Patents

Literature

43results about How to "Meet ingredient requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purpose of heavy metal sludge, acid pellet and preparation method and purpose thereof

ActiveCN101805827AEnsure the quality of the furnaceImproving the Blast Furnace Charge StructureBlast furnace detailsHeavy metalsSludge

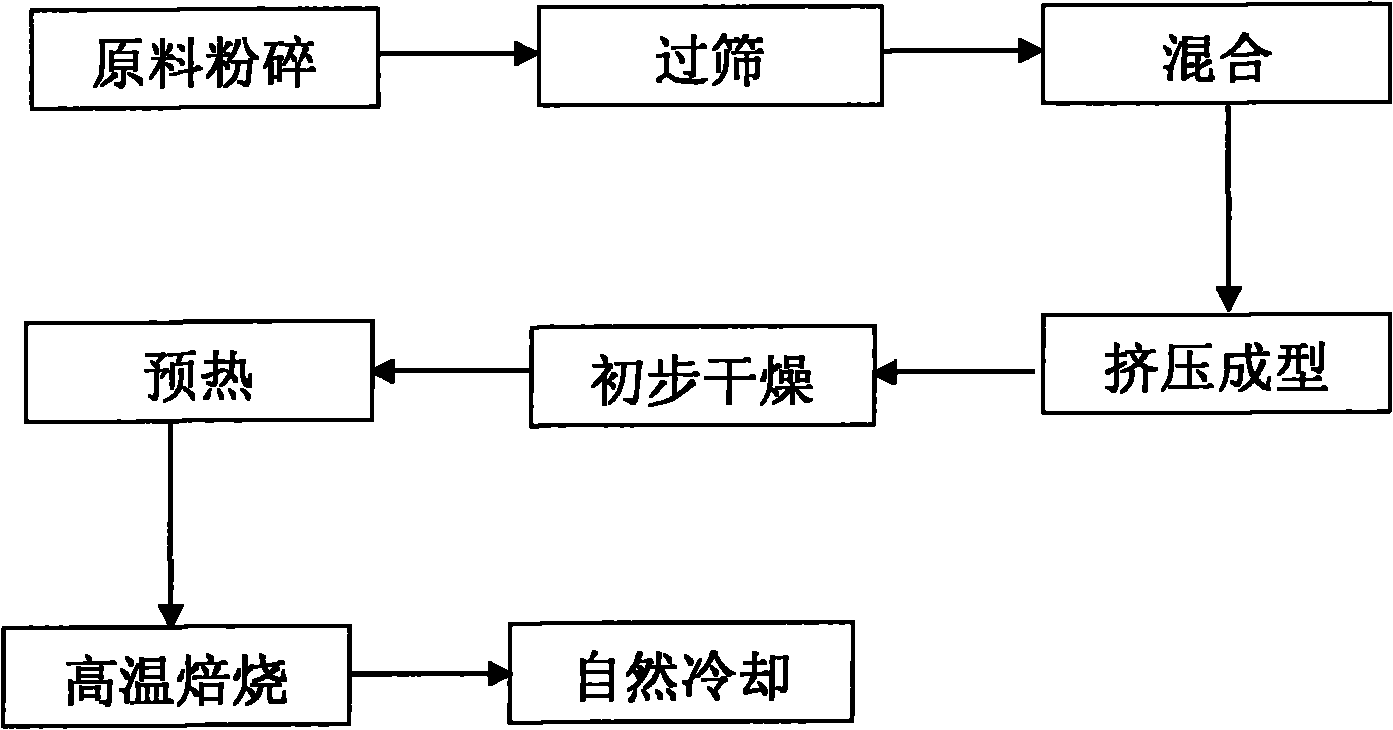

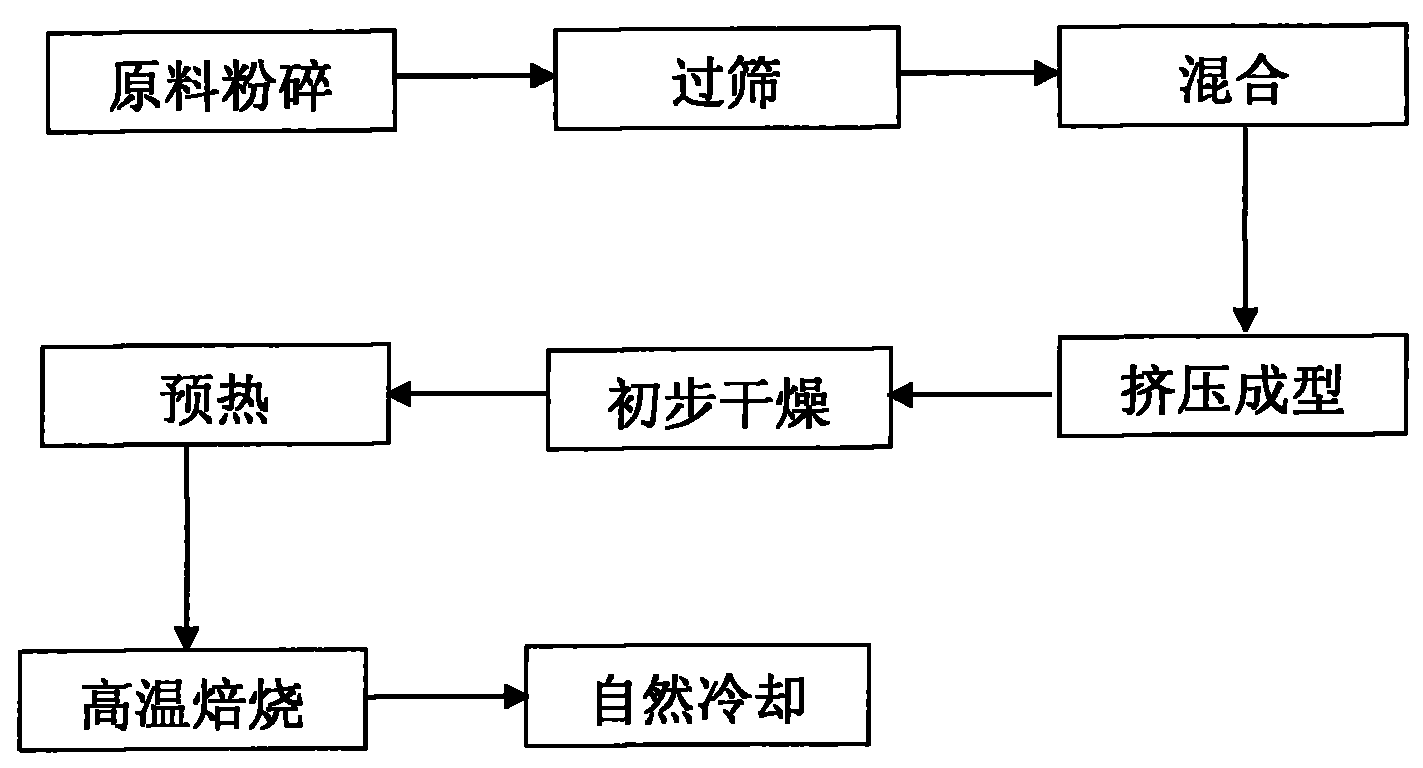

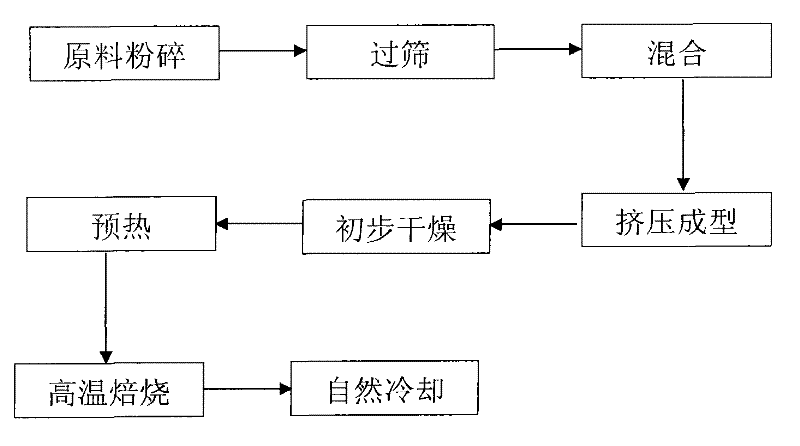

The invention discloses a purpose of heavy metal sludge, an acid pellet and a preparation method and a purpose thereof. The invention takes stainless steel cold-rolling heavy metal sludge as a raw material for preparing the acid pellet of the sludge. The acid pellet of the sludge is mainly prepared by the following raw materials by weight percent: 5-50 percent of stainless steel cold-rolling heavy metal sludge, 30-70 percent of iron ore concentrate, 2-8 percent of composite binding agent, 4-15 percent of carbon powder and 10-30 percent of water. The preparation method of the acid pellet of the sludge comprises the main steps of pretreatment of raw materials, mixing of raw materials, pelletizing and roasting. The acid pellet of the sludge is used as a raw material of a blast furnace. The invention solves the problems that the prior art can not effectively treat and comprehensively utilize the stainless steel cold-rolling heavy metal sludge.

Owner:BAOSHAN IRON & STEEL CO LTD

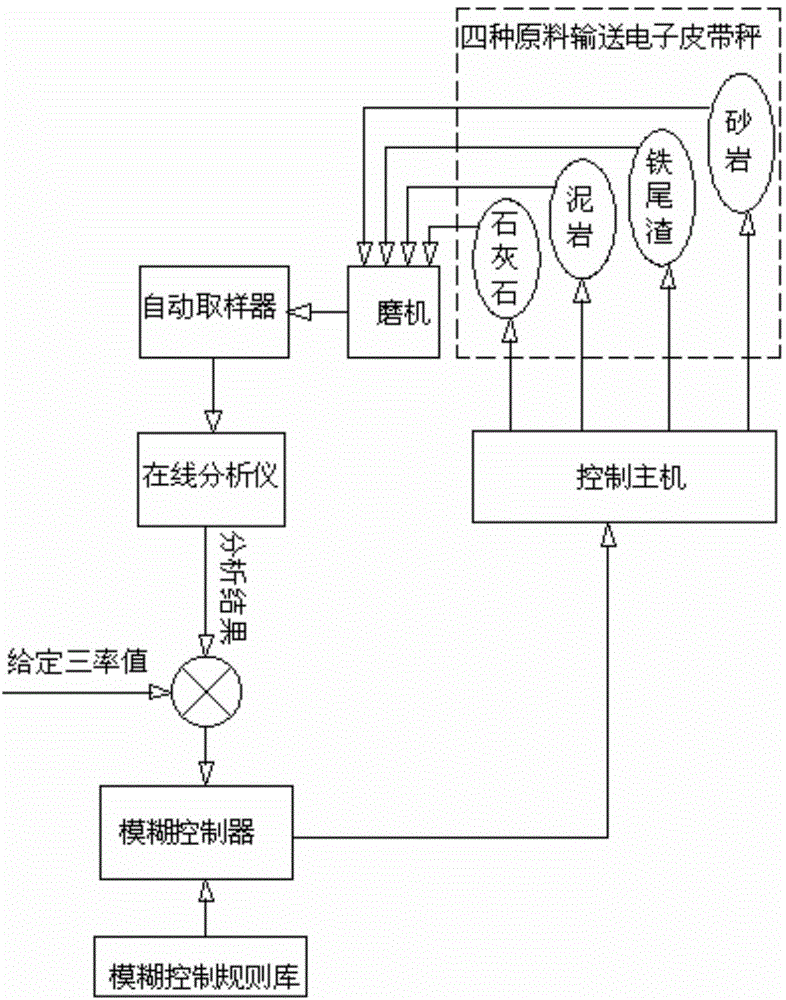

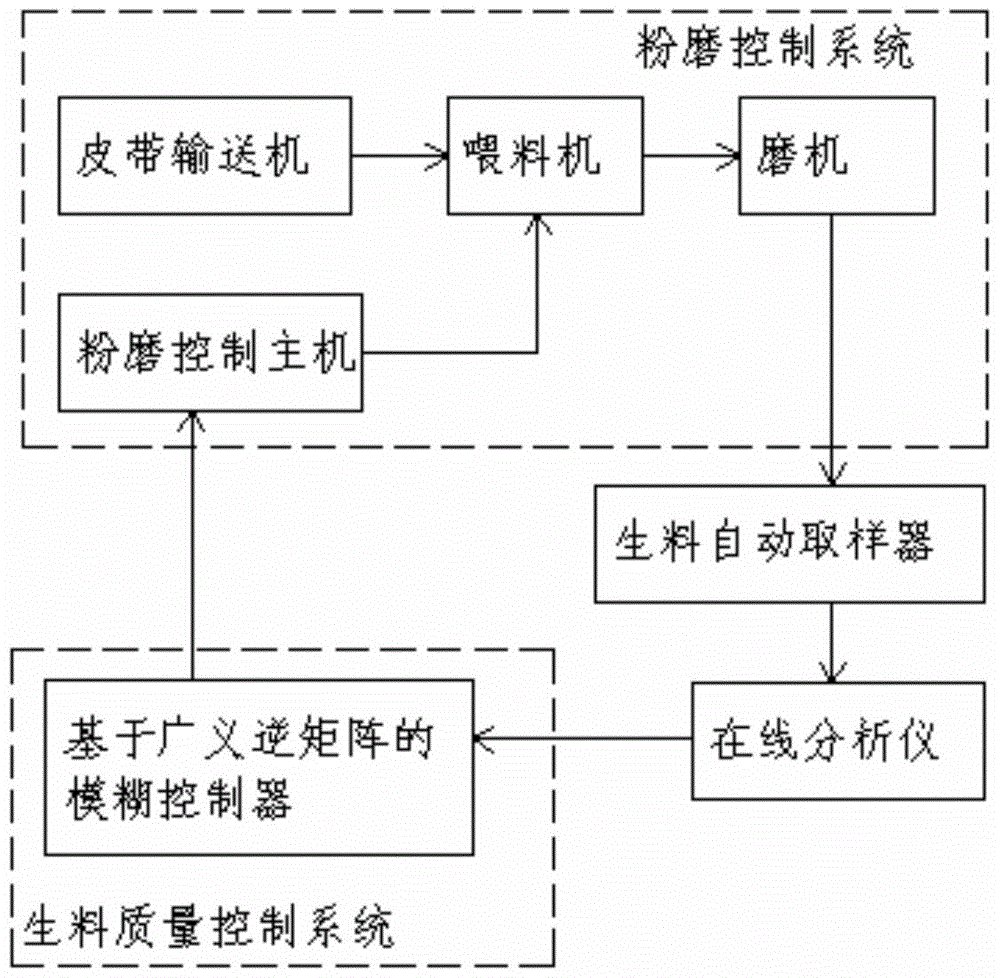

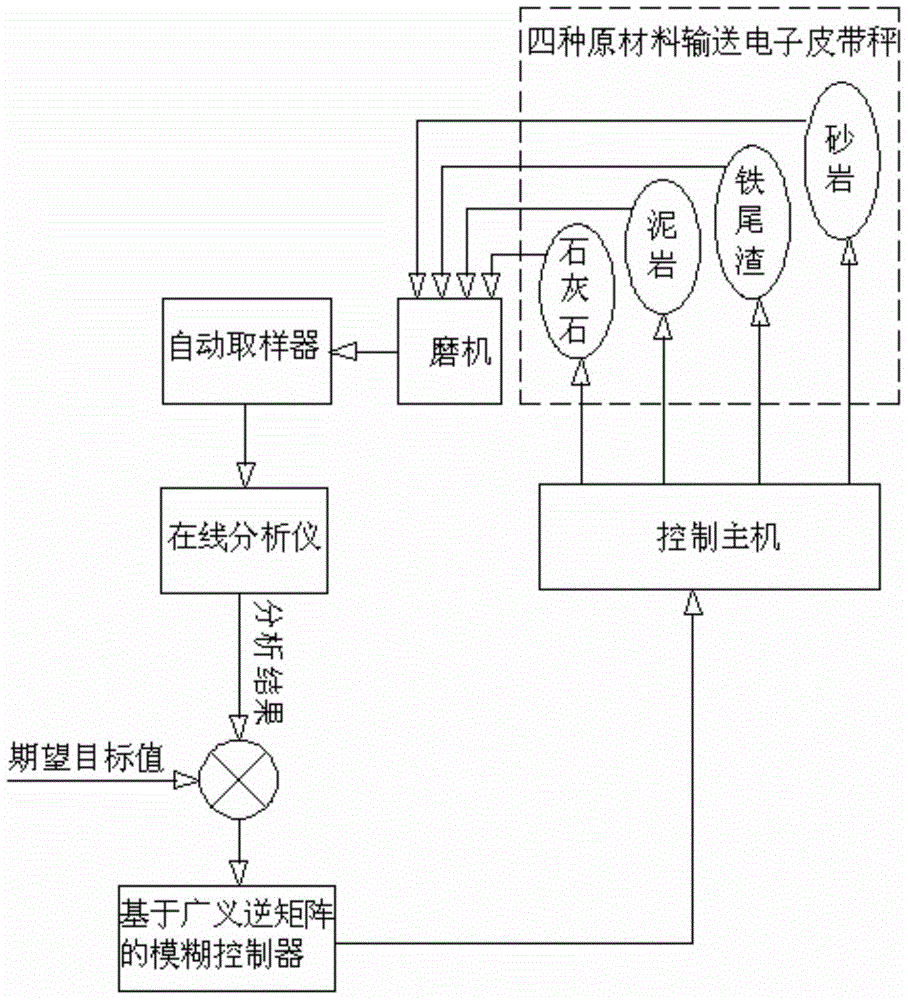

Cement raw material ingredient control system and method

ActiveCN104965532AQuality assuranceReduce volatilityControlling ratio of multiple fluid flowsAdaptive controlControl systemAdditive ingredient

