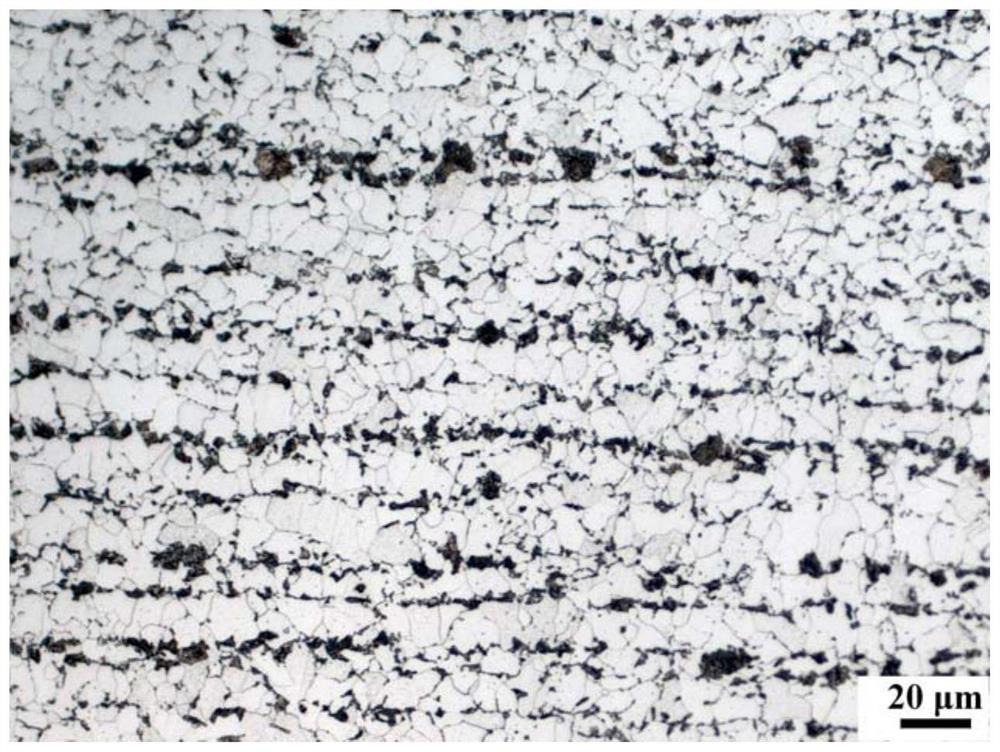

Method for improving quality of high-carbon steel in continuous casting process

The invention belongs to the technical field of improving the internal quality of high-carbon steel, and particularly relates to a method for improving the internal quality of high-carbon steel in the continuous casting process. The method comprises the following steps that 1, the parameter of an electromagnetic stirring crystallizer is set; 2, the coil parameter of the electromagnetic stirring crystallizer is set; 3, the water volume parameter of the crystallizer is set; 4, tundish black slag operation is carried out; 5, the temperature of tundish molten steel is controlled; and 6, a pouring mode is selected. The method has the beneficial effects that the set electromagnetic stirring parameter, a pull speed system, a cooling system and a temperature system are combined, and the internal quality of the high-carbon steel is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

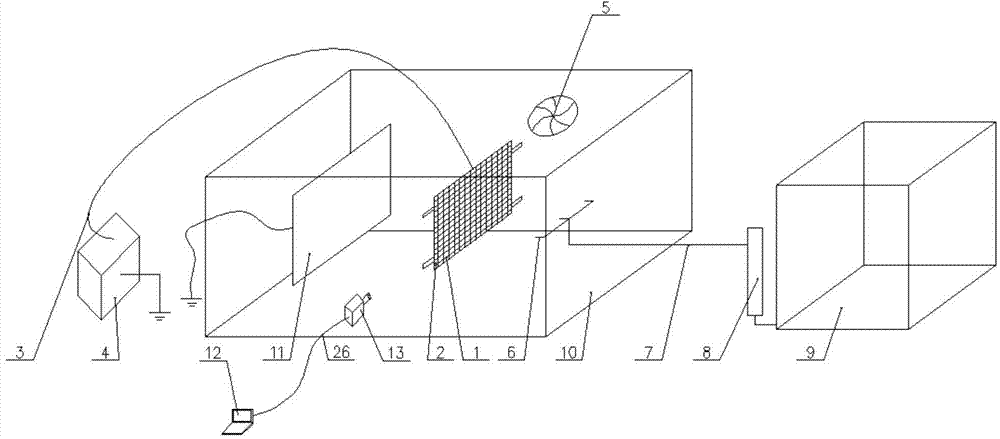

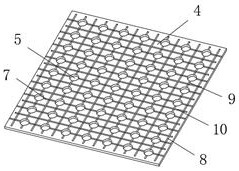

Cooling device for heat treatment of metal belts

ActiveCN104846186AImprove passabilityGuaranteed cooling uniformityFurnace typesHeat treatment furnacesSpray nozzleCooling chamber

The invention relates to a cooling device for the heat treatment of metal belts. The cooling device for the heat treatment of metal belts is characterized by comprising a cooling chamber, a spray system and a high-voltage system, wherein the cooling chamber is provided with an inlet and an outlet through which a metal belt continuously passes; the spray system comprises a medium supply system, a medium supply system pipe and a nozzle, and a spout of the nozzle faces the metal belt in the cooling chamber; and the high-voltage system comprises a high-voltage power supply, a net electrode and an insulation device; the net electrode is arranged between the metal belt in the cooling chamber and the nozzle, the net electrode is arranged on the inner wall of the cooling chamber by the insulation device, and the net electrode is connected with the high-voltage power supply by a high-voltage power line. According to the invention, atomized droplets can be subjected to charging treatment by high voltage loaded by the net electrode, and under the joint action of surface tension, electric field force, gravity, coulomb force and the like, the sizes of atomized droplets sprayed to the metal belt are more uniform, thereby facilitating the achievement of a good surface quality of the metal belt.

Owner:WISDRI WUHAN WIS IND FURNACE

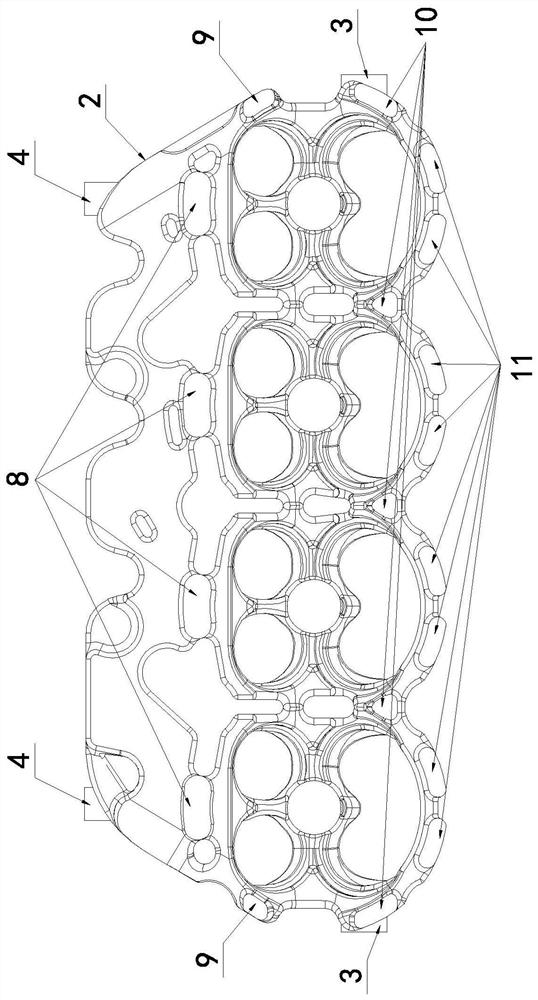

Cylinder cover double-layer water jacket structure of cross-flow cooling engine

ActiveCN113606053AImprove cooling effectReasonable cooling effectCylinder headsCylindersCombustion chamberExhaust valve

The invention discloses a cylinder cover double-layer water jacket structure of a cross-flow cooling engine, and relates to a cylinder cover water jacket structure. Four groups of combustion chamber areas are arranged at the rear end of an upper-layer water jacket, each group of combustion chamber areas comprises a spark plug area, an intake valve area and an exhaust valve area, a lower-layer water jacket is stacked and fixed at the front end of the bottom of the upper-layer water jacket to form a double-layer structure, and the four groups of combustion chamber areas of the upper-layer water jacket are exposed; two water feeding machining channels are formed in the positions, at the front end of the double-layer structure, between the lower-layer water jacket and the upper-layer water jacket in a vertically communicated manner, eight water jacket water feeding openings are formed in the rear end of the bottom face of the lower-layer water jacket, four nose bridge water feeding openings and five cylinder cover water feeding openings are formed in the bottom face of the upper-layer water jacket, and five cylinder cover water outlets and eight water jacket water outlets are formed in the bottom face of the upper-layer water jacket; and a water flow guide bulge is arranged in a cavity of the upper-layer water jacket. The double-layer water jacket structure is designed for the four-cylinder engine, a cross-flow form of water inlet at the exhaust side and water outlet at the air inlet side is adopted, the cooling uniformity is guaranteed, and the thermal load is effectively reduced.

