An adaptive cement raw meal batching system and its batching method based on typical working conditions

A technology for cement raw meal and typical working conditions, which is applied in batching and batching instruments, control/regulating systems, chemical instruments and methods, etc. Fluctuation and other problems, to achieve the effect of stable raw meal composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the embodiments.

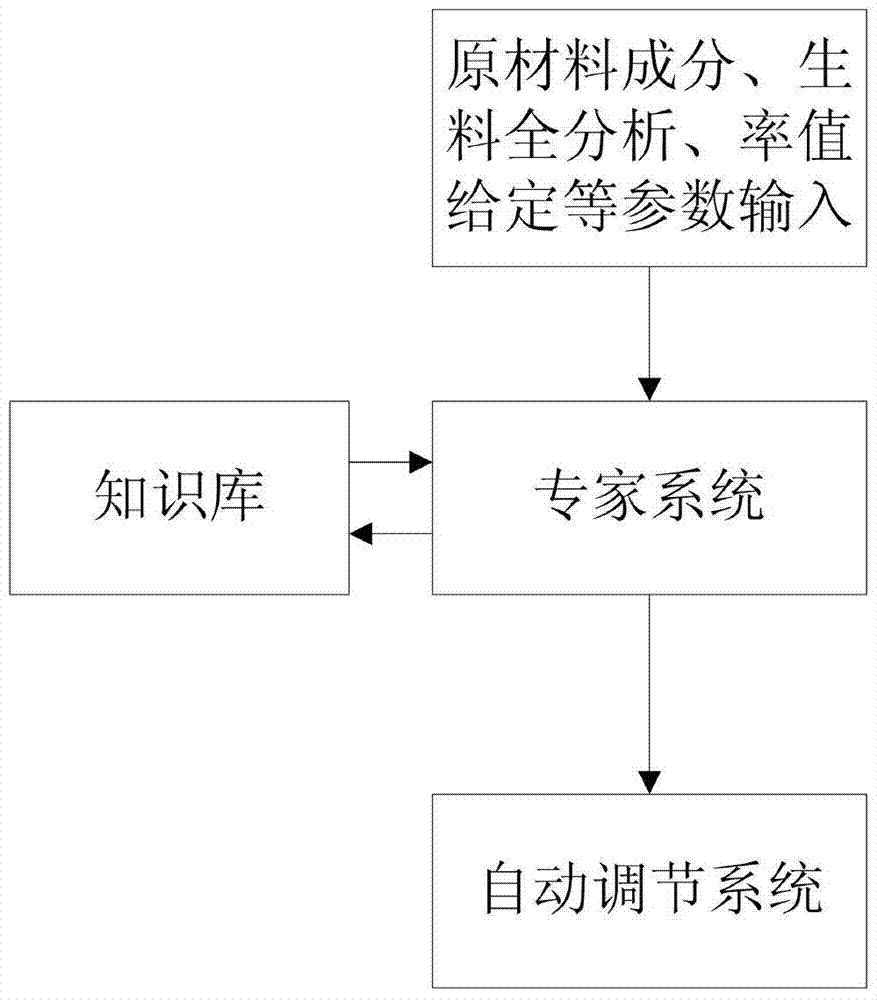

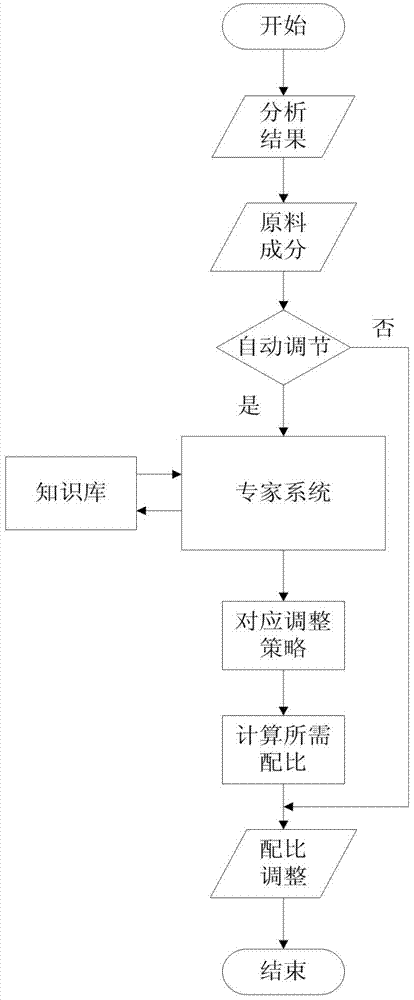

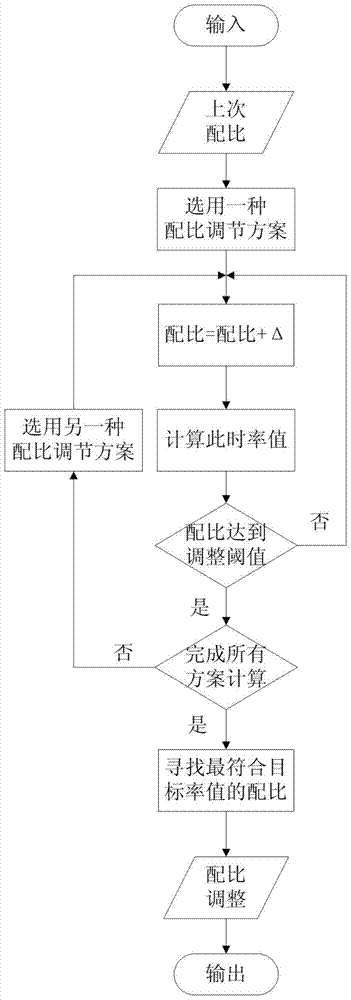

[0045] like figure 1 As shown, the self-adaptive cement raw meal batching system based on typical working conditions in the present invention includes: an expert system, a knowledge base for distinguishing cement batching working conditions, connecting to the expert system, and adding calculation strategies for different working conditions, There should be corresponding artificial intelligence control rules for each working condition, adding the experience of manual adjustment ratio to the control rules, and selecting the optimal strategy, that is, intelligently judging the working conditions, and automatically selecting the optimal ratio adjustment scheme;

[0046] The automatic adjustment system is connected to the expert system, and the ratio adjustment is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com