Patents

Literature

105results about How to "No efflux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

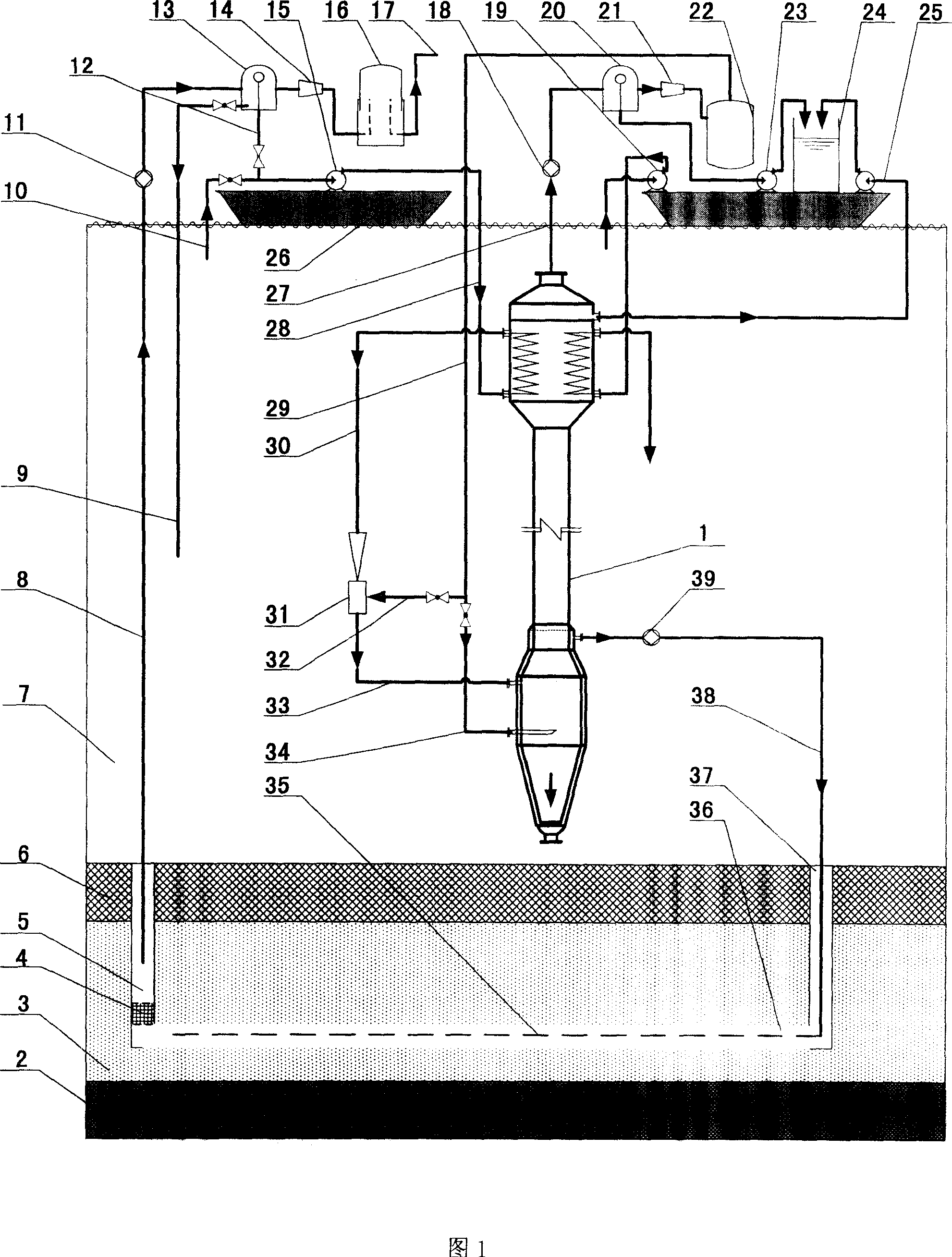

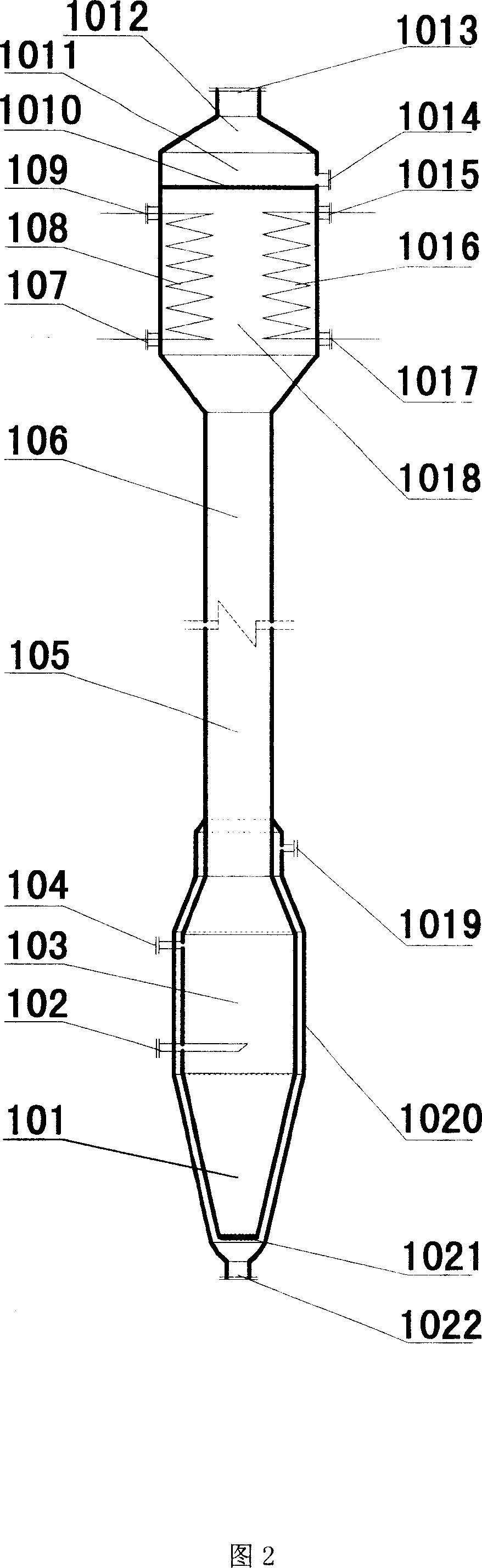

Method for exploiting natural gas hydrates and device thereof

ActiveCN101016841AImprove energy efficiencySimplify mining processConstructionsMineral miningSaline waterSalt water

The invention discloses a method for developing natural gas hydrate, which comprises that building developing well, horizontal well and collecting well, building floating platform and natural gas hydrate developer on sea, building sea concentration heater, preparing hot salt water, decomposing natural gas hydrate and collecting natural gas. And the inventive device comprises a sea floating platform, a developing well, a collecting well, a horizontal well, a hydrate recycling system, a fresh water groove, a hot salt water tube, a hot salt water pump, and a seawater concentrating heater. The invention has simple process, low energy consumption and low cost, without pollution.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

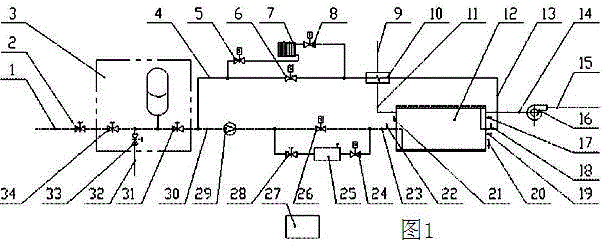

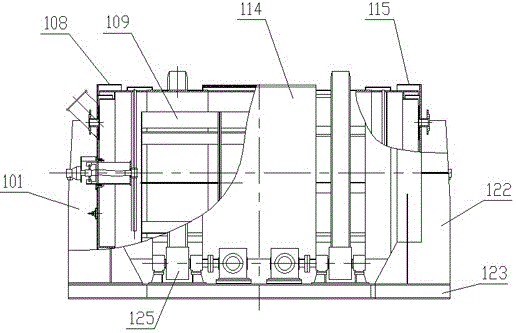

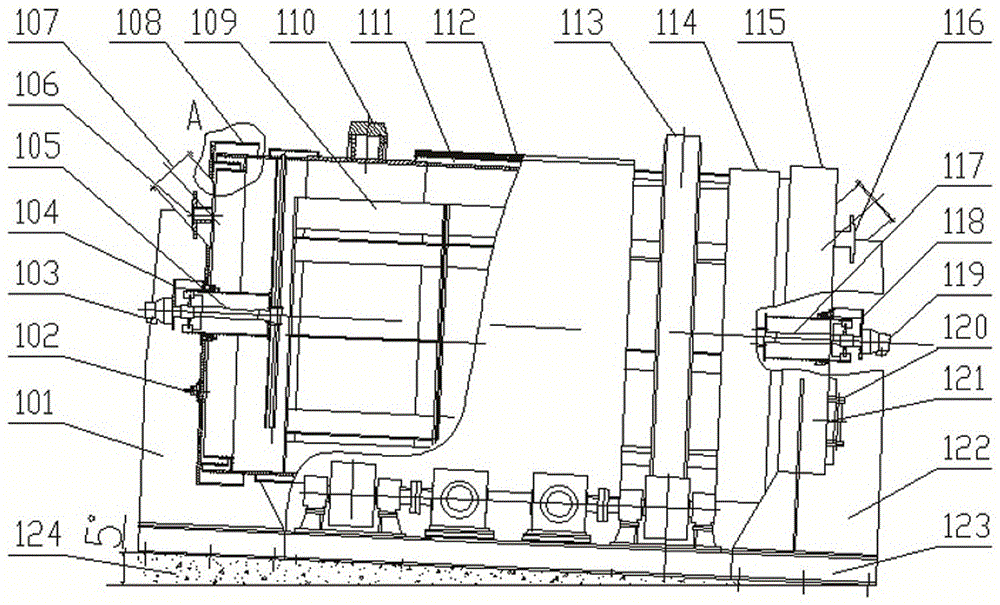

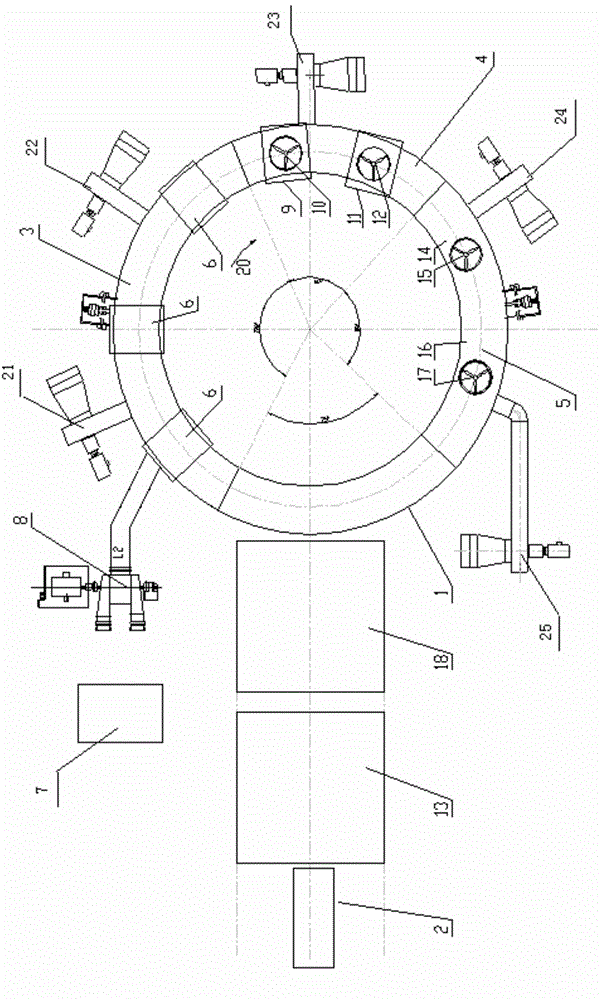

High-efficiency intelligent aerobic fermentation reaction system and method

ActiveCN102617204AFacilitate domestication and mass reproductionImprove reaction efficiencyBio-organic fraction processingOrganic fertiliser preparationControl systemProcess engineering

The invention discloses an aerobic fermentation reaction system and method. The high-efficiency intelligent aerobic fermentation reaction system comprises an aerobic fermentation reactor, a circular water system, a gas intake and exhaust system, a detection system and a control system, wherein a water jacket is arranged outside a horizontal roller of the aerobic fermentation reactor; a material feeding and discharging hole and a gas intake and exhaust hole are respectively formed in sealing covers at two sides of the horizontal roller; the circular water system is connected and communicated with the water jacket on the horizontal roller; the gas intake and exhaust system is connected and communicated with the gas intake and exhaust hole in the sealing cover of the horizontal roller; a sensor of the detection system is arranged in the aerobic fermentation reactor and on a water passing pipe of the aerobic fermentation reactor; a signal output by the sensor is respectively connected with the control system; and the control system is used for controlling the circular water system, the gas intake and exhaust system, the aerobic fermentation reactor and external feeding and discharging conveying equipment. According to the high-efficiency intelligent aerobic fermentation reaction system and method disclosed by the invention, the occupied area is smaller and the fermentation efficiency is higher; no secondary pollution occurs; and the reduction, harmlessness and resourceful treatment of organic wastes can be quickly realized.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