Owner:HARBIN DONGAN AUTO ENGINE

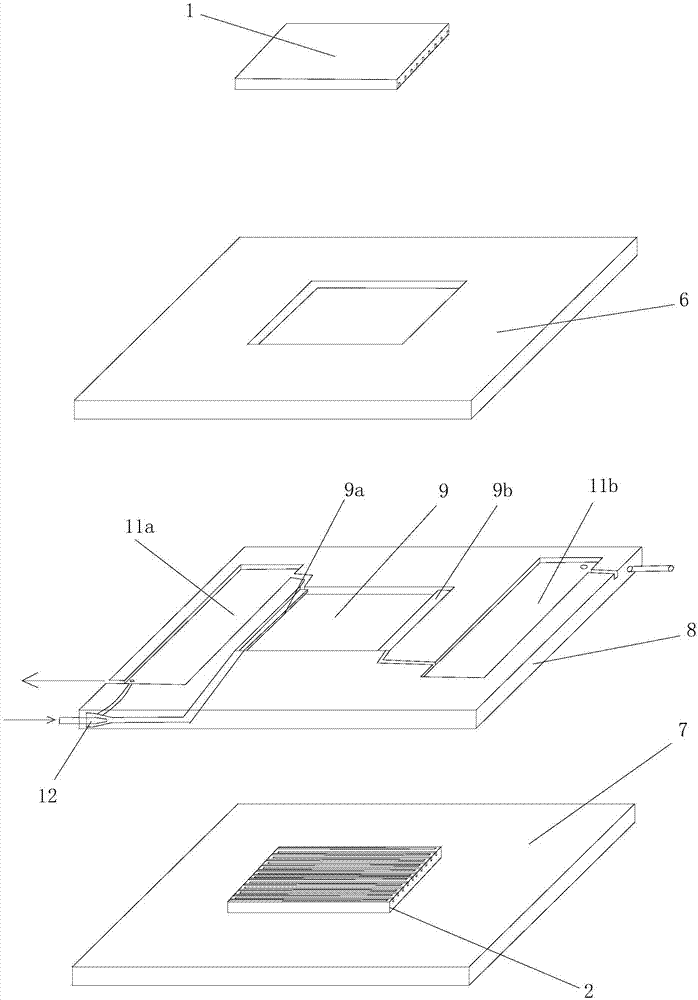

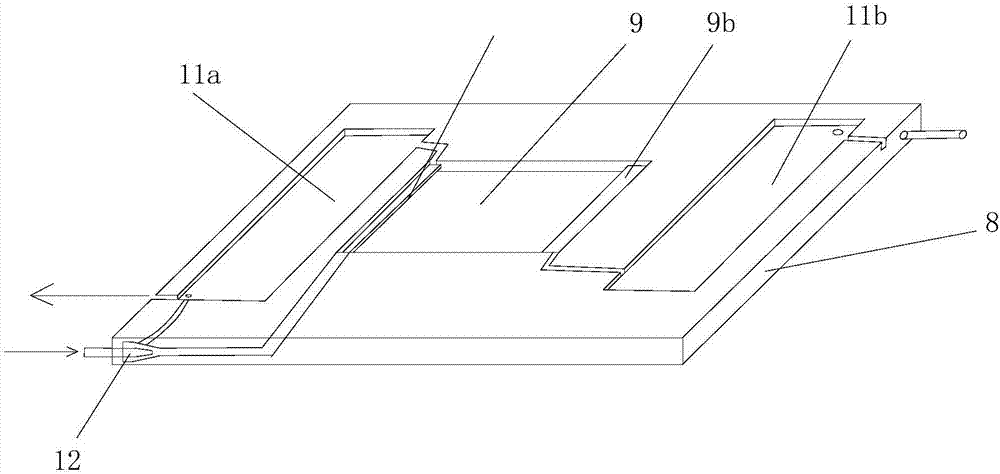

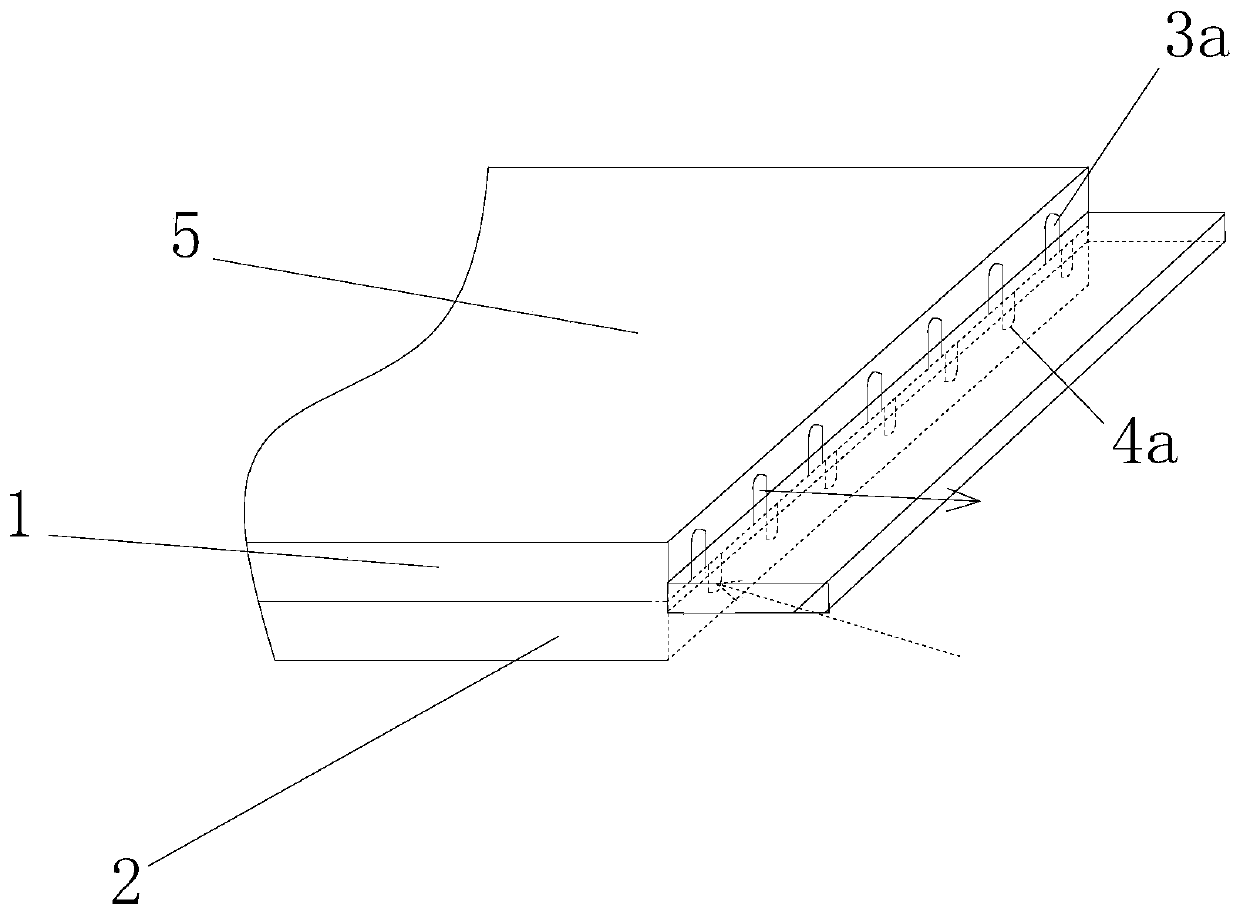

High-power laser diode array throttling micro-evaporation refrigeration heat sink

ActiveCN107104360ADecrease productivityGuaranteed to workLaser detailsSemiconductor lasersHigh power lasersEvaporation

The invention discloses a high-power laser diode array throttling micro-evaporation refrigeration heat sink. The high-power laser diode array throttling micro-evaporation refrigeration heat sink at least comprises a heat sink upper plate and a heat sink lower plate which are overlapped; a plurality of upper strip-shaped grooves are formed in the bottom surface of the heat sink upper plate; a plurality of lower strip-shaped grooves which communicate with the upper strip-shaped grooves in a one-to-one correspondence manner are formed in the top surface of the heat sink lower plate; each upper strip-shaped groove and the corresponding lower strip-shaped groove are staggered and communicate with each other to form a single flow path; the flowing directions of cooling liquid in each two adjacent flow paths are opposite; the top surface of the heat sink upper plate is a working surface for dissipating heat of a high-power laser diode array; the cooling efficiency of the heat sink can be improved effectively; uniformity of cooling of the heat sink is improved; the circumstance that the working efficiency is low due to uneven temperature of the high-power laser diode array is avoided; normal and efficient operation of the high-power laser diode array is guaranteed; and meanwhile, the high-power laser diode array throttling micro-evaporation refrigeration heat sink is high in structural precision and convenient to manufacture.

Owner:深圳德元激光科技有限公司

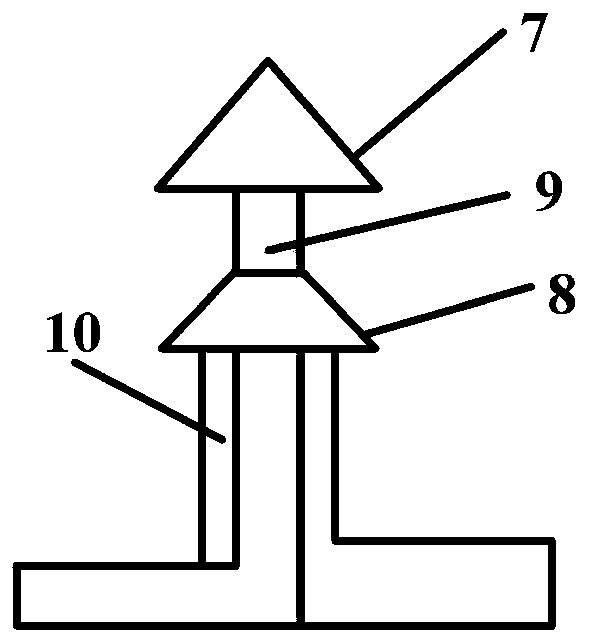

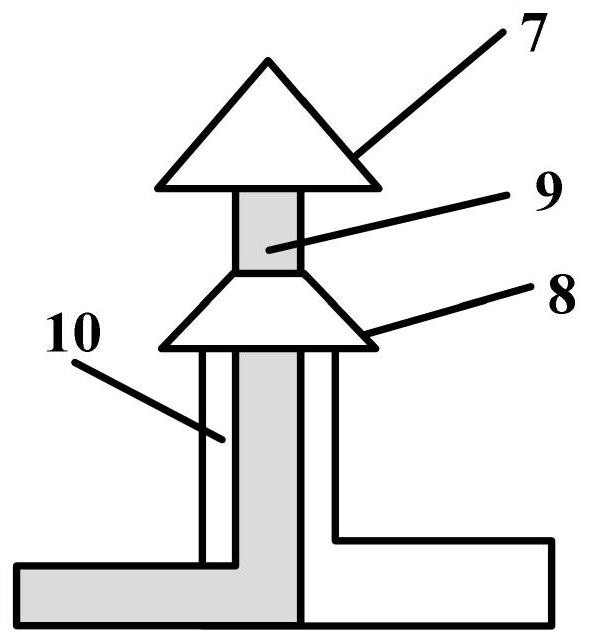

Air distributor system used in gas-solid heat exchange process and gas-solid heat exchange method

ActiveCN110360845ASpread evenlyGuaranteed cooling uniformityHandling discharged materialDirect contact heat exchangersGas solidDistribution system

The invention relates to an air distributor system used in the gas-solid heat exchange process and a gas-solid heat exchange method, and belongs to the field of industry waste heat utilization. The problems that an existing air distribution system is uneven in air distribution, heat exchange between wind and high-temperature materials is uneven, the heat recycling efficiency is low, and the temperature generated after heat exchange is low are solved. The air distributor system comprises hoods, a circulation hot air pipe, an air duct and a gas-solid heat exchange device. High-temperature solidmaterials enter the gas-solid heat exchange device, circulation hot air and air are led into a circulation hot air inlet and an air inlet correspondingly, the hoods are evenly arranged at the lower portion of the gas-solid heat exchange device, the two-layer air outlet design is adopted in the hoods, the high-temperature solid materials sequentially exchange heat with upper-layer circulation hot air and lower-layer air, and stepped cooling is finished. By means of the air distributor system used in the gas-solid heat exchange process and the gas-solid heat exchange method, gas-solid uniform heat exchange can be achieved, stepped heat exchange recycling of high-temperature solid sensible heat through two paths of gas can be achieved, heat exchanging can be uniform, high-quality hot air canbe obtained, and the waste heat utilization efficiency can be better improved.

