Moderate and high strength large-thickness component narrow gap or ultra-narrow gap magnetic control jet molten welding method

A fusion welding, narrow gap technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can not solve the problem of droplet transfer stability in the continuous high current range, the shape and structure of the external box-shaped nozzle is complicated, and the height adjustment device Adjust the problems such as low precision to achieve the effect of reducing chemical inhomogeneity, reducing welding defects, and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

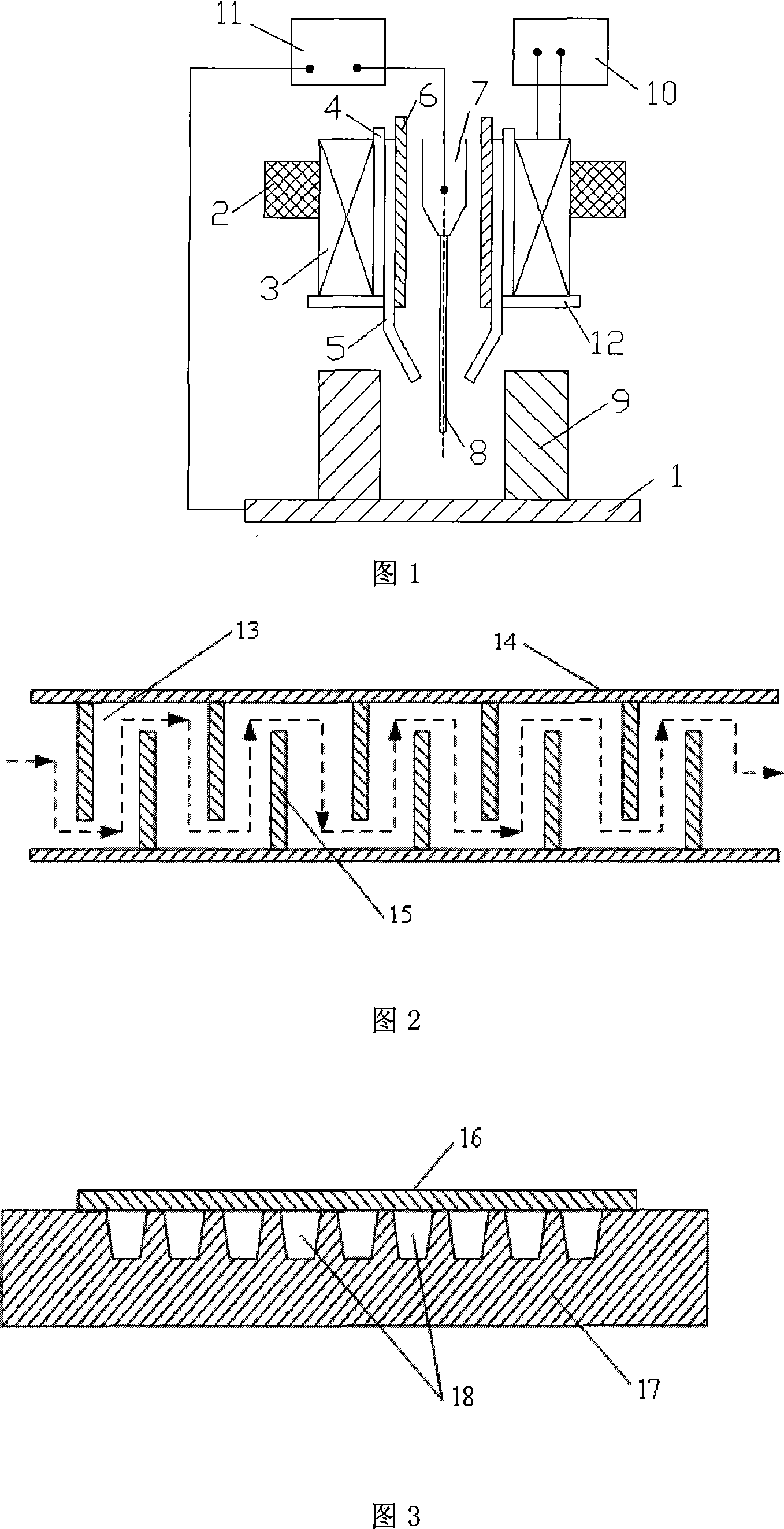

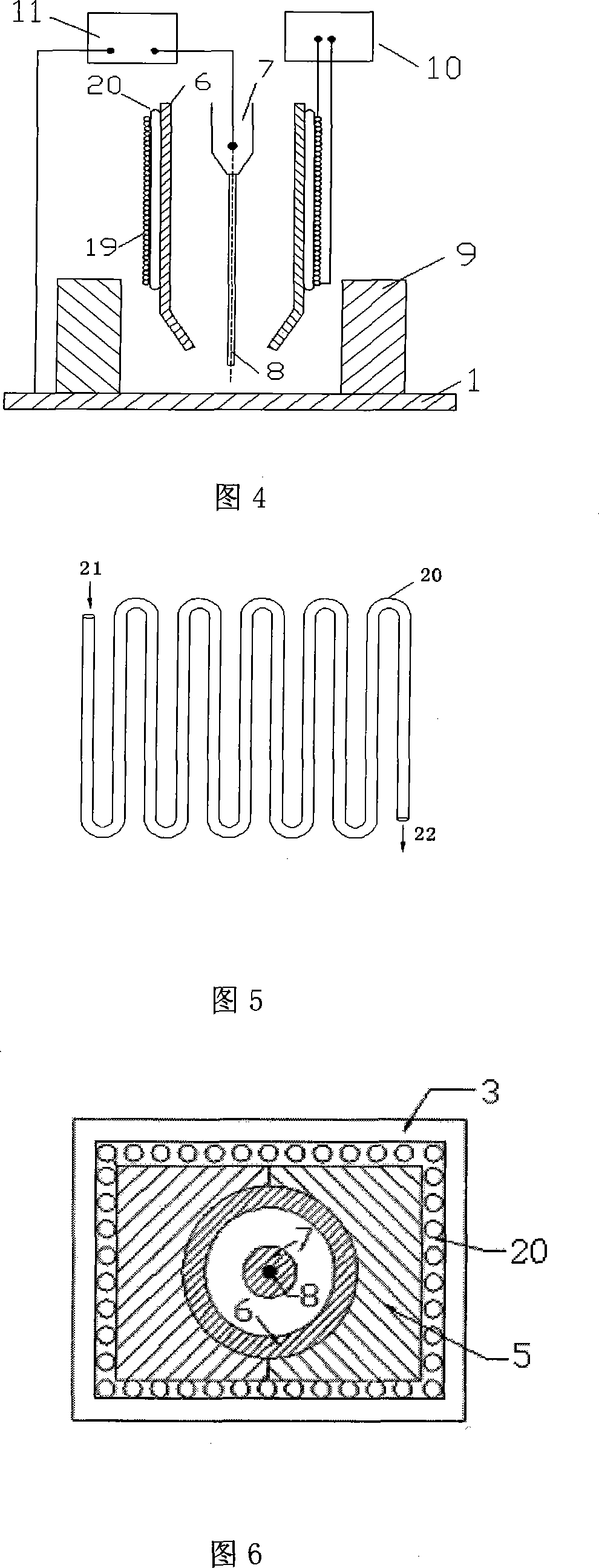

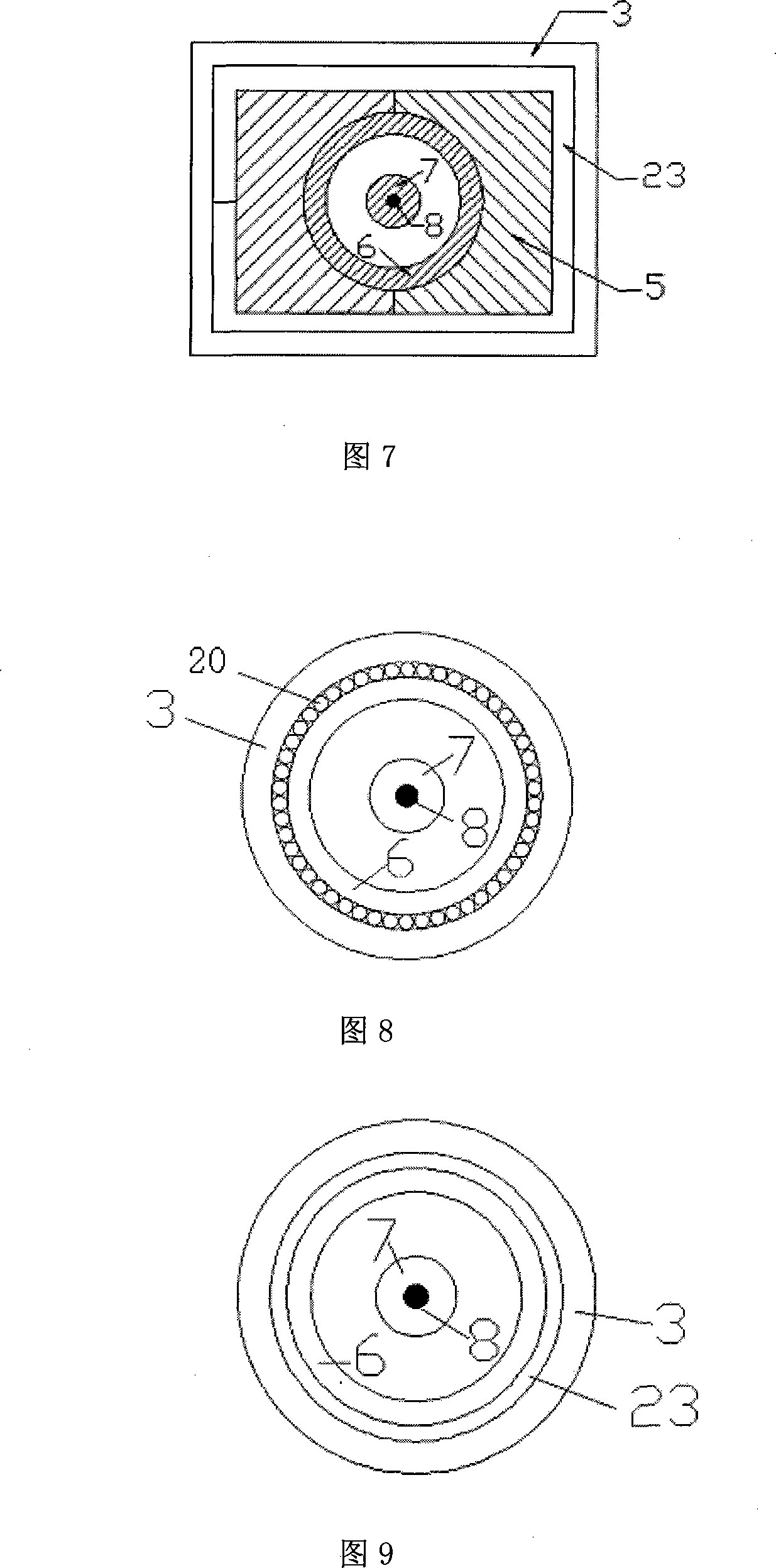

example 1

