Waste incineration fly ash recycling method and system

A waste incineration fly ash and treatment system technology, applied in waste heat treatment, furnace control devices, lighting and heating equipment, etc., can solve problems such as energy consumption, high energy consumption of plasma treatment technology, secondary hazardous waste, etc., and achieve flue gas The effect of small emissions, increased proportion, and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

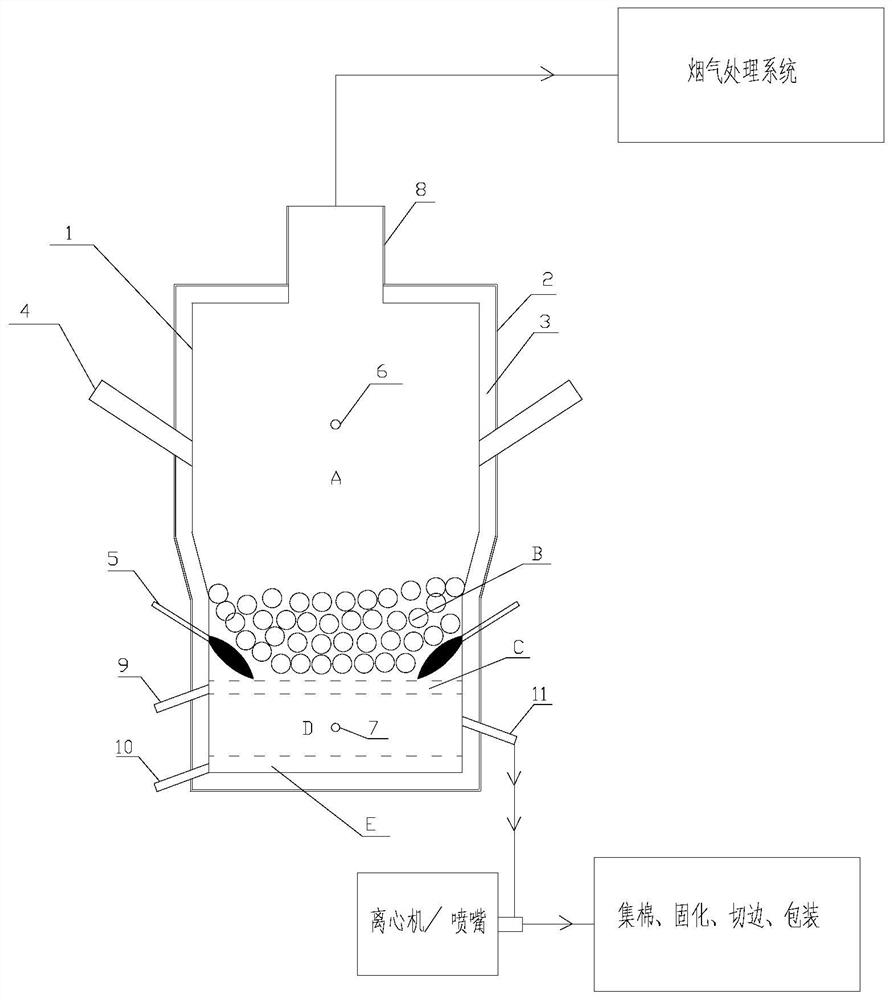

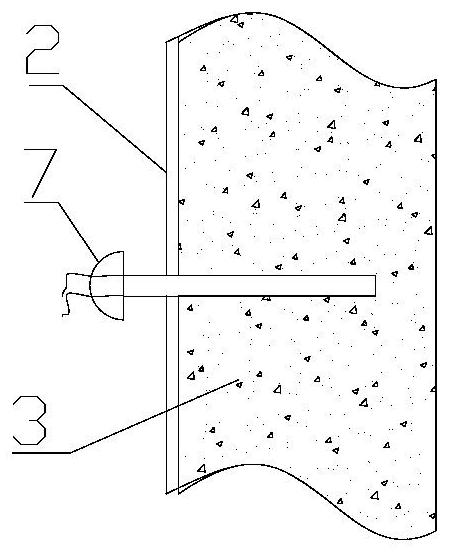

[0036] The waste incineration fly ash recycling system of this embodiment, such as figure 1 As shown, it is specifically a pure oxygen combustion melting furnace 1. The pure oxygen combustion melting furnace 1 is composed of a furnace wall 2 and a refractory material 3. The furnace can be divided into a gas phase area A, a fly ash particle solid phase area B, and a chloride salt melting area C. , slag zone D, alloy melting zone E;

[0037] In the gas phase area A, two feed ports 4 are evenly distributed along the furnace wall to ensure the uniformity of the feed. The angle between the feed port and the furnace wall is 40°; the top of the furnace body is provided with a smoke exhaust port;

[0038] Two pure oxygen burners 5 are evenly distributed in the solid phase area B of fly ash particles to ensure the uniformity of temperature in the solid phase and liquid phase areas of the fly ash fusion, and the angle between the pure oxygen burner and the furnace wall is 40°;

[0039]...

Embodiment 2

[0044] Adopt the stove of embodiment 1 to be example to fly ash, the material composition analysis of this fly ash is as shown in table 1:

[0045] Table 1

[0046] components Mass fraction % SiO 2

[0047] Taking 1t of fly ash in Table 1 as an example, add 300kg of limestone and 80kg of starch as a binder to granulate before putting into the furnace. The granulated particle size is 30-50mm.

Embodiment 3

[0049] Taking 1t of fly ash in Table 1 as an example, add 320kg of quartz sand (purity 98%) and 100kg of starch as a binder to granulate before putting into the furnace, with a particle size of 30-50mm. The granulation formula can ensure the acidity coefficient Mk=1.2 after the fly ash is melted, which meets the composition requirement of slag wool.

[0050] The granulated material is fed into the pure oxygen combustion melting furnace from the feed port 4. By controlling the height of the solid material, the temperature of the gas phase zone A in the furnace is maintained at 500-700°C. At the same time, by adjusting the pure oxygen burner The amount of natural gas is used to maintain the temperature of the melting zone at 1500-1600°C.

[0051] Table 2 shows the chemical analysis results of the chlorine salt discharge port discharge, the alloy discharge port discharge material, and the slag discharge port discharge material in this embodiment.

[0052] Table 2

[0053]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com