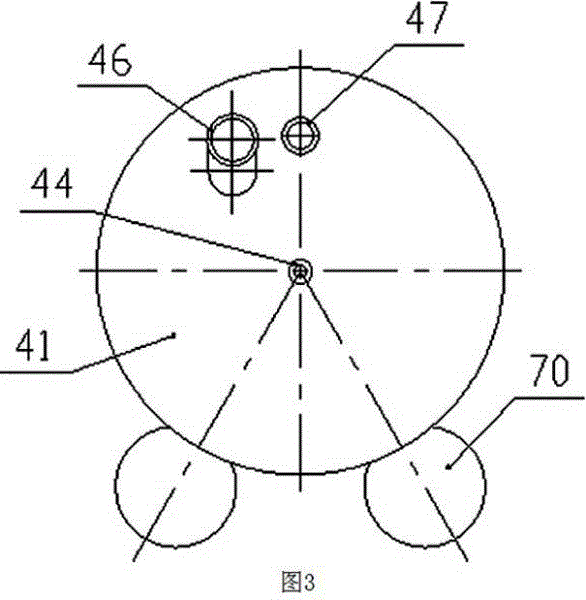

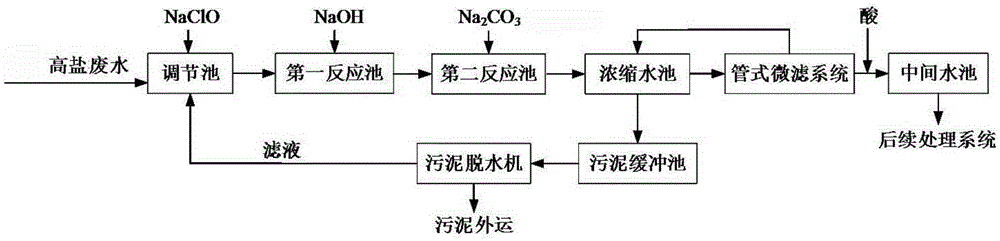

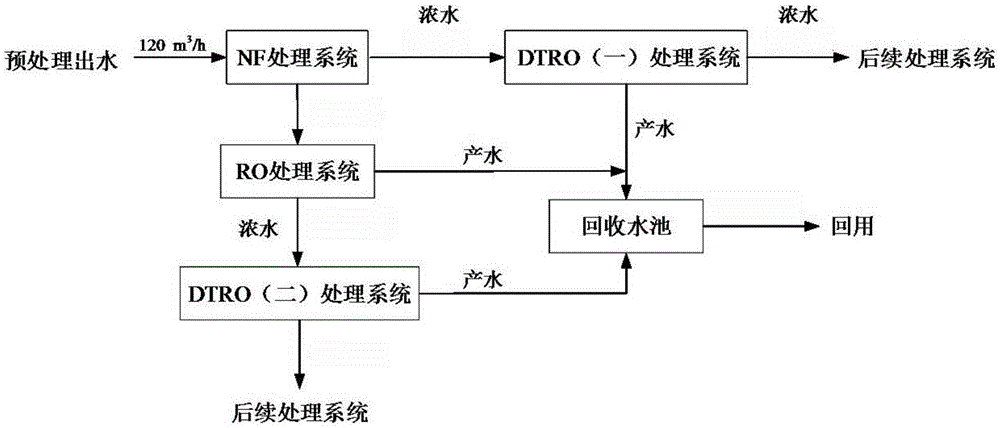

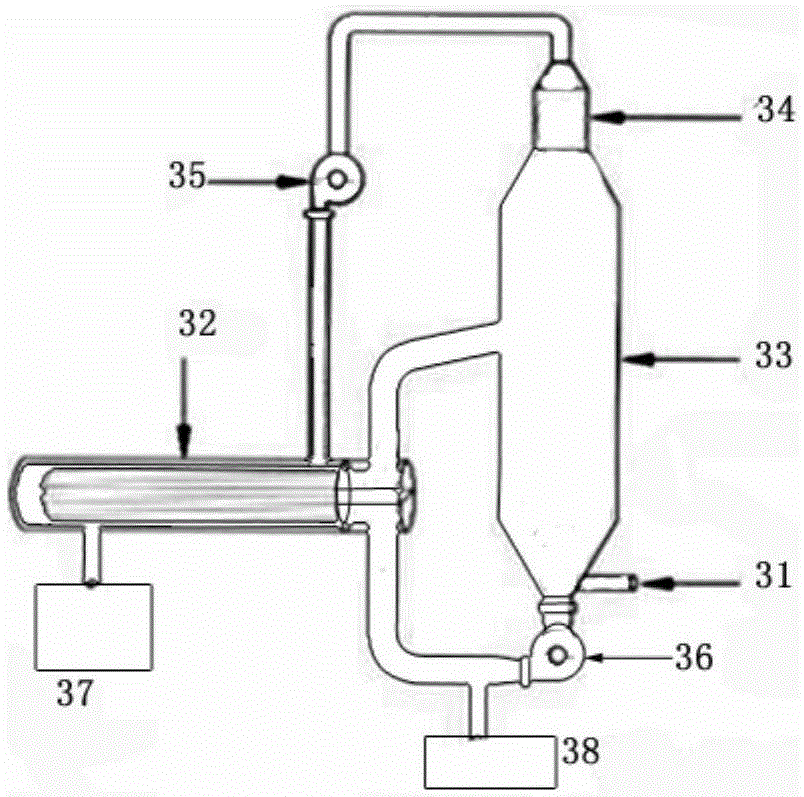

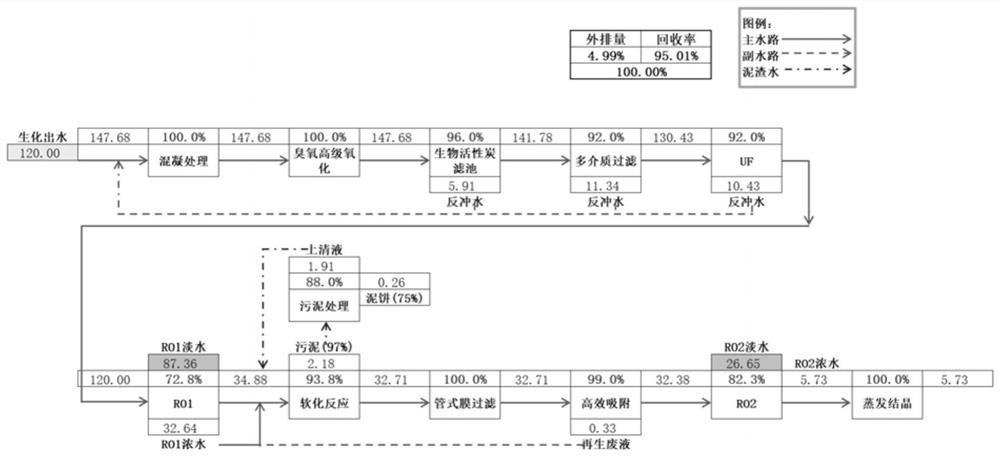

High-salt waste water zero emission and salt separation processing method and device

ActiveCN105254106AShort processReduce doseWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryPre treatment

The invention discloses a high-salt waste water zero emission and salt separation processing method and device. The method includes the following steps of 1, waste water preprocessing, 2, waste water decrement and concentration and 3, crystallization. By means of the high-salt waste water zero emission and salt separation processing method and device, waste water can be processed efficiently, liquid and salt ingredients in the waste water are effectively separated, a product obtained after waste water can be recycled or sold as other industrial products, so that zero emission of waste water is achieved. The method is simple and easy to implement, high in processing efficiency and small in energy consumption; by the adoption of the method, pollution to the environment is avoided, an active function is played on improvement of regional water environment quality, the utilization rate of waste water is raised, production cost is saved, and environmental and social benefits are quite remarkable. The device is high in operation efficiency, convenient to assemble, low in cost and small in energy consumption.

Owner:华电水务工程有限公司 +1

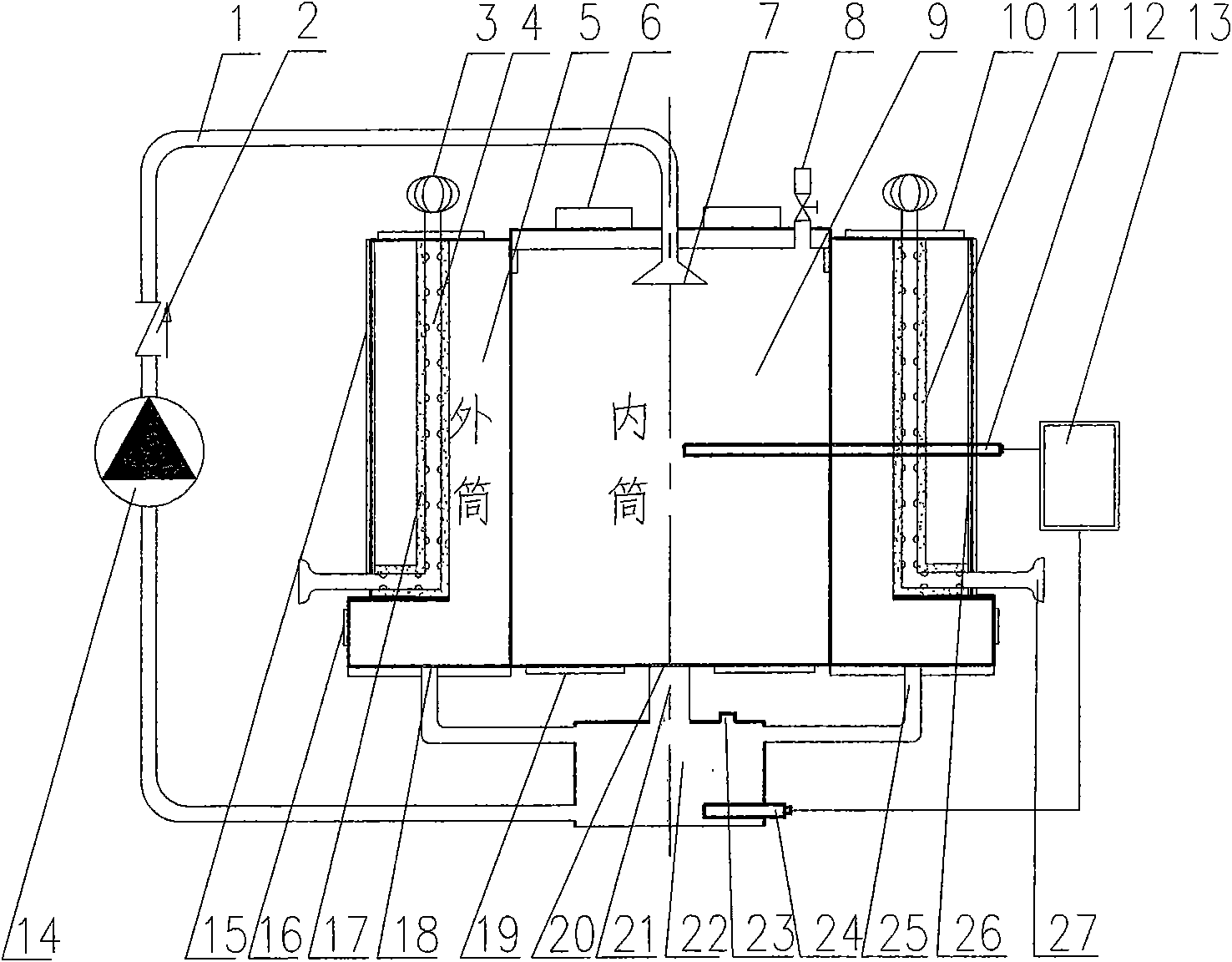

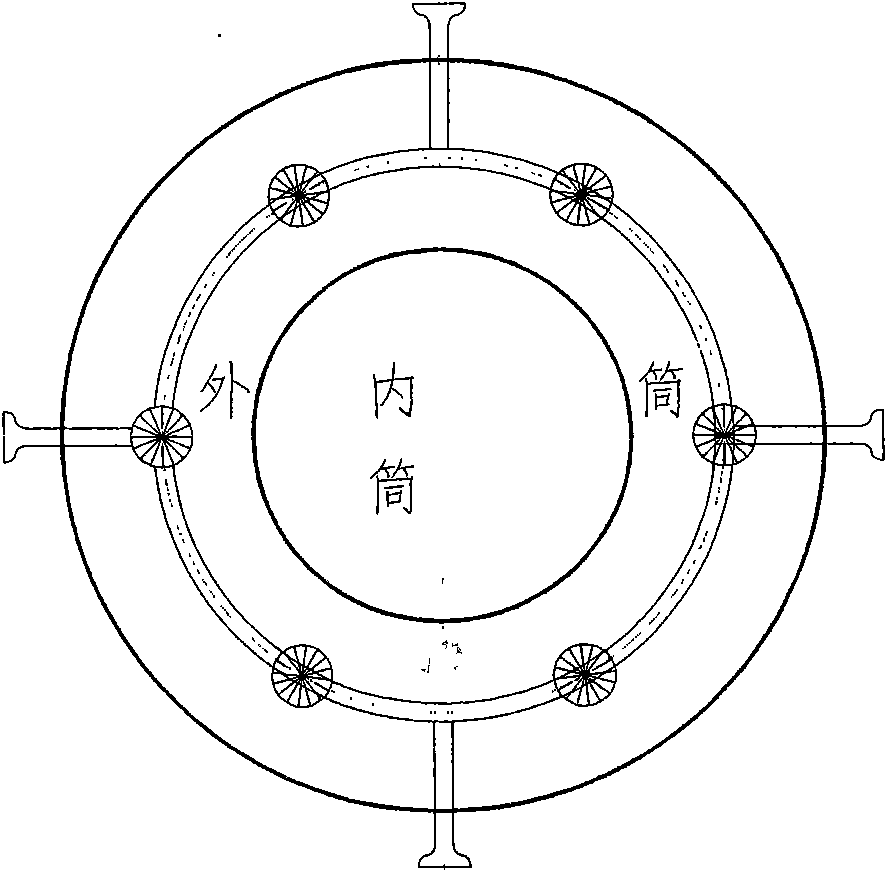

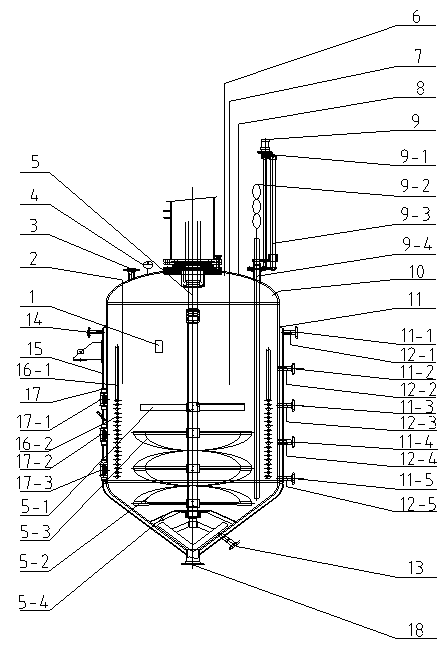

Integrated methane dry fermentation device

InactiveCN101560466AMeet aerobic needsImprove bioprocessabilityBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityTemperature control

The invention relates to an integrated methane dry fermentation device and belongs to the field of energy conservation. The device consists of two parts, namely an anaerobic fermentation tank 9 of an inner cylinder and a stack retting tank 5 of an outer cylinder; and the anaerobic fermentation tank 9 of the inner cylinder is wrapped by the stack retting tank 5 of the outer cylinder, wherein the stack retting tank 5 of the outer cylinder consists of an outer cylinder feed port 10, an outer cylinder discharge port 16, a heat insulating layer 15, a thermal reflecting film 26, an outer cylinder filter screen 18, an outer cylinder fermenting liquid outlet 25, a liquid storage box 22, an air draft cover 27, an air cap 3, an air guide pipeline 4, a gravel stratum 17 and a net 11; and the anaerobic fermentation tank 9 of the inner cylinder consists of an inner cylinder feed port 6, an inner cylinder discharge port 19, an air outlet 8, a temperature sensor 12, an inner cylinder filter screen 20, an inner cylinder fermenting liquid outlet 21, a temperature controller 13, a liquid storage box 22, an electric heater 24, a circulating water pump 14, a liquid storage pipeline 1, a one way valve 2 and a nozzle 7. The device strengthens a ventilation control system, a liquid stream stirring system and a temperature controlling system of the methane dry fermentation device, has the advantages of reasonable structure, high processing efficiency, energy conservation, convenient subsequent processing, no environmental pollution and the like and is in particular suitable for the methane fermentation of a low-temperature region.

