Patents

Literature

124results about How to "Craftsmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purpose of heavy metal sludge, acid pellet and preparation method and purpose thereof

ActiveCN101805827AEnsure the quality of the furnaceImproving the Blast Furnace Charge StructureBlast furnace detailsHeavy metalsSludge

The invention discloses a purpose of heavy metal sludge, an acid pellet and a preparation method and a purpose thereof. The invention takes stainless steel cold-rolling heavy metal sludge as a raw material for preparing the acid pellet of the sludge. The acid pellet of the sludge is mainly prepared by the following raw materials by weight percent: 5-50 percent of stainless steel cold-rolling heavy metal sludge, 30-70 percent of iron ore concentrate, 2-8 percent of composite binding agent, 4-15 percent of carbon powder and 10-30 percent of water. The preparation method of the acid pellet of the sludge comprises the main steps of pretreatment of raw materials, mixing of raw materials, pelletizing and roasting. The acid pellet of the sludge is used as a raw material of a blast furnace. The invention solves the problems that the prior art can not effectively treat and comprehensively utilize the stainless steel cold-rolling heavy metal sludge.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for adding rare earth metal into steel to improve performance

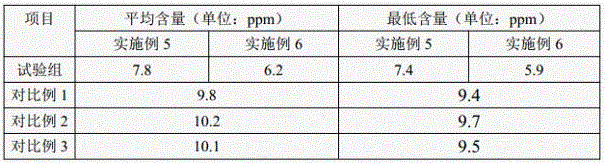

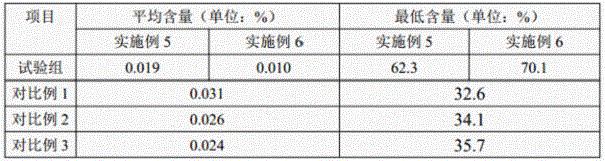

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for producing sulfur free cutting and non-hardened and tempered steel

InactiveCN1667129AQuality improvementIncrease reflectionManufacturing convertersProcess efficiency improvementSystems researchOxygen content

This invention relates to manufacturing method of sulfurous free machining non- quenched and tempered steel. Desulfurization operation is not used in convertor, residue consumption is reduced, and convertor few residue smelting technology is realized. Appropriate deoxidizer and deoxidation technique is selected and high sulfur steel sulfide inclusion is controlled efficiently to make it tiny, uniform distributing, it realizes innocent treatment of high sulfur steel sulfide inclusion. Sulfur element absorptivity, narrow composition control and inclusion removal is ensured by refining technique and residue system research. The contradiction of reducing oxygen content and ensuring sulfur content is solved and high sulfur steel continuous casting low control problem. Sulfur in steel can be stably controlled to 0.040~0.060% by this invention, the history domestic convertor-refinery-continuous casting-binding and cold control technique can not produce sulfurous free machining non- quenched and tempered steel is changed. The steel quality is good and reaches to convertor-refinery-molded casting-binding and cold control technique level. It has been mass produced, and has good reflection from consumer.

Owner:SHOUGANG CORPORATION

Method for producing nickel-iron alloy by smelting red earth nickel mineral at low temperature

