Patents

Literature

31results about How to "Loose process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

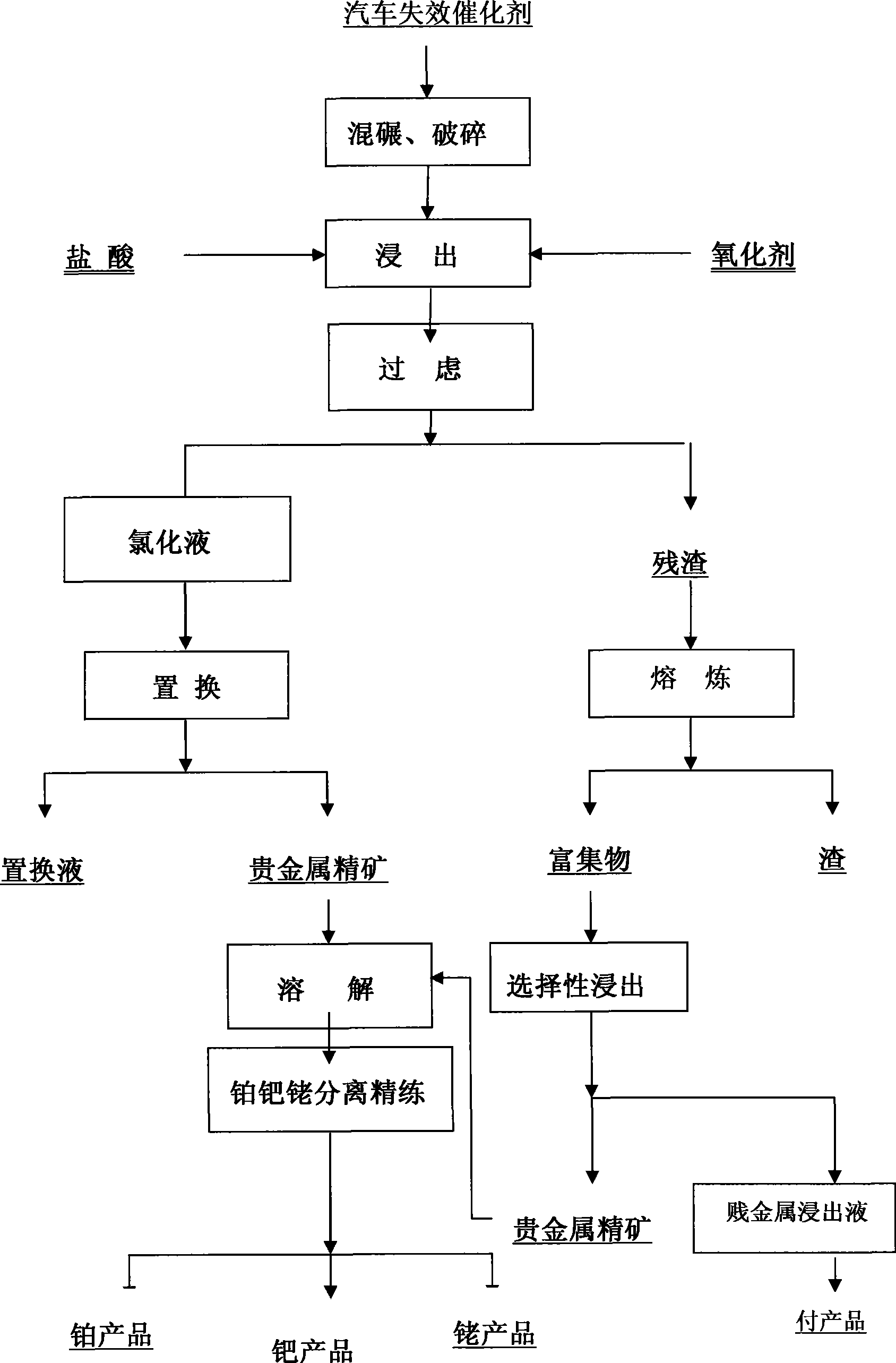

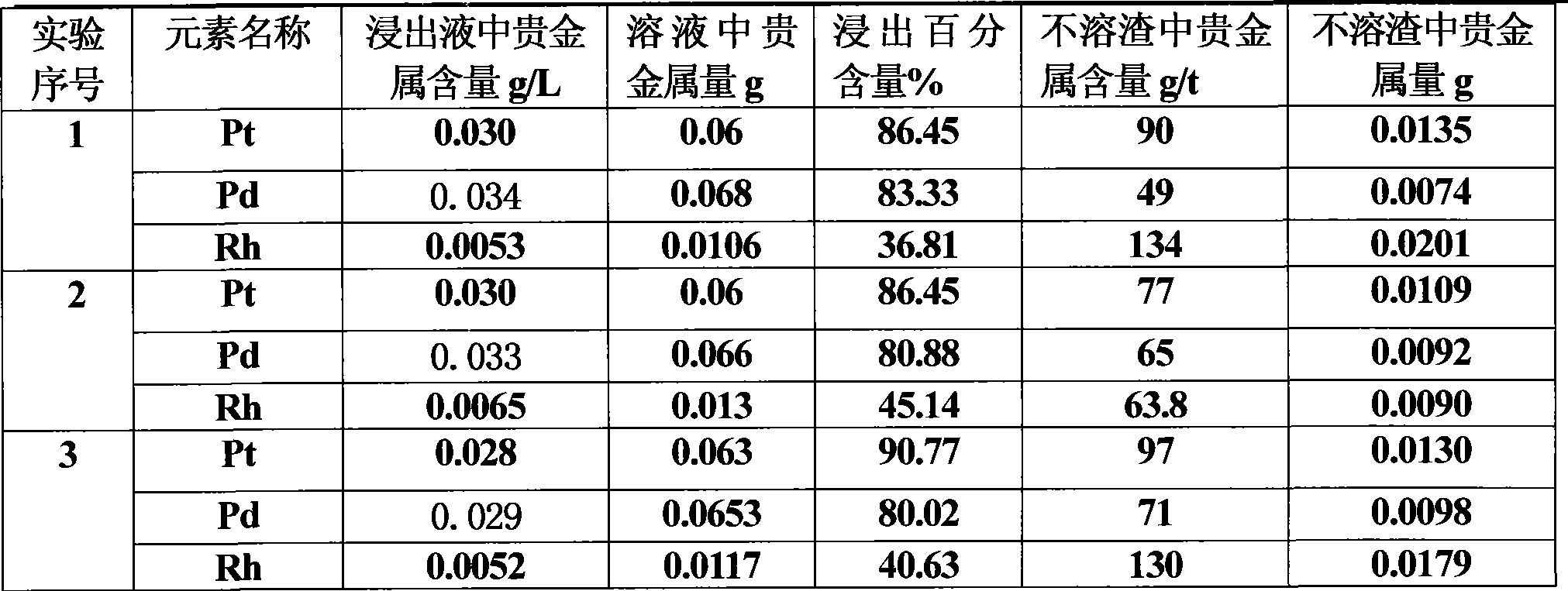

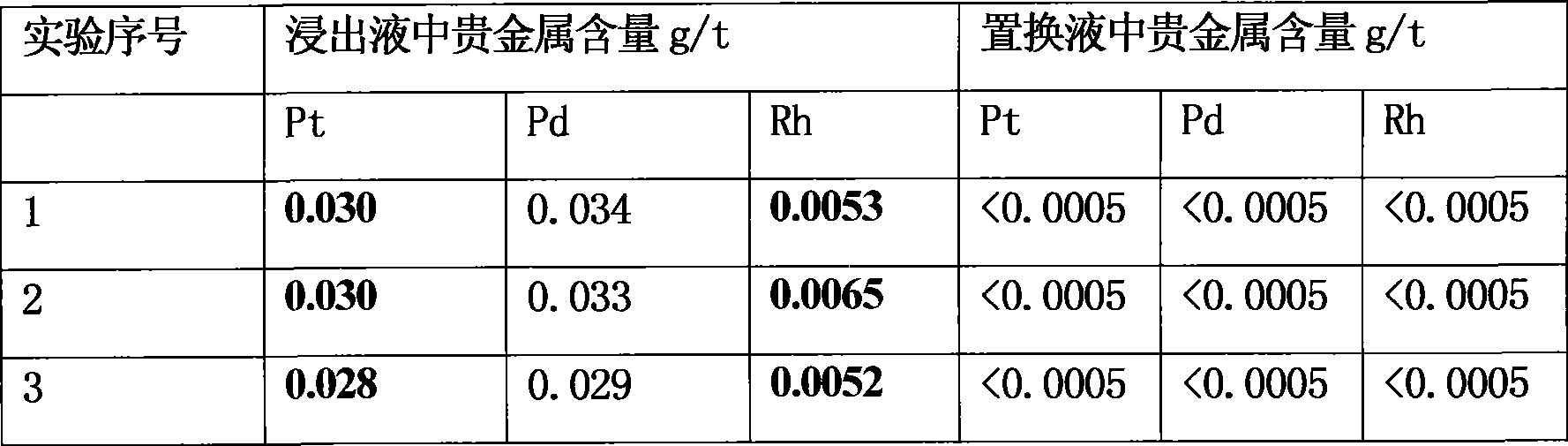

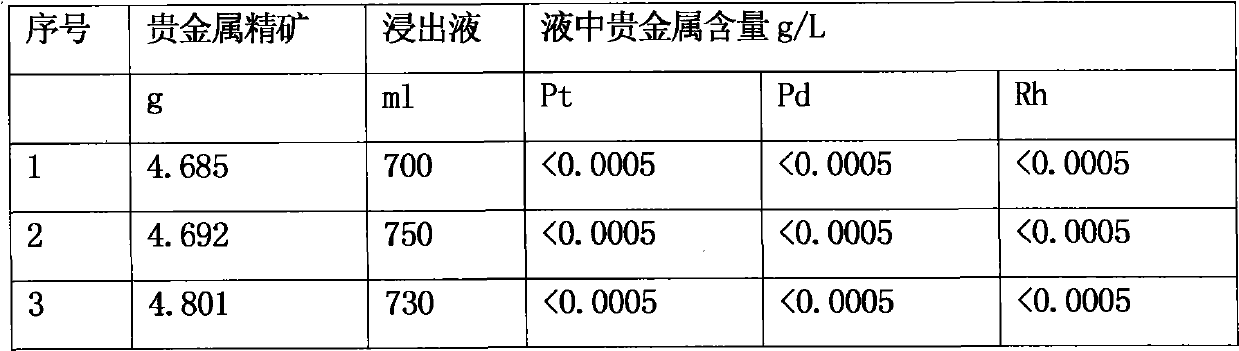

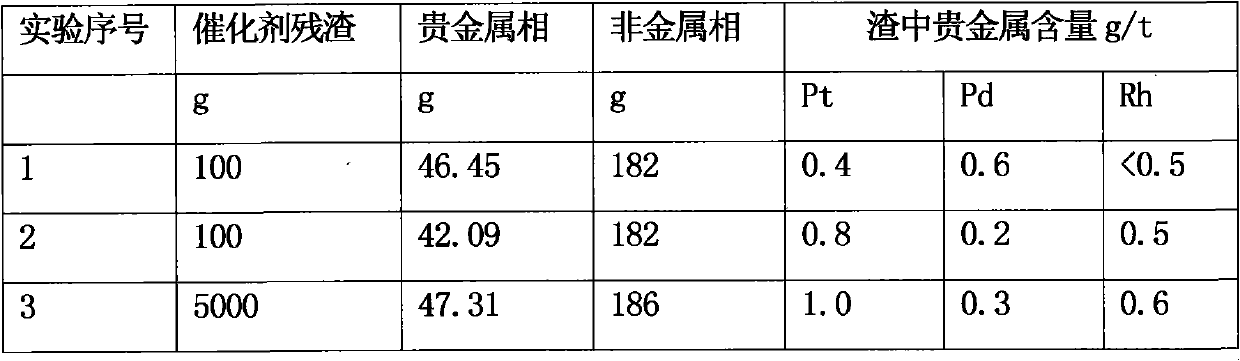

Method for extracting precious metal from auto-exhaust catalyst by hydrometallurgy and pyrometallurgy complex process

InactiveCN101519725ALoose process conditionsImprove leaching rateProcess efficiency improvementPregnant leach solutionPlatinum

The invention relates to a method for extracting precious metal from a disabled auto-exhaust catalyst, which comprises the following steps: 1. lixiviating precious metal from the disabled auto-exhaust catalyst by a hydrometallurgy process and obtaining precious metal concentrates after permuting lixivium; 2. lixiviating slag, collecting precious metal of the slag by a pyrometallurgy process to obtain a precious metal phase and selectively lixiviating base metal in the precious metal phase to obtain precious metal concentrates; and 3 combining the precious metal concentrates obtained in the first two steps and refining the precious metal concentrates to produce platinum, palladium and rhodium products. The invention compensates the deficiency that the percent recovery of the precious metal is low by simply treating the disabled auto-exhaust catalyst with the hydrometallurgy process and has the advantages that the contents of platinum, palladium and rhodium in the waste slag are smaller than 1g / t and the product purity reaches 99.95 percent.

Owner:KUNMING INST OF PRECIOUS METALS

Adsorbing material, preparation thereof and method for purifying sewage by using adsorbing material

InactiveCN101733067ALarge adsorption capacityImprove removal efficiencyOther chemical processesWater/sewage treatment by sorptionClay mineralsSludge

The invention discloses an adsorbing material for removing phosphorous and nitrogen, a preparation method thereof and a method for purifying sewage by using the adsorbing material. The preparation method for the adsorbing material comprises a step of mixing a clay mineral material, an organic modifier and a proper amount of deionized water to performing organic modification treatment on the clay mineral material. The adsorbing material prepared by the method can efficiently remove the phosphorous and the nitrogen, has high adsorption capacity, high removal efficiency and strong water quality change impact capacity resistance, and can be used for treating the sewage which cannot be treated by a biochemical method, the treatment does not produce sludge, and the treatment cost is low.

Owner:浙江瑞普环境技术有限公司

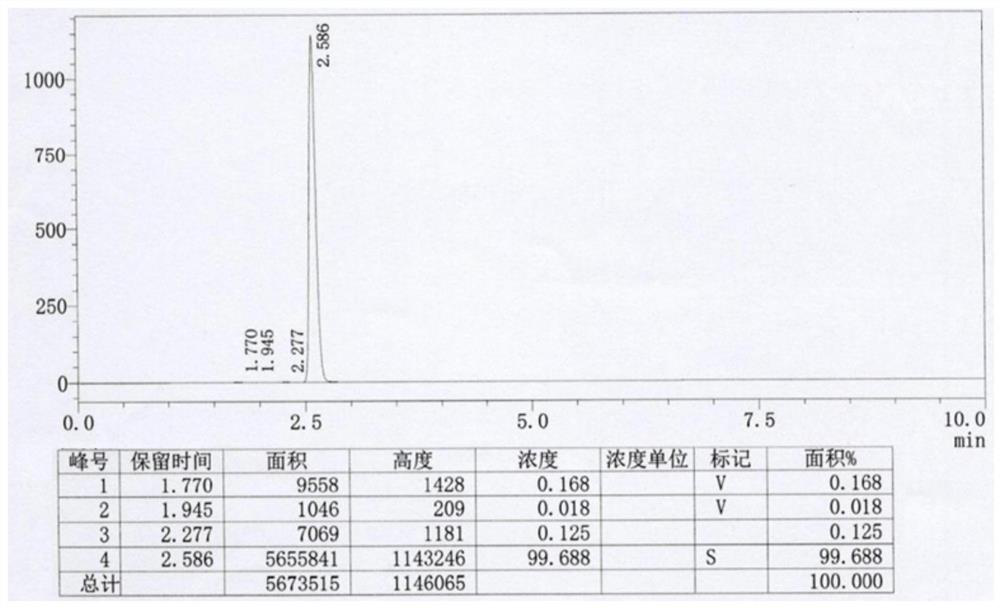

Method for continuously extracting and separating 1-deoxynojirimycin (DNJ) and flavone from folium mori

ActiveCN101671294AMaintain biological activityEasy to operateOrganic chemistryMetabolism disorderImpurityPrecipitation

The invention relates to a method for continuously extracting and separating 1-deoxynojirimycin (DNJ) and flavone from folium mori; the key points are that: folium mori and ethanol are mixed, and extracted and filtered centrifugally, and then flocculating agents are added for flocculation and precipitation after being concentrated; the precipitation is removed, and the filterate is added in a plurality of cation exchange resin columns which are communicated, and flows through a macroporous absorption resin column connected with the resin columns in series; after the filtrate adding is finished, the filtrate is washed until outflow liquid from the macroporous absorption resin column is colourless, and then the macroporous absorption resin column is disconnected, and then the 1-deoxynojirimycin (DNJ) is eluated with ammonia water or ammoniac ethanol solution from the cation exchange resin columns; the eluate is eluated by the cation exchange resin columns again, the operation is repeated, and then the eluate is collected, is concentrated and filtered with a 80D nanofiltration membrane and then is spray-dried, so as to obtain claybank powdery 1-deoxynojirimycin (DNJ). 3-10 percent ofalcohol is used for washing the macroporous absorption resin column to remove colloidal impurities, and then 50-70 percent of alcohol is used for washing flavone, the claybank eluate is collected, decompression and concentration are carried out to recover alcohol, and then spray-drying is carried out to obtain the claybank powdery folium mori general flavone.