Owner:UNIV OF SCI & TECH BEIJING

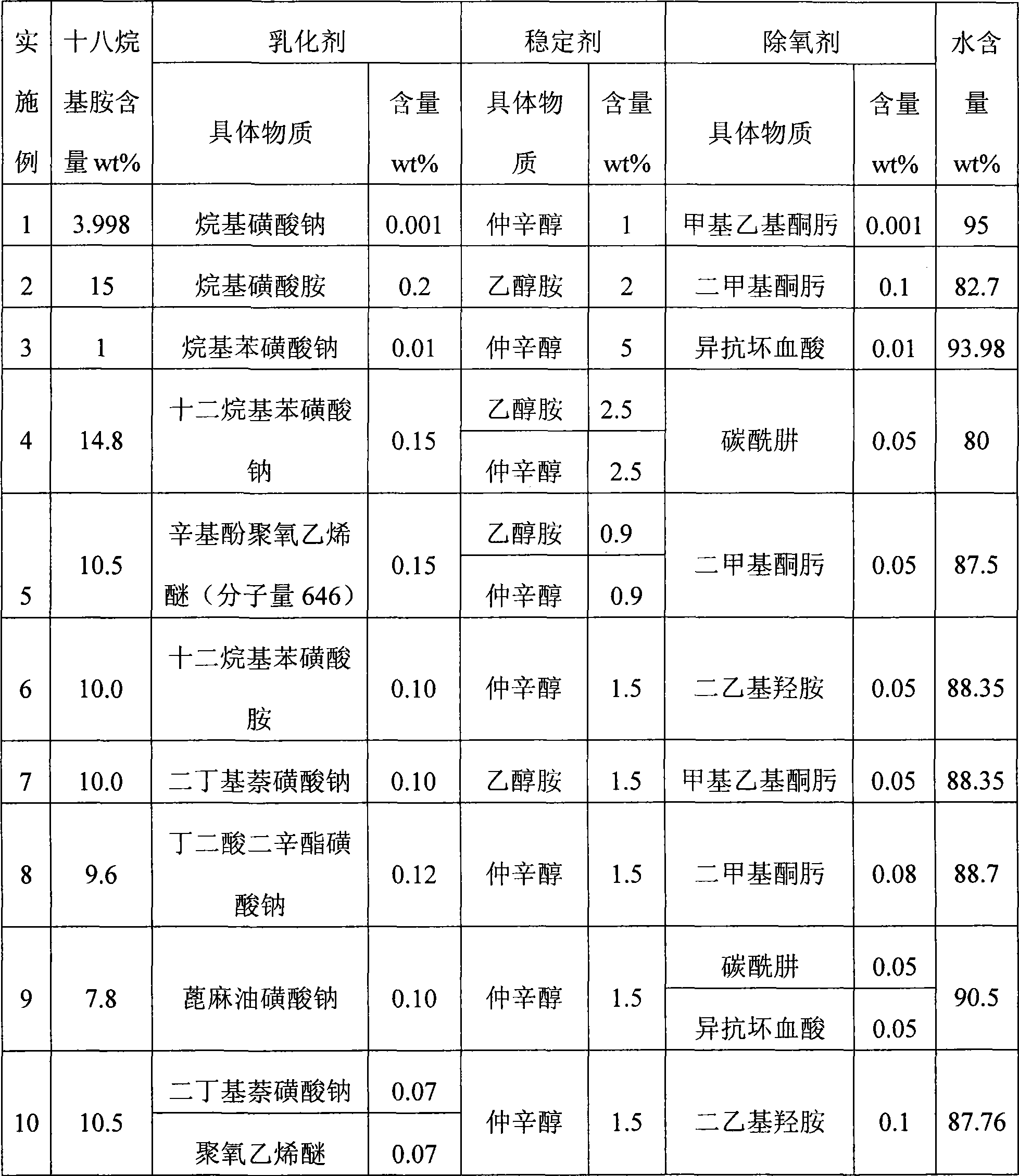

Anti-corrosive protective film agent for marine boiler

ActiveCN101498001AMaintain propertiesSolve the problem of insoluble in waterMarine engineeringAntiseptic

The invention discloses an antiseptic protective film used in a ship boiler, which comprises octadecylamine, emulsifier, stabilizer, deoxidant and water. The antiseptic protective film used in the ship boiler has good antiseptic effect, high stability, long preservation time, safety and environmental protection and can be used in both an operation condition and an idle condition when used in the ship boiler.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

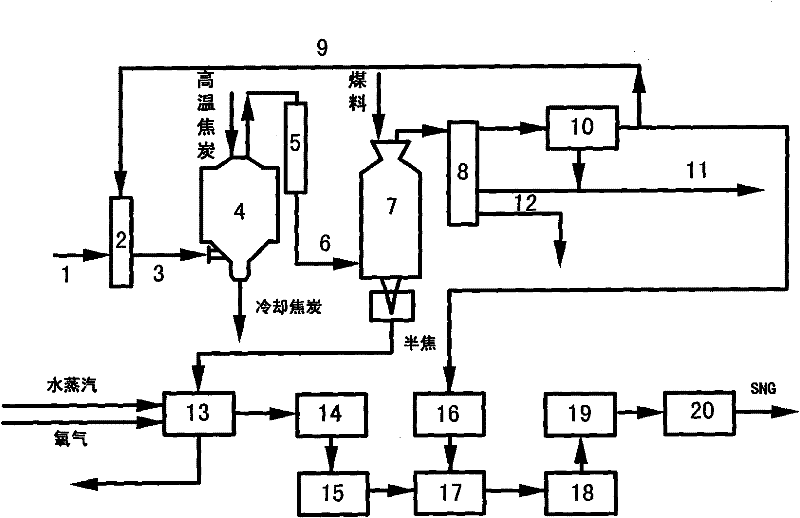

Method for preparing natural gas by dry quenching co-production coal

InactiveCN101747918AAvoid pollutionAchieve emissionsCoke quenchingDirect heating destructive distillationMethanationQuenching

The invention provides a method for preparing natural gas by dry quenching co-production coal. In the method, reducing gas is taken as heat-carrying gas, refrigerant and a pyrolytic process thereof are adopted to recover a great quantity of sensible heat of high-temperature coke so as to couple the dry-method coke quenching process and the coal pyrolytic process of high-temperature metallurgical coke, thus cancelling a gas and air supply system, a combustion control system and a waste gas discharging system in the original pyrolytic process, avoiding pyrolytic combustion process, saving a great quantity of energy, and realizing smoke-free, NOX-free, SOX-free and CO2-free discharging. Meanwhile, gasification gas produced by pyrolytic gas and semi-coke gasification is used for producing andsynthetizing natural gas in a methanation manner so as to realize clean conversion of coal. In addition, the method cancels N2 preparation equipment and waste heat boiler systems in dry quenching, thus simplifying the operation and maintenance process and greatly lowering investment and operation cost.

Owner:山西中元煤洁净技术有限公司

Method for recycling tungsten, vanadium and titanium from SCR waste catalysts

InactiveCN106011503ASequential extractionAchieve mutual separationProcess efficiency improvementTungstateRaffinate

The invention discloses a method for recycling tungsten, vanadium and titanium from SCR waste catalysts. The method comprises the following steps: after the SCR waste catalysts are cleaned, the SCR waste catalysts are smashed and screened, sodium carbonate is doped into the SCR waste catalysts to be evenly stirred, mixed powder is sintered at a high temperature to obtain a sintered material, water is added for leaching out, and a sodium salt mixed solution containing tungsten and vanadium is obtained; under the condition that the pH value of the solution is large than 12, tungsten is selectively extracted, and an ammonium salt solution is used for reverse extraction to obtain an ammonium tungstate solution; under the condition that the pH value of raffinate obtained after tungsten extraction ranges from 10 to 11.5, vanadium is extracted, and a sodium hydroxide solution is used for reverse extraction to obtain a sodium vanadate solution containing a small amount of tungsten; and titanium is left in leaching residues to obtain a rich-titanium material. According to the method, separation of tungsten and vanadium from impurities such as phosphorus, arsenic and silicon is achieved, and primary separation and efficient enrichment of tungsten, vanadium and titanium are achieved.

Owner:无锡市华东电力设备有限公司

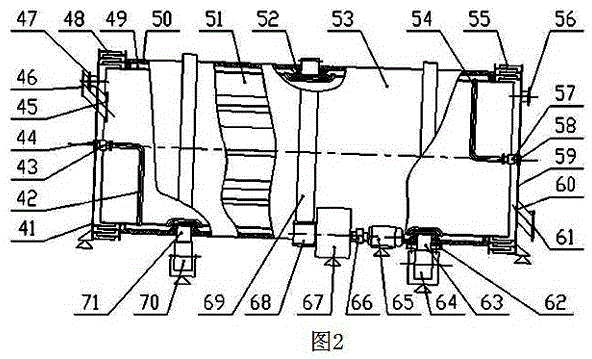

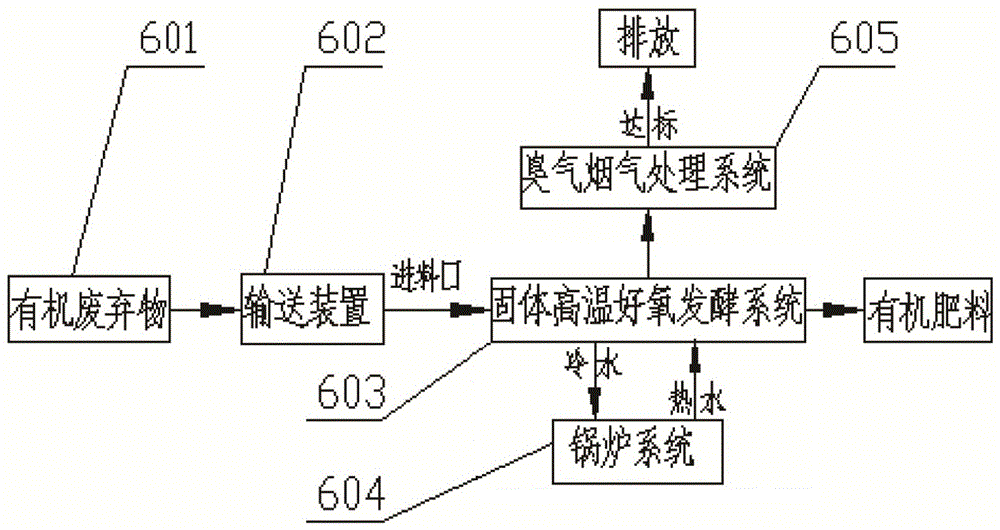

Solid high-temperature aerobic fermentation reaction system and method

ActiveCN106119105AAvoid stickingEasy to use and maintainBioreactor/fermenter combinationsBio-organic fraction processingEnvironmental resistanceSmall footprint