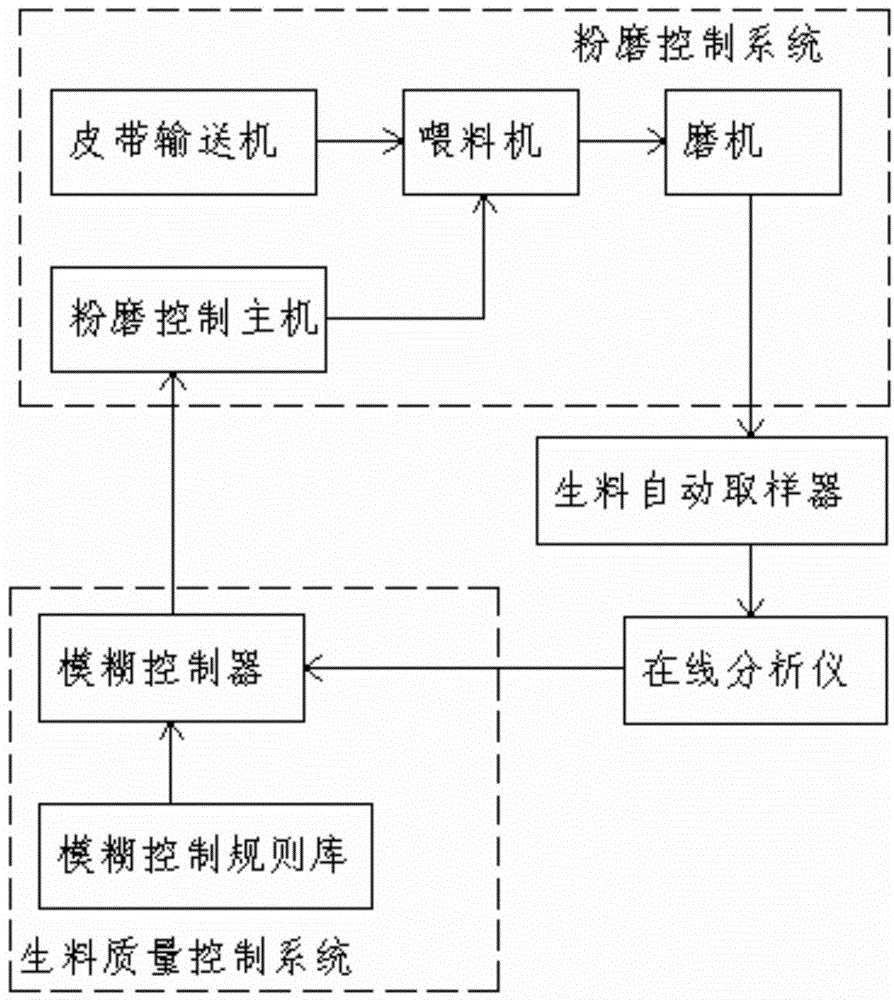

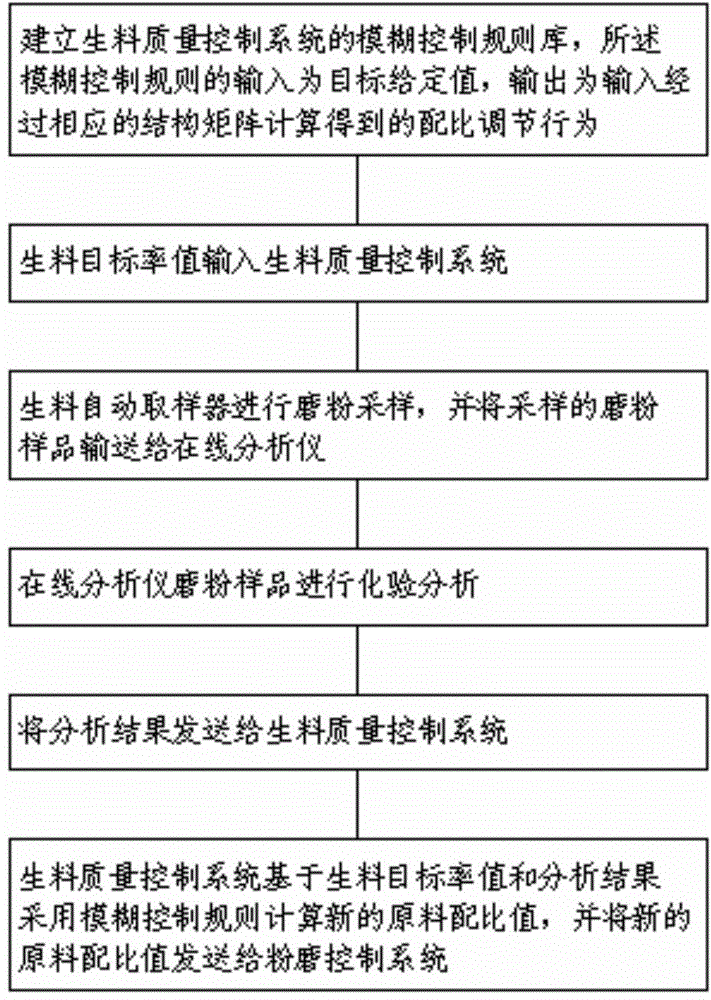

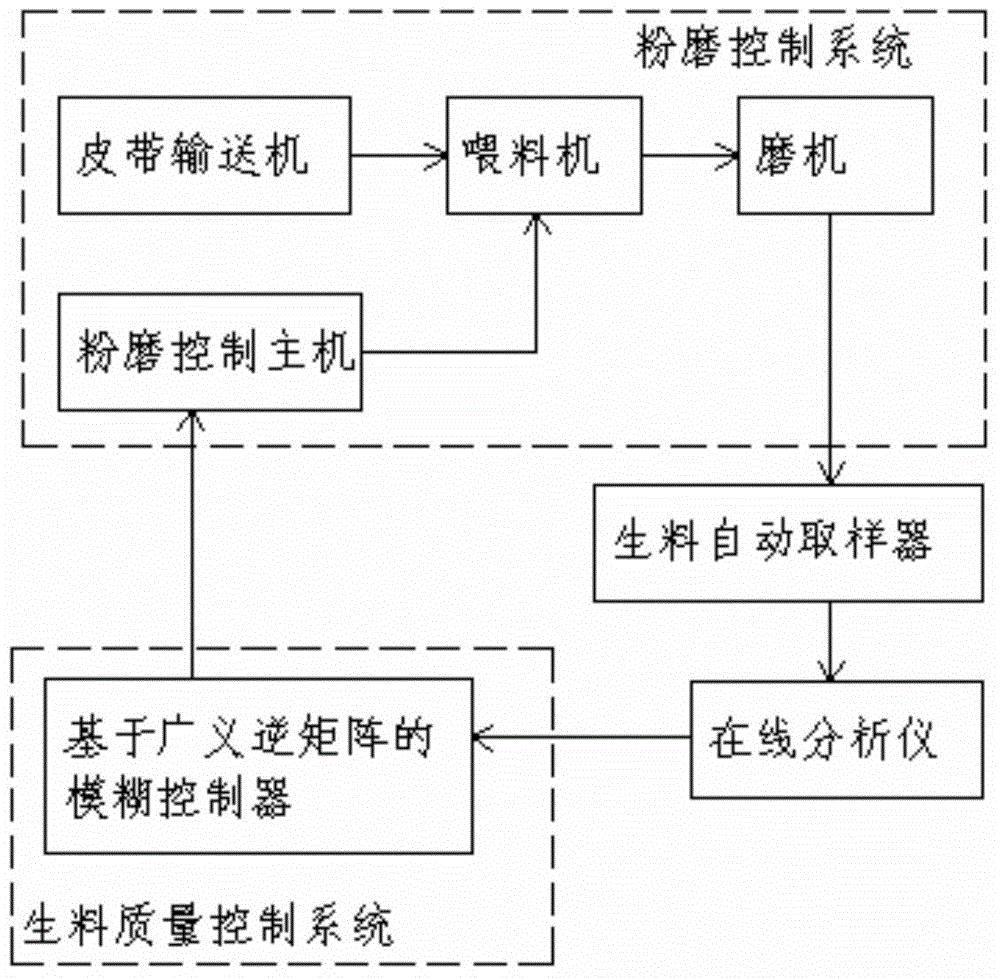

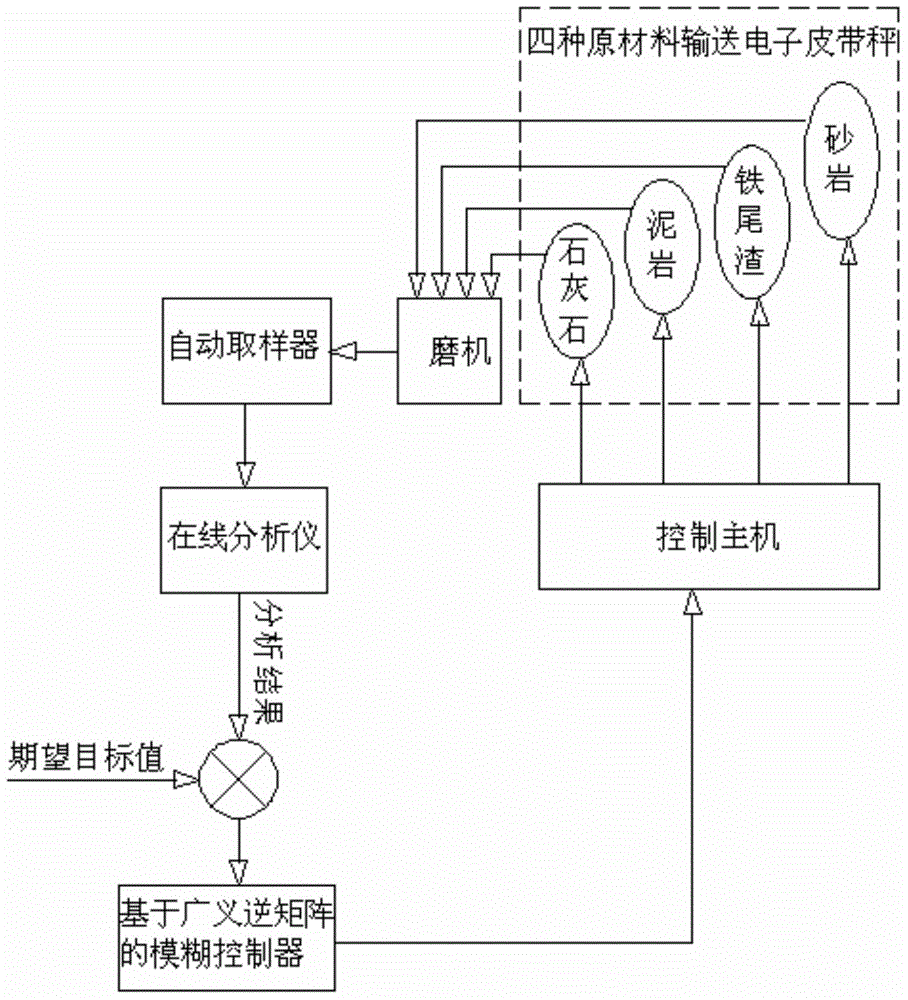

Provided are a cement raw material ingredient control system and method. The cement raw material ingredient control system comprises a grinding control system, a raw material automatic sampler, an on-line analyzer and a raw material quality control system. The raw material automatic sampler is arranged at a grinding machine raw material outlet, carries out grinding powder sampling, and conveys the grinding powder sample to the on-line analyzer, component analysis is carried out, the on-line analyzer sends the analysis result of the grinding powder sample to the raw material quality control system, the raw material quality control system carries out self-adaptive adjustment of raw material ratios according to the analysis result of the grinding powder sample and a raw material object rate value, and the adjusted raw material ratio values are sent to the grinding control system. Component analysis of raw materials is carried out on the on-line analyzer, the matrix semi-tensor product theory and the fuzzy control theory are employed to carry out self-adaptive adjustment of raw material ratios according to the raw material object ratio values, therefore real-time and self-adaptive adjustment of raw materials is carried out, fluctuation of the raw material ratio value is lowered, and the raw material quality is ensured.

Owner:UNIV OF JINAN +1

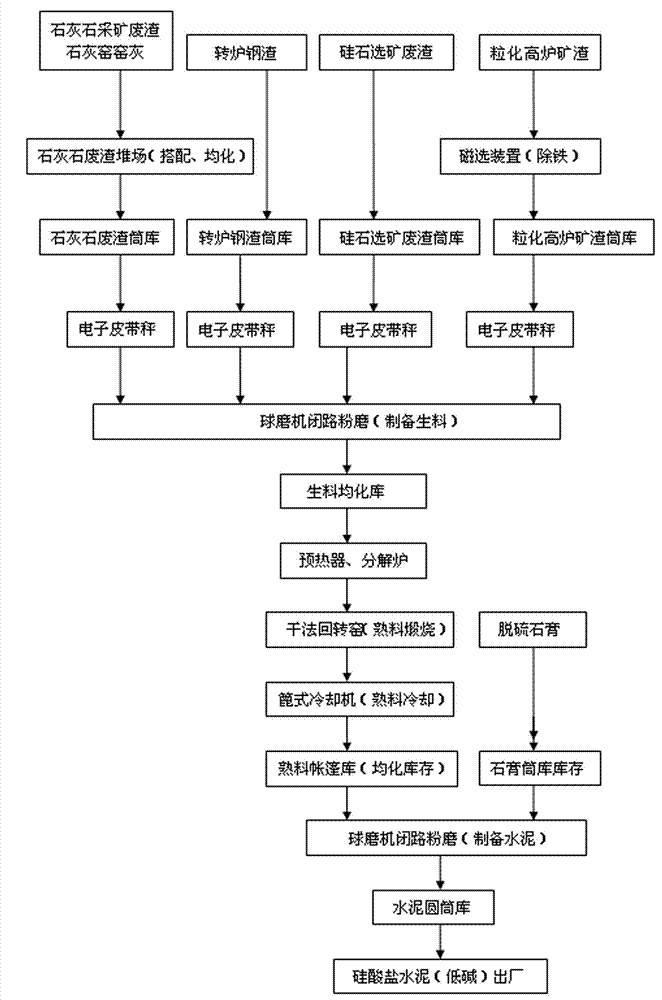

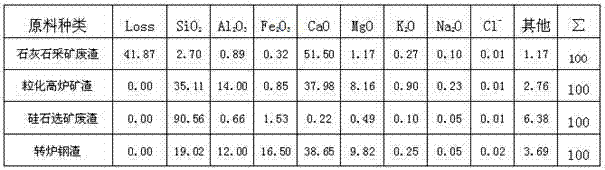

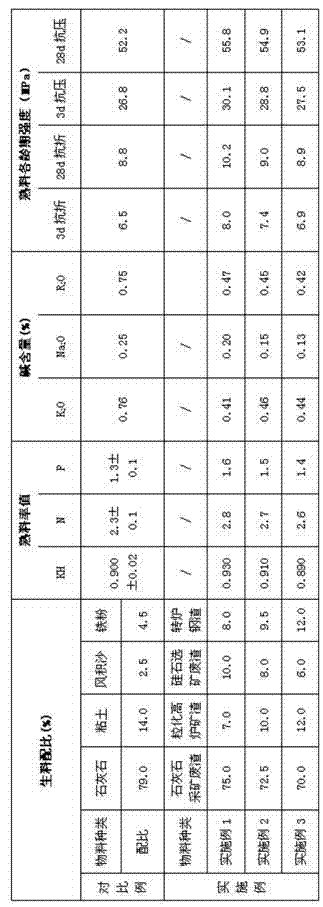

Method for producing low-alkali Portland cement by using industrial solid waste

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

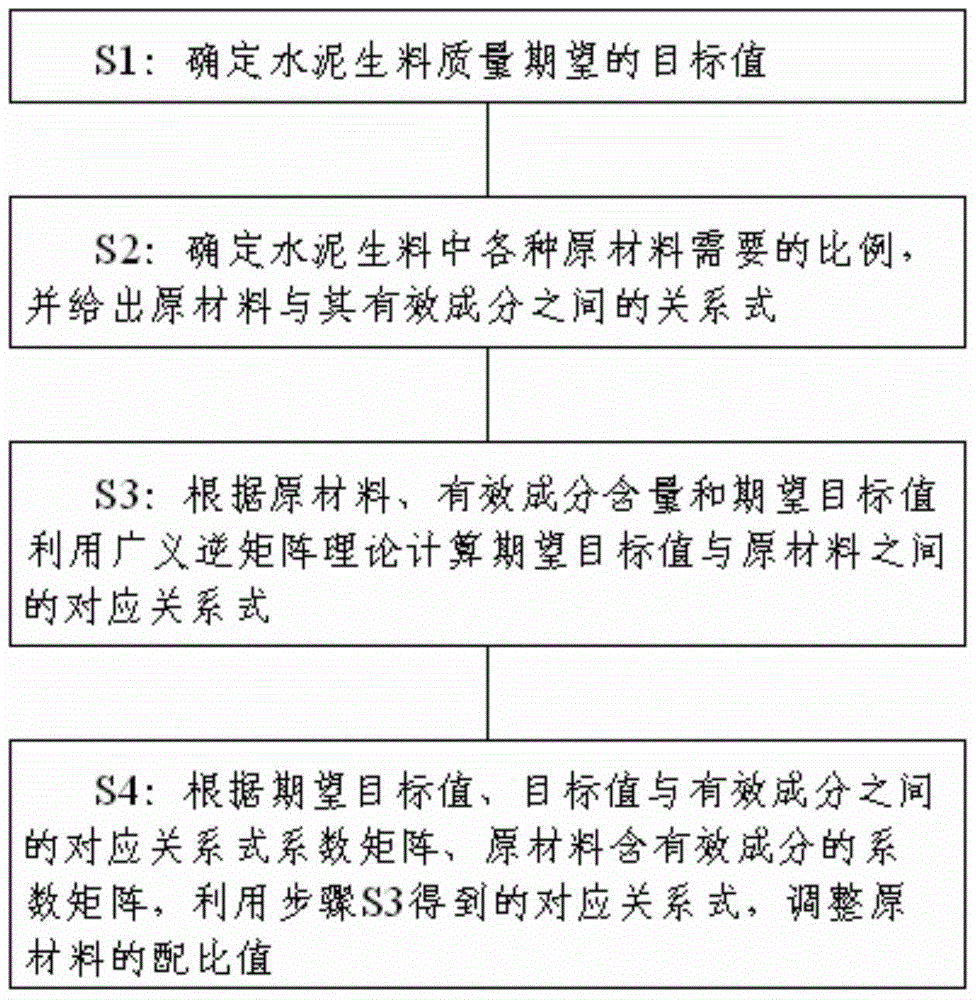

Raw cement material quality control method and system based on generalized inverse matrix

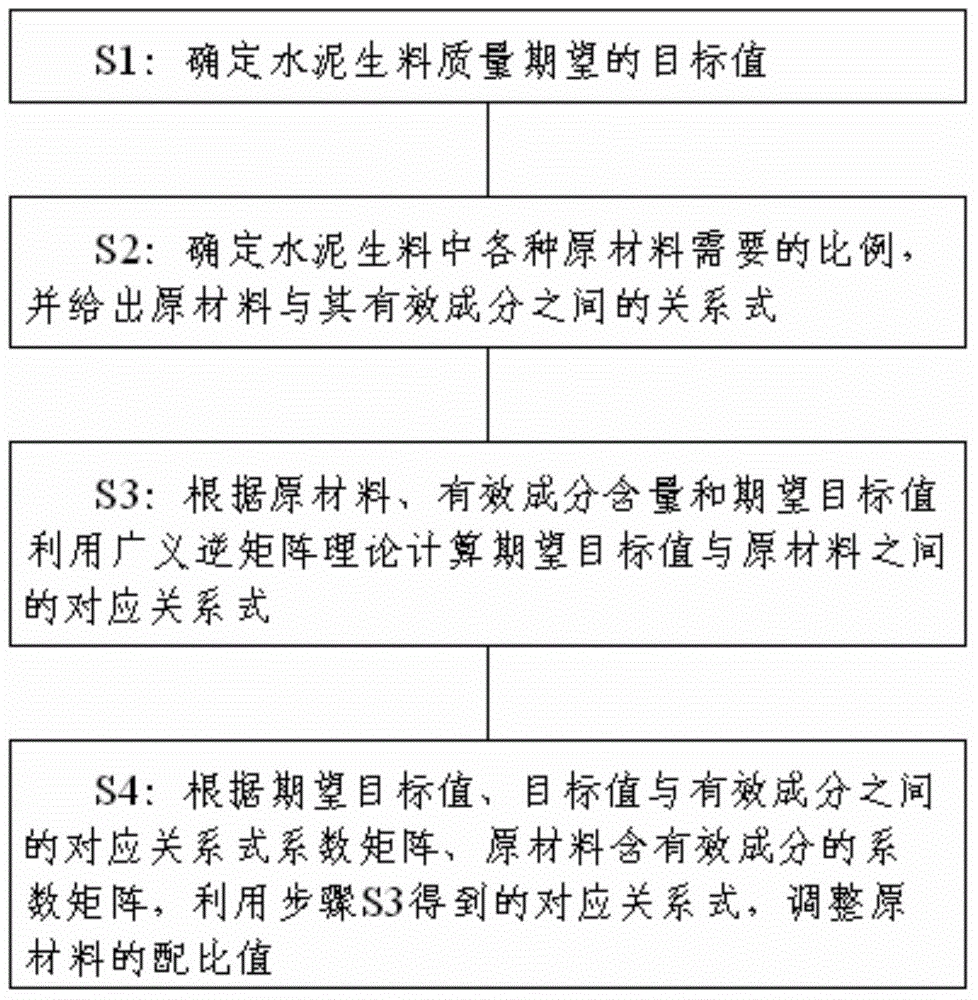

ActiveCN104950861AGuaranteed stabilityMeet ingredient requirementsTotal factory controlProgramme total factory controlQuality control systemQuality control

The invention discloses a raw cement material quality control method and system based on a generalized inverse matrix. The method comprises steps as follows: S1, determining a target value expected by raw cement material quality; S2, determining the required proportion of all raw materials in a raw cement material and giving the relation between the raw materials and effective ingredients; S3, calculating the corresponding relation between the expected target value and the raw materials by using a generalized inverse matrix theory according to the raw materials, the effective ingredient content and the expected target value; S4, adjusting the proportion of the raw materials by using the corresponding relation obtained in Step 3 according to a coefficient matrix of the corresponding relation among the expected target value, a given target value and the effective ingredients as well as a coefficient matrix of the effective ingredients contained in the raw materials. According to the method, the proportion of the raw materials is calculated according to the given target value, the stability of ingredients of the ground raw material is guaranteed, batching requirements under different process conditions are met, the proportion of the raw materials is adjusted in real time, the raw material rate fluctuation is reduced, and the quality of the raw materials and the robustness of the whole raw material quality control system are guaranteed.

