Patents

Literature

59results about How to "Ensure billet quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

ActiveCN103586433AImprove internal qualityImprove the qualified rate of flaw detectionMetallurgyContinuous casting

The invention discloses a method for increasing the flaw detection yield of a continuous casting sheet head billet and a tail billet. The flaw detection yield of the head billet and the tail billet is increased by improving internal quality of casting billets in the casting process and after the casting stopping process and optimizing technological operation. According to the method, through technological optimization and control under the unstable state condition, the internal quality of the head billet and the internal quality of the tail billet are improved, and then the flaw detection yield of steel sheets is increased. The method is suitable for the field of sheet billet continuous casting, and has significant economical value and practical significance in improving the quality of the casting billets under the continuous casting billet unstable state condition, and especially in improving the quality of variety steel and the material yield.

Owner:NANJING IRON & STEEL CO LTD

Method for producing sulfur free cutting and non-hardened and tempered steel

InactiveCN1667129AQuality improvementIncrease reflectionManufacturing convertersProcess efficiency improvementSystems researchOxygen content

This invention relates to manufacturing method of sulfurous free machining non- quenched and tempered steel. Desulfurization operation is not used in convertor, residue consumption is reduced, and convertor few residue smelting technology is realized. Appropriate deoxidizer and deoxidation technique is selected and high sulfur steel sulfide inclusion is controlled efficiently to make it tiny, uniform distributing, it realizes innocent treatment of high sulfur steel sulfide inclusion. Sulfur element absorptivity, narrow composition control and inclusion removal is ensured by refining technique and residue system research. The contradiction of reducing oxygen content and ensuring sulfur content is solved and high sulfur steel continuous casting low control problem. Sulfur in steel can be stably controlled to 0.040~0.060% by this invention, the history domestic convertor-refinery-continuous casting-binding and cold control technique can not produce sulfurous free machining non- quenched and tempered steel is changed. The steel quality is good and reaches to convertor-refinery-molded casting-binding and cold control technique level. It has been mass produced, and has good reflection from consumer.

Owner:SHOUGANG CORPORATION

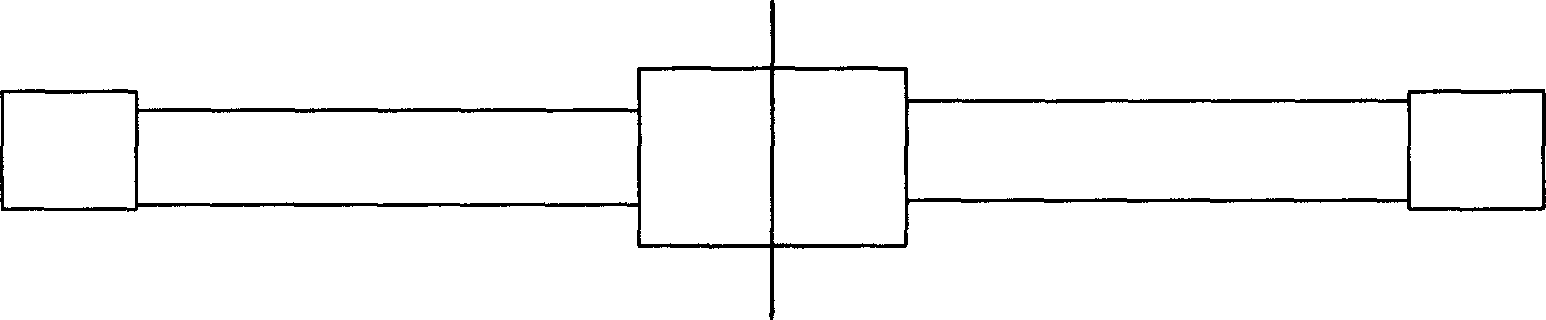

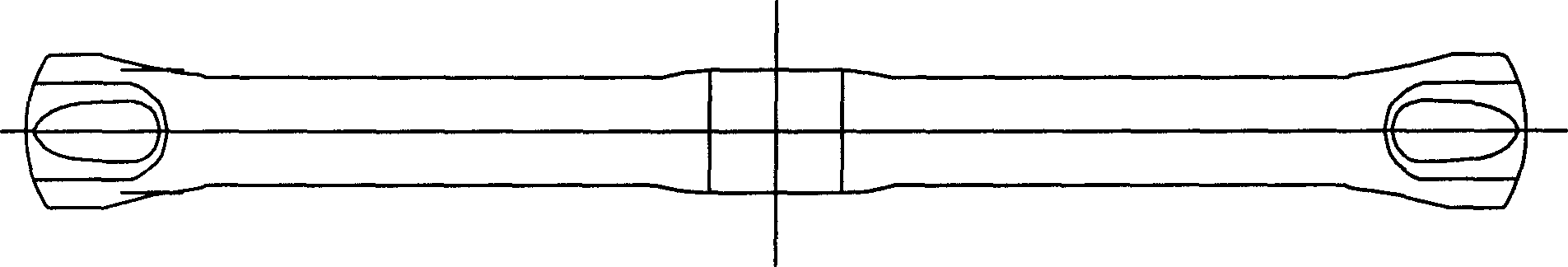

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087AEnsure billet qualitySimplify the traditional die forging processEngine componentsRheniumRare-earth element

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to 94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

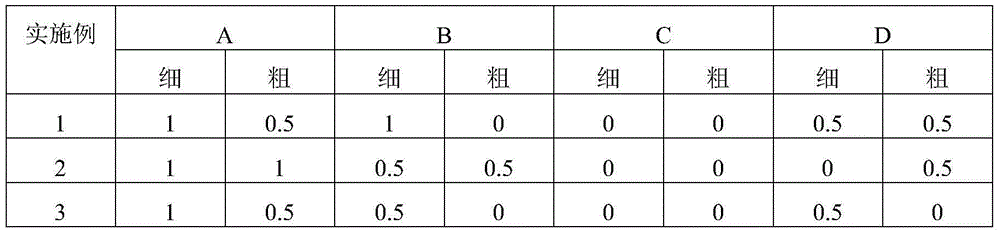

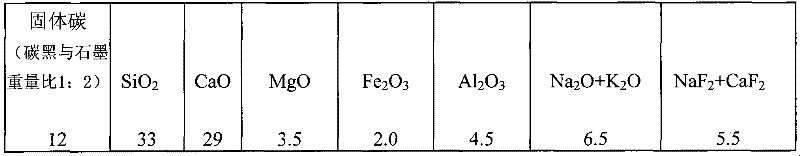

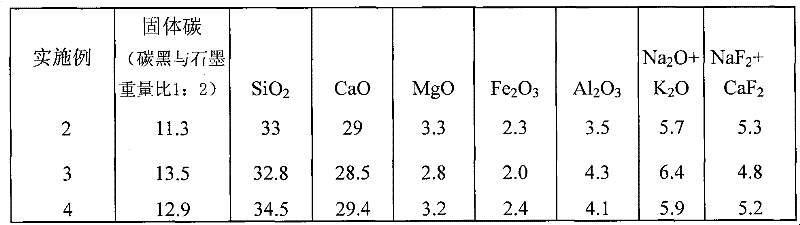

Cogged ingot continuous casting crystallizer protecting slag and preparation method thereof

The invention relates to a cogged ingot continuous casting mold powder, belonging to the iron and steel smelting technical field. The mold powder comprises the following chemical components with the weight percent of 30-35 percent of SiO2, 25-30 percent of CaO, 2.5-3.5 percent of MgO, 1.5-2.5 percent of Fe2O3, 3.5-4.5 percent of Al2O3, 4.5-5.5 percent of NaF2+CaF2, 5.5-6.5 percent of Na2O+K2O, 11-14.5 percent of solid carbon, and the rest is binder used for pelleting and water. A preparation method of the mold powder is also provided by the invention. The mold powder is exclusively applied to the cogged ingot continuous casting mold powder, in particular to cogged ingot 27SiMn continuous casting mold. The zero defect production of continuous casting can be realized, the hot delivery and hot charging of the continuous casting can be guaranteed, the systematic energy consumption from the continuous casting to rolled products can be lowered, the production cycle from the continuous casting slab to the rolled products can be shortened, and the quality of steels can be ensured.

Owner:SHANDONG IRON & STEEL CO LTD

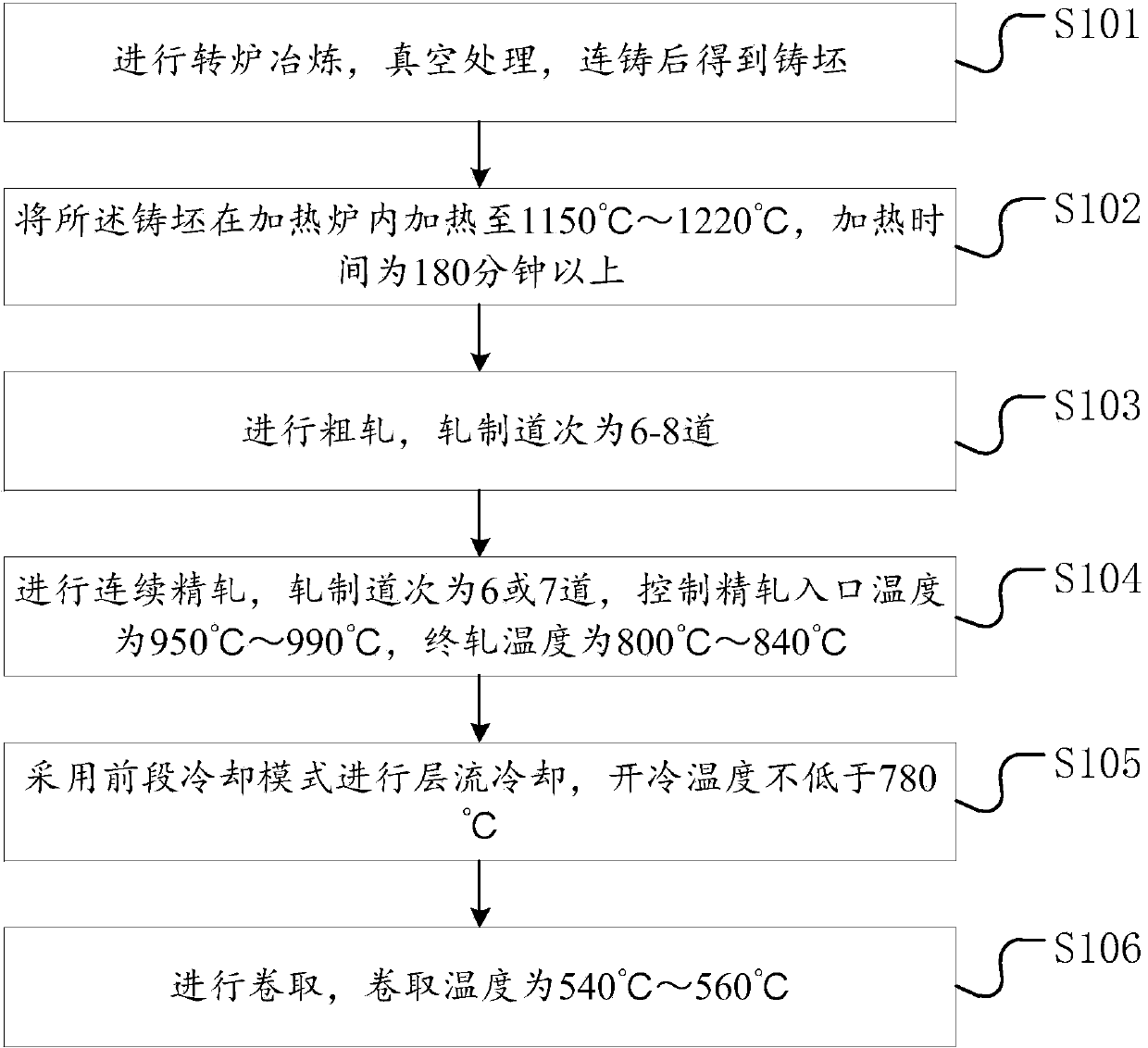

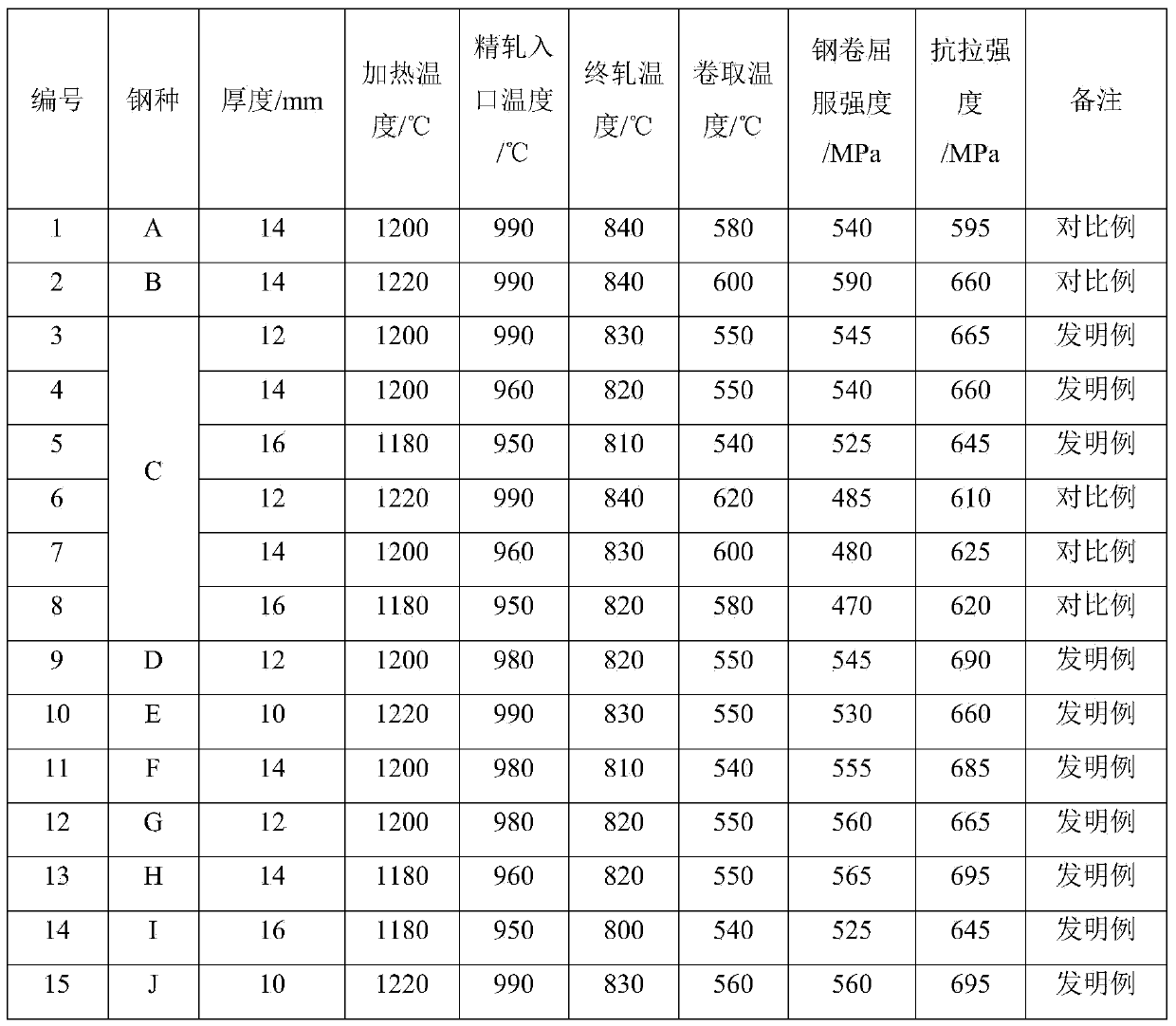

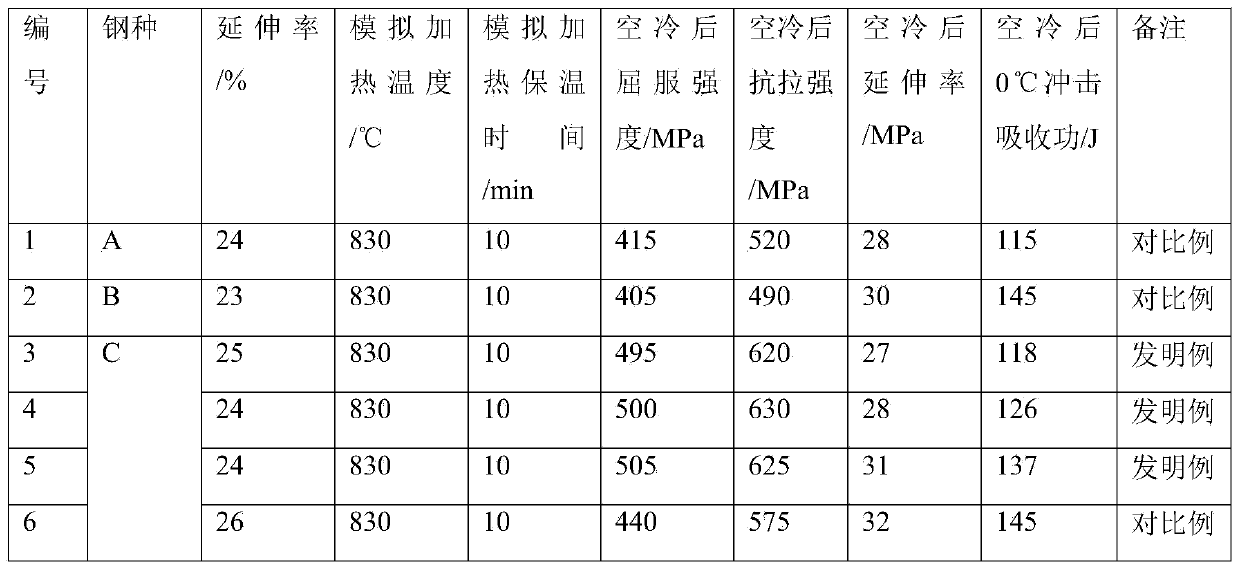

600 MPa level automobile axle housing steel and production method thereof

The invention discloses 600 MPa level automobile axle housing steel and a production method of the 600 MPa level automobile axle housing steel. Compositions of the steel comprise, by weight, 0.21 percent to 0.26 percent of C, 0.51 percent to 0.6 percent of Si, 1.1 percent to 1.5 percent of Mn, 0.01 percent to 0.06 percent of Al, P smaller than or equal to 0.02 percent, S smaller than or equal to 0.01 percent, 0.05 percent to 0.06 percent of V, 0.012 percent to 0.016 percent of N, and the balance Fe and inevitable impurities. The ratio of V to N is smaller than or equal to 5:1. According to the method, the accurate V content, the accurate N content and the controlled rolling and controlled cooling process window are designed, hot rolling strip steel for a 600 MPa level automobile axle housing is produced, the strip steel has the good strength and toughness, and meanwhile various mechanical performance indexes of the axle housing after hot forming at the temperature more than 800 DEG C can be ensured. The method can be applied to automobile axle housing production, the thickness of materials can be effectively reduced, and on the premise that the safety of an automobile is ensured, the lightweight aim can be effectively achieved.