Owner:GUANGDONG APOLLO GRP

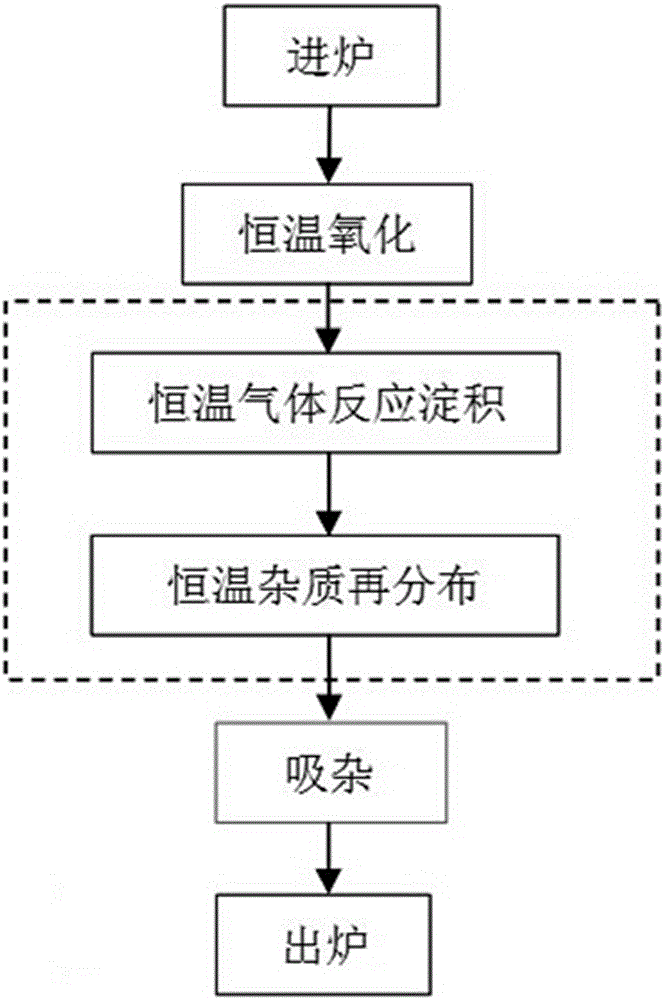

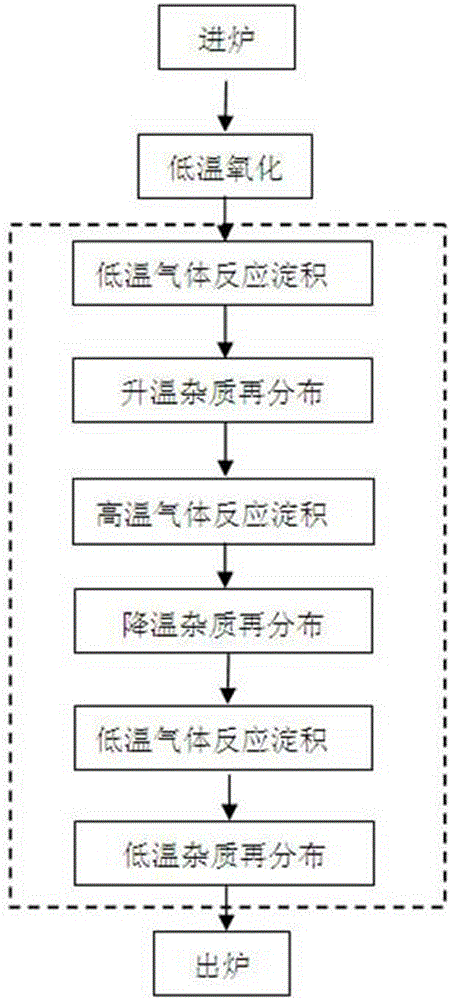

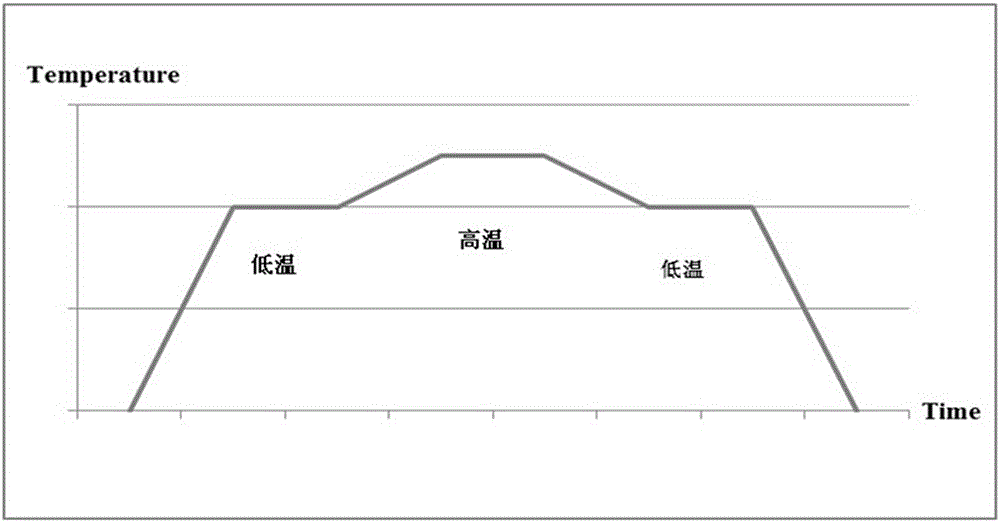

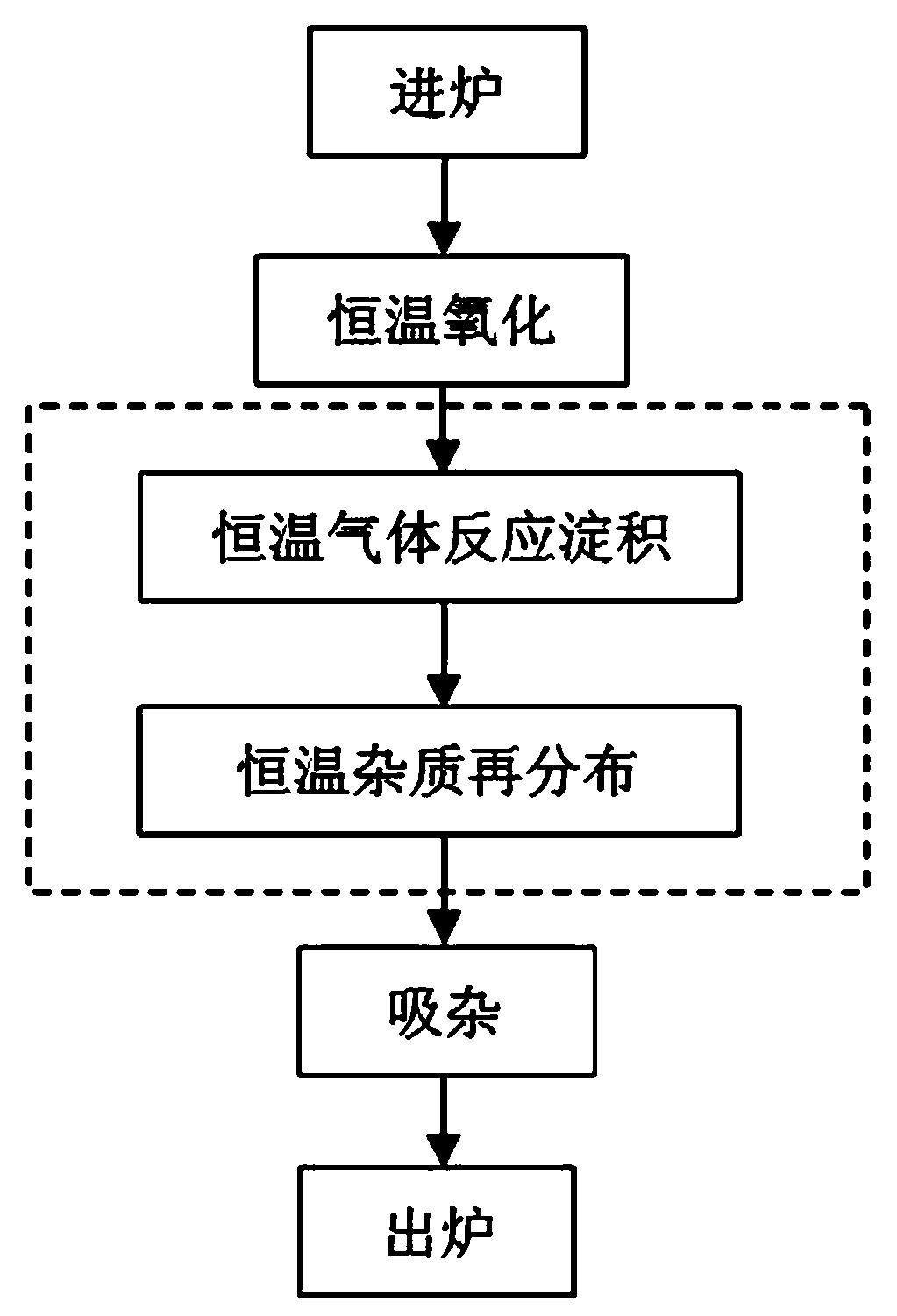

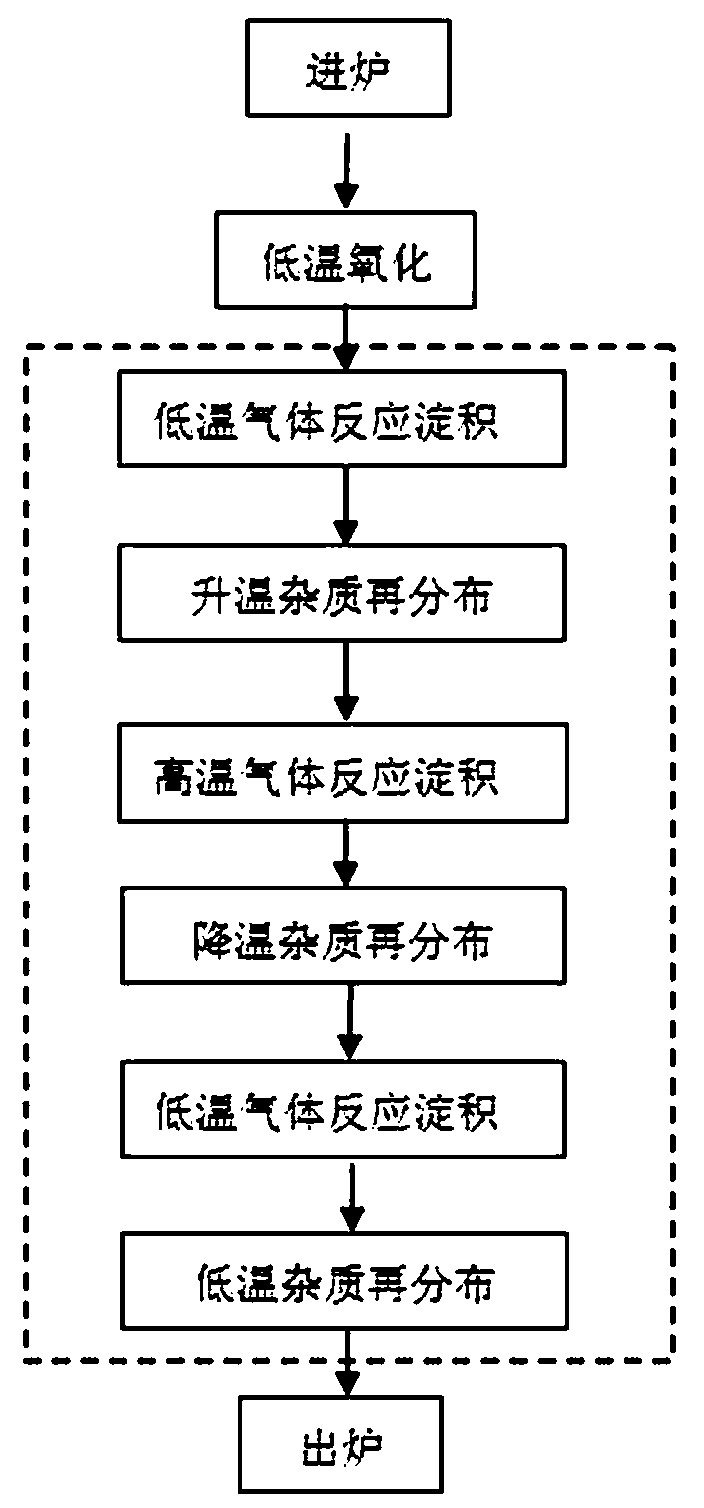

Diffusion technique of crystal-silicon efficient high-sheet-resistance battery piece

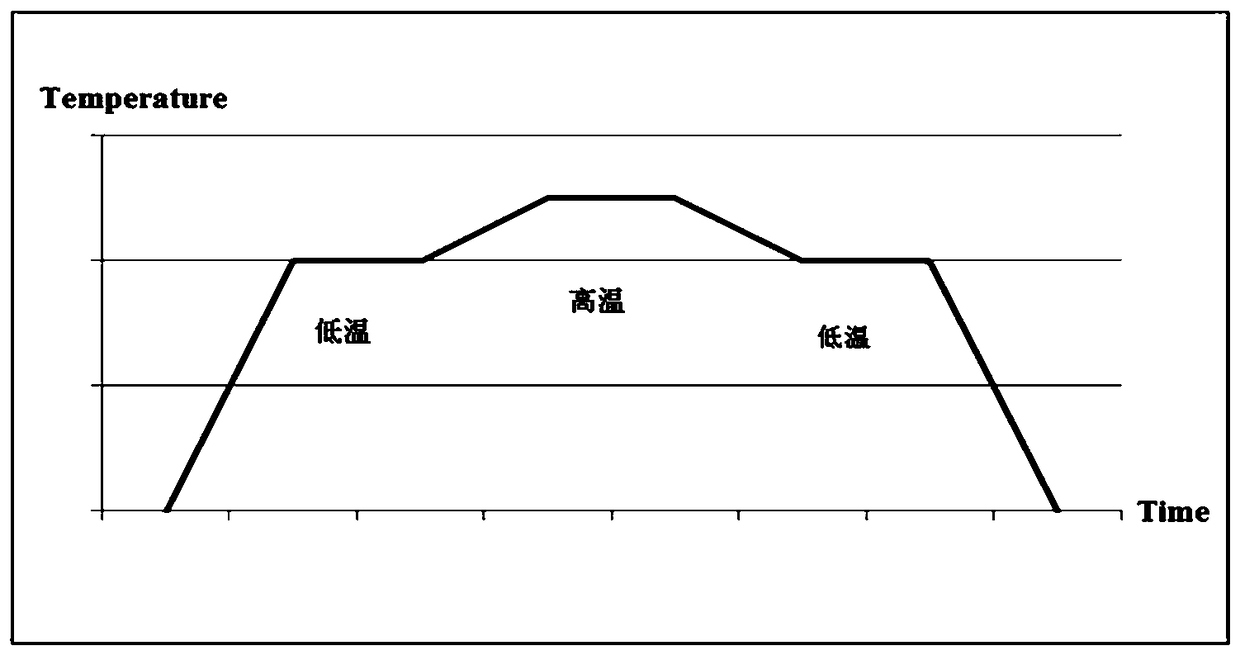

ActiveCN105280484AImprove photoelectric conversion rateReduce surface recombinationFinal product manufactureSemiconductor/solid-state device manufacturingDopantEngineering

The present invention relates to a diffusion technique of a crystal-silicon efficient high-sheet-resistance battery piece. The diffusion technique comprises the steps of furnace entering, low-temperature oxidation, low temperature gas reaction deposition, low temperature dopant redistribution, high temperature gas reaction deposition, cooling dopant redistribution, low temperature gas reaction deposition, low temperature dopant redistribution and discharge. With adoption of the diffusion technique provided by the present invention, photoelectric conversion efficiency of the battery pieces can be raised, the production time is shortened, and the production efficiency is raised.