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

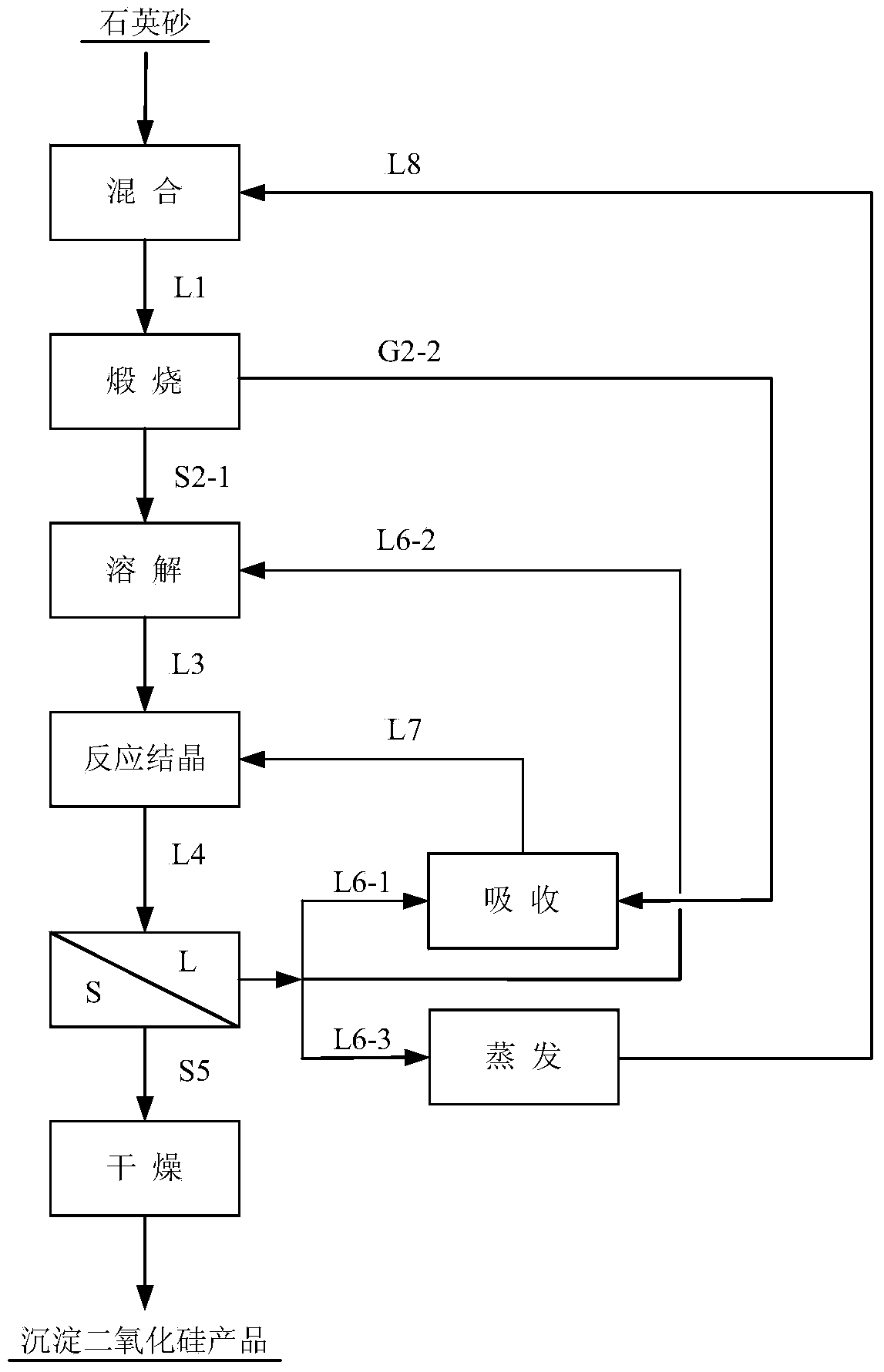

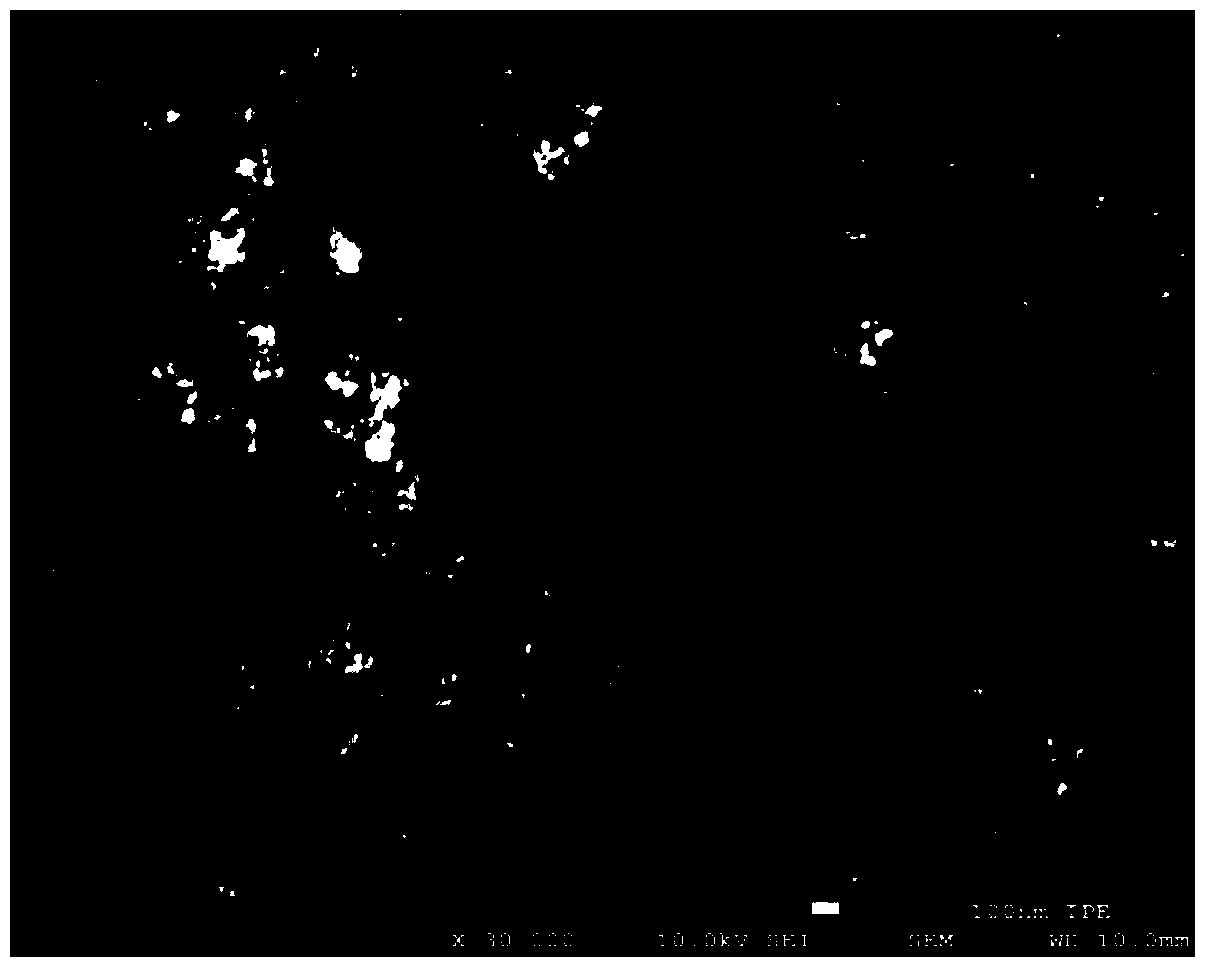

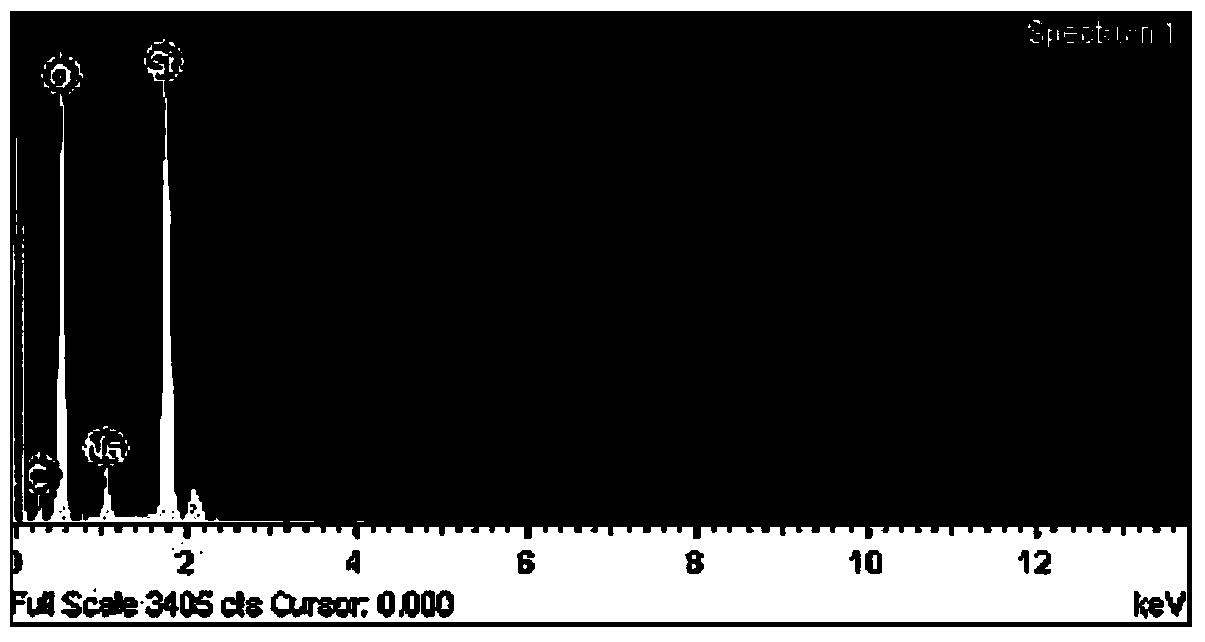

Method for producing precipitate silicon dioxide by using sodium bicarbonate to control supersaturation degree

InactiveCN103466637AEasy to operateImprove controllabilitySilicon oxidesSodium bicarbonateEvaporation

A method for producing precipitate silicon dioxide by using sodium bicarbonate to control a supersaturation degree comprises the steps of taking quartz sand and soda as raw materials, roasting, dissolving a sodium carbonate solution to prepare a sodium silicate solution, allowing the sodium silicate solution to react with a sodium bicarbonate solution, separating out a hydrated silicon dioxide precipitate by a method for controlling the reaction crystallization supersaturation degree, washing and drying the filtered precipitate, and finally obtaining precipitate silicon dioxide, namely white carbon black. Filtered filtrate is the sodium carbonate solution which is recycled for absorbing carbon dioxide from a roasting working section to prepare a concentrated sodium bicarbonate solution required for crystallization reaction, dissolving solid sodium silicate, and returning to the quartz sand roasting working section after evaporation and concentration. Precipitate silicon dioxide prepared by the method is high in purity and uniform in particle size distribution; materials are recycled during the whole production flow; and the problem of sodium sulfate sewage discharge in conventional production is solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

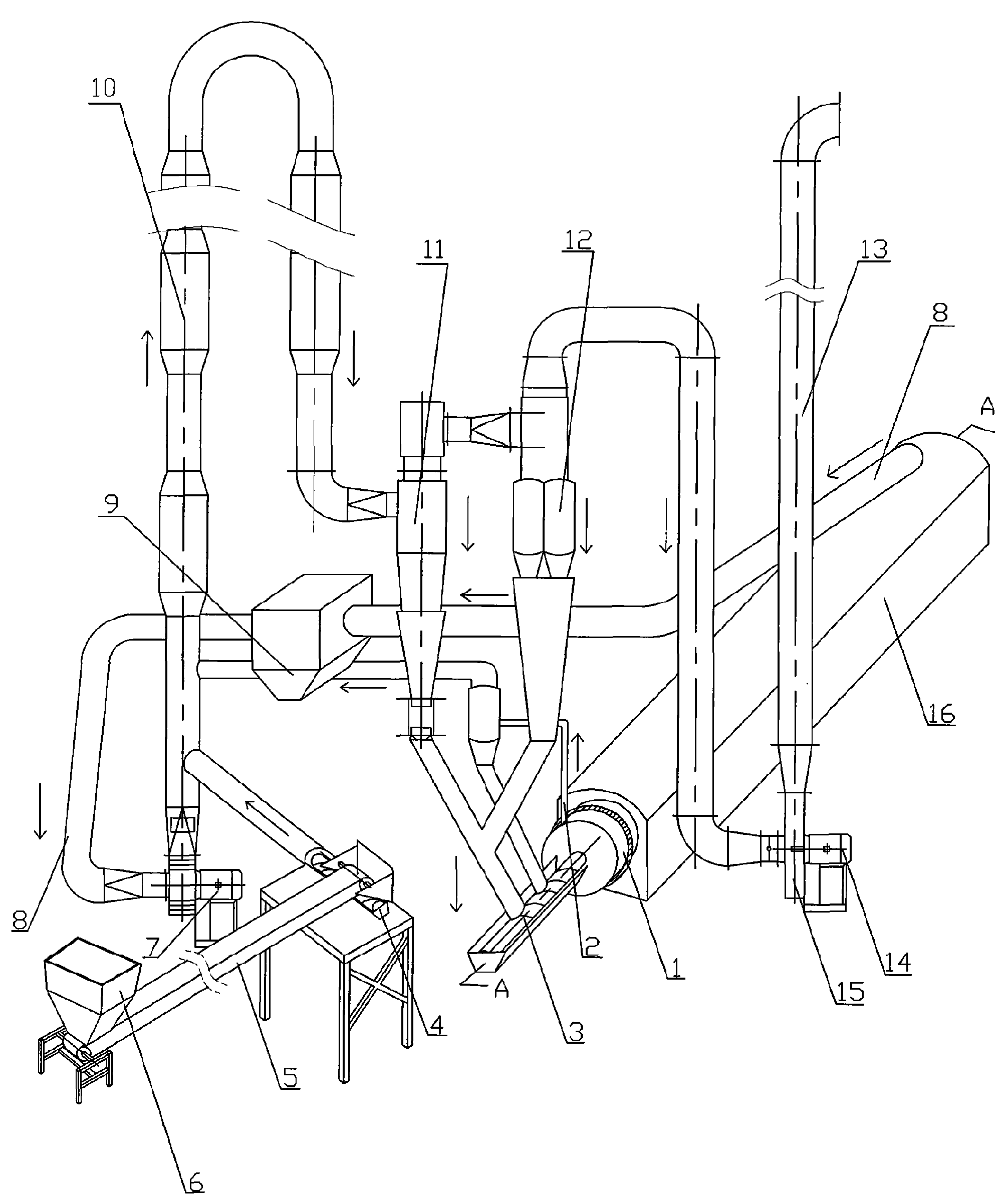

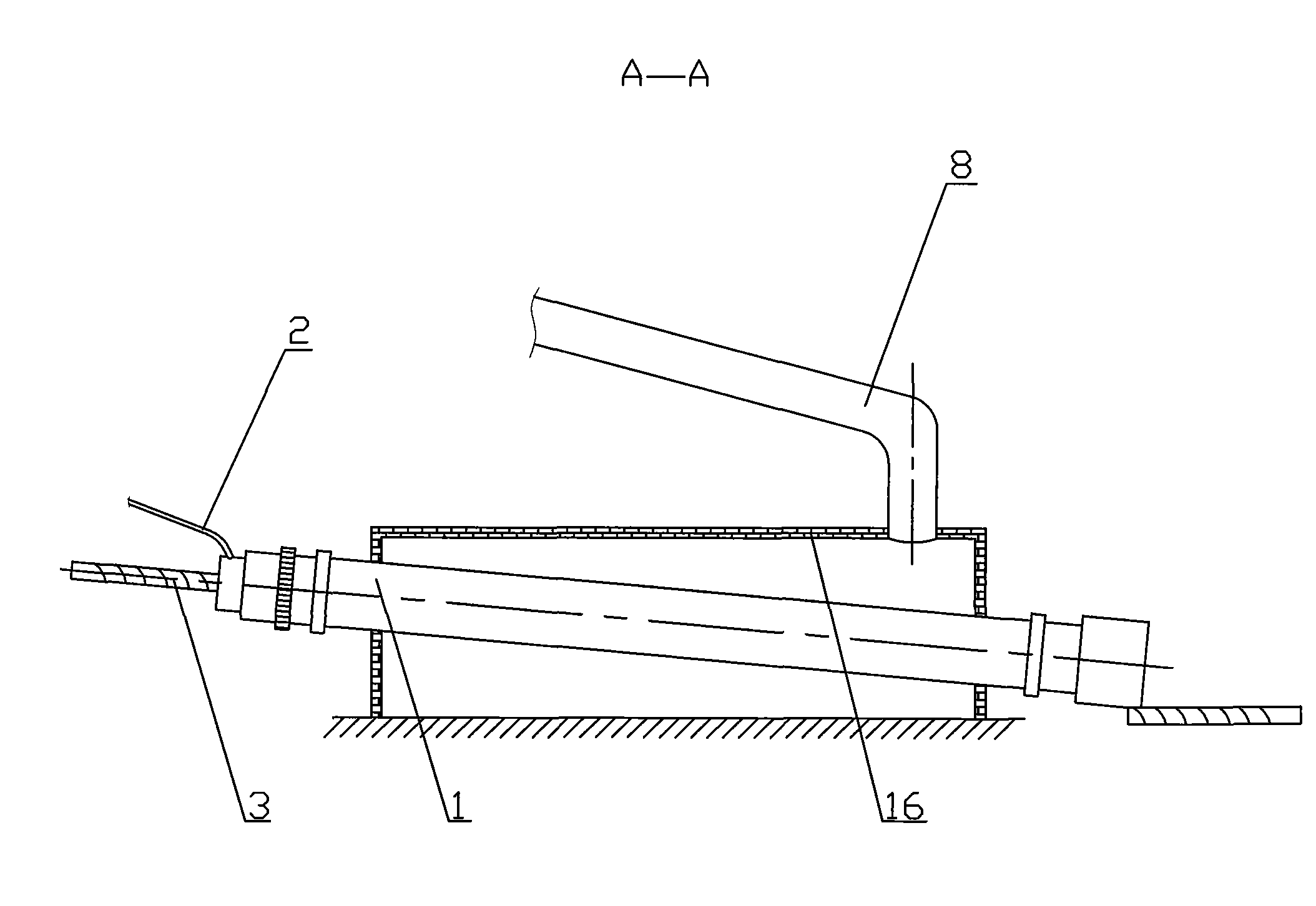

Energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas

The present invention relates to an energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas, including a circumversion frying pan (1) and a hearth box (16), wherein the circumversion frying pan is provided with a packing auger feeder (3), characterized in that a tail gas collecting tube (8) is connected with one end of a impulse drying tube (10), the other end of the impulse drying tube (10) is connected with a cyclonic collector (11), a feed end of the cyclonic collector (11) is connected with the packing auger feeder (3), and an exhaust end of the cyclonic collector (11) is connected with a draught fan (14). The beneficial effect of the apparatus is that the gypsum raw material is dried by using the high-temperature tail gas and aqueous vapour generated by the circumversion frying pan. The gas drying contact area is large, and the thermal efficiency is high. The tail gas contains microparticle flue dust which may play a function of the activated carbon to remove yellow, so that the white content of the gypsum powder is improved. The tail gas and the aqueous vapour is purified by a dedusting environment protection apparatus, thus the pollutant will be not discharged outside, and the environment protection effect is good.