Owner:UNIV OF JINAN +1

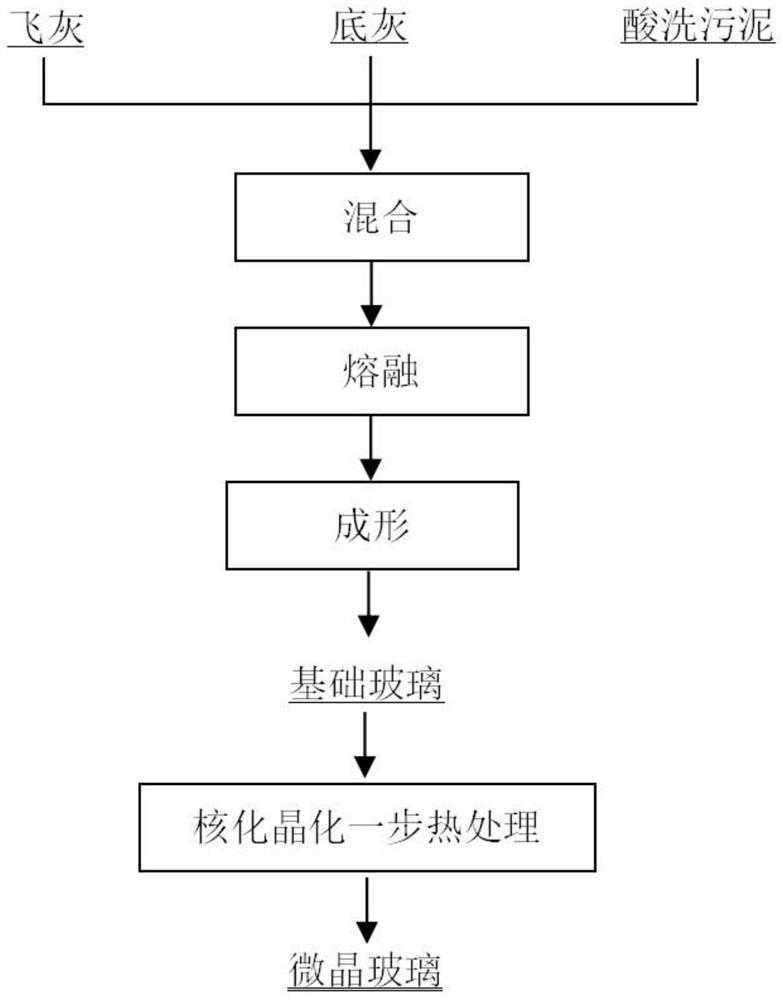

Method for preparing glass ceramics by using waste incineration ash synergistic pickling sludge

Owner:UNIV OF SCI & TECH BEIJING

Method for efficiently smelting Galfan alloy

ActiveCN103614580ASolving Oxygen Combustion ProblemsImprove absorption rateLoss rateChemical composition

The invention relates to a Galfan alloy, particularly a method for efficiently smelting a Galfan alloy. The invention solves the problem in addition of the high-melting-point alloy and low-ignition-point alloy in the non-ferrous metal alloy preparation process, especially solves the problem of oxidizing combustion of the low-ignition-point alloy in the preparation process, and has obvious effects. A partition process adopted in the zinc-rare earth interalloy smelting process prevents the burning loss and oxidation of the rare earth, so that the burning loss rate is low, and the alloy element absorptivity is high; and thus, the partition process can effectively purify the solution and refine the grain. When being used for smelting a zinc-aluminum alloy, the method lowers the percentage of zinc and the mass ratio of aluminum zinc, reduces the segregation of aluminum, ensures the accuracy and uniformity of the chemical components, satisfies the requirements for the alloy components, and is suitable for mass production of the Galfan alloy.

Owner:CHANGZHOU UNIV

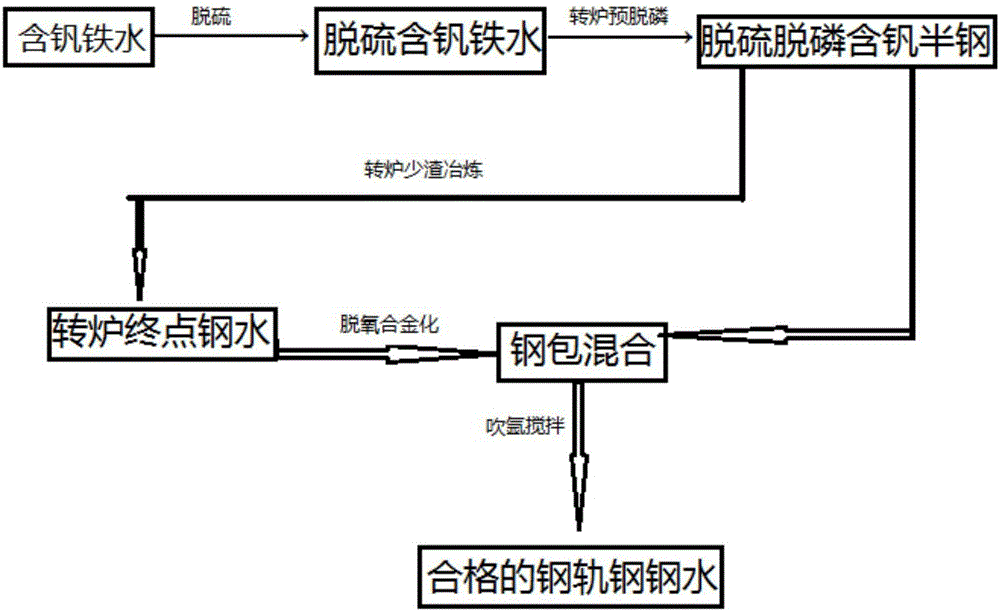

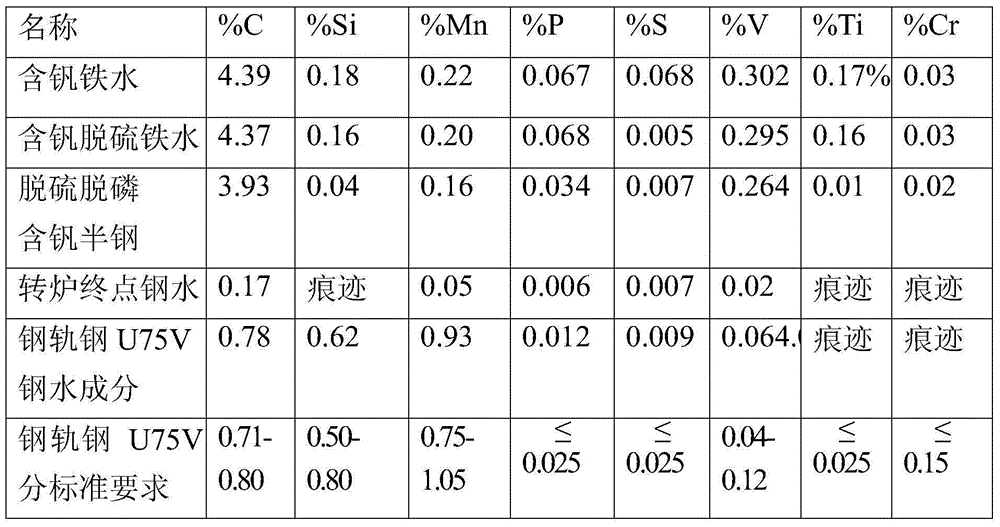

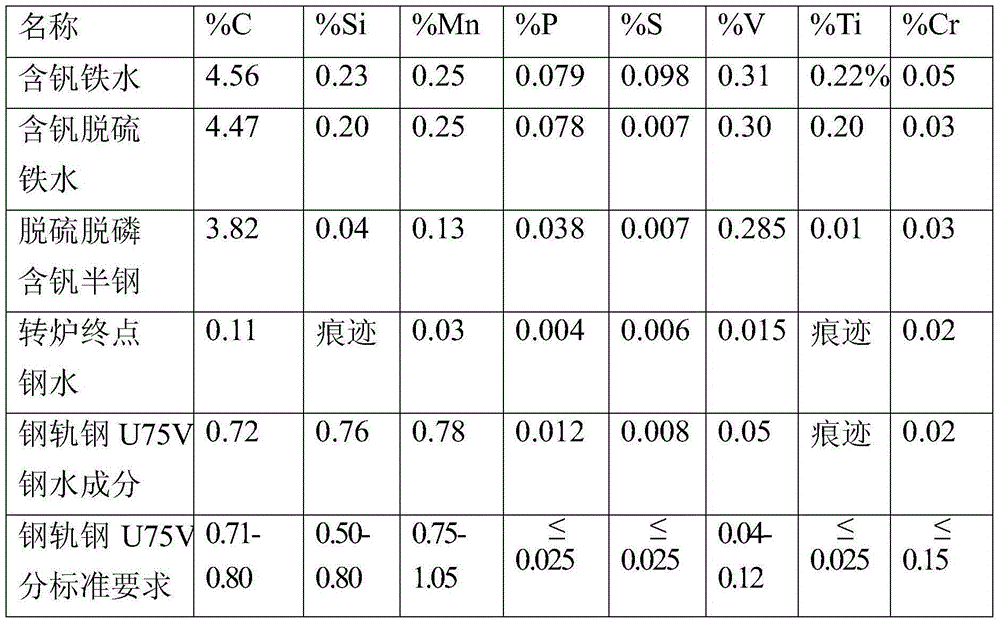

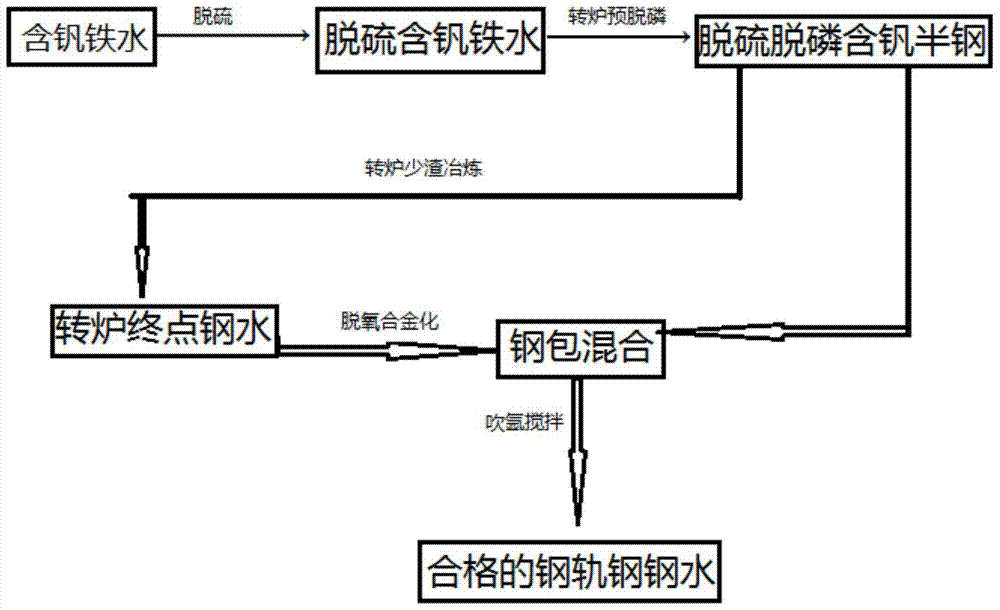

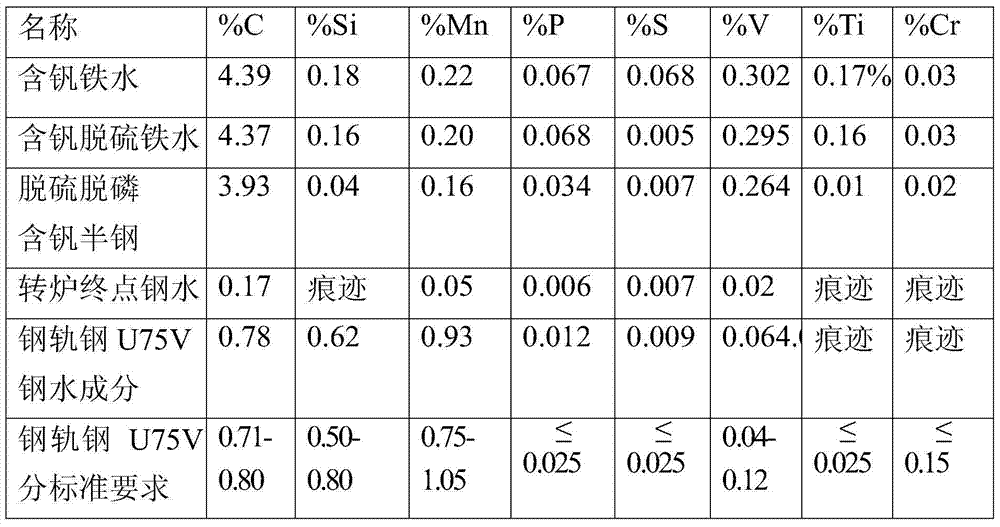

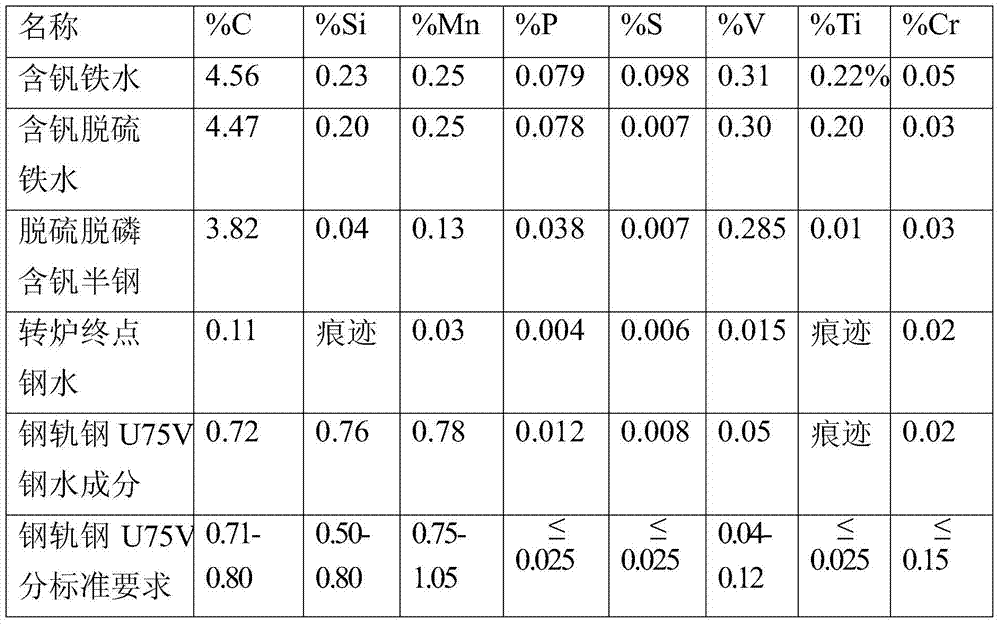

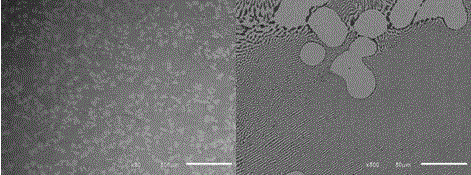

Method for smelting rail steel with vanadium-bearing hot metal as raw materials

ActiveCN105018670AMeet ingredient requirementsLow costManufacturing convertersProcess efficiency improvementSteelmakingAlloy

The invention discloses a method for smelting rail steel with vanadium-bearing hot metal as raw materials. The method comprises the steps that firstly, deep desulphurization is carried out on the vanadium-bearing hot metal through a combined injection method, and thus low-sulfur vanadium-bearing hot metal with the sulphur content smaller than 0.008% is obtained; then, the low-sulfur vanadium-bearing hot metal is put in a converter, a dephosphorization agent is added, blowing vanadium and carbon holding pre-dephosphorization is carried out, and thus vanadium-bearing semisteel with the P content smaller than or equal to 0.040% is obtained; a part of the vanadium-bearing semisteel is tapped in a steel ladle, smelting deep dephosphorization continues to be carried out on the rest part of the vanadium-bearing semisteel through converter slag formation, and thus end point molten steel with the P content smaller than or equal to 0.008% is obtained; and finally, tapped steel of the end point molten steel and the vanadium-bearing semisteel are mixed, a proper amount of deoxidization alloy and high-alkalinity refining slag is added, bottom argon blowing mixing is carried out on the steel ladle, and qualified molten rail steel is obtained. According to the method disclosed by the invention, the operation method is simple, and the production cost is low; the effective utilization and extraction of vanadium resources are guaranteed, and dephosphorization and little slag smelting can be effectively achieved in the converter steelmaking process; meanwhile, the energy is saved, the amount of adopted ferrovanadium alloy and carburant is greatly lowered, and the smelting cost is lowered.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Low-carbon and high-chromium steel and converter smelting technology thereof

ActiveCN103352168AMeet ingredient requirementsManufacturing convertersSmelting processDecarburization

The invention discloses low-carbon and high-chromium steel and a converter smelting technology thereof and belongs to the technical field of metal smelting. The low-carbon and high-chromium steel comprises the components in percentage by weight as follows: 4.5-5.5 percent of Cr, no more than 0.06 percent of C, no more than 1.0 percent of Mn, no more than 0.50 percent of Si, no more than 0.010 percent of S, no more than 0.015 percent of P, no more than 0.0080 percent of N, and the balance of Fe and unavoidable impurities. The converter smelting technology of the low-carbon and high-chromium steel comprises a converter process, an RH decarbonization process, an LF (Ladle Furnace) smelting process and an RH degasification process, adopts common molten iron and smelting equipment, reasonably utilizes the procedure capacity of the equipment so as to successfully obtain the low-carbon and high-chromium steel via smelting, the content of chromium is controlled within the range of 4.5-5.5%., and the content of C is less than or equal to 0.06 percent, so that the requirement of anti-corrosion steel on components is required.