Owner:CENT IRON & STEEL RES INST +1

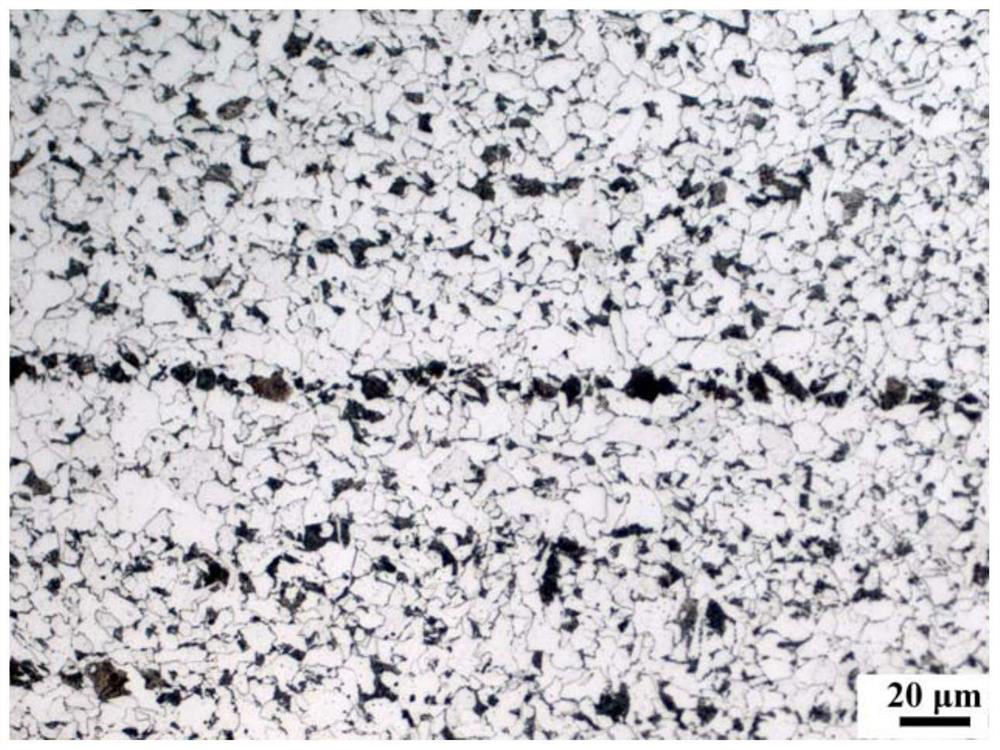

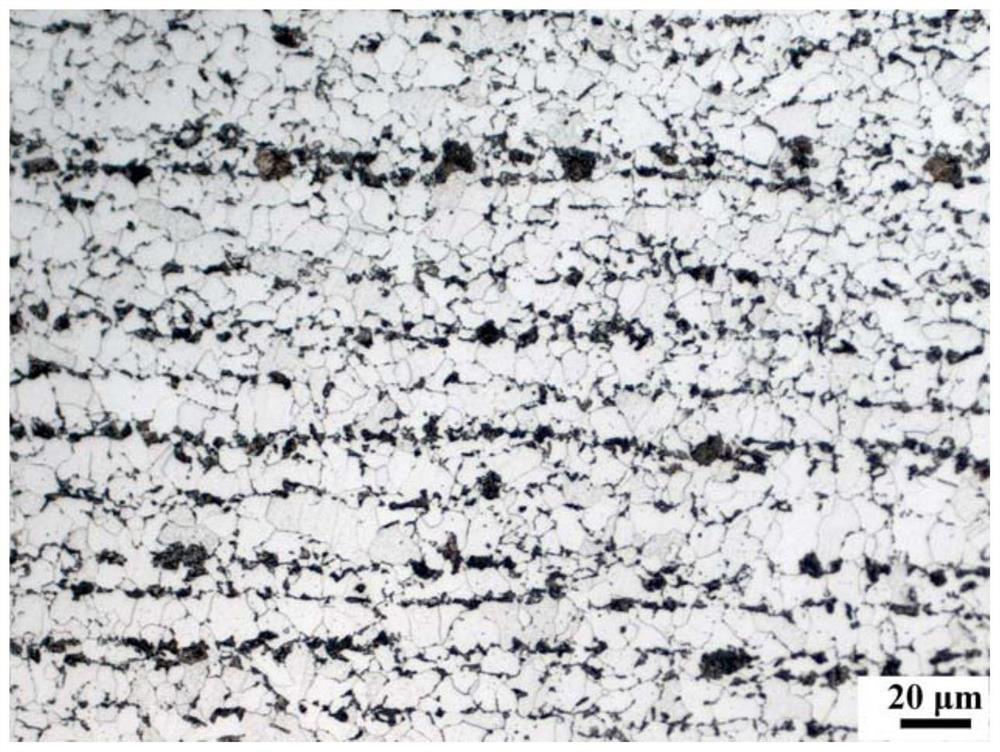

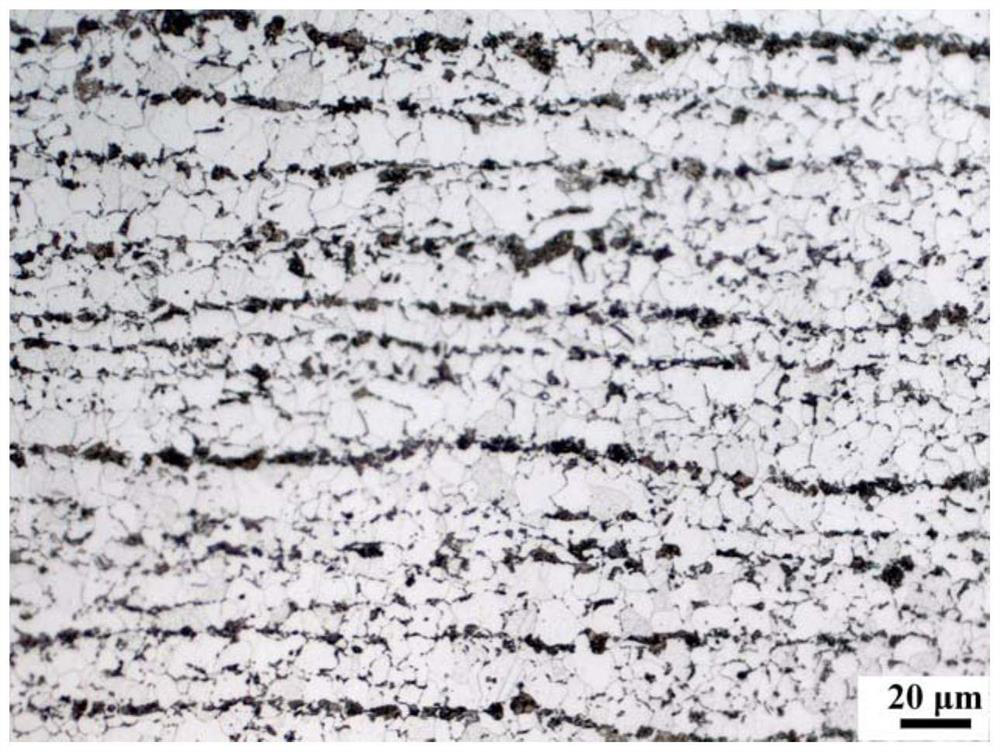

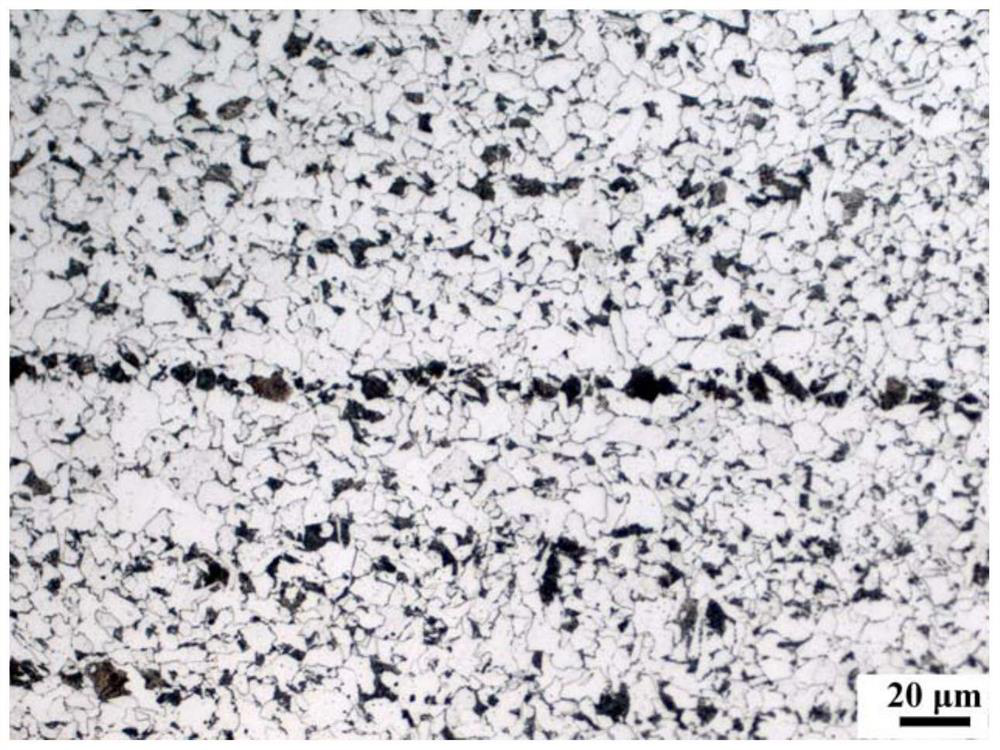

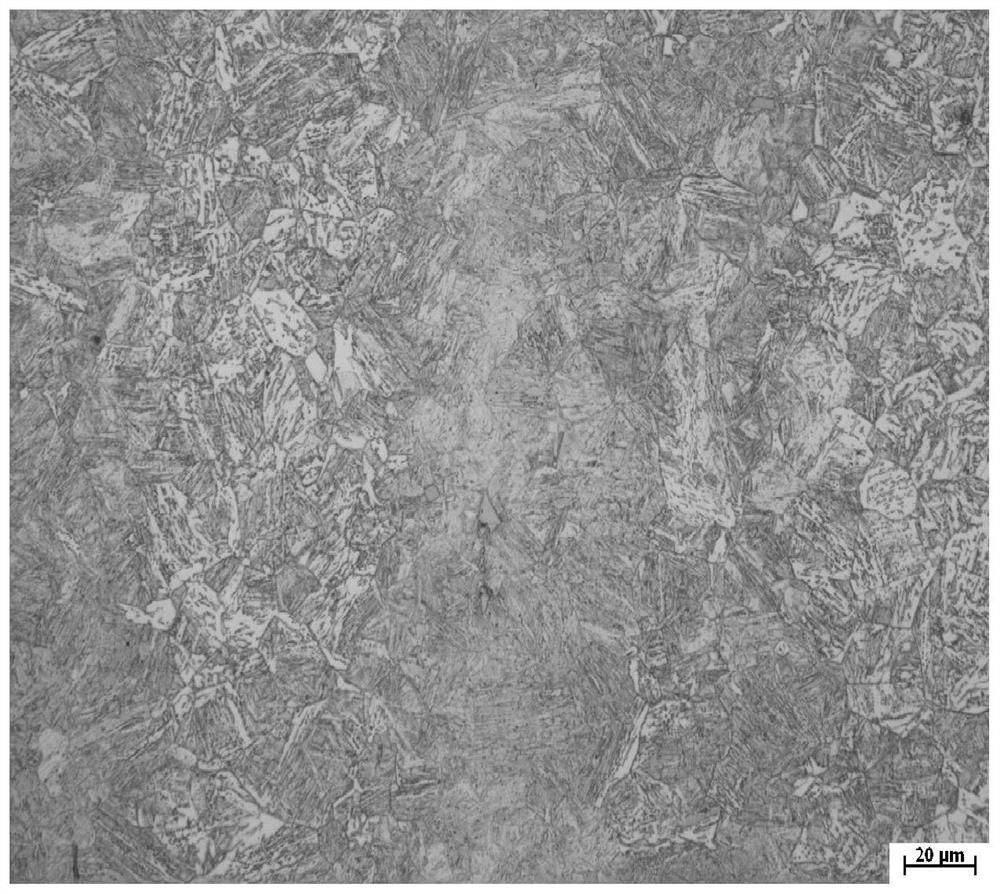

TMCP type bridge steel plate with small same-plate strength difference and production method thereof