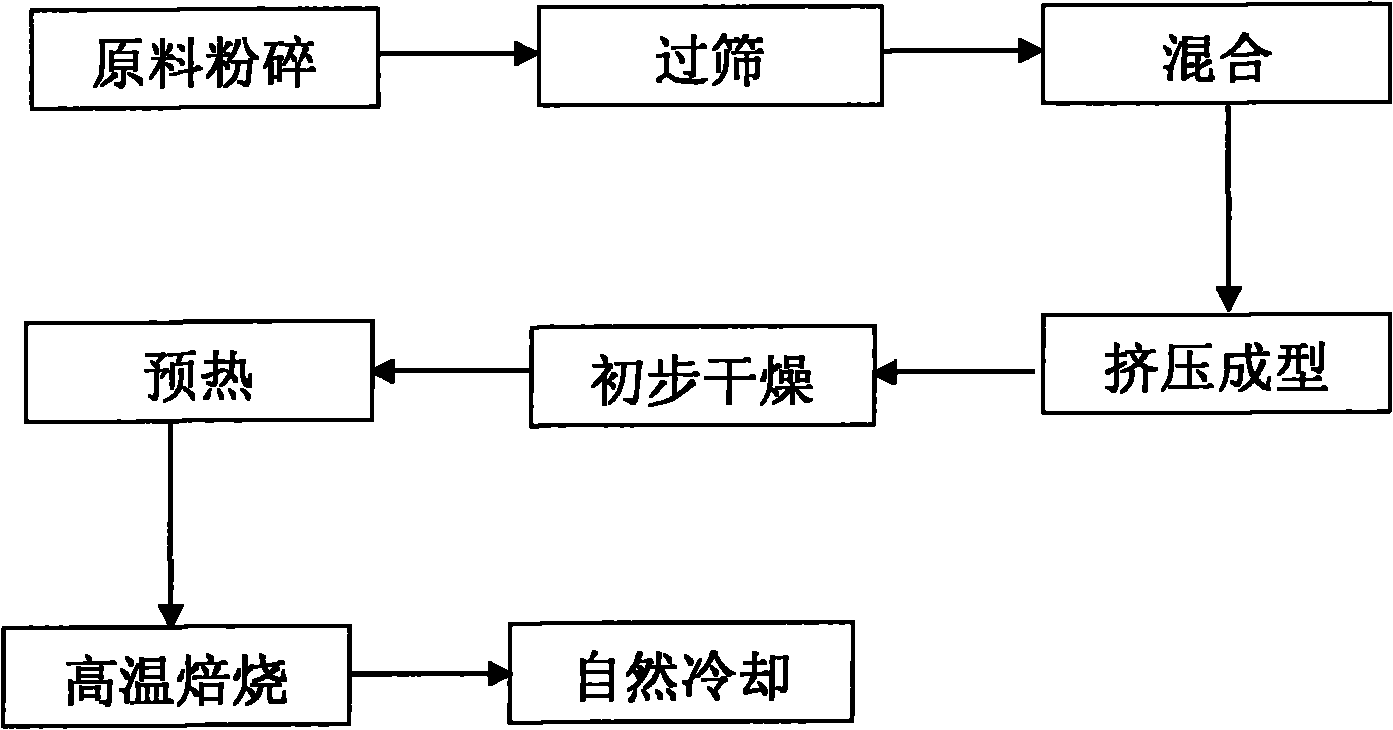

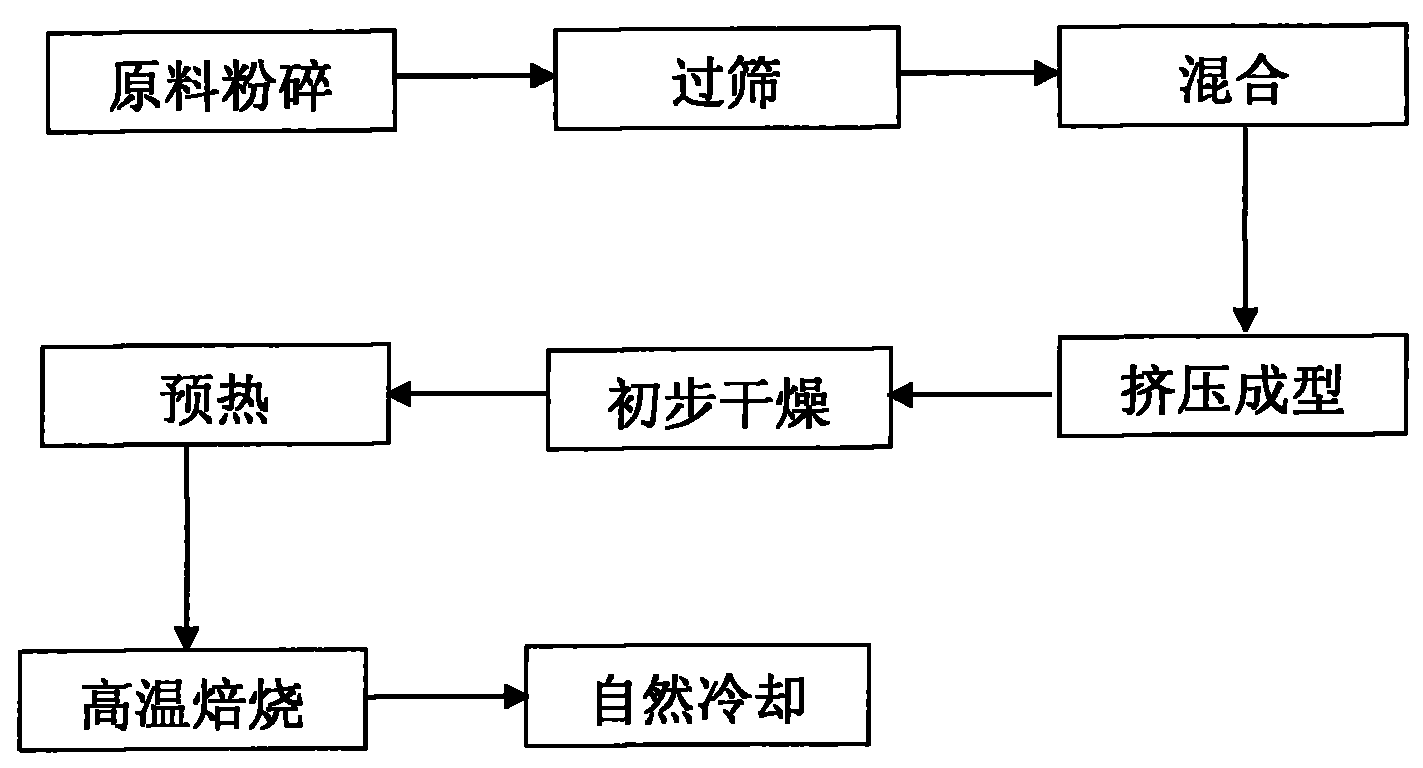

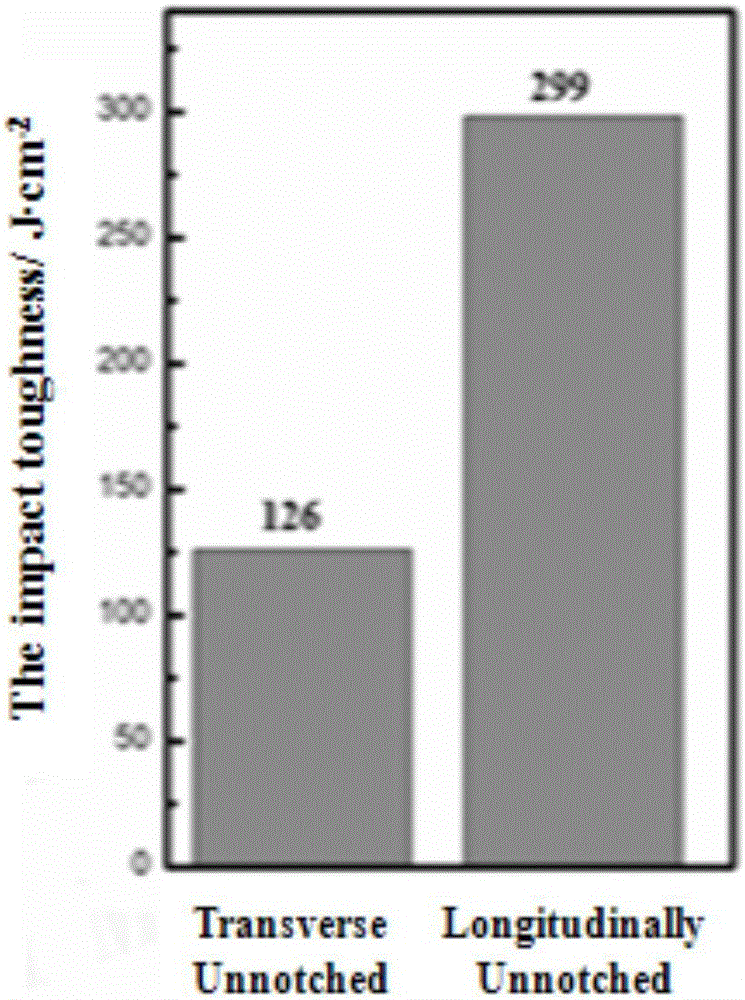

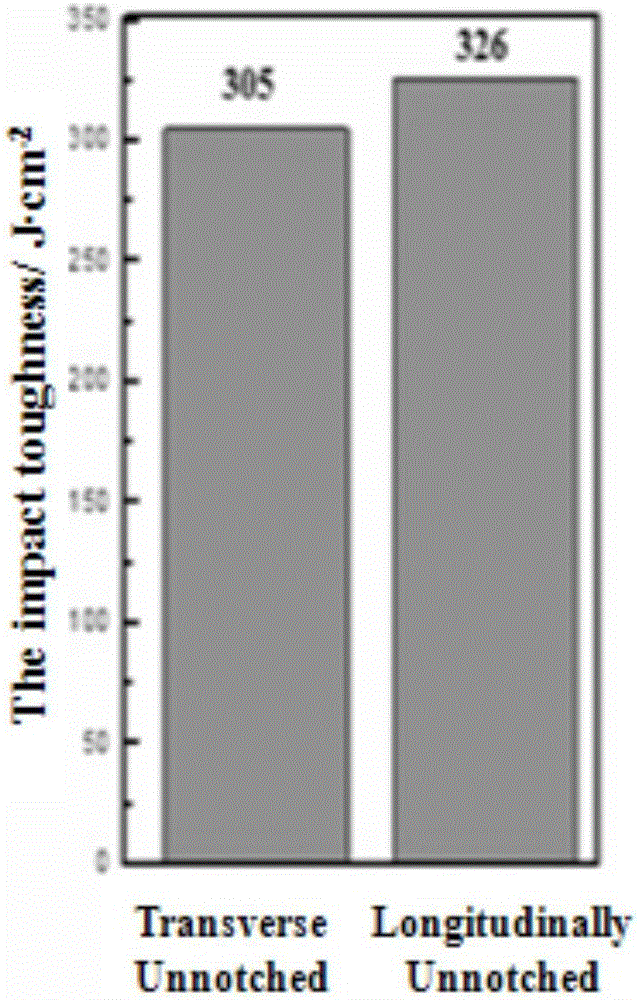

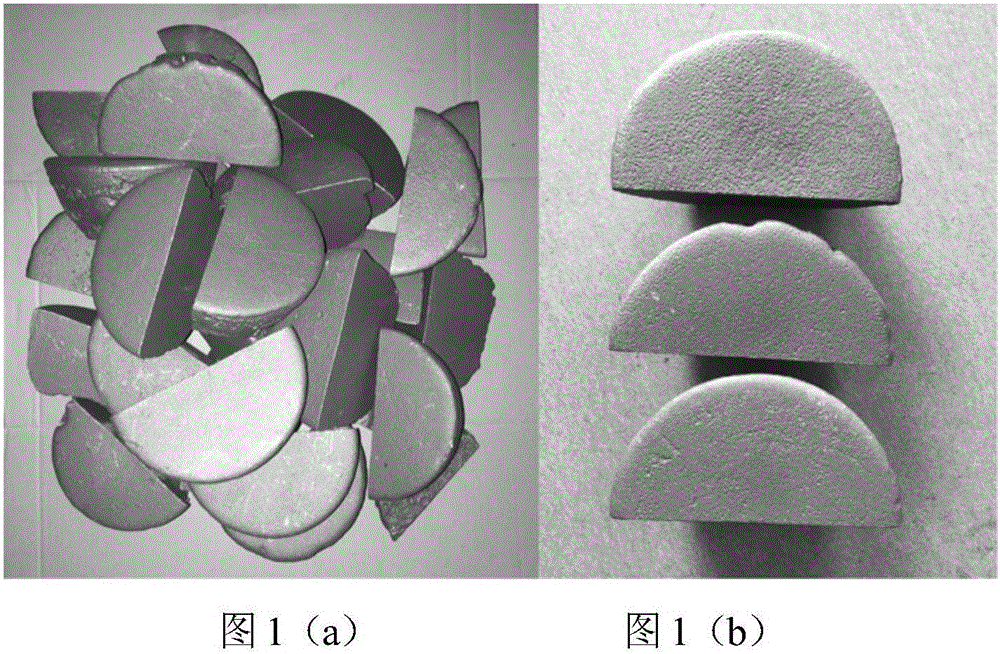

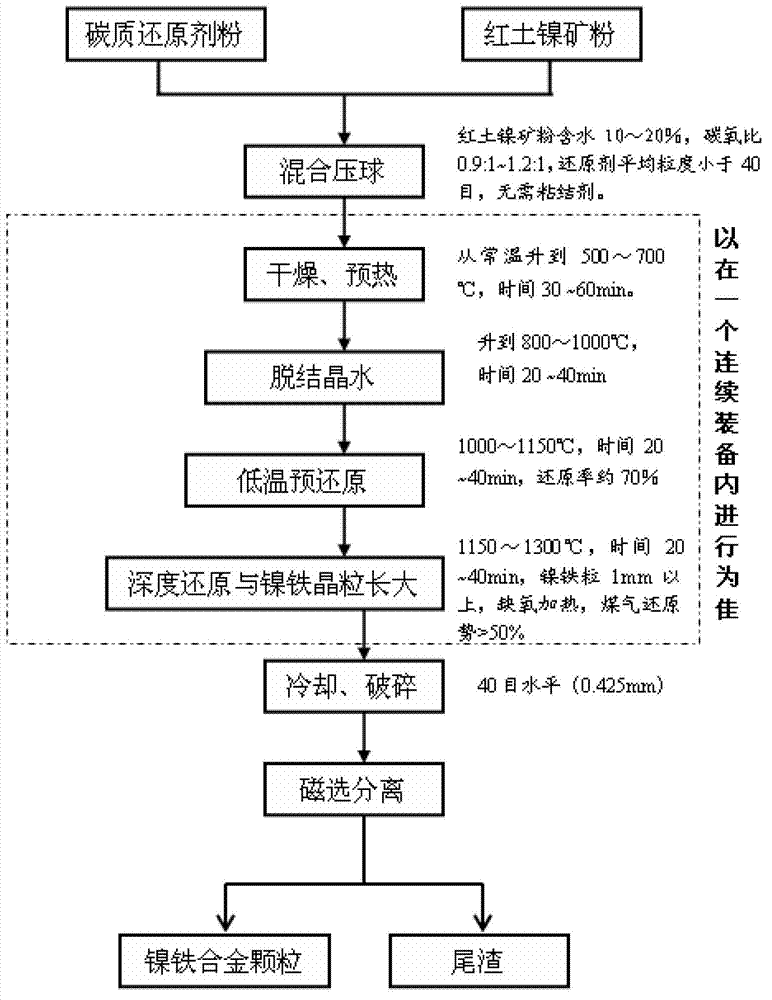

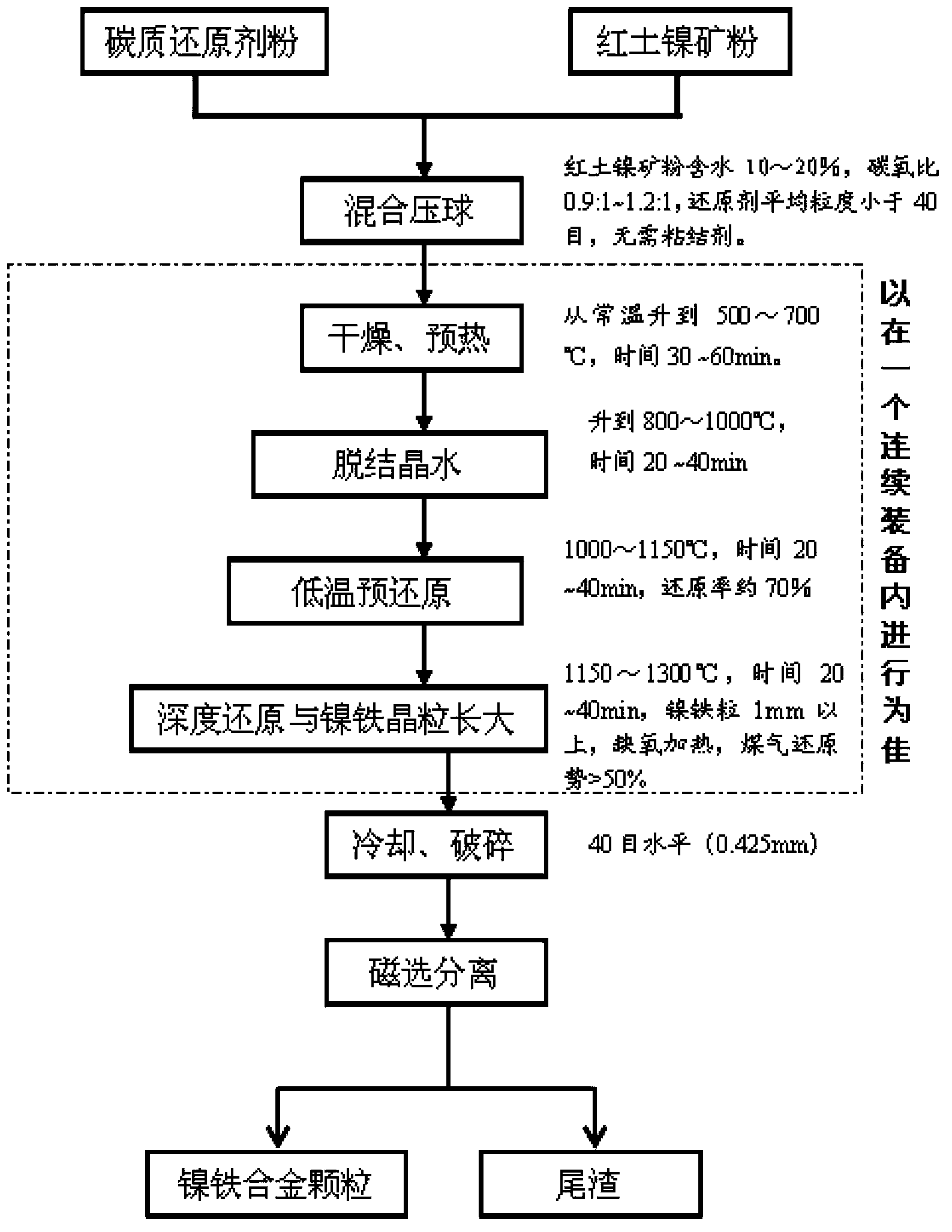

The invention provides a method for producing nickel-iron alloy by smelting a red earth nickel mineral at a low temperature and belongs to the field of preparation of non-ferrous metallurgy. A process flow is as follows: after the red earth nickel mineral and a carbon reducing agent are molded, molding raw materials are subjected to drying, pre-heating and crystallization water removing; pre-reduction, deep reduction and growth of nickel-iron alloy grains are carried out; and after a cooling step, the separation of the nickel-iron alloy and furnace dregs is realized in a magnetic selection manner. Compared with the prior art, the method has the advantages of being low in reaction temperature, low in energy consumption, easy to obtain the high-quality nickel-iron alloy grains, simple in preparation process and low in production cost.