[0106] Example 1: Pulse jet welding of 40mm thick 20G steel with 10mm wide and narrow gaps is controlled by an external longitudinal magnetic field. The welding process parameters are as follows to obtain a good welded joint: the external magnetic field strength is 0.01-0.05T, and the magnetic field frequency is 1-5Hz (that is, the intensity of the excitation current 8~40A, excitation current frequency is 1~5Hz), magnetic field duty ratio is 20~80%, welding current is 300~600A, welding current frequency is 1~50Hz, welding current duty ratio is 30~70%, welding speed 0.4~5m / min, argon shielding gas 15L / min, wire feeding speed 1~60m / min, welding wire dry elongation 12~25mm, welding wire diameter 1.2mm, welding wire grade H08A.

example 2

[0107] Example 2: A 50mm thick A3 steel ultra-narrow gap 4.5mm wide pulse jet welding is controlled by an external longitudinal magnetic field. Current intensity is 10-50A, excitation current frequency is 1-8Hz), magnetic field duty ratio is 20-80%, welding current is 200-600A, welding current frequency is 1-20Hz, welding current duty ratio is 30-70% , welding speed 0.3 ~ 7m / min, argon shielding gas 18L / min, wire feeding speed 15 ~ 50m / min, dry elongation of welding wire 18 ~ 28mm, wire diameter 1.2mm, wire grade H08A.

[0108] It can be seen from the above examples that the reasonable matching of the electromagnetic field and welding process parameters should be considered comprehensively, such as the length of the welding wire, the composition of the shielding gas, the welding arc voltage, the strength and frequency of the electromagnetic stirring magnetic field, etc., and the main process parameters should be systematically analyzed according to the actual welding objects an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com