Owner:蚌埠百佳新型建材有限公司

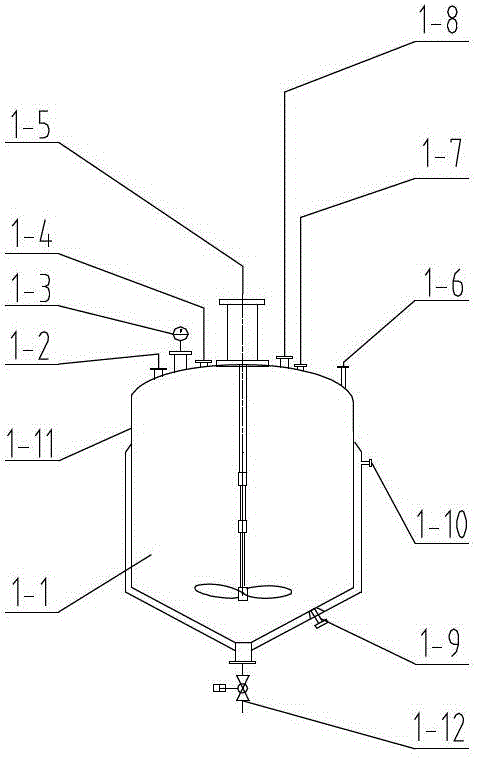

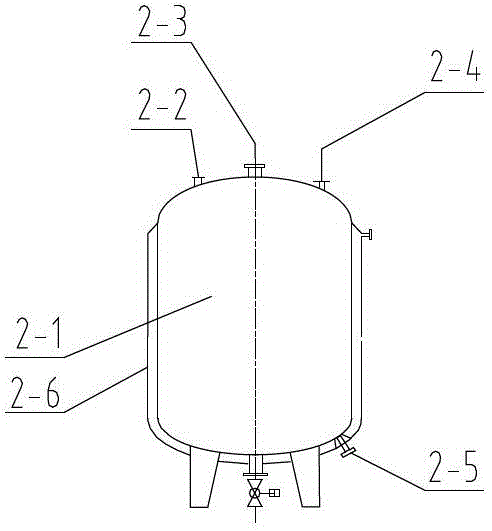

Extraction kettle apparatus for separating coal tar through mild extraction method

InactiveCN103275743AHigh recovery rateEmission reductionTar working-up by solvent extractionInsulation layerAgitator

The invention relates to an extraction kettle apparatus for separating coal tar, and concretely relates to an extraction kettle apparatus for separating coal tar through a mild extraction method. A strong magnetic stirrer is arranged in the center of a top cover, and a temperature measuring port, a pressure measuring port, a material inlet, an extractant inlet, a nitrogen inlet, a nitrogen outlet, a diffusing port, and valves connected with relevant tube ports are uniformly arranged in the circumference of the top cover respectively; an electric lift type lift tube lightweight component discharging system is arranged at the upper right side of the top cover; two hot steam heating coilers and corresponding hot steam inlets are arranged at the center outside a kettle; the material outlets of downward spreading valves are arranged at the outside surface portion of the kettle, and the downward spreading valves are respectively connected with a glass sight cup; three groups of sight glasses are arranged at the center outside the kettle; an interlayer heat insulation layer is arranged at the center outside the kettle; and a steam outlet, a material outlet and a valve are arranged at the bottom of the kettle. The apparatus has the advantages of simple operation, obvious energy saving and consumption reduction, high solvent recovery rate, easy automatic operation, low-carbon clean production, low investment cost, and less discharge of waste residues, the exhaust gas and wastewater.

Owner:ZAOZHUANG MINING GRP CO LTD +1

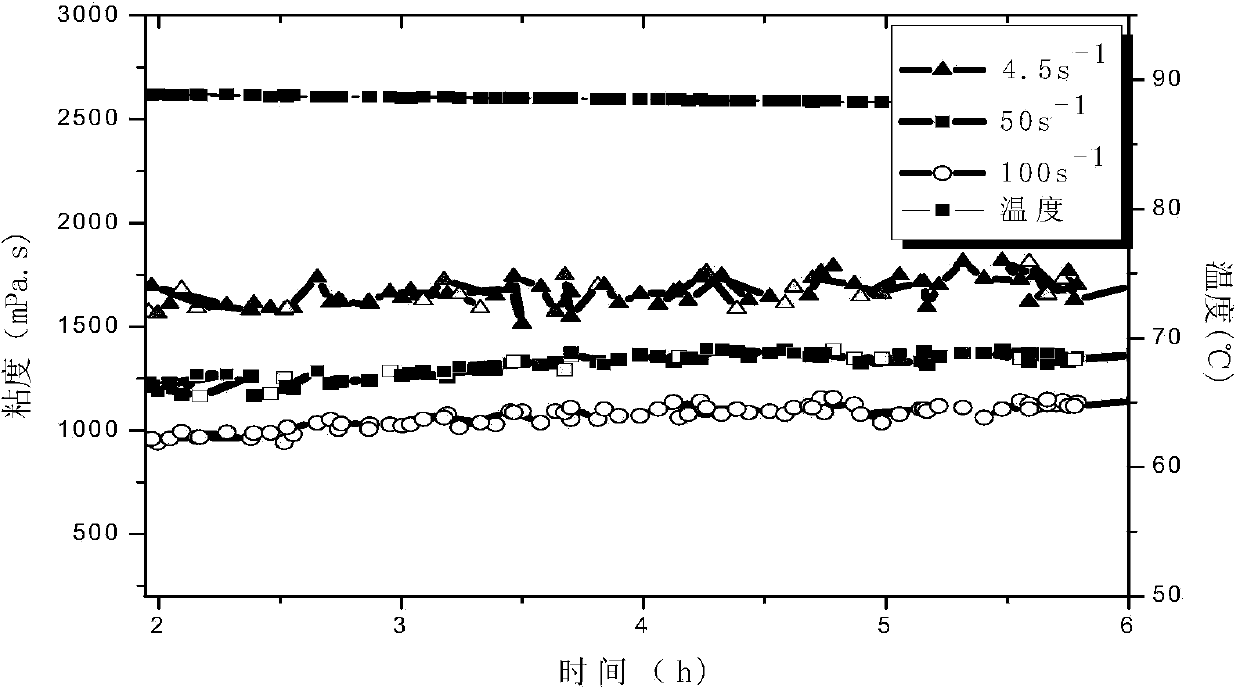

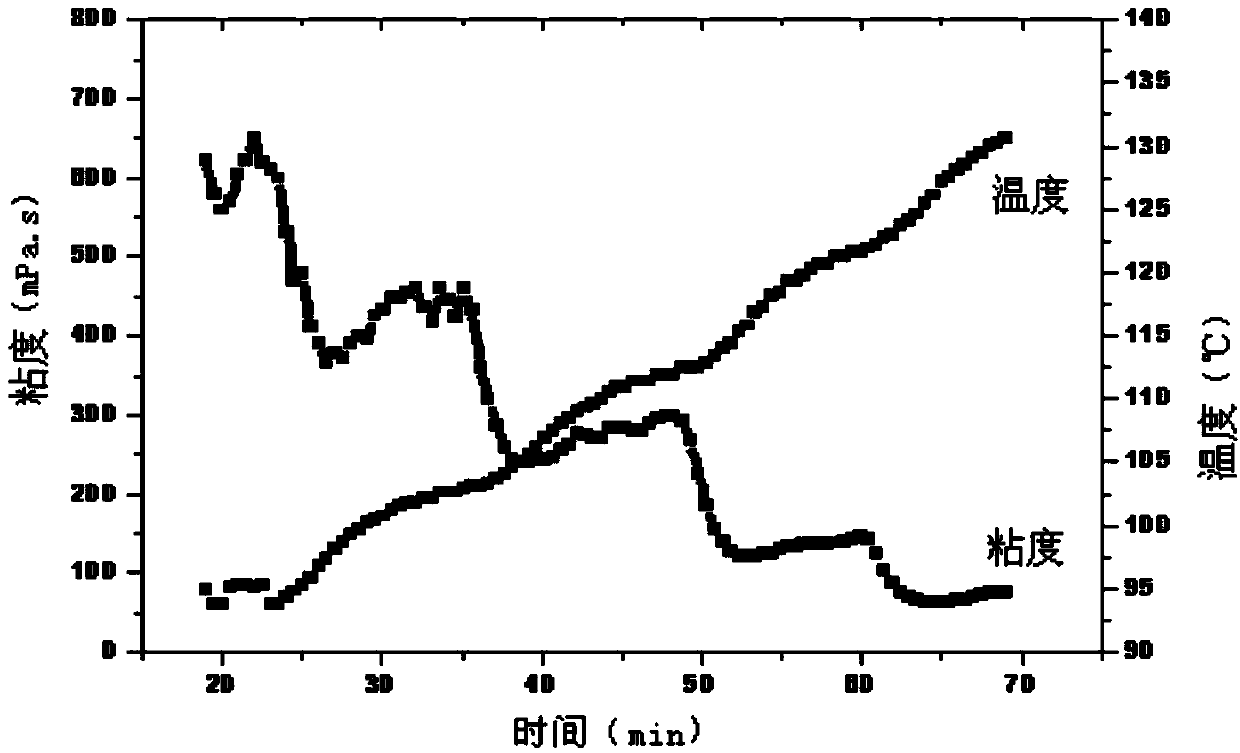

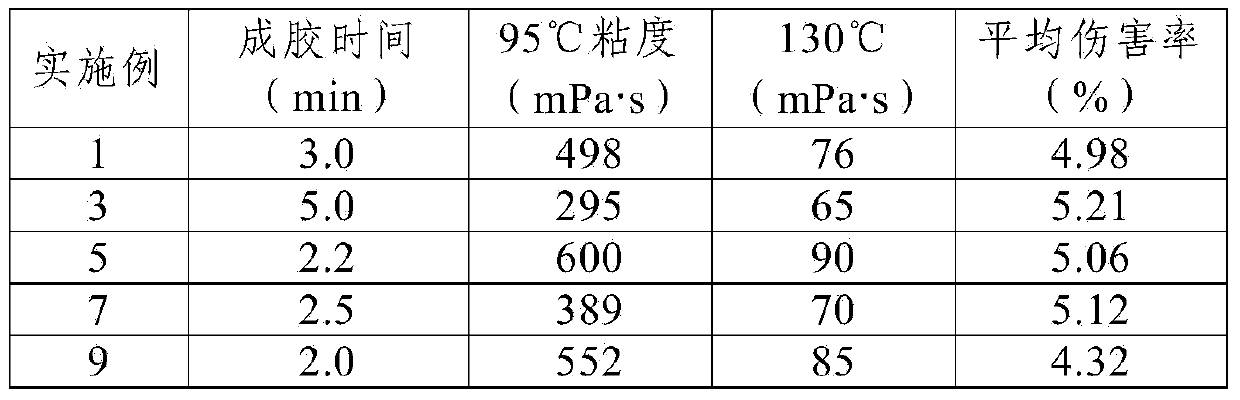

Anhydrous fracturing fluid suitable for unconventional reservoir fracturing and preparing method of anhydrous fracturing fluid

InactiveCN104004506ASimple manufacturing processFast gelationDrilling compositionPhosphateAlkylphosphate

The invention discloses anhydrous fracturing fluid suitable for unconventional reservoir fracturing. The anhydrous fracturing fluid comprises, by mass, 1.0-2.0% of gelling agent, 2.0-4.0% of micelle accelerant, 0.1-0.5% of temperature stabilization agent and the balance alkyl hydrocarbon. The temperature stabilization agent is sulfamic acid or dodecylbenzene sulfonic acid, the alkyl hydrocarbon is one kind or more kinds of propane, butane and pentane, the gelling agent is dialkyl group phosphate ester iron, and the micelle accelerant is an organic complex containing trivalent metal ions. The invention further discloses a preparing method of the anhydrous fracturing fluid. The gelling agent is liquid at the normal temperature and is good in liquidity, the fracturing fluid is simple in preparing technology, the glue forming speed is controllable, the fracturing transformation of shale beds below 130 DEG C can be met, a gel breaker is not needed, the fracturing fluid is gasified under the formation temperature and the pressure and can be recycled after begin discharged out of the ground through a well pipe, external discharge and pollution of waste liquid are avoided, and the anhydrous fracturing fluid has the advantages of being environmentally friendly and the like.