Owner:NEW METALLURGY HI TECH GRP

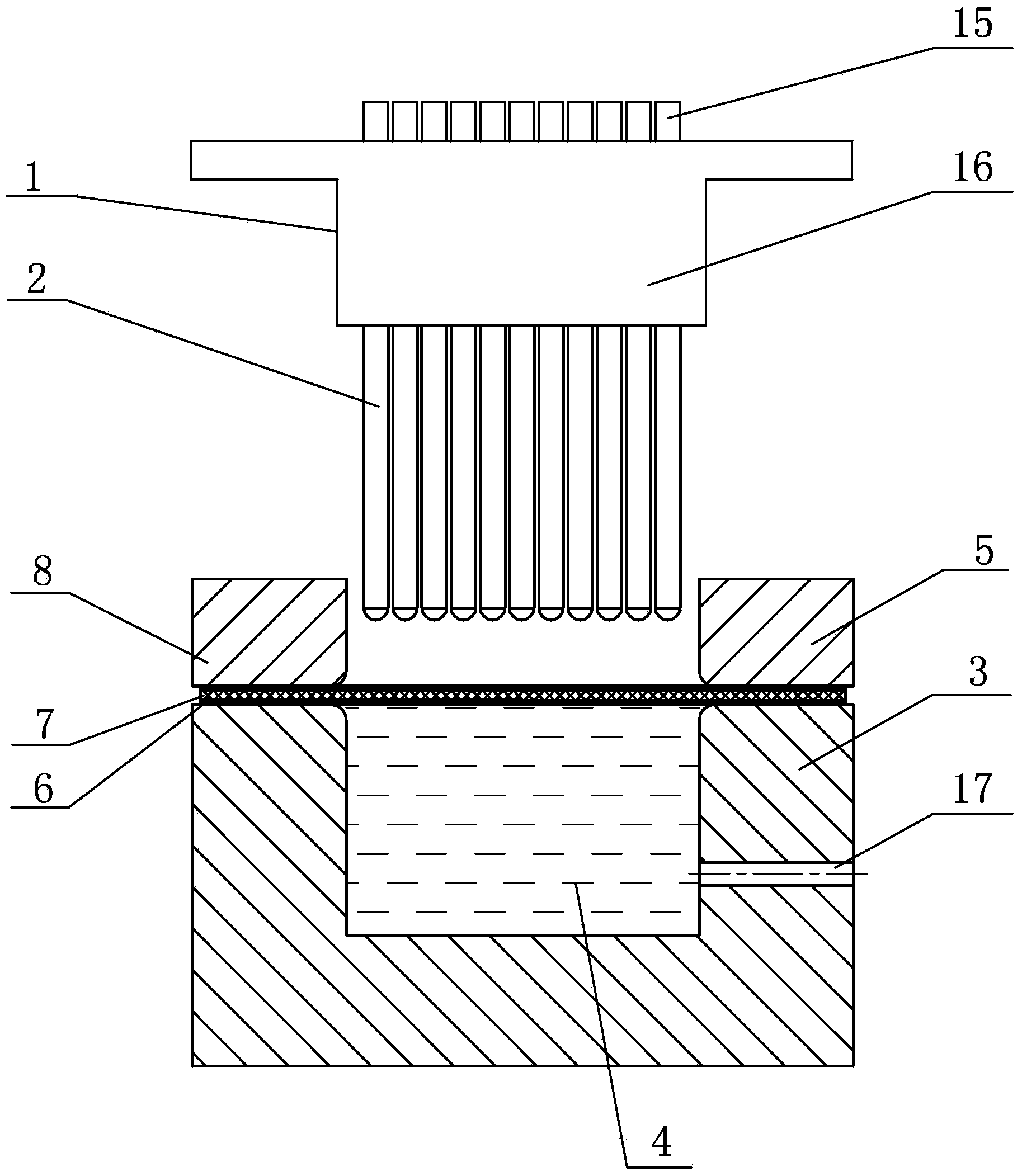

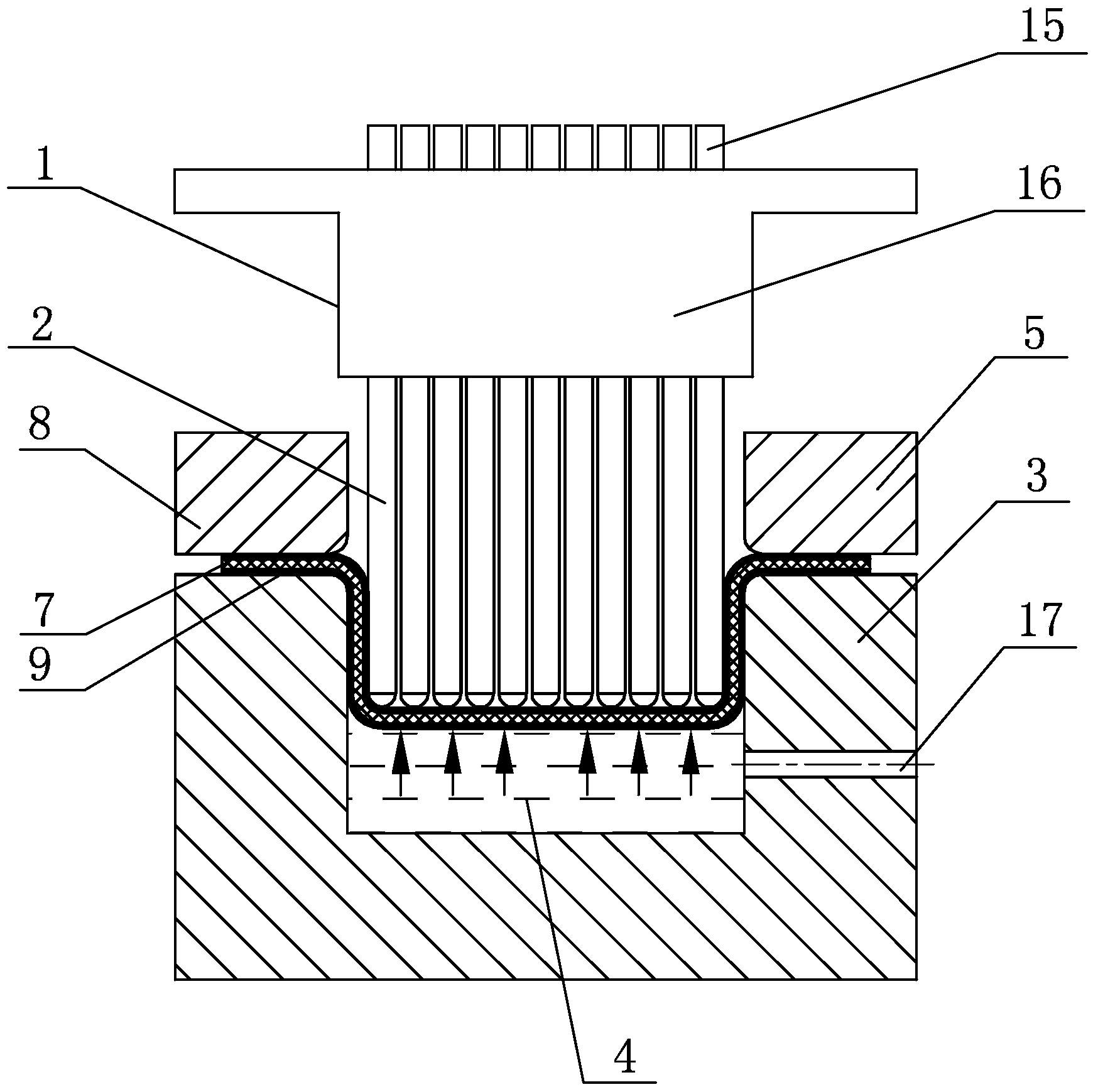

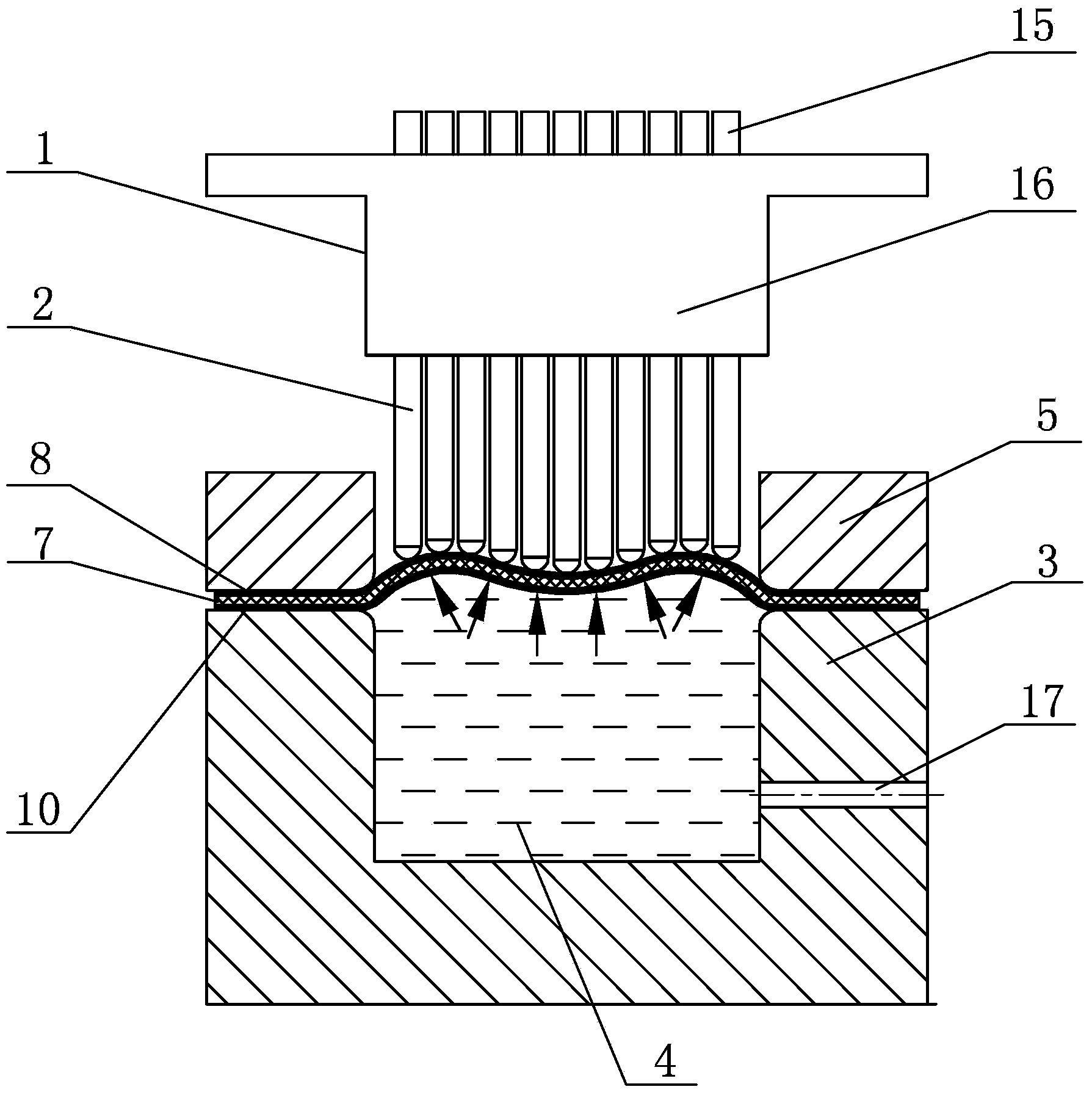

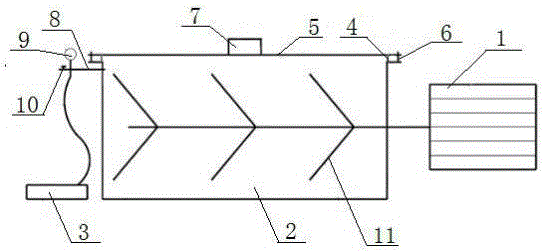

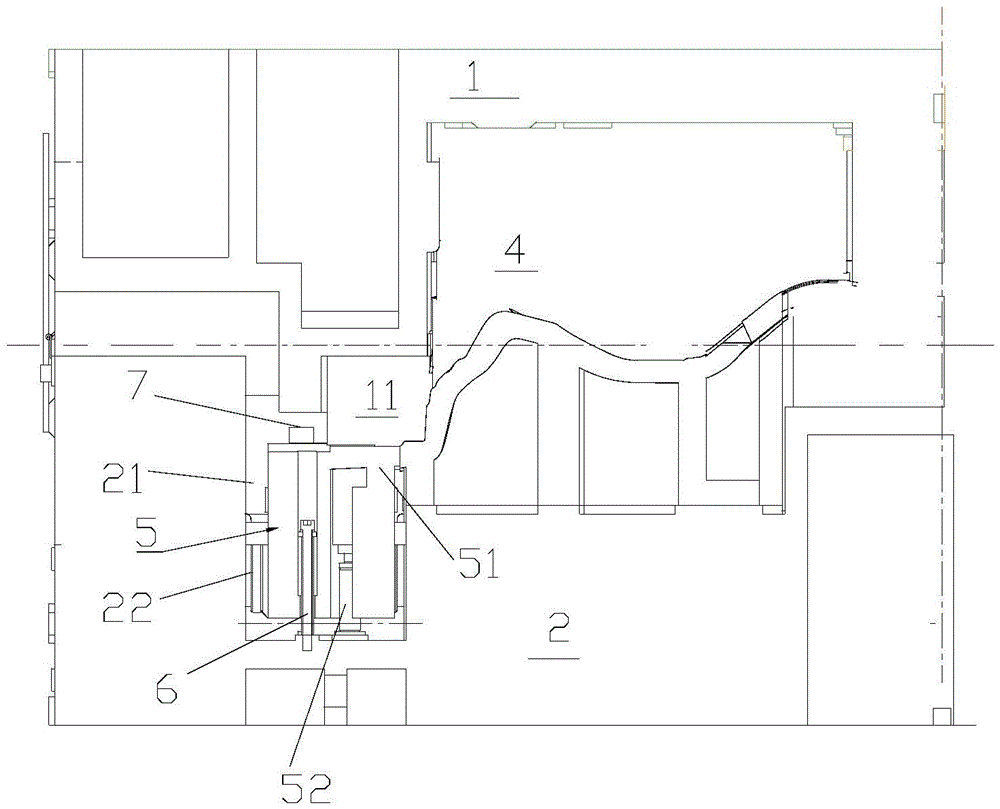

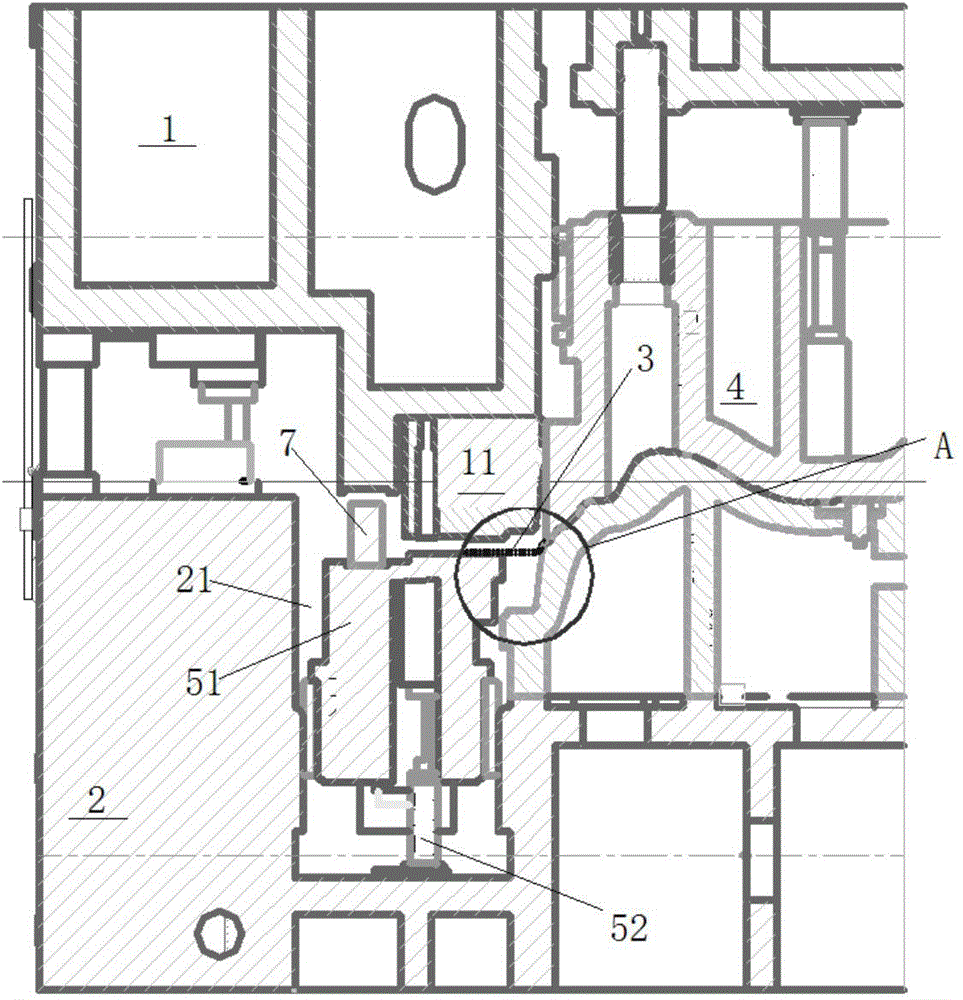

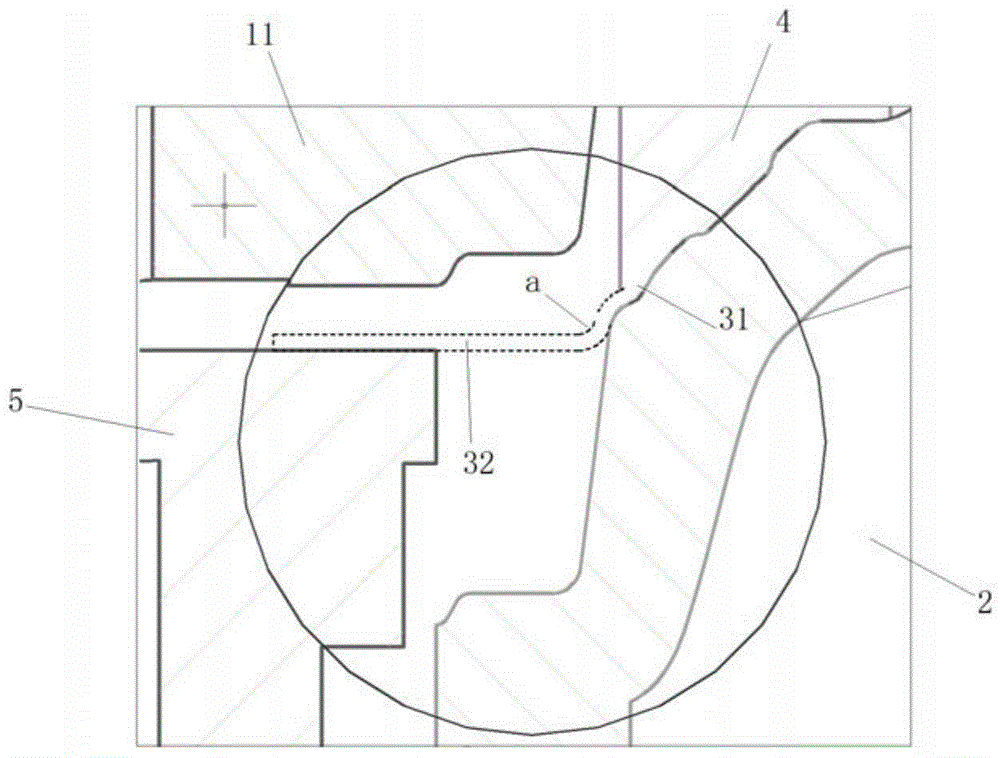

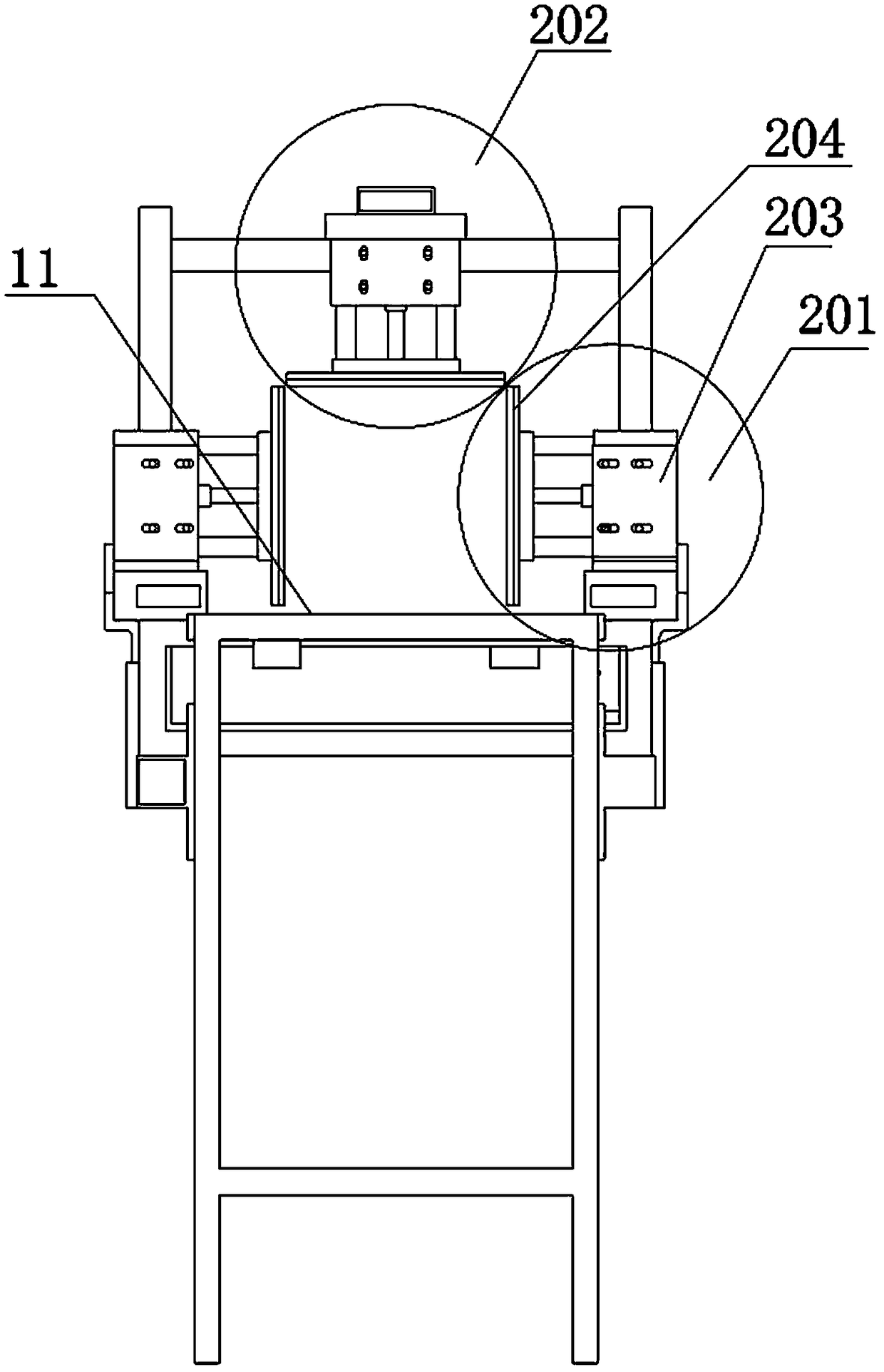

Multi-point male die liquid-filling drawing forming device and method for plate

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

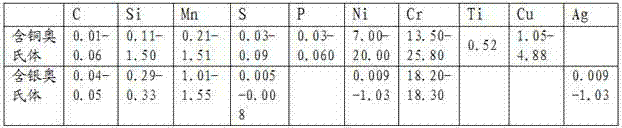

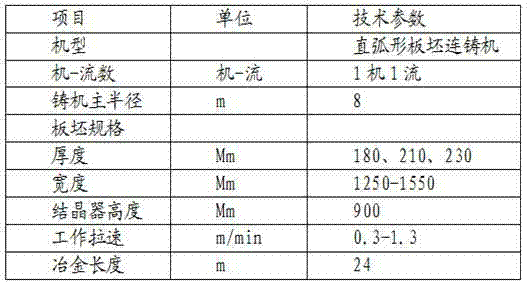

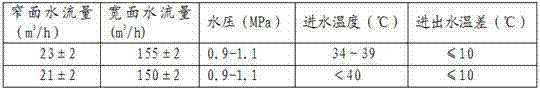

Crystallizer casting powder for austenite antibacterial stainless steel

ActiveCN103785808AMeet the needs of shrinkage characteristicsGood control of heat transferHeat resistanceField tests

The invention discloses continuous casting crystallizer casting powder for austenite antibacterial stainless steel. The alkalinity of the continuous casting crystallizer casting powder ranges from 1.0 to 1.1, and the continuous casting crystallizer casting powder can achieve a very good heat transfer control effect and meet the requirement for shrinkage characters of the austenite antibacterial stainless steel. The viscosity is set as 0.10 Pa*s-0.18 Pa*s at the temperature of 1300 DEG C, so that the casting powder flows in gaps between blank shells and a crystallizer copper plate more evenly, casting blanks are lubricated, the requirement for the consumption of the crystallizer casting powder is met, and the viscosity is mainly controlled Al2O3, MgO and F-. The melting point ranges from 1130 DEGC to 1190 DEG C, heat resistance of the casting powder is increased, the heat transfer uniformity index of the crystallizer casting powder is increased, and cracks are difficult to produce. Raw materials of the continuous casting crystallizer casting powder are easy to obtain, and cost is relatively low. By means of field tests, the casting powder is melt uniformly and stably, the indentation rate of the edges of the casting blanks is decreased by about 9.5%-19%, quality of the casting blanks is improved, and smooth operation of processes of a steel mill is guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