Owner:SHOUGANG CORPORATION

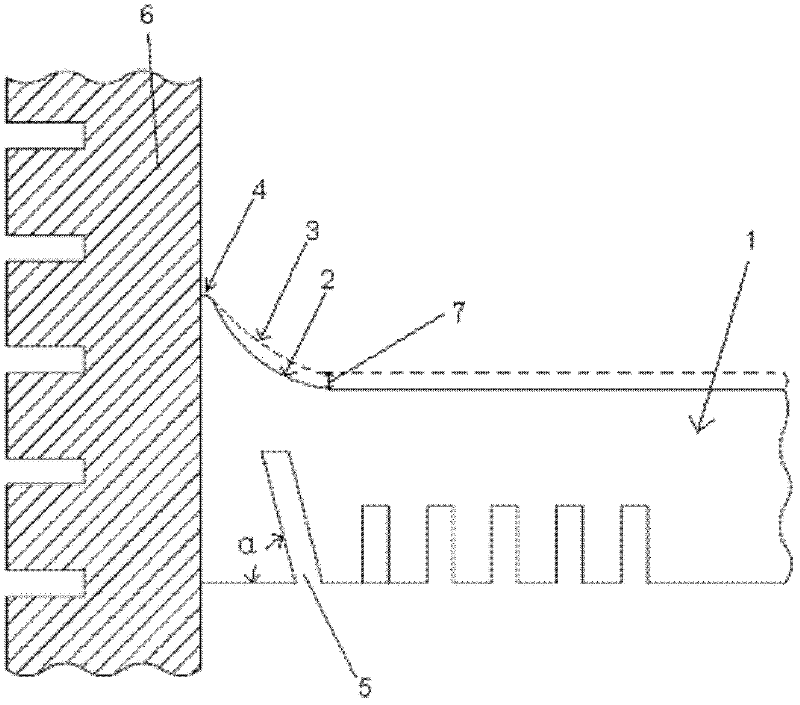

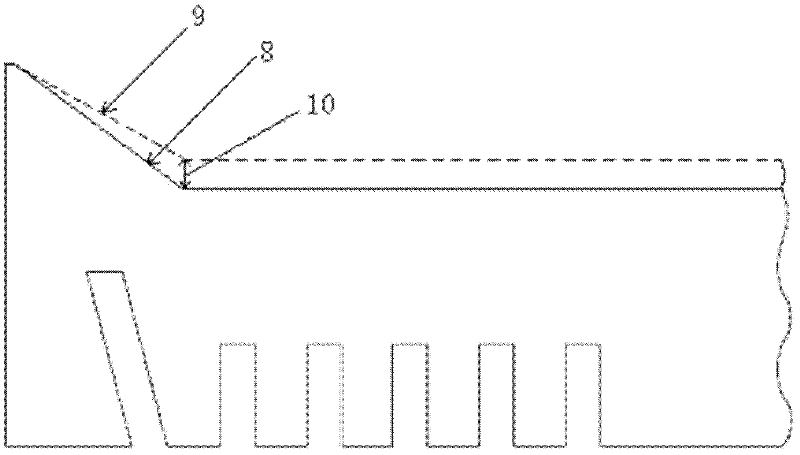

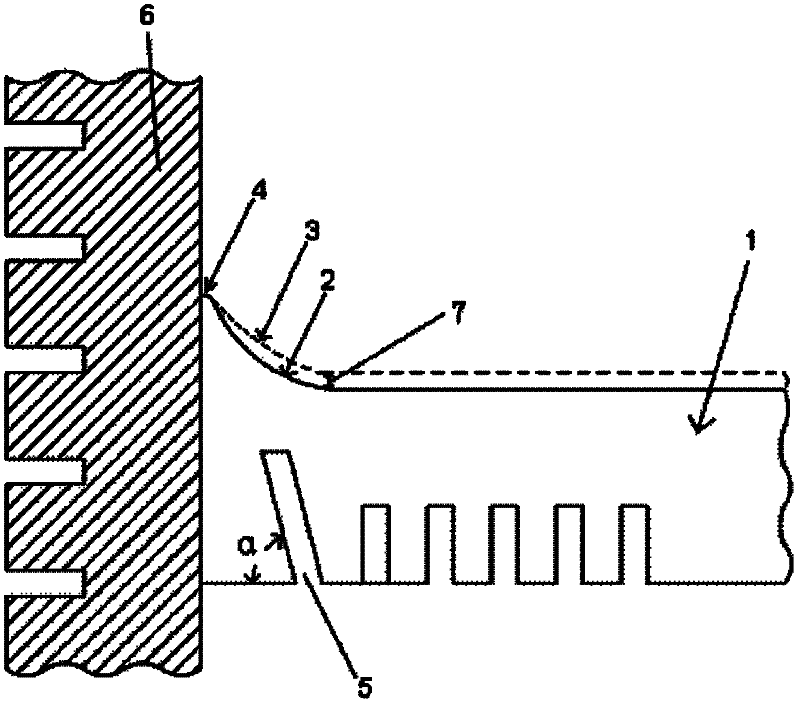

Chamfered crystallizer with taper continuous casting plate blank

InactiveCN102328037AIncrease temperatureAdapt to solidification shrinkage characteristicsSteelmakingCopper

The invention discloses a chamfered crystallizer with a taper continuous casting plate blank, and belongs to the technical field of steel-making-casting. The chamfered crystallizer comprises relatively wide copper plates and relatively narrow copper plates and is characterized in that the chamfered crystallizer is composed of two relative wide copper plates and two relative narrow copper plates; a chamfer surface transitioned from an inner surface of the narrow copper plate to the inner surface of the wide copper plate is a circular arc curved surface or plane, the chamber surface has a natural inverted taper from an upper opening to a lower opening of the crystallizer; an included angle of two ends of the narrow copper plate and the wide copper plate is 90 degrees, the platform width of the chamfer surfaces at two ends is 0-6 mm; and the chamfer surface has a taper. A multi-variety and multi-specification mature industrial application is realized, the transverse corner crack of the continuous casting plate blank is eliminated, and the longitudinal corner crack defect is avoided. The thickness specification range of the proper continuous casting plate blank is 130-420 mm, and the width specification ranges from 1000 to 3000 mm. The matched casting process is reliable and stable. The structure is relative simple and the popularization is strong.

Owner:SHOUGANG CORPORATION

Novel method for controlling casting blank pull rate of round continuous casting machine

ActiveCN103537642ALess attention should be paid to the straightening temperature of the slabOvercoming technical biasMechanical engineeringContinuous caster

The invention belongs to the technical field of alloy steel continuous casting and particularly relates to a novel method for controlling casting blank pull rate of a round continuous casting machine. The method for controlling the casting blank pull rate includes two stages. Stage one, before a continuous casting blank is released from a dummy bar head (about 10-30 minutes), the pull rate of the casting blank is set according to a traditional method that the pull rate is set according to actual degree of superheat of middle bag molten steel. Stage two, after the casting blank is released from the dummy bar head, the actual pull rate of the casting blank is determined according to the actual temperature of the casting blank surface of the casting blank in a straightening section, namely actual pull rate data of the casting blank is adjusted according to surface actual data of the casting blank at the straightening section position, the casting blank is released from a dangerous temperature range of 723-912 DEG C of a theoretical brittleness temperature range as soon as possible, possibility of cracks on the casting blank surface due to casting blank self texture phase change is greatly reduced, and the middle bag molten steel temperature is also considered. By means of the method, the phenomenon that cracks are prone to occur on a billet surface of an arc large round continuous casting machine is effectively reduced or basically avoided, under the premise that the casting blank quality is guaranteed, the whole production efficiency of the continuous casting machine is greatly improved, casting blank yield is further improved, and large round continuous casting blank surface quality is well improved.

Owner:SHANDONG XIWANG SPECIAL STEEL

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

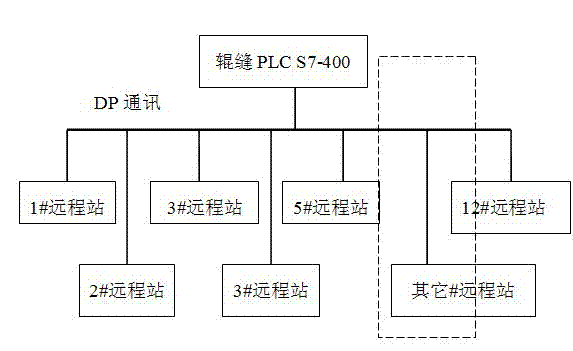

Dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method

InactiveCN102310179AAvoid production accidentsAvoid getting out of controlControl systemControl engineering

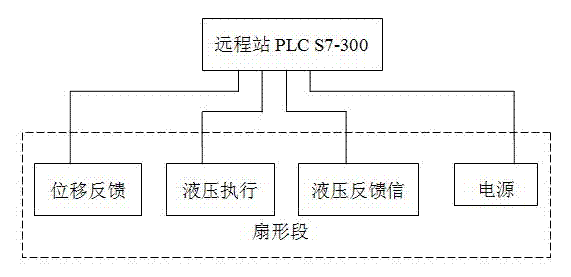

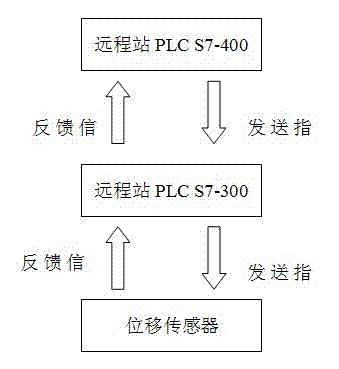

The invention relates to a dynamic slight press fan-shaped section hydraulic system leakage fault on-line judging and early warning method, which belongs to the technical field of continuous casting equipment maintenance in the metallurgical industry. The method has the technical scheme that (1) a roll gap control system PLCS7-300 sends a 'fan-shaped section hydraulic system locking' order to a remote station PLCS7-300; (2) the pressure value of the fan-shaped section hydraulic system is fed back; (3) the value of a fan-shaped section displacement sensor is fed back; (4) the roll gap control system PLCS7-400 judges the feedback pressure value of the hydraulic system and the value of the fan-shaped section displacement sensor combinedly; and further the results are output to a continuous casting master control system. With the method disclosed by the invention, roll gap control loss caused by the leakage fault of the hydraulic system can be prevented, the actual roll gap is controlledto meet the scope designed by the technology, the contraction taper of the roller gap is ensured to guarantee casting blank quality, an early warning function is played to protect fan-shaped section equipment, key equipment is monitored comprehensively and managed automatically in the whole continuous casting production process, the continuous casting production is stabilized, the technical control level is improved, the product quality is improved, and economic benefits are created.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