ActiveCN112359191AHigh strengthImprove toughnessHeat treatment process controlUltimate tensile strengthMechanical engineering

The invention discloses a TMCP type bridge steel plate with small same-plate strength difference and a production method thereof. According to the production method, a continuous casting billet is sequentially and continuously subjected to a heating procedure, a recrystallization zone rolling procedure, an intermediate billet head and tail shielding and cooling procedure, a non-recrystallization zone rolling procedure and a cooling procedure to be manufactured into the bridge steel plate, in the intermediate billet head and tail shielding and cooling procedure, multi-stage cooling is carried out on a intermediate billet until the intermediate billet is cooled to the final cooling temperature of 860 DEG C + / -15 DEG C and the temperature difference between the head, the middle and the tail of intermediate billet is smaller than or equal to 30 DEG C; and the cooling process of each stage comprises the following steps of determining head and tail low-temperature parts and shielding percentage of the intermediate billet according to a temperature detection result of a whole plate; carrying out non-shielding water cooling on the middle main body of the intermediate billet; and meanwhile,carrying out shielding cooling on the head and tail low-temperature parts according to the determined shielding percentage. The same-plate strength difference of the obtained bridge steel plate is smaller than or equal to 30 MPa, the structure is uniform, the plate shape is good, the head and tail excision amount is reduced, the yield and percent of pass are improved, and the short-length rate ofthe steel plate is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Supporting roll air cooling device

InactiveCN112797802AUniform hardnessGuaranteed cooling uniformityFurnace typesHandling discharged materialBackup rollAir blast

The invention discloses a supporting roller air cooling device, and belongs to the field of heat treatment. The supporting roll air cooling device aims to realize uniform cooling and reduce the overall hardness deviation of a workpiece. The supporting roll air cooling device comprises a tire rolling device and a blower device, wherein the rolling tire device comprises a base and rolling tires supported on the base, the rolling tires are movably connected with the base around the axis of the rolling tire, two groups of the rolling tires are arranged in parallel, a gap is formed between the two groups of rolling tires, a lifting area for lifting a supporting roll is formed by the two groups of rolling tires, and a driving device for driving the rolling tires to rotate is arranged; the blower device is arranged on the sides of the rolling tires in the rotating axial direction of the rolling tires, the blower device comprises a support, air supply pipelines and N groups of nozzles which are vertically distributed along the support, the nozzles are installed on the support, one ends of the nozzles communicate with the air supply pipelines, and the other ends of the nozzles directly face the lifting area. According to the supporting roll air cooling device, through rotary blower cooling, the cooling uniformity is ensured, so that the hardness uniformity of the supporting roll is ensured, and the cooling speed can be accelerated through rotary cooling.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Air-water mist cooling system for continuous annealing of strip and control method

PendingCN111394567AGuaranteed cooling rateGuaranteed cooling uniformityFurnace typesHeat treatment process controlWater vaporSprayer

The invention relates to an air-water mist cooling system for continuous annealing of a strip and a control method. The air-water mist cooling system is characterized by comprising an air-water mist cooling device, an air blowing device, a water supply device and an air discharge device; the air-water mist cooling device comprises a box and multiple sets of air-water mist sprayers, and each set ofair-water mist sprayers comprises two air-water mist sprayers which are arranged up and down in the box to form an opposite up-down spray structure; the top of the box is provided with an air outlet,and the air discharge device is arranged at the air outlet to form a forced air discharge structure so as to discharge hot air and water vapor in the box from the air outlet; the air outlet end of the air blowing device is connected with air inlets of the multiple sets of air-water mist sprayers to form an adjustable air inlet structure; and the water outlet end of the water supply device is connected with water inlets of the multiple sets of air-water mist sprayers to form an adjustable water inlet structure. The air-water mist cooling system has the outstanding substantive features of realizing uniform cooling for continuous annealing of the strip, having a good stress relief effect, keeping the shape of the strip (workpiece) unchanged and the like, and also has significant technological progress.

Owner:GUANGDONG STRONG METAL TECH

Freezing device and freezing method for medicament preparation

ActiveCN112378139AMinimize Freezing Rate DifferencesFreezing Rate Difference ReducedLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The invention discloses a freezing device and a freezing method for medicament preparation. The device comprises a freezing box, wherein a placing box is fixed in the freezing box; a connecting cavityis formed between the outer wall of the placing box and the inner wall of the freezing box; the bottom of the connecting cavity and the bottom of the freezing box are connected with connecting pipes;a plurality of placing seats are connected between the inner walls of the two sides of the placing box in a sliding mode; placing holes which are distributed at equal intervals are formed in the topsof the placing seats; and communicating holes which are horizontally arranged in a penetrating mode are formed in the positions, corresponding to the placing holes, of the outer walls of one sides ofthe placing seats. According to the method, cold air is rapidly distributed in the placing holes in all positions of the same placing seat along the penetrating holes, the communicating holes and theplacing holes, so that the freezing rate difference of reagents at all positions is reduced, and as a result, the actual freezing effect is improved. According to the device and the method, the coldair cooled at the openings of the side communicating holes is uniformly dispersed to the reagent positions at all positions, so that the freezing rate difference of the reagents is further reduced.

Owner:ZHEJIANG CUIZE PHARM TECH CO LTD

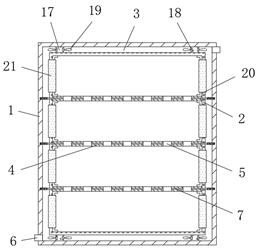

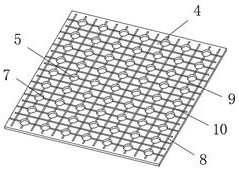

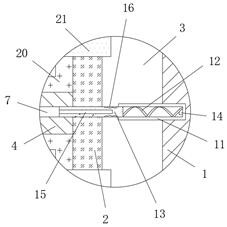

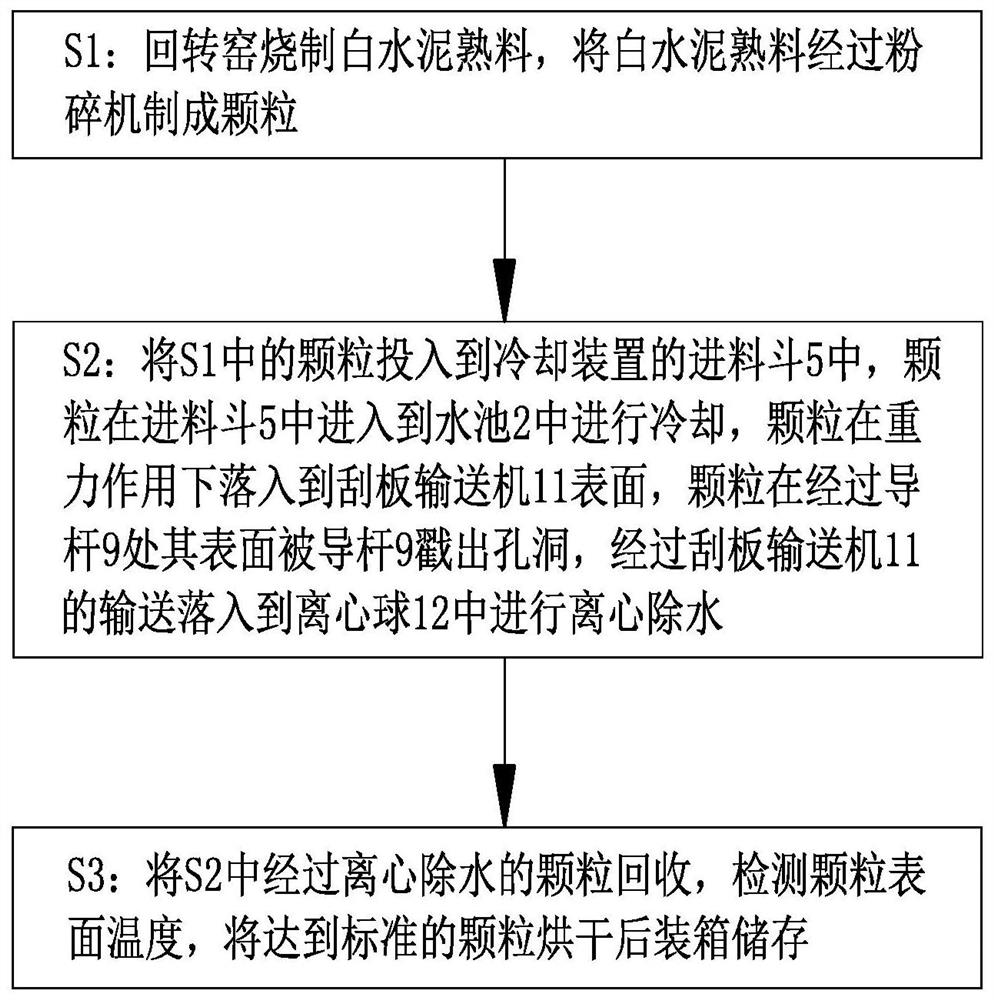

White cement clinker bleaching process

InactiveCN111807733AIncrease productivitySpeed up coolingGranular material dryingDrying solid materials without heatProcess engineeringEnvironmental geology

The invention belongs to the technical field of cement production, and especially relates to a white cement clinker bleaching process. A cooling device used in the process comprises a bottom plate, awater pool is fixed to the top end of the bottom plate, a water inlet pipe is arranged on the side wall of the water pool, a spray head is fixed at one end of the water inlet pipe in the water pool, the spray head is used for spraying water mist to water clinker, a water outlet is formed in the bottom end of the water pool, a feeding hopper is fixed to the top end of the water pool and used for feeding clinker, two supports are fixed to the top end of the water pool, a push rod motor is fixed between the two supports, and a rectangular plate is fixed to the output shaft end of the push rod motor. Holes are formed in the surface of the large-particle clinker, so that the interior of the large-particle clinker is in contact with external cooling water, the cooling speed and the cooling efficiency of the large-particle clinker are improved, the cooling uniformity of the large-particle clinker is guaranteed, the water immersion time is shortened, and the production efficiency of white cement is improved.

