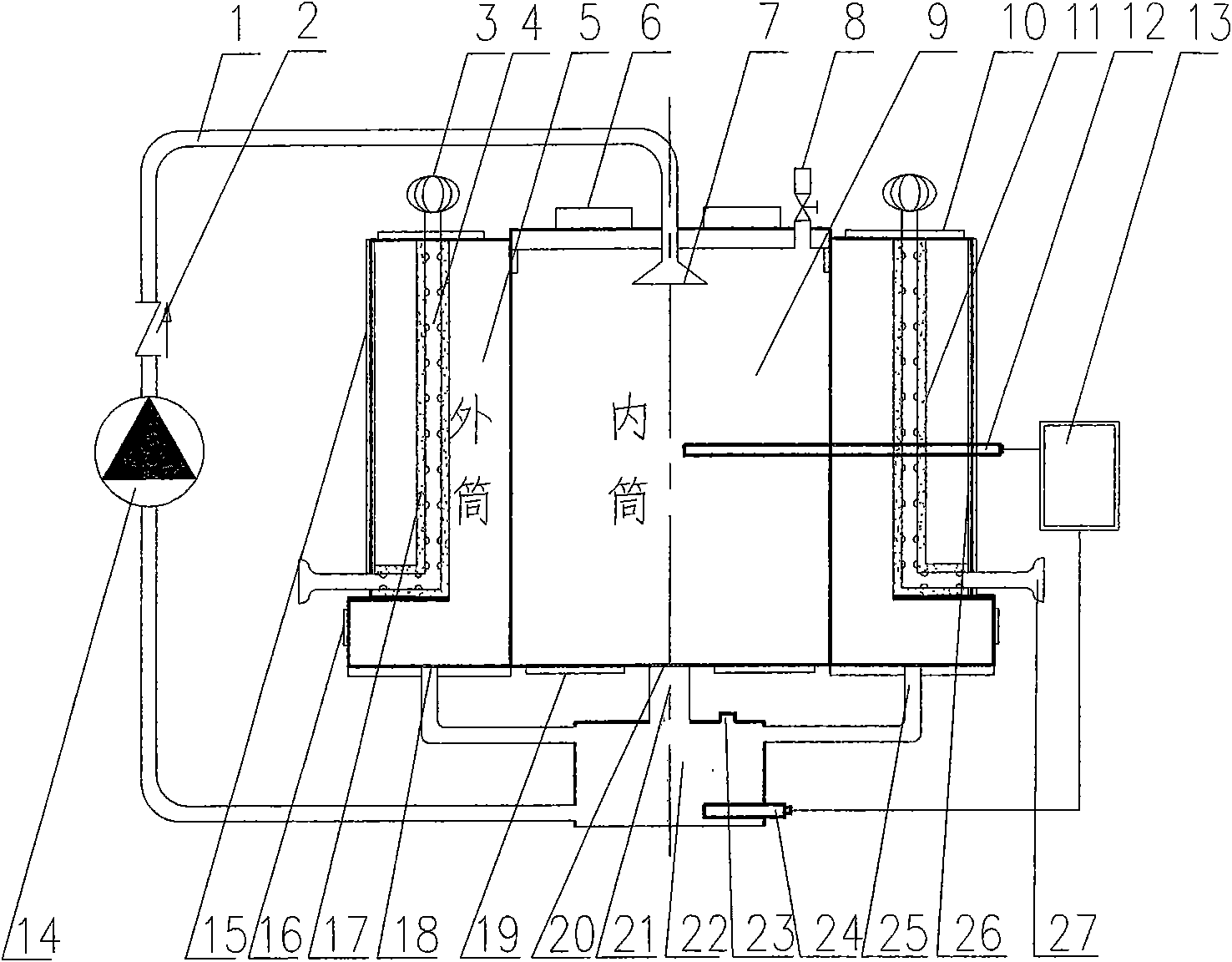

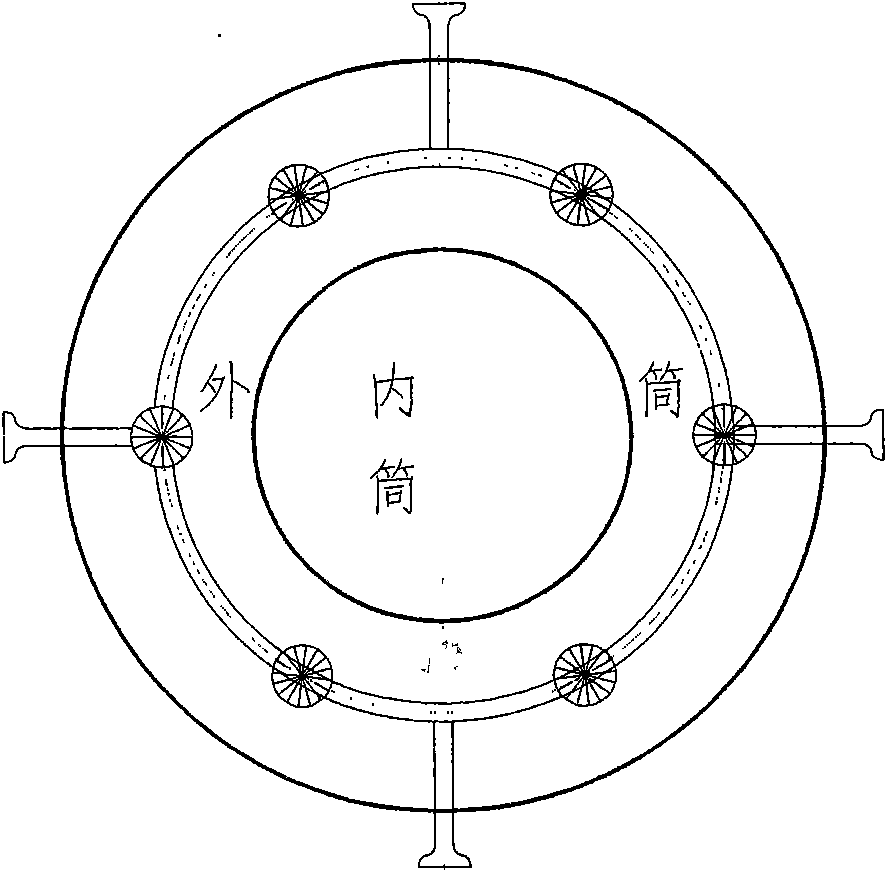

Integrated methane dry fermentation device

A dry fermentation device, biogas technology, applied in biochemical cleaning devices, enzymology/microbiology devices, solid-phase fermentation bioreactors, etc., can solve the problems of insufficient thermal energy utilization, complicated heating methods, and large footprint , to achieve the effect of improving volume capacity, compact structure and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0030]Embodiment 1: Use enzyme bacteria to pretreat corn stalks, then crush the corn stalks to 3~5cm, put them into the outer cylinder retting tank for retting, and the oxygen required during this period is determined by the suction hood, air guide pipeline and wind cap Composed ventilation control system supply, stack retting 5d, remove from the outlet of the outer cylinder, then add the inoculum and pig manure, the ratio is 30:1 carbon-nitrogen ratio, fermentation concentration is 20%, pH value is 7.0 After that, these materials are sent to the anaerobic fermentation tank of the inner cylinder through the inlet of the inner cylinder for fermentation. At this time, the outer cylinder retting tank continues to add the pretreated and crushed corn stalks, after the retting treatment, it is mixed with the inoculum and pig manure, and then moved into the inner cylinder anaerobic fermentation tank for fermentation, and so on. , until the volume of the fermented material in the inne...

Embodiment approach 2

[0031] Embodiment 2: The fermentation material can be other organic solid materials, such as rice straw, wheat straw, distiller's grains, etc. The processing method is the same as that in the first embodiment.

Embodiment approach 3

[0032] Embodiment 3: The organic solid material is pretreated by white rot fungus, and then crushed. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com