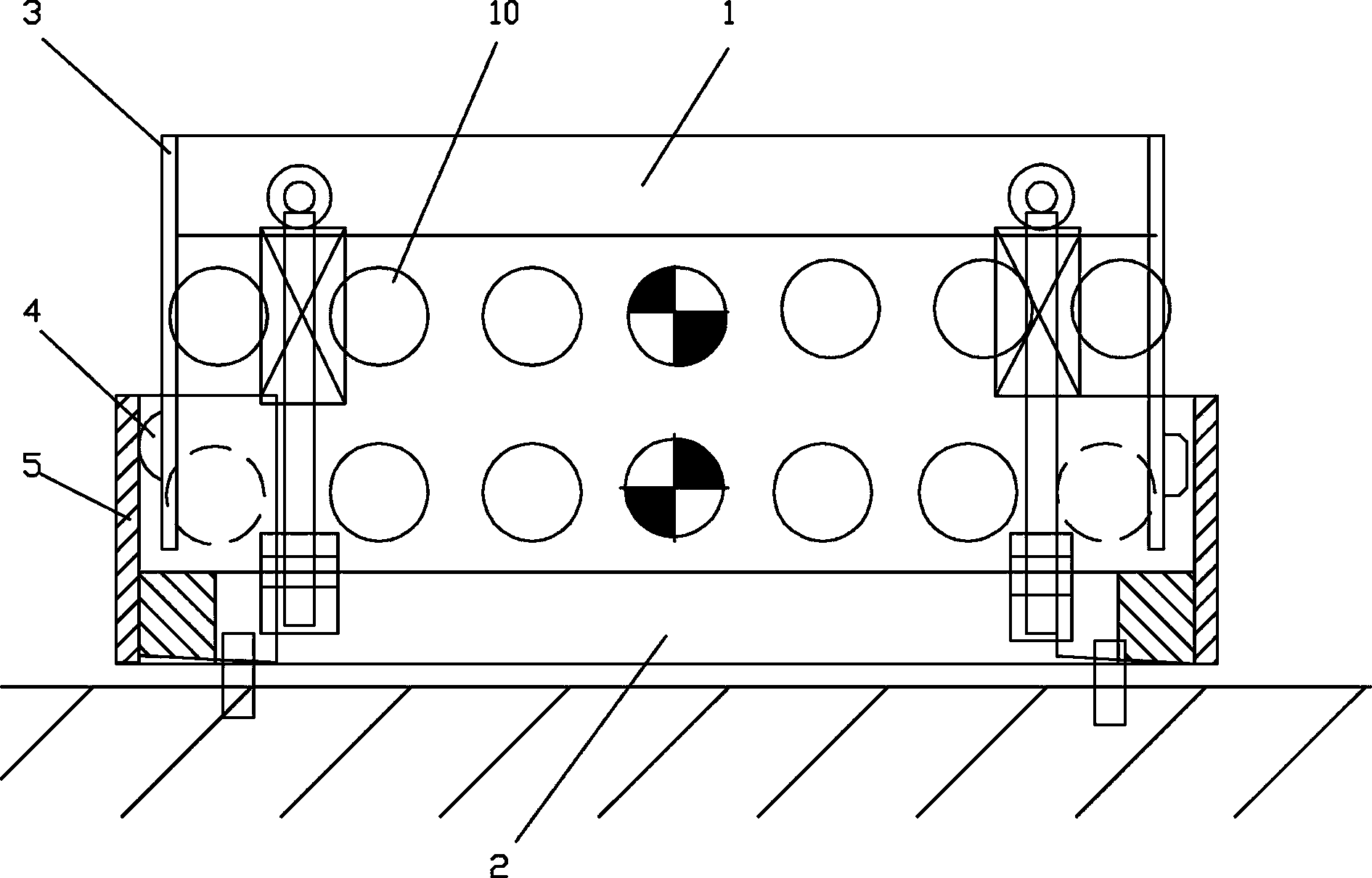

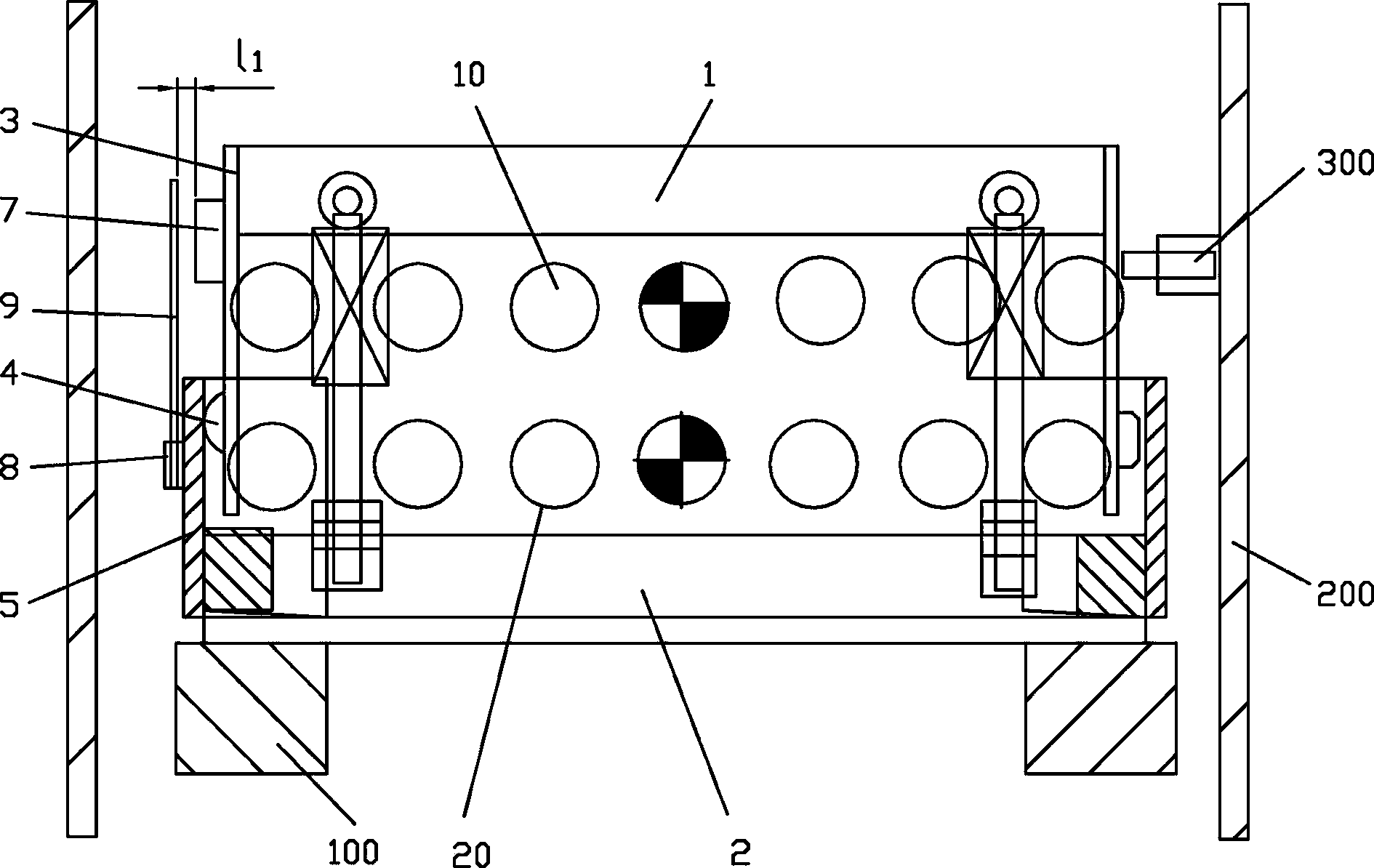

Method for controlling gap between upper framework and lower framework of continuous casting hydraulic fan-shaped section

The invention relates to a method for controlling a gap between an upper framework and a lower framework of a continuous casting hydraulic fan-shaped section. The method comprises the following steps of arranging guide mounting plates and guide blocks at the front and back sides, corresponding to the front and back sides of the lower framework, of the upper framework of the hydraulic fan-shaped section; taking the upper framework and the lower framework of the fan-shaped section off line, putting the upper framework and the lower framework on a standard maintenance table, and arranging a maintenance framework and a jack at the two sides of the standard maintenance table; opening a jack to jack up the upper framework to the outlet direction of the fan-shaped section, stopping jacking when an upper roll system and a lower roll system of the fan-shaped section are aligned, and measuring a gap value between each guide block of the upper framework and the inside surface of a guide plate of the lower framework; disassembling the fan-shaped section, and hoisting the upper framework away; loosening a fixing bolt of each guide block, selecting an adjusting gasket by using the gap value as the thickness value, inserting the adjusting gasket between each guide block and the corresponding guide mounting plate of the upper framework, and tightening each fixing bolt, so as to close the fan-shaped section. The method has the advantages that on the premise of aligning the roll systems of the upper framework and the lower framework of the fan-shaped section, the influence on the lifting operation and the implementation of the slight pressing function is avoided, and the purposes of improving the accuracy control level of the roll gap and overcoming the defect of a gap between toothed rolls are realized.

Owner:BAOSHAN IRON & STEEL CO LTD

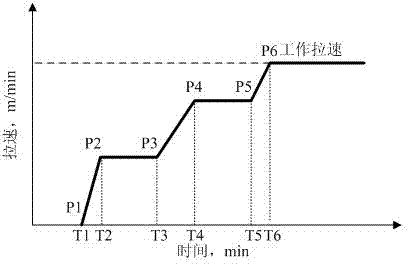

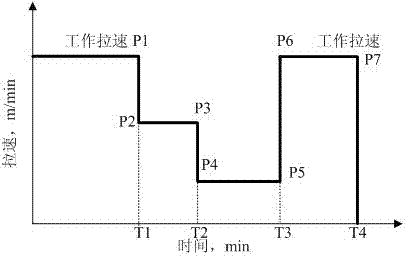

Method for increasing fast replacement success rate by decreasing drawing speed through continuous casting machine

The invention relates to the technical field of steelmaking, in particular to a method for increasing the fast replacement success rate by decreasing the drawing speed through a continuous casting machine. According to the method for increasing the fast replacement success rate by decreasing the drawing speed through the continuous casting machine, the drawing speed is decreased when a tundish isreplaced, the time of passing of a casting blank through a secondary cooling chamber is prolonged, and thus the cooling strength of the casting blank is improved; the temperature of the casting blankis lower before the fast replacement drawing speed returns to zero, in this way, the relative deformation quantity of the casting blank staying in the secondary cooling chamber is smaller in the period that the fast replacement drawing speed returns to zero and casting is started again, it is ensured that when a new tundish starts to be cast, the casting blank can be normally drawn out of a crystallizer under the current pressure of straightening rollers, straightening cracks are avoided, the success rate of fast replacement and casting starting is increased, the quality of the casting blank is guaranteed, and operation is easy; and in addition, when casting is started again, connecting rods are utilized as a connector, after high-temperature molten steel flowing into a copper pipe in thecrystallizer makes contact with the connecting rods, heat of the molten steel is absorbed, the molten steel is solidified while the connecting rods are smelted, thus the connecting effect is achieved,the breed-out situation is avoided, and successful casting starting is guaranteed.

Owner:ZENITH STEEL GROUP CORP

Low-carbon Mn-Cr steel for engine camshaft and manufacturing method thereof

InactiveCN101805874AGood effectImprove hardenabilityTemperature control deviceProcess efficiency improvementQuenchingImpurity

The invention relates to a low-carbon Mn-Cr steel for a camshaft and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.17-0.22% of C, 0.17-0.37% of Si, 1.00-1.50% of Mn, 1.00-1.50% of Cr, 0.005-0.025% of P, 0.001-0.020% of S, 0.01-0.20% of Cu, 0.01-0.20% of Ni, 0.010-0.060% of Al, 0-0.15*10-4% of <0> and the balance of Fe and inevitable impurity. The manufacturing method comprises: smelting, alloying, continuously casting, pouring, casting blank, carrying out hot rolling technology and electrosmelting; the terminal point <C> =>0.10%, P <=0.015%, and steel tapping is carried out at the temperature of 1620-1650 DEG C; and LF external refining is carried out, and VD vacuum deaeration is carried out. The invention adopts complete-protection continuously casting, pouring, casting blank and hot rolling to prepare the material. The low-carbon Mn-Cr steel of the invention has high quenching degree and high purity and is used for manufacturing large-power engine camshafts.