Owner:明光市宝德利装饰材料贸易有限公司

tmcp type bridge steel plate with small strength difference between the same plates and production method thereof

ActiveCN112359191BHigh strengthImprove toughnessHeat treatment process controlTemperature differenceUltimate tensile strength

The invention discloses a TMCP type bridge steel plate with small strength difference between the same plates and a production method thereof. In the production method, the continuous casting slab is successively processed into a bridge steel plate through the heating process, the rolling process in the recrystallization zone, the head and tail blocking cooling process of the intermediate billet, the rolling process in the non-recrystallization zone, and the cooling process. In the shading cooling process, the intermediate billet is cooled in multiple stages until the intermediate billet is cooled to a final cooling temperature of 860±15°C and the temperature difference between the head, middle and tail of the intermediate billet is ≤30°C; the cooling process of each stage includes: According to the temperature detection results of the entire plate , determine the head and tail low-temperature parts and the shading percentage of the intermediate billet; perform unshielded water cooling on the middle body of the middle billet, and at the same time perform shading cooling on the head and tail low-temperature parts according to the determined shading percentage. The resulting bridge steel plate has a strength difference of less than or equal to 30 MPa, a uniform structure and a good plate shape, reduces head and tail cuts, improves the finished product rate and pass rate, and reduces the short-length rate of the steel plate.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