Owner:TRINA SOLAR CO LTD +1

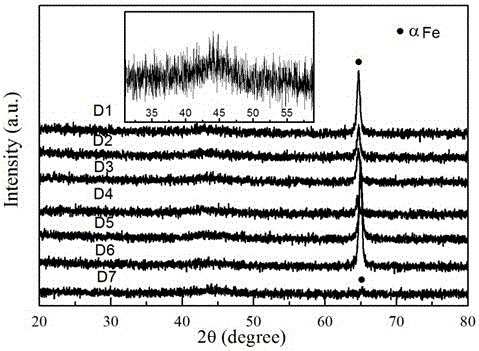

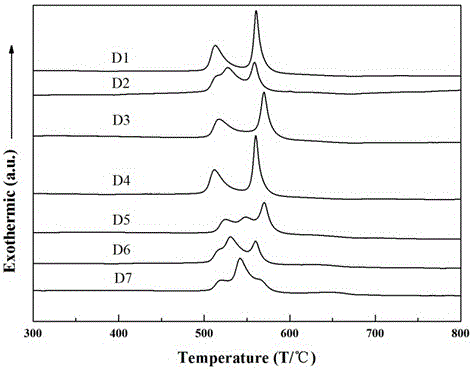

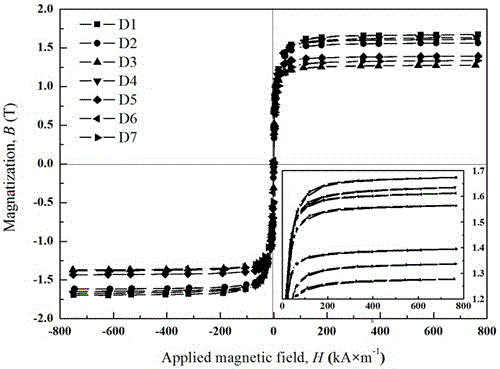

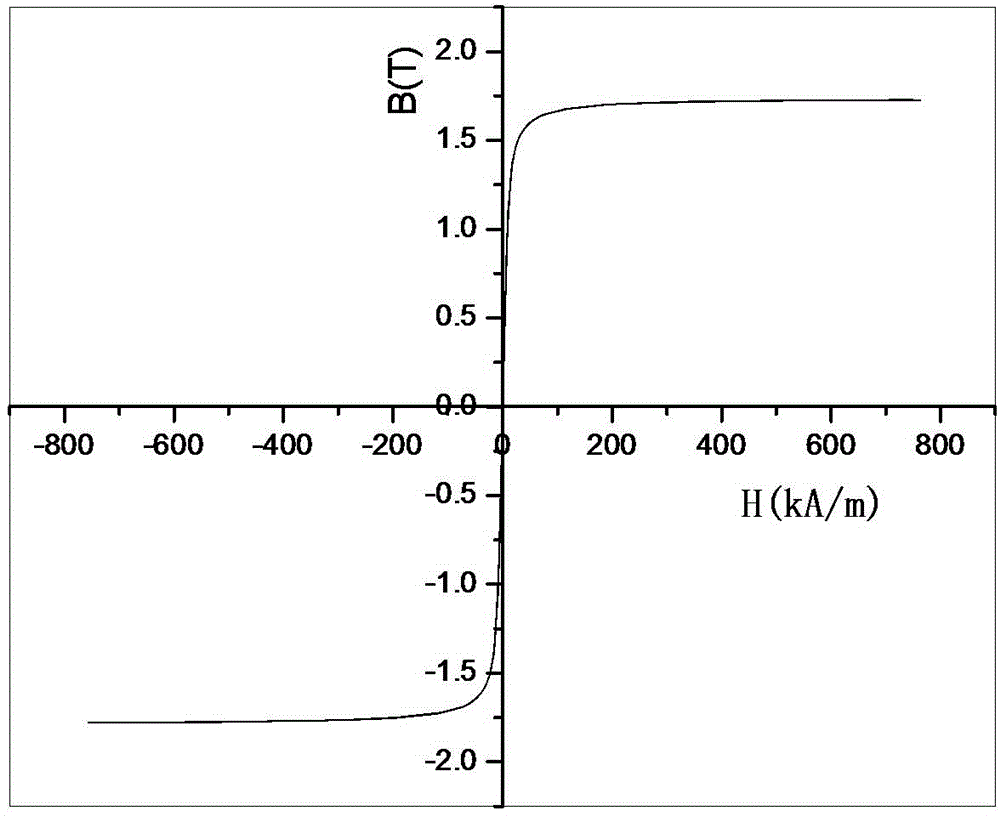

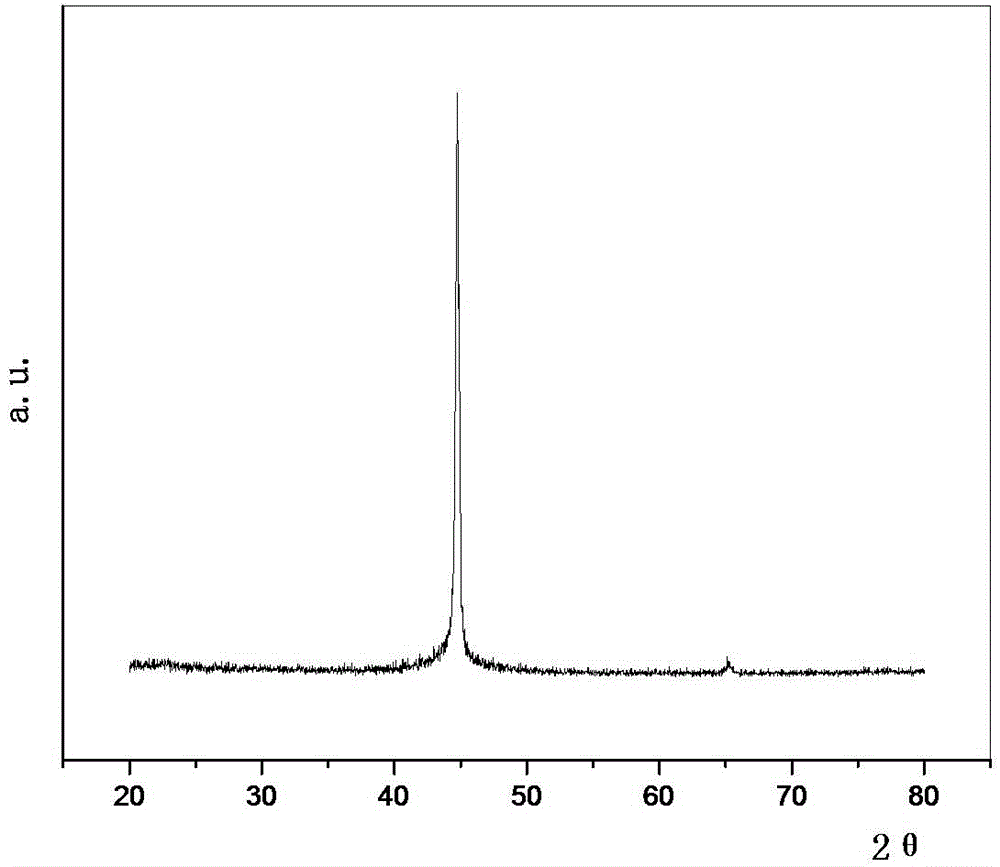

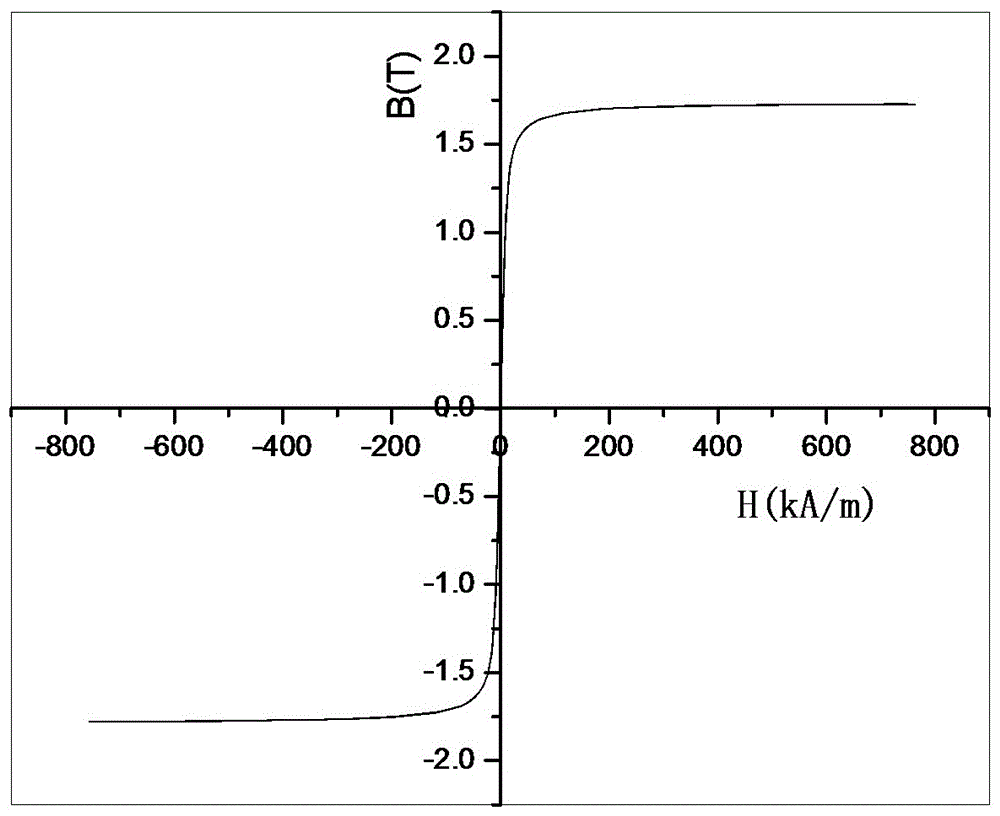

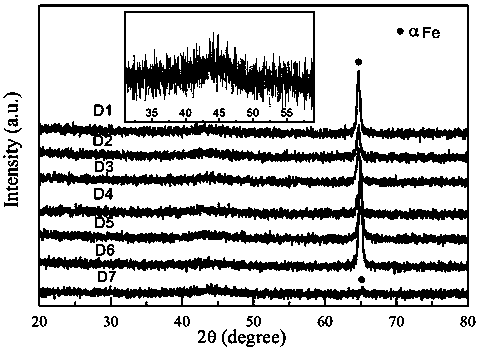

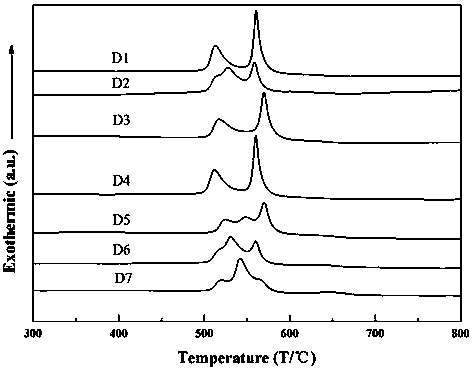

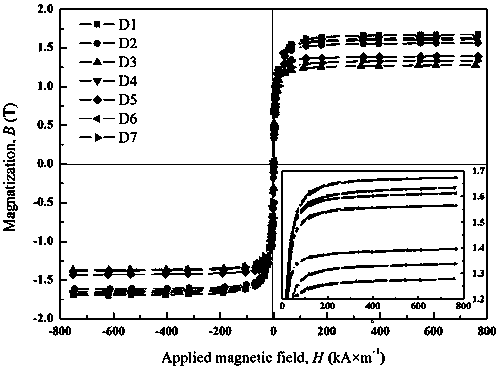

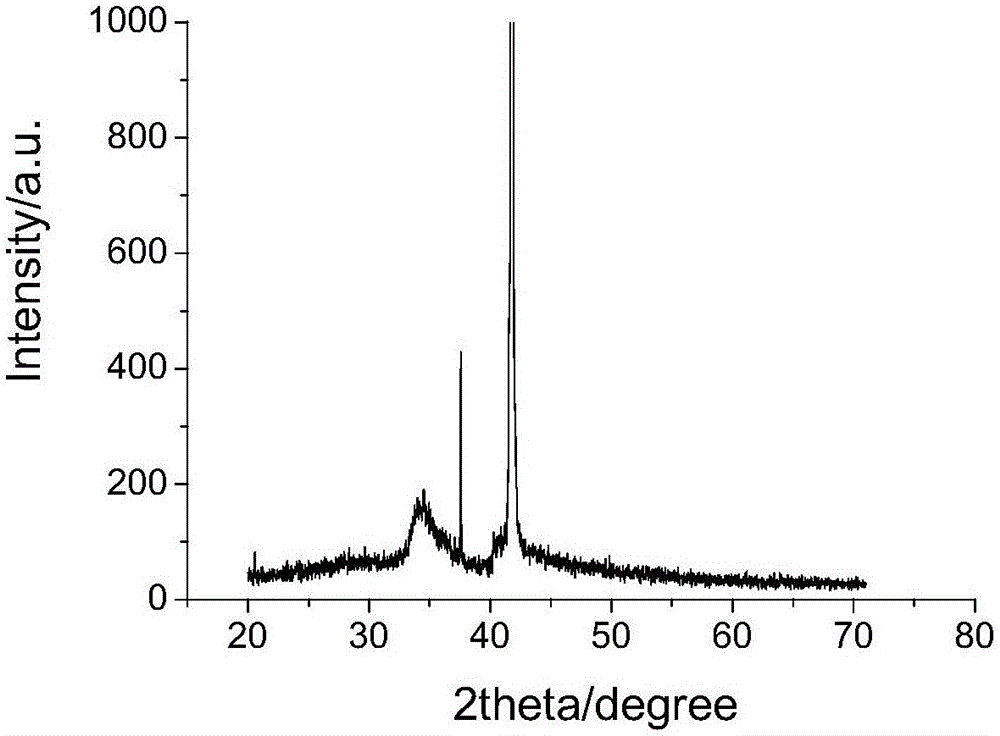

Iron-based amorphous nanocrystalline magnetically soft alloy and preparation method thereof

ActiveCN106119739AHigh saturation magnetic inductionLow coercivityMagnetic materialsStress reliefImpurity

The invention relates to novel iron-based amorphous nanocrystalline magnetically soft alloy which can be directly obtained through rapid cooling without the need for annealing and a preparation method thereof. The composition of the magnetically soft alloy is FeaSibBcCdMnePfCrgNihCujMojCok except for unavoidable impurities. The iron-based amorphous nanocrystalline magnetically soft alloy has high saturated magnetic induction density Bs, low coercivity Hc, high and stable magnetic conductivity [mu]i and other excellent soft magnetic properties after stress relief annealing. Compared with existing nanocrystalline alloy applied in the industry and obtained through crystallization annealing, the annealing temperature is greatly lowered, and the iron-based amorphous nanocrystalline magnetically soft alloy does not contain or contain a trace of precious metal elements, so that the production cost is greatly lowered.

Owner:ZHENGZHOU UNIV

Production process for preparing aluminium fluoride by using ammonium bicarbonate

InactiveCN101654273AReduce utilizationEfficient use ofAluminium fluoridesAluminium chlorideO-Phosphoric Acid

The invention relates to a production process for preparing aluminium fluoride by using ammonium bicarbonate, which solves the problem that the prior wet-method aluminium fluoride production process adopts more expensive aluminium hydroxide as a raw material, reduces production cost and is easy to carry out industrial production. The process is characterized in that fluosilicic acid reacts with ammonium bicarbonate to generate ammonium fluoride solution and silicon dioxide deposition; then, the filtered and separated ammonium fluoride solution reacts with aluminum chloride hexahydrate to prepare soluble Beta-AlF3.3H2O and ammonium chloride solution; soluble Alpha-AlF3.3H2O is converted into insoluble Beta-AlF3.3H2O through crystallization; and the finished product of aluminium fluoride isobtained through separation, washing, drying and calcination. The process is the most economical process for producing aluminium fluoride from a by product fluosilicic acid of enterprises for producing phosphoric acid and calcium superphosphate by a wet-method.

Owner:HUBEI YUANDA FUCHI PHARMA CHEM

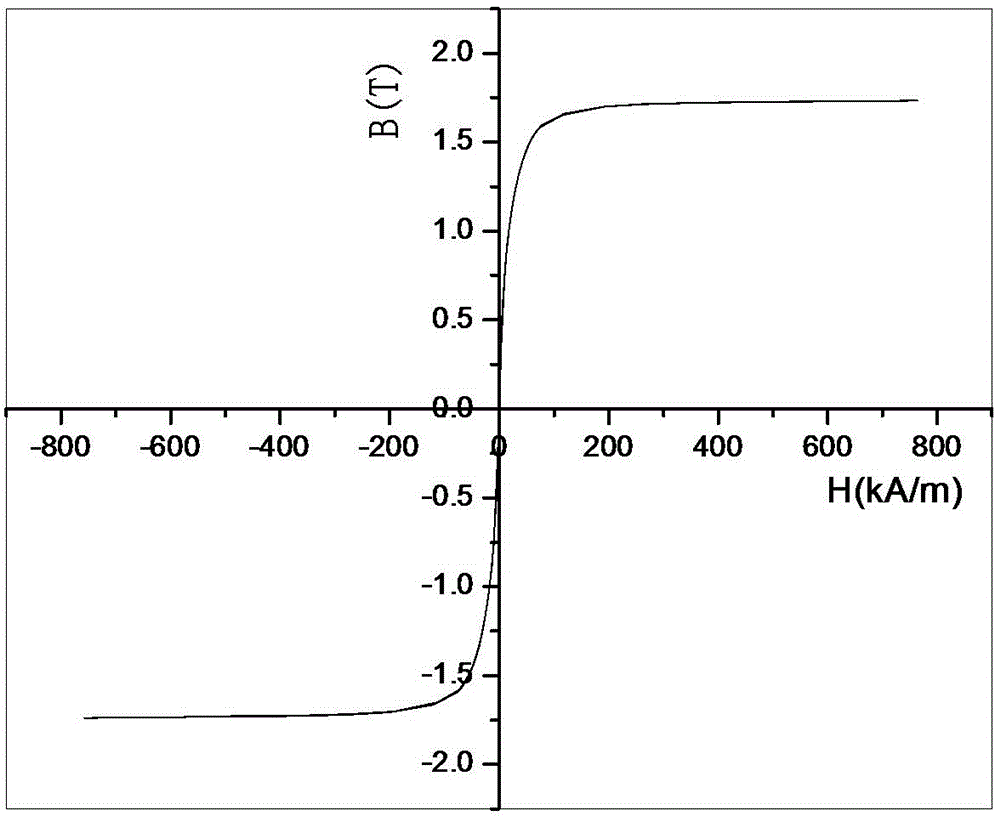

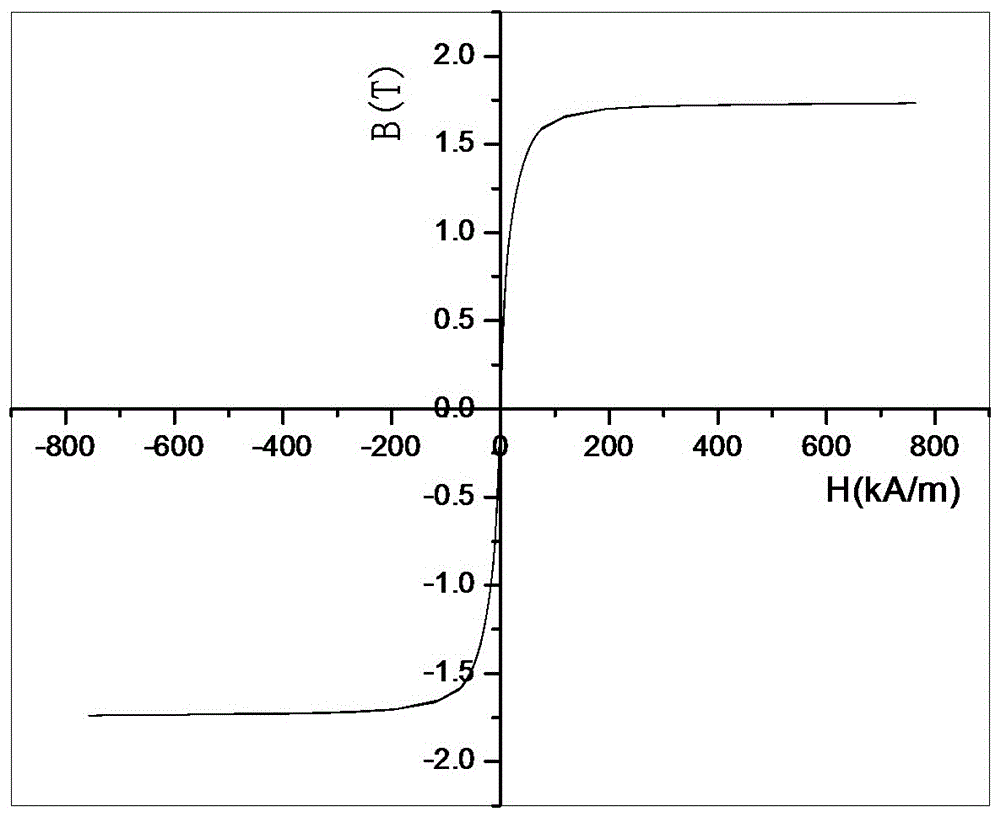

Iron-based amorphous-nanometer crystalline state magnetically soft alloy with high saturation magnetic induction density and application thereof

ActiveCN103915231ACorrosion resistanceHigh saturation magnetic inductionMagnetic materialsAlloyStress relief

The invention relates to an iron-based amorphous-nanometer crystalline state magnetically soft alloy with high saturation magnetic induction density and an application thereof. FeaSibBcAld series amorphous-nanometer crystalline state magnetically soft alloy is formed by adding a certain amount of Al capable of improving the saturation magnetic induction density of the amorphous alloy into Fe-Si-B series amorphous alloy, wherein a is 78-86 atom percents, b is 2-9 atom percents, c is 9-14 atom percents, and d is 1-5 atom percents. The iron series amorphous-nanometer crystalline magnetically soft alloy has the advantages of being good in formability, high in saturation magnetic induction density, low in cost, corrosion-resistant, simple in process and the like. After stress relief annealing is conducted on the alloy, the saturation magnetic induction density can reach 1.62-1.778T.