Owner:LAIWU IRON & STEEL GRP

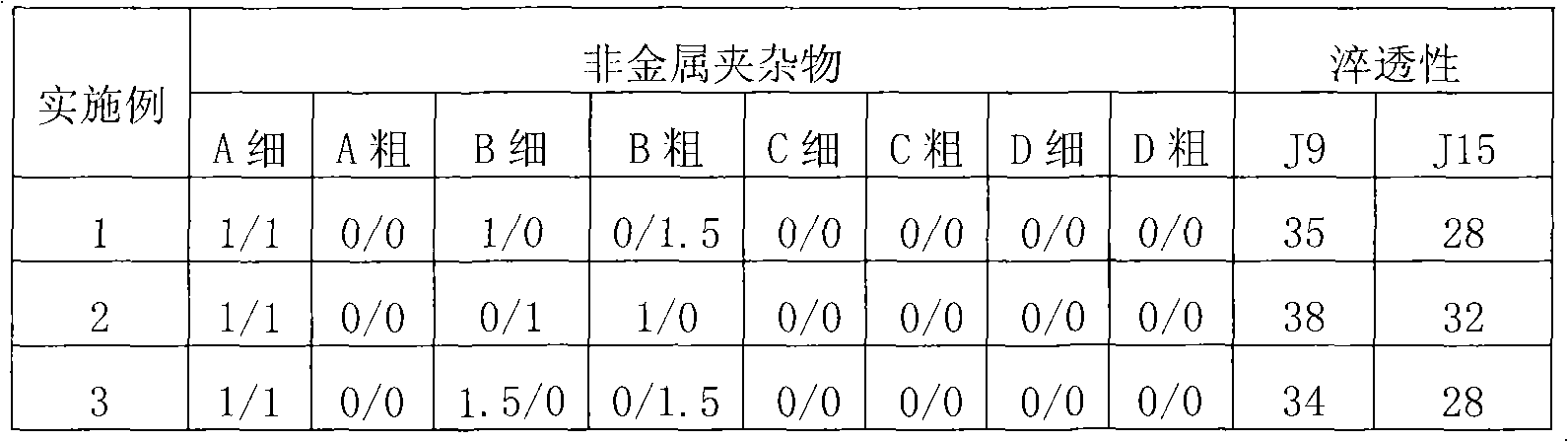

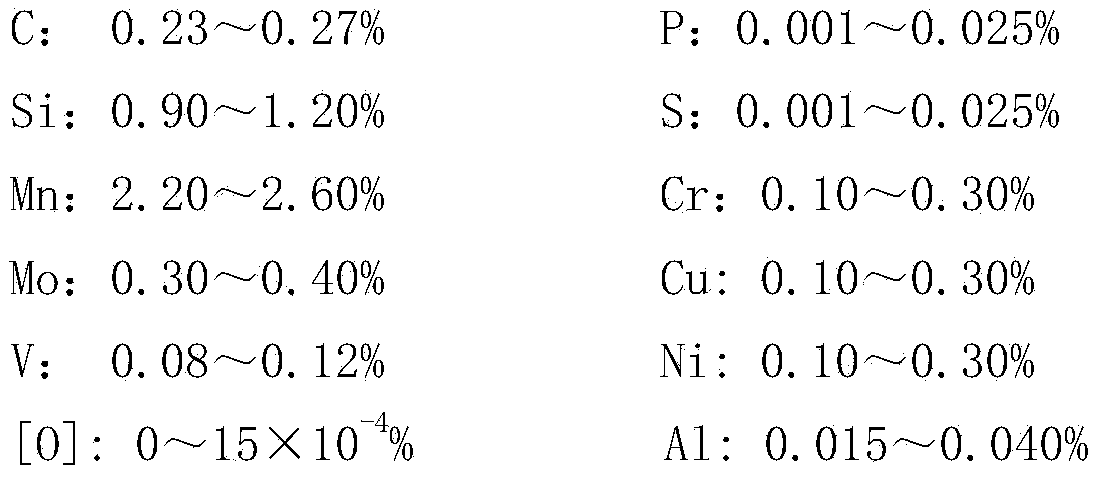

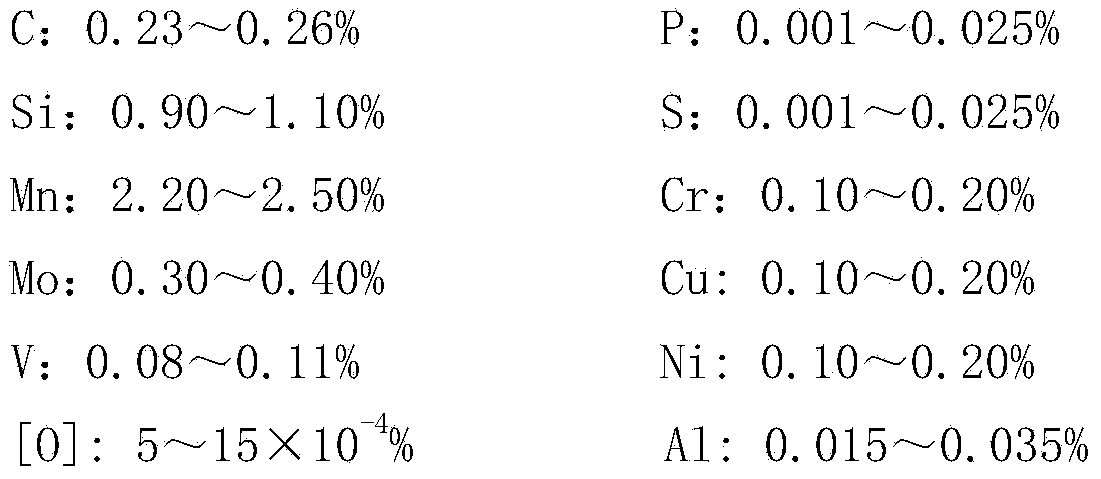

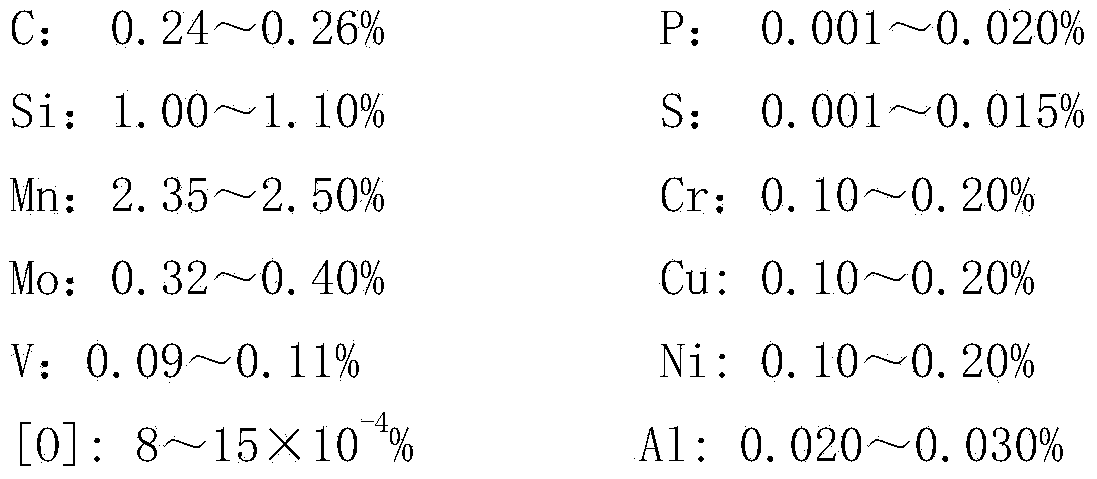

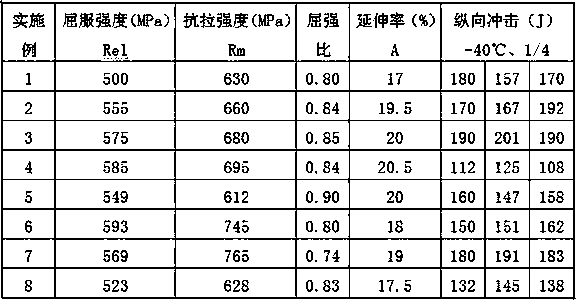

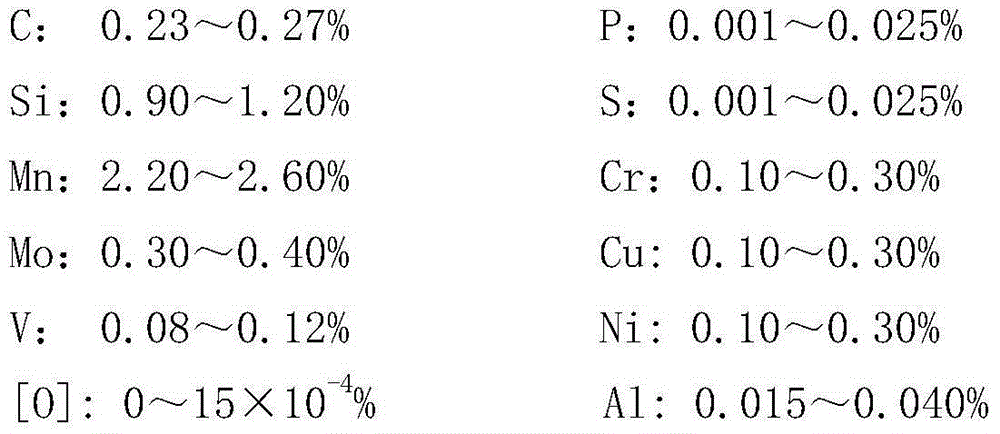

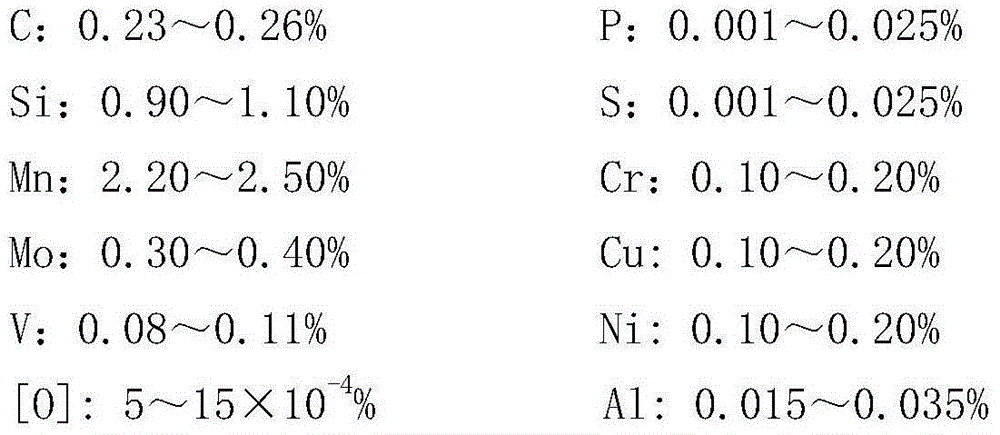

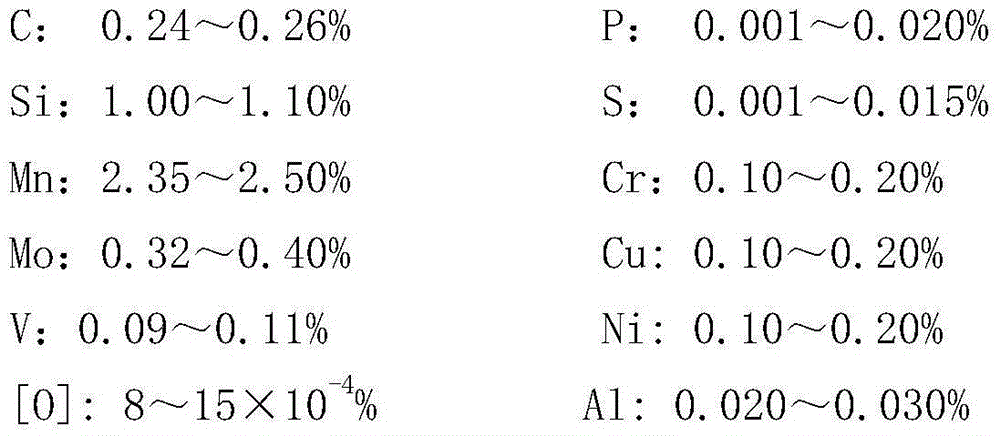

High-strength high-toughness wear-resisting steel for excavator bucket teeth and manufacturing method thereof

The invention relates to high-strength high-toughness wear-resisting steel for excavator bucket teeth and a manufacturing method thereof. The high-strength high-toughness wear-resisting steel comprises the following components in percentage by weight: 0.23-0.27% of C, 0.001-0.025% of P, 0.90-1.20% of Si, 0.001-0.025% of S, 2.20-2.60% of Mn, 0.10-0.30% of Cr, 0.30-0.40% of Mo, 0.10-0.30% of Cu, 0.08-0.12% of V, 0.10-0.30% of Ni, 0-15*10<-4>% of [O], 0.015-0.040% of Al and the balance of Fe and inevitable impurities. The invention also provides the manufacturing method of the steel for the excavator bucket teeth. The prepared low carbon silicon-magnesium-molybdenum-vanadium alloy has high strength, high toughness and high purity and is used for forging the excavator bucket teeth working in severe environments.

Owner:LAIWU IRON & STEEL GRP

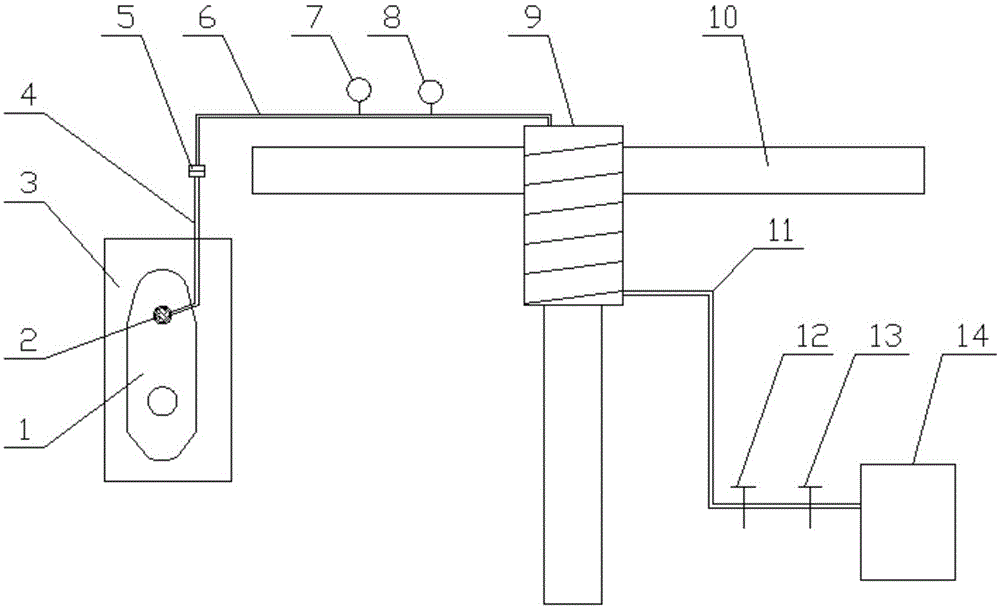

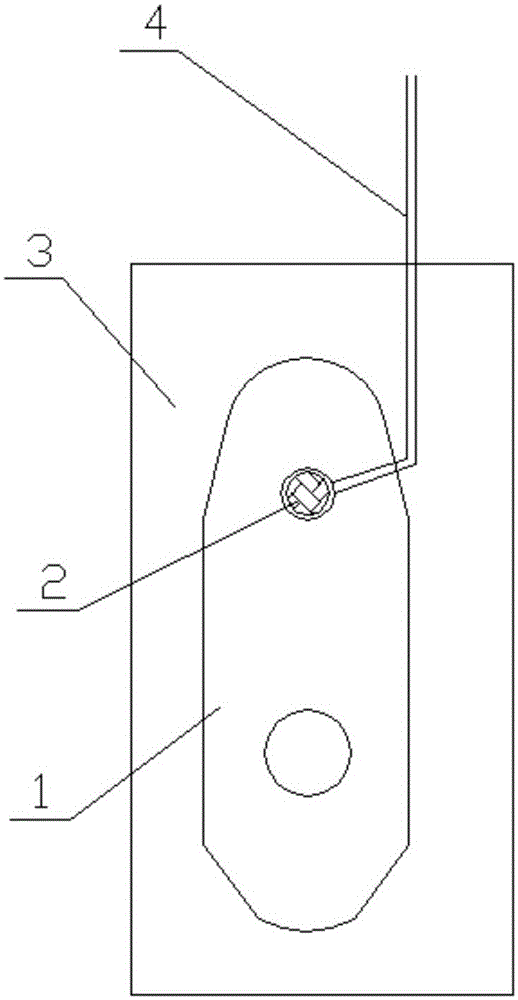

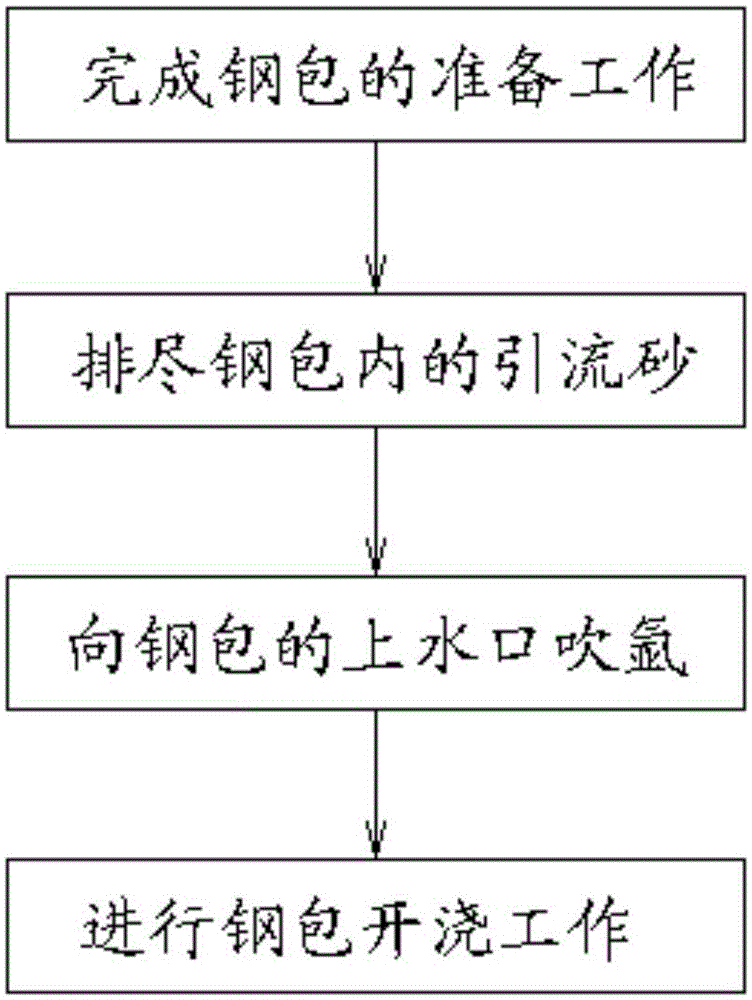

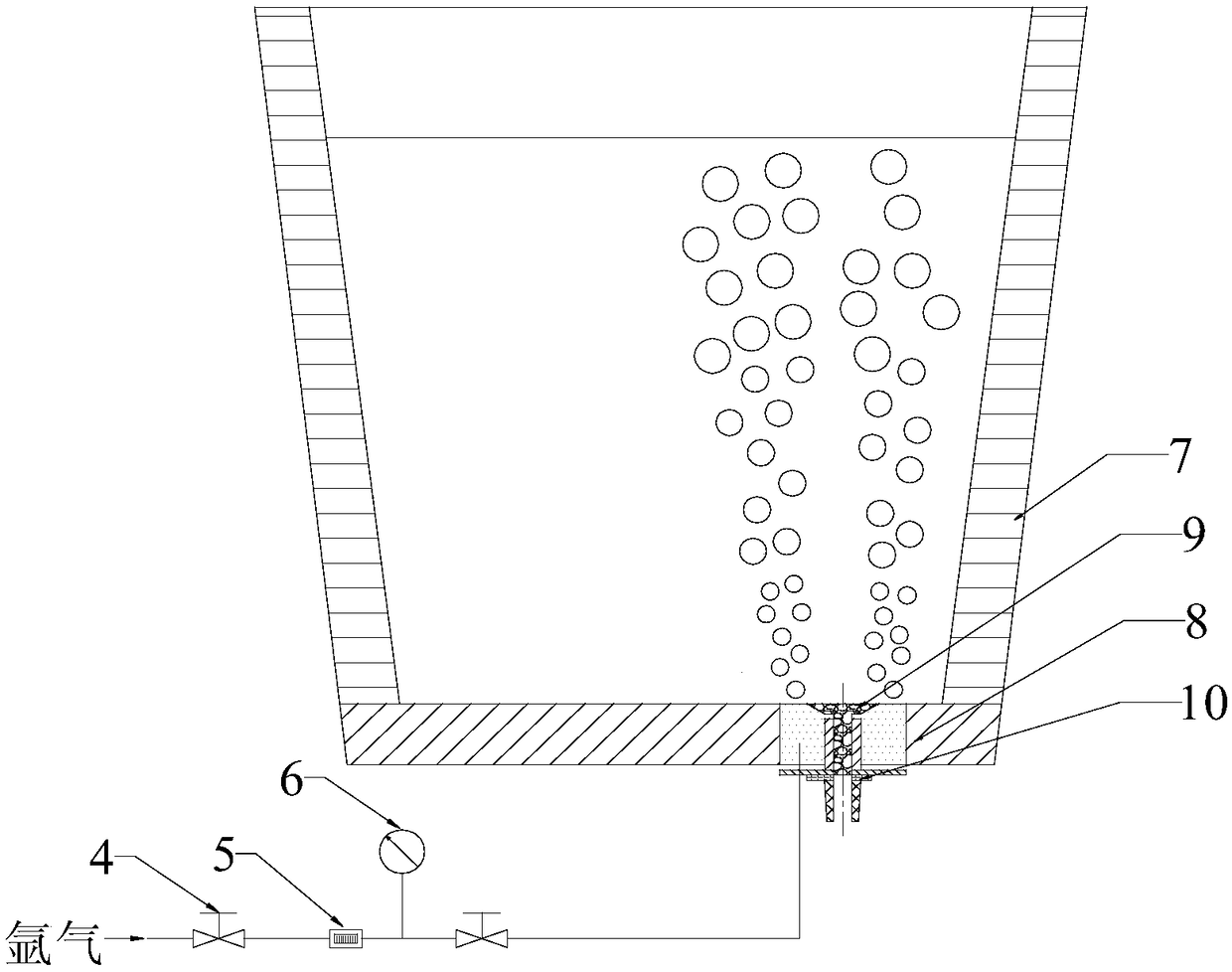

Ladle filler sand discharge device and continuous casting ladle casting starting method

ActiveCN105033236AReduce self-opening rateReduce the probability of being forced to pour nakedMelt-holding vesselsSlide plateTundish

The invention relates to a ladle filler sand discharge device and a continuous casting ladle casting starting method. The ladle filler sand discharge device comprises a sliding plate, a vent plug and an argon supply component. The sliding plate is fixed into a movable frame of a ladle mechanism and provided with a vent plug hole. The vent plug is fixed into the vent plug hole. The argon supply component is communicated with the vent plug through an argon pipeline. The continuous casting ladle casting starting method comprises the steps of completing ladle preparation work, discharging ladle filler sand in a ladle completely, blowing argon into an upper nozzle of the ladle and starting casting of the ladle. By the adoption of the ladle filler sand discharge device and the continuous casting ladle casting starting method, the ladle filler sand can be effectively prevented from entering into a tundish, the quality of casting blanks is guaranteed, the free opening rate of the ladle is improved, and forced naked casting probability of the ladle is lowered, and the quality of molten steel is guaranteed.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Smelting process of low-carbon high-sulfur free cutting steel

The invention relates to a smelting process of low-carbon high-sulfur free cutting steel. The smelting process comprises the following steps: (1) stirring after converter tapping, wherein the content of end-point oxygen required for converter tapping is less than or equal to 600 ppmm; (2) de-slagging firstly and then tapping; (3) enabling a refining slag system to be Al2O3-CaO-SiO2 and controlling the alkalinity to be 1.5-2.5; (4) performing precipitation and deoxidization in the refining process by adopting an aluminum line and a calcium line, feeding no aluminum line to deoxidize within 10-15 minutes before ladle hanging; (5) blowing argon for 3-5 minutes after deoxidization alloying and then fixing oxygen and entering a static mixing stage after the oxygen content is 20-50 ppm; (6) adopting covering slag and a low-carbon covering agent in the continuous casting process and ensuring the quality of a casting blank, wherein the degree of superheat is 20-40 DEG C, the quantity of water in a crystallizer is 90-120 m<3> / h, and the specific water flow is 0.6-0.9 L / kg. The smelting process provided by the invention has the benefits that the difficulty of a production process of the low-carbon high-sulfur free cutting steel can be solved, the stable flow control in the pouring process is ensured, the continuous pouring time is 10 h or above, and the yield is improved while the quality of the casting blank is ensured.