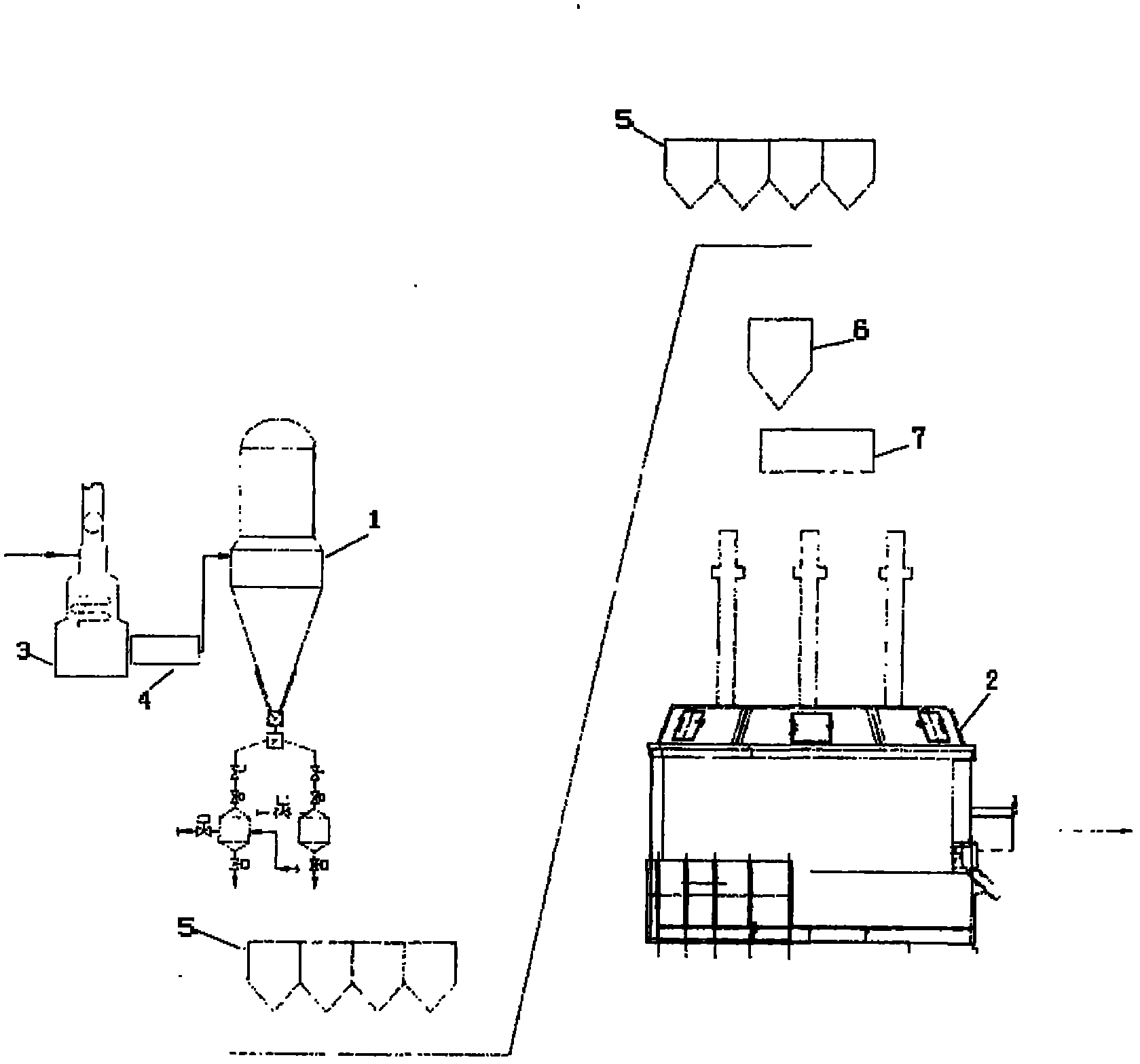

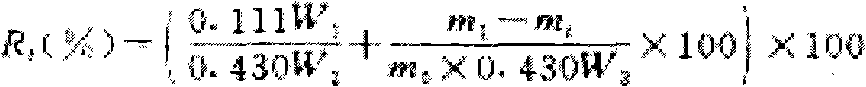

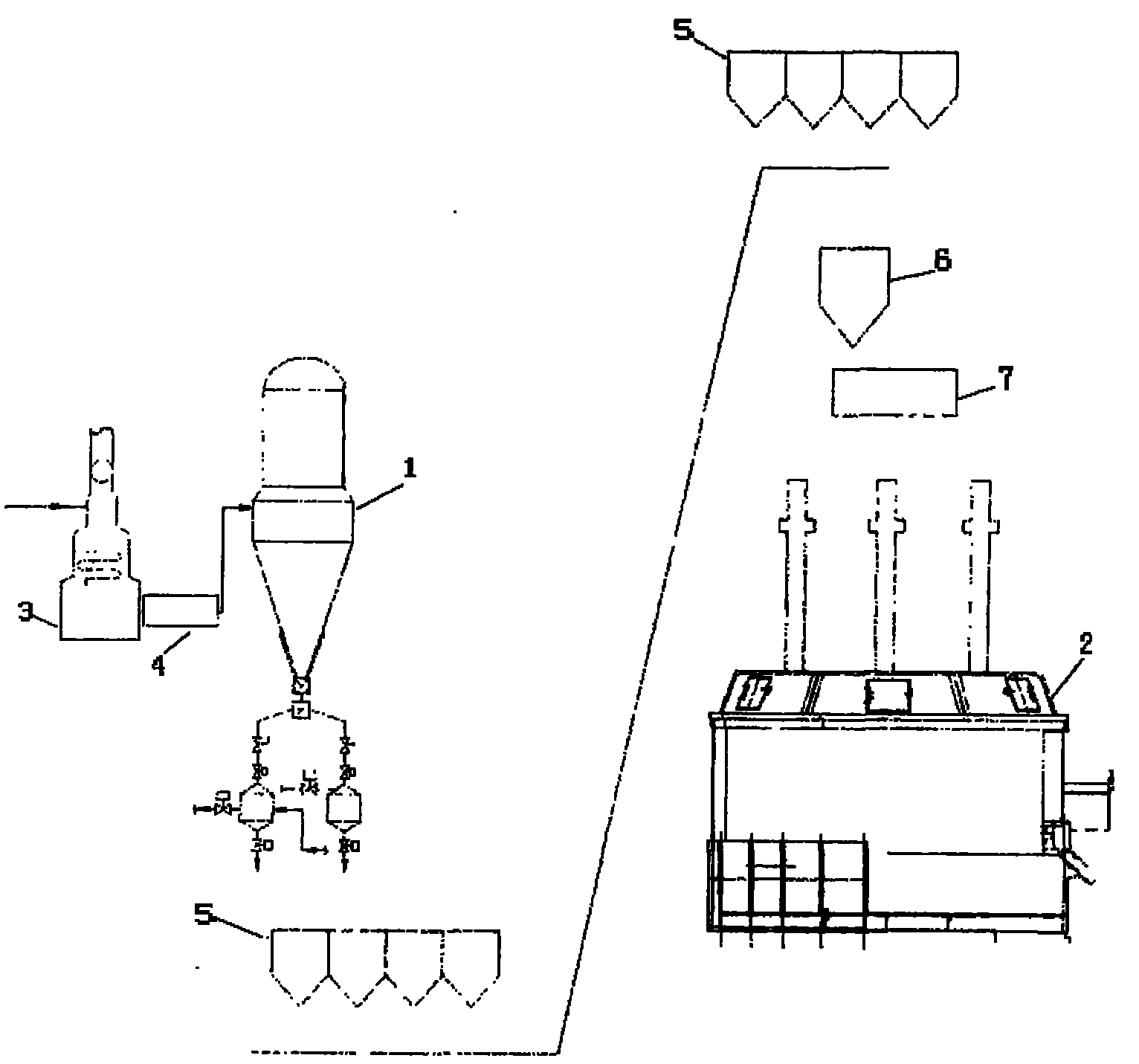

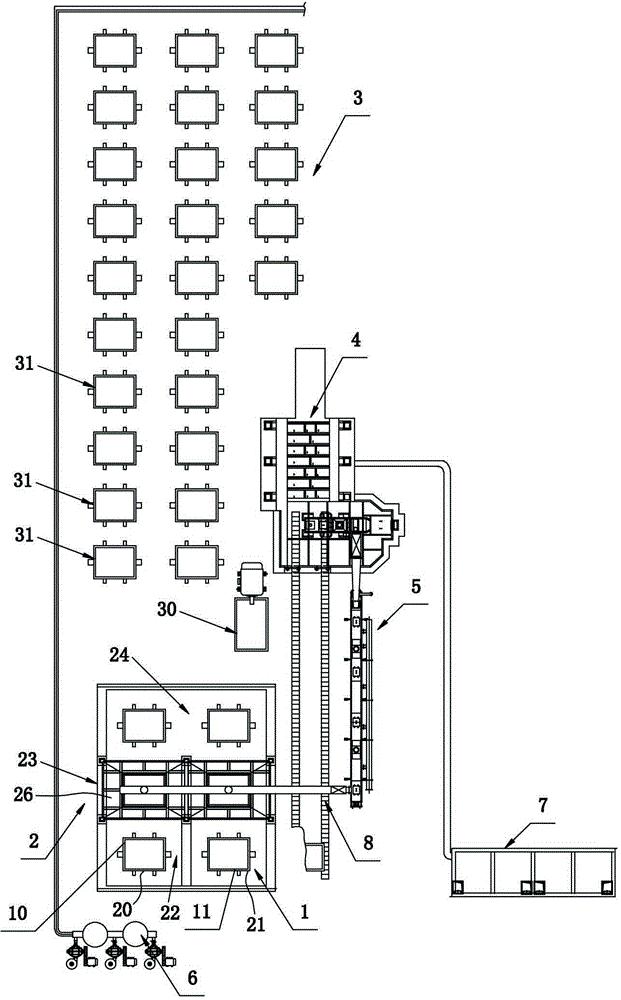

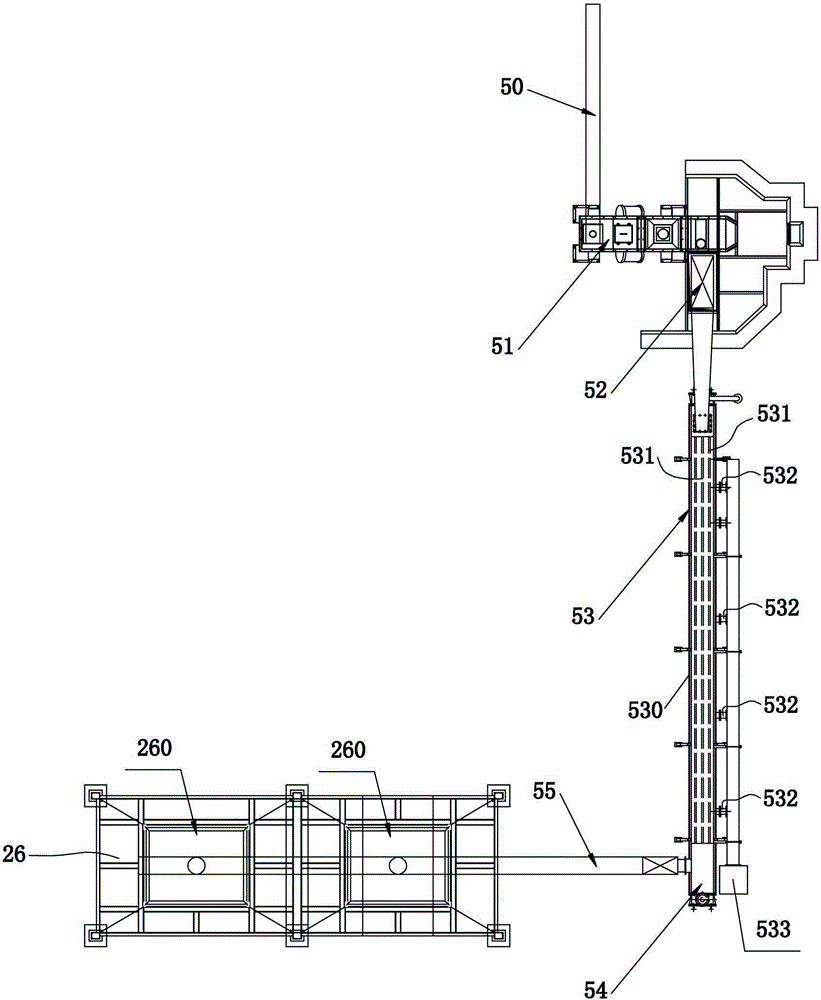

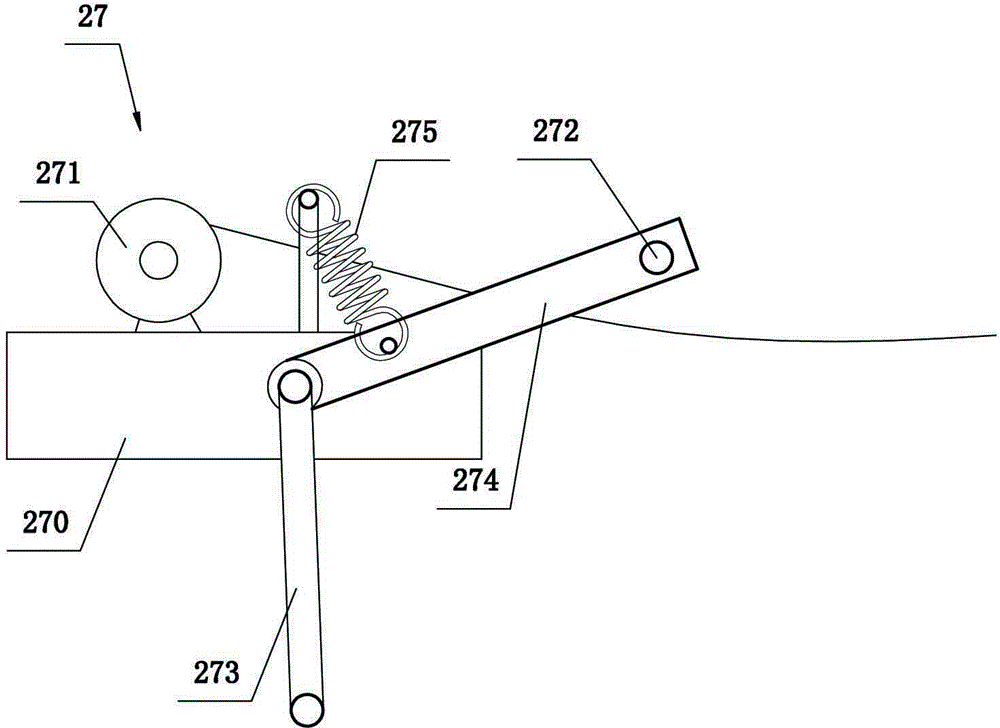

Iron making method and device by virtue of gas-based smelting reduction

ActiveCN102559981ARaw materials are easy to getLow costGas emission reductionHeating furnaceWeight/volume ratio

The invention provides an iron making method and device by virtue of gas-based smelting reduction. The method comprises the following steps of: step 1, preparing raw materials: preparing pellet or lump ores as the raw material; step 2, carrying out pre-reduction: carrying out pre-reduction on the pellet or lump ores and a reducing gas in a vertical furnace (1) to obtain pre-reduced ores, wherein the weight / volume ratio of pellet or lump ores to reducing gas is 1kg: (0.7-0.9Nm<3>), preferably, 1kg: 0.8Nm<3>, the pressure of the reducing gas at the gas inlet of the vertical furnace is 0.6MPa-0.65MPa, and the temperature of the reducing gas at the gas inlet of the vertical furnace is 930 DEG C-970 DEG C; and step 3, carrying out final reduction: carrying out final reduction on the pre-reduced ore obtained by pre-reduction in the vertical furnace in an ore heat furnace (2) with semicoke or coke powder. According to the invention, the existing vertical furnace and the ore heat furnace can be adopted; and in the iron making process, process parameters are easy to strictly control, the reducing degree of the pre-reduced ore is controlled to 83-88%, thus the technical difficulty of a gas-based reduction process is reduced, and the utilization rate of the reducing gas for gas-based reduction is improved.