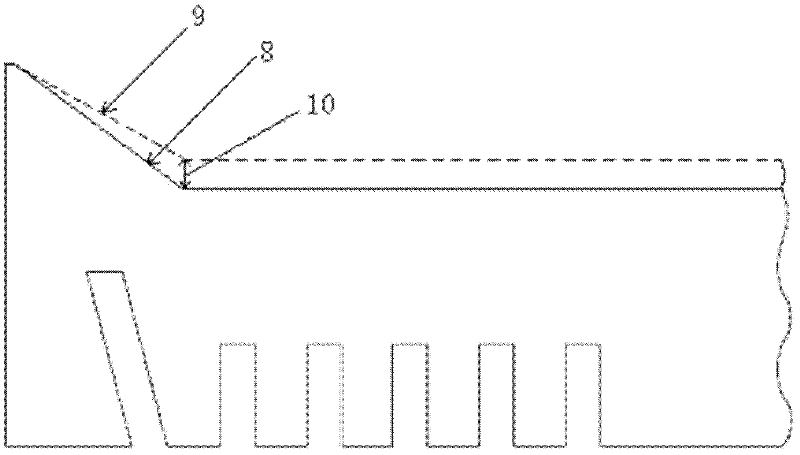

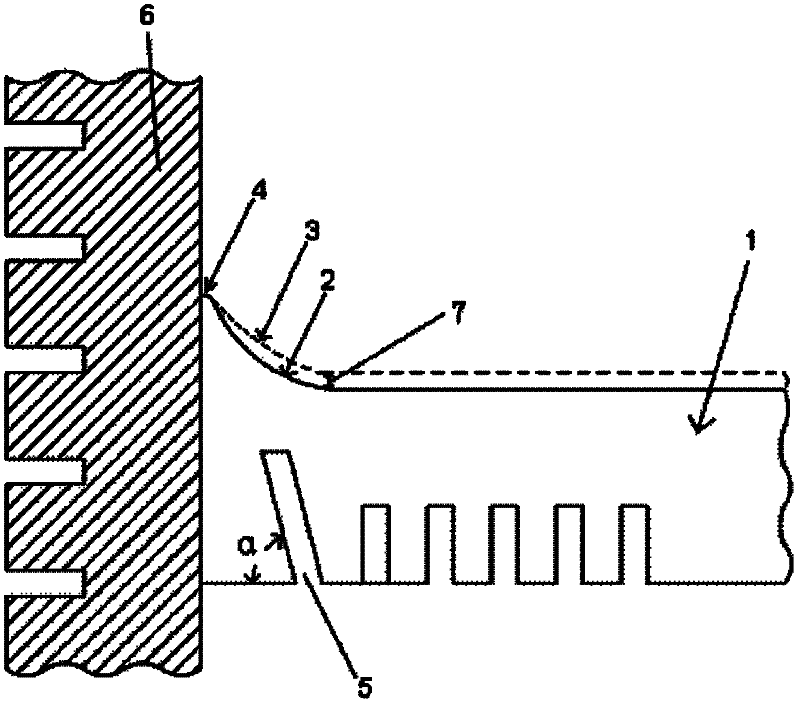

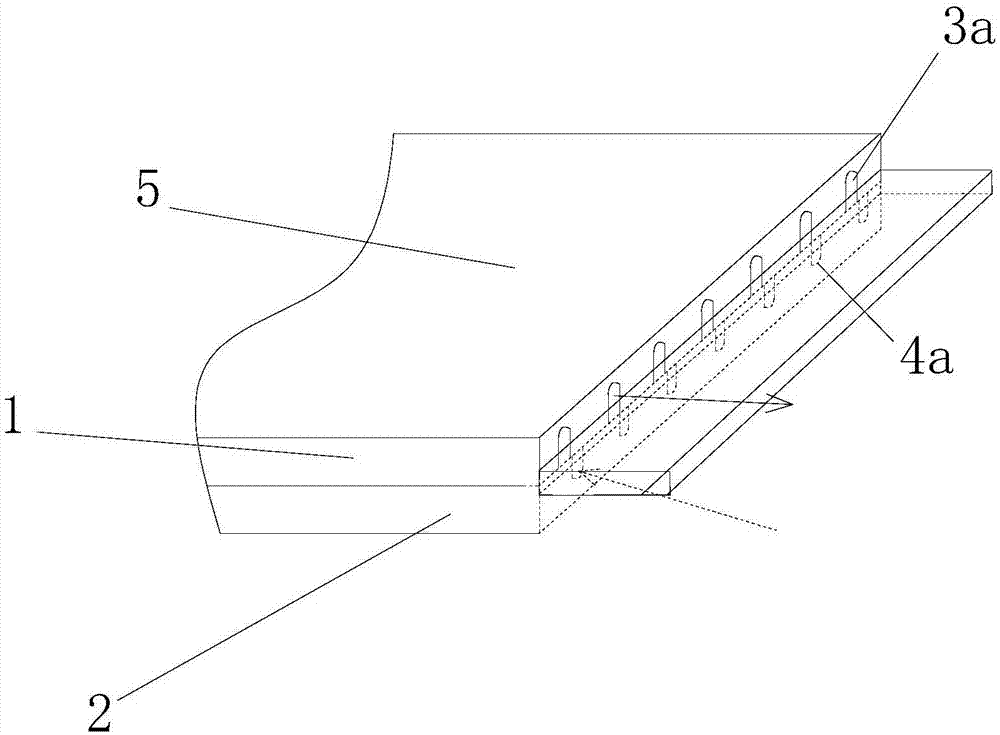

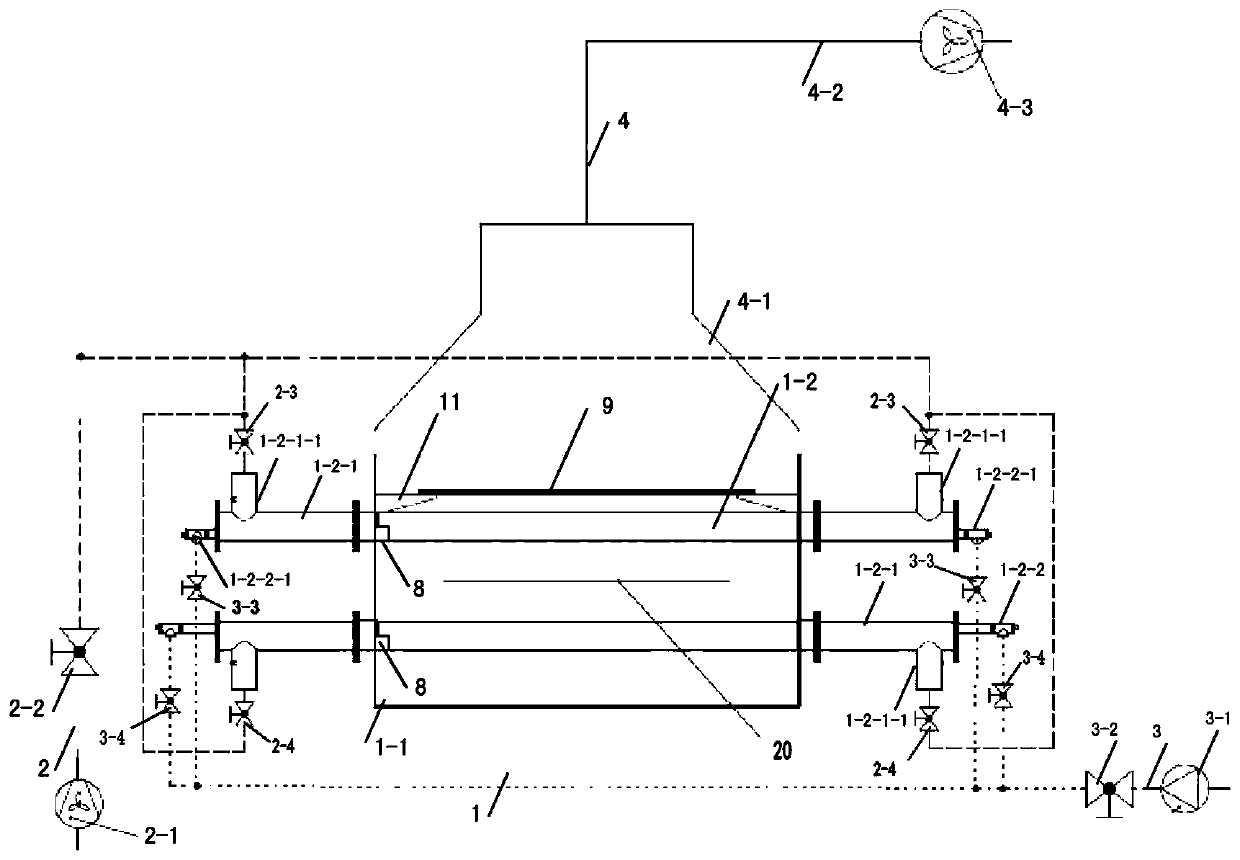

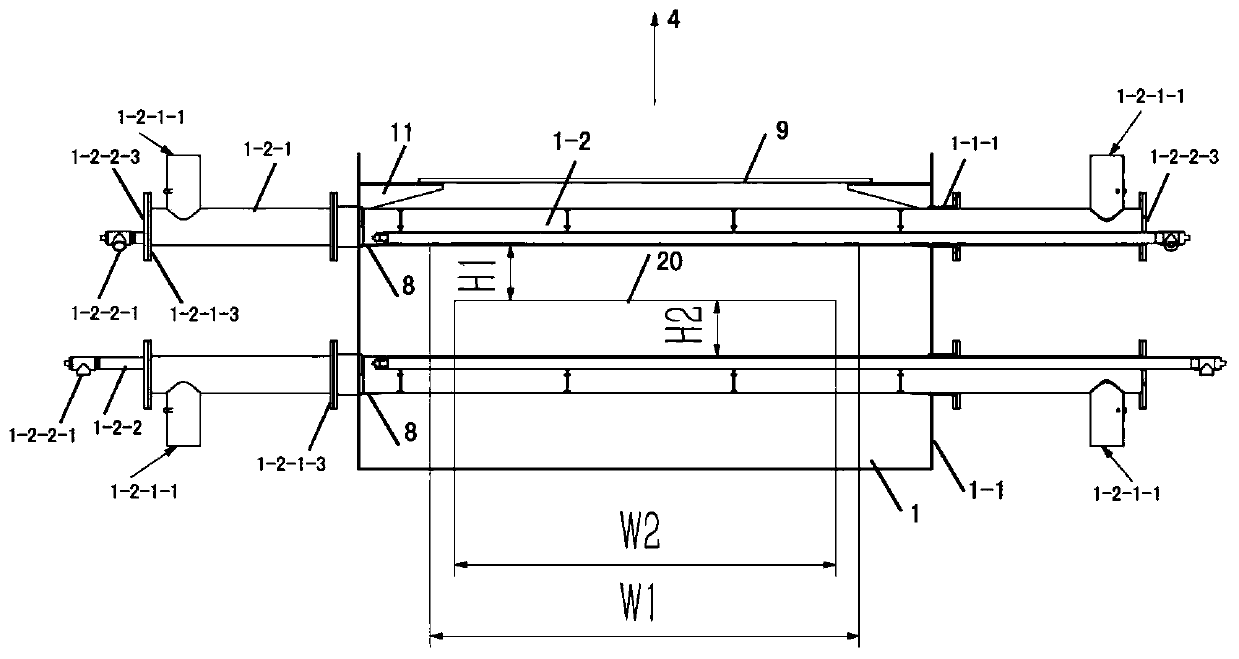

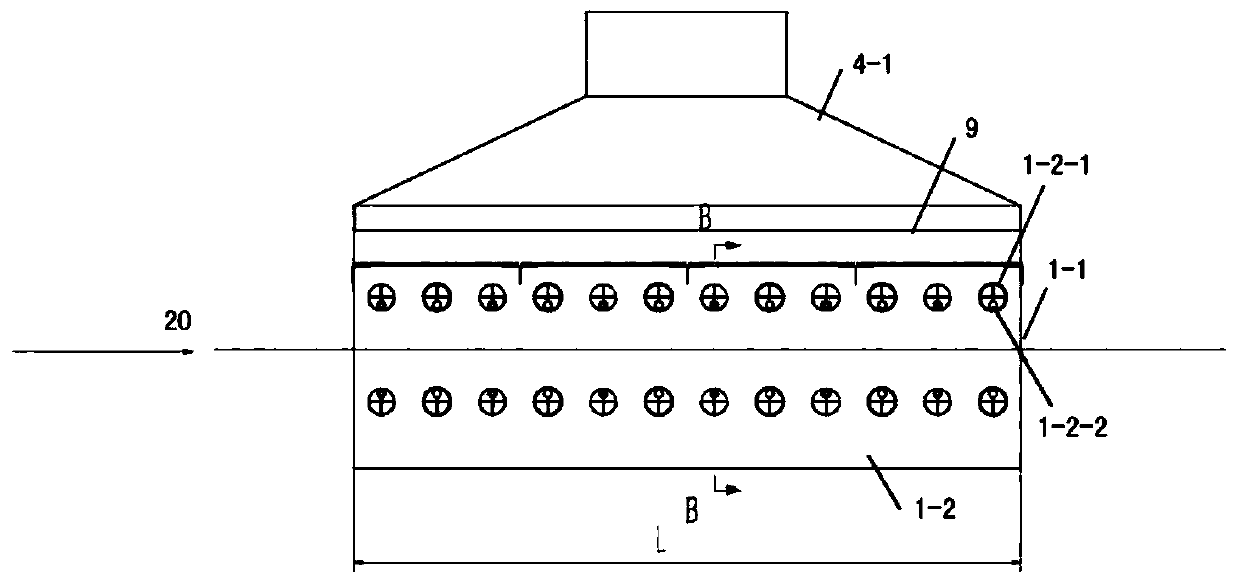

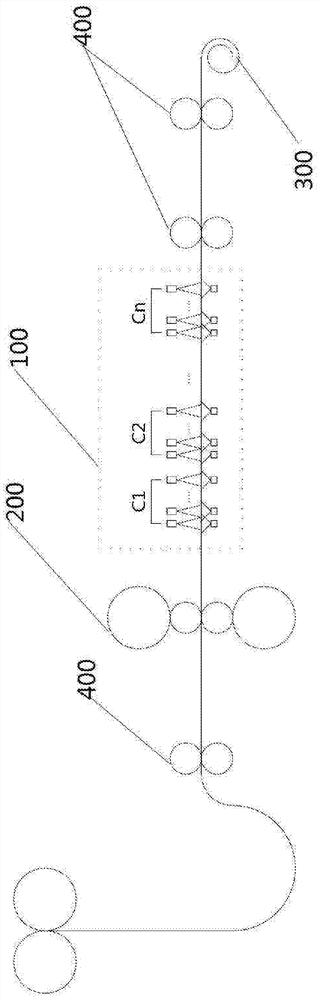

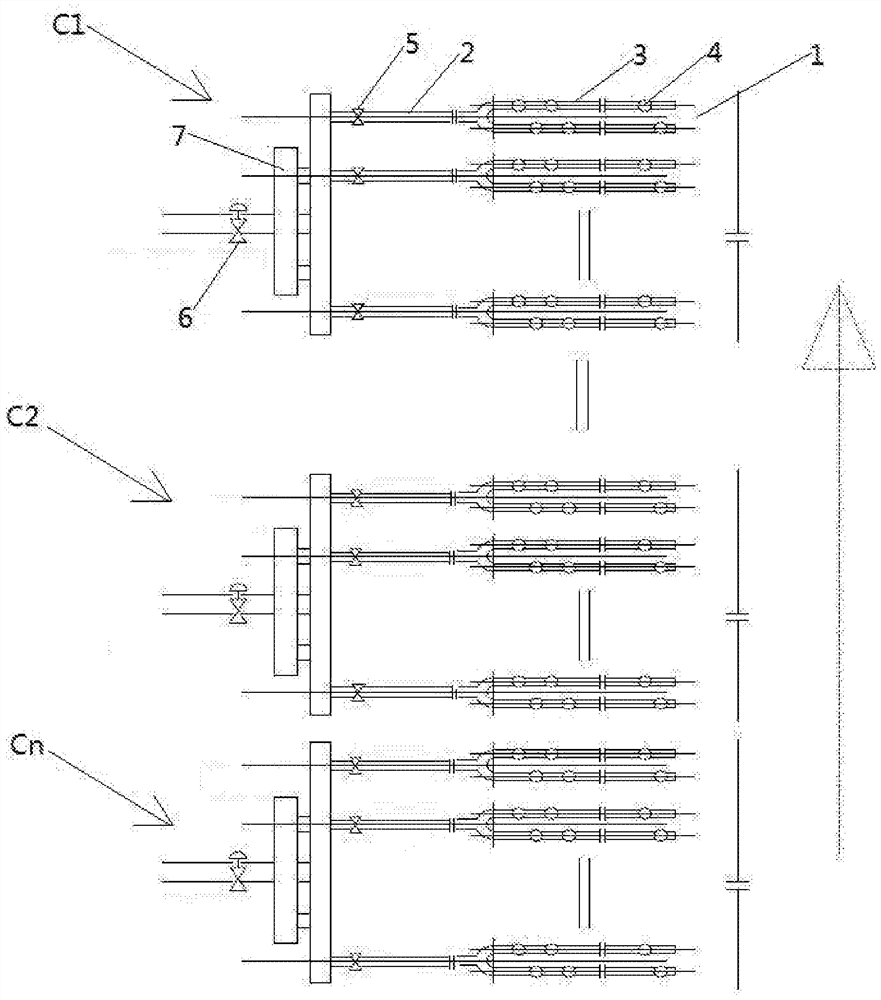

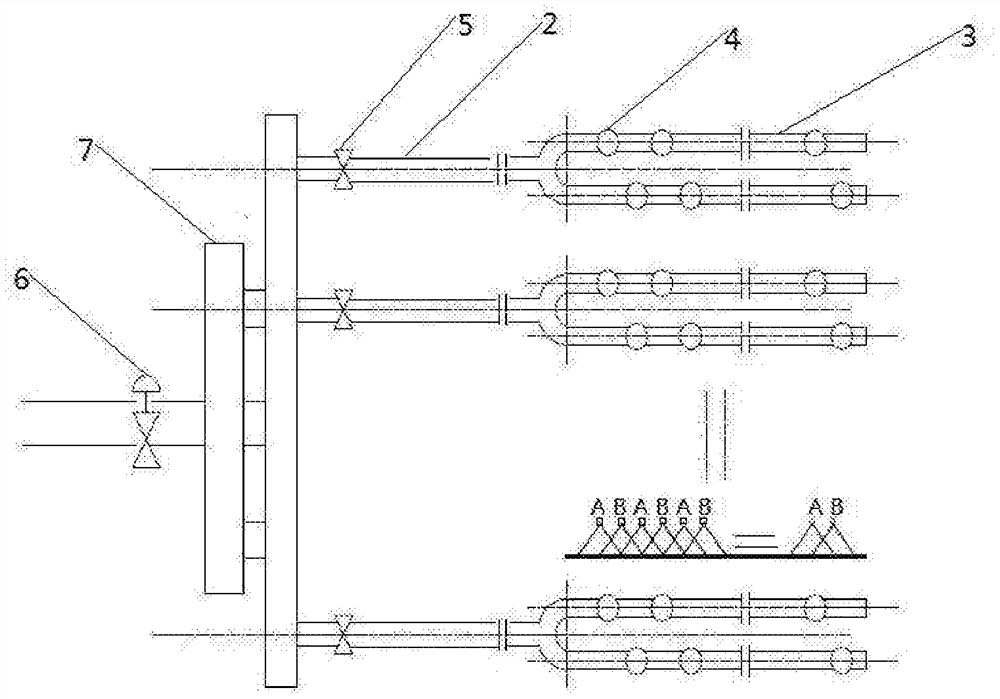

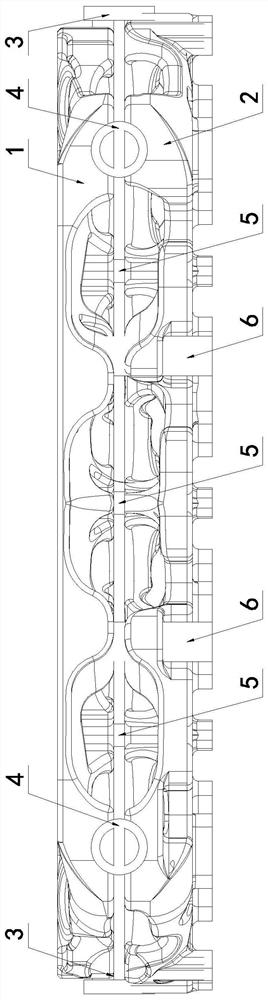

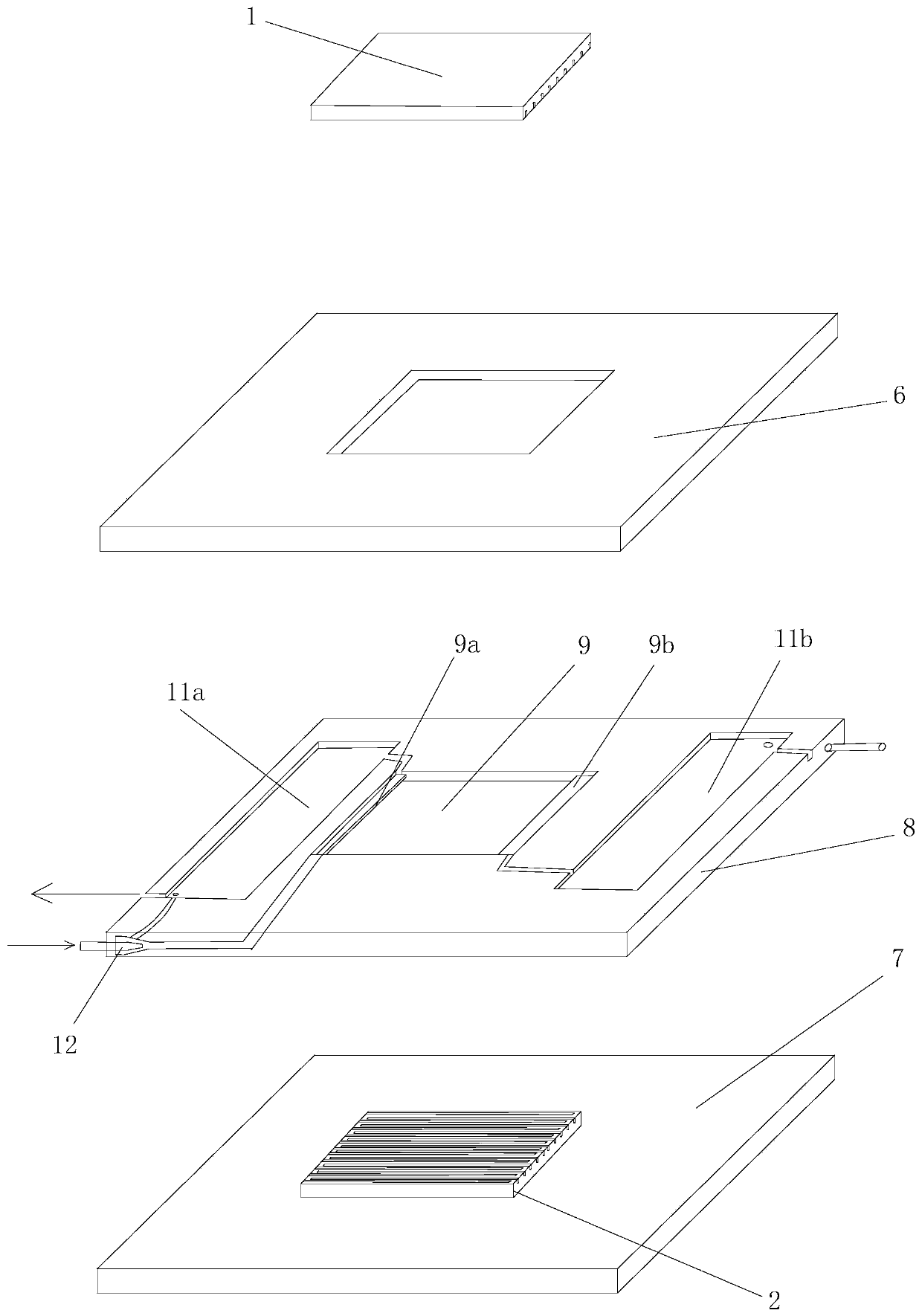

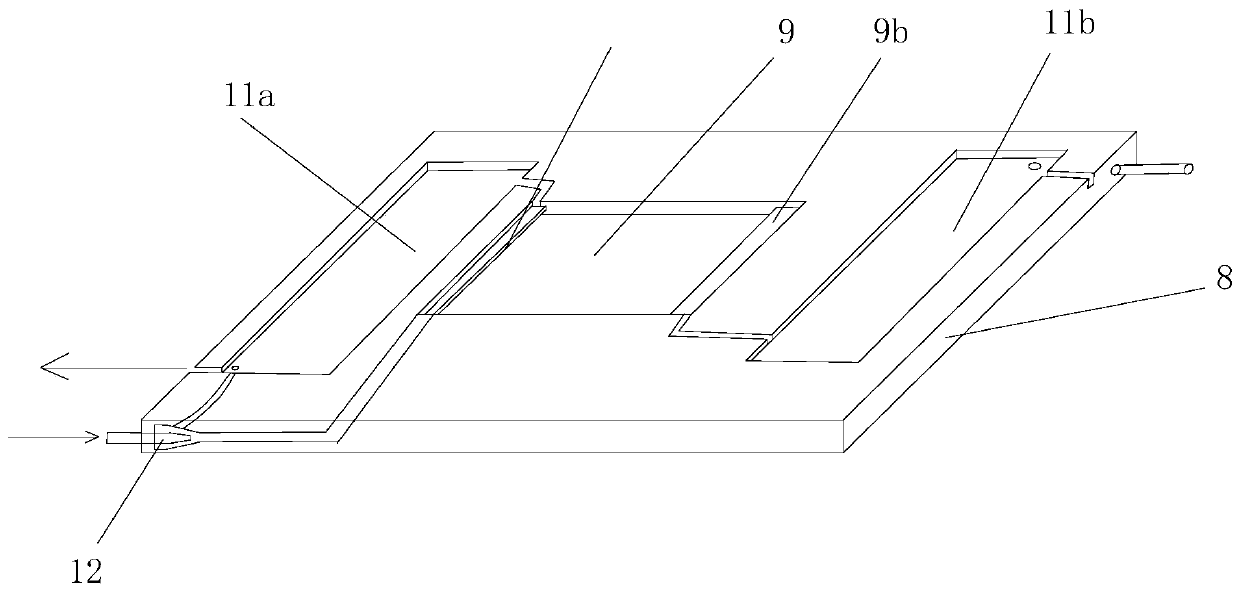

A thin strip continuous casting strip steel cooling mechanism and cooling method thereof

A thin strip continuous casting strip steel cooling mechanism, which is provided with a plurality of cooling groups (C1, C2, ..., Cn), each cooling group includes at least one cooling unit (1), each cooling group The cooling method of the cooling unit is at least one of air mist cooling, laminar flow cooling, and jet cooling; the cooling units are respectively located on the upper side and the lower side of the roller table, and include a header main road (2 ) and at least two header branches (3) connected to the header main road, a plurality of nozzles (4) are arranged on the header branch, and an on-off switch ( 5), the water pipe and the air pipe are also provided with an opening control valve (6) for controlling the flow of gas and liquid in the cooling unit. The cooling mechanism realizes the control of the cooling speed of the steel strip, and has the effect of uniformly cooling the steel strip. It also includes a cooling method for the thin strip continuous casting strip steel cooling mechanism.

Owner:BAOSHAN IRON & STEEL CO LTD +1

A double-layer water jacket structure of a cylinder head for a cross-flow cooling engine

ActiveCN113606054BReasonable layoutImprove cooling effectInternal combustion piston enginesCylinder headsCombustion chamberExhaust valve

A double-layer water jacket structure of a cylinder head of a cross-flow cooling engine relates to a water jacket structure of a cylinder head. The upper water jacket and the lower water jacket are stacked and fixed to form a double-layer structure. There are four groups of combustion chamber areas at the rear end, each group including a spark plug area, an intake valve area and an exhaust valve area. The bottom surface of the lower water jacket has four The upper nozzle of the cylinder head and the two upper nozzles of the water jacket, the upper water jacket and the lower water jacket are vertically connected with two water supply channels and three water supply channels, and there are five cylinder covers on the bottom surface of the lower water jacket. The water outlet and the eight water jacket water outlets are respectively provided with water flow guiding protrusions in the cavities of the upper water jacket and the lower water jacket. A double-layer water jacket structure is designed for the four-cylinder engine, which adopts the cross-flow form of water inlet on the exhaust side and water outlet on the intake side to ensure the uniformity of cooling and effectively reduce the heat load.

Owner:HARBIN DONGAN AUTO ENGINE

A kind of air distributor system used in gas-solid heat exchange process and gas-solid heat exchange method

ActiveCN110360845BSpread evenlyGuaranteed cooling uniformityHandling discharged materialDirect contact heat exchangersGas solidThermodynamics