Owner:NANJING IRON & STEEL CO LTD

Steel for wind power yaw gear ring and manufacturing method thereof

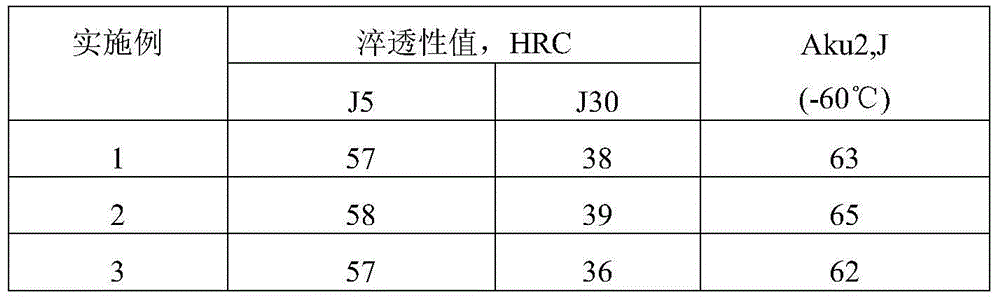

ActiveCN104694851AEnsure billet qualityImprove hardenabilityProcess efficiency improvementElectric furnaceHigh latitudeMetallurgy

The invention relates to steel for a wind power yaw gear ring and a preparation method thereof. The steel for the wind power yaw gear ring comprises the following components: 0.37-0.45 percent of C, 0.17-0.37 percent of Si, 0.60-0.90 percent of Mn, smaller than or equal to 0.015 percent of P, smaller than or equal to 0.005 percent of S, 0.90-1.20 percent of Cr, 0.20-0.30 percent of Mo, 0.30-0.80 percent of Ni, smaller than or equal to 0.20 percent of Cu, 0.015-0.040 percent of Alt, smaller than or equal to 0.005 percent of Ti, smaller than or equal to 0.020 percent of As, smaller than or equal to 0.020 percent of Sn, smaller than or equal to 0.0025 percent of Pb, smaller than or equal to 0.025 percent of Sb, smaller than or equal to 0.005 percent of Bi, smaller than or equal to 20 ppm of [O], smaller than or equal to 70 ppm of [N], smaller than or equal to 1.5 ppm of [H] and the balance of Fe and inevitable impurities. A prepared round billet is forged into the wind power yaw gear ring, the hardenability performance is stable and the low-temperature performance is good, the ultrasonic flaw detection result meets the standard requirement, and the use requirement under the marine environmental condition (60 DEG C below 0) at high-latitude extremely cold areas can be met.

Owner:SHANDONG IRON & STEEL CO LTD

A kind of smelting process of low-carbon high-sulfur free-cutting steel

The invention relates to a smelting process of low-carbon high-sulfur free cutting steel. The smelting process comprises the following steps: (1) stirring after converter tapping, wherein the content of end-point oxygen required for converter tapping is less than or equal to 600 ppmm; (2) de-slagging firstly and then tapping; (3) enabling a refining slag system to be Al2O3-CaO-SiO2 and controlling the alkalinity to be 1.5-2.5; (4) performing precipitation and deoxidization in the refining process by adopting an aluminum line and a calcium line, feeding no aluminum line to deoxidize within 10-15 minutes before ladle hanging; (5) blowing argon for 3-5 minutes after deoxidization alloying and then fixing oxygen and entering a static mixing stage after the oxygen content is 20-50 ppm; (6) adopting covering slag and a low-carbon covering agent in the continuous casting process and ensuring the quality of a casting blank, wherein the degree of superheat is 20-40 DEG C, the quantity of water in a crystallizer is 90-120 m<3> / h, and the specific water flow is 0.6-0.9 L / kg. The smelting process provided by the invention has the benefits that the difficulty of a production process of the low-carbon high-sulfur free cutting steel can be solved, the stable flow control in the pouring process is ensured, the continuous pouring time is 10 h or above, and the yield is improved while the quality of the casting blank is ensured.

Owner:NANJING IRON & STEEL CO LTD

Casting and forging combined technique of aluminum alloy linkage rod

InactiveCN101486087BEnsure billet qualitySimplify the traditional die forging processEngine componentsRare-earth elementRhenium

The invention discloses technology for casting and forging an aluminum alloy connecting rod, wherein an aluminum alloy composition of the connecting rod is adjusted by addition of rare earth element in casting technology, and the addition of the rare earth element is 2 to 5 percent of an aluminum liquid; the aluminum alloy connecting rod is guaranteed to comprise the following compositions: 88 to94 percent of aluminum, 3.8 to 4.9 percent of copper, 0.5 to 1.5 percent of silicon, 0.4 to 1.2 percent of manganese, 0.4 to 1.0 percent of magnesium, 0.8 to 1.8 percent of rhenium and 0.4 to 0.14 percent of iron; and a casting head is not cut off and reheated in the casting technology and taken as one part or a scrapped part of a forged piece, and casting afterheat is utilized for forging. The technology simplifies the prior die forging technology, improves reasonable floatation, the streamline and mechanical properties of casting metals, improves a metallurgical structure close to the casting head on the forged piece, and has the effects of high technological utilization rate of materials, shortened technological process and energy conservation and consumption reduction. Moreover, the casting and forging technology can obviously improve the internal quality and the mechanical properties of casting blanks, and the production cost of the casting blanks is lower than that of the prior die forging.