Owner:BERIS ENG & RES CORP

Surface treatment method for magnesium alloy

The invention discloses a surface treatment method for magnesium alloy. The method includes the following steps of (1) primary washing, (2) ungrease treatment, (3) secondary washing, (4) primary acid pickling, (5) secondary acid pickling, (6) alkali washing, (7) anodic oxidation, (8) third-time washing and (9) drying and heat preservation. All the steps of the processing method are scientific, reasonable and ingenious in process. The structure of surface oxidation films of a magnesium alloy material is effectively improved, the strong acid resistance, strong base resistance and organic solvent corrosion resistance are improved obviously, the surface strength is improved by 30%-35%, and the brittleness is well improved. A special cellular structure is achieved, the deep processing technique like dyeing is facilitated, and the use value is good.

Owner:刘洪建

Vacuum concrete mixing process

The invention provides a vacuum concrete mixing process. The vacuum concrete mixing process is characterized in that via simple structural modification, after a mixing drum of a mixer is sealed, the interior of the mixing drum is vacuumized, that is, before mixing, a certain vacuum degree is formed in the mixing drum, so that contact between freshly mixed concrete slurry and air in the mechanical mixing process is greatly reduced, formation of bubbles in concrete is reduced, and accordingly, the porosity is greatly reduced. Furthermore, the minimum pressure in the mixing drum is controlled, so that the ambient temperature is lower than the boiling point of moisture in the mixing drum, accordingly, moisture evaporation is avoided, the phenomenon that pores are formed by moisture evaporation is prevented, and the porosity is further reduced. The vacuum concrete mixing process is simple, is convenient to operate, and can efficiently improve the concrete compactness, strength and durability.

Owner:HUNAN UNIV OF TECH

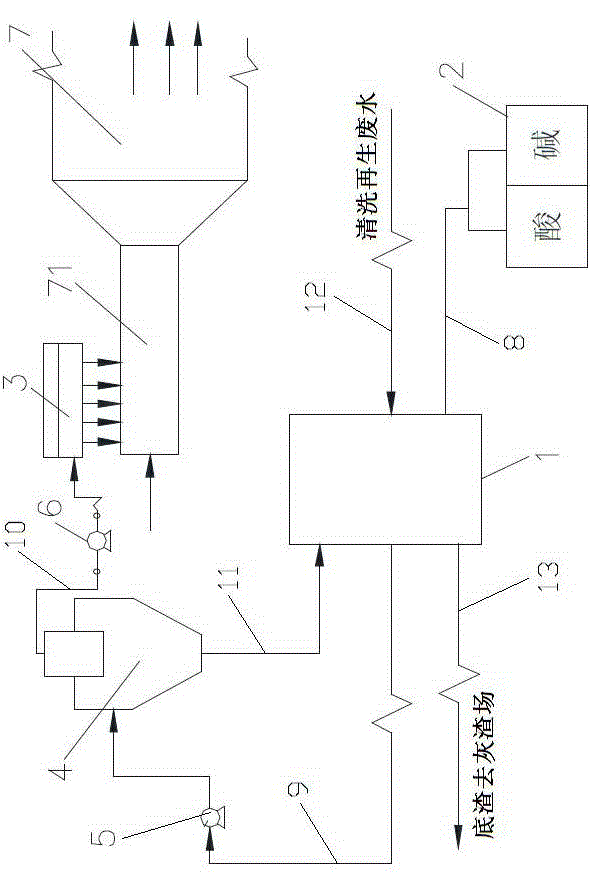

Treatment device and treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue

ActiveCN104591460AAchieve reuseImprove applicabilityUsing liquid separation agentMultistage water/sewage treatmentHigh energyWastewater

The invention relates to a treatment device and a treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue. A treatment device and a treatment technology for denitration catalyst cleaning regeneration wastewater and waste residue, which have high energy utilization rate and can realize recycling of the denitration catalyst cleaning regeneration wastewater, are unavailable now. The treatment device is characterized by comprising a wastewater buffer sedimentation tank, an acid-base dosing box, an ultrasonic atomizing nozzle, a wastewater hydrocyclone, a liquid conveying pump, a deduster, an acid-base supply pipe and an underflow return pipe, wherein a cleaning regeneration wastewater conveying pipe and a bottom residue conveying pipe are both connected to the wastewater buffer sedimentation tank; and the acid-base dosing box is connected to the wastewater buffer sedimentation tank through the acid-base supply pipe. The treatment technology comprises the following steps: conveying the denitration catalyst cleaning regeneration wastewater into the wastewater buffer sedimentation tank; adjusting the pH value; standing for sedimentation; performing solid-liquid separation of the supernate; and atomizing the overflow filtrate and spraying into the deduster. The treatment device and treatment technology provided by the invention can be used for realizing recycling of the denitration catalyst cleaning regeneration wastewater.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Processing method capable of improving surface strength of aluminum and aluminum alloy

The invention discloses a processing method capable of improving the surface strength of aluminum and aluminum alloy. The processing method includes the following steps of (1) primary washing, (2) ungrease treatment, (3) secondary washing, (4) primary acid pickling, (5) secondary acid pickling, (6) alkali washing, (7) anodic oxidation, (8) third-time washing and (9) drying and heat preservation. All the steps of the processing method are scientific, reasonable and ingenious in process. The structure of surface oxidation films of an aluminum or aluminum alloy material is effectively improved, the strong acid resistance, strong base resistance and organic solvent corrosion resistance are improved obviously, and the surface strength is improved by 20%-25%. Furthermore, a special cellular structure is achieved, the deep processing technique like dyeing is facilitated, and the use value is good.

Owner:刘洪建

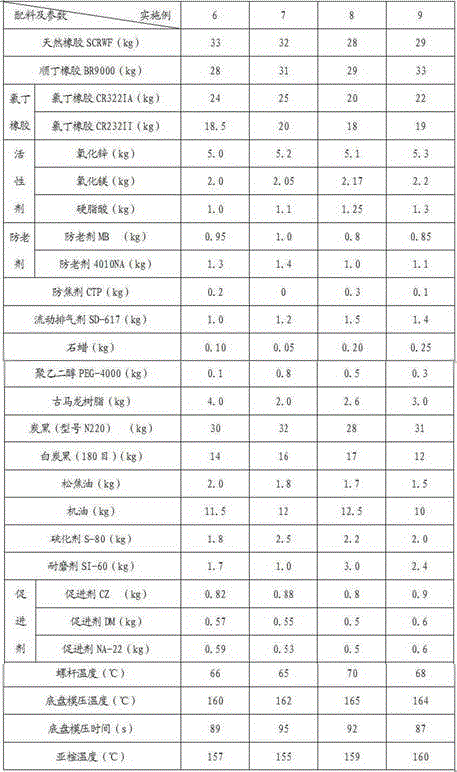

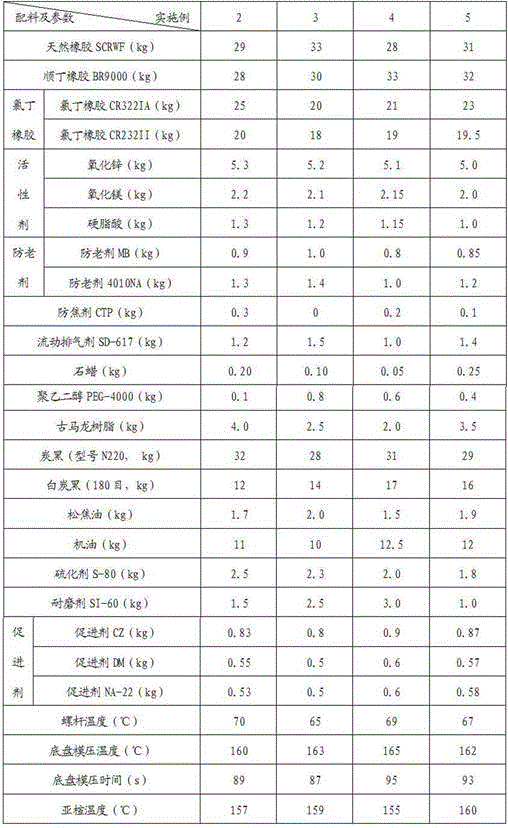

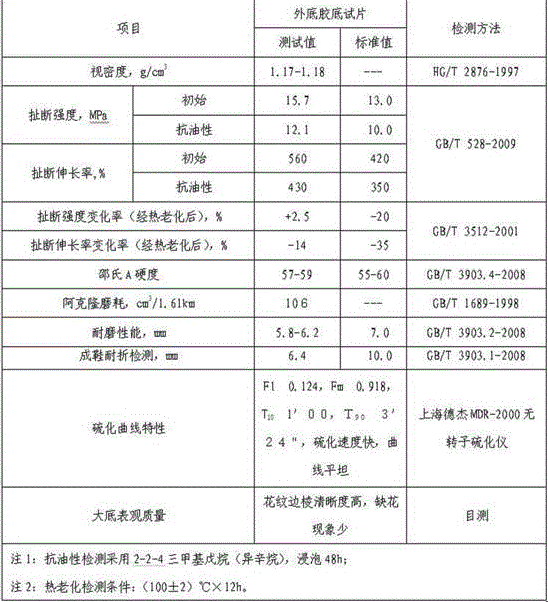

Oil-resistant and abrasion-resistant dual-density shoe rubber outsole and preparation method thereof

The invention discloses an oil-resistant and abrasion-resistant dual-density shoe rubber outsole. Original ingredients are in reasonable compatibility, natural rubber, butadiene rubber and chloroprene rubber serve as main materials and are matched with other accessory ingredients capable of achieving good co-vulcanization of the natural rubber and the chloroprene rubber, and the advantage of considering manufacturability and physical and chemical properties of vulcanized rubber is achieved. The invention further provides a preparation method of the rubber outsole. The method includes the steps of rubber plastifying, sizing material co-smelting, sizing material banburying, sizing material mixing, manufacturing of the rubber outsole and the like in sequence. The method is simple, the process is easy to control, and the prepared shoe outsole is moderate in hardness and good in durability and abrasion resistance. The preparation method is suitable for preparation of shoe rubber outsoles, rubber tubes, sealing rings and other rubber objects.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Manufacturing method of sports skateboard

A manufacturing method of a sports skateboard includes the steps: selecting the materials of a board core; machining a groove; manufacturing a PU lateral strip; manufacturing the board core: curing the board core with the PU lateral strip in the groove, and placing on a machining part again to manufacture the board core required by design through computer program control; molding the skateboard: wrapping the board core with glass fiber or carbon fiber materials, brushing resin on the board core wrapped with the glass fiber or carbon fiber materials, placing the board core with the resin between a bottom board and a surface board and jointly placing into a mold, performing compression molding in the mold with pressure being 6-8MPa and temperature being 80-90 DEG C, and stripping the mold to obtain the sports skateboard. The manufacturing method of the sports skateboard has the advantages that the method is simple in process, high in automation level, high in efficiency, high in machining precision, high in procedure flexibility, wide in application range, simple in temperature and pressure requirements, low in energy consumption, few in requirements and low in cost, many kinds of materials can be selected, and the sports skateboard can be used normally in a wet and slippery environment due to the fact that an antiskid pad is adhered to the sports skateboard.

Owner:沈爱甫

Continuous casting mold flux for special-shaped blank low-carbon steel

The invention provides a continuous casting mold flux for special-shaped blank low-carbon steel and belongs to the technical field of steelmaking auxiliary materials. This flux comprises, in percent by weight: 7.5-47.5% of CaO3, 34-42% of SiO2, 0.2-2.8% of Fe2O3, 2-5% of MgO, 3.5-5.5% of Al2O3, 3-7% of R2O, 4.0-8.0% of F, 1.12-1.25 of CaO / SiO2. The flux is used for continuous casting of special-shaped blank low-carbon steel, it is possible to observe the flux to flow and spread well in the mold and melt uniformly and to evenly cover molten steel level with no cluster on the level, full lubrication of a casting blank is ensured, the obtained casting blank has evidently reduced cracks, and the chance for the casting blank to crack is less than 0.10%.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Square seasoned duck steak and manufacture method thereof

InactiveCN108041471AHas the effect of nutritional complementarityRich in proteinFood scienceSodium bicarbonateMonosodium glutamate

The present invention discloses a square seasoned duck steak and a manufacture method thereof. The square seasoned duck steak is prepared from the following raw materials: duck meat, edible salt, white granulated sugar, monosodium glutamate, super I+G, garlic powder, lemon essence, beef extract, carrageenan, shallot oil, ginger powder, rosemary, black pepper powder, glucose, soy sauce, salad oil,corn modified starch, ice water, sodium bicarbonate, sodium carbonate, sodium citrate, fructooligosaccharides, polydextrose, Chinese chestnuts, marinating materials, phosphate starch, sodium starch octenyl succinate, xanthan gum, maltodextrin, glucono-delta-lactone, trehalose and sodium alginate. Beneficial effects are as follows: non-medicine residual duck breast meat is used, and the square seasoned duck steak is rich in protein content, has effects of supplementing nutrition, and is healthy and delicious food, and in line with concepts of modern healthy life. The square seasoned duck steakis prepared by processes of rolling and still-putting, the technology is simple, and the prepared square seasoned duck steak is flexible in mouthfeel inside and strong in meat appearance.

Owner:诸城外贸有限责任公司

Method for manufacturing extrusion molding sculptured natural glazed wood grain bricks

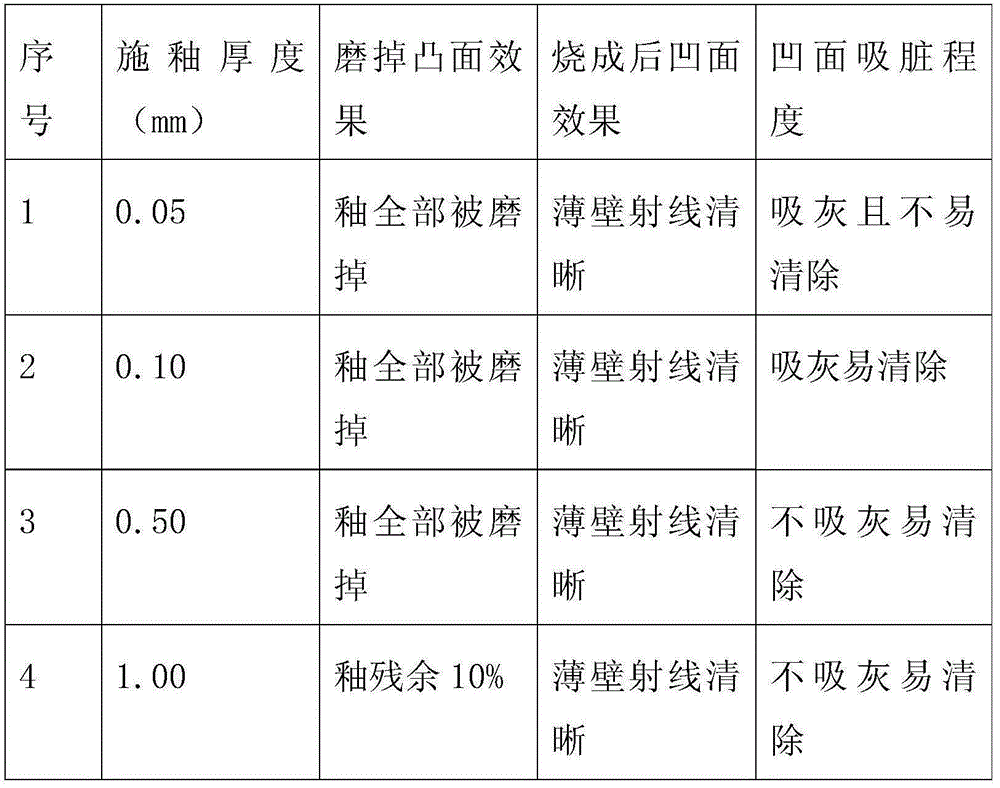

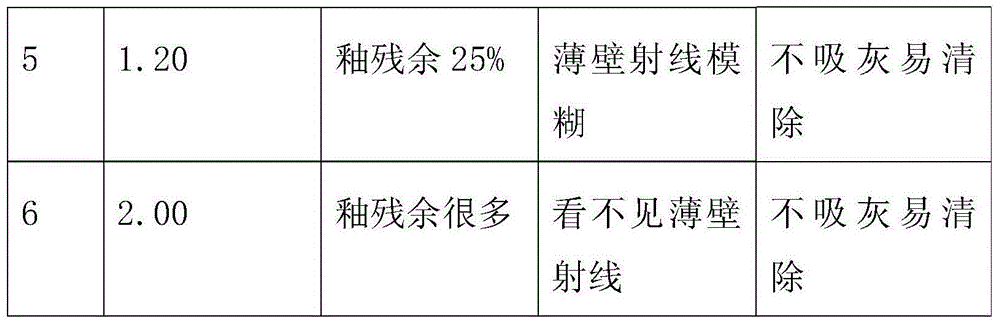

ActiveCN104591792AImprove realismCraftsmanshipCeramic shaping apparatusEmbossing decorationsCeramic glazeThin walled

The invention relates to a method for manufacturing extrusion molding sculptured natural glazed wood grain bricks. Natural wood grain bricks with very realistic effects can be manufactured, and the bricks can be manufactured under the conditions that the moisture content of the green brick is larger than 16 percent and the diameter of a wood grain carving roller is larger than the green brick cutting length. The method comprises the following manufacturing steps: 1. pressing the green brick by virtue of a stereoscopic carving sculptured wood grain roller so as to enable the texture of the pressed green brick to have the texture and sculpture which are consistent with those of the original wood plate xylem and thin-walled rays; and 2. cutting each green brick into a green brick with the needed length after pressing, and drying in a drying kiln so as to reduce the moisture of the green brick to be 1 percent or below, applying matt or dull glaze with contrast from the color of the green brick of the ceramic tiles on the surface of the green brick, erasing the glaze on the protruding part of the glazed body, remaining the glaze in the concave texture, filling the glaze, firing the tiles in a kiln so as to form contrast between the color of the green brick and the color of the embossing, thereby obtaining the wood grain ceramic bricks. The process is ingenious, the green brick has clean patterns, and contrast is formed between the color of the green brick and the color of the embossing. Therefore, natural wood grain ceramic bricks of which the patterns are different from one another are obtained.