Owner:ZHENGZHOU UNIV

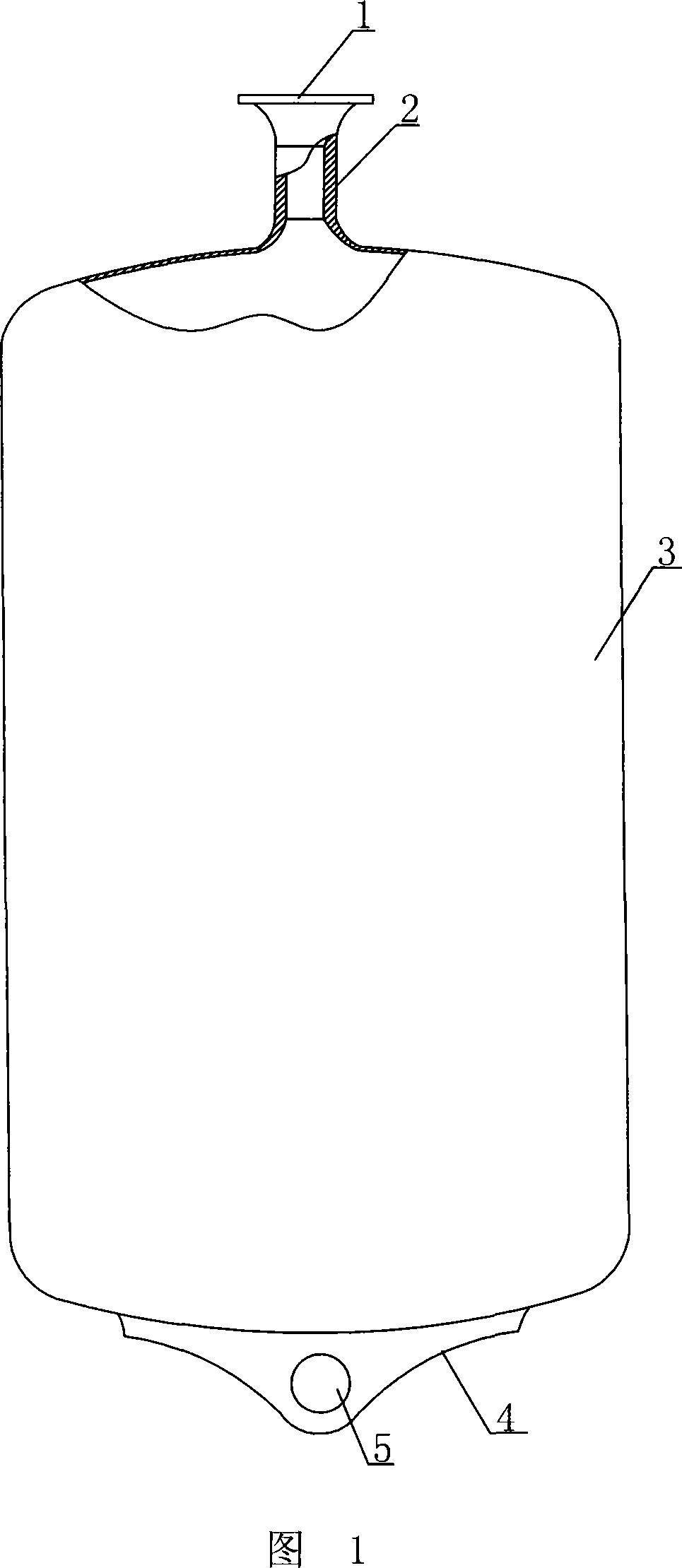

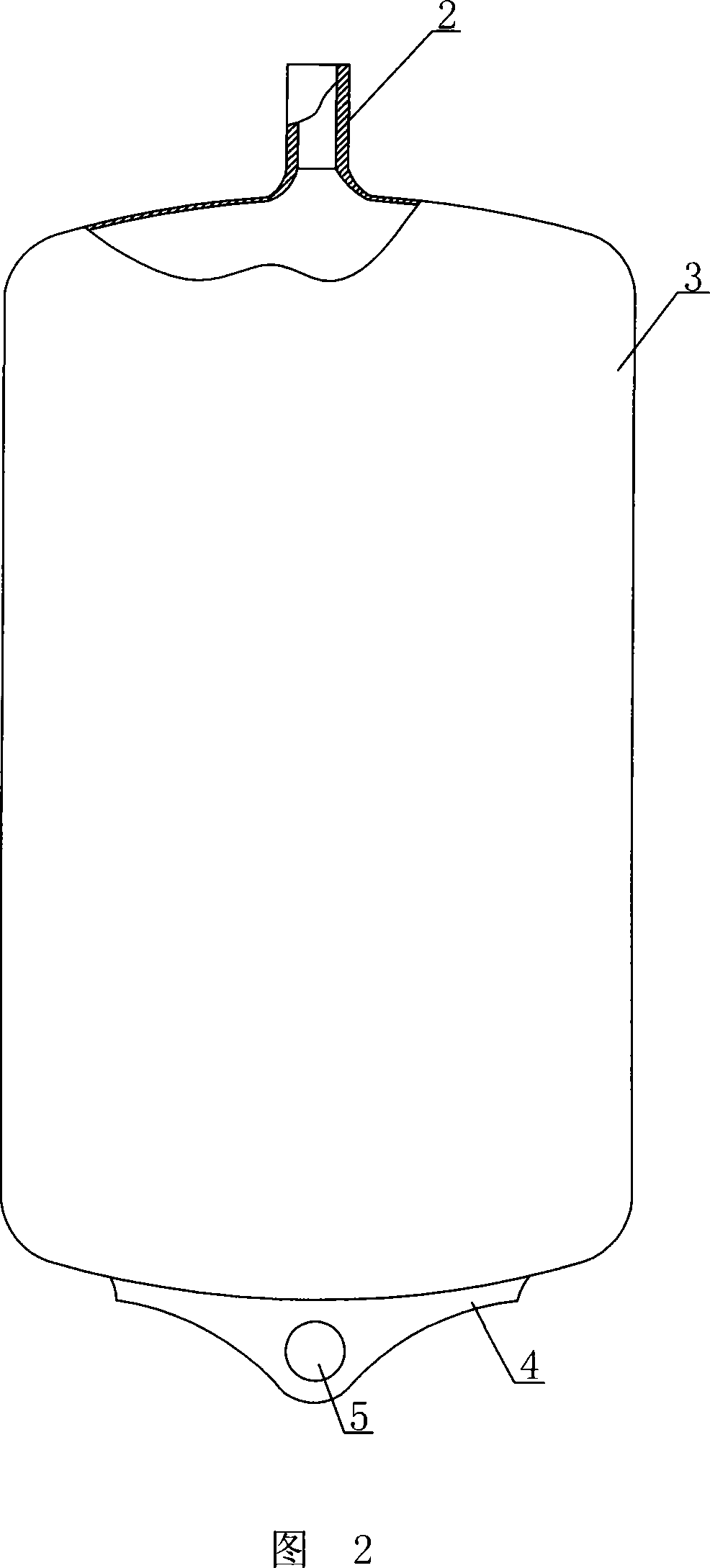

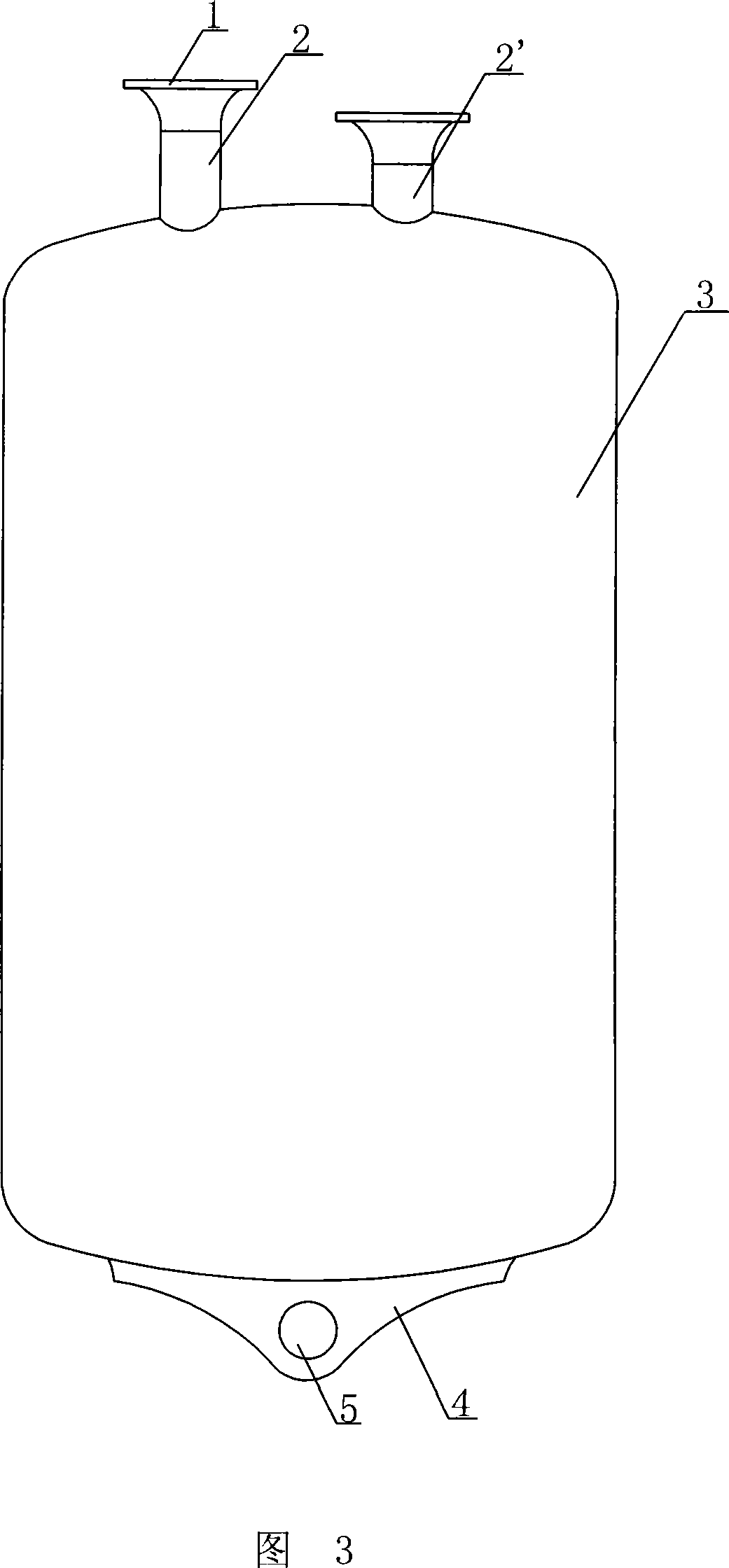

Blow molding medical bag and preparing method thereof

InactiveCN101229097APrevent leakageAvoid pollutionPharmaceutical containersMedical packagingBlow moldingBottle

The invention relates to a blow molding medical bag and a preparation method thereof. The blow molding medical bag includes a bag body. One end of the bag body is provided with a convex filling opening and the other end is provided with a lifting ring. The bag body, the filling opening and the lifting ring form an integral structure. The preparation method includes: taking medical polythene, medical polypropylene or medical modified-polypropylene as the raw materials and adopting a hollow blow molding method and a hollow blowing device to carry out one-time blow molding on the medical polythene, the medical polypropylene or the medical modified-polypropylene to acquire the blow molding medical bag. The blow molding medical bag has the advantages of reasonable structure, being convenient for mechanized filling and packaging, effectively preventing a loaded liquid from leaking and divulging. The invention can not only ensure the pollution free property during the filling and packaging processes, but also realize high speed manufacture with low cost, thus solving a plurality of defects existed in the existing perfusion bag of non PVC materials and polypropylene perfusion bottle. The preparation method can realize industrialized and mechanized manufacture and automatic filling and has the advantages of low cost and high output.

Owner:辽宁九洲龙跃药业有限公司

Hydrofluoric acid arsenic removal process

InactiveCN108609585ALoose process conditionsEasy to operateHydrogen fluorideHydrogen fluorideHydrofluoric acid

The invention relates to the technical field of chemical engineering, in particular to a hydrofluoric acid arsenic removal process. The process includes steps: 1) sampling from anhydrous hydrogen fluoride to be subjected to arsenic removal, and adopting hydrogen peroxide solution for titration of reducing substances in a sample to obtain hydrogen peroxide consumption T of the sample; 2) after chemical pretreatment, feeding the anhydrous hydrogen fluoride to be subjected to arsenic removal into a first elevated tank through a feeding pump, feeding anhydrous hydrogen fluoride in the first elevated tank into a rectifying tower, and distilling for 1h; 3) feeding anhydrous hydrogen fluoride distilled in the step 2) into an absorption tower through a condenser, and adding high-purity water in asecond elevated tank into the absorption tower to obtain 30%-50% hydrogen fluoride solution. By adoption of hydrogen peroxide as an oxidizing agent for hydrofluoric acid arsenic removal, process conditions are loose, simplicity, convenience and feasibility in operation are realized, extraneous impurities are avoided, and accordingly product quality stability is guaranteed, and production efficiency is improved.

Owner:XUANCHENG HENGTAI ELECTRONICS CHEM MATERIAL

Method for preparing honeysuckle flower extract by jointly adopting membrane separation and column chromatography

ActiveCN102391115AHigh content of active ingredientsConducive to subsequent processingCarboxylic acid esters separation/purificationMedicinal herbsChlorogenic acid

A method for preparing a honeysuckle flower extract by jointly adopting membrane separation and column chromatography includes the steps as follows: after preparation of filtrate A and filtrate B, membrane separation, ethanol recycling, column-giving sample-adding and impurity washing, eluting a macroporous resin column by ethanol in volume percentage concentration of 5%-25%, allowing the eluent to pass through a 700-Dalton membrane, conducting pressure reduction and concentration on membrane concentrate in the temperature of 50-80DEG C, and then conducting spray drying, thus obtaining a chlorogenic acid extract; and eluting the macroporous resin column by ethanol in volume percentage concentration of 55%-85%, conducting pressure reduction and concentration on the eluent in the temperature of 50-80DEG C, and then conducting spry drying, thus obtaining a flavone extract. Compared with the prior art, the method adopts the membrane separation technology and the column chromatography technology jointly to prepare the honeysuckle flower extract and can obtain the chlorogenic acid extract and the flavone extract in the honeysuckle flower simultaneously; and the method has such advantages as follows: the utilization rate of medicinal materials is high and the content of the obtained active ingredients is high, so that the subsequent processing and using are facilitated; and the method is simple in technology, low in energy consumption during operation, and convenient for large-scale industrial production and popularization.