Owner:XI'AN PETROLEUM UNIVERSITY +1

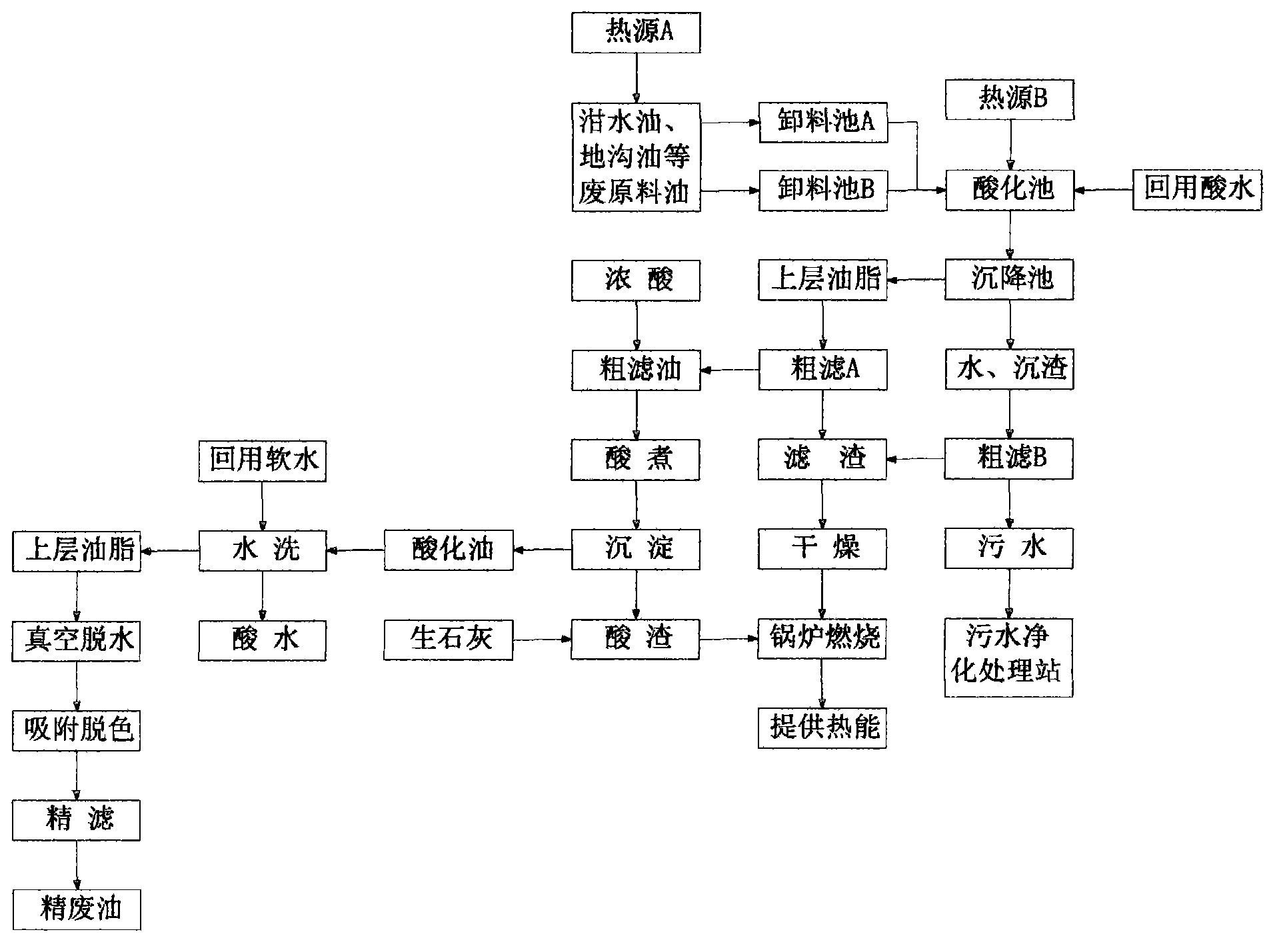

Pre-treatment method used for preparing biodiesel from swill oil and trench oil

InactiveCN103571630AUniform qualityReduce wasteFatty acid chemical modificationFatty acids production/refiningWater contentChemistry

The invention discloses a pre-treatment method used for preparing biodiesel from swill oil and trench oil. The pre-treatment method comprises following steps: step 1, swill oil and trench oil are chosen as waste raw oil, and are delivered into a discharging pond; step 2, an acid solution is added, and the mixed solution is heated and mixed so as to realize complete acidification of the waste raw oil; step 3, after acidification, the mixed solution is allowed to stand so as to realize liquid separation, and an upper oil layer, a middle waste water layer and a lower residue layer are obtained; step 4, the upper oil layer is collected, and is filtered so as to remove slag; step 5, after filtration , a concentrated acid is added into the filtered oil layer, and the mixture is boiled by heating so as to realize carbonization polymerization and precipitation separation of a large amount of impurities, and obtained acidized oil; and step 6, the acidized oil is subjected to water washing, dehydrating and decolouring so as to obtain refined waste oil. Beneficial effects of the pre-treatment method are that: the pre-treatment method is capable of preparing refined waste oil, which is low in water content and impurity content, is uniform in quality, and is suitable for application in stable biodiesel production lines, from waste cooking oil with complex composition and nonuniform quality.

Owner:SHAANXI DERONG NEW ENERGY

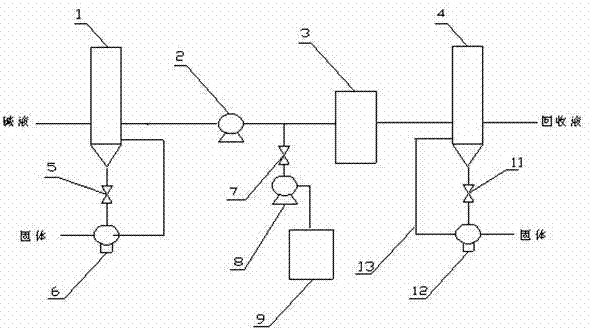

Process and system for recycling and decoloring denim mercerizing alkali and penetrant

ActiveCN103498312AOxidizingFunctionalTextile treatment machine arrangementsMultistage water/sewage treatmentDenimProcess engineering

The invention discloses a process and system for recycling and decoloring denim mercerizing alkali and penetrant. The process includes the steps that denim mercerizing alkali liquor is placed in a first precipitation tank; the liquor on the upper portion enters a conveying pipeline through a flow pump after precipitation, meanwhile, a metering pump pumps a decolorising agent into the liquor in the conveying pipeline, and then the decolorising agent and the liquor are conveyed to an evaporation concentrator together; the decolorising agent and the liquor enter a second precipitation tank after being evaporated and concentrated; supernatant liquor obtained after precipitation is conveyed to a production line directly; solid substances in precipitation liquor on the lower portion are separated and conveyed to a waste solid storage tank after the precipitation liquor on the lower portion is treated through a centrifugal machine, and clear liquor returns the first precipitation tank and is conveyed backed to the production line. The system comprises the first precipitation tank, the flow pump, the metering pump, a decolorising agent box, the evaporation concentrator and the second precipitation tank. The first precipitation tank, the flow pump, the evaporation concentrator and the second precipitation tank are connected directly through pipelines, and the decolorising agent box is connected to the metering pump below the pipeline where the flow pump and the evaporation concentrator are connected. The process for recycling and decoloring the denim mercerizing alkali and penetrant is simple, the useful alkali and penetrant are recycled, and production cost is greatly reduced.

Owner:SHENZHEN YUEPENG ENVIRONMENTAL PROTECTION TECH

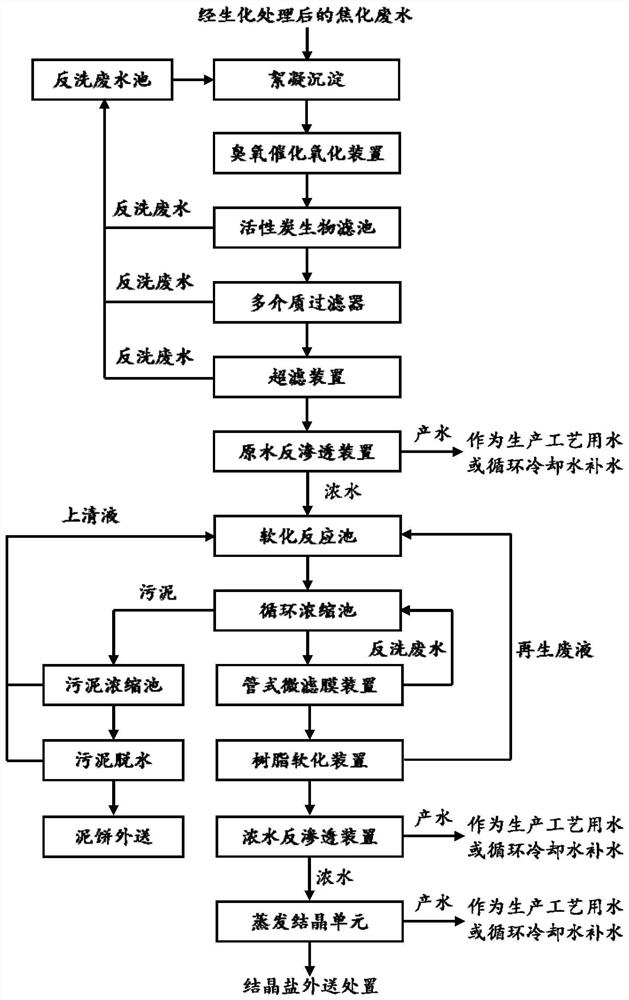

Coking wastewater advanced treatment and evaporative crystallization zero discharge process

PendingCN112919734AReduce the risk of organic contaminationPrevent scalingScale removal and water softeningTreatment involving filtrationChemistryUltrafiltration

The invention provides a coking wastewater advanced treatment and evaporative crystallization zero discharge process which comprises the following steps: A) sequentially performing flocculation treatment, catalytic ozonation treatment, biological activated carbon filter treatment, multi-medium filtration, ultrafiltration treatment and first reverse osmosis concentration treatment on coking wastewater subjected to biochemical treatment, so as to obtain first treated water and first concentrated water; (B) sequentially subjecting the first concentrated water to two-stage softening treatment and second reverse osmosis concentration treatment to obtain second treated water and second concentrated water, wherein the first-stage softening adopts chemical softening and microfiltration combined filtration treatment, the second-stage softening adopts resin softening; and C) carrying out evaporative crystallization on the second concentrated water to obtain third treated water and crystal salt. The process is reasonable in linkage, stable, efficient and safe to operate and good in treatment effect, the treated water can be used as production process water or circulating cooling water replenishing water, finally zero emission of the coking wastewater is achieved, and economic benefits are remarkable.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