Owner:肇庆市来德利陶瓷有限公司

Vacuum forming equipment-based precision casting method of casting products

ActiveCN104475679AHigh surface regularityCraftsmanshipFoundry mouldsFoundry coresProduction lineMachining process

The invention discloses a vacuum forming equipment-based precision casting method of casting products. The method comprises the following steps by a vacuum forming production line: a, vacuum forming; b, casting cooling; c, taking out of casting; d, sand recovery; repeating the steps a-d until the precision casting of all the casting products is finished. The vacuum forming equipment-based precision casting method of casting products is ingenious in process and high in automation degree; through the vacuum forming production line, the steps such as vacuum forming, casting cooling, taking out of casting and sand recovery are respectively completed and the steps are repeated until the precision casting of all the casting products is finished, so that the connection of links in the production process is smooth and the operation is more convenient; both the vacuum forming and the casting cooling are carried out under vacuum condition, so that the surface regularity of the casting products is high the subsequent complicated secondary machining process can be eliminated and the product value is greatly improved.

Owner:FUJIAN BAOSHAN MACHINERY

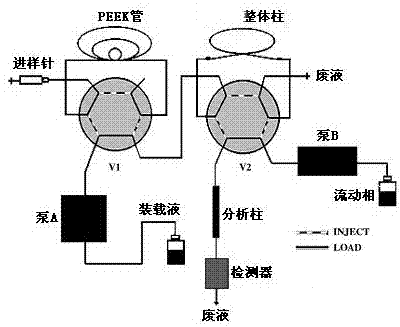

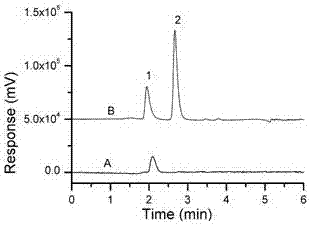

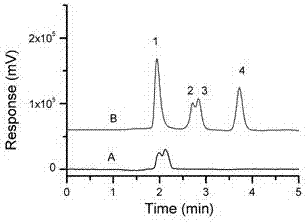

Solid phase microextraction method of unsaturated fatty acid

ActiveCN107290455AEasy to separateMeet the requirements of efficient detectionComponent separationIodo fatty acidSolid-phase microextraction

The invention discloses a solid phase microextraction method of unsaturated fatty acid. A silver nanoparticle immobilized monolithic column is used as a solid phase microextraction monolithic column, and the solid phase microextraction method of unsaturated fatty acid is established in combination with an in-tube solid phase microextraction-high performance liquid chromatography system. The unsaturated fatty acid is enriched under the interaction of silver nanoparticles on the surface of the monolithic column and carbon-carbon double bonds of the unsaturated fatty acid; different isomers of the unsaturated fatty acid are sequentially eluted under different acting forces between the silver nanoparticles and the isomers of the unsaturated fatty acid. The method is simple, the process is ingenious, required instruments have higher popularization degree, the method is easy to popularize, efficient enrichment of the unsaturated fatty acid and sequential elution of different cis-trans-isomers can be realized, and the efficient detection requirement of trans-fatty acid can be met.

Owner:FUZHOU UNIV

Method for preparing sodium alginate based on powder form absorption and separation

The invention discloses a method for preparing sodium alginate based on powder form absorption and separation. The method comprises the following steps: S1, carrying out pretreatment; S2, carrying outabsorption and separating; S3, carrying out digestive foaming; S4, filtering; S5, carrying out calcification and decalcification; S6, neutralizing for realizing replacement. According to the method,silicon dioxide aerogel powder is added into powdered kelp liquid, the powdery kelp liquid is enabled to stand still so as to form a layered state by means of the absorption characteristics of the silicon dioxide aerogel powder, and a filtering membrane is cooperatively used for realizing filtration and separation; the method is ingenious in process, and enables the extraction of the powdered kelpnot to be affected while enabling the kelp to fully absorb formaldehyde for realizing fixation. The absorption way of the method provided by the invention is more convenient and quicker than that ofsponge.

Owner:江苏中大生物科技集团有限公司

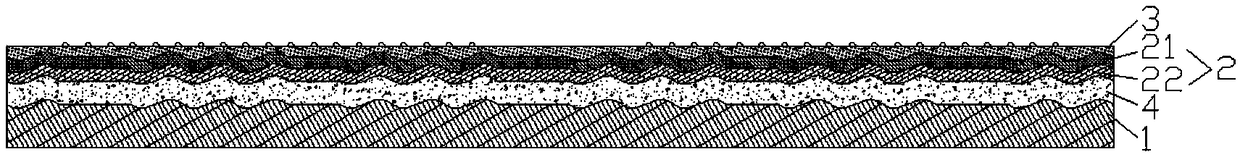

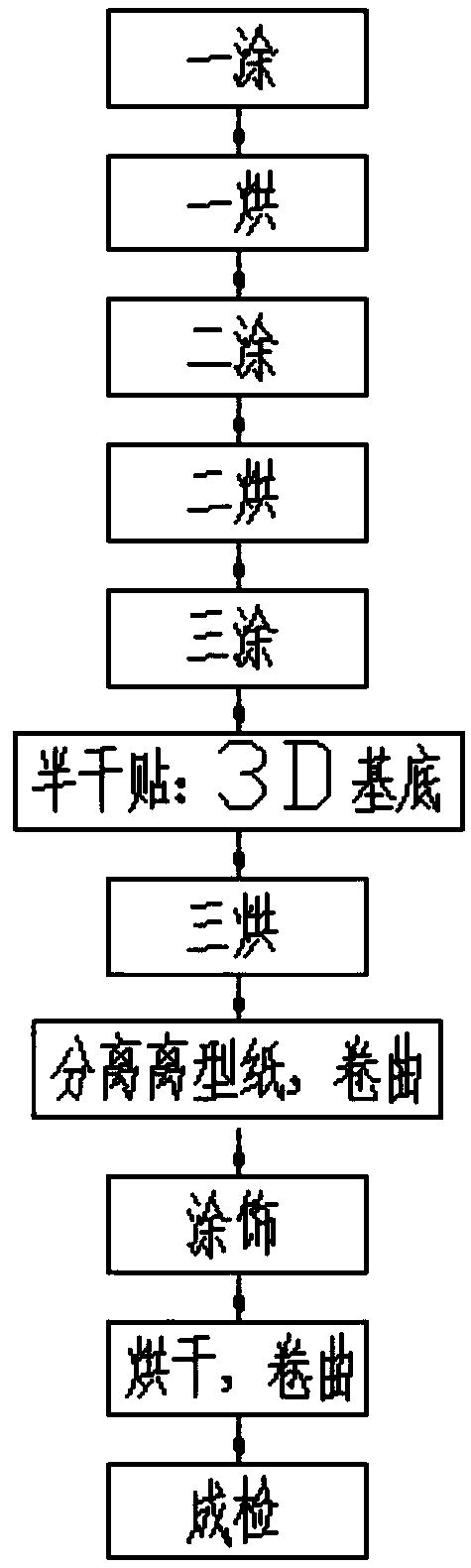

PU (polyurethane) composite leather with 3D effect and preparation method of PU composite leather

InactiveCN108729252AHigh degree of bonding integrationDurableVehicle componentsTextiles and paperSolvent freeFire retardant

The invention discloses PU (polyurethane) composite leather with a 3D effect. The leather successively comprises a 3D basal layer, a PU composite layer and a finishing layer, a bonding agent layer isarranged between the 3D basal layer and the PU composite layer, a solvent-free PU bonding agent serves as the raw material of the bonding agent layer, the finishing layer is a waterborne finishing layer, the PU composite layer comprises a PU monolayer and a high solid layer, and the PU monolayer is prepared from the following raw materials in parts by weight: 95-105 parts of PU resin, 62-70 partsof DMF (dimethyl formamide), 13-16 parts of acetic ether and 7.5-9 parts of color paste; the high solid layer is prepared from the following raw materials in parts by weight: 95-105 parts of high solid resin, 6-7.5 parts of cross-linking agent, 2.5-4 parts of propylene glycol methyl ether acetate, 12-16 parts of fire retardant, 0.55-0.7 part of flatting agent, 0.25-15 parts of color paste and 0.6-1 part of foaming agent. According to the PU composite leather with the 3D effect and the preparation method of the PU composite leather, base cloth is removed compared with previous PU composite materials, the materials are lighter, and the supporting performance is strong; before the process of automotive trim forming, the process in which PU leather is combined with 3D is left out, and the costis reduced when the PU composite leather has a prominent 3D effect.

Owner:SUZHOU RUIGAO NEW MATERIAL CO LTD

Preparation method of zeolite microsphere sound-absorbing material

ActiveCN107083047ACraftsmanshipShort preparation processElectrical transducersAnhydrous ethanolMicrosphere

The invention relates to a preparation method of a zeolite microsphere sound-absorbing material. The method comprises the steps of preparing a polyurethane solution with the concentration of 5-20%; placing the polyurethane solution on a magnetic stirrer to stir at a constant rate for 1-2 h; mixing zeolite materials with anhydrous ethanol to prepare a zeolite suspension, and using the magnetic stirrer to stir and make the zeolite suspension even; mixing the zeolite suspension with the polyurethane solution according to the mass ratio of 1:1 to prepare an electronic fuel injection liquid, and placing the electronic fuel injection liquid on the magnetic stirrer to stir at a constant rate for 1-2 h; adopting an electrostatic spraying technology to obtain the zeolite microsphere sound-absorbing material. The preparation method adopts the electrostatic spraying technology to prepare the zeolite microsphere sound-absorbing material, and has the advantages of artful technology, short preparation process, simple control and convenient operation.

Owner:苏州夸克新材料科技有限公司

Workpiece flange forming method and mould

ActiveCN104826906AReduce residual stressSolving Elasticity ProblemsShaping toolsPlastic propertyFlange

The present invention discloses a workpiece flange forming method and mould. The workpiece flange forming method comprises a material pressing step and a forming step. In the material pressing step, a workpiece is pressed and a to-be-flanged part is exposed; in the forming process, a forming force is applied to one side of the to-be-flanged part and a supporting force which is smaller than the forming force is applied to the other side of the to-be-flanged part, so that the to-be-flanged part is gradually turned and folded towards an edge which is far away from the pressed part. Therefore, different from a manner of overturning the whole part of the to-be-flanged part in the prior art, the flaning process provided by the present invention is used for gradually turning and folding the to-be-flanged part, that is, the whole material of the to-be-flanged part is gradually subjected to once plastic deformation process from the pressed part in the turning and folding process, so that the residual stress to the to-be-flanged part is further eliminated and the to-be-flanged part can be flanged once with high quality; and the problems that a flanged edge is restored, and has folds and turning and folding line traces are solved, and the process is simple and ingenious.