Owner:GUANGDONG APOLLO GRP

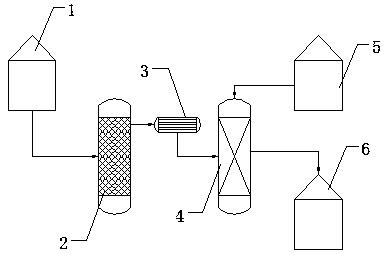

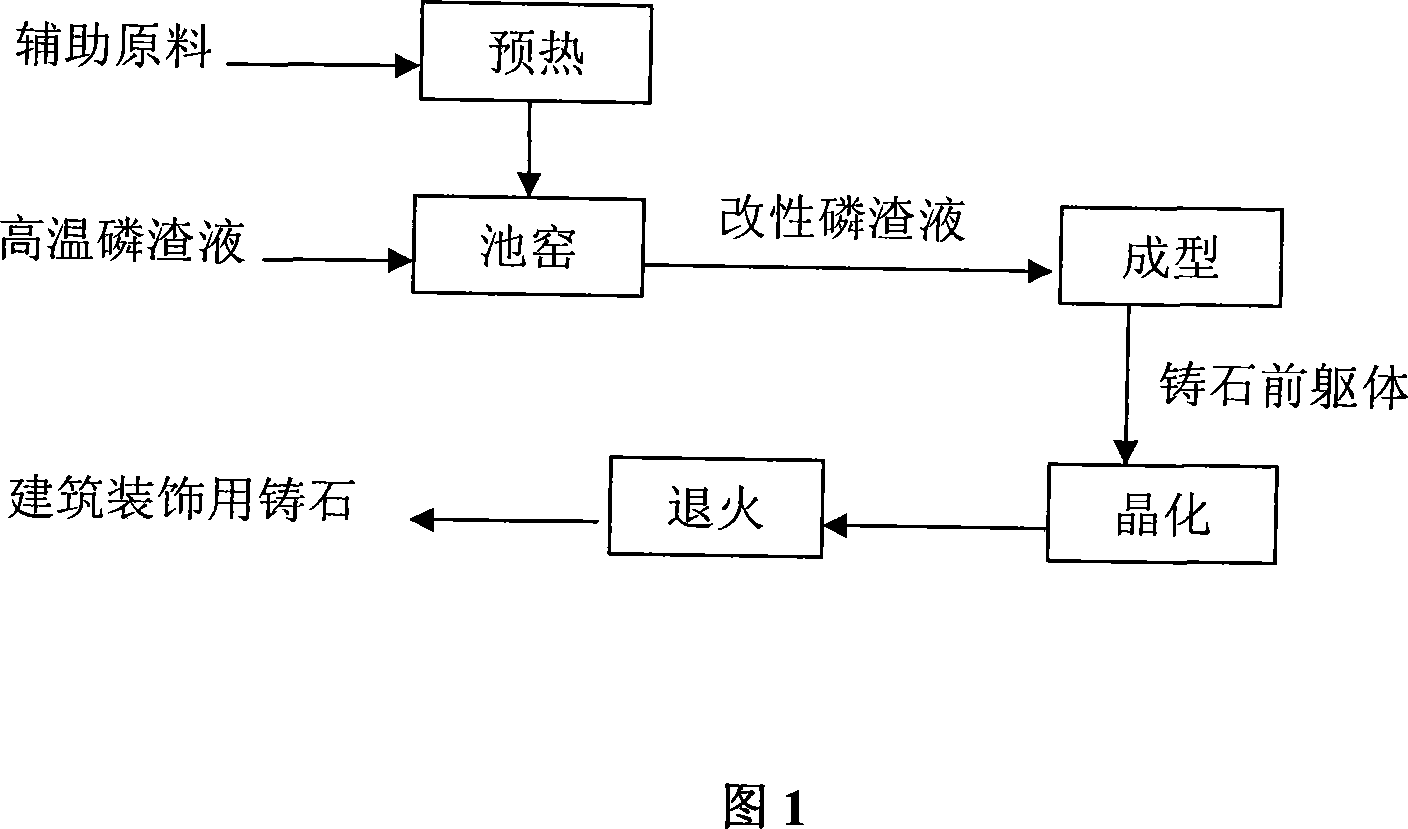

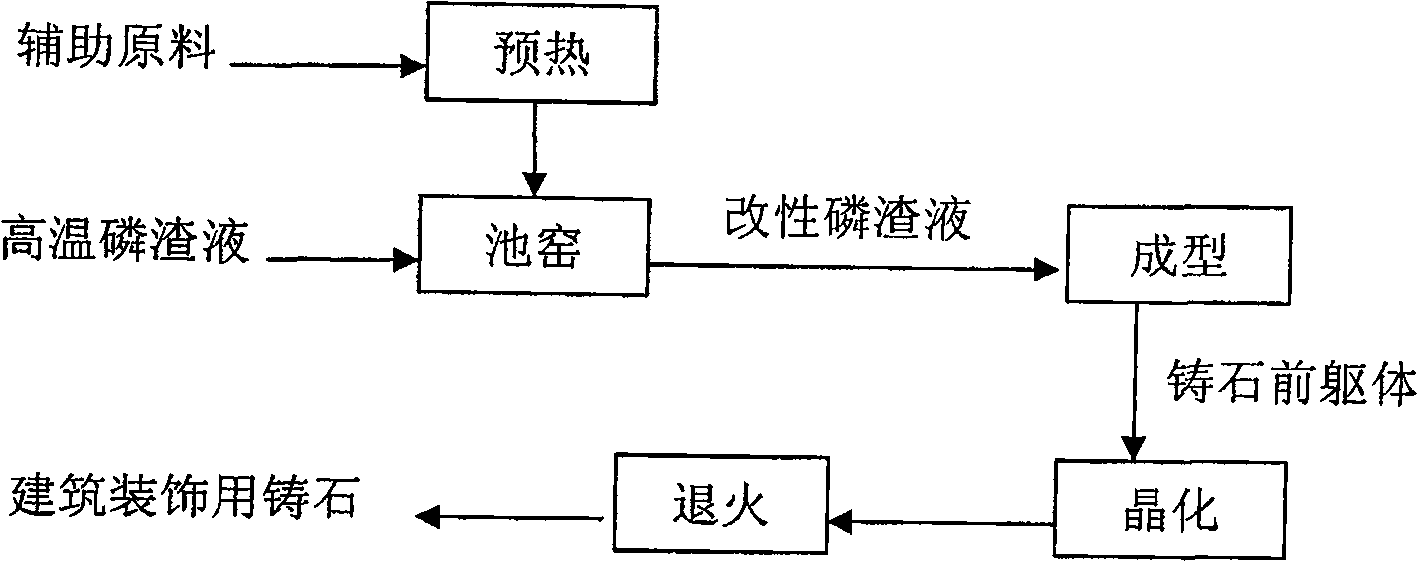

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

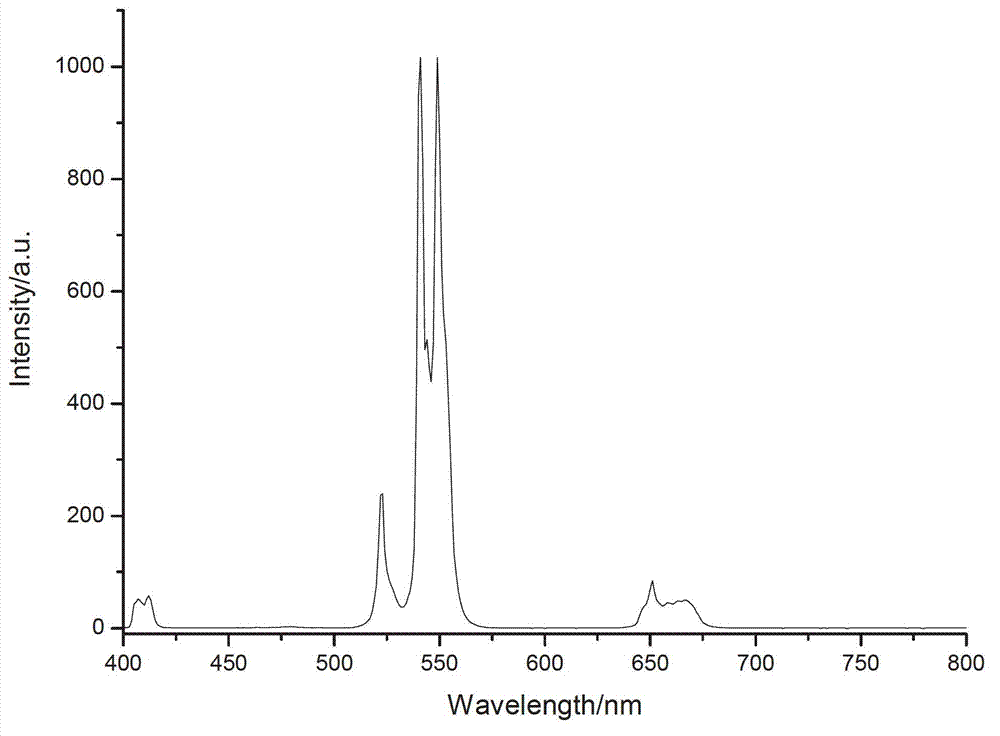

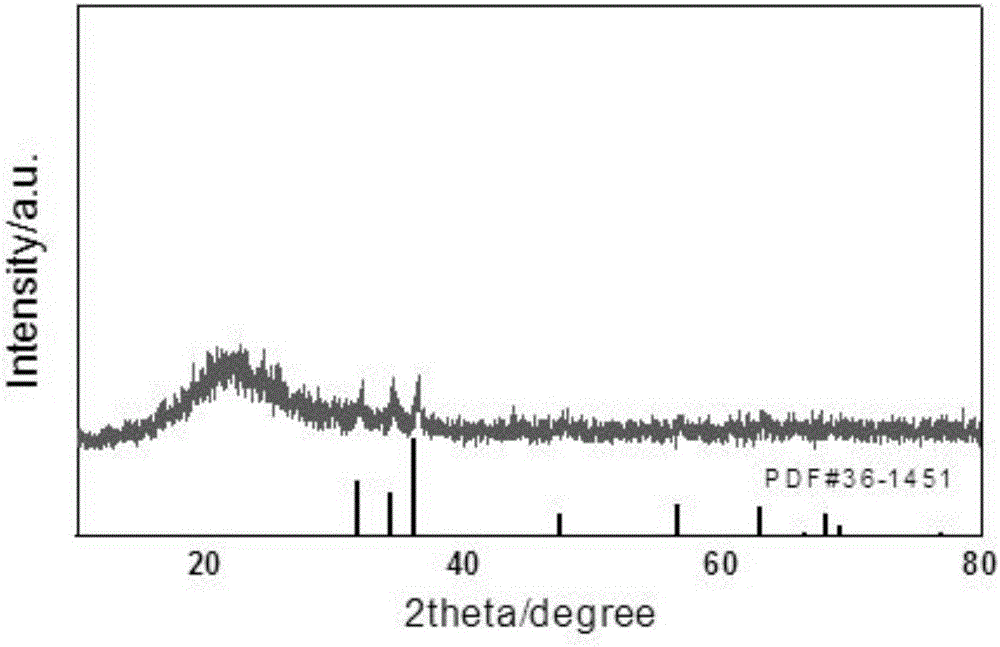

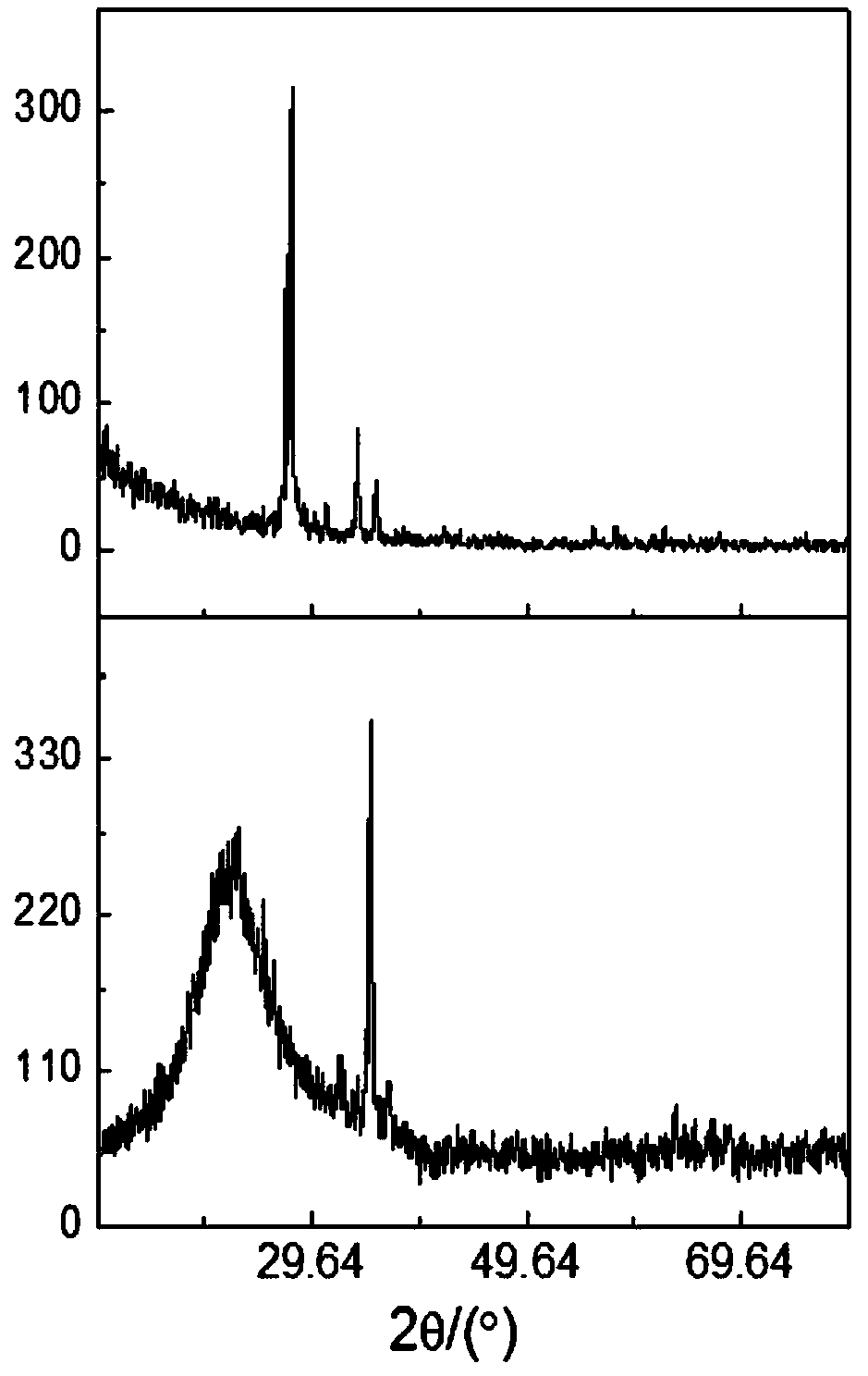

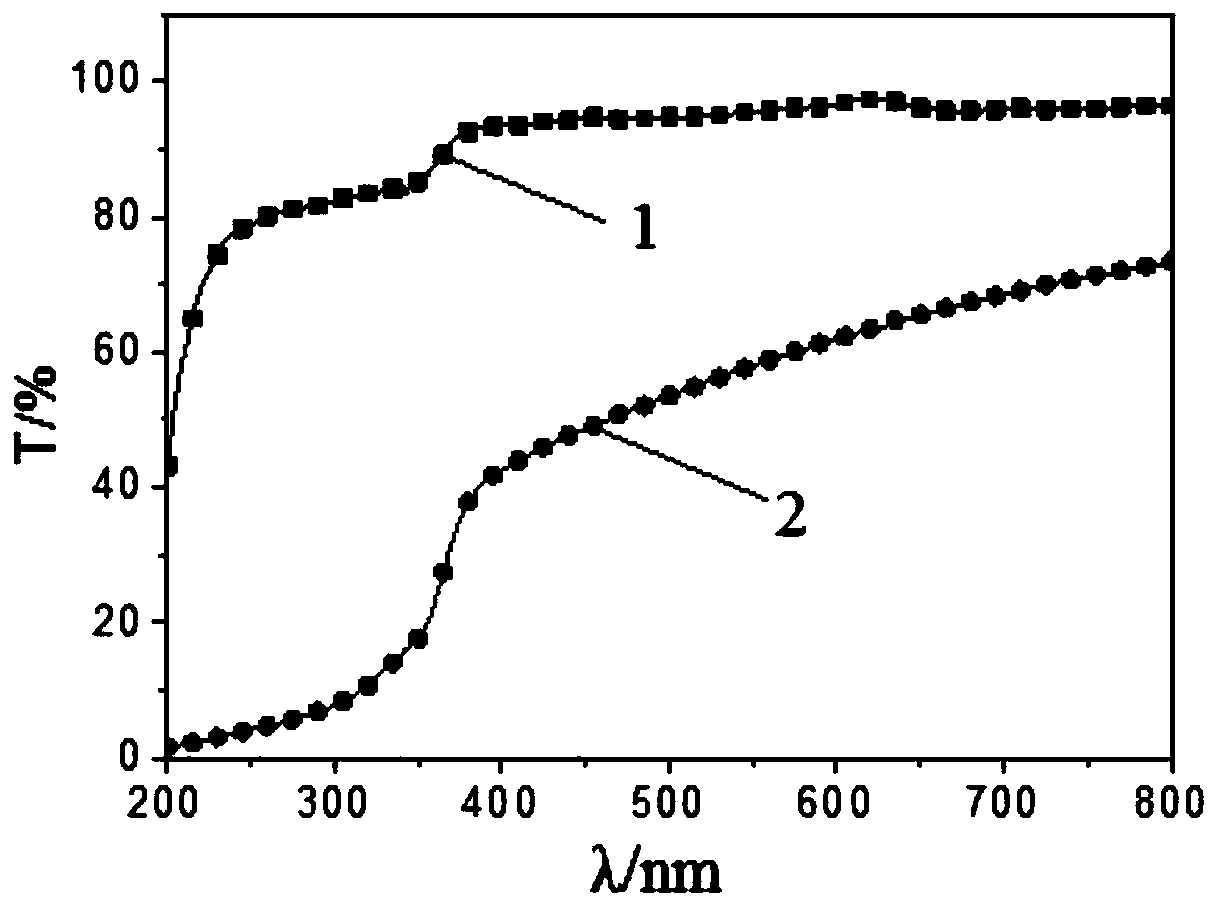

Barium fluoride up-conversion transparent ceramic and preparation method thereof

InactiveCN102826850AImprove up-conversion luminous efficiencyLow phonon energyRare earthUp conversion

The invention discloses a barium fluoride up-conversion transparent ceramic and a preparation method thereof, and belongs to the technical field of optically functional materials. The existing alumina up-conversion transparent ceramic has low up-conversion luminous efficiency and is prepared difficultly. The barium fluoride up-conversion transparent ceramic utilizes barium fluoride transparent ceramic as a matrix and comprises: by mole, 60 to 89% of barium fluoride, 10 to 25% of ytterbium fluoride, and 1 to 15% of one or more of fluorides of erbium, holmium, neodymium, thulium and promethium. The preparation method comprises the following steps of blending raw material nanometer powder according to the mole percentage, wherein barium fluoride powder has particle sizes of 20 to 80nm and rare earth fluoride powder has particle sizes of 10 to 90nm, pressing the blended raw material nanometer powder into a biscuit, pre-sintering the biscuit at a temperature of 500 to 800 DEG C for 0.5 to 5 hours, carrying out vacuum sintering of the pre-sintered biscuit under the conditions of pressure of 50 to 500MPa, a vacuum degree of 10<-2> to 10<-3>Pa, a heating rate of 1 to 20 DEG C / min, a sintering temperature of 600 to 1200 DEG C and sintering time of 0.5 to 5 hours, and cooling to a room temperature at a rate of 1 to 20 DEG C / min to obtain the barium fluoride up-conversion transparent ceramic.