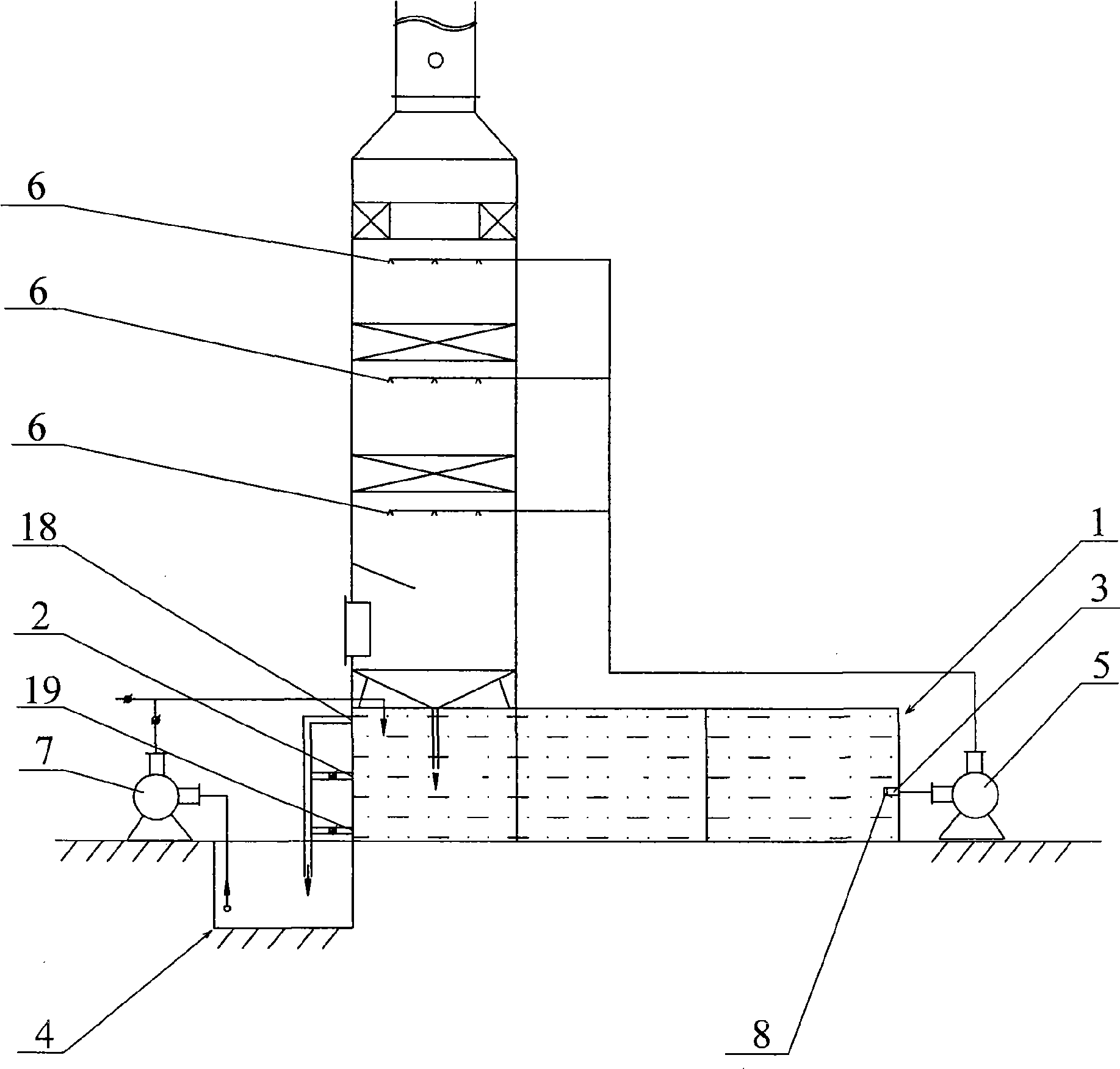

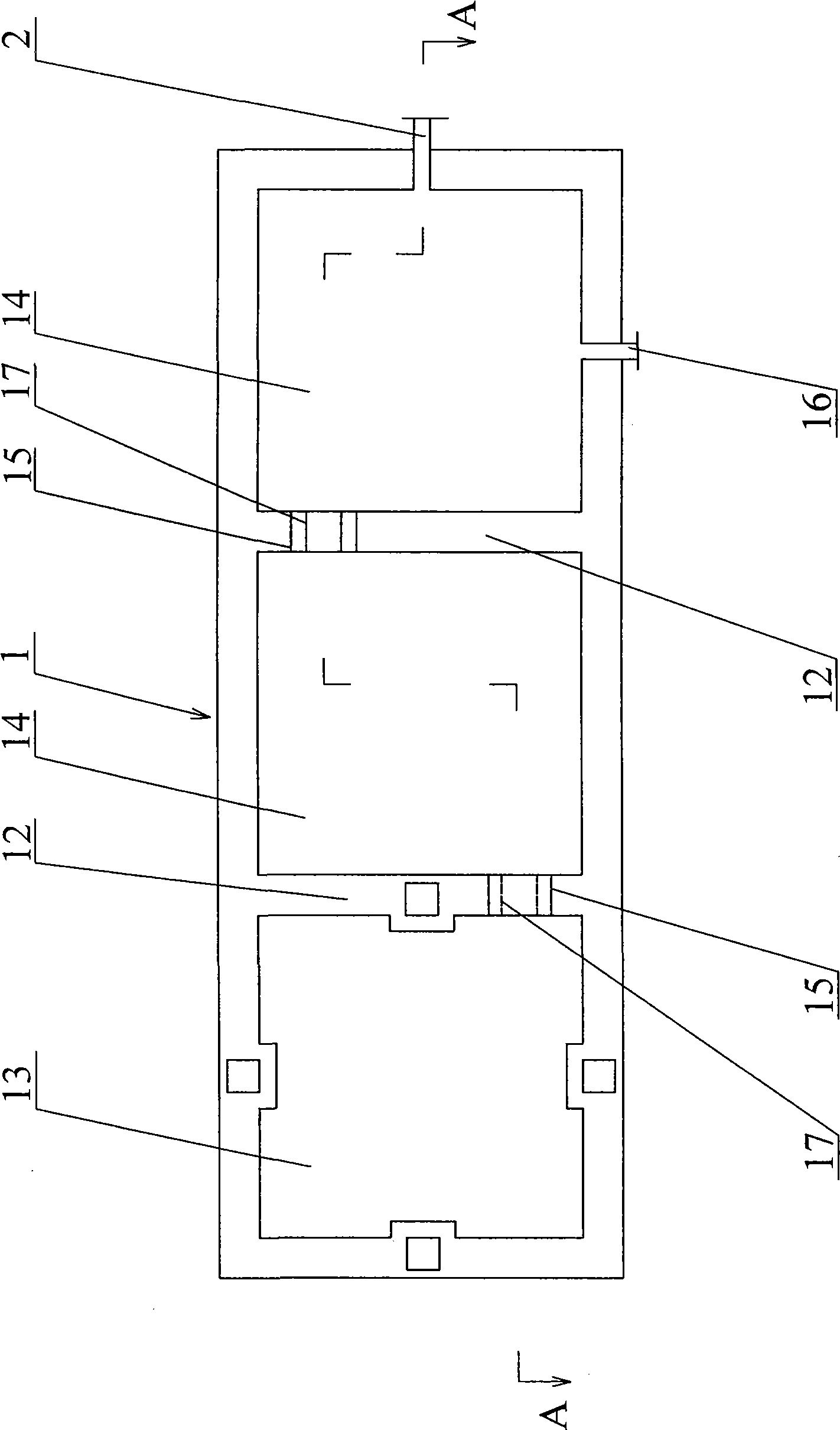

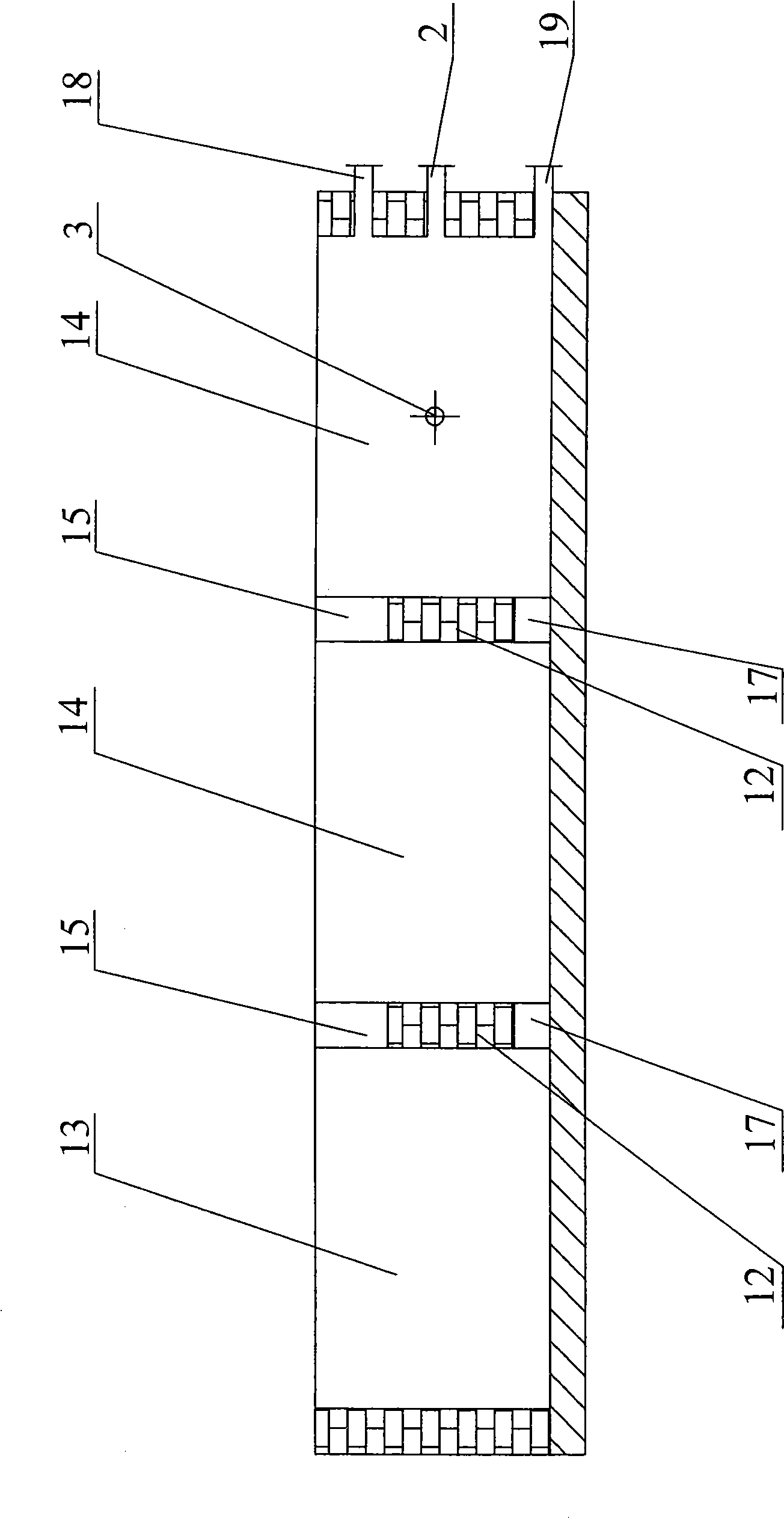

Non-secondary pollution water circulating system for spraying dust removing

InactiveCN101486505ANo secondary pollutionSave waterUsing liquid separation agentWater/sewage treatment by flocculation/precipitationWater reservoirEngineering

The invention relates to a water cycling system, in particular to a secondary pollution-free water cycling system used for spraying and de-dusting. According to the technical proposal provided by the invention, the secondary pollution-free water cycling system used for spraying and de-dusting comprises a water outlet hole and a pump suction inlet arranged on the main body of a sedimentation tank; water is supplied through pipelines from the water outlet hole to a hardening and tempering water reservoir; the pump suction inlet is connected with the water inlet end of a spraying pump by pipelines; the water outlet end of the spraying pump is connected with a plurality of spraying heads by pipelines; a cycling pump is arranged between the main body of the sedimentation tank and the hardening and tempering water reservoir; and the water inlet end of the cycling pump is positioned in the hardening and tempering water reservoir, and the water outlet end of the cycling pump supplies water for the main body of the sedimentation tank through pipelines. When in use, the water cycling system has the advantages of no exclusion and no secondary pollution and can effectively save water resources and the like.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

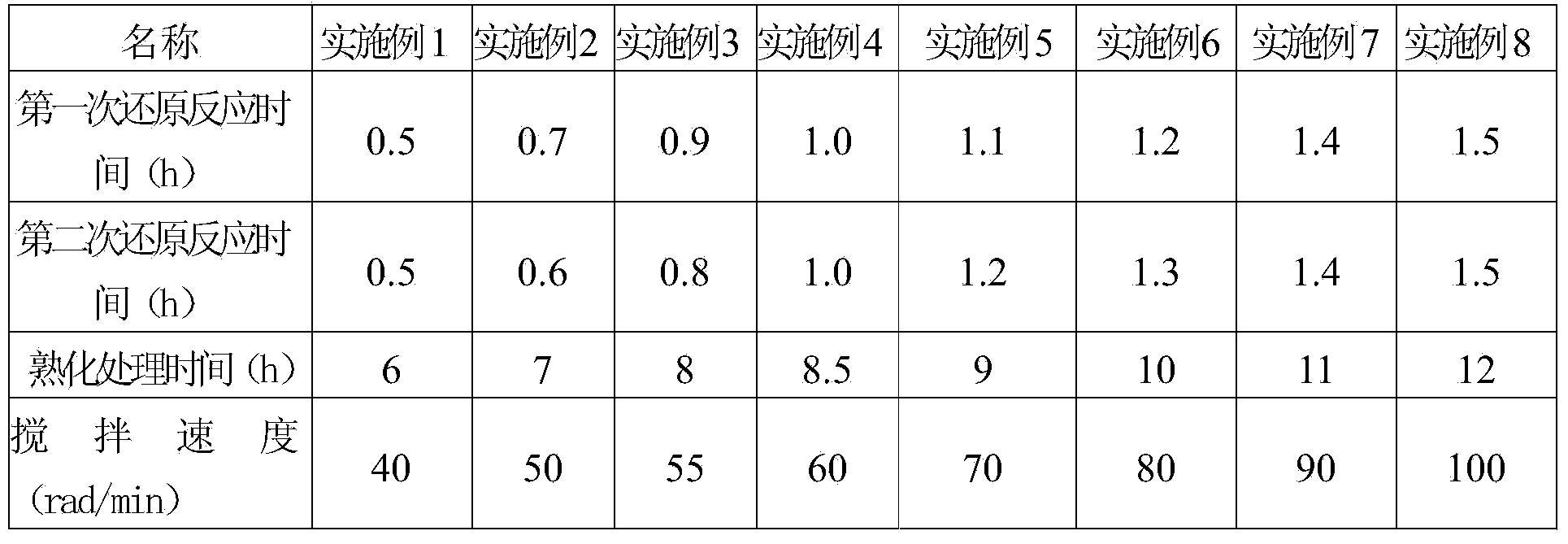

Wet detoxification method for chromium slag and chromium-containing pollutants

ActiveCN103934256AShorten the timeImprove ball milling efficiencySolid waste disposalSulfate radicalsChromium(III) hydroxide

The invention relates to a wet detoxification method for chromium slag and chromium-containing pollutants. The wet detoxification method comprises the following steps: screening and crushing the chromium slag and the chromium-containing pollutants, performing wet milling on the chromium slag and the chromium-containing pollutants in a ball mill, adding a filtrate containing sulfate ions, leaching out acid-soluble calcium chromate in chromium slag slurry, adding the chromium slag slurry and a first reducing agent sequentially into a reaction tank, stirring and mixing the chromium slag slurry with the first reducing agent to perform reduction reaction, reducing the acid-soluble calcium chromate in chromium slag slurry to trivalent chromium, adding concentrated sulfuric acid and to stirring and mixing for regulating, adjusting pH value of the chromium slag slurry to be 7+ / -0.5, then adding a second reducing agent into the reaction tank and stirring and mixing for reducing, stirring the reduced slag slurry to cure the reduced slag slurry, and converting hexavalent chromium in the chromium slag slurry to chromic hydroxide sediment; and separating solid and liquid of the cured chromium slag slurry. The wet detoxification method has the characteristics of low cost, no waste liquid, no slag returning phenomenon, good detoxification effect and capability of being applicable to the large-scale industrial production.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