Owner:NANJING IRON & STEEL CO LTD

Method for preparing water-insoluble drug supported fat emulsion from soybean emulsion with aqueous enzymatic method

InactiveCN106039319AMeet ingredient requirementsReduce processing complexityHydroxy compound active ingredientsPharmaceutical delivery mechanismEmulsionFat emulsion

The invention discloses a method for preparing a water-insoluble drug supported fat emulsion from a soybean emulsion with an aqueous enzymatic method. The method comprises steps as follows: a water-insoluble drug is added to an emulsion obtained through enzymolysis of soybeans; the emulsion is subjected to shear mixing under the protection of nitrogen, and a primary emulsion is prepared; the primary emulsion is homogenized for multiple times under the pressure of 15,000 psi-20,000 psi, an emulsion system is obtained, the emulsion system is subjected to micromembrane filtering, nitrogen charging and sterilization, and the fat emulsion is obtained. The method adopts a simple process and is convenient to operate, and under the condition that auxiliary materials such as an emulsifier and the like are not added, surface protein and phospholipid of the emulsion have a synergistic effect, so that the stability of the fat emulsion is improved and dissolving of the water-insoluble drug is enhanced. The homogeneity of the emulsion system is enhanced, and the stability of the fat emulsion is improved; the preparation method of the fat emulsion is performed at normal temperature and normal pressure, accordingly, adverse effects of the emulsion are reduced, medication safety is improved, and expanded production is facilitated.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

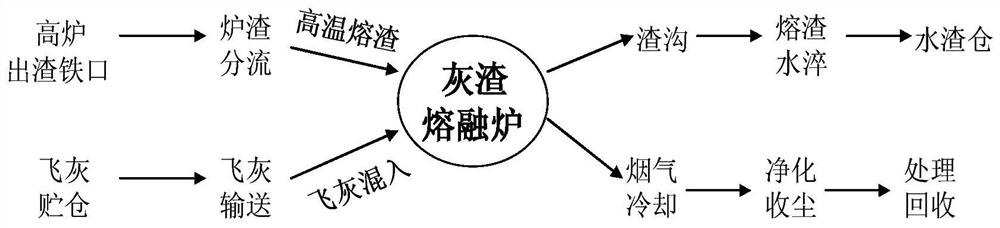

Method and device for disposing waste incineration fly ash in low-energy-consumption, recycling and environment-friendly manner

PendingCN112441759AReduce energy consumptionReduce disposal costsSolid waste managementIncinerator apparatusAggregate (composite)Fly ash

The invention discloses a method and device for disposing waste incineration fly ash in a low-energy-consumption, recycling and environment-friendly manner. The method comprises the following steps that: 1) 1480-1510 DEG C blast furnace slag is added into a melting furnace, fly ash is simultaneously or subsequently added, and an obtained mixture is fully stirred, and the addition amount of the flyash accounts for not more than 25% of the total mass of the blast furnace slag and fly ash; 2) the temperature of the composite slag in the melting furnace is kept at 1400-1450 DEG C, and the reaction time is kept for 20-40 minutes under the temperature; and 3) deslagging, cooling, and water quenching treatment are carried out to obtain powdery water granulated slag, and the powdery water granulated slag is used as cement aggregate after being subjected to fine grinding.

Owner:BAOSHAN IRON & STEEL CO LTD

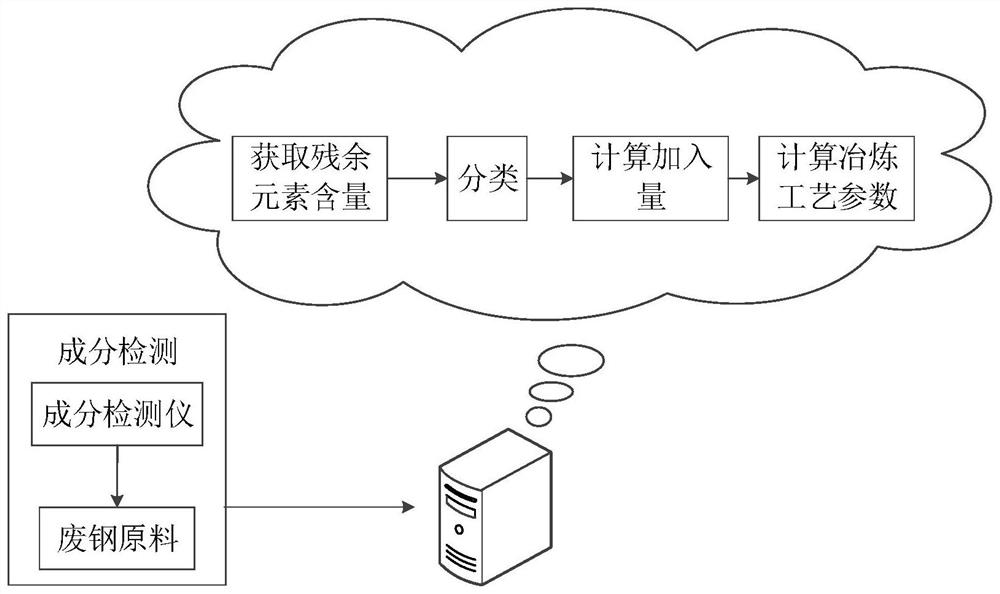

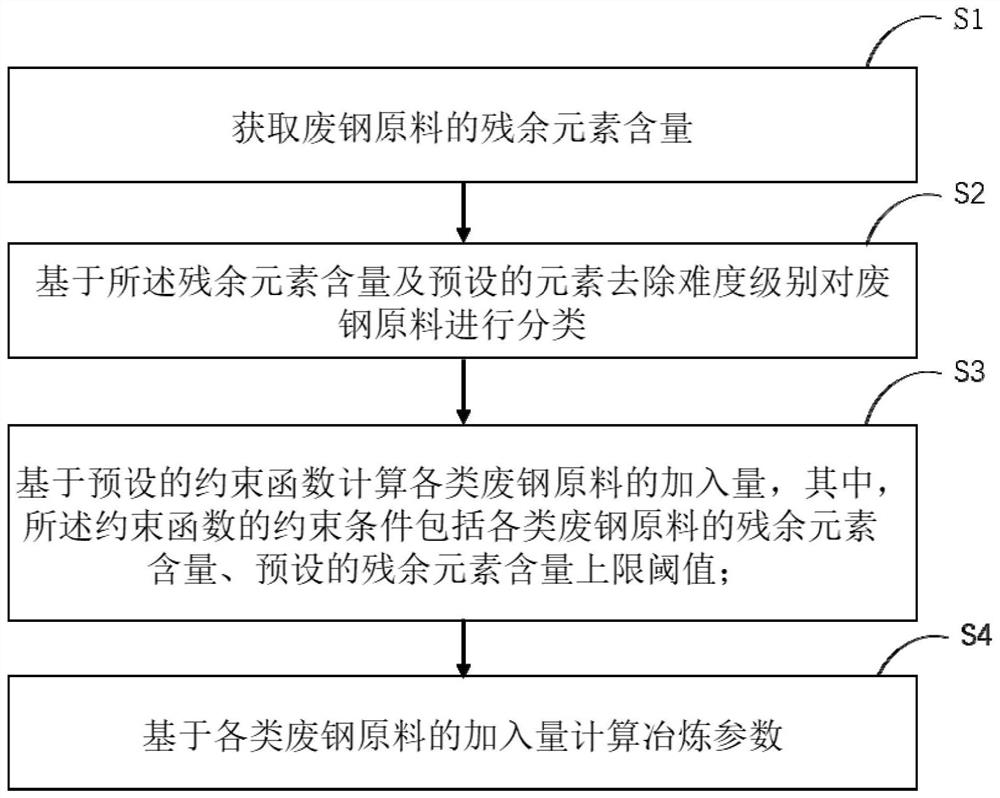

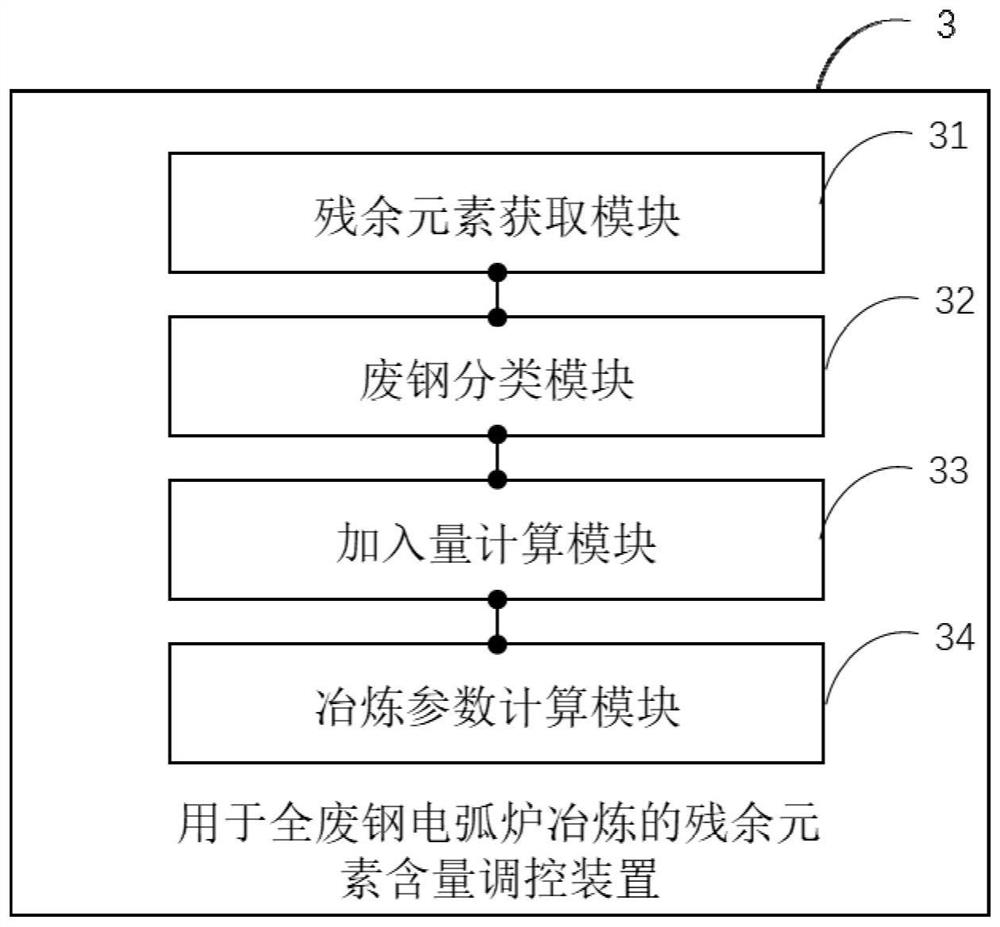

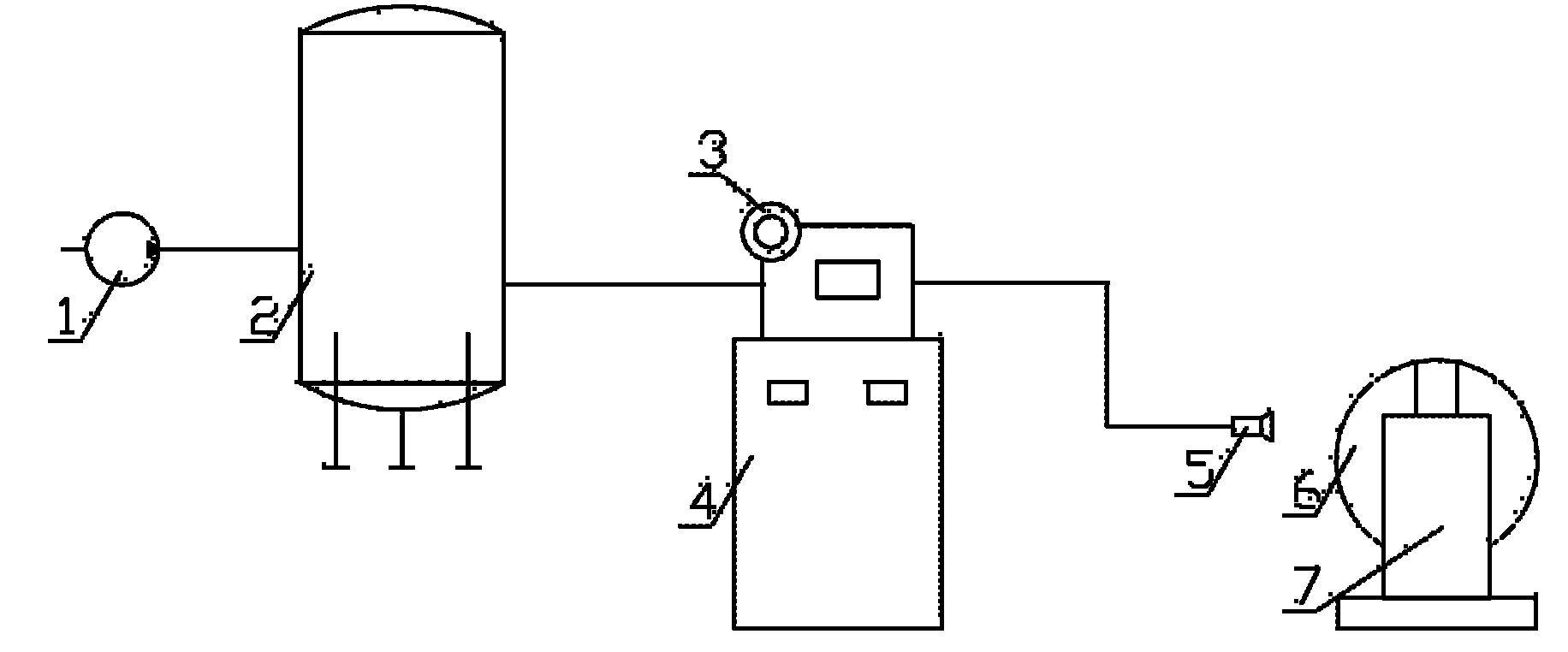

Residual element content regulation and control method for full scrap steel electric arc furnace smelting

ActiveCN114317884AMeet ingredient requirementsSolve the problem of residual element content controlElectric furnaceProcess efficiency improvementElectric arc furnaceMaterials science

The invention provides a residual element content regulation and control method for full scrap steel electric arc furnace smelting. The method comprises the following steps: obtaining the residual element content of a waste steel raw material; the waste steel raw materials are classified based on the residual element content and the preset element removal difficulty level; based on a preset constraint function, the adding amount of the various waste steel raw materials is calculated, and constraint parameters of the constraint function comprise the residual element content of the various waste steel raw materials and a preset residual element content upper limit threshold value; and smelting parameters are calculated based on the addition amount of various waste steel raw materials. According to the method, the waste steel raw materials can be classified according to the content of the residual elements, the adding amount of each type of waste steel raw materials is calculated based on the preset constraint function according to the content of the residual elements of the waste steel raw materials and the preset threshold value of the content of the residual elements, the smelting parameters are obtained, and the component requirement of smelting for the residual elements is met; the problem of regulating and controlling the content of the residual elements in the full-scrap steel electric arc furnace smelting is solved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

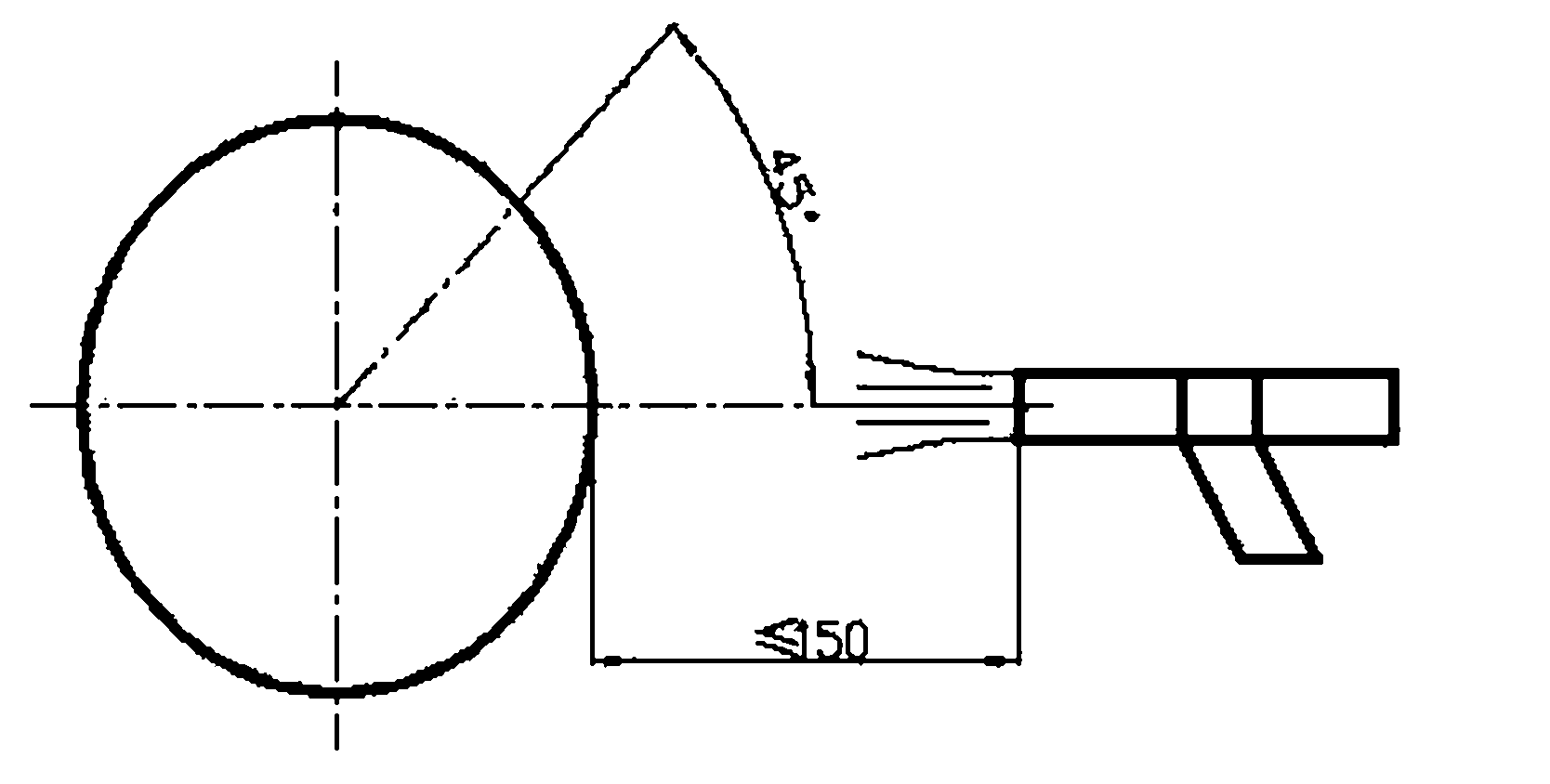

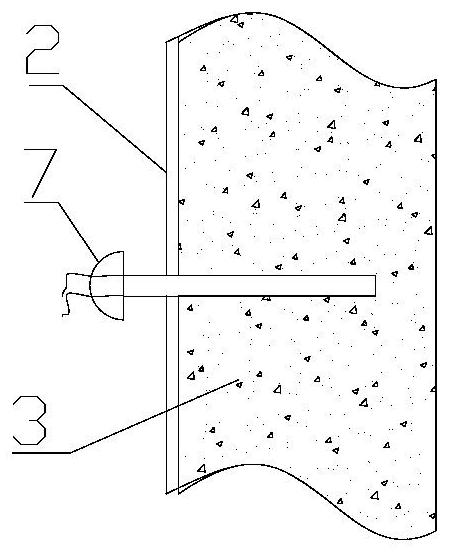

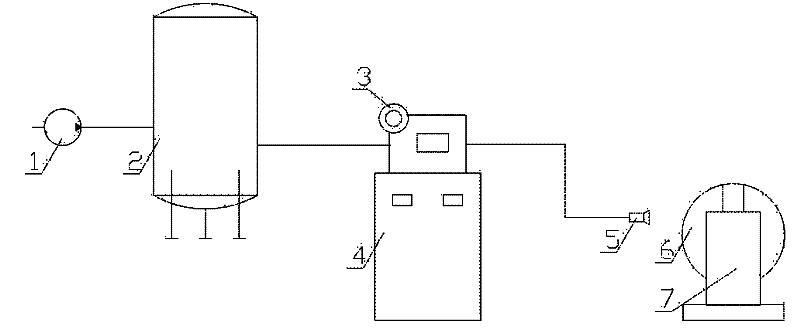

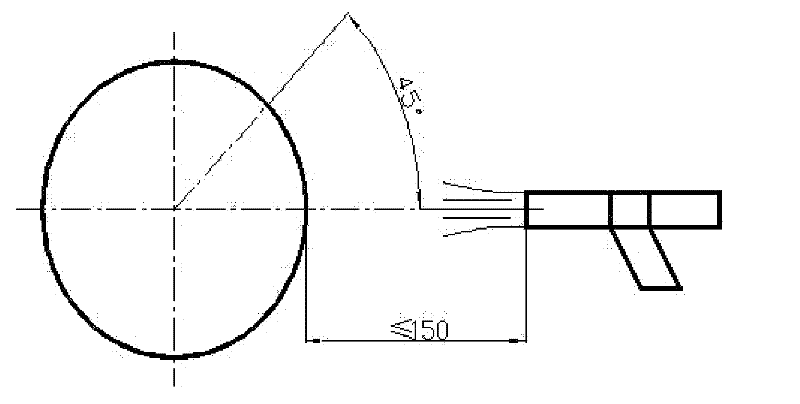

Method for spray-welding anisotropic material on cast iron valve plate

ActiveCN101786193AThe spray welding process is simpleStrong combinationArc welding apparatusCast ironCorrosion

The invention relates to a method for spray-welding anisotropic material on a cast iron valve plate. The specific technique includes the steps of: valve plate selecting, valve plate sealing surface polishing, sanding and coursing, adopting special valve plate sealing surface spray-welding device to spray weld the valve plate sealing surface, adjusting the current of a wire feeder to 200A-400A and the voltage to 10V-40V to maintain the wire-feeding speed at 3-8m / min, obtaining the supersonic speed particle radiation under the working conditions that the gas flow is adjusted to be 3-6 square meters per hour and the power is adjusted to be 50-80kw, opening the spray gun opening for spray-welding, ensuring the welding wire from the spray gun to form beam-shaped flame, sending two electriferous welding wires to the spray gun, generating electric arc at the contact tips of the two welding wires to form molten drops, spraying the melt molten drops through compressed air onto the surface of working piece to form a coating layer,and detecting. The invention has the beneficial effects that the spray-welding process is simple; the heating before welding and the heat processing after welding are not needed for the valve plate; the stainless steel spray-welding layer is firmly combined with the valve plate main body, the valve plate is prevented from crackles; thereby the purposes of increasing the wearing resistance and the corrosion resistance of the valve plate are achieved.