Owner:CHANGCHUN UNIV OF SCI & TECH

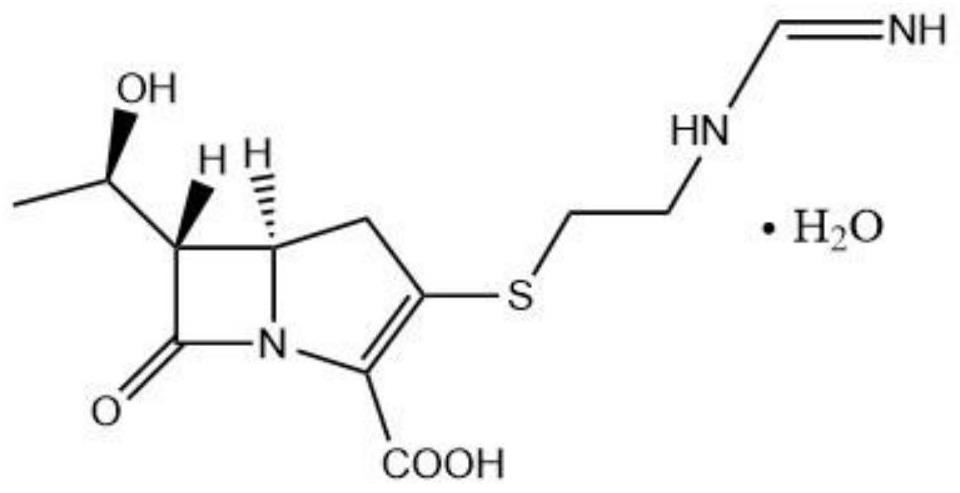

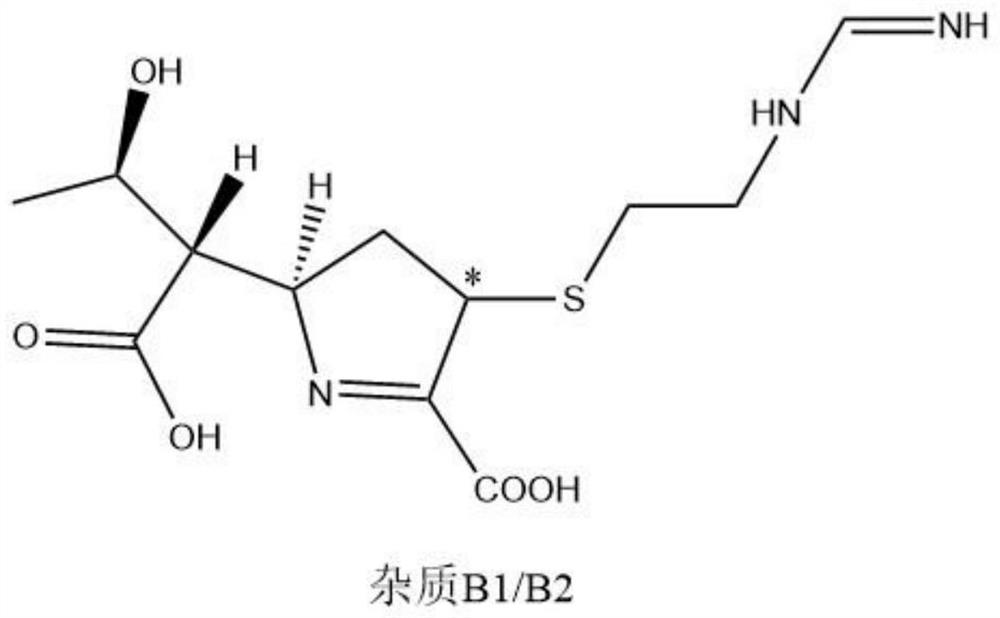

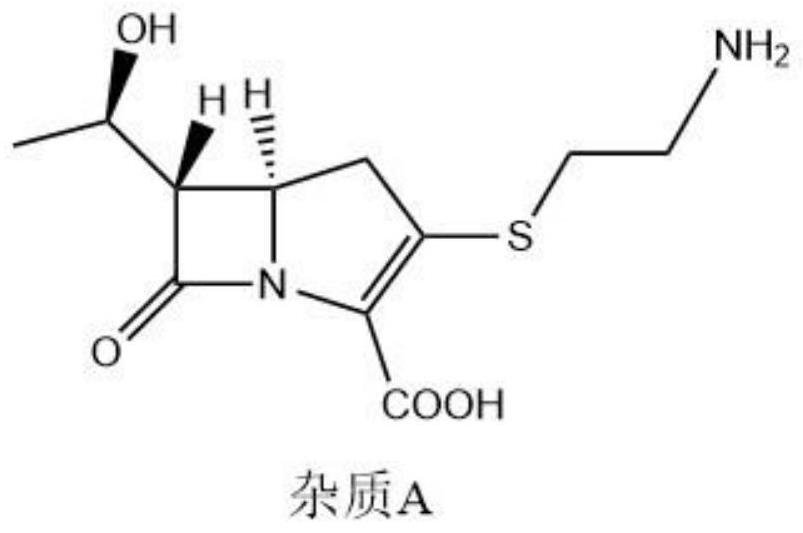

Refining method of imipenem

ActiveCN114671877ASmall and uniform particle sizeAvoid introducing microbiological risksOrganic chemistryMicroorganismChemical compound

The invention relates to the technical field of preparation of heterocyclic compounds, in particular to a refining method of imipenem. The method comprises the following steps: dissolving, filtering, sub-packaging crystal growing seeds, growing crystals, and growing the crystals again. Natural seed crystals are formed in the production process in a segmented crystallization mode, and the risk of introducing microorganisms caused by external seed crystals can be avoided. According to the invention, an anti-crystallization mode is adopted for crystallization, and the prepared crystal product is small and uniform in particle size; the process is the same as the original grinding process. Meanwhile, the process conditions are loose, operation is easy, and the method is suitable for large-scale production.

Owner:ZHUHAI UNITED LAB

Method for deep desulfurization of gasoline

InactiveCN101824335ADoes not lower octaneLow costTreatment with plural serial refining stagesChemistrySulfur content

The invention provides a method for the deep desulfurization of gasoline, belonging to the oxidation-extraction desulfurization technology. The method comprises the following steps: adding ionic liquid and solid manganese dioxide to the gasoline to be subjected to deep desulfurization to form a three-phase system; heating and stirring the three-phase system under the microwave condition so as to conduct the deep oxidation desulfurization reaction; and standing and carrying out solid-liquid separation; and washing the obtained filtrate by adding clean water, then, standing, and carrying out liquid separation to obtain the gasoline with lower sulfur content. Compared with the prior art of hydrodesulfurization, the invention has the advantage that the octane number of the gasoline cannot be reduced; compared with the prior art of oxidation desulfurization, the invention has the advantages of relaxed technological conditions, secondary pollution prevention, simple operation and lower cost; and the invention further has the advantage that the method is favorable for recycling the solid manganese dioxide and ionic liquid used in the reaction process.

Owner:CHONGQING UNIV

Method for extracting precious metal from auto-exhaust catalyst by hydrometallurgy and pyrometallurgy complex process

InactiveCN101519725BLoose process conditionsImprove leaching rateProcess efficiency improvementHydrometallurgyPyrometallurgy

The invention relates to a method for extracting precious metal from a disabled auto-exhaust catalyst, which comprises the following steps: 1. lixiviating precious metal from the disabled auto-exhaustThe invention relates to a method for extracting precious metal from a disabled auto-exhaust catalyst, which comprises the following steps: 1. lixiviating precious metal from the disabled auto-exhaust1g / t and the product purity reaches 99.95 percent.than 1g / t and the product purity reaches 99.95 percent.catalyst by a hydrometallurgy process and obtaining precious metal concentrates after permuting lixivium; 2. lixiviating slag, collecting precious metal of the slag by a pyrometallurgy process to obt catalyst by a hydrometallurgy process and obtaining precious metal concentrates after permuting lixivium; 2. lixiviating slag, collecting precious metal of the slag by a pyrometallurgy process to obtain a precious metal phase and selectively lixiviating base metal in the precious metal phase to obtain precious metal concentrates; and 3 combining the precious metal concentrates obtained in the firain a precious metal phase and selectively lixiviating base metal in the precious metal phase to obtain precious metal concentrates; and 3 combining the precious metal concentrates obtained in the first two steps and refining the precious metal concentrates to produce platinum, palladium and rhodium products. The invention compensates the deficiency that the percent recovery of the precious metalst two steps and refining the precious metal concentrates to produce platinum, palladium and rhodium products. The invention compensates the deficiency that the percent recovery of the precious metalis low by simply treating the disabled auto-exhaust catalyst with the hydrometallurgy process and has the advantages that the contents of platinum, palladium and rhodium in the waste slag are smalleris low by simply treating the disabled auto-exhaust catalyst with the hydrometallurgy process and has the advantages that the contents of platinum, palladium and rhodium in the waste slag are smallerthan