Owner:DANYANG RONGJIA PRECISION MACHINERY

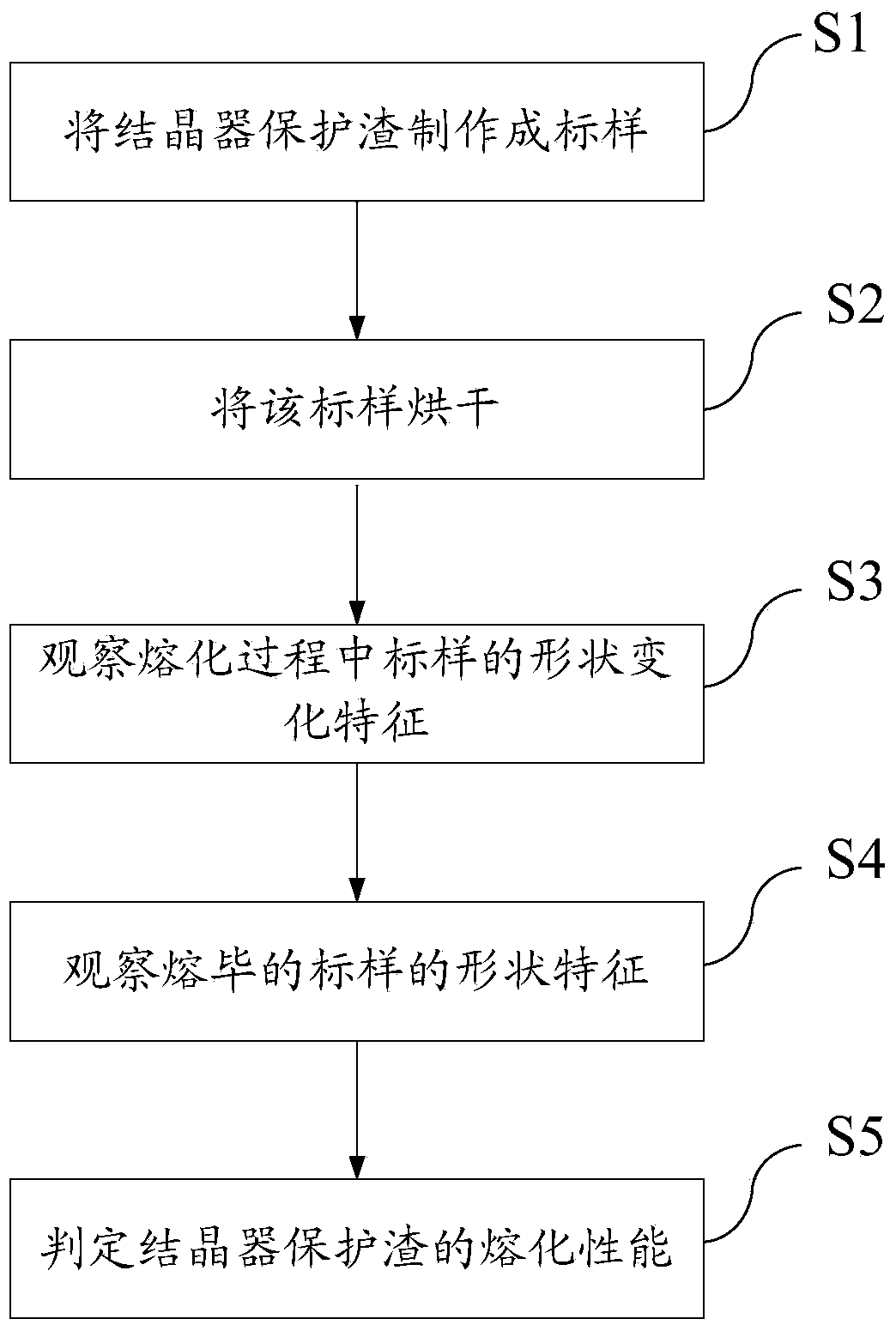

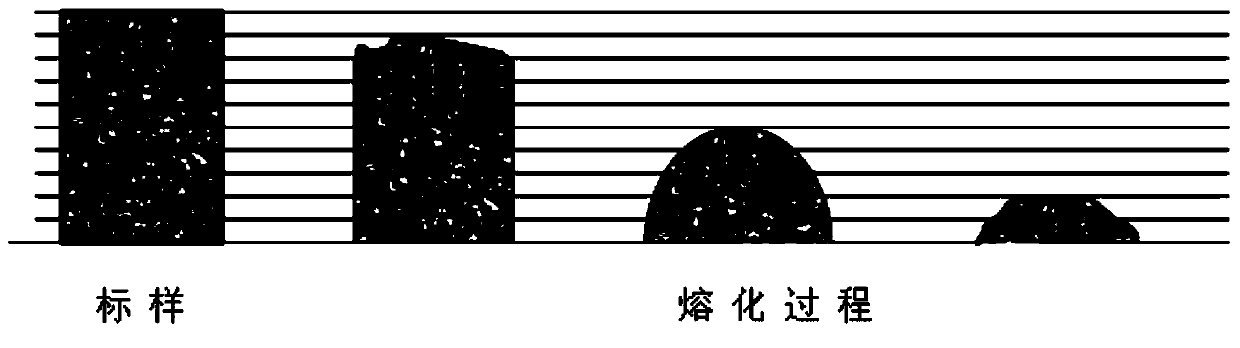

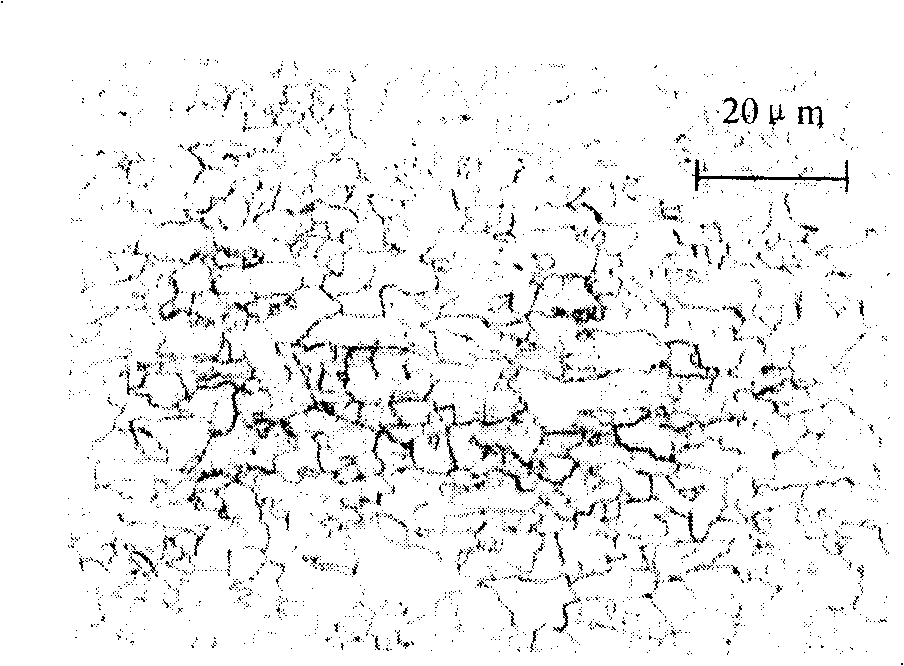

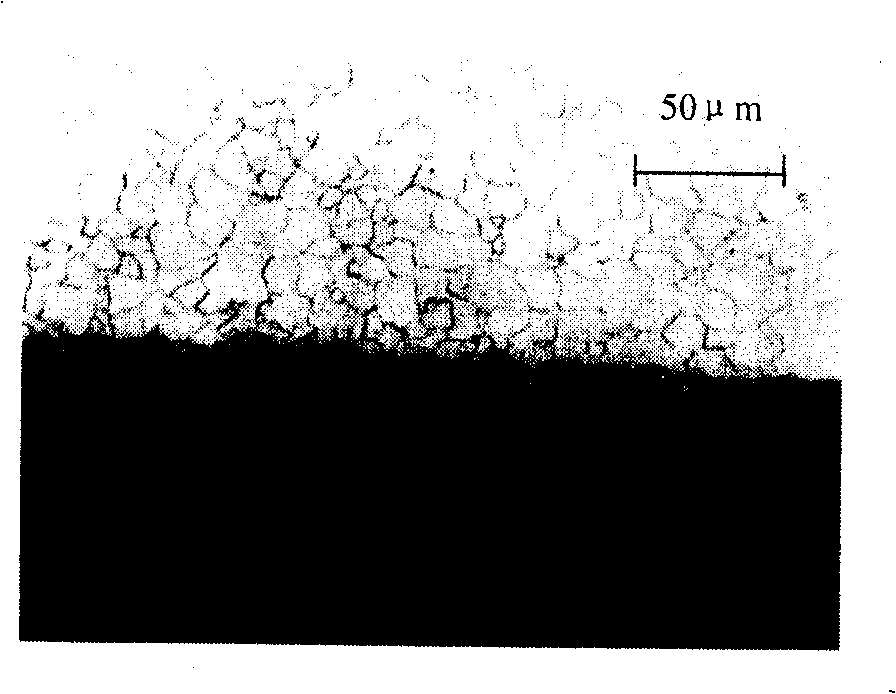

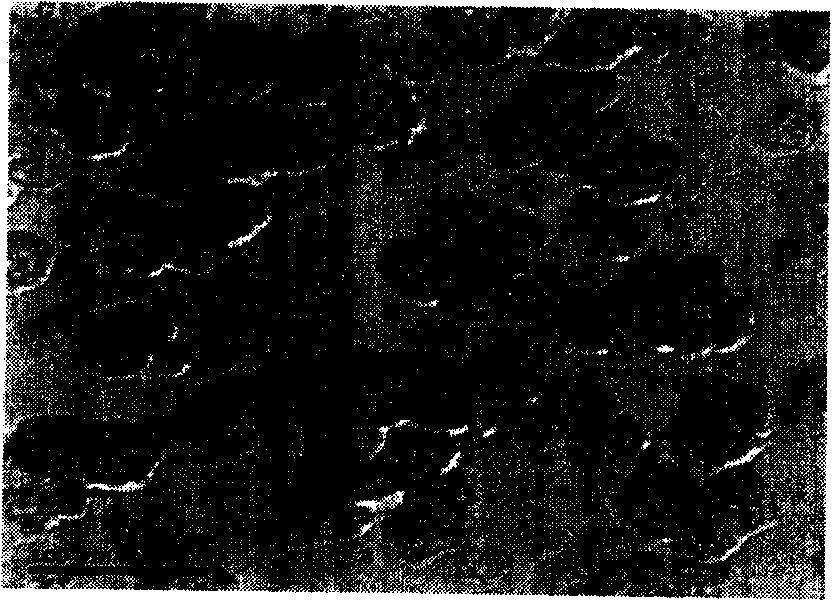

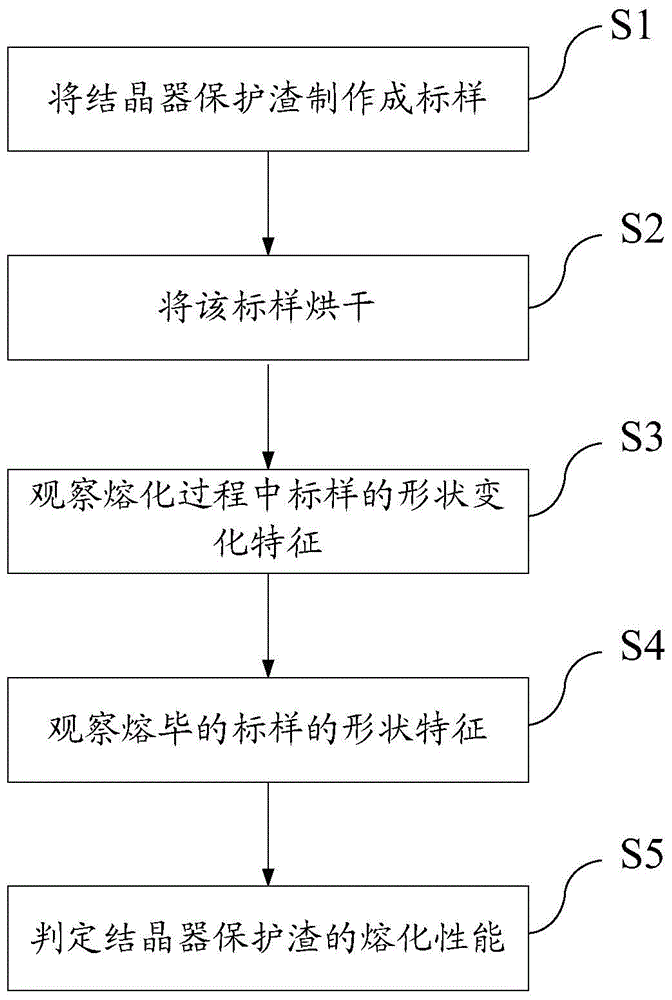

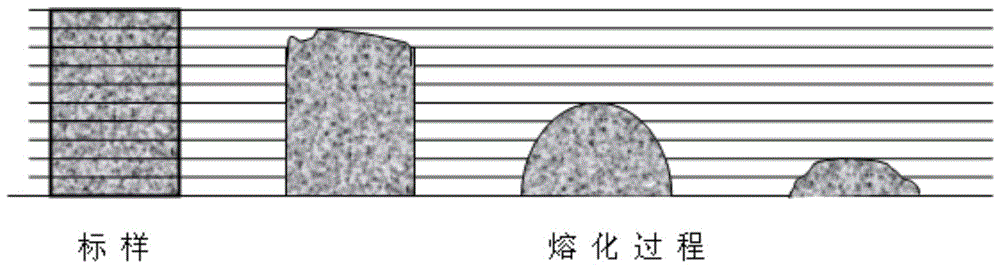

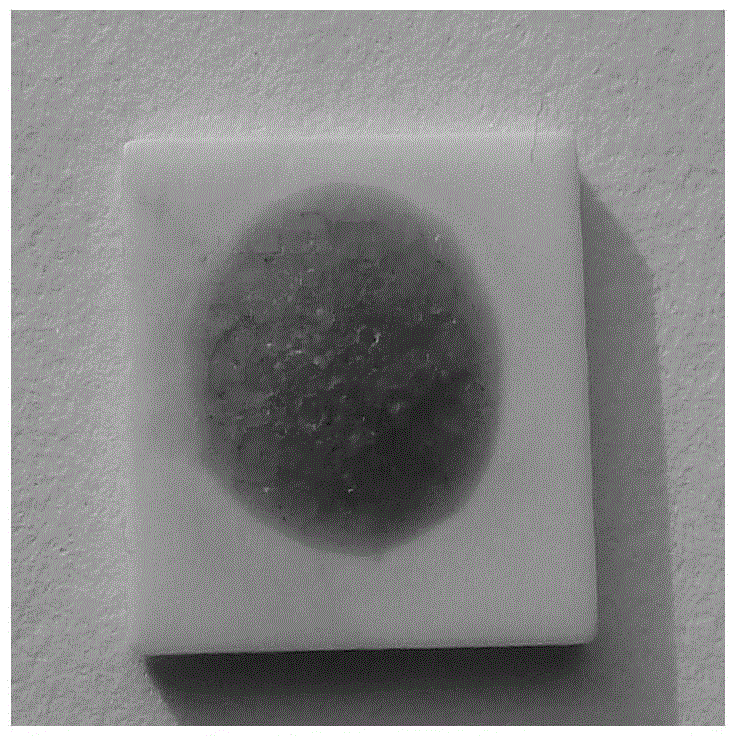

Method for determining melting performance of crystallizer protection slag

InactiveCN103472084AJudgment of melting performanceImprove reliabilityInvestigating phase/state changeShape changeSlag

The invention discloses a method for determining the melting performance of crystallizer protection slag. The method comprises the following steps: processing the crystallizer protection slag to prepare a standard sample; melting the standard sample, and observing the shape change characteristic of the standard sample in the melting process; cooling the standard sample to room temperature after the standard sample is completely molten, and observing the shape characteristic of the melt-down standard sample; and determining the melting performance of the crystallizer protection slag according to the shape change characteristic of the standard sample in the melting process and the shape characteristic of the melt-down standard sample. The melting performance of the crystallizer protection slag is comprehensively and accurately determined through the introduction of a slag shape characteristic concept, the detection of a melting temperature and the combination of the slag shape and the melt-down sample characteristic, so the method has a high reliability; and the method has a guiding effect on the onsite continuous casting production, can guarantee the smooth implementation of the continuous casting and the casting blank quality, and has large social and economic benefits.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