Owner:TIANJIN FSK FLOW CONTROL EQUIP

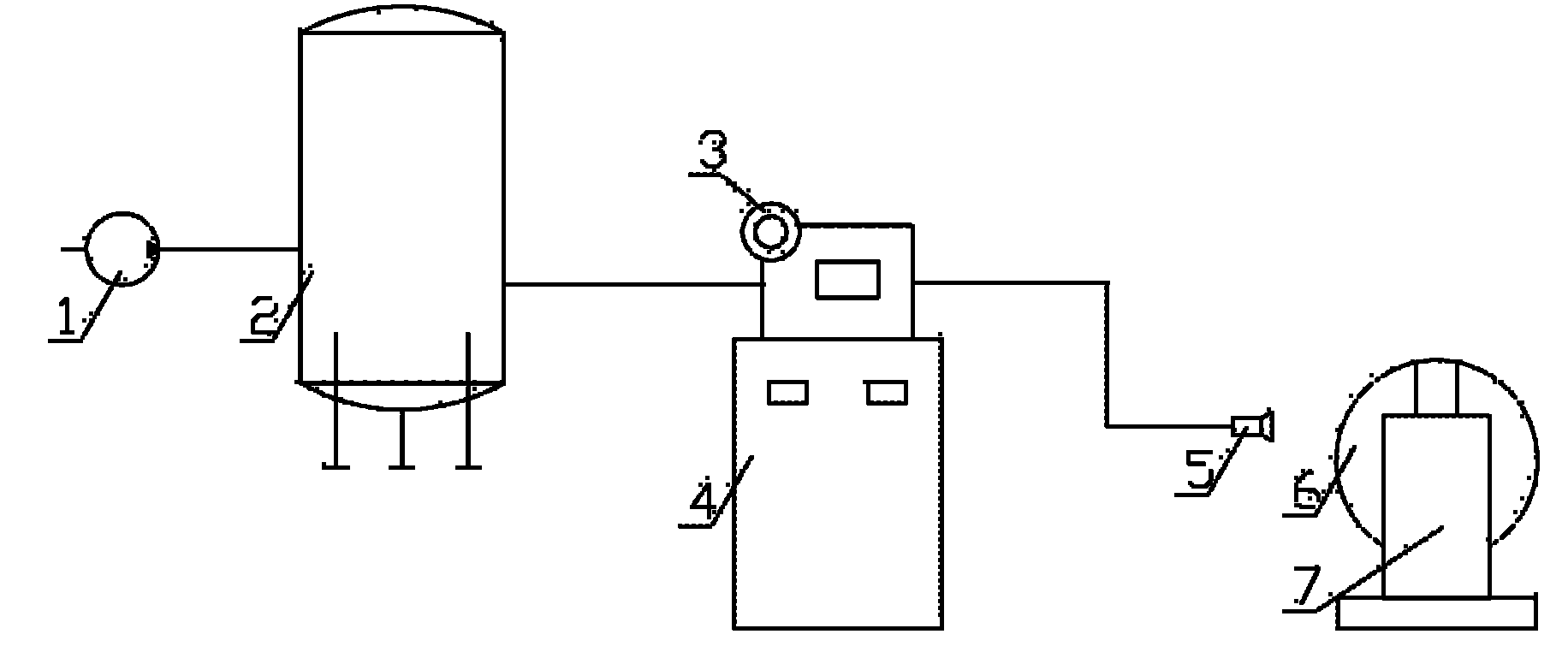

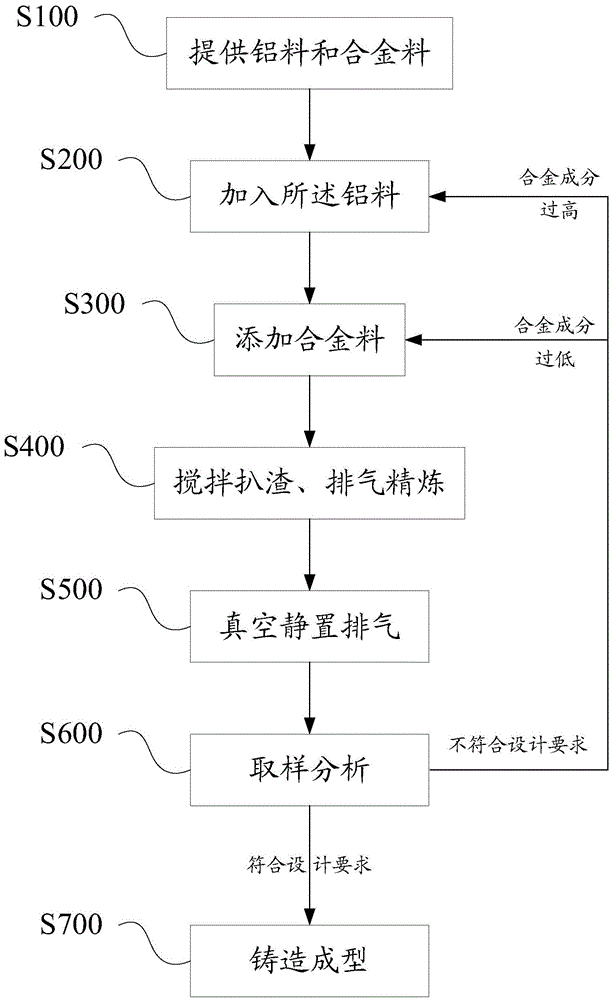

Preparation method of aluminum alloy for semiconductor

A preparation method of aluminum alloy for a semiconductor comprises the following steps: preparing aluminum and alloy; smelting the aluminum; adding the alloy to the molten aluminum to form aluminum alloy; sequentially performing stirring, slagging off, exhausting and refining; performing vacuum standing and exhausting treatment on the aluminum alloy; sampling the aluminum alloy, and analyzing to determine whether the component ratio of the aluminum alloy meets the design requirement; if the component ratio does not meet the design requirement, adding the alloy or the aluminum again based on the analyzing result until the component ratio of the aluminum alloy meets the design requirement, and performing the steps of stirring, slagging off, exhausting, refining, vacuum standing and exhausting treatment, and sampling and analyzing; and if the component ratio meets the design requirement, casting and forming to obtain the aluminum alloy. The aluminum alloy prepared by the method is uniform in mixing of main elements, and low in impurity content, and meets the requirement on the material components of the semiconductor.

Owner:宁波创润新材料有限公司

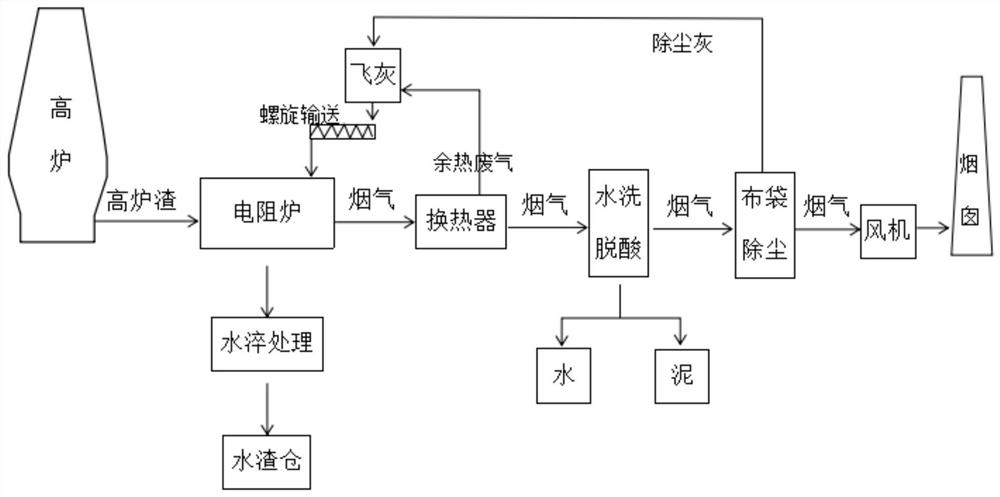

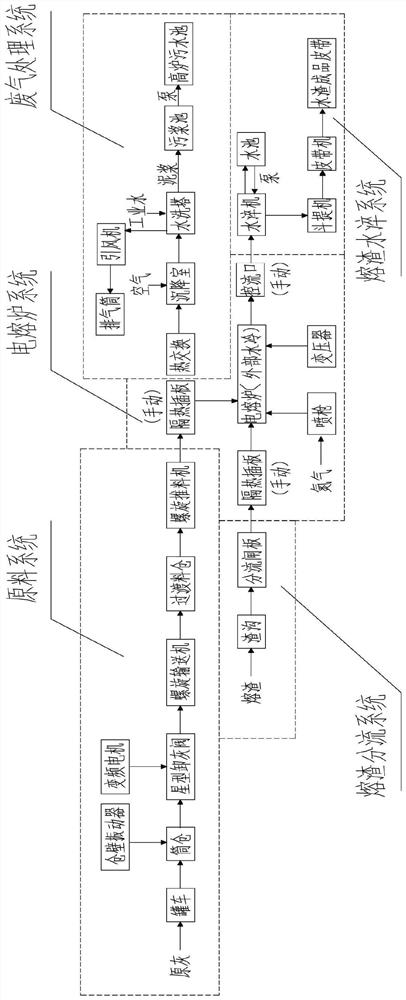

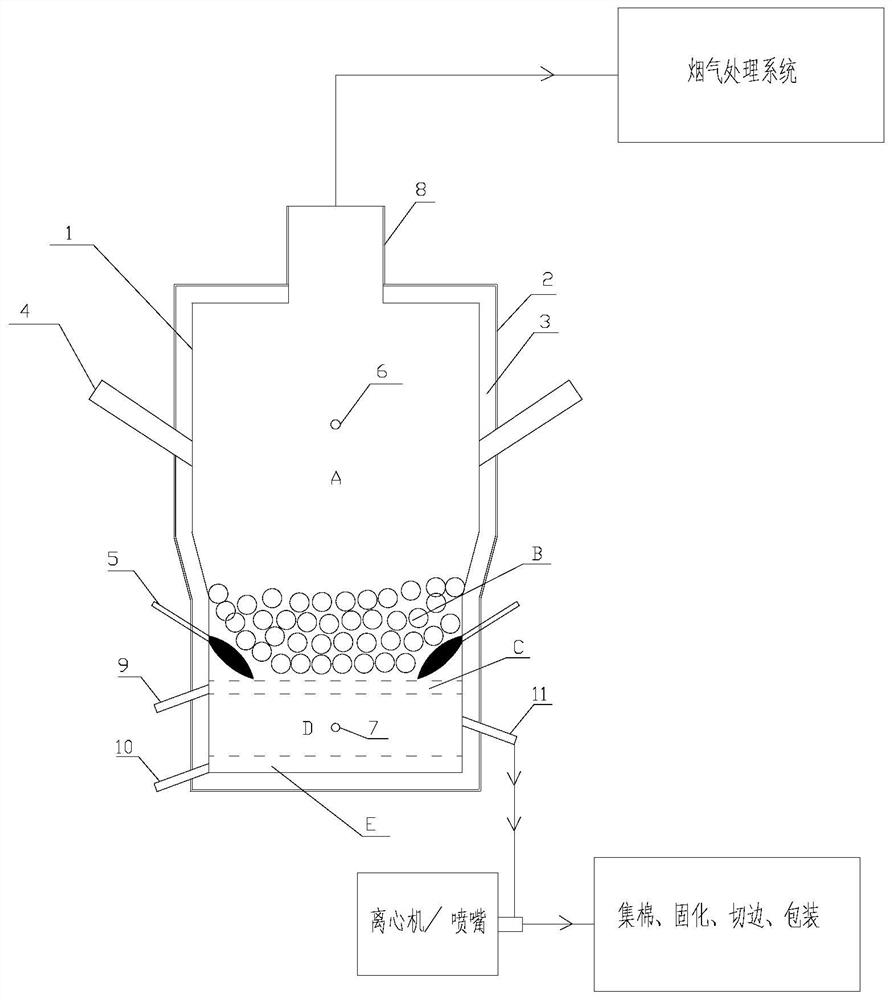

Waste incineration fly ash recycling method and system

ActiveCN112414132ARaise the ratioEmission reductionCharge manipulationFurnace typesFlue gasProcess engineering

The invention discloses a waste incineration fly ash recycling method and system. The waste incineration fly ash recycling method comprises the following steps that 1, after fly ash particles are fedinto a furnace from a feeding port in an upper area of a furnace body, the fly ash particles are cooled to a middle-lower area in the furnace to be combusted and melted by a pure oxygen combustor, andsmoke generated in the melting process rises to the temperature of 500-700 DEG C in an upper area in the furnace and then is exhausted; 2, a liquid chlorine salt layer, a slag layer and a liquid alloy layer are formed from top to bottom in the process that molten liquid sinks to a bottom area in the furnace; and 3, the liquid chlorine salt layer, the slag layer and the liquid alloy layer are recycled in a layered manner. The waste incineration fly ash recycling system mainly comprises a melting furnace, and a gas phase area, a solid phase area, a chlorine salt melting area, a slag area and analloy melting area are sequentially arranged in the melting furnace from top to bottom. According to the waste incineration fly ash recycling method and system, the heat utilization rate is high, theflue gas emission is small, and the equipment investment of a subsequent flue gas treatment system can be reduced; Moreover, after fly ash is treated by the method, chlorine salt, alloy and slag layers are formed after the fly ash is molten, and all the layers can be recycled.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

Method for spray-welding anisotropic material on sealing surface of cast iron valve plate

ActiveCN101786193BWon't crackImprove wear resistanceArc welding apparatusMaterials scienceHeat treated

The invention relates to a method for spray-welding anisotropic material on a cast iron valve plate. The specific technique includes the steps of: valve plate selecting, valve plate sealing surface polishing, sanding and coursing, adopting special valve plate sealing surface spray-welding device to spray weld the valve plate sealing surface, adjusting the current of a wire feeder to 200A-400A and the voltage to 10V-40V to maintain the wire-feeding speed at 3-8m / min, obtaining the supersonic speed particle radiation under the working conditions that the gas flow is adjusted to be 3-6 square meters per hour and the power is adjusted to be 50-80kW, opening the spray gun opening for spray-welding, ensuring the welding wire from the spray gun to form beam-shaped flame, sending two electriferous welding wires to the spray gun, generating electric arc at the contact tips of the two welding wires to form molten drops, spraying the melt molten drops through compressed air onto the surface of working piece to form a coating layer, and detecting. The invention has the beneficial effects that the spray-welding process is simple; the heating before welding and the heat processing after welding are not needed for the valve plate; the stainless steel spray-welding layer is firmly combined with the valve plate main body, the valve plate is prevented from crackles; thereby the purposes of increasing the wearing resistance and the corrosion resistance of the valve plate are achieved.

Owner:TIANJIN FSK FLOW CONTROL EQUIP

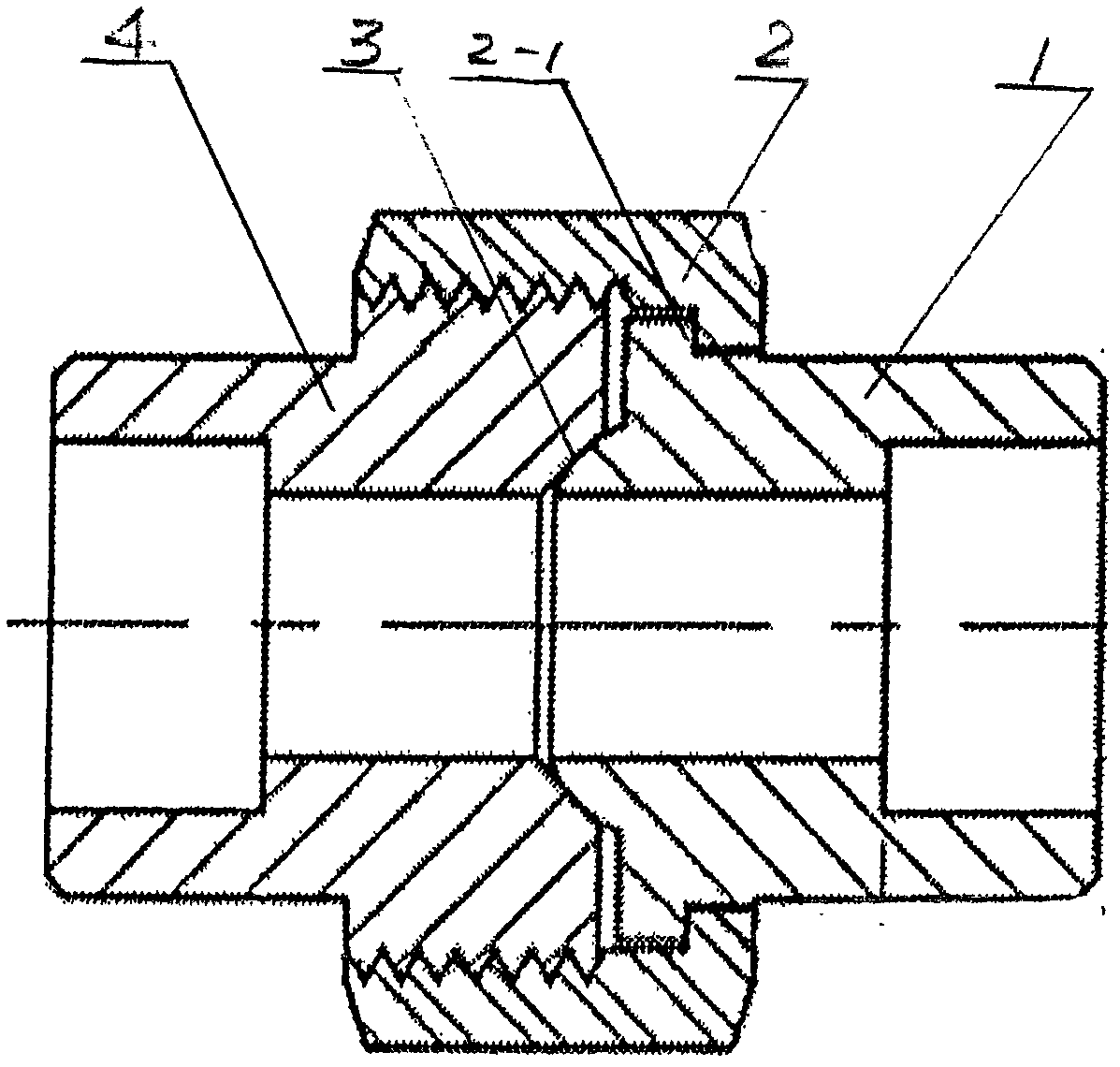

Copper-nickel-iron pipeline connection pipe fitting and preparation thereof

The invention provides a copper-nickel-iron pipeline connection pipe fitting and preparation thereof. The copper-nickel-iron pipeline connection pipe fitting comprises an outwards protruded surface joint, an inwards concave surface joint and a locking nut. The copper-nickel-iron pipeline connection pipe fitting is characterized in that the meshed positions of the outwards protruded surface joint and the inwards concave surface joint are provided with meshed arc surfaces. The preparation includes shove charging, smelting, sampling, analyzing, deoxidizing, refining, casting, forging and pressing, and finish machining. Compared with the prior art, a rubber pad is removed, cost is relatively saved, and the copper-nickel-iron pipeline connection pipe fitting is completely adapted to pipeline connection on the condition of high pressure or high temperature. Meanwhile, as the forging and pressing process is utilized, mechanical performance is improved, non-cutting or little cutting is achieved, alloy material is saved, and production cost is reduced. The copper-nickel-iron pipeline connection pipe fitting has the advantages of being convenient to connect, firm to connect, and high in seal degree, and pipeline connection is safe.