Owner:KUNMING INST OF PRECIOUS METALS

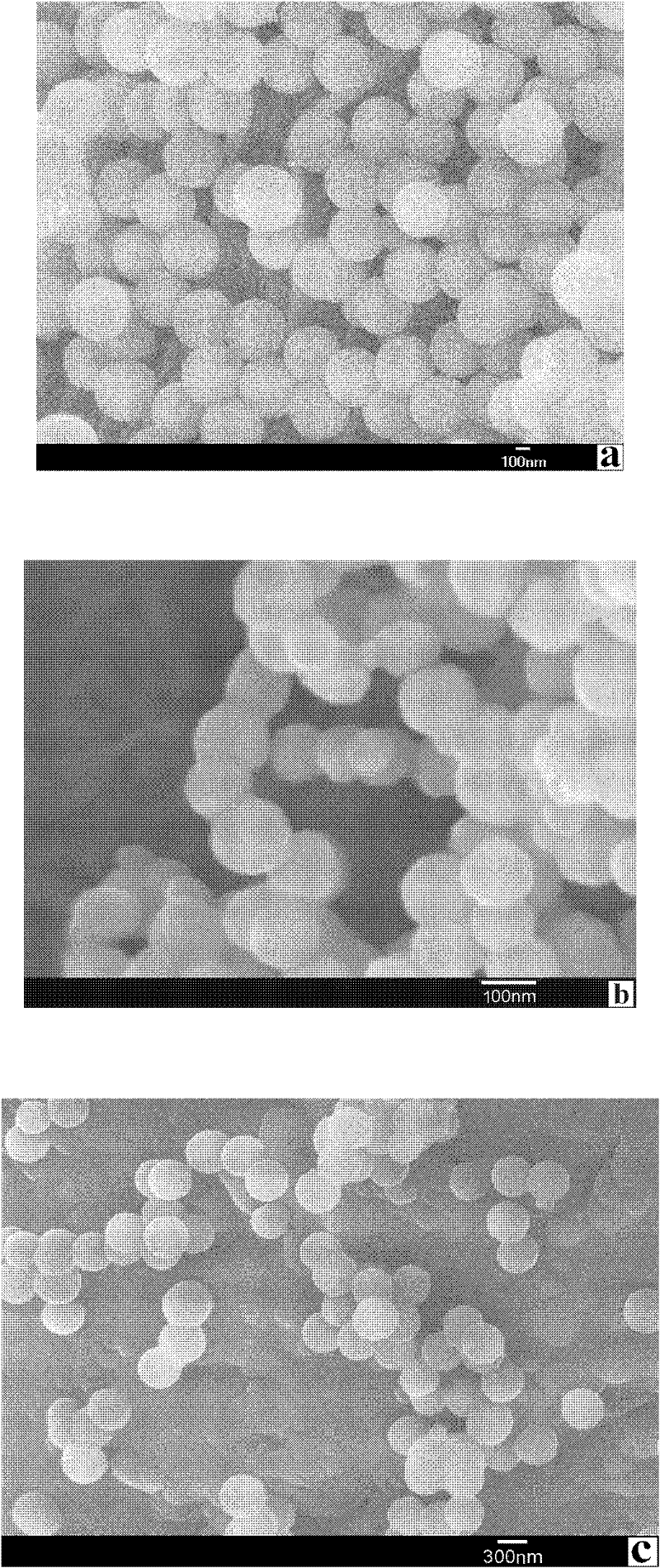

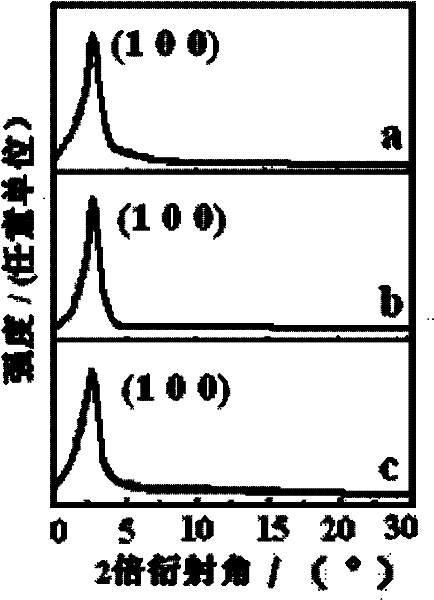

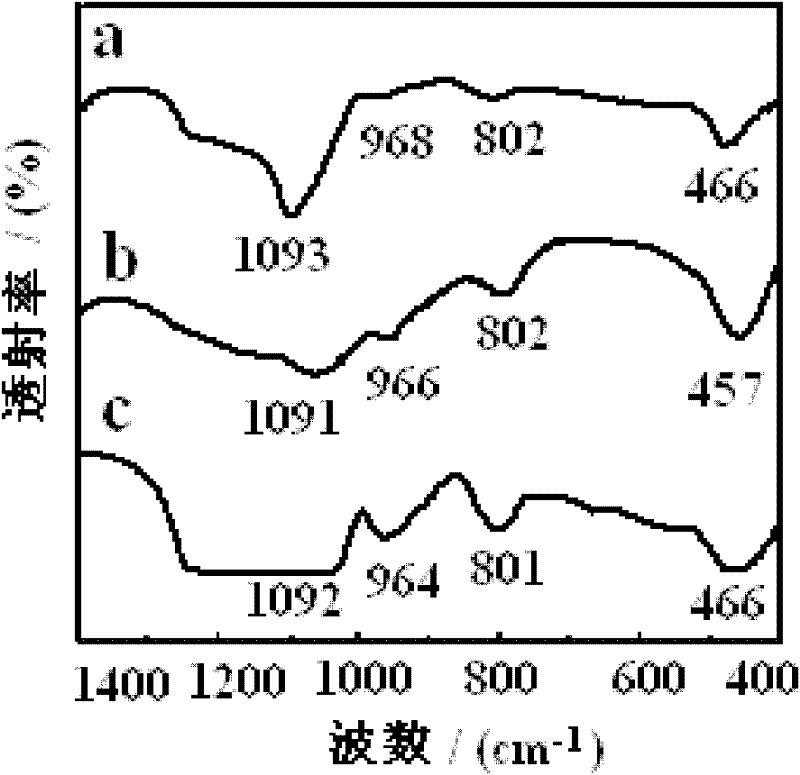

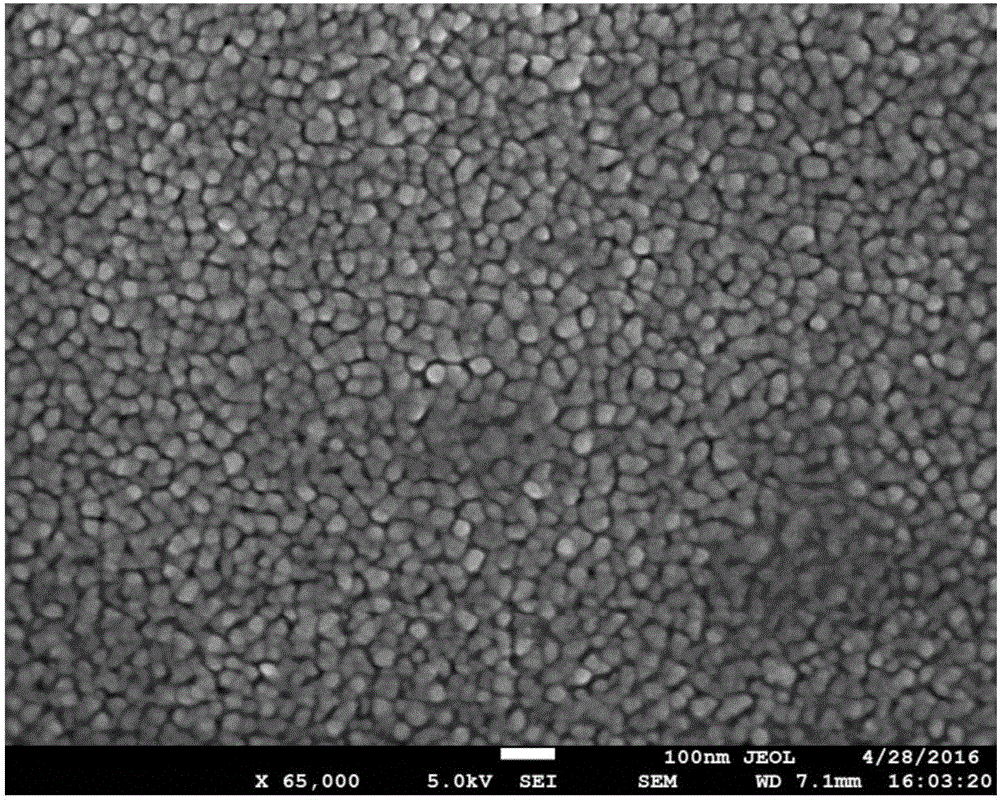

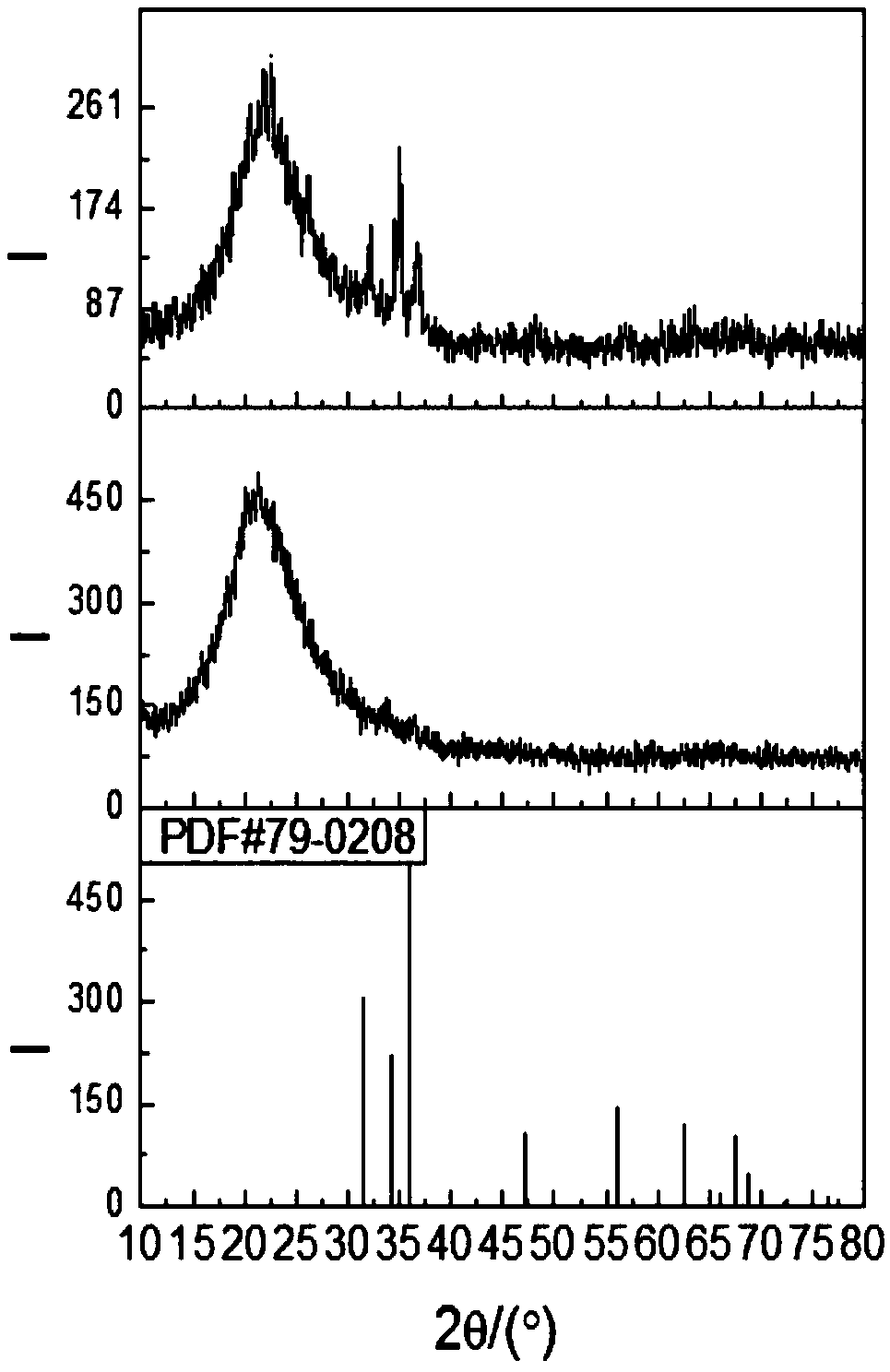

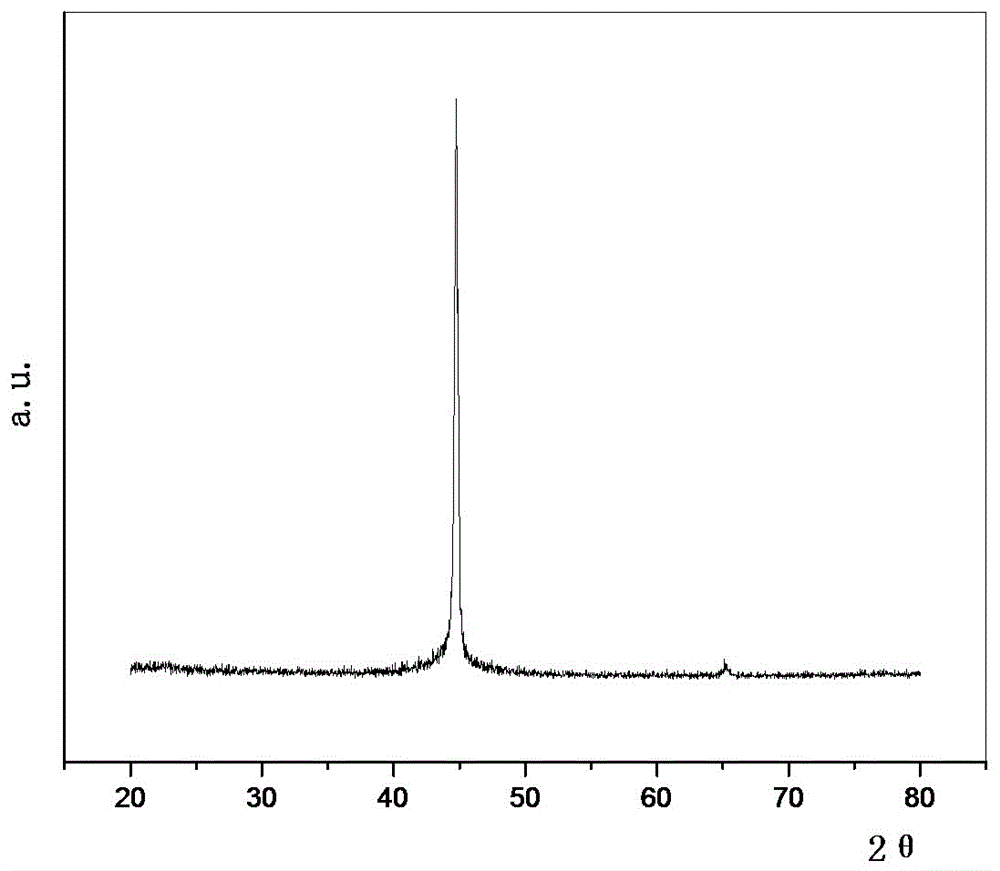

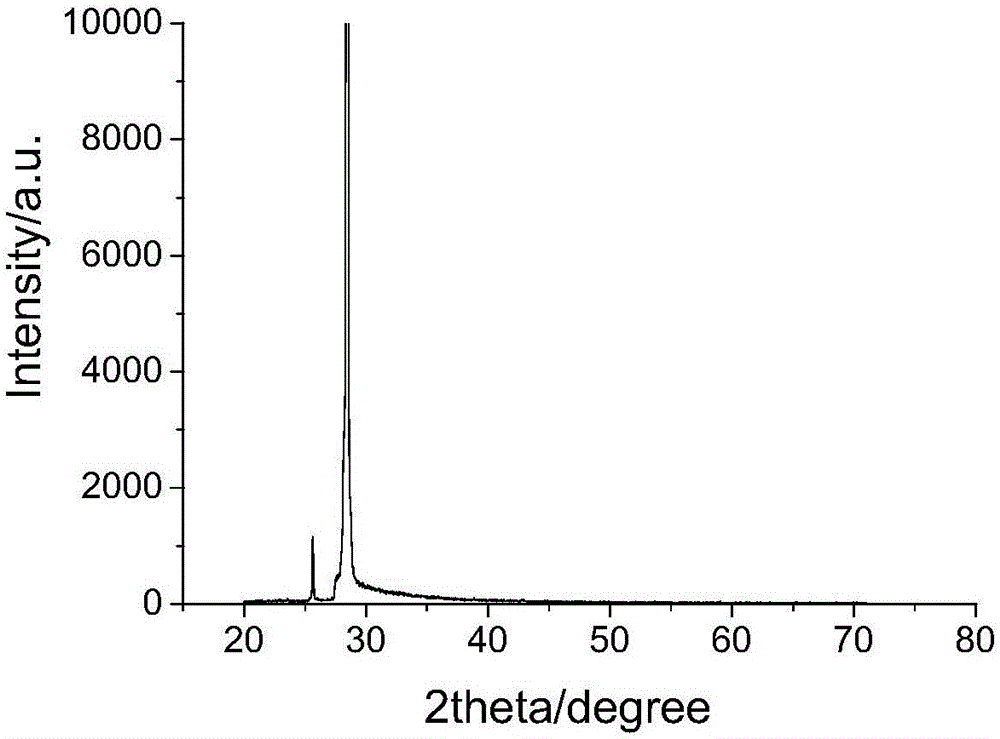

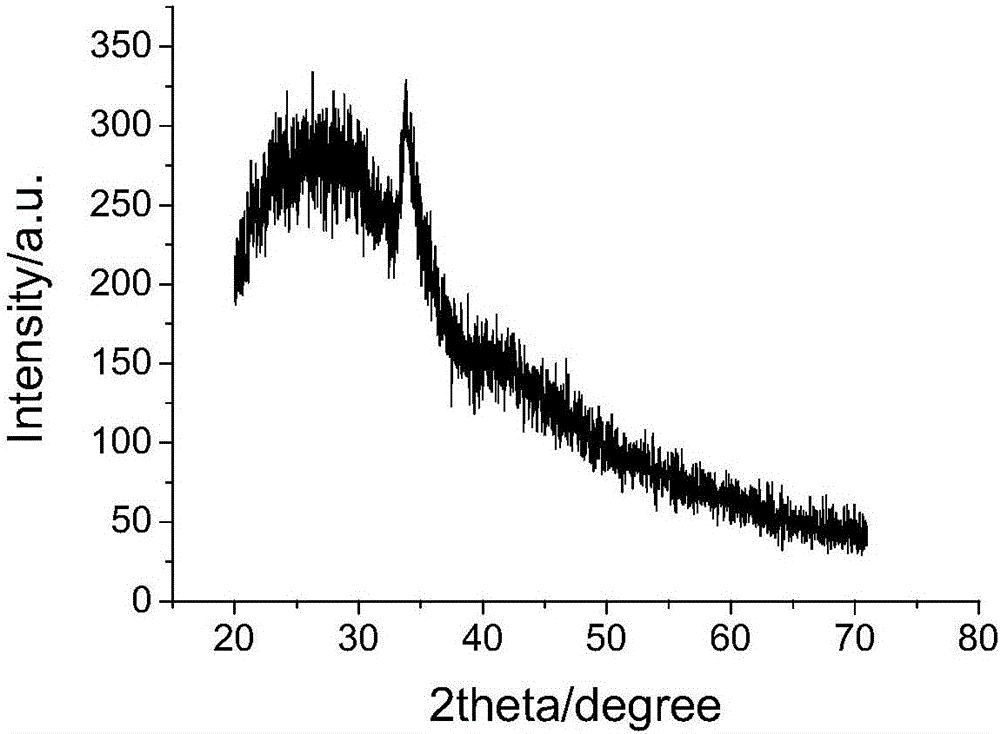

Spherical MCM-41 molecular sieve with particle size more than 400 nanometers, and synthesis method for the same

InactiveCN102336411AUniform deliveryUniform heat conductionNanotechnologyCrystalline aluminosilicate zeolitesSynthesis methodsAmmonium bromide

The invention discloses a spherical MCM-41 molecular sieve with the particle size more than 400 nanometers, and a synthesis method for the same, belonging to the technical field of inorganic functional materials. The average particle size of the existing MCM-41 molecular sieve particles is only 100 nm, and the existing MCM-41 molecular sieve particles are irregular in shape and non-uniform in size; and the synthesis method for the existing MCM-41 molecular sieve particles needs strict conditions and consumes long time. The MCM-41 molecular sieve particles provided by the invention are spherical, and the particle size of the MCM-41 molecular sieve particles is not less than 436 nm and not more than 485 nm. In synthesis method for the MCM-41 molecular sieve particles provided by the invention, a single template is used, the template raw material is decyl trimethyl ammonium bromide, the synthesis process is executed under normal pressure, the pH value of the reaction system is adjusted by sodium hydroxide or ammonia water, and the synthesis process takes 1.5-2.5 hours. The synthesized molecular sieve particles are used for manufacturing chemical sensors, electronic and optical devices and the like.

Owner:CHANGCHUN UNIV OF SCI & TECH

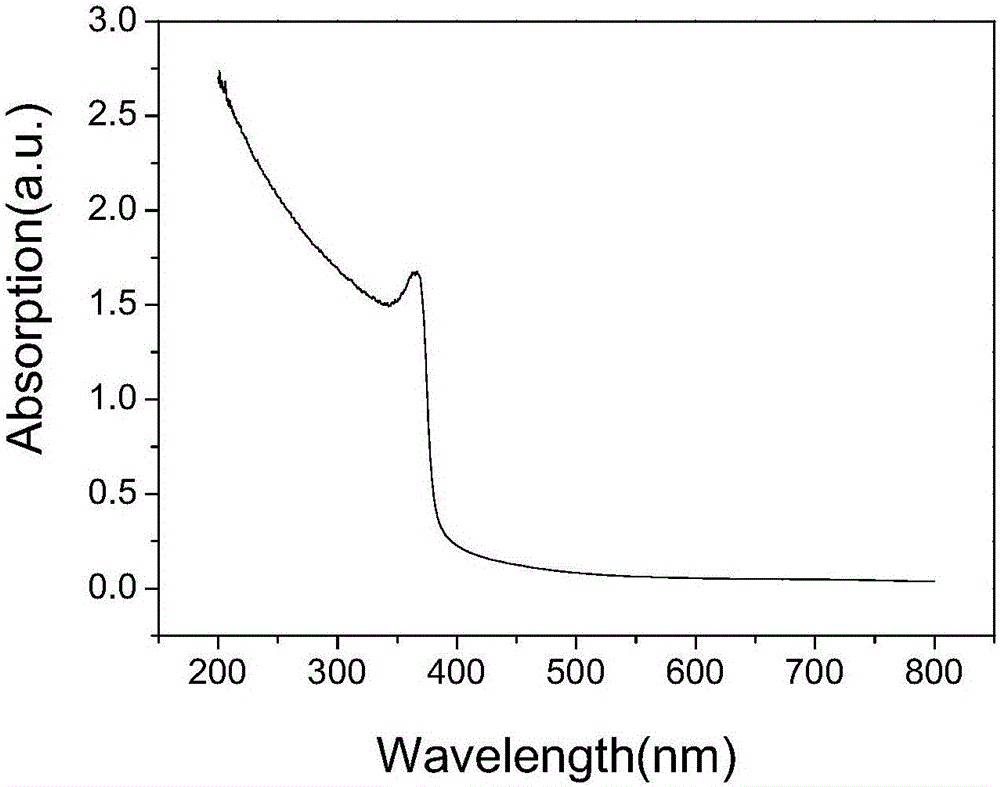

ZnO thin film laser ablation fabrication method

InactiveCN106548932ALoose process conditionsSimple manufacturing methodSemiconductor/solid-state device manufacturingOptoelectronicsLaser light

The invention relates to a ZnO thin film laser ablation fabrication method and belongs to the optical functional material technical field. An existing method for fabricating a ZnO thin film is very difficult to implement. The ZnO thin film laser ablation fabrication method of the invention is a sol-gel method. The ZnO thin film laser ablation fabrication method includes the following steps that: zinc acetate is dissolved in an organic solvent, ethanolamine of which the molar quantity is equal to that of zinc ions is added into an obtained solution, and the solution is stirred, and a sol liquid is obtained; a substrate is spin-coated with the sol liquid, and the substrate spin-coated with the sol liquid is subjected to lower-temperature heat treatment, so that a sol film can be obtained; and laser is adopted to ablate the sol film, the power of the laser ranges from 5 to 30 W, ablation time ranges from 1 to 1000 sec, a distance from a laser light source to the sol film ranges from 1 to 50 cm, and a ZnO thin film is obtained. According to the method of the invention, a vacuum environment and a special protective atmosphere are not required, and a ZnO ceramic target is not required to be produced, and therefore, compared with an existing pulsed laser deposition method, the method of the invention has lower requirements for process conditions and is greatly simplified in thin film fabrication.

Owner:CHANGCHUN UNIV OF SCI & TECH

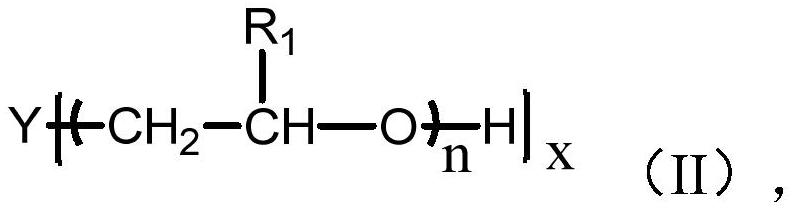

Polyether polyol for polyurethane foam plastic as well as preparation method and application of polyether polyol

The invention provides polyether polyol for polyurethane foam plastic as well as a preparation method and application of the polyether polyol. The polyurethane foam plastic prepared on the basis of the polyether polyol obtained by the invention is not only high in compression strength, good in dimensional stability and few in moisture absorption and swelling problems in rainy days, but also excellent in solvent resistance and flame retardant property, and the application requirements of polyurethane spraying can be well met. The preparation method provided by the invention of the polyether polyol for the polyurethane foam plastic comprises the steps of S1, carrying out phosphate esterification modification on the polyether polyol by adopting polyphosphoric acid to generate polyether polyol phosphate, and enabling the polyether polyol phosphate to contain part of hydroxyl groups; and S2, conducting epoxidation modification on the polyether polyol phosphate obtained in the step S1 by adopting epoxy resin, and generating polyether polyol for the polyurethane foam plastic, wherein the molecular structure of the epoxy resin contains benzene rings.