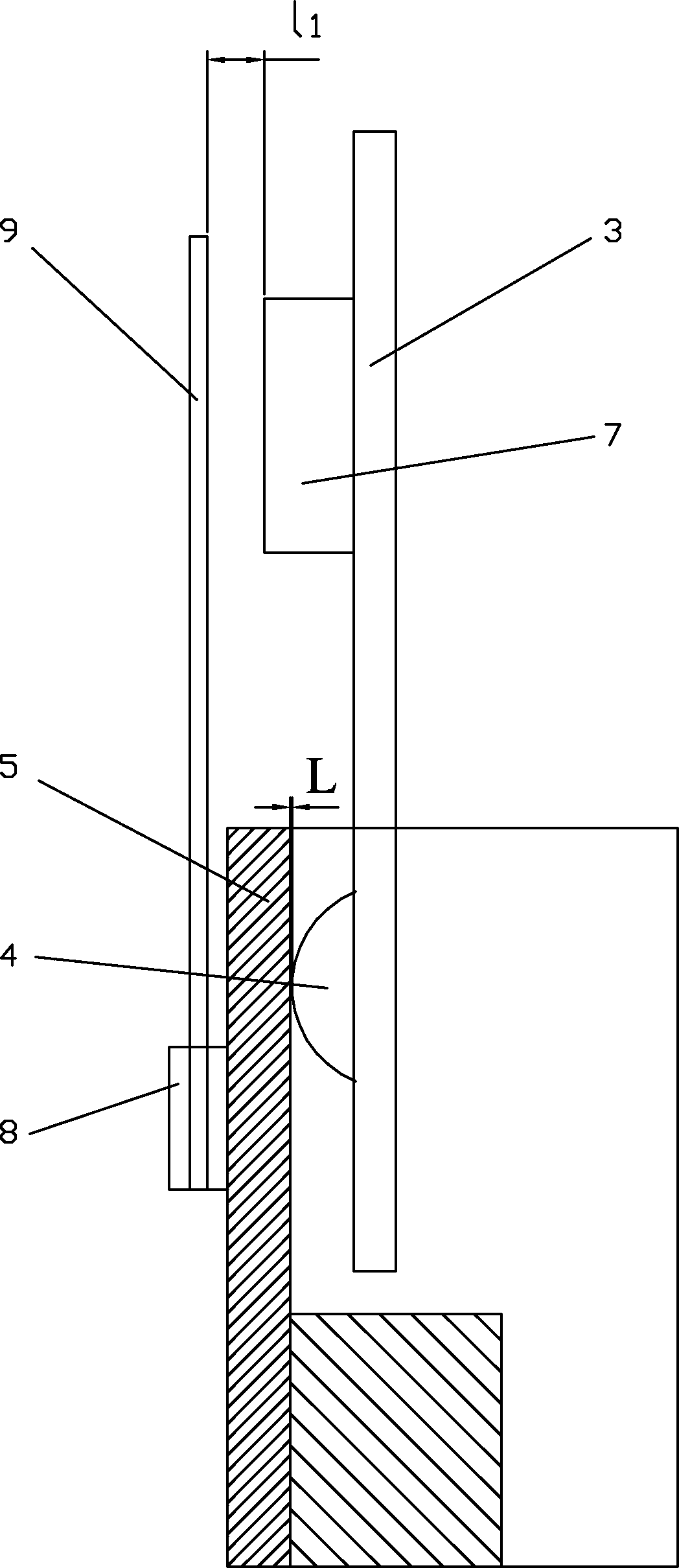

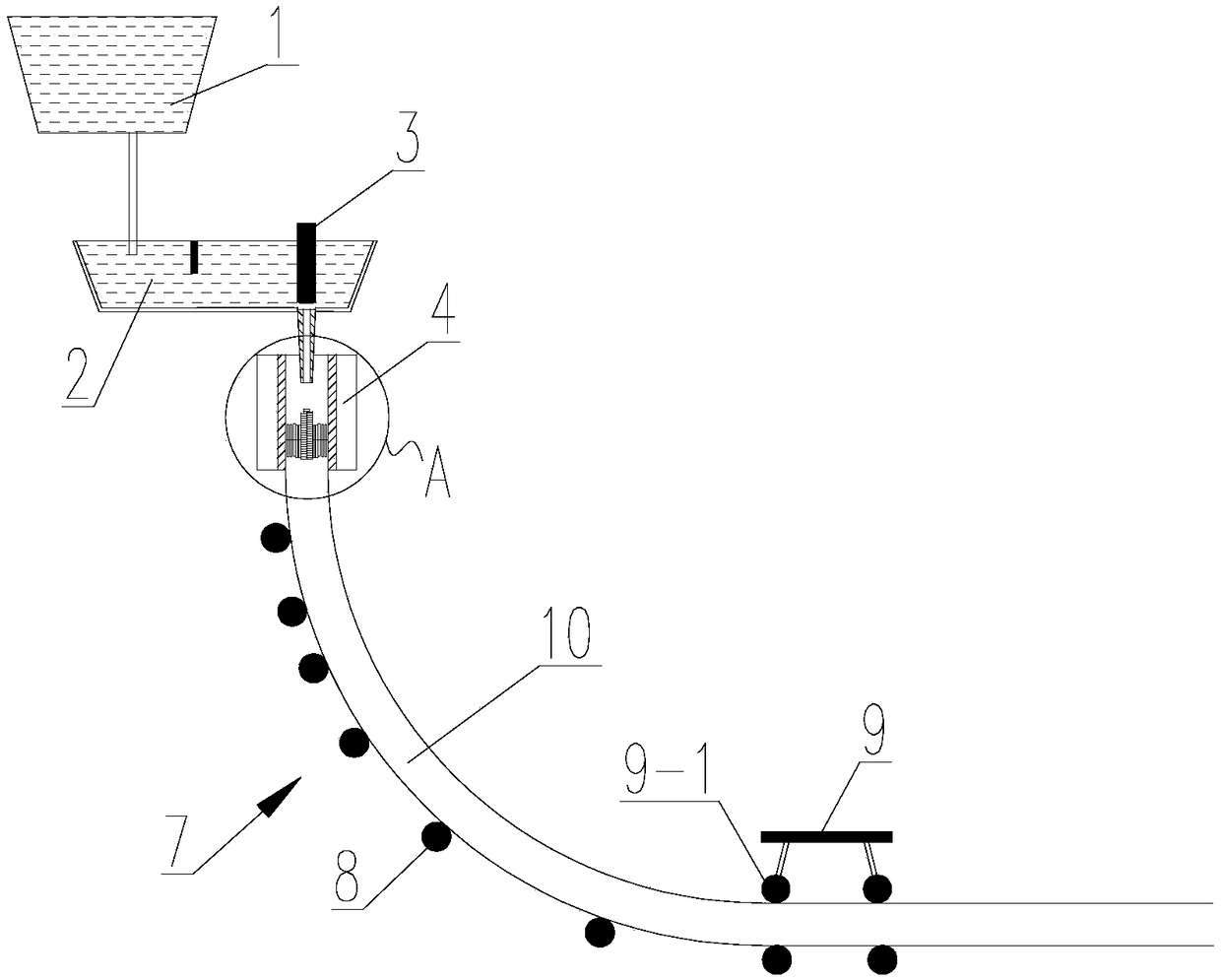

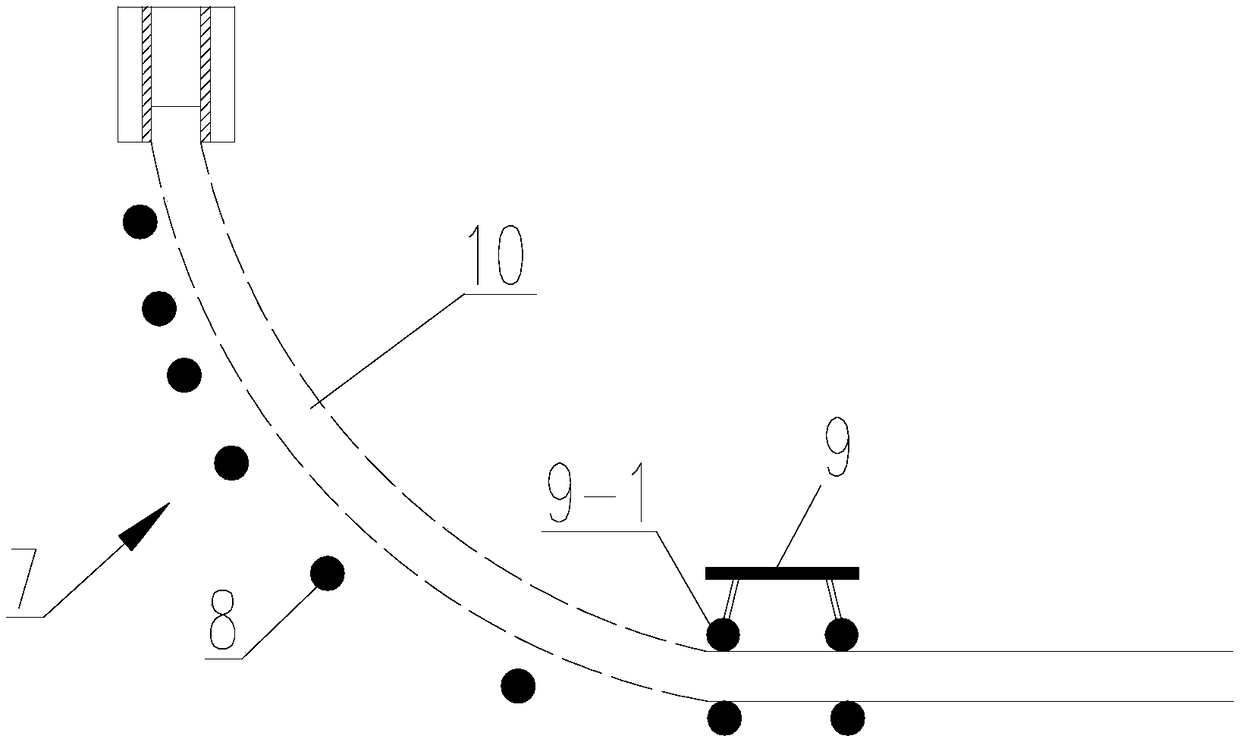

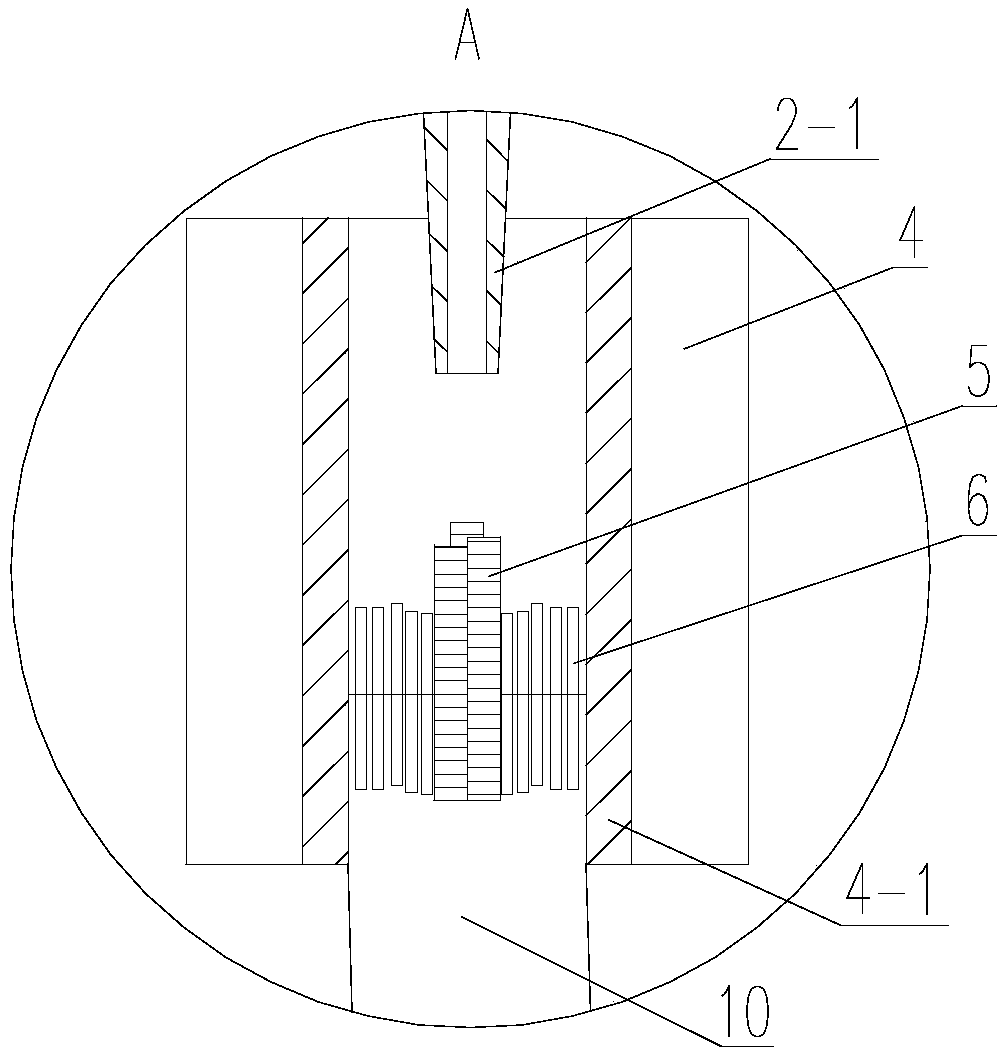

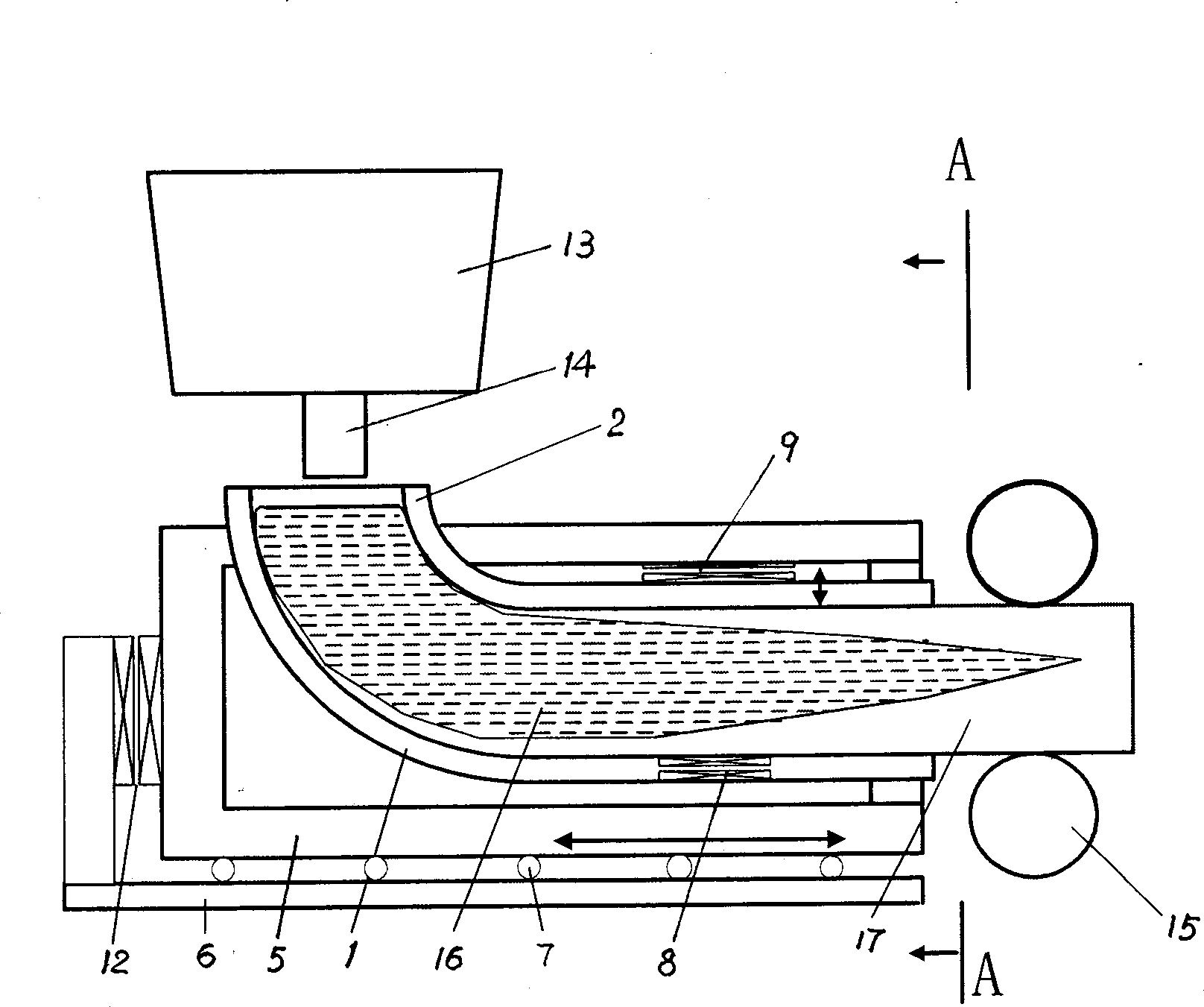

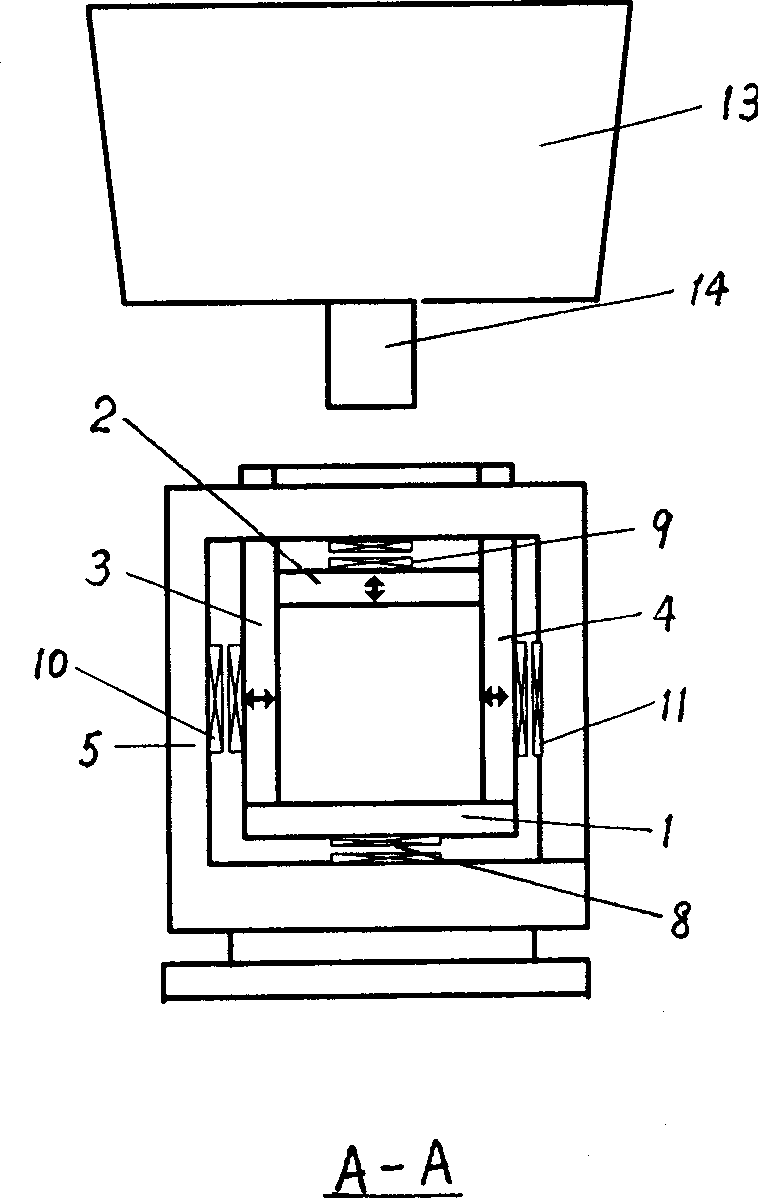

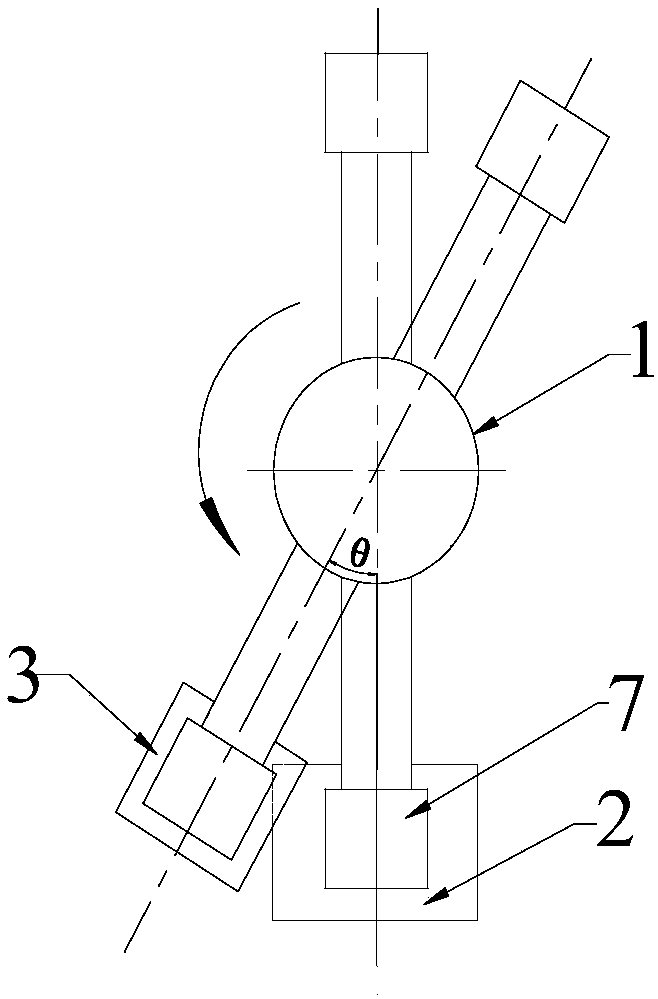

Horizontal conticaster and technique of billet withdrawal

A horizontal conticasting machine has a tundish, a crystallizer and a horizontal billet-pulling unit for horizontally pulling the steel billet out of said crystallizer. Said crystallizer has a movable casting cavity formed by at least 4 copper plates and consisting of an arc segment and a straight segment, and the vertical and horizontal drivers for generating horizontal and vertical vibrations.

Owner:广州工业投资控股集团有限公司

Cogged ingot continuous casting crystallizer protecting slag and preparation method thereof

The invention relates to a cogged ingot continuous casting mold powder, belonging to the iron and steel smelting technical field. The mold powder comprises the following chemical components with the weight percent of 30-35 percent of SiO2, 25-30 percent of CaO, 2.5-3.5 percent of MgO, 1.5-2.5 percent of Fe2O3, 3.5-4.5 percent of Al2O3, 4.5-5.5 percent of NaF2+CaF2, 5.5-6.5 percent of Na2O+K2O, 11-14.5 percent of solid carbon, and the rest is binder used for pelleting and water. A preparation method of the mold powder is also provided by the invention. The mold powder is exclusively applied to the cogged ingot continuous casting mold powder, in particular to cogged ingot 27SiMn continuous casting mold. The zero defect production of continuous casting can be realized, the hot delivery and hot charging of the continuous casting can be guaranteed, the systematic energy consumption from the continuous casting to rolled products can be lowered, the production cycle from the continuous casting slab to the rolled products can be shortened, and the quality of steels can be ensured.

Owner:SHANDONG IRON & STEEL CO LTD

Production method for large-thickness Q500-grade steel plate

InactiveCN110453055AQuality improvementEnsure billet qualityElectron beam welding apparatusMetal rolling arrangementsVacuum chamberElectron

The invention discloses a production method for a large-thickness Q500-grade steel plate, and the method comprises the processes of blanking, heating, rolling and heat treatment; after the spot welding and centering process, the blank is loaded in a small heating furnace to be preheated in a vacuum chamber by electric heating in the blanking process, the preheating temperature is 300-500 DEG C, the heat preservation time is 30-50min; when in vacuum welding, two vacuum electron beam welding guns are used for welding, one electron beam welding gun performs small-energy welding, the energy of a welding line is 20-25 KJ / cm3, and the energy of the other electron beam welding gun line is 30-50 KJ / cm3. The production method realizes the production of the steel plate with the thickness of 300-350mm through the reasonable vacuum composite welding blanking process and the subsequent homogenization heating technology and the rolling technology under the atmosphere, and the thick tensile performance satisfies the section shrinkage rate Z greater than or equal to 35%, and the flaw detection of the steel plate can be above GB / T2970 -2004 III grade or above.

Owner:WUYANG IRON & STEEL

High-strength, high-toughness, wear-resistant steel for excavator bucket teeth and manufacturing method thereof

The invention relates to high-strength high-toughness wear-resisting steel for excavator bucket teeth and a manufacturing method thereof. The high-strength high-toughness wear-resisting steel comprises the following components in percentage by weight: 0.23-0.27% of C, 0.001-0.025% of P, 0.90-1.20% of Si, 0.001-0.025% of S, 2.20-2.60% of Mn, 0.10-0.30% of Cr, 0.30-0.40% of Mo, 0.10-0.30% of Cu, 0.08-0.12% of V, 0.10-0.30% of Ni, 0-15*10<-4>% of [O], 0.015-0.040% of Al and the balance of Fe and inevitable impurities. The invention also provides the manufacturing method of the steel for the excavator bucket teeth. The prepared low carbon silicon-magnesium-molybdenum-vanadium alloy has high strength, high toughness and high purity and is used for forging the excavator bucket teeth working in severe environments.

Owner:LAIWU IRON & STEEL GRP

Steel plate for hot-rolled double-side enamel and method for producing same

InactiveCN100453678CIncrease productivityUniform compositionTemperature control deviceHigh pressure waterUltimate tensile strength

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

Production method of large-thickness S135 stainless steel plate

The invention discloses a production method of a large-thickness S135 stainless steel plate. The production method comprises the processes of original steel billet preheating treatment, billet making,steel billet heating and steel billet rolling. According to the production method of the large-thickness S135 stainless steel plate, through a reasonable vacuum composite welding billet-making technique, the billet making quality of a composite billet is guaranteed, and through a subsequent soaking heating technology and a high-reduction rolling technology, the excellent internal quality of the steel plate is guaranteed; and through a double-gun-type electronic beam welding technology, the good quality of an original composite billet of the S135 stainless steel plate is guaranteed, and the basic conditions are provided for subsequent heating and rolling production. The large-thickness S135 stainless steel plate with the maximum thickness being 200 mm and flaw detection conforming to JB / T4730-2005 III grade or above is produced through the production method, the Z-direction property meets the Z35 grade, and the advantages of large thickness, large piece weight, high production efficiency and low cost are achieved.

Owner:WUYANG IRON & STEEL

Method for controlling flow guiding sand to enter tundish in continuous casting process

The invention discloses a method for controlling flow guiding sand to enter tundish in the continuous casting process and belongs to the field of continuous casting of iron and steel. The method includes the steps that firstly, before casting of a previous furnace steel ladle is completed, for a steel ladle without casting starting, located on a standby position of a steel ladle revolving platformand provided with flow guiding sand, inert gas is blown into molten steel through a breathable water gap base brick at the bottom of the steel ladle; and when the steel ladle rotates on the steel ladle revolving platform till an angle with a steel ladle casting position is 20 degrees to 50 degrees, rotation stops; secondly, a waste steel groove is placed below a steel ladle water gap, due to continuous gas blowing in the period from the time when it is started to blow in the inert gas to the time when rotation stops for the first time, the temperature of molten steel over the breathable watergap base brick is made to increase by 2-5 DEG C, a sliding water gap is opened for the first time, and the flow guiding sand and an extremely small amount of molten steel are discharged; and when allthe flow guiding sand is discharged, the sliding water gap is closed; and thirdly, it is kept to blow in the inert gas, the steel ladle is fast rotated to the casting position, and is connected witha large ladle long water gap, the sliding water gap is opened for the second time, and normal casting starting starts; and after normal casting starting of the steel ladle starts, it is stopped to blow in the inert gas.

