Welding process method of brass H62

A welding process and brass technology, applied in the field of brass H62 welding process, can solve problems such as deformation, poor forming, pores, etc., and achieve the effects of simple operation, improved heat utilization, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Base material: brass tube H62, specification φ28×5mm.

[0050] (2) Welding materials: welding wire SCu6810A (HSCuZn-3), specification φ2.5mm; flux CJ301; argon purity 99.99%; cerium tungsten electrode diameter φ2.5mm.

[0051] (3) Groove processing: the pipe is cut with a lathe, and the V-shaped groove is processed with a portable grinder. The groove angle is 37.5° and the blunt edge is 0mm.

[0052] (4) Surface cleaning: Before welding, use a combination of mechanical cleaning and chemical cleaning to remove oil, moisture, and oxides on both sides of the brass H62 welding groove and on the surface of the welding wire within 30mm until the metallic luster is exposed. Specifically, first use a file and a stainless steel wire brush to machine the welding groove and its edge surface to remove oxides, and then scrub and degrease with acetone.

[0053] (5) Flux coating: Prepare the flux CJ301 with absolute ethanol into a paste, and apply it on the cleaned pipe bevel and...

Embodiment 2

[0064] (1) Base material: brass tube H62, specification φ60×5mm.

[0065] (2) Welding materials: welding wire SCu6810A (HSCuZn-3), specification φ2.5mm; flux CJ301; argon purity 99.99%; cerium tungsten electrode diameter φ3.0mm.

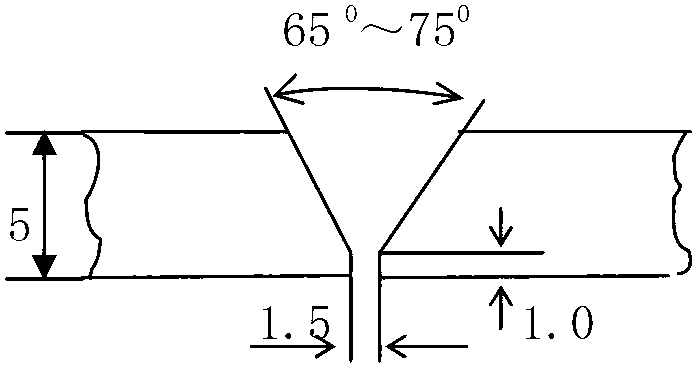

[0066] (3) Groove processing: the pipe is cut with a lathe, and the butt V-shaped groove is processed with a portable grinder. The groove angle is 32.5° and the blunt edge is 1.5mm.

[0067] (4) surface cleaning: with embodiment 1,

[0068] (5) Flux coating: same as in Example 1,

[0069] (6) Carry out weldment assembly, the assembly gap is 3.0mm, and it is not allowed to touch the groove with hands when welding assembly assembly.

[0070] (7) Preheating before welding: the pipe is preheated after adding paste flux, using oxyacetylene flame heating method, the preheating temperature is 250 ℃,

[0071] (8) Welding operation: first release the impure gas on the gas cylinder, and use an inverter argon arc welding machine for welding. The inner diamet...

Embodiment 3

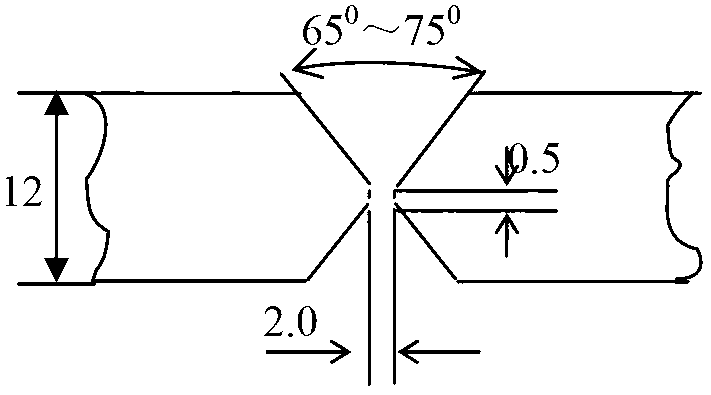

[0079] (1) Base material: brass plate H62, specification δ=12mm.

[0080] (2) Welding materials: welding wire SCu6810A (HSCuZn-3), specification φ2.5mm; flux CJ301; argon purity 99.99%; cerium tungsten electrode diameter φ3.2mm.

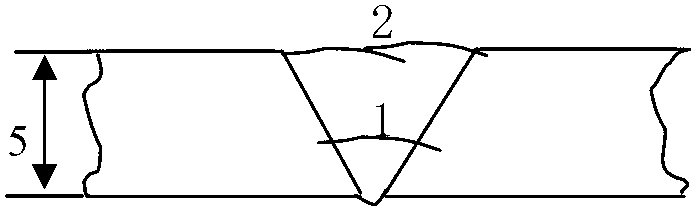

[0081] (3) Groove processing: the pipe is cut with a lathe, and the X-shaped groove is processed with a portable grinder, the groove angle is 35°, and the blunt edge is 1.0mm (see figure 2 a).

[0082] (4) surface cleaning: with embodiment 1,

[0083] (5) Flux coating: same as in Example 1,

[0084] (6) Carry out weldment assembly, the assembly gap is 2.0mm, and it is not allowed to touch the groove with hands when welding assembly.

[0085] (7) Preheating before welding: the pipe is preheated after adding paste flux, using oxyacetylene flame heating method, the preheating temperature is 300°C,

[0086] (8) Welding operation: First release the impure gas on the gas cylinder, and use an inverter argon arc welding machine for welding. The inner di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com