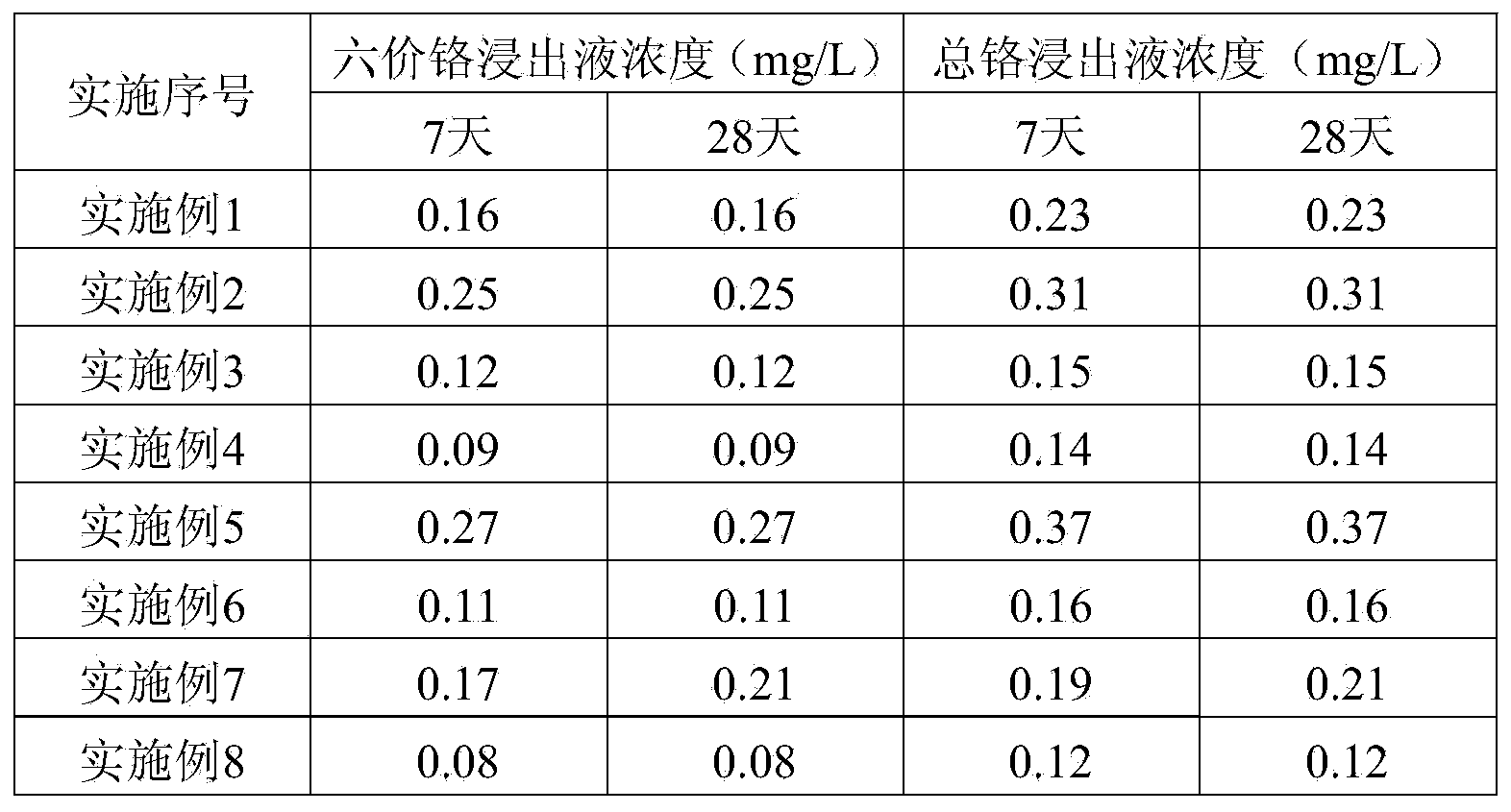

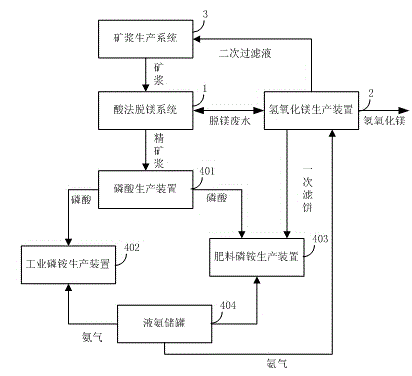

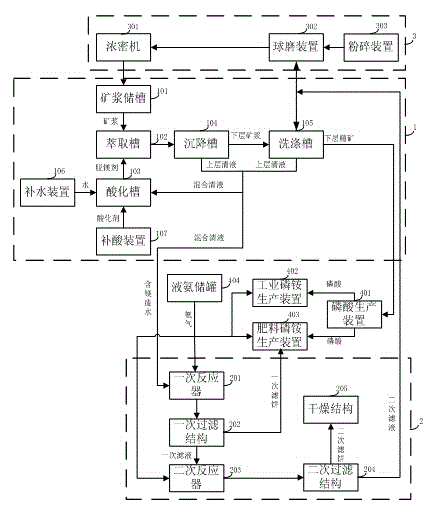

Phosphorite comprehensive utilization method

InactiveCN105110308AAchieving Theoretical UtilizationEasy to processCalcium/strontium/barium sulfatesPhosphorus compoundsMagnesium phosphatePhosphate product

The invention discloses a phosphorite comprehensive utilization method. The method is characterized by comprising the following steps: a. decomposing phosphorite by using acid; b. purifying an acidolysis solution; c. using raw materials containing ammonia compounds to gradually adjust the pH value of the acidolysis solution, and separating produced phosphate precipitate. d. storing the acidolysis solution containing water-soluble calcium; and e. adding a precipitating agent that generates calcium compound to the acidolysis solution containing water-soluble calcium so as to generate calcium compound precipitation. According to the phosphorite comprehensive utilization method disclosed by the invention, phosphorite can be completely, efficiently and comprehensively utilized, and the method is especially applicable to low grade phosphate and magnesium phosphate; acidolysis can be performed on the phosphorite to turn the phosphorite into phosphate, potassium dihydrogen phosphate, potassium nitrate, ammonium dihydrogen phosphate, feed-grade DCP, calcium dihydrogen phosphate fertilizers, high purity calcium carbonate, industrial calcium chloride, high purity calcium sulfate whisker. The process is simple and high in efficiency; phosphate products and calcium products are excellent in quality, and are free of waste water, exhaust gas and waste residue discharge, and the method can be completely compatible with current phosphorus product technology.

Owner:武善东 +1

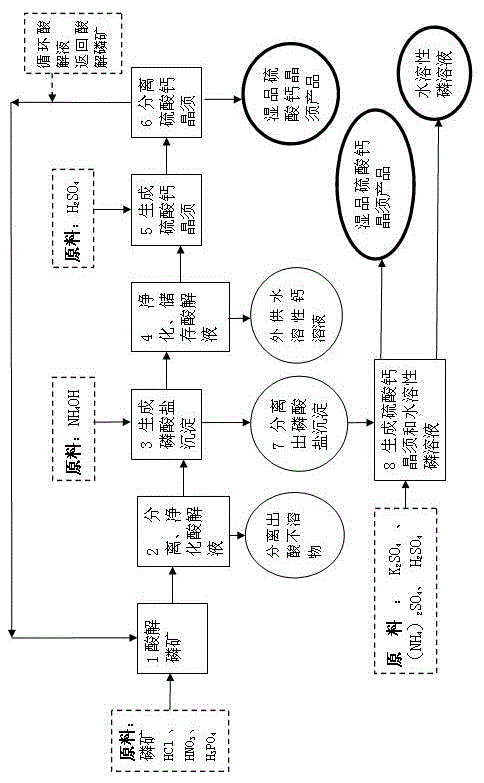

Harmless treatment method of waste triethyl aluminum

InactiveCN102961844AEliminate potential safety hazardsEasy to handleHydrocarbonsAluminium oxides/hydroxidesAluminium hydroxideEconomic benefits

The invention provides a harmless treatment method of waste triethyl aluminum, which is characterized by comprising the following steps of: absorbing waste triethyl aluminum with white oil; adding the white oil containing triethyl aluminum into clean water, and stirring to sufficiently dissolve the white oil in water; collecting aluminum hydroxide waste residues and ethane waste gas generated in the hydrolysis process; collecting the ethane waste gas with a gas cabinet and recycling as fuel gas; and recycling the aluminum hydroxide waste residues. The method provided by the invention directly solves the problem of potential safety hazards of the chemical enterprise in the process of producing waste triethyl aluminum, and indirectly creates environmental and economic benefits. Through the method provided by the invention, the equipment is simple, the operation is easy, and the safety is high.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

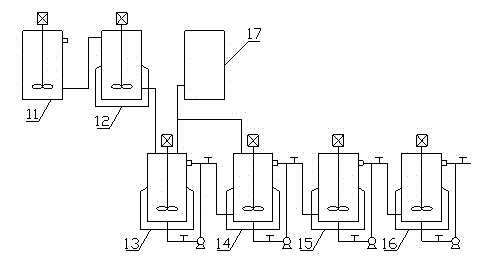

Co-production method and system of ammonium phosphate and magnesium hydrate

ActiveCN104445120AReduce lossesReduce supplementationPhosphatesMagnesium hydroxideReaction temperaturePhosphoric acid

The invention discloses a co-production method and system of ammonium phosphate and magnesium hydrate, belonging to the technical field of fertilizer production. The method comprises the following steps: raising the temperature of phosphoric ore pulp containing magnesium to 40-60 DEG C, adding a de-magging agent, reacting for 2-3 hours, controlling the pH value of slurry at the finished point at 4.5-5.0, and carrying out solid liquid separation, wherein the solid phase is used for producing phosphoric acid while the liquid phase is recycled to be used as a de-magging agent and / or enters into a magnesium hydrate production device; and feeding the obtained liquid phase isolate into the magnesium hydrate production device, carrying out reaction with ammonia for primary sedimentation, reacting for 20-40 minutes by controlling the pH at 8.5-9.5, and carrying out solid liquid separation, wherein a primary filter cake enters into an ammonium phosphate production device while a primary filtrate cake is reacted with ammonia for secondary sedimentation, the reaction temperature is 35-50 DEG C, the reaction pH is 9.5-10.5 and the reaction time is 2-3.5 hours; and carrying out solid liquid separation, wherein a secondary filter cake is used for magnesium hydrate and a secondary filtrate is used for a defibrinating process of the phosphoric ore pulp containing magnesium or / and washing and de-magging to obtain a solid phase isolate.

Owner:HUBEI XIANGYUN GROUP CHEM

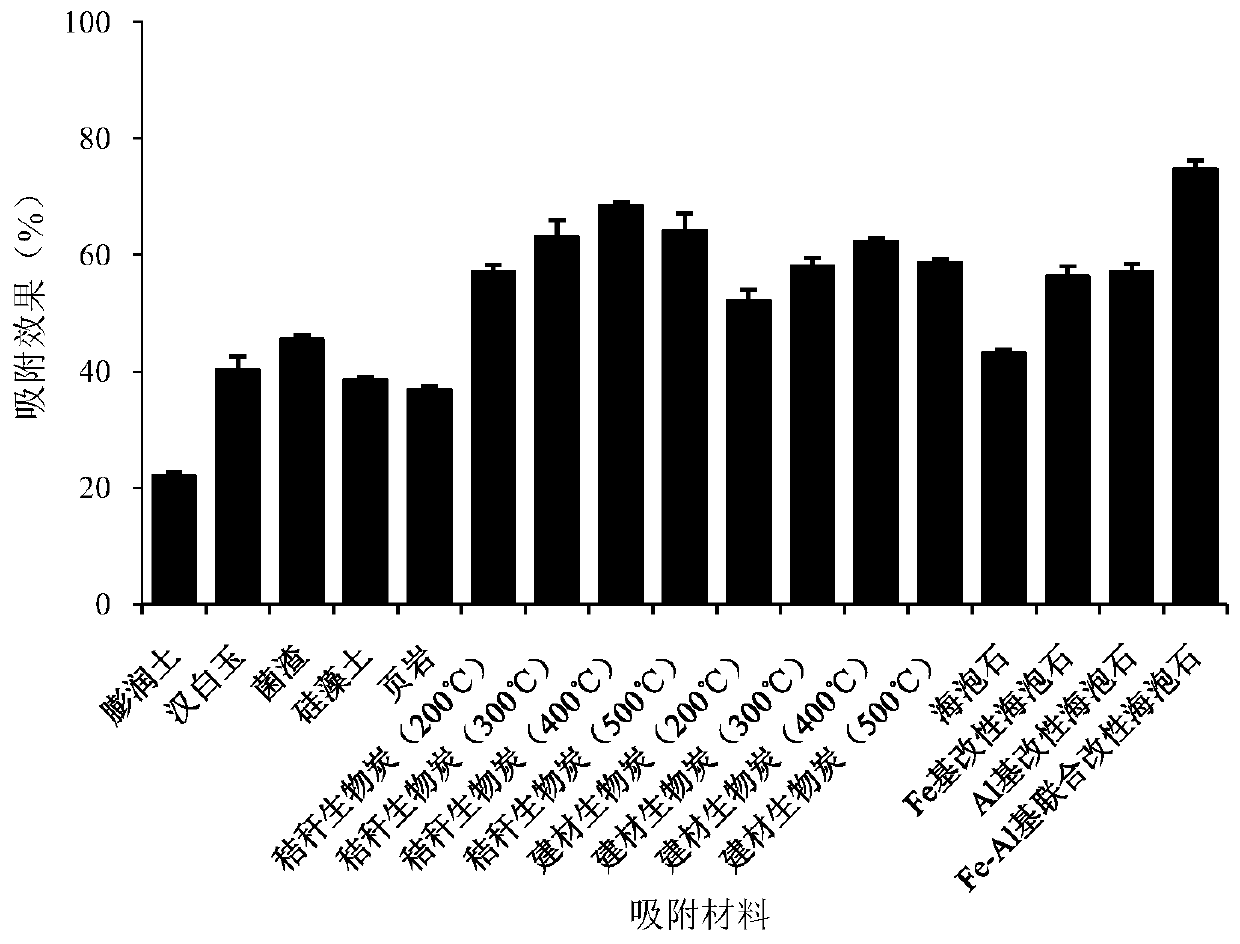

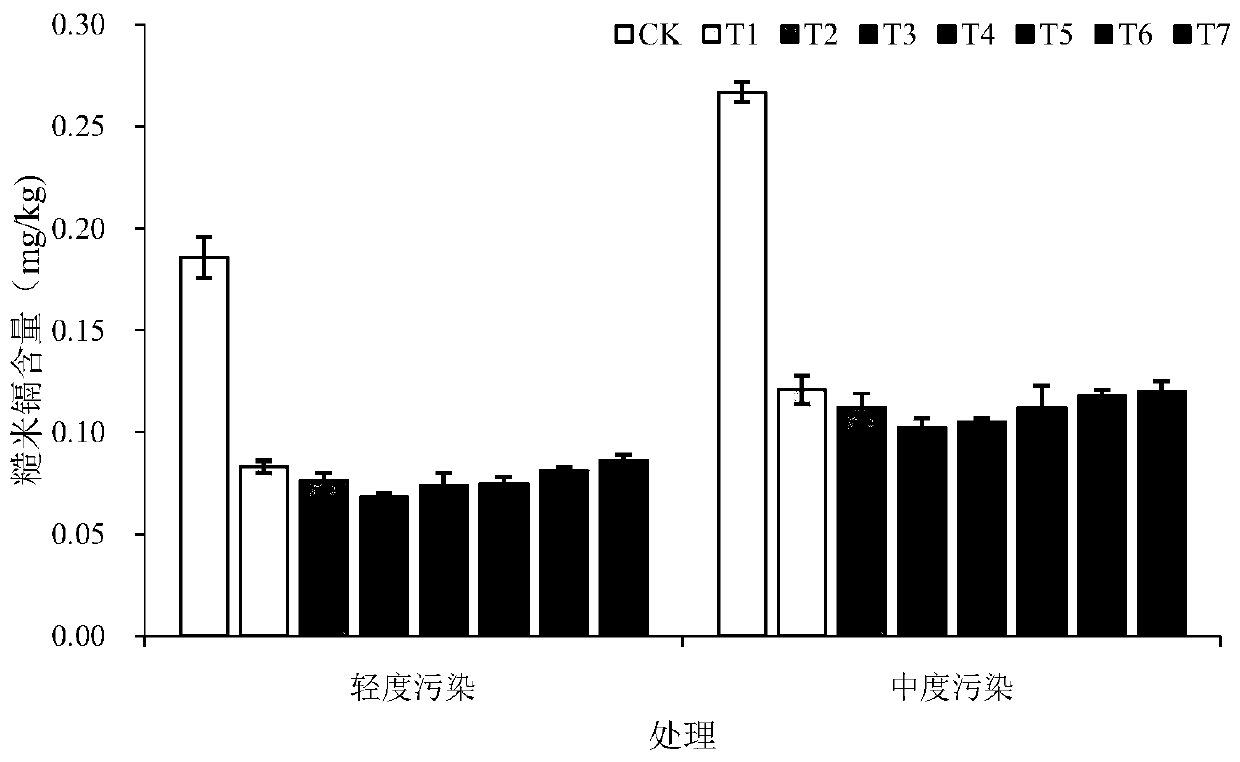