Owner:上海世航铜镍管件有限公司

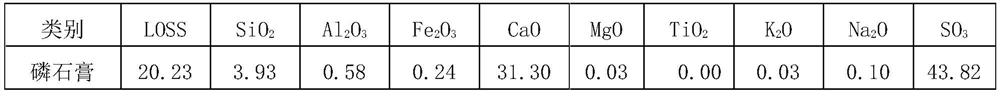

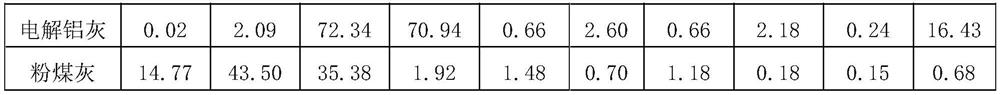

A method for calcining belite sulphoaluminate cement clinker with phosphogypsum and cement clinker

The invention discloses a method for calcining Belite sulphoaluminate cement clinker by using phosphogypsum and the cement clinker, and belongs to the field of cement. The method for calcining the Belite sulphoaluminate cement clinker by using phosphogypsum comprises the following steps of 1, weighing, by mass, 75-80% phosphogypsum, 10-15% of aluminum raw materials and 10-15% of siliceous raw materials, and conducting mixing and grinding to obtain a cement raw material; 2, preheating the cement raw material at 1,000-1,100 DEG C, conducting desulfurization for 160-180 minutes, and calcining thecement raw material at 1,320-1,350 DEG C for 60-80 minutes until the clinker mineral is completely formed. The method for calcining the Belite sulphoaluminate cement clinker by using phosphogypsum and the cement clinker have the advantages that the original calcium raw material is not used in the accessory material, and phosphogypsum is utilized to the maximum degree.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

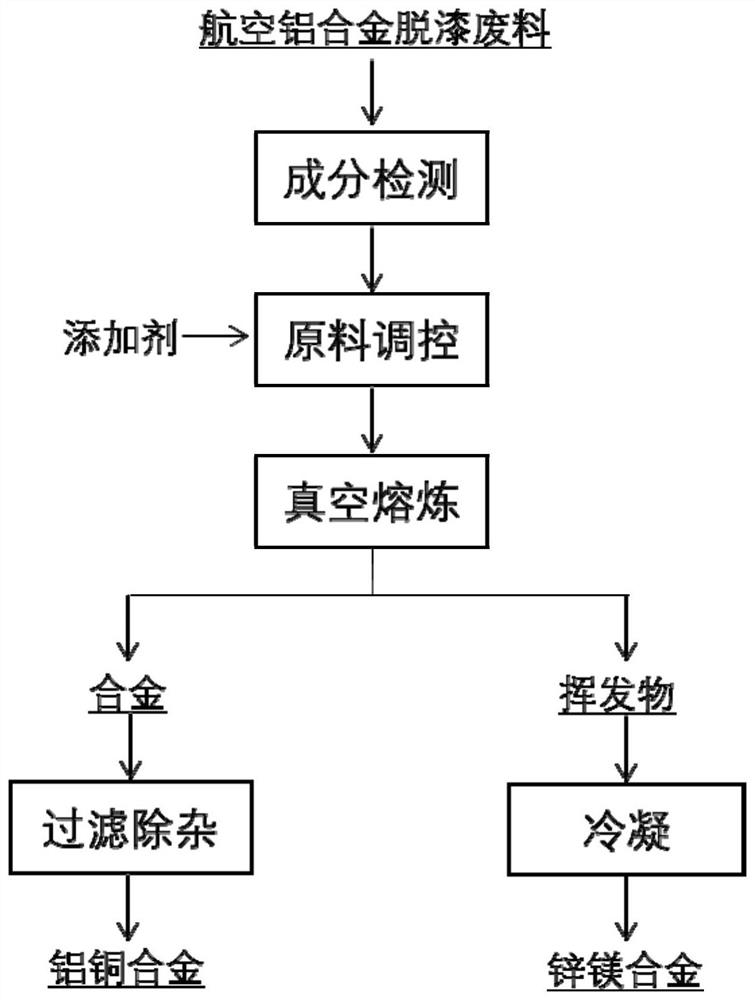

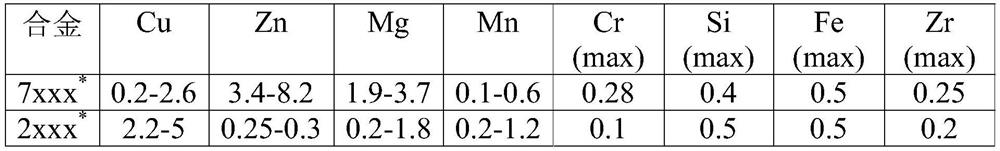

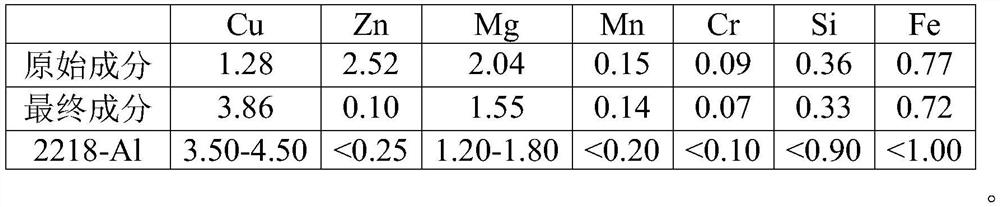

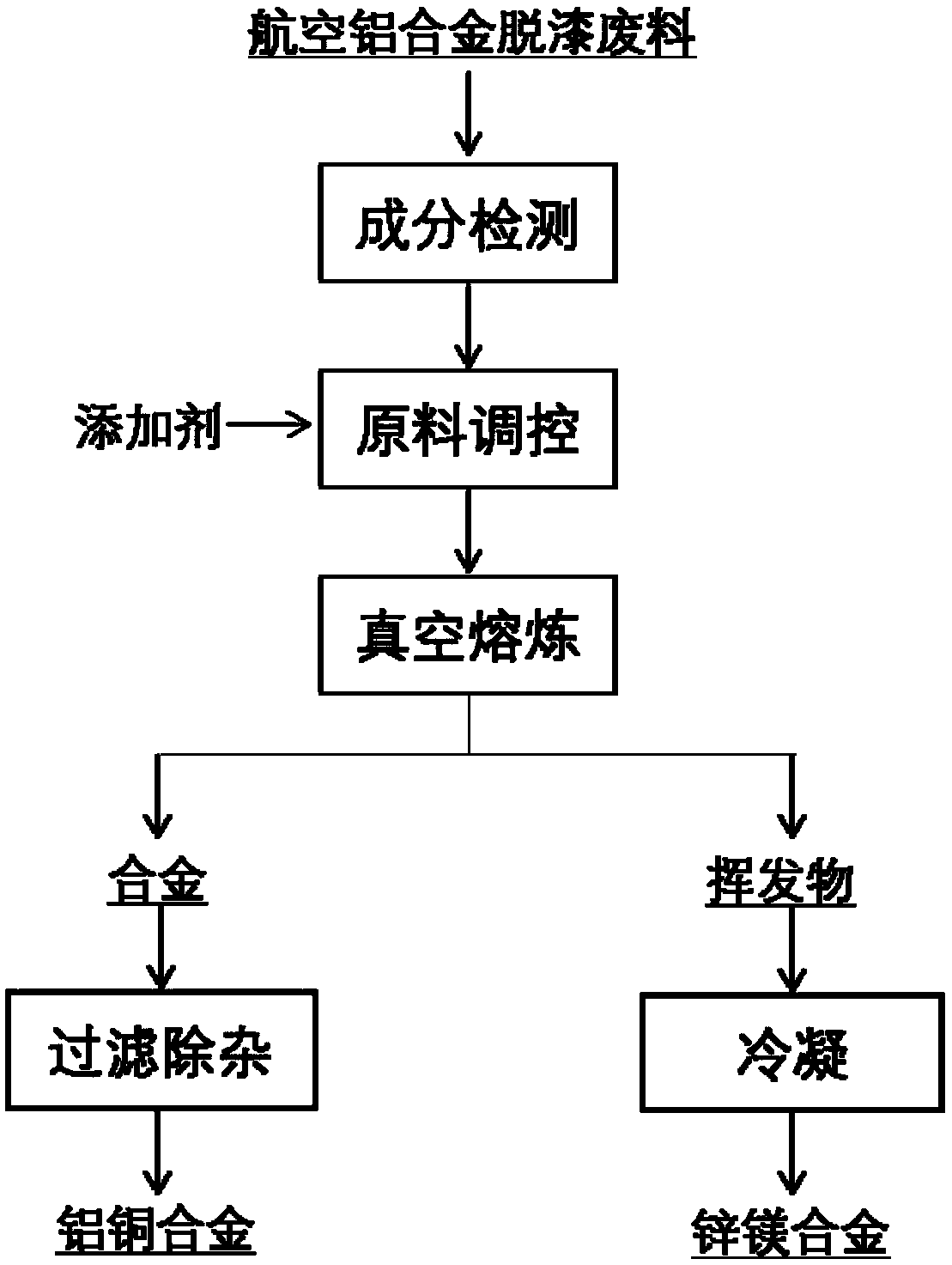

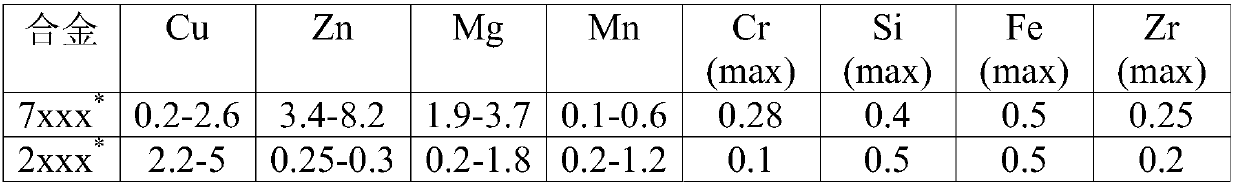

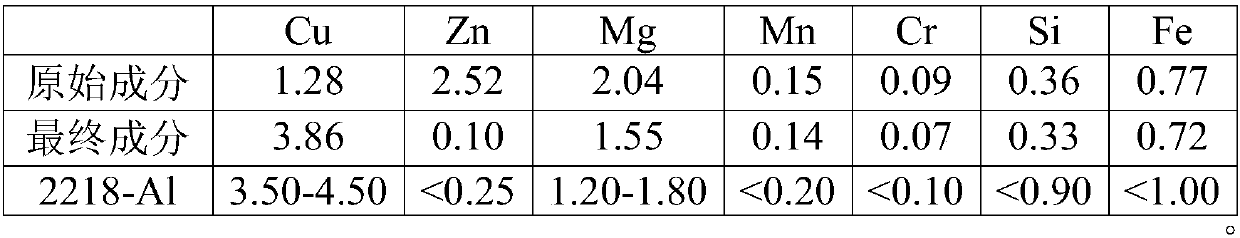

A method for preparing copper-containing aluminum alloy from aviation industry aluminum alloy waste regeneration

ActiveCN110760706BEffective for short rangeEasy to realize industrial applicationProcess efficiency improvementAviationSocial benefits

The invention discloses a method for preparing copper-containing aluminum alloy by regenerating aluminum alloy waste from aviation industry. The invention belongs to the fields of circular economy technology and environmental protection. Its main technical scheme is to use the aviation industry aluminum alloy mixed waste after stripping, according to the target alloy composition requirements, add an appropriate amount of metal or alloy for composition control, smelting in a vacuum furnace, and achieve aluminum alloy impurity removal by controlling the smelting conditions process. Removal and alloying are carried out simultaneously, and the target copper-containing aluminum alloy is prepared by casting after filtering and removing impurities. The invention makes full use of the alloy components in the aluminum alloy waste of the aviation industry, and can realize the regeneration of different types of aluminum-copper alloys without additional degassing through on-line / off-line alloy component control and short-range smelting. The recovery cost is low, the industrial production is easy, and the Significant economic, environmental and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

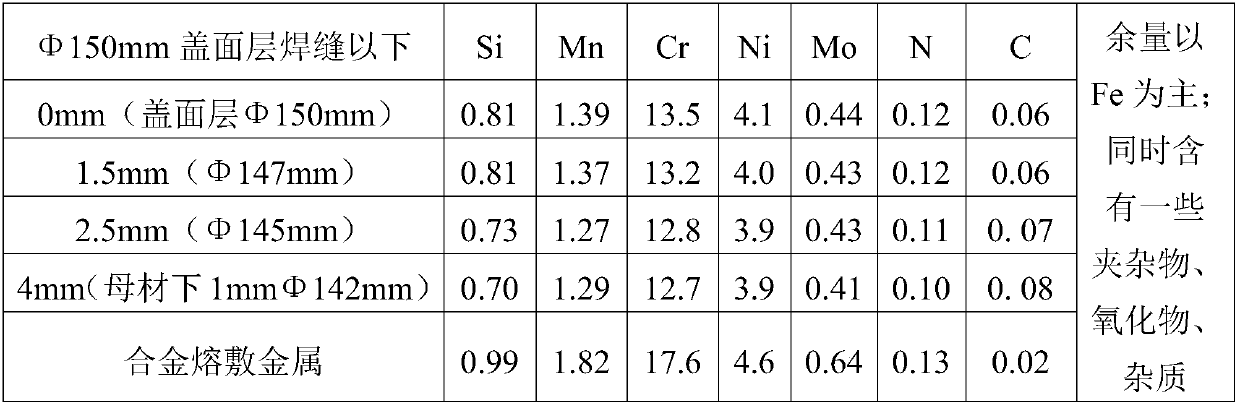

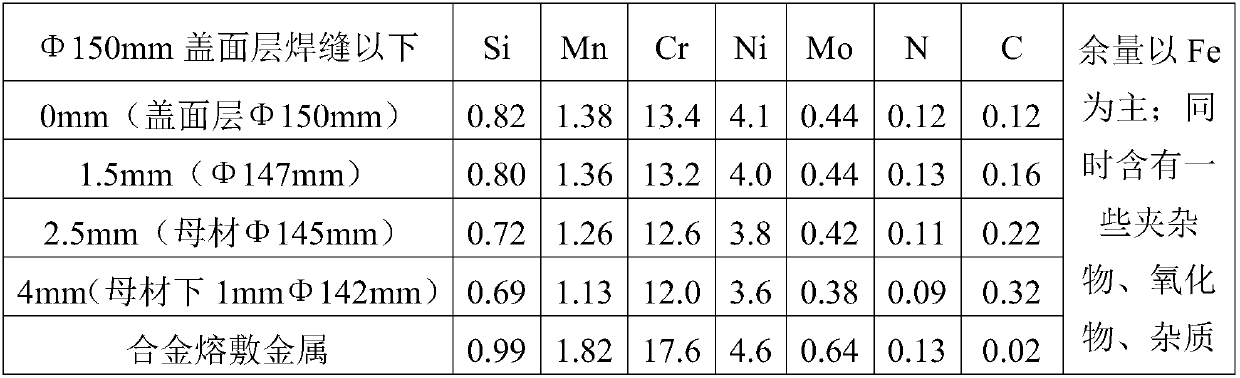

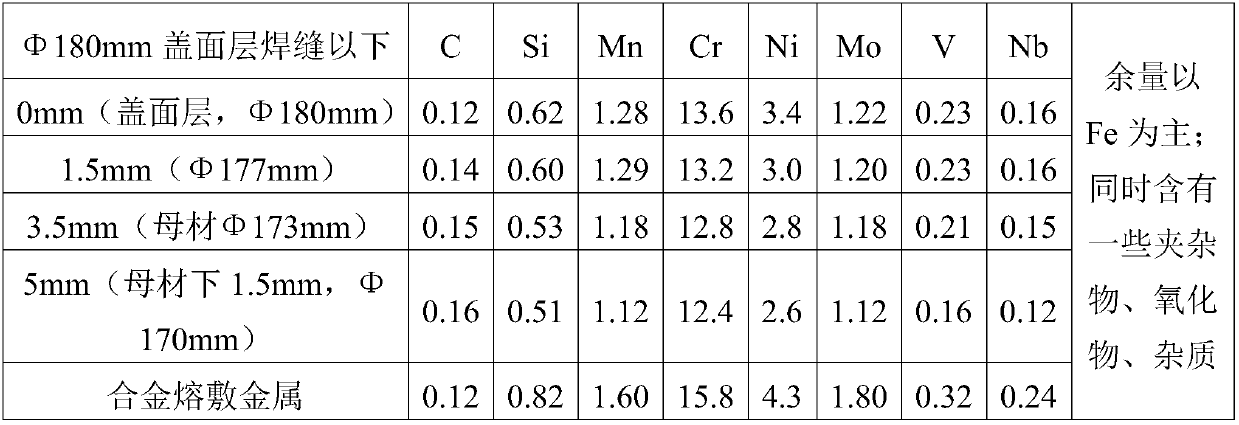

Novel process for high-efficiency surfacing composite manufacturing (remanufacturing) of continuous casting roll

InactiveCN109514038AIncrease the surfacing thicknessHigh dilution rateWelding accessoriesNon destructiveButt welding

The invention discloses a novel process for high-efficiency surfacing composite manufacturing (remanufacturing) of a continuous casting roll. The novel process comprises the following steps that (1),a surfacing process is determined after surfacing process evaluation according to a parent metal, surfacing materials and a surfacing mode and method, and process parameters are determined according to the surfacing process; (2), the roll is turned to 0.1 mm to 3 mm above the surfacing size required by a drawing according to the surfacing process parameters and in combination with the drawing requirements; (3), roll inspection is carried out before welding, wherein non-destructive inspection of the size, parent metal compositions, performance and internal and external defects is carried out; (4), single-layer surfacing for one-time forming is carried out, wherein the single-side surfacing thickness of the roll after single-layer surfacing reaches the surfacing thickness of +0.5-2.5 mm specified in the drawing; and (5), according to the drawing requirements, the compositions, hardness and structure of different positions after butt welding are inspected according to the drawing requirements, and meanwhile flaw detection is carried out on a surfacing layer. By the adoption of the continuous casting roll produced by surfacing composite manufacturing (remanufacturing) of the process, the uniformity of structure and performance is facilitated, and the service life of the roll is prolonged; and the efficiency and cost performance can be improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Regeneration preparation method for copper-containing aluminium alloy through aviation industry aluminium alloy waste materials

ActiveCN110760706AEase of industrial applicationImprove use valueProcess efficiency improvementVacuum furnaceScrap