Owner:BEIQI FOTON MOTOR CO LTD

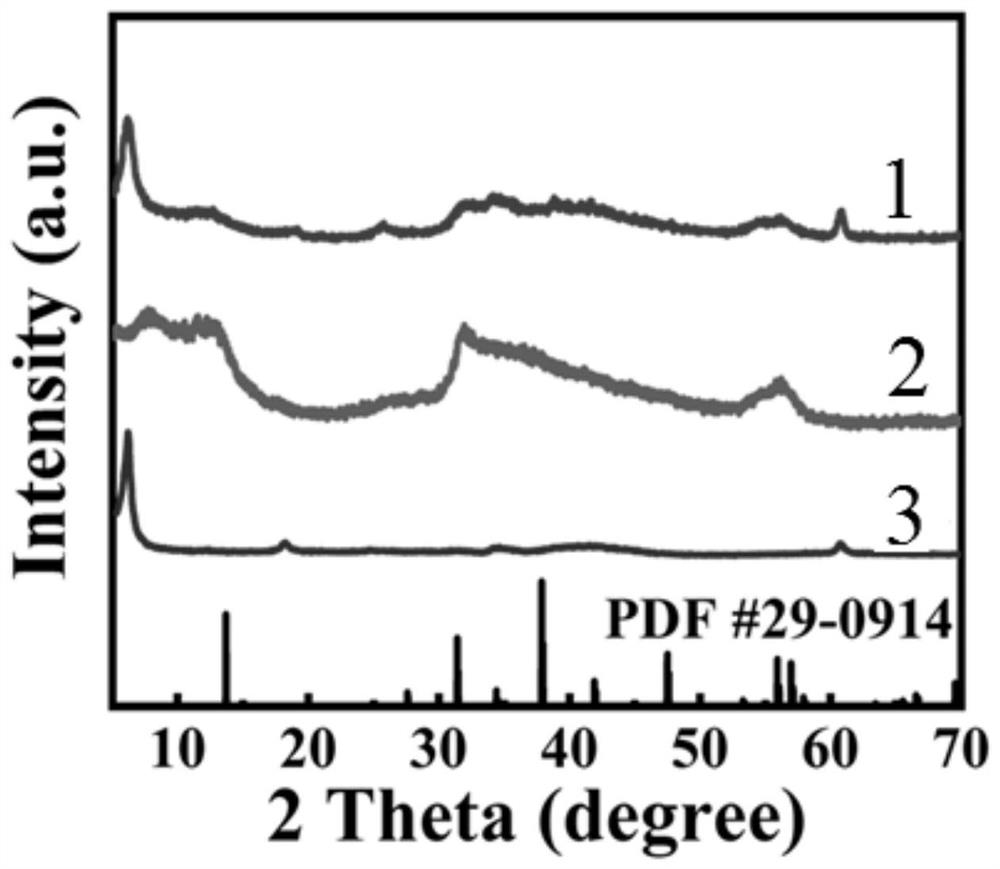

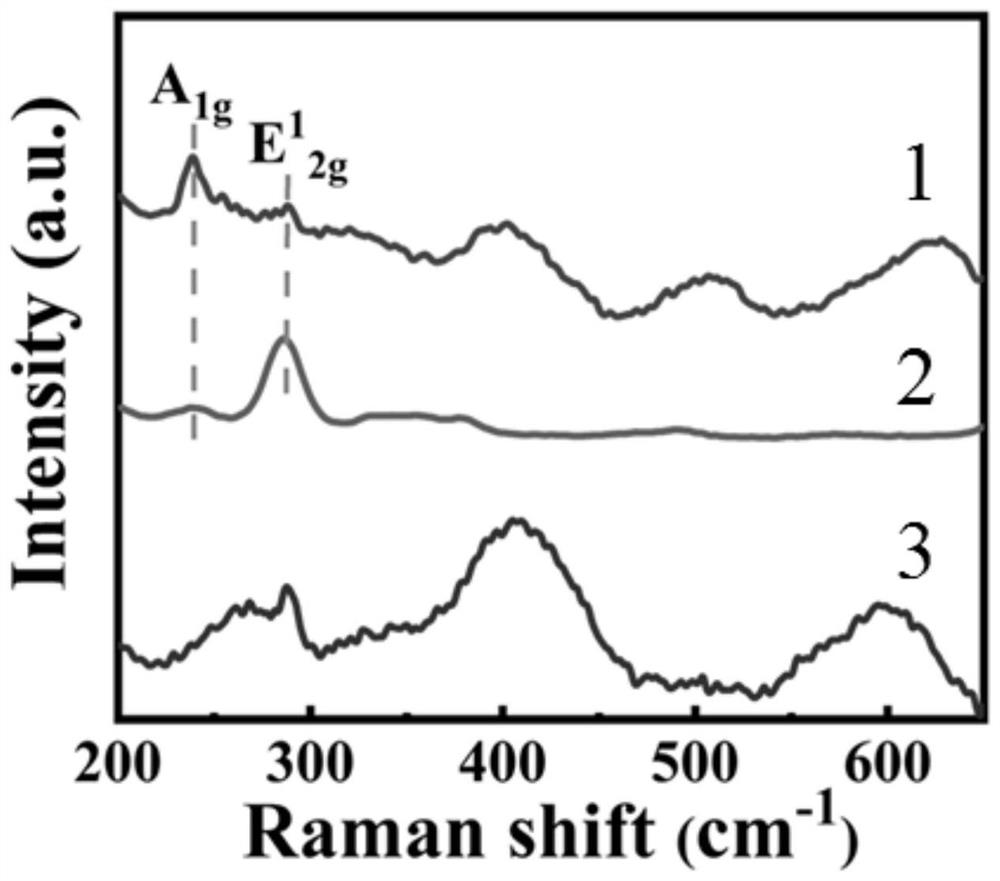

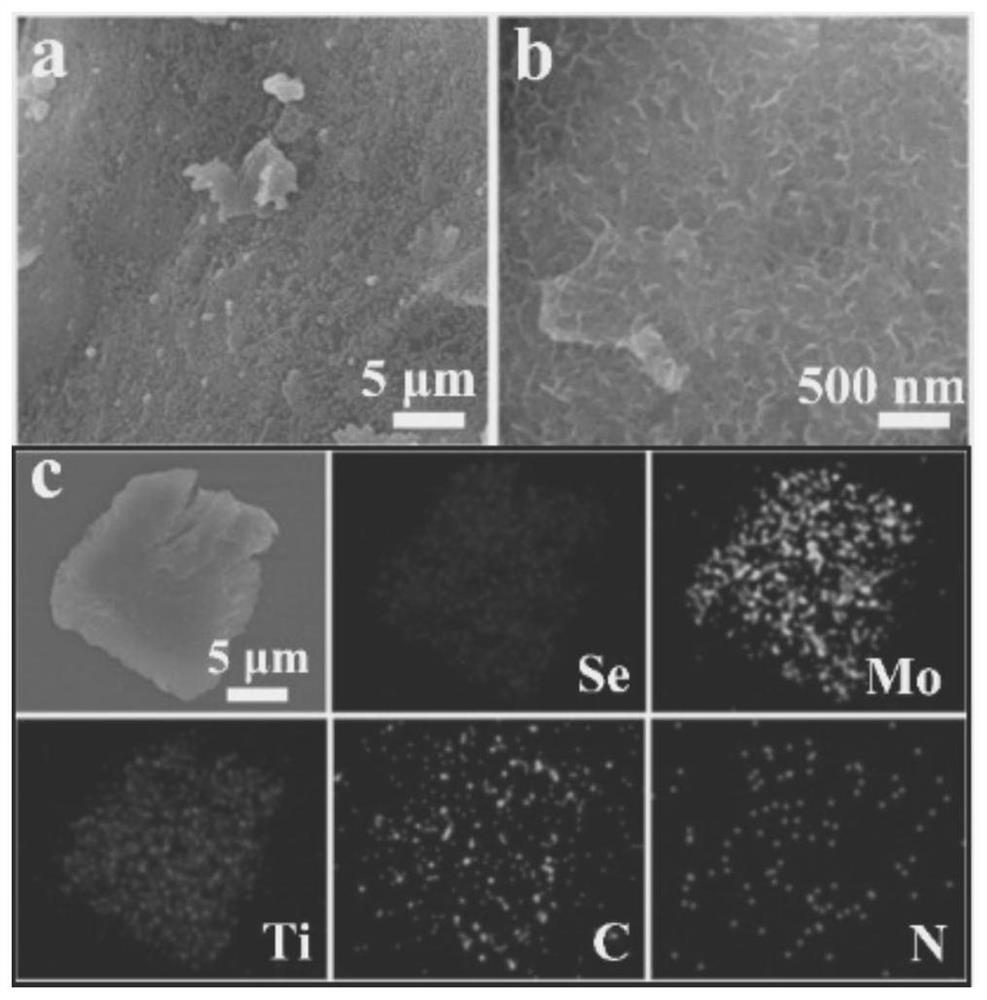

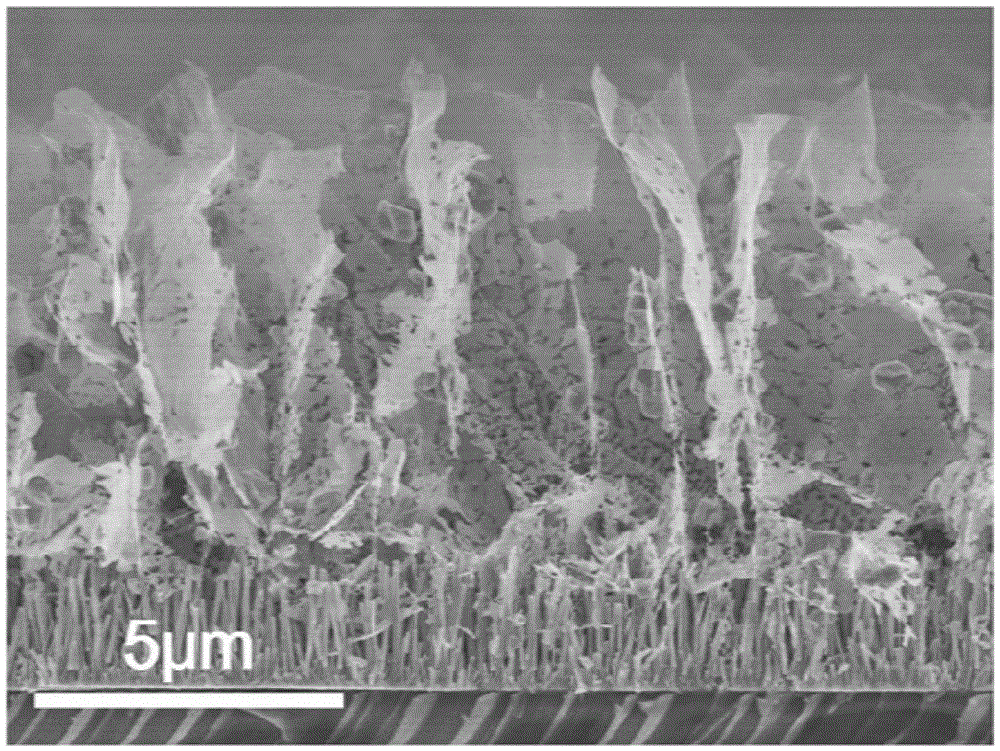

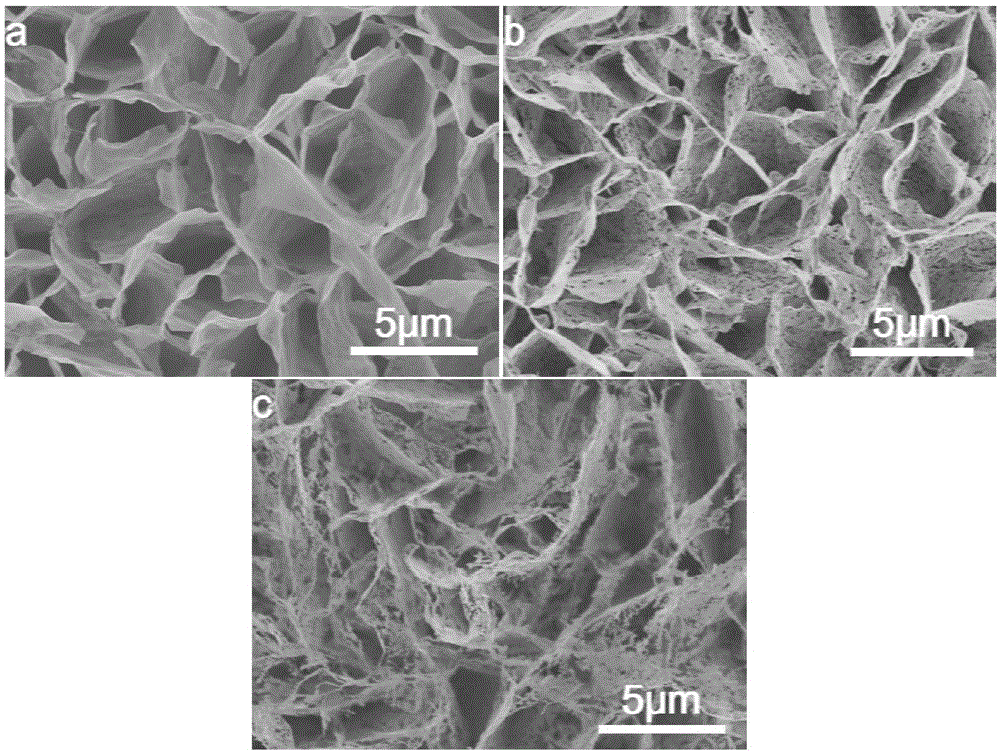

Two-dimensional titanium carbide supported stable biphase molybdenum diselenide composite material and preparation method and application thereof

ActiveCN113249751AGood charge conductivityAvoid stackingEnergy inputNanotechnologyPtru catalystTitanium carbide

The invention discloses a two-dimensional titanium carbide supported stable biphase molybdenum diselenide composite material as well as a preparation method and application thereof, and relates to a composite hydrogen evolution catalyst and a preparation method thereof. The invention aims to solve the problems of high cost and poor stability of the existing electrocatalytic hydrogen evolution catalyst. The two-dimensional titanium carbide supported stable biphase molybdenum diselenide composite material contains an N element with the atomic percentage being 0.2%-5%, titanium carbide serves as a conductive framework of MoSe2 nanosheets to form three-dimensional network structures which are communicated with one another, and the MoSe2 nanosheets evenly grow on the surface of the titanium carbide in an in-situ mode. The method comprises the following steps of: 1, preparing a Na2MoO4-Ti3C2 solution; 2, preparing a Se-N2H4 solution; and 3, mixing and carrying out hydrothermal reaction. The two-dimensional titanium carbide supported stable two-phase molybdenum diselenide composite material is used as a catalyst for producing hydrogen by electrolyzing water. The two-dimensional titanium carbide supported stable two-phase molybdenum diselenide composite material can be obtained.

Owner:HARBIN NORMAL UNIVERSITY

Simple cow split leather color changing technology

ActiveCN105133398AHigh degree of depigmentationReasonable control of process parametersDyeing processSocial benefitsEconomic benefits

The invention discloses a simple cow split leather color changing technology which comprises the steps of cow split leather weighing, water returning, decolorization, retanning, dyeing, liquid expansion, color fixation and emergence and stacking. The raw materials are semi-finished leather blanks, scientific processing is carried out, technological parameters are reasonably controlled, the decoloration degree of the leather blanks is high, the cow split leather is bright and uniform in color, soft and comfortable after dyeing is carried out again, a leather board is solid, and no adverse influence is produced on the fiber strength. By carrying out decolorization and retanning on the semi-finished cow split leather blanks, the leather blanks can be recolored again, and the product is non-toxic and environmentally friendly. The simple two-layer cow leather color changing technology can be applied to secondary production of leather, a new path is developed for secondary utilization of the leather blanks, the flexibility and safety of business operation can be greatly improved, and the economic benefits and social benefits are remarkable.

Owner:CHINA LIGHT IND WUHAN DESIGN ENG

Production technology of grooved metal gasket

The invention discloses a production technology of a grooved metal gasket. The production technology comprises the following steps: 1) uniformly mixing rubber and powdered graphite with an accelerant according to a weight proportion of 5:2:2 for future use; 2) placing the mixture in a mold, placing the mold in a heating furnace, controlling the initial furnace temperature to be lower than 200 DEG C, raising the temperature to 500 DEG C, keeping the temperature for 3-4 hours, continuously raising the temperature to 1200-1300 DEG C, keeping the temperature for 2-4 hours, cooling the mold in the furnace to 750 DEG C, and carrying out stabilized thermal treatment in an argon environment; 3) taking out the sheet, placing the sheet in a vulcanizing machine, rolling and vulcanizing for 30-40 minutes under a condition that the temperature is 300-350 DEG C; 4) taking out the vulcanized sheet, using running water to rinse the sheet, and drying the sheet with induced draught equipment. The production technology disclosed by the invention is simple to operate and ingenious in the technology; the produced sealing gasket is not liable to abrade and durable in use.

Owner:无锡市新颖密封材料厂

In-situ synthesis of cadmium oxide nanometer gas-sensitive element with secondary pore structure

InactiveCN105548274AOvercome the problem of easy reunionHigh selectivityDecorative surface effectsMaterial resistanceDiethyl etherNitrogen gas

The invention discloses a cadmium oxide nanometer gas-sensitive element with a secondary pore structure. The cadmium oxide nanometer gas sensitive element is synthesized through the following steps: with ethylene glycol monomethyl ether as a solvent, preparing a mixed solution of 0.1 M of zinc acetate and 0.2 M of ethanolamine, soaking a glass slide into the mixed solution, and carrying out annealing treatment; preparing a mixed solution of 0.025 M of zinc nitrate and 0.025 M of hexamethylene tetramine, soaking the above-mentioned glass slide into the mixed solution, and carrying out heat-preserving so as to obtain a nanorod array of zinc oxide, wherein the nanorod array is used as a seed layer for growing cadmium oxide; placing cadmium sulfide (CdS) powder into an evacuated tubular furnace, placing an above-mentioned zinc oxide-grown substrate at a position 30 cm below the cadmium sulfide (CdS) powder, then introducing nitrogen and air, carrying out heating to 650 DEG C so as to obtain a nanosheet array of cadmium (Cd), and carrying out heat-preserving at 360 to 440 DEG C for 30 min so as to obtain a nanometer structure of cadmium oxide; and cutting the glass slide into a rectangular shape with a size of 0.5 cm * 1.0 cm, and carrying out coating with electrodes so as to prepare the gas-sensitive element. The gas-sensitive element provided by the invention has the following advantages: at a temperature of 215 DEG C, sensitivity to diethyl ether with a concentration 100 ppm is 138%, and response time and recovery time are 15 seconds and 27 seconds, respectively; meanwhile, the synthetic process is simple, safe and controllable, has low cost and is applicable to large-scale production.

