Novel process for high-efficiency surfacing composite manufacturing (remanufacturing) of continuous casting roll

A new process, continuous casting roll technology, applied in the field of high-efficiency surfacing composite manufacturing of continuous casting rolls and single-layer surfacing composite manufacturing of continuous casting rolls, can solve the problems of long surfacing welding time, many surfacing welding defects, and low cost performance. Achieve the effect of reducing surfacing time, good process performance and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

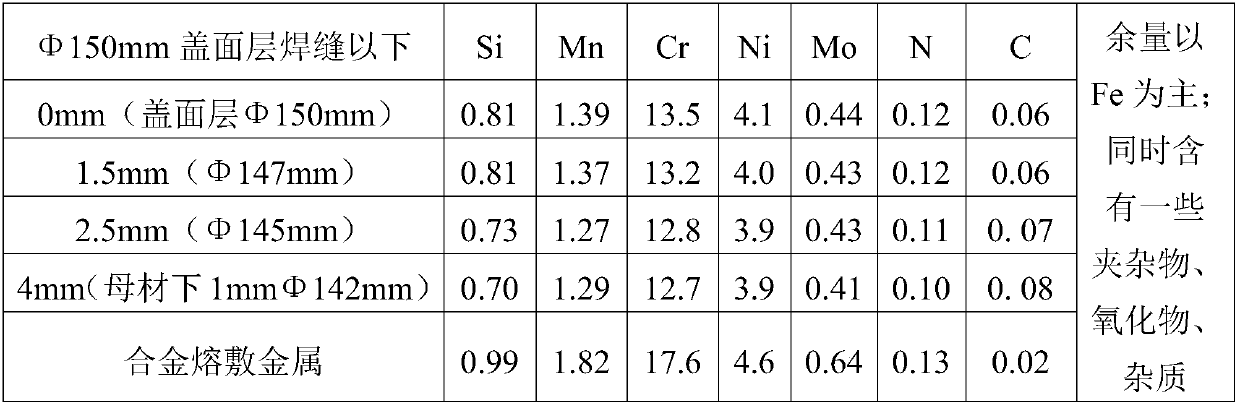

[0024] Embodiment 1 (single-layer open-arc swing surfacing composite manufacturing of new rolls)

[0025] Taking surfacing composite manufacturing of Φ150mm continuous casting roll, the base material is 21CrMoV511 as an example, the drawing stipulates that the thickness of one side is 4mm, and the alloy composition (including carbon) meets voestalpine (TSC 4-TS No.03 / 94).

[0026] The surfacing composite manufacturing process is:

[0027] 1.1 Process the new roll blank to Φ144mm (that is, the design size of the base metal drawing + 1mm (one side)), and do the corresponding inspection;

[0028] 1.2 Select the appropriate self-shielding open arc surfacing welding consumables, especially the composition at Φ150mm and 142mm can meet the technical and mechanical performance requirements of voestalpine composition, structure and so on.

[0029] 1.3 Before welding, the roll blank is not preheated.

[0030] 1.4 Parameter requirements of surfacing welding specification (reference): ...

Embodiment 2

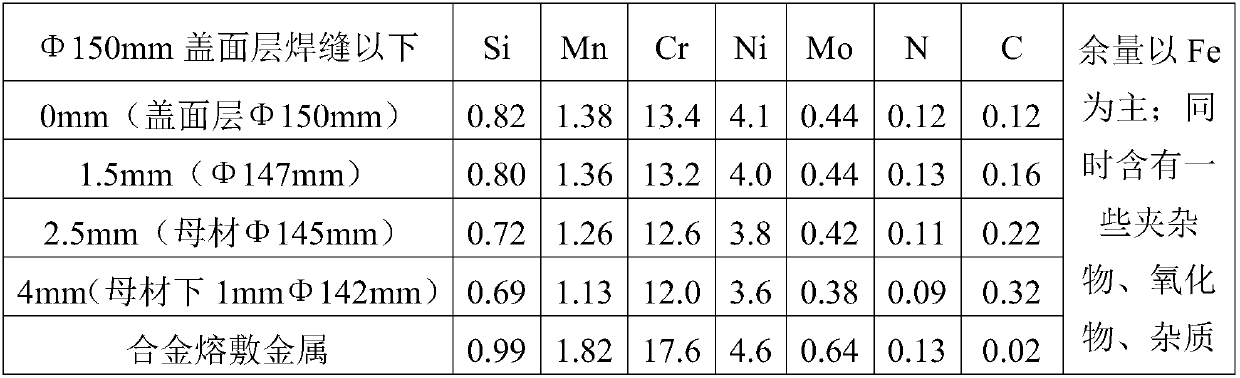

[0052] Embodiment 2 (single-layer open-arc swing surfacing composite manufacturing of new rolls)