The invention discloses a regeneration preparation method for copper-containing aluminium alloy through aviation industry aluminium alloy waste materials and belongs to the field of circular economy technologies and environment protection. According to the main technical scheme, the method comprises the steps that the aviation industry aluminium alloy mixed waste materials after being subjected topaint removal are used, according to the target alloy component demand, a proper amount of metal or alloy is added for component regulation, smelting is conducted in a vacuum furnace, by controllingthe smelting condition process, aluminium alloy impurity removal and alloying are synchronously conducted, after filtering and impurity removal, casting is conducted, and the target copper-containingaluminium alloy is prepared. According to the method, the alloy component in the aviation industry aluminium alloy waste materials is sufficiently used, through online / offline alloy component regulation and short-range smelting, aluminium copper alloy different in type can be regenerated without additional degassing, the recycle cost is low, industrial production is easily achieved, and the methodhas obvious economical, environmental and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

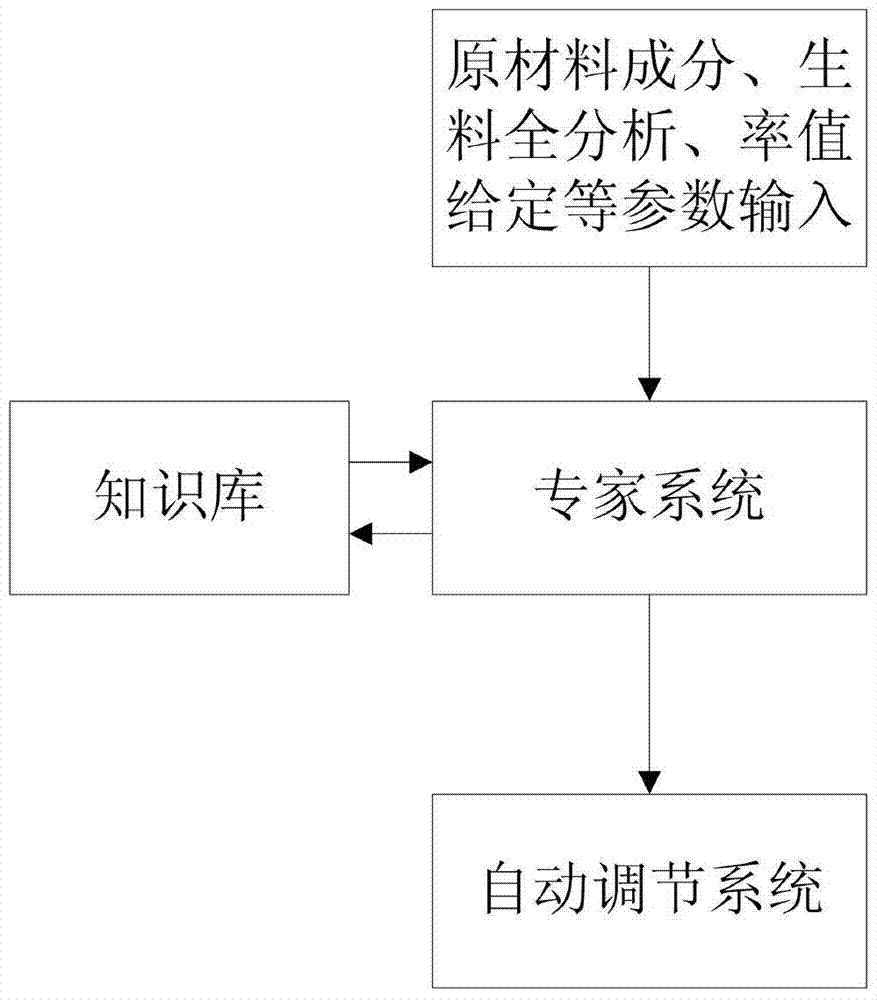

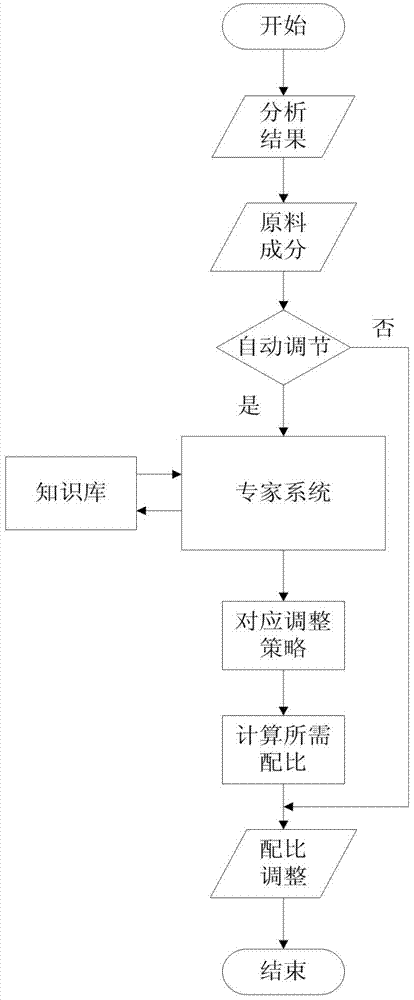

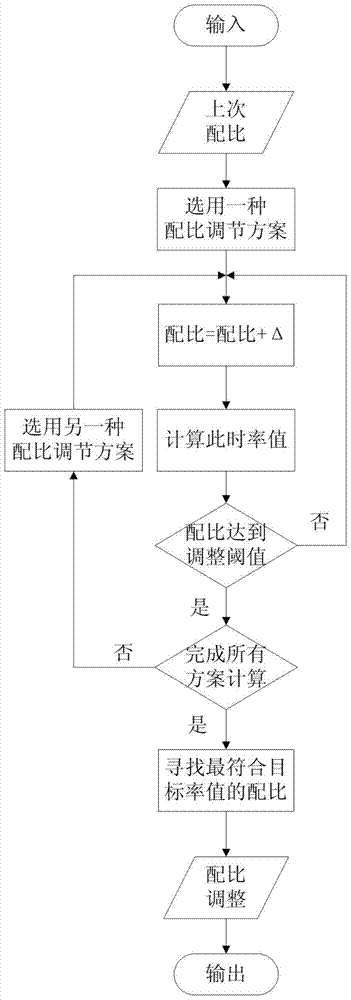

An adaptive cement raw meal batching system and its batching method based on typical working conditions

ActiveCN104339453BComposition is stableAdjust the online monitoring intervalMixing operation control apparatusIngredients proportioning apparatusAuto regulationAdditive ingredient

The invention discloses a typical-working-condition-based adaptive cement raw meal batching system and a batching method thereof. The batching system comprises an expert system for judging a working condition, a knowledge base for selecting the optimal proportion adjustment strategy, and an automatic adjusting system for adjusting the proportion; and the batching method comprises the following steps: (1) firstly, building the knowledge base for control rules of typical working conditions in a cement raw meal batching process, wherein the typical working conditions comprise ideal working conditions and special working conditions; (2) judging the working conditions by virtue of the expert system; and (3) adopting different control rules according to different working conditions, automatically selecting the optimal proportion adjustment scheme. The system and the method integrate theoretical calculation and artificial intelligent unique control rules to realize self-adaptation to various work conditions of raw material fluctuation, and thus the components of the raw materials are stable; and the batching requirements under different technological conditions can be met by adopting a plurality of adjustment modes and strategies.

Owner:UNIV OF JINAN +1

Method for smelting rail steel with vanadium-containing molten iron as raw material

ActiveCN105018670BMeet ingredient requirementsLow costManufacturing convertersProcess efficiency improvementSteelmakingAlloy

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A method for efficiently melting galfan alloy

ActiveCN103614580BSolving Oxygen Combustion ProblemsImprove absorption rateLoss rateChemical composition

The invention relates to a Galfan alloy, particularly a method for efficiently smelting a Galfan alloy. The invention solves the problem in addition of the high-melting-point alloy and low-ignition-point alloy in the non-ferrous metal alloy preparation process, especially solves the problem of oxidizing combustion of the low-ignition-point alloy in the preparation process, and has obvious effects. A partition process adopted in the zinc-rare earth interalloy smelting process prevents the burning loss and oxidation of the rare earth, so that the burning loss rate is low, and the alloy element absorptivity is high; and thus, the partition process can effectively purify the solution and refine the grain. When being used for smelting a zinc-aluminum alloy, the method lowers the percentage of zinc and the mass ratio of aluminum zinc, reduces the segregation of aluminum, ensures the accuracy and uniformity of the chemical components, satisfies the requirements for the alloy components, and is suitable for mass production of the Galfan alloy.

Owner:CHANGZHOU UNIV

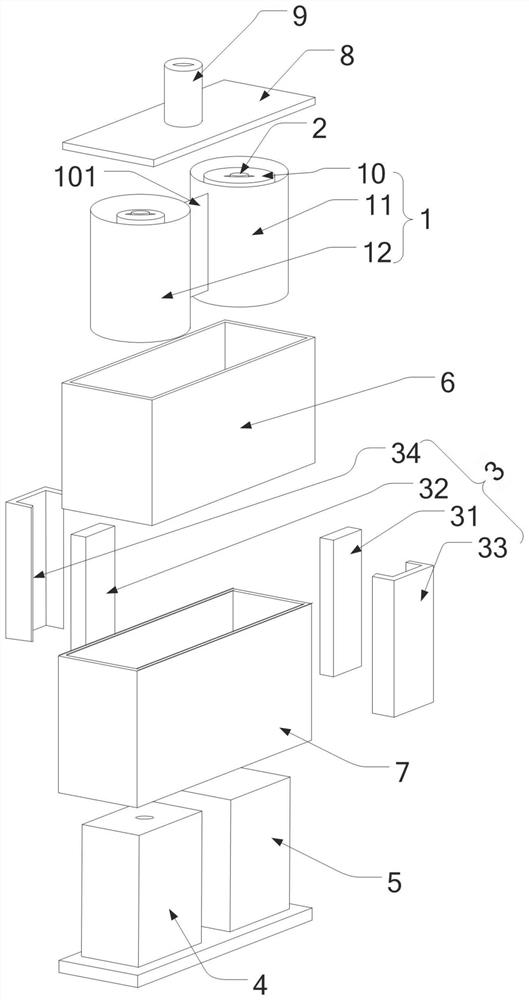

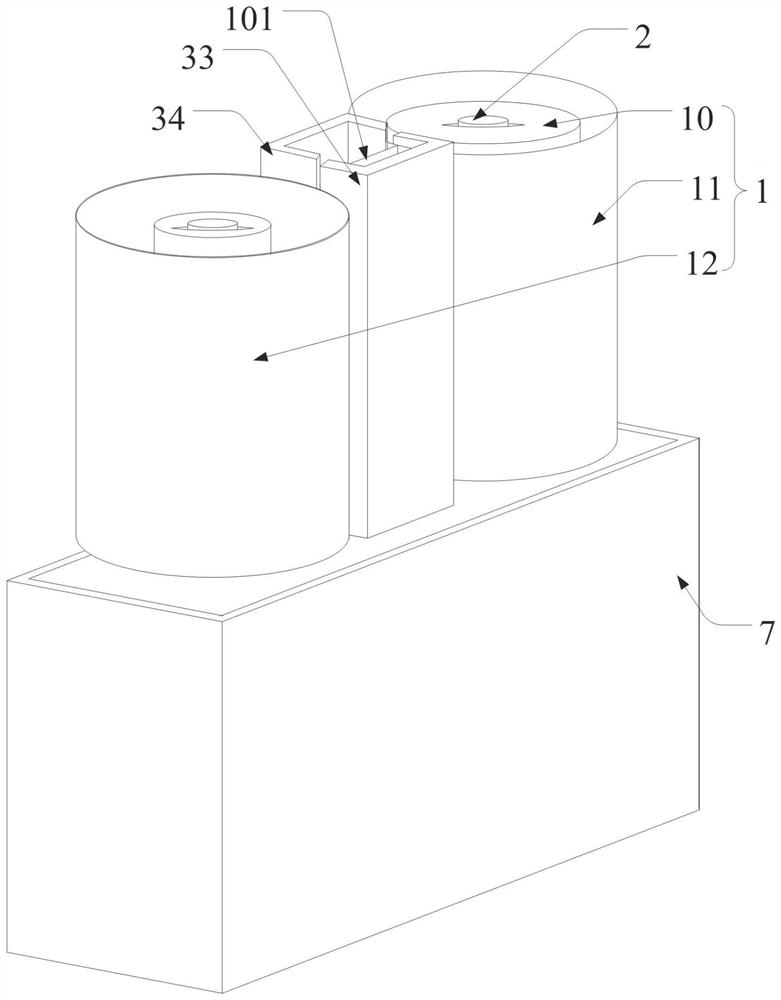

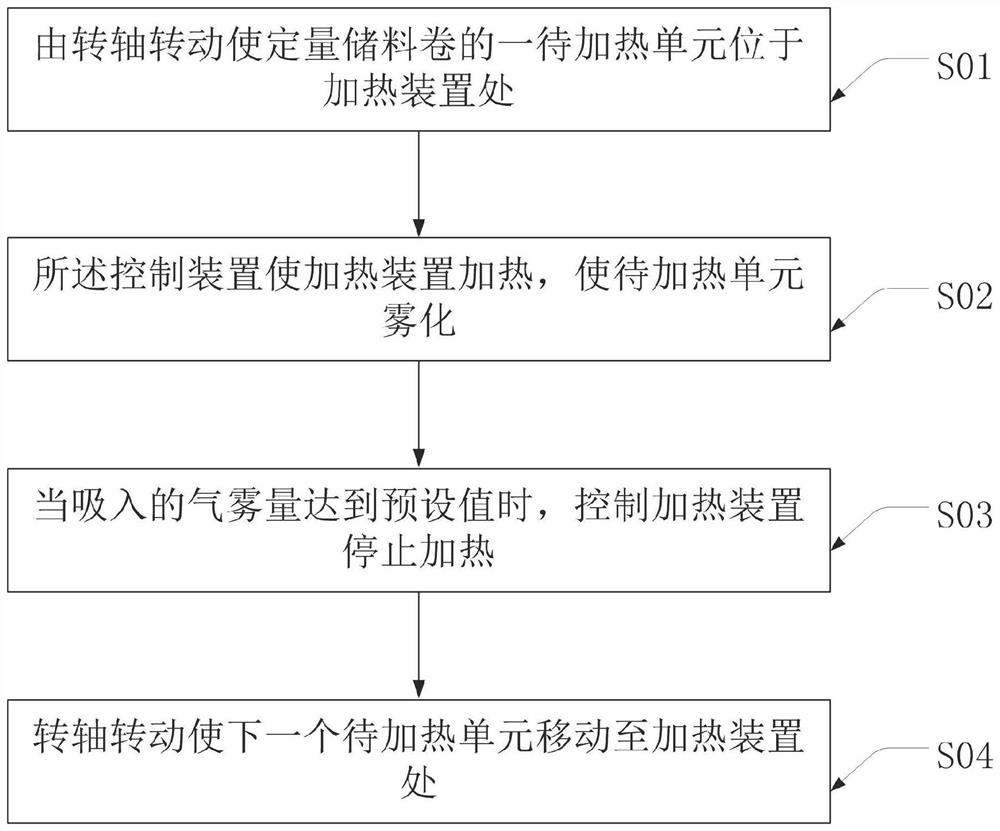

A quantitative feeding heater and its heating method

ActiveCN111195573BEvenly heatedSmooth releaseSpraying apparatusTobacco devicesAerosolizeAerosol Mist

The invention discloses a quantitative feeding heater and a heating method thereof, wherein the quantitative feeding heater comprises a coil storage device, a rotating shaft, and a heating unit for heating one of the to-be-heated units of the coil storage device. A device, an airflow sensor and a control device, the rotating shaft rotates so that the unit to be heated is located at the heating device, when the heater is activated, the control device quickly heats the unit to be heated to a set temperature for the user to inhale, and the airflow sensor detects the inhaled air When the amount of aerosol inhaled reaches a preset value, the heating device is controlled to stop heating, so that the heater has the function of quantitative atomization, so as to meet the needs of consumers. During use, the roll storage device is controlled by the rotating shaft to transport one of the units to be heated to the heating device, and heated by the heating device, so that the unit to be heated is heated evenly, so that the useful components in the aerosol are released during use. Homogeneous to meet the requirements of quantitatively providing the desired ingredients.

Owner:董美文

A method and system for quality control of cement raw meal based on generalized inverse matrix

ActiveCN104950861BGuaranteed stabilityMeet ingredient requirementsTotal factory controlProgramme total factory controlAdditive ingredientQuality control system

A method and system for quality control of cement raw meal based on generalized inverse matrix, the method includes the following steps: S1: determine the expected target value of cement raw meal quality; S2: determine the required ratio of various raw materials in cement raw meal, and give The relationship between raw materials and their active ingredients; S3: According to the raw materials, active ingredient content and expected target value, use the generalized inverse matrix theory to calculate the corresponding relationship between the expected target value and raw materials; S4: According to the expected target value, given target The coefficient matrix of the corresponding relationship between the value and the active ingredient, and the coefficient matrix of the effective ingredient contained in the raw material, use the corresponding relationship obtained in step S3 to adjust the ratio of the raw material. The present invention calculates the ratio of raw materials according to the given target value, ensures the stability of the raw meal components after grinding, meets the batching requirements under different process conditions, realizes the real-time adjustment of raw material ratios, and reduces the ratio of raw materials Value fluctuations ensure the quality of the raw meal and the robustness of the entire raw meal quality control system.