Owner:TIANJIN UNIV

Method for producing nickel-iron alloy by smelting red earth nickel mineral at low temperature

Owner:NEW METALLURGY HI TECH GRP

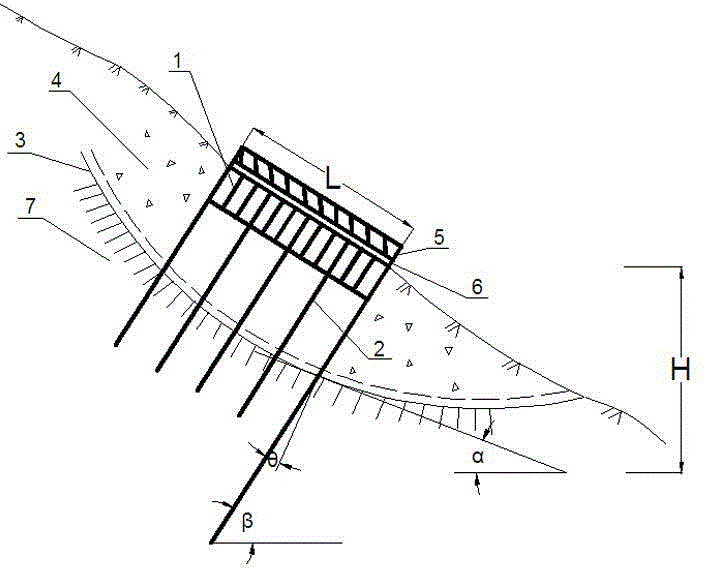

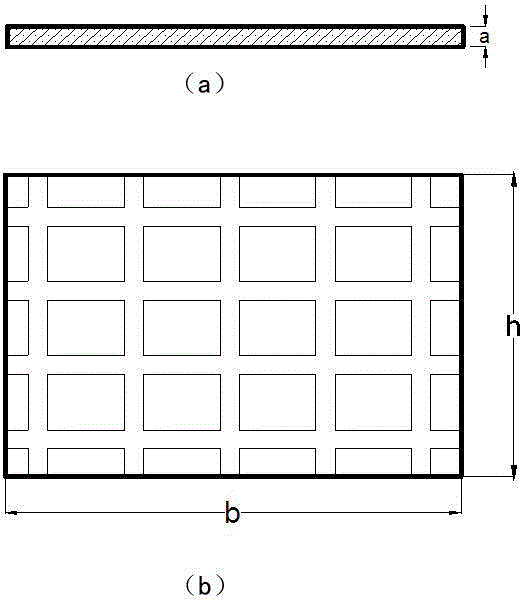

Soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid structure and soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid method

InactiveCN104652455AImprovement of mechanical parametersIncreased shear strengthExcavationsReinforced concreteLandslide

The invention provides a soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid structure and a soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid method. The soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid structure comprises a raft type lattice, anchor rods and anchor cables, wherein the raft type lattice comprises a raft foundation and lattice beams; the raft foundation is constructed on the surface of a control area and is of a beam plate type structure, a bottom plate of the raft foundation adopts a rectangular bidirectional plate, the thickness a of a raft is not smaller than 30cm, the plane dimension of the raft is b*h, and the unit of the plane dimension is m; the lattice beams which are arranged in a criss-cross way are constructed at the upper part of the raft foundation, and a reinforced concrete lattice is formed by the lattice beams; the expansive type anchor rods are uniformly arranged on the lattice beams, and the anchor cables are uniformly arranged at intersecting positions of the lattice beams. The soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid structure provided by the invention has the beneficial effects that a quasi-rigid body is formed by combined action of the expansive type anchor rods, a soil mass and the pre-stressed anchor cables, thus the shearing strength of a slip mass and the mechanical parameters of the soil mass are increased, and the integrated stability of the slip mass is greatly increased; the soil landslide raft type lattice-anchor rod-anchor cable combined anti-skid structure can be widely applied to slope control engineering and has the characteristics of flexible technology, wide applicability, quick construction speed, low manufacturing cost and the like; the operability is strong, and the practical value is large.

Owner:CHONGQING JIAOTONG UNIVERSITY

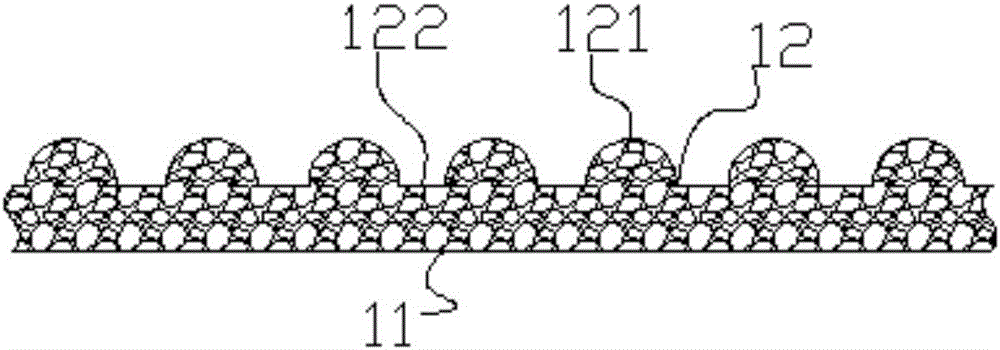

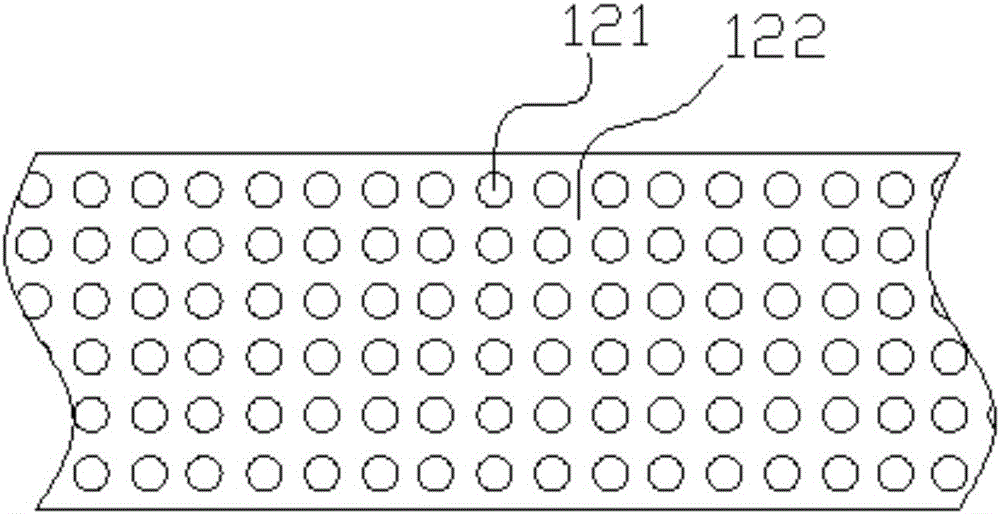

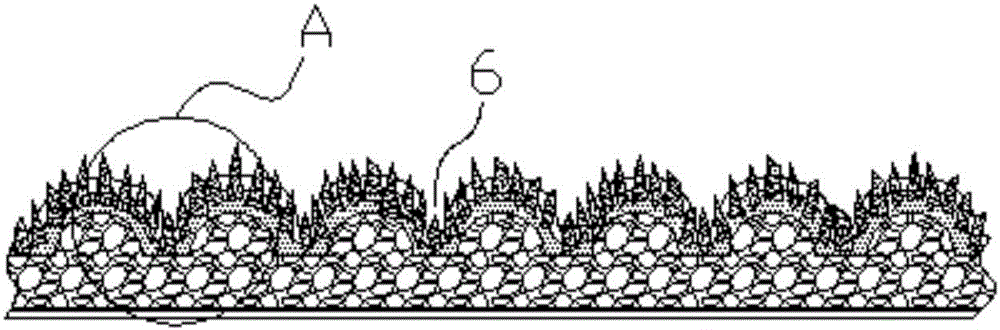

PVA elastic anti-blocking abrasive belt and manufacturing method thereof

ActiveCN106346381AWith grinding functionImprove grinding abilityAbrasion apparatusGrinding devicesAdhesive beltPolyvinyl alcohol

The invention relates to a PVA elastic anti-blocking abrasive belt and a manufacturing method thereof. The PVA elastic anti-blocking adhesive belt comprises apolyvinyl alcohol concave-convex sponge, a PVC soft film, a bottom rubber layer, a composite rubber layer and an abrasive material, wherein a front face of the polyvinyl alcohol concave-convex sponge is covered with dot patterns, namely, patterns formed by a plurality of hemispherical salient points arranged uniformly, and voids between adjacent salient points are connected to form a communicating groove; the PVC soft film is formed on the back face of the polyvinyl alcohol concave-convex sponge; the front face of the polyvinyl alcohol concave-convex sponge is coated with the bottom rubber layer; the upper surface of the bottom rubber layer is coated with the composite rubber layer; the lower end of the abrasive material is embedded into the bottom rubber layer, and the upper end of the abrasive material protrudes from the upper surface of the composite rubber layer; and recessed positions, corresponding to the communicating groove, of the surface of the abrasive belt communicate with one another to form a chip removal groove. The PVA elastic anti-blocking abrasive belt has the properties of blocking prevention and elastic grinding, and also the advantages of simple process, low equipment investment, low cost, wear resistance, long service life, no toxicity, and the like.

Owner:东莞市俊盛五金磨具有限公司

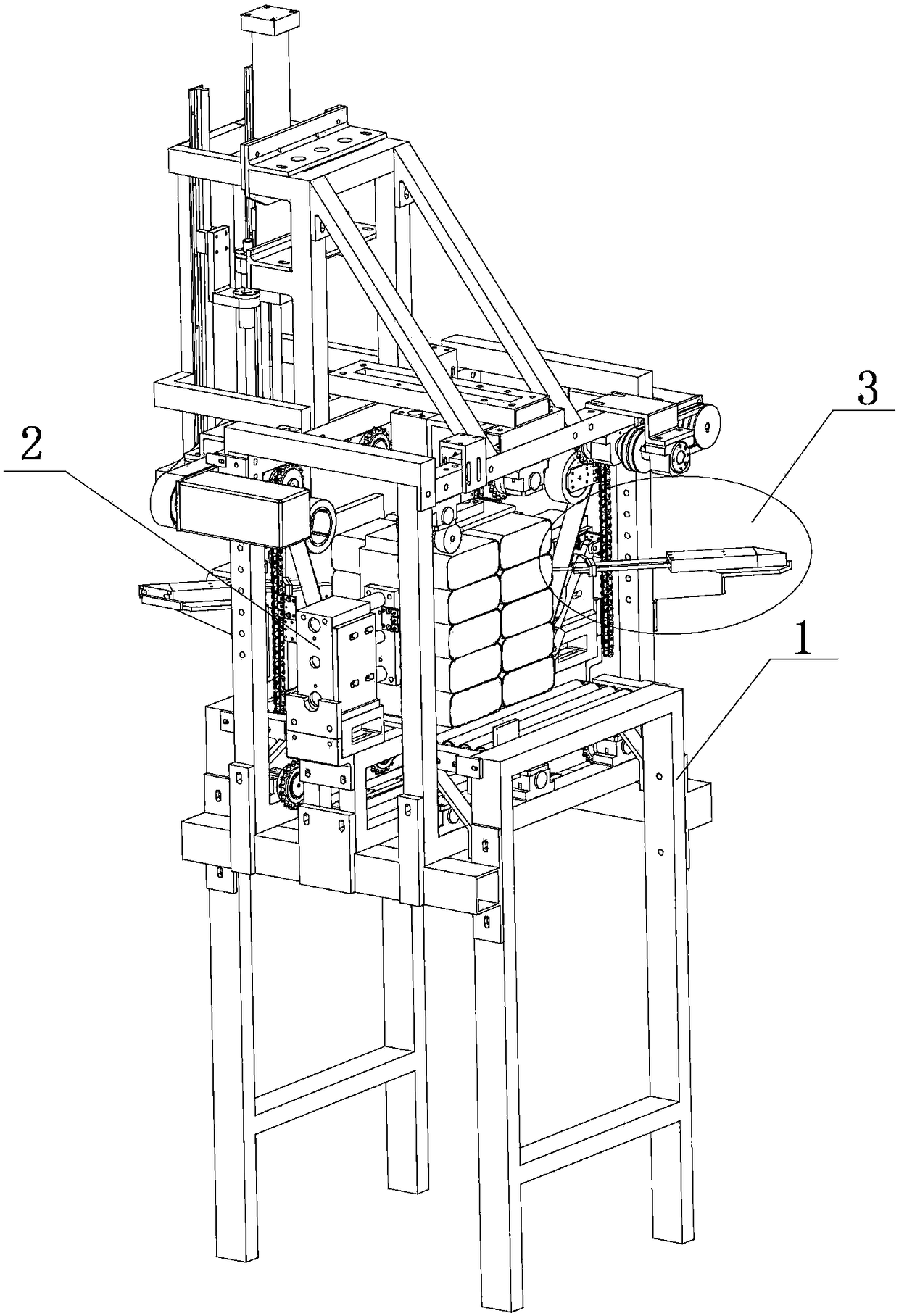

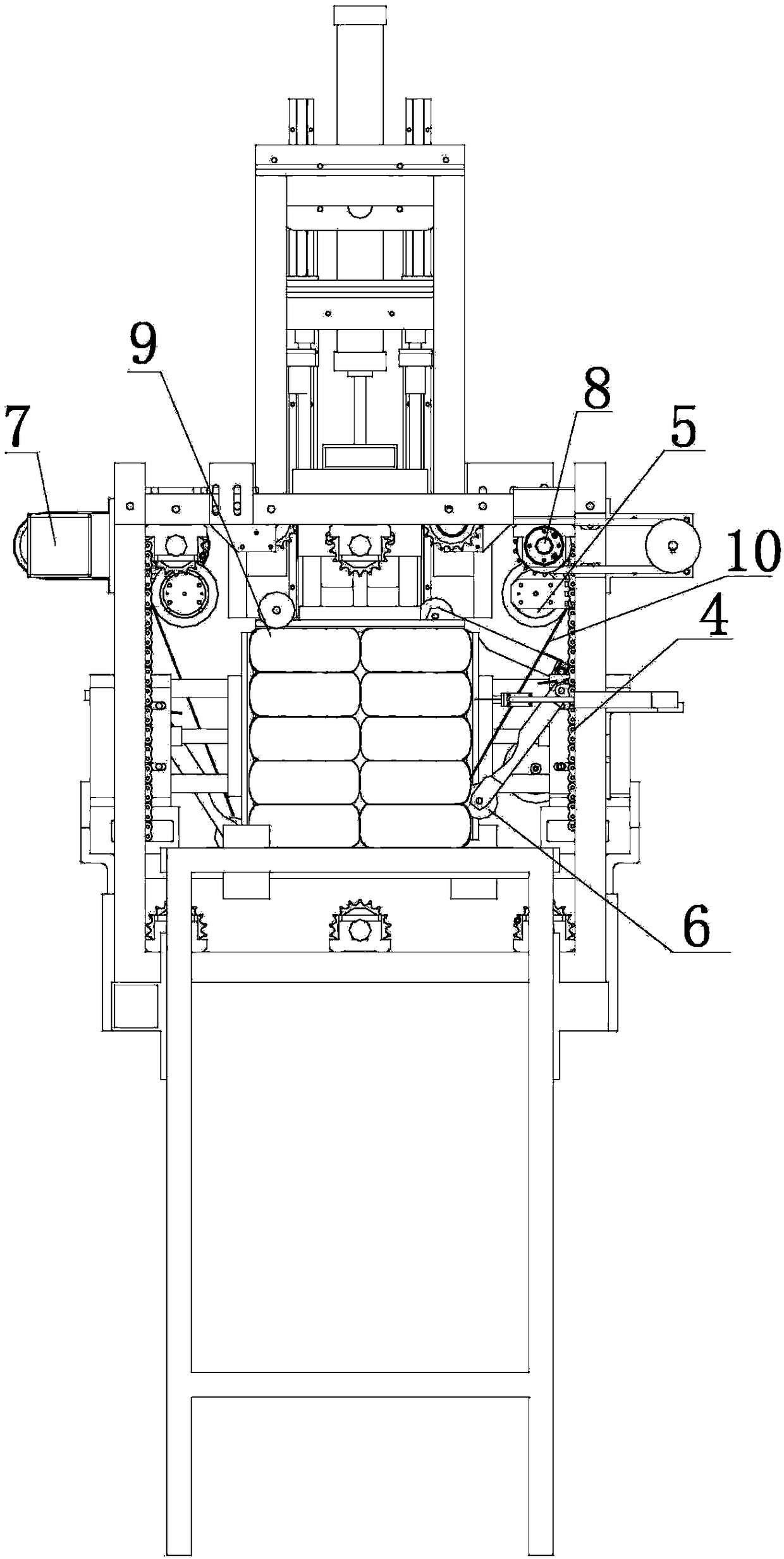

Toilet paper carton or bag sealing technology

InactiveCN108528786ACraftsmanshipReduce volumeWrapping material feeding apparatusWrappingMotor driveCarton

The invention relates to a toilet paper carton or bag sealing technology. According to the toilet paper carton or bag sealing technology, firstly, a plurality of toilet paper inner packages are evenlyand sequentially arranged on a platform of a toilet paper box sealing device and kept in a regular rectangle; after the positions of the toilet paper inner packages are adjusted, a motor of a plasticfilm wrapping device is started, the motor drives a chain to rotate, a plastic film roll and a pressing wheel which are fixedly arranged on the chain rotate along with the chain, the plastic film iswrapped around the toilet paper inner packages, the pressing wheel tightly presses the plastic film, and when the plastic film is wrapped to a certain extent, a cutting device is started to automatically cut the plastic film at a designated position; the toilet paper inner packages which are bundled together are conveyed to a box or bag sealing procedure, and then box or bag sealing is conducted.The toilet paper carton or bag sealing technology has the advantages that the toilet paper inner packages are arranged and bundled well on the outer side through a manual combination device, then thebox or bag is sealed, so that time is saved, the volume is reduced due to bundling, and the problems of insufficient packaging space and missing packaging are avoided.

Owner:江苏妙卫纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com