Polishing liquid and its preparation method and application

A polishing liquid and brightener technology, applied in the field of electrochemical polishing, can solve the problems of poor surface brightness, high roughness, and increased difficulty in waste liquid treatment, and achieve the effect of loose process conditions, good polishing effect, and easy follow-up treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

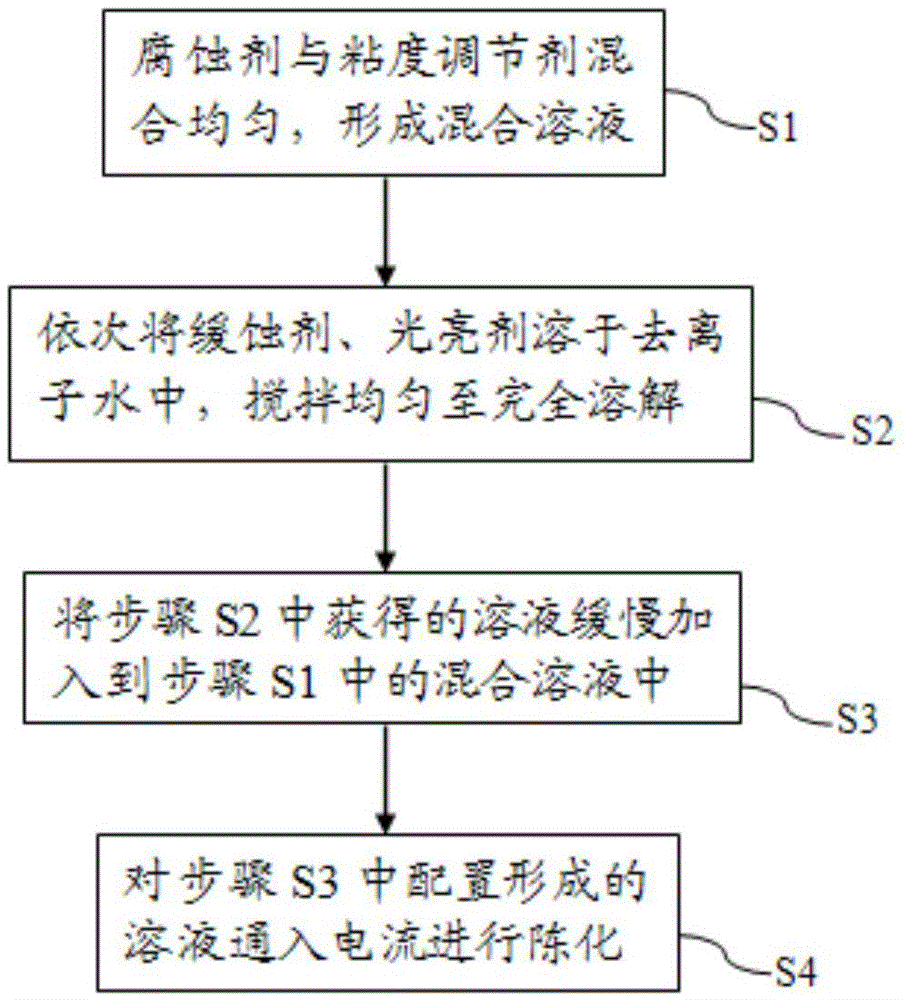

[0032] Such as figure 1 Shown, the present invention also provides a kind of preparation method for above-mentioned polishing liquid, and this preparation method comprises the steps:

[0033] S1. Mix the corrosive agent and the viscosity regulator evenly to form a mixed solution.

[0034] Preferably, when uniformly mixing the corrosive agent and the viscosity modifier, one component of the viscosity modifier is selected to be uniformly mixed with the corrosive agent, and the component is glycerol.

[0035] S2. Dissolve the corrosion inhibitor and the brightener in deionized water in sequence, and stir evenly until completely dissolved.

[0036] Preferably, step S2 further includes: dissolving another component of the viscosity modifier that is not easily miscible with acid, the corrosion inhibitor, and the brightener in deionized water in sequence, and stirring evenly until completely dissolved. Another component of the viscosity modifier is polyethylene glycol.

[0037] In...

Embodiment 1

[0046] Mix 30kg of sulfuric acid, 50kg of phosphoric acid, and 1.6kg of glycerin evenly, then dissolve 0.8kg of polyethylene glycol, 0.3kg of thiourea, 0.2kg of ethylenediaminetetraacetic acid, and 0.2kg of sodium benzoate in 25L of 70℃ deionized water. Stir evenly for a period of time until the solution is completely dissolved. Slowly add this solution into the mixed solution of sulfuric acid, phosphoric acid and glycerin while stirring, and circulate at 50°C for 24 hours.

[0047] The above-mentioned prepared solution was aged at 40° C. by passing an electric current. The anode current density is controlled at 3000A / m 2 , aged for 24 hours.

Embodiment 2

[0049] Mix 40kg of sulfuric acid, 60kg of phosphoric acid, and 1.8kg of glycerin evenly, then dissolve 1kg of polyethylene glycol, 0.4kg of thiourea, 0.3kg of ethylenediaminetetraacetic acid, and 0.1kg of sodium benzoate into a 30L 70°C dehydrator in order. ionized water. Stir evenly for a period of time until the solution is completely dissolved. Slowly add this solution into the mixed solution of sulfuric acid, phosphoric acid and glycerin while stirring, and circulate at 50°C for 24 hours.

[0050] The above-mentioned prepared solution was aged at 40° C. by passing an electric current. The anode current density is controlled at 2000A / m 2 , aged for 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com