[0053]Take surfacing composite manufacturing Φ150mm continuous casting roll, the base material is 42CrMo as an example, the drawing stipulates that the single side thickness is 4mm, and the alloy composition (except carbon) meets voestalpine (TSC 4-TS No.03 / 94).

[0054] The surfacing composite manufacturing process is:

[0055] 2.1 Process the new roll blank to Φ144mm (that is, the design size of the base metal drawing + 1.0mm (single side)), and perform corresponding inspections;

[0056] 2.2 Select the appropriate self-shielding open arc surfacing welding consumables, especially the composition at Φ150mm and 142mm can meet the technical and mechanical performance requirements of voestalpine composition, structure and so on.

[0057] 2.3 Before welding, the roll blank is not preheated.

[0058] 2.4 Parameter requirements of surfacing welding specification (reference):

[005...

Embodiment 3

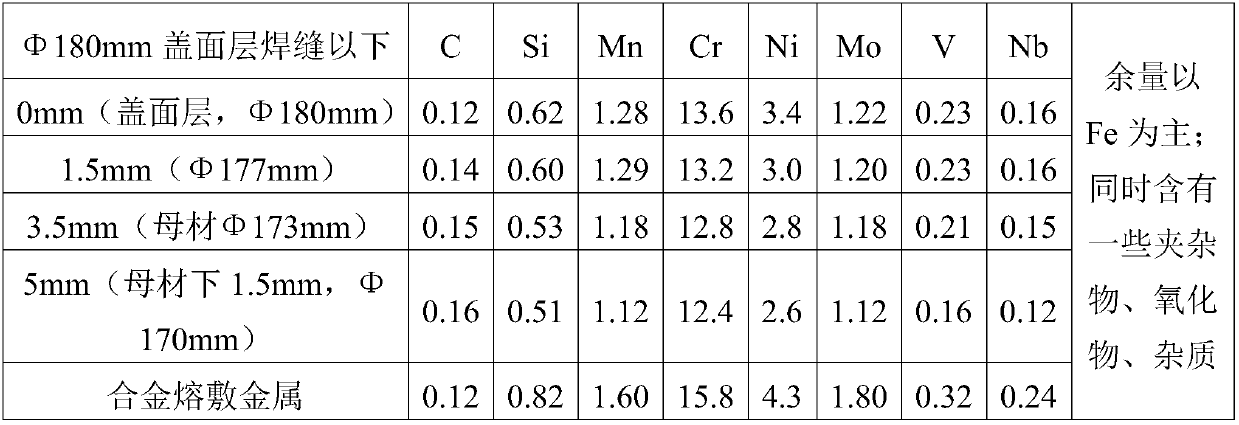

[0081] Embodiment 3 (submerged arc single-layer submerged arc oscillating surfacing welding composite remanufacturing roll)

[0082] Taking 21CrMoV511 as an example for surfacing composite remanufacturing Φ180mm continuous casting base metal, the drawing stipulates that the thickness of one side is 5mm, and the alloy composition meets VAI (TSC 4-TS No.02 / 93).

[0083] The surfacing composite remanufacturing process is:

[0084] 3.1 The old roll blank is processed to Φ173mm (that is, the design size of the base metal drawing + 1.5mm (one side)), and the corresponding inspection is carried out. If there are local defects such as cracks, continue turning. For local defects, the mechanical properties similar to the base metal should be used. Repair welding with low alloy welding consumables;

[0085] 3.2 Select suitable submerged arc surfacing welding consumables, especially Φ180mm and Φ170mm to meet the requirements of VAI such as composition and hardness.

[0086] 3.3 Before w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com