Owner:WANHUA CHEM GRP CO LTD

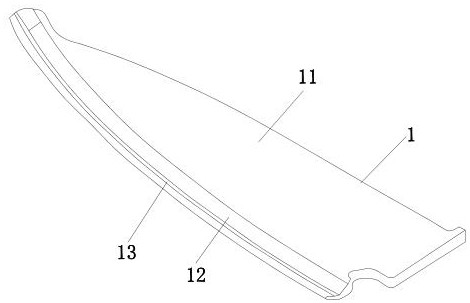

Alloy powder sleeve cutter and alloy filling method thereof

PendingCN114799734AHigh hardnessImprove wear resistanceMetallic material coating processesLaser beam welding apparatusAlloyWear resistance

The alloy powder sleeve cutter comprises a cutter body, the cutter body comprises a cutter body, a cutting edge and a filling groove, the cutting edge is arranged at the edge of the cutter body, the filling groove is formed in the cutting edge, the appearance of the filling groove has a radian, and the filling groove is filled with alloy powder. The preparation method is simple, the process conditions are loose, implementation is easy, the alloy powder layer is sprayed and welded through laser cladding, one side of the cutting edge part is filled with alloy powder, the other side of the cutting edge part is the base material, and the hardness and wear resistance of the alloy powder layer are higher than those of the base material, so that when the kitchen cutter is frequently used, the cutting edge part is not damaged at the cutting edge position; the base material layer can be abraded during cutting, the alloy powder layer cannot be abraded, the base material layer can be thinned by grinding, the cutting edge is sharper and sharper under the condition of long-term use, the cutter is good in lasting sharpness, alloy powder is dispersed uniformly, the longitudinal and transverse uniformity of the internal organization structure of a product is guaranteed, and the abrasion resistance is improved.

Owner:陈远明

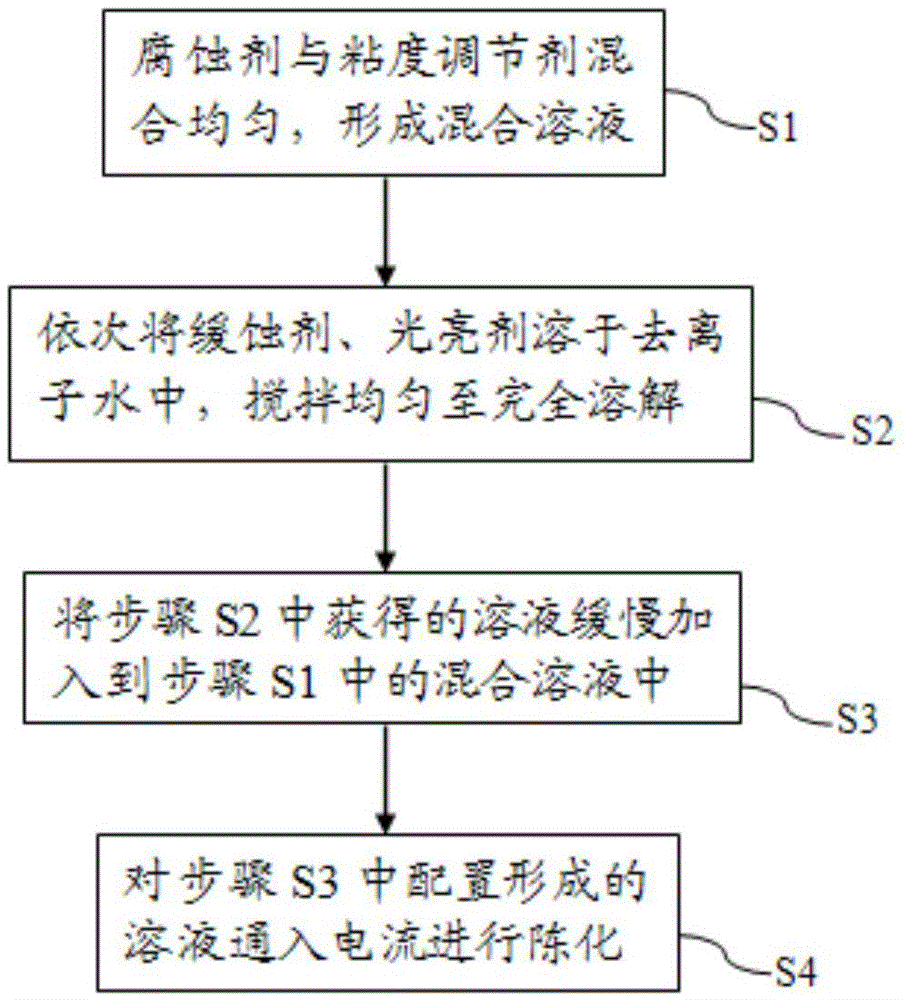

Polishing liquid and its preparation method and application

ActiveCN103923571BEasy to follow upGood polishing stabilityAqueous dispersionsThioureaPhosphoric acid

The invention discloses a polishing solution as well as a preparation method and application of the polishing solution, wherein the polishing solution comprises a corrosive agent, a viscosity regulator, a corrosion inhibitor, a brightening agent and deionized water. The corrosive agent comprises sulfuric acid and phosphoric acid; the viscosity regulator is one or more selected from the following substances: polyethylene glycol, gelatin, polyhydric alcohol, glycerol and dextrin; the corrosion inhibitor is one or more selected from the following substances: rodine, thiourea, diamylamine, methylphenylthiourea and ethylenediamine tetraacetic acid; the brightening agent is one or more selected from the following substances: salicylic acid, sulfonic acid, sodium benzoate, benzenediol and fluorine-contained quaternary ammonium. The polishing solution disclosed by the invention is free of heavy metal components, easy to realize subsequent treatment, relatively good in polishing stability and capable of obtaining a relatively good polishing effect within a relatively wide concentration change range. In addition, the preparation method of the polishing solution disclosed by the invention is low in process condition requirement and capable of obtaining the relatively good polishing effect within a wide current density range.

Owner:SUZHOU NEW MATERIAL INST +2

Fabrication method of metastable high magnesium mgzno solid solution alloy film by laser ablation

ActiveCN106756901BLoose process conditionsLiquid/solution decomposition chemical coatingLaser lightZinc Acetate Dihydrate

The invention provides an ablation manufacturing method of a metastable-state high-magnesium MgZnO solid solution alloy film, and belongs to the technical field of optical functional materials. In the prior art, the doping amount of Mg is generally smaller than 0.33. The ablation manufacturing method of the metastable-state high-magnesium MgZnO solid solution alloy film belongs to a Sol-Gel method, and is characterized by comprising the following steps: determining the value of x in MgxZn1-xO as follows: 0.25<=x<=0.75, determining the mole ratio of zinc acetate to magnesium acetate according to the value of x, dissolving the zinc acetate and the magnesium acetate in an organic solvent, adding ethanol amine of which the amount is equal to the amount of zinc ions and the amount of magnesium ions, and stirring to obtain a sol solution; spin-coating a substrate with the sol solution, and carrying out low-temperature heat treatment to obtain a gel film; and ablating the gel film by using laser to obtain the metastable-state high-magnesium MgZnO solid solution alloy film, wherein laser power is 5-30 W, the ablation time is 1-1,000 seconds, and the distance between a light outlet of a laser light source and the gel film is 1-50 cm.

Owner:CHANGCHUN UNIV OF SCI & TECH

A method for continuous extraction and separation of 1-deoxynojirimycin (dnj) and flavonoids from mulberry leaves

ActiveCN101671294BMaintain biological activityEasy to operateOrganic chemistryMetabolism disorderMacroporous resinImpurity

A method for continuously extracting and separating 1-deoxynojirimycin (DNJ) and flavonoids from mulberry leaves, the main points of the method are: extracting after mixing mulberry leaves and ethanol, centrifuging and filtering, adding a flocculant to flocculate and precipitate after concentrating; removing the precipitate Finally, the filtrate is added to a plurality of connected cation exchange resin columns, and flows through the macroporous adsorption resin column connected in series with the resin column; after the filtrate is added, it is washed with pure water until the macroporous resin column effluent is colorless. It is disconnected, and then eluted 1-deoxynojirimycin (DNJ) from the cationic resin column with ammonia water or ammonia-containing ethanol solution; Concentrate and filter with a filter membrane, and then spray dry to obtain 1-deoxynojirimycin (DNJ) in the form of brown yellow powder. Wash the macroporous resin column with 3%-10% ethanol to remove colloidal impurities, then elute flavonoids with 50%-70% ethanol, collect the brown-red eluate, concentrate under reduced pressure to recover ethanol, and then spray dry to obtain yellow-brown Powdered total flavonoids of mulberry leaves.

Owner:GUANGDONG APOLLO GRP

Micro relay contacts, reed gold plating process

The invention discloses a gold-plating process method for contacts and reeds of miniature relays. The materials and the composition thereof are: gold trichloride of 6-14g / L in terms of gold content; anhydrous sodium nitrite 100-200g / L ; Potassium citrate 30-100g / L; Potassium chloride 30-90g / L; EDTA 5-15g / L; Cobalt sulfate heptahydrate 0.5-5g / L; The electroplating of silver nitrate 0.01-0.3g / L Put the electroplating workpiece into the solution for electroplating. Compared with the prior art, in terms of structural features of the present invention, the density is higher than that of the original cyanide gold-plated cobalt alloy gold plating, the purity of the gold coating reaches 99.99%, and the hardness is (110-120) HV, which is higher than the original cyanide gold-plated cobalt alloy gold plating The hardness of the gold layer (85-100) HV is high, which is lower than that of the original cyanide gold-plated nickel alloy (180-220) HV; in terms of technical improvement, the stability of the electrolyte and the dispersion ability are greatly improved, and the compactness of the coating layer is improved; quality; In terms of improvement, the contact resistance failure rate of its products decreased by 95%, the bonding failure rate decreased by 70%, and the consistency of coating quality increased by 80%.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

Method for preparing honeysuckle flower extract by jointly adopting membrane separation and column chromatography

ActiveCN102391115BHigh content of active ingredientsConducive to subsequent processingCarboxylic acid esters separation/purificationMedicinal herbsChlorogenic acid

A method for preparing honeysuckle extract by membrane separation column chromatography, comprising preparation of filtrates A and B, membrane separation, recovery of ethanol, adding samples to the column and washing impurities with water; the volume percentage concentration is 5% to 25% Elute the macroporous resin column with ethanol, pass the eluate through a 700 Dalton membrane, concentrate the membrane concentrate under reduced pressure at 50°C to 80°C, and spray dry to obtain the chlorogenic acid extract; The macroporous resin column is eluted with 55% to 85% ethanol, the eluate is concentrated under reduced pressure at 50°C to 80°C, and spray-dried to obtain flavonoid extract. Compared with the prior art, the present invention adopts the combination of membrane separation technology and column chromatography separation technology to prepare honeysuckle extract, and can simultaneously harvest chlorogenic acid extract and flavonoid extract in honeysuckle, and has high medicinal material utilization. , It has the advantages of high active ingredient content, convenient subsequent processing and use, simple process, low energy consumption in the operation process, and convenient large-scale industrial production and promotion.

Owner:GUANGDONG APOLLO GRP

Iron-based amorphous-nanocrystalline soft magnetic alloy with high saturation magnetic induction and its application

ActiveCN103915231BCorrosion resistanceHigh saturation magnetic inductionMagnetic materialsStress reliefCorrosion resistant

The invention relates to an iron-based amorphous-nanometer crystalline state magnetically soft alloy with high saturation magnetic induction density and an application thereof. FeaSibBcAld series amorphous-nanometer crystalline state magnetically soft alloy is formed by adding a certain amount of Al capable of improving the saturation magnetic induction density of the amorphous alloy into Fe-Si-B series amorphous alloy, wherein a is 78-86 atom percents, b is 2-9 atom percents, c is 9-14 atom percents, and d is 1-5 atom percents. The iron series amorphous-nanometer crystalline magnetically soft alloy has the advantages of being good in formability, high in saturation magnetic induction density, low in cost, corrosion-resistant, simple in process and the like. After stress relief annealing is conducted on the alloy, the saturation magnetic induction density can reach 1.62-1.778T.

Owner:ZHENGZHOU UNIV

Iron-based amorphous nanocrystalline soft magnetic alloy and preparation method thereof

ActiveCN106119739BHigh saturation magnetic inductionLow coercivityMagnetic materialsStress reliefImpurity

The invention relates to novel iron-based amorphous nanocrystalline magnetically soft alloy which can be directly obtained through rapid cooling without the need for annealing and a preparation method thereof. The composition of the magnetically soft alloy is FeaSibBcCdMnePfCrgNihCujMojCok except for unavoidable impurities. The iron-based amorphous nanocrystalline magnetically soft alloy has high saturated magnetic induction density Bs, low coercivity Hc, high and stable magnetic conductivity [mu]i and other excellent soft magnetic properties after stress relief annealing. Compared with existing nanocrystalline alloy applied in the industry and obtained through crystallization annealing, the annealing temperature is greatly lowered, and the iron-based amorphous nanocrystalline magnetically soft alloy does not contain or contain a trace of precious metal elements, so that the production cost is greatly lowered.

Owner:ZHENGZHOU UNIV

Laser ablation manufacturing method for metastable-state AlZnO solid solution alloy film

InactiveCN106783534AAny solid solutionLoose process conditionsSemiconductor/solid-state device manufacturingAluminum IonLaser light

The invention discloses a laser ablation manufacturing method for a metastable-state AlZnO solid solution alloy film, and belongs to the technical field of optical function materials. An existing method for manufacturing an AlZnO solid solution alloy film is extremely tedious. The laser ablation manufacturing method for the metastable-state AlZnO solid solution alloy film disclosed by the invention belongs to a Sol-Gel method, and is characterized by comprising the following steps: determining the value of x in AlxZn1-xO to be greater than 0 and smaller than 1, determining the molar ratio of zinc acetate to aluminum acetate according to the value of x, dissolving zinc acetate and aluminum acetate into an organic solvent, adding ethanol amine with the mass being equal to that of zinc ions and aluminum ions, and stirring to obtain a sol rubber solution; spin-coating the sol rubber solution onto a substrate, and carrying out low-temperature treatment to obtain a gel film; carrying out laser ablation on the gel film to obtain the metastable-state AlZnO solid solution alloy film, wherein the laser power is 5 to 30 W, the ablation time is 1 to 1000 sec, and the distance between a laser light source light outlet and the gel film is 1 to 50 cm.

Owner:CHANGCHUN UNIV OF SCI & TECH

Diffusion process of a crystalline silicon high-efficiency high-resistivity solar cell

ActiveCN105280484BImprove photoelectric conversion rateReduce surface recombinationFinal product manufactureSemiconductor/solid-state device manufacturingDopantHigh resistance

The present invention relates to a diffusion technique of a crystal-silicon efficient high-sheet-resistance battery piece. The diffusion technique comprises the steps of furnace entering, low-temperature oxidation, low temperature gas reaction deposition, low temperature dopant redistribution, high temperature gas reaction deposition, cooling dopant redistribution, low temperature gas reaction deposition, low temperature dopant redistribution and discharge. With adoption of the diffusion technique provided by the present invention, photoelectric conversion efficiency of the battery pieces can be raised, the production time is shortened, and the production efficiency is raised.

Owner:TRINA SOLAR CO LTD +1

A kind of synthetic method of phthalonitrile

ActiveCN112920080BAvoid unmanageable side effectsImprove conversion ratePreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsO-XylenePtru catalyst

The invention provides a new synthesis method of phthalonitrile. In the method, o-xylene is used as a raw material to carry out hierarchical catalytic synthesis in the presence of a catalyst. During the synthesis process, there are very few side reactions, the yield is high, and the amount of ammonia used is greatly reduced. The catalyst used in the invention has good selectivity, reduces the requirements for reaction conditions, reduces the generation of three wastes, and is beneficial to industrial production.

Owner:ANSHAN HIFICHEM CO LTD

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a production process for preparing phosphorus slag cast stone for architectural decoration. The production process of using high-temperature phosphorus slag liquid to prepare phosphorus slag cast stone for architectural decoration is characterized in that it includes the following steps: (1) preparation and preheating of auxiliary raw materials: using quartz sand and kaolin as auxiliary raw materials, preheating to 1300 ~ 1450°C; (2) Hot batching: the phosphorus slag liquid above 1350°C discharged from the phosphorus smelting electric furnace flows into the kiln through the liquid flow tank, and the auxiliary raw materials are synchronously put into the pool kiln. Among them, the mass ratio of the phosphorus slag liquid to the auxiliary raw materials 65~75:25~35; (3) mixed melting: the mixed melting temperature of phosphorus slag liquid and auxiliary raw materials in the tank kiln is 1450~1580 °C; (4) molding; (5) crystallization and annealing: at 1000 Crystallization treatment at ~1150°C for 60-120 minutes, then annealing and cooling to room temperature to obtain the product. The invention can effectively utilize the heat energy of the high-temperature phosphorus slag liquid, realize the direct recycling of the phosphorus slag liquid, reduce the energy consumption and production cost of cast stone production, and make the phosphorus slag cast stone suitable for large-scale architectural decoration.

Owner:浙江中地大科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com