Owner:CENT IRON & STEEL RES INST +1

High-speed wire rod air cooling roller way slow cooling process control method

InactiveCN113351654ASolve the problem that the characteristic value of mechanical properties does not meet the requirements of the national standardIncrease production capacityTemperature control deviceWire rodSpinning

The invention discloses a high-speed wire rod air cooling roller way slow cooling process control method. The process comprises heating furnace heating, finishing mill rolling, spinning and Stelmor air cooling roller way controlled cooling. The slow cooling process control method comprises the following steps: (1) the rolling temperature of a finishing mill is 1000 DEG C; (2) the spinning temperature ranges from 940 DEG C to 1000 DEG C; and (3) by controlling the speed of an air cooling roller way, the number of started draught fans and the speed of the draught fans, the slow cooling time of steel materials on the air cooling roller way within the interval of 727 to 500 DEG C is prolonged, and after pearlite transformation is promoted, secondary cooling is conducted till the coil collecting temperature is reached. According to the slow cooling process control method provided by the invention, the problem that the mechanical property characteristic values of HPB300 and HRB400E products cannot meet the national standard after the productivity of high-speed wire rods is improved can be effectively solved, the qualified product quality and normal accelerated production can be ensured, and the improvement of enterprise productivity is promoted.

Owner:XINXING DUCTILE IRON PIPES XINJIANG

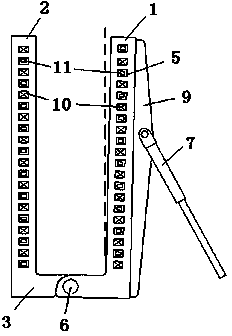

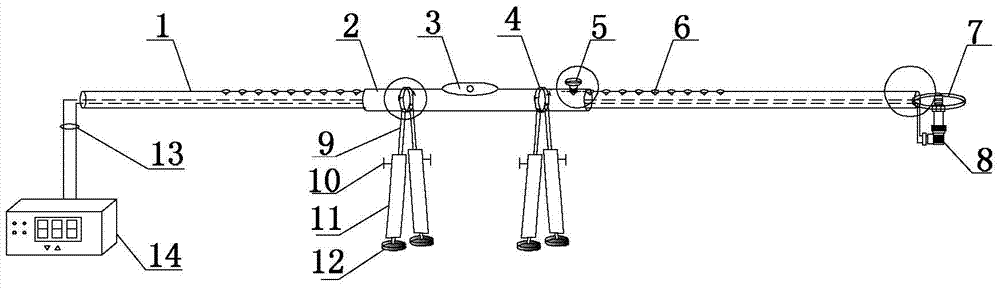

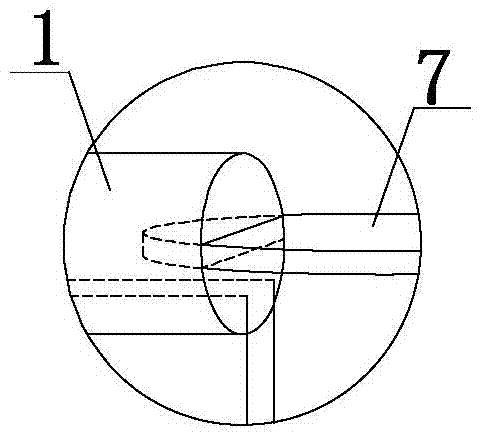

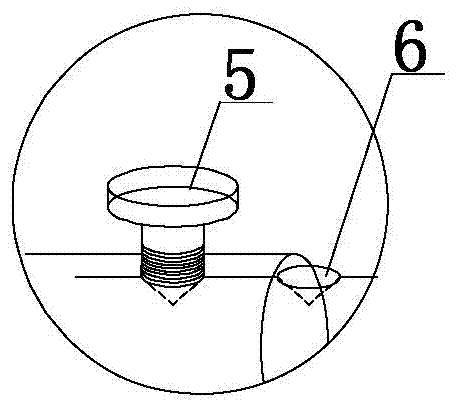

A single-point test device for impact pressure in the cooling zone of rolling steel and its test method

ActiveCN105032954BEasy to testGuaranteed cooling uniformityWork treatment devicesMeasuring devicesMeasurement devicePlate pressure

The invention provides a single-point test device for impact pressure in the steel rolling cooling zone, which includes a fixed rod, a fixed sleeve, a level, a bracket fixed ring, a pressure transmitter fixed plate, a pressure transmitter, a bracket, a bracket sleeve and a display instrument ;The center of the pressure transmitter fixing plate is opened and connected with the fixing rod; the pressure transmitter is connected to the fixing plate through threads; the output wire of the pressure transmitter passes through the inner cavity of the fixing rod and is connected to the display instrument; the fixing rod Go through the fixing sleeve and fix it with positioning screws and positioning holes; the level is embedded in the fixing sleeve, and the bracket fixing ring is set outside the fixing sleeve and fixed with fixing bolts; the bracket and the bracket fixing ring are welded together; the bracket sleeve is fixed through The bolts adjust the height of the support; the display instrument is used to display the pressure signal output from the pressure transmitter. The invention is a single-point pressure measurement device with simple structure, easy manufacture, repeated disassembly and assembly, movable testing of one-dimensional pressure field, and change of measuring range by replacing the pressure sensor.