Owner:UNIV OF JINAN +1

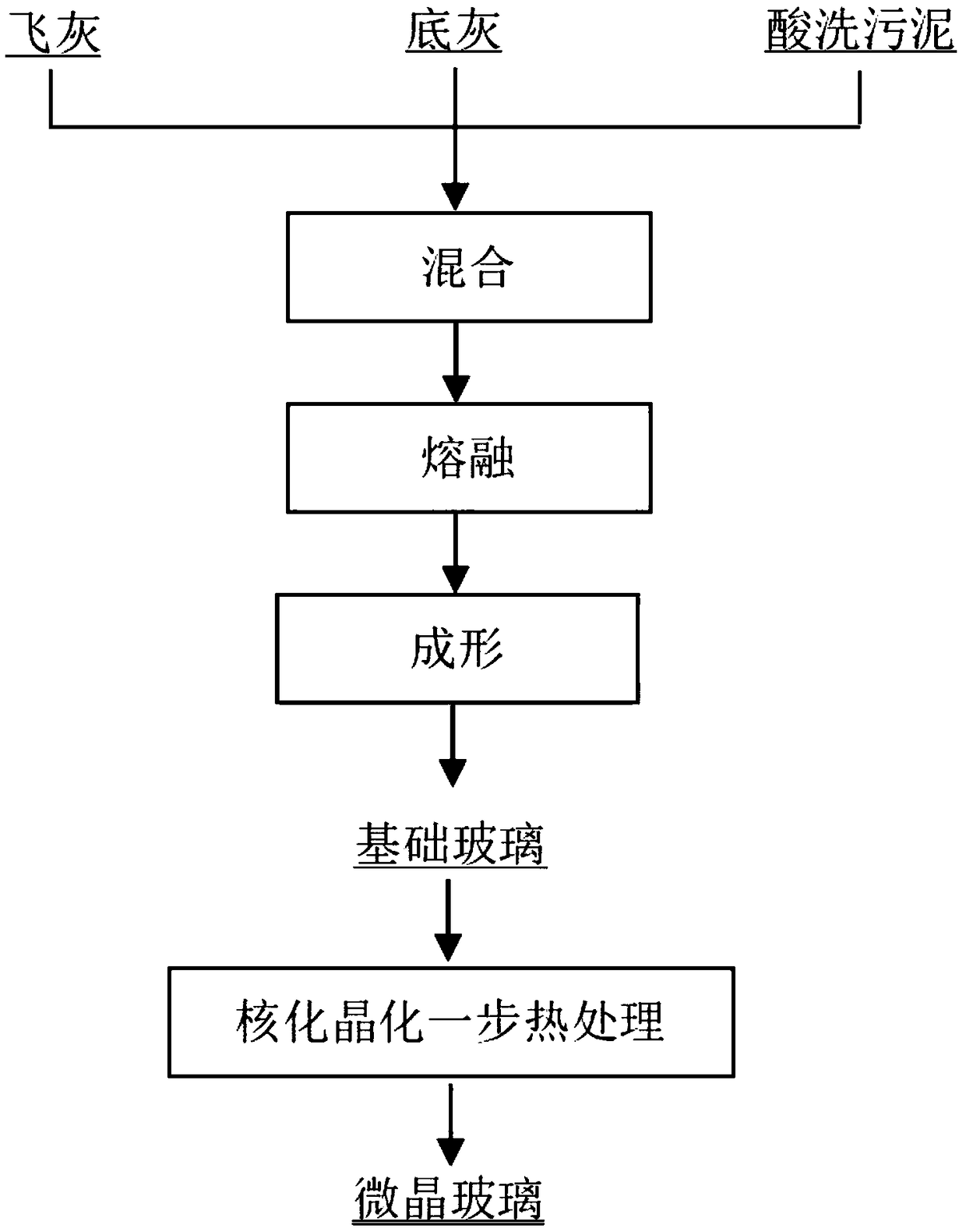

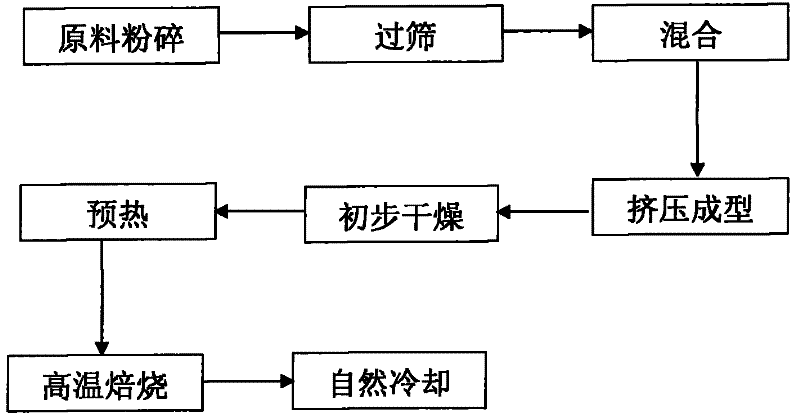

A method for preparing glass-ceramics from waste incineration ash and pickling sludge

The invention belongs to the field of solid waste resource utilization,and discloses a method for preparing glass ceramics by using waste incineration ash synergistic pickling sludge. The method useswaste incineration ash as a main raw material,uses the pickling sludge as a nucleating agent,obtains base glass by high temperature melting,and obtains the glass ceramic by one-step heat treatment. The method achieves the harmless disposal and high-value utilization of the waste incineration ash and the pickling sludge,prepares the glass ceramic through a melting-one-step heat treatment method,andhas the advantages of short process flow,energy saving and easy industrialization.

Owner:UNIV OF SCI & TECH BEIJING

A kind of production method of low carbon high manganese steel

ActiveCN106544468BReduce processing timeMeet ingredient requirementsManufacturing convertersMetallurgyOxygen

The invention relates to a method for producing low-carbon high-manganese steel. The converter-RH furnace-ladle furnace (LF) production process route is adopted, Mn losses are reduced by controlling the vacuum degree in the treatment process, and LF treatment time is shortened for reducing recarburization. The method has the advantages that RH treatment time is shortened by means of converter low-carbon high-manganese tapping, RH oxygen blowing is performed for forced decarbonization, the vacuum degree is controlled below 100pa, and the oxygen blowing lance position is 6.5m so that the Mn gasification losses can be reduced; and finally the LF treatment time is reduced for reducing recarburization, and the effect that molten steel can meet the finished product ingredient requirement is guaranteed, namely C of the steel type is smaller than or equal to 0.02%, Mn of the steel type is 17%-18% and S of the steel type is smaller than or equal to 0.005%.

Owner:ANGANG STEEL CO LTD

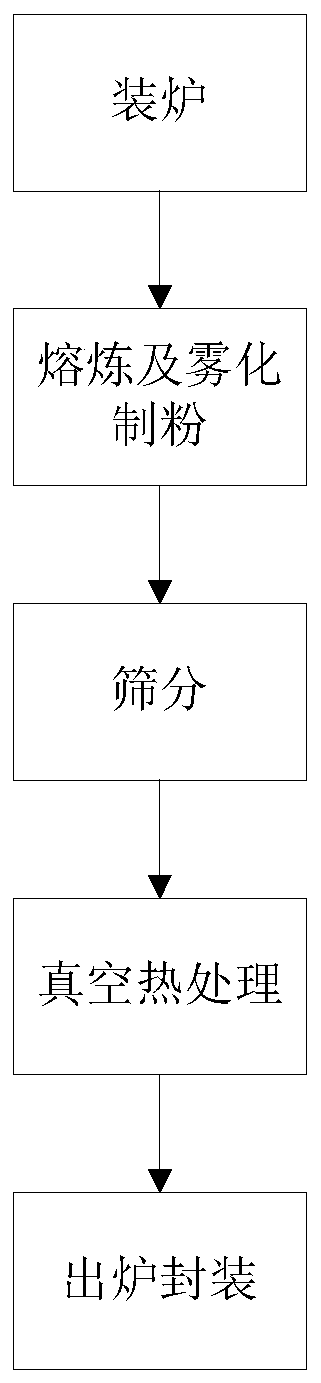

Zirconium alloy powder and preparing method thereof

InactiveCN110496968AReduce hydrogen contentImprove liquidityTransportation and packagingMetal-working apparatusNuclear powerHydrogen content

The invention discloses a preparing method of zirconium alloy powder. The method comprises the following steps of A, furnace charging, wherein vacuumizing is carried out in an atomization furnace, andinert gases are replaced; B, smelting and atomizing for powder making, wherein a zirconium alloy bar is heated until the bottom end of the zirconium alloy bar is molten to form molten dripping, and inert atomized gas is used for crushing the molten dripping to form the zirconium alloy powder; C, screening, wherein, under the protective atmosphere, screening is carried out to obtain the zirconiumalloy powder with the granularity meeting the meets; D, vacuum heat treatment, wherein in a vacuum heat treatment furnace, heat treatment is carried out on the zirconium alloy powder obtained throughscreening in the step C, and the zirconium alloy powder with the content of hydrogen lower than 25 micrograms / g; and E, discharge packaging. After screening, the vacuum heat treatment step is introduced for treating the zirconium alloy powder, the hydrogen content of the zirconium alloy powder can be obviously reduced, the nuclear-pure-level component needs are met, the fluidity of the zirconium alloy powder can be obviously improved, and the made zirconium alloy powder can be directly applied to 3D printing process making of nuclear power station fuel assembly related parts like cladding.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Sludge oxidation pellets and manufacturing method

The invention discloses a sludge oxidation pellet and a manufacturing method. The sludge oxidation pellets of the present invention are mainly made of the following raw materials in weight percentage: 5-50% of stainless steel cold-rolled heavy metal sludge, 30-70% of iron fine powder, 2-8% of composite binder, carbon powder 4-15%, moisture 10-30%. The above-mentioned method for producing sludge oxidation pellets mainly includes pretreatment of raw materials, mixing of raw materials, pelletizing, and roasting. The purpose of the sludge oxidized pellets is to be used as a blast furnace raw material. The invention solves the problem that the prior art cannot effectively process and comprehensively utilize the stainless steel cold rolling heavy metal sludge.

Owner:BAOSHAN IRON & STEEL CO LTD

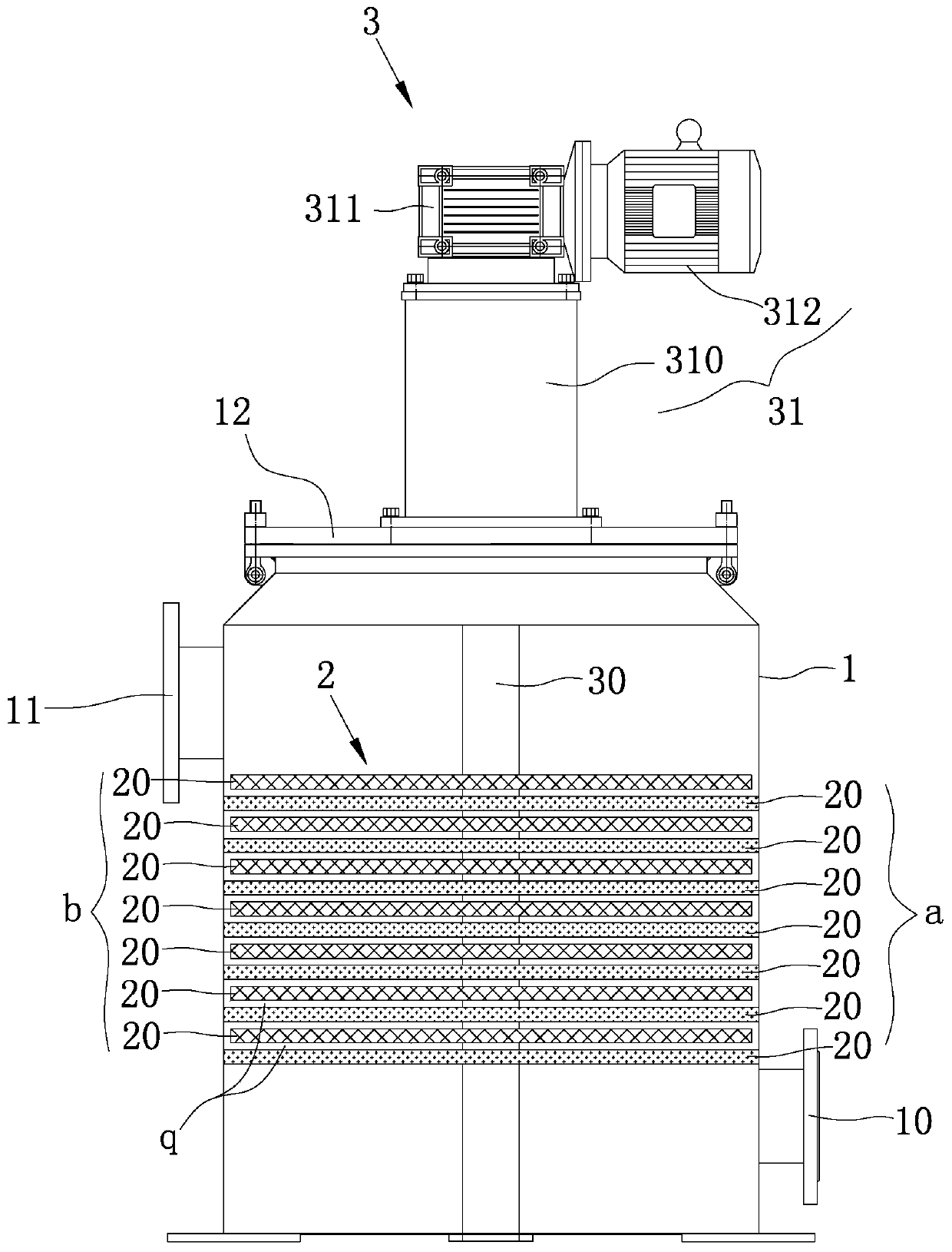

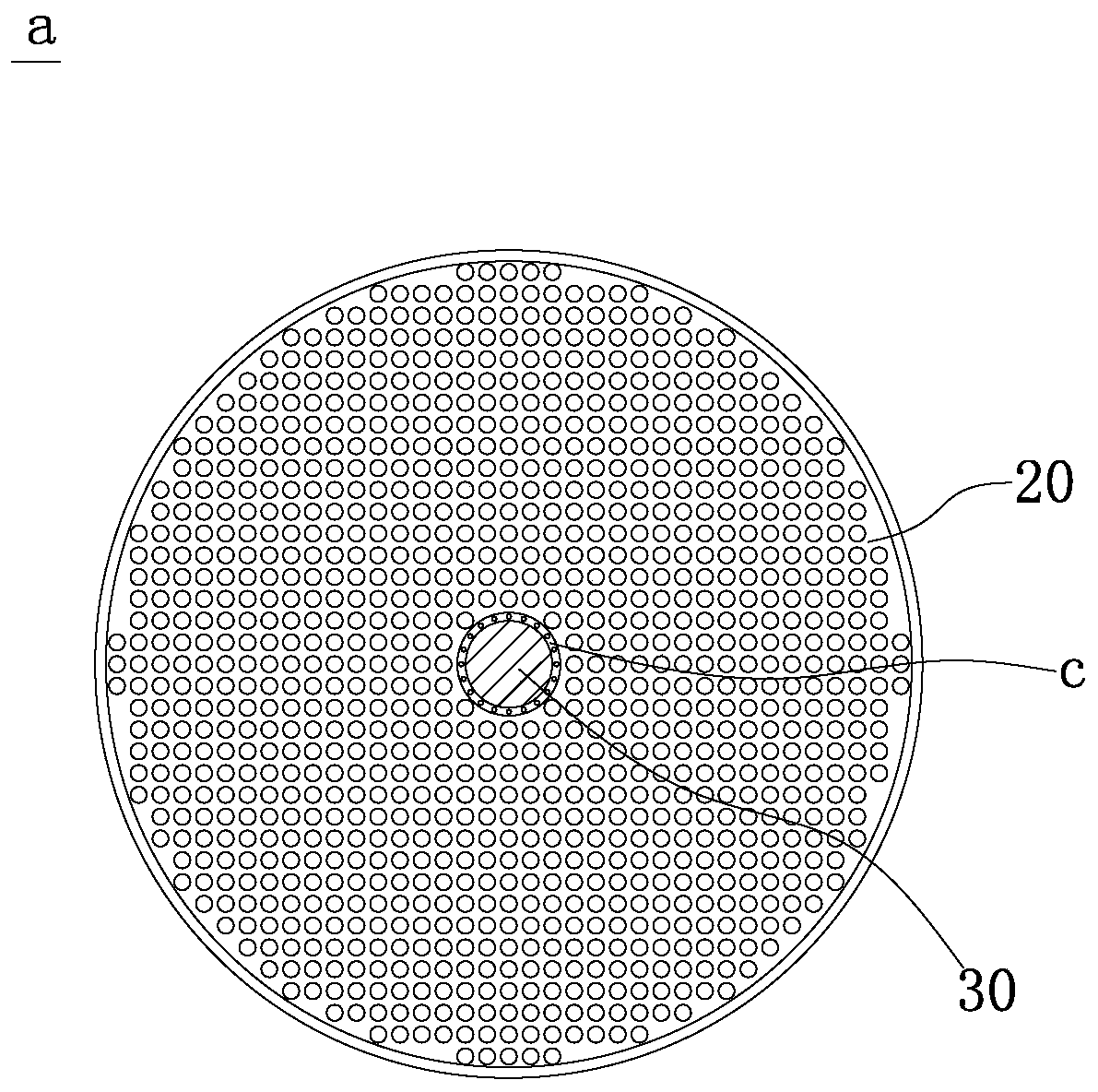

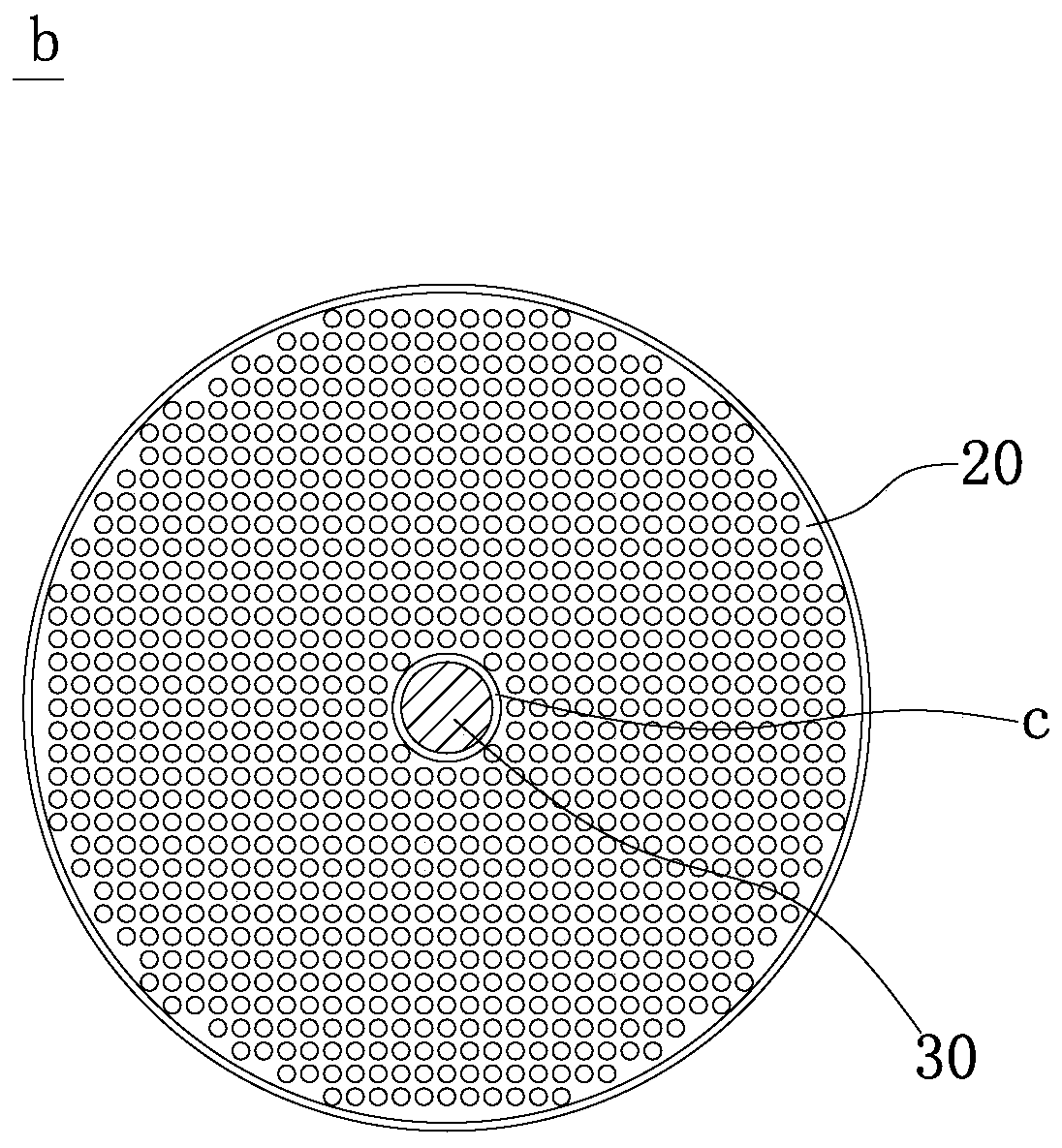

Grinding filter suitable for uniform proportioning of modified asphalt

The invention relates to a grinding filter suitable for uniform proportioning of modified asphalt. The grinding filter comprises a device tank with a feeding channel and a discharging channel, and a filtration assembly which is arranged inside the device tank in an intercept mode, the device tank is vertically arranged, the feeding channel is located on one side of the lower part of the device tank, the discharging channel is located on one side of the upper part of the device tank, the filtration assembly comprises a plurality of layers of filter screens which are sequentially arranged from bottom to top at intervals, wherein the pore diameters of the filter screen are gradually reduced layer by layer, the multiple layers of filter screens are divided into two sets, one set is a fixed filter screen set which is fixed to the inner wall of the device tank, the other set is a grinding filter screen set which is horizontally arranged in the device tank in a rotating mode around the centerof the grinding filter screen set, the filter screens which are used for correspondingly forming the fixed filter screen set and the grinding filter screen set are sequentially distributed at intervals, and the special grinding filter further comprises a driving mechanism used for driving the grinding filter screen set to rotate. According to the grinding filter, agglomerated materials with different particle diameters from large to small can be stepwise ground and filtered, so that the materials discharged from the discharging channel are fine and homogenized, and the proportioning requirements of the modified asphalt are met.

Owner:中建材苏州防水研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com