Owner:NORTHEASTERN UNIV

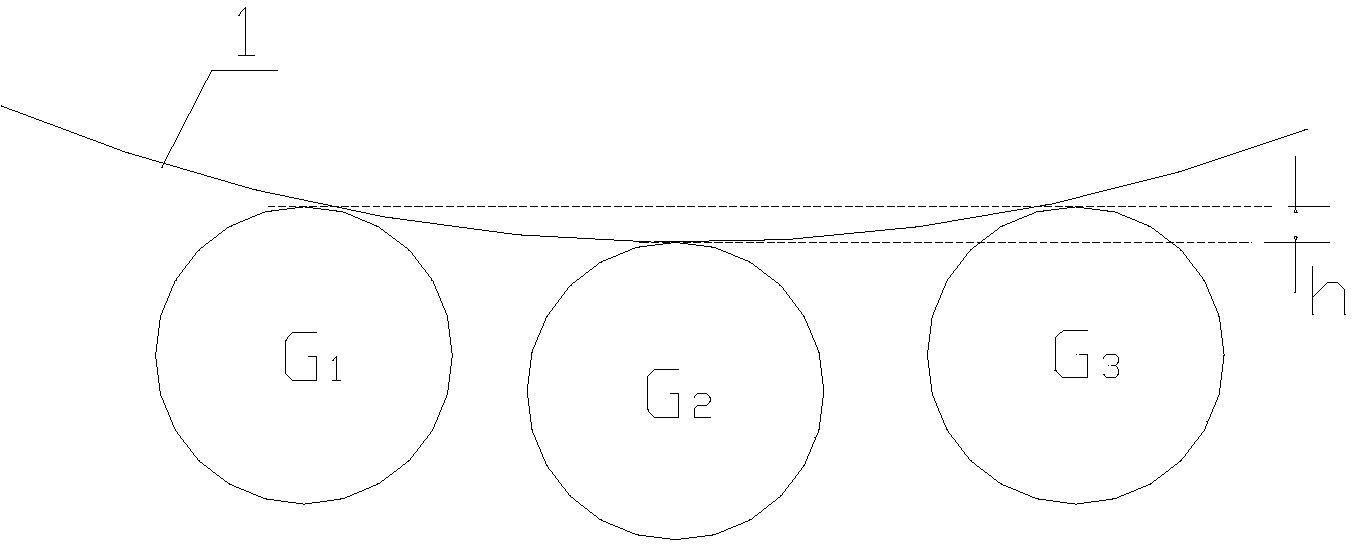

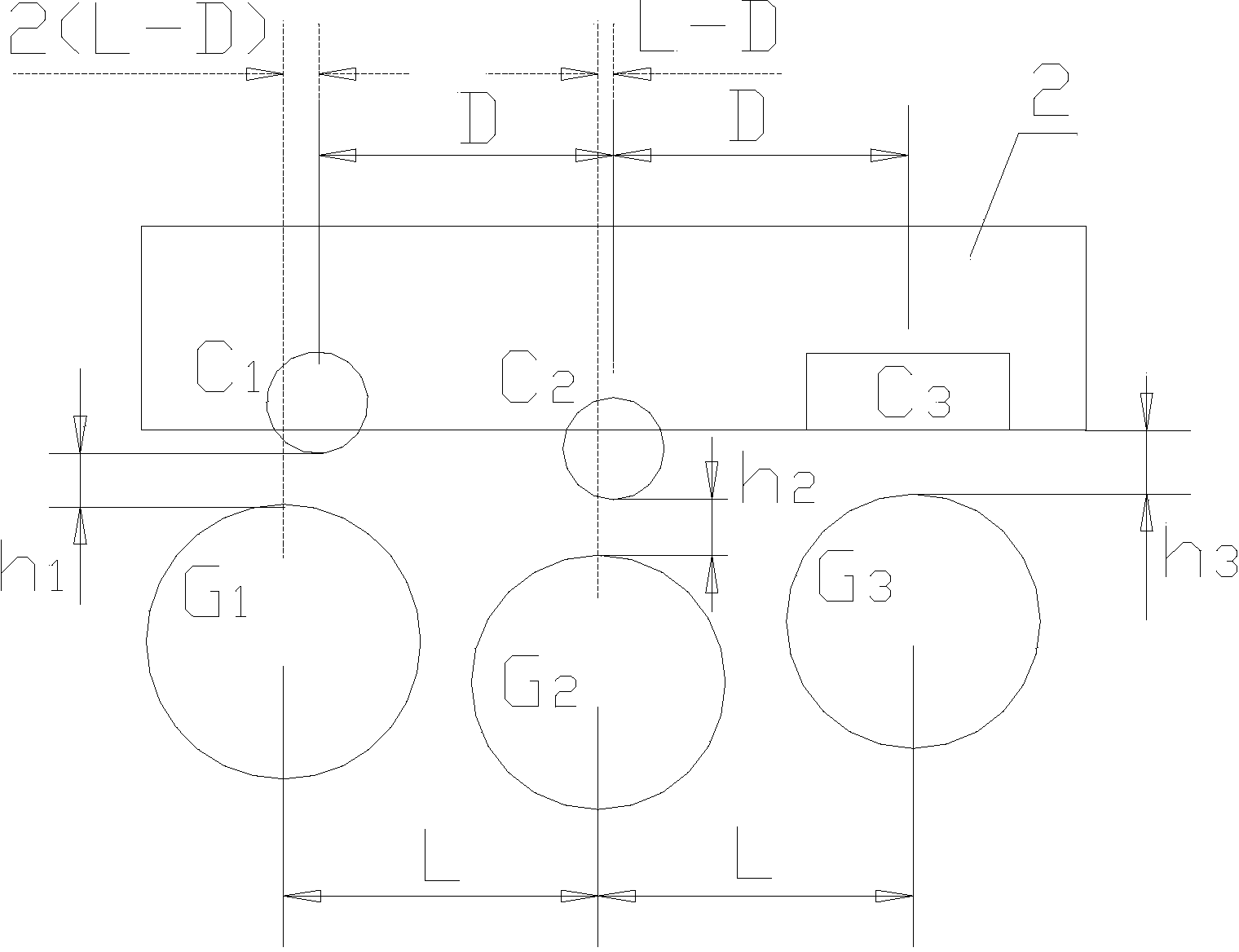

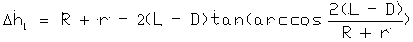

Online continuous caster outer arc segment row arc measurement method

ActiveCN103900519AGuaranteed uptimeEnsure billet qualityMeasurement devicesEngineeringContinuous caster

The invention discloses an online continuous caster outer arc segment row arc measurement method. A continuous caster roller clearance instrument moves straight forward along the outer arc segment row, three probes of the roller clearance instrument measures the distances with the adjacent three outer arc roller surfaces in real time, and the disatcnes respectively represent the diatnce between the roller clearance instrument corresponding to the probe position and the outer arc roller; when the third probe measures the top of the corresponding outer arc roller, deviation values between the second probe measurement position and the corresponding outer arc roller top and the first probe measurement position and the corresponding outer arc roller top can be obtained respectively; the distances with the corresponding outer arc rollers detected by the second probe and the first probe can be corrected according to the deviation values, and the distance values after correction are obtained; the difference value between the second probe and the first probe and the corresponding outer arc rollers after correction can be obtained after calculation, when the third probe detects the distance of the corresponding outer arc roller is zero, the difference value represents the arc value of the continuous caster outer arc segment row. The method can measure the arc value of the continuous caster outer arc segment row, ensures normal operation fo the continuous casting equipment and the quality of the casting blank.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

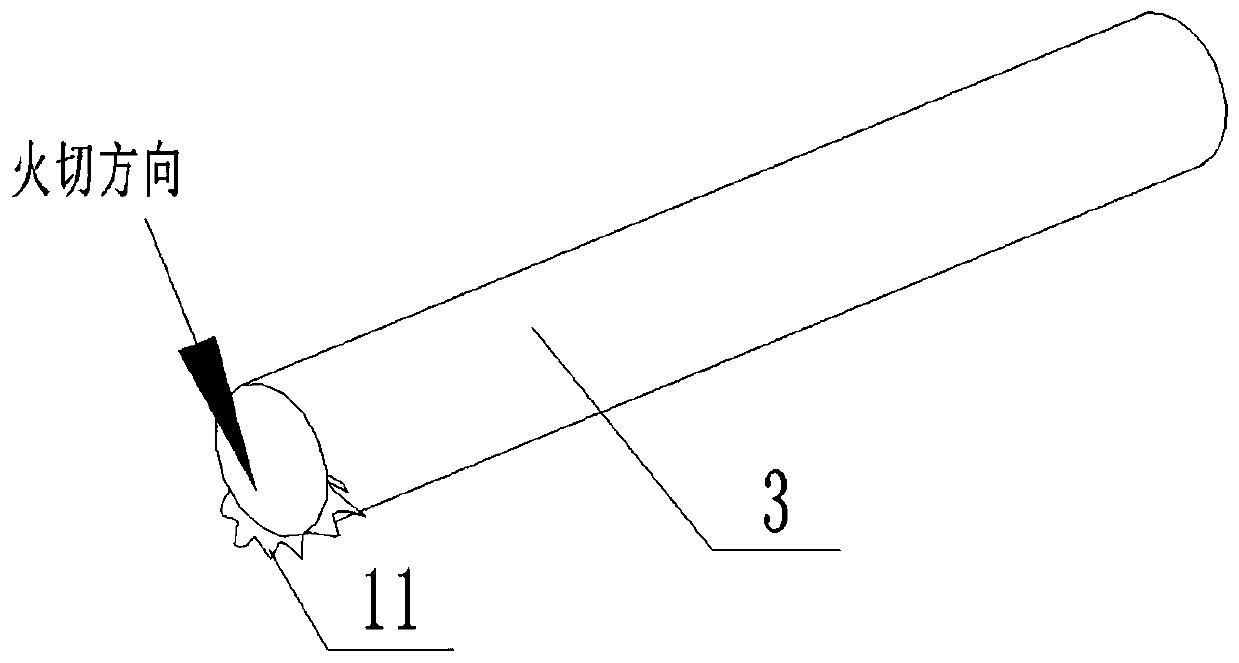

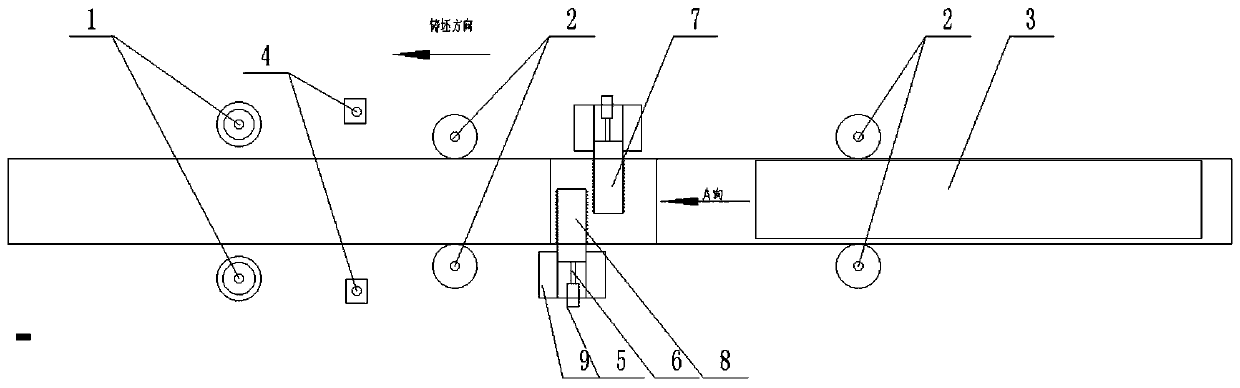

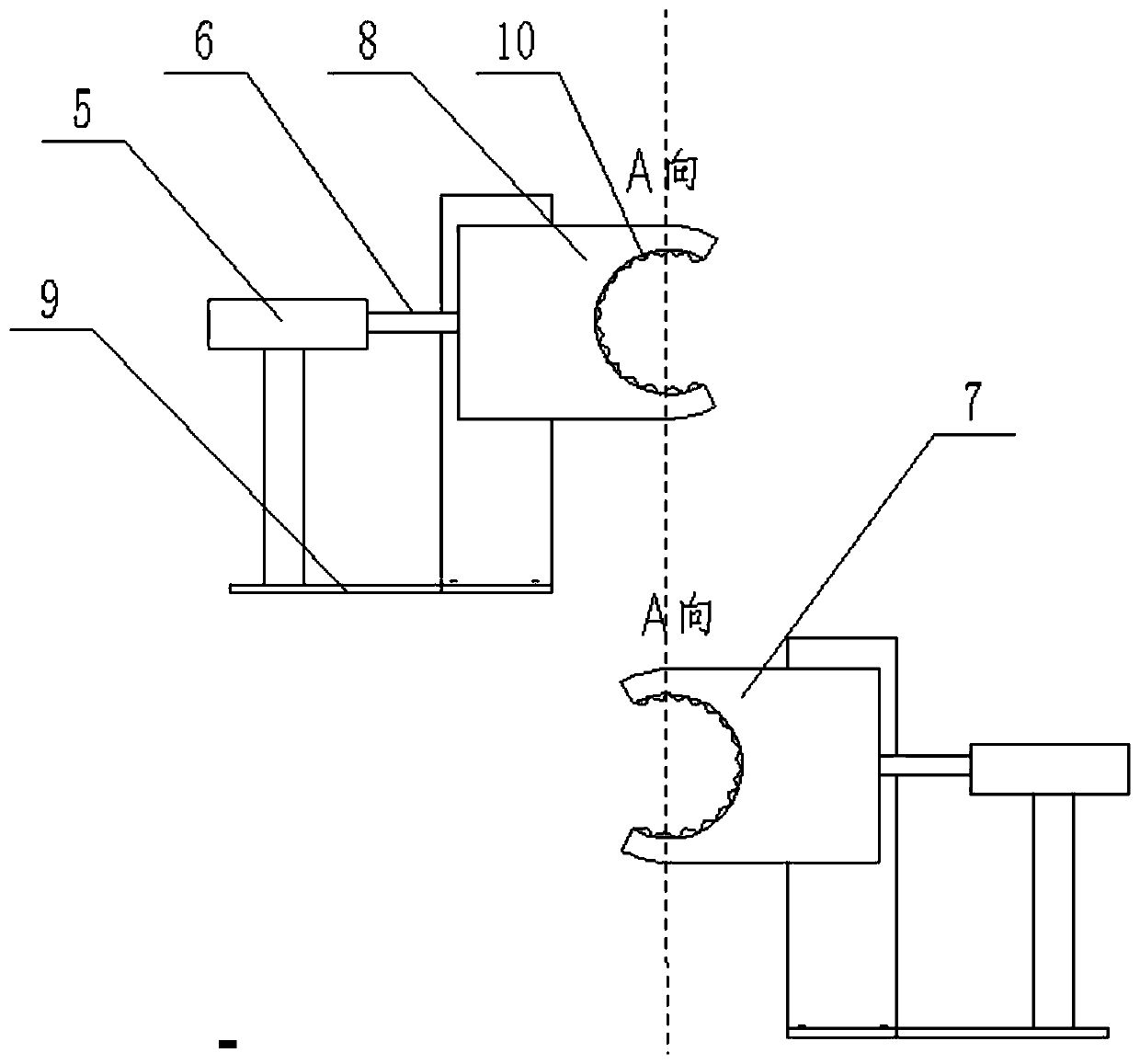

Deburring machine for round billet and working method of deburring machine

The invention relates to the technical field of continuous casting production, in particular to a deburring machine for a round billet and a working method of the deburring machine. The deburring machine comprises a left arc-shaped serrated knife and a right arc-shaped serrated knife which are mounted in the advancing direction of a casting billet in a front-back manner, are integrally located inthe middle of a roller bed and are fixedly connected to the free end of a piston rod of a reciprocating hydraulic oil cylinder; the reciprocating hydraulic oil cylinder is fixed to a knife holder; when the piston rod of the reciprocating hydraulic oil cylinder completely stretches out, a center perfect circle machining hole is formed in the front portion and the rear portion of the left arc-shapedserrated knife and the right arc-shaped serrated knife; and scraping is generated in the casting billet retreating process, and the effect of deburring is achieved. According to the deburring machine, the roundness of the round casting billet can be guaranteed while deburring is carried out, the shape of the casting billet cannot be damaged, and the quality of the casting billet is guaranteed. Compared with high-speed rotating striking of a hammer knife, reciprocating motion scraping has the beneficial effects that safety is achieved, filings cannot be splashed, noise is low, and 360-degree complete deburring is achieved.

Owner:TAIHE CONTINUOUS CASTING APP

Formula and preparation method of smelting q345b steel with low cost and high quality

The invention relates to a low-cost and high-quality formula of smelting Q345B steel and a preparation method of the formula. Raw materials comprise iron ores, silicon-manganese alloys Si15Mn65, ferrotitanium alloys 50TiFe and aluminum alloys Al99. 6.6kg-9.6kg of silicon-manganese alloys Si15Mn65 are added into each ton of Q345B steel, 0.6kg-0.9kg of ferrotitanium alloys 50TiFe are added into each ton of Q345B steel, and 1.69kg of aluminum alloys Al99 are added into each ton of Q345B steel. The titanium alloys and the aluminum alloys are used for replacing parts of Mn reinforced crystal grains to improve strength, segregation caused by high Mn steel is decreased, smelting cost is reduced, cast billet quality is ensured, and the quality and the yield of the Q345B steel are greatly improved.

Owner:河北中重冷轧材料有限公司

Method for judging the melting performance of mold powder

InactiveCN103472084BJudgment of melting performanceImprove reliabilityInvestigating phase/state changeShape changePowder method

The invention discloses a method for judging the melting performance of mold flux, comprising: making mold flux into a standard sample; melting the standard sample, and observing the shape change characteristics of the standard sample during the melting process; After the standard sample is completely melted, cool the standard sample to room temperature, observe the shape characteristics of the melted standard sample; Shape features determine the melting performance of the mold flux. The invention introduces the concept of slag shape characteristics, and through the detection of melting temperature, combined with the shape of slag and the characteristics of the sample after melting, can judge the melting performance of mold mold slag more comprehensively and accurately, with high reliability; The production plays a guiding role, guarantees continuous casting and billet quality, and has great social and economic benefits.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com