Owner:NANJING IRON & STEEL CO LTD

High-power laser diode array throttling micro-evaporative refrigeration heat sink

ActiveCN107104360BDecrease productivityGuaranteed to workLaser detailsSemiconductor lasersHigh power lasersEvaporation

The invention discloses a high-power laser diode array throttling micro-evaporation refrigeration heat sink. The high-power laser diode array throttling micro-evaporation refrigeration heat sink at least comprises a heat sink upper plate and a heat sink lower plate which are overlapped; a plurality of upper strip-shaped grooves are formed in the bottom surface of the heat sink upper plate; a plurality of lower strip-shaped grooves which communicate with the upper strip-shaped grooves in a one-to-one correspondence manner are formed in the top surface of the heat sink lower plate; each upper strip-shaped groove and the corresponding lower strip-shaped groove are staggered and communicate with each other to form a single flow path; the flowing directions of cooling liquid in each two adjacent flow paths are opposite; the top surface of the heat sink upper plate is a working surface for dissipating heat of a high-power laser diode array; the cooling efficiency of the heat sink can be improved effectively; uniformity of cooling of the heat sink is improved; the circumstance that the working efficiency is low due to uneven temperature of the high-power laser diode array is avoided; normal and efficient operation of the high-power laser diode array is guaranteed; and meanwhile, the high-power laser diode array throttling micro-evaporation refrigeration heat sink is high in structural precision and convenient to manufacture.

Owner:深圳德元激光科技有限公司

A kind of freezing device and freezing method for pharmaceutical preparation

ActiveCN112378139BMinimize Freezing Rate DifferencesFreezing Rate Difference ReducedLighting and heating apparatusDomestic refrigeratorsCold airMechanical engineering

The invention discloses a freezing device and a freezing method for pharmaceutical preparation. The device comprises a freezing box, a placing box is fixed inside the freezing box, and a connecting cavity is provided between the outer wall of the placing box and the inner wall of the freezing box , the bottom and bottom of the connection cavity are connected with connecting pipes, a plurality of placement seats are slidably connected between the two inner walls of the placement box, and the top of the placement seats is provided with placement holes distributed at equal distances. The position corresponding to the side outer wall and the placement hole is provided with a communication hole arranged horizontally through; the method enables the cold air to be quickly distributed in the placement hole of each position on the same placement seat along the perforation, the communication hole and the placement hole, so as to reduce the size of each position The freezing rate of the reagents varies, thereby increasing the actual freezing effect. The invention makes the cold air cooled at the opening of the side communication hole evenly dispersed to the reagent positions at various positions, and further reduces the difference in the freezing rate of the reagents.

Owner:ZHEJIANG CUIZE PHARM TECH CO LTD

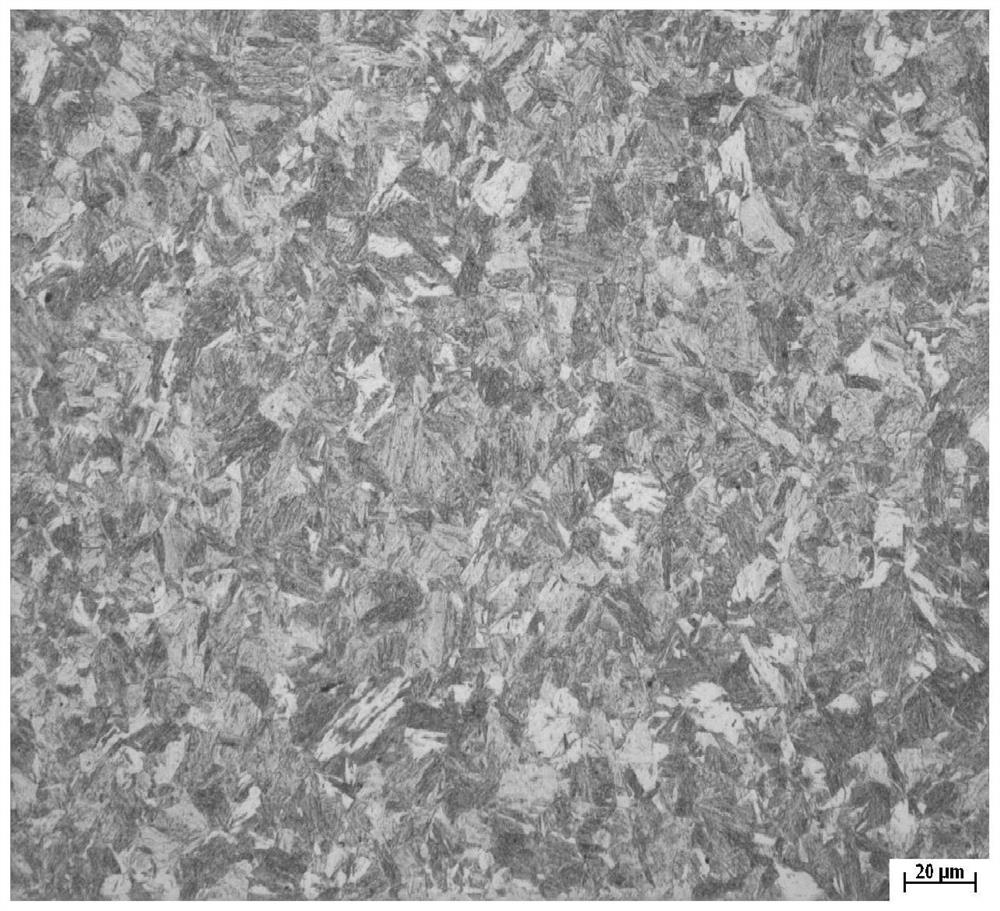

A manufacturing method for quenching heat treatment of super-wide and extra-thick steel containment nuclear power steel

ActiveCN110616298BPrevent surface oxidationEvenly heatedHeat treatment process controlQuenching devicesAustenite grainNuclear power

The invention provides an ultra-wide and extra-thick steel containment nuclear power steel quenching heat treatment manufacturing method. The method adopts radiant tube heating under the protection of nitrogen to avoid surface oxidation of the steel plate; through precise control of the furnace temperature, the steel plate is evenly heated and ensured. Homogeneity of tissue performance. Through a reasonable heating temperature process, the austenite grains are increased, and carbides and other non-metallic inclusions are dissolved into the austenite, and at the same time, the composition is homogenized to improve the stability of the supercooled austenite, thereby improving the steel plate Hardenability. When the middle gun nozzle is opened, it cooperates with the side gun nozzle to spray water on the width direction of the steel plate to ensure the uniformity of cooling of the steel plate in the width direction. The partition cooling control process is matched with reasonable water volume, roll speed, roll gap and other process parameters to shorten the quenching steam film stage, prolong the convection stage and boiling stage, and improve the cooling capacity. Ensure the cooling uniformity of the steel plate in the thickness direction, and obtain a quenched martensite structure with excellent performance in the entire thickness direction.

Owner:NANJING IRON & STEEL CO LTD

Quenching cradle for cast grinding balls

InactiveCN105525070AFully contactedGuaranteed cooling uniformityFurnace typesHeat treatment furnacesQuenchingCasting

The invention discloses a quenching cradle for cast grinding balls. The quenching cradle comprises a longitudinal supporting rod, a supporting rod, a transverse supporting rod, a handle, a cradle frame, a bottom supporting plate, a connecting device, a rack, a rod body and a containing frame; and the quenching cradle is characterized in that the supporting rod is arranged on the top of the longitudinal supporting rod, the rod body of the supporting rod is connected with the transverse supporting rod through a roller, and the handle penetrates the center of the transverse supporting rod; the bottom of the handle is connected with the cradle frame, and the bottom supporting plate is arranged at the bottom of the cradle frame; and the center of the upper surface of the bottom supporting plate is connected with the rack through the connecting device, and one end of the upper surface of the bottom supporting plate is connected with the containing frame through the rod body. The quenching cradle can move up and down in a front-and-back manner, the grinding balls and a grinding segment can constantly and freely roll in the cradle, it is ensured that the grinding balls and the grinding segment can be in sufficient contact with quenching media, cooling uniformity of a casting is ensured, and the surface hardness of the casting is consistent.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD

Ultra-fast cooling method for hot-rolled extra-thick plate

ActiveCN113976646ASuper fast and even coolingSpeed up coolingWork cooling devicesMetal rolling arrangementsThick plateAerosol Mist

The invention discloses an ultra-fast cooling method for a hot-rolled extra-thick plate, belongs to the technical field of steel rolling processes, and solves the problems that in the prior art, ultra-fast cooling is conducted only through cooling water, cooling is not uniform within the thickness range, and the requirement for ultra-fast cooling cannot be met due to the fact that an aerial fog cooling production line is long and the cooling speed is low. The ultra-fast cooling method comprises the following steps that the hot-rolled extra-thick plate is moved to a cooling water area to be cooled through cooling water; the hot-rolled extra-thick plate from the cooling water area is moved to an aerial fog area, and aerial fog cooling is performed; the hot-rolled extra-thick plate subjected to aerial fog cooling is subjected to temperature returning; and the step 1 to the step 2 are repeated for at least one time, and ultra-fast cooling of the hot-rolled extra-thick plate is completed. The ultra-fast cooling method can be used for ultra-fast cooling of the hot-rolled extra-thick plate.

Owner:CENT IRON & STEEL RES INST

Dynamic control method for online cooling control system of medium-thickness steel plate

ActiveCN102294366BOvercome the effects of uneven temperature distributionHigh control precisionTemperature control deviceControl systemEngineering

The invention discloses a dynamic control method for an online cooling control system of a medium-thickness steel plate. The method comprises the following steps of: setting a surface temperature set value and a central temperature set value of a medium-thickness steel plate at any position in a cooling area, and storing the set value in an optimizer; measuring the surface temperature value and central temperature value of the medium-thickness steel plate at any position at a k moment in real time by using an observer, transmitting the surface temperature value and the central temperature value to a speed responding module which is connected with an observer, calculating by using the speed responding module to obtain the surface temperature value and the central temperature value of the medium-thickness steel plate at any position at a k+1 moment, comparing the obtained surface temperature value and the central temperature value with the surface temperature set value and the central temperature set value, and calculating the optimized walking speed and optimized walking acceleration of the medium-thickness steel plate from the k moment to the k+1 moment; and obtaining the optimized walking speed and the optimized walking acceleration by using the online cooling control system of the medium-thickness steel plate and applying the optimized walking speed and the optimized walkingacceleration to the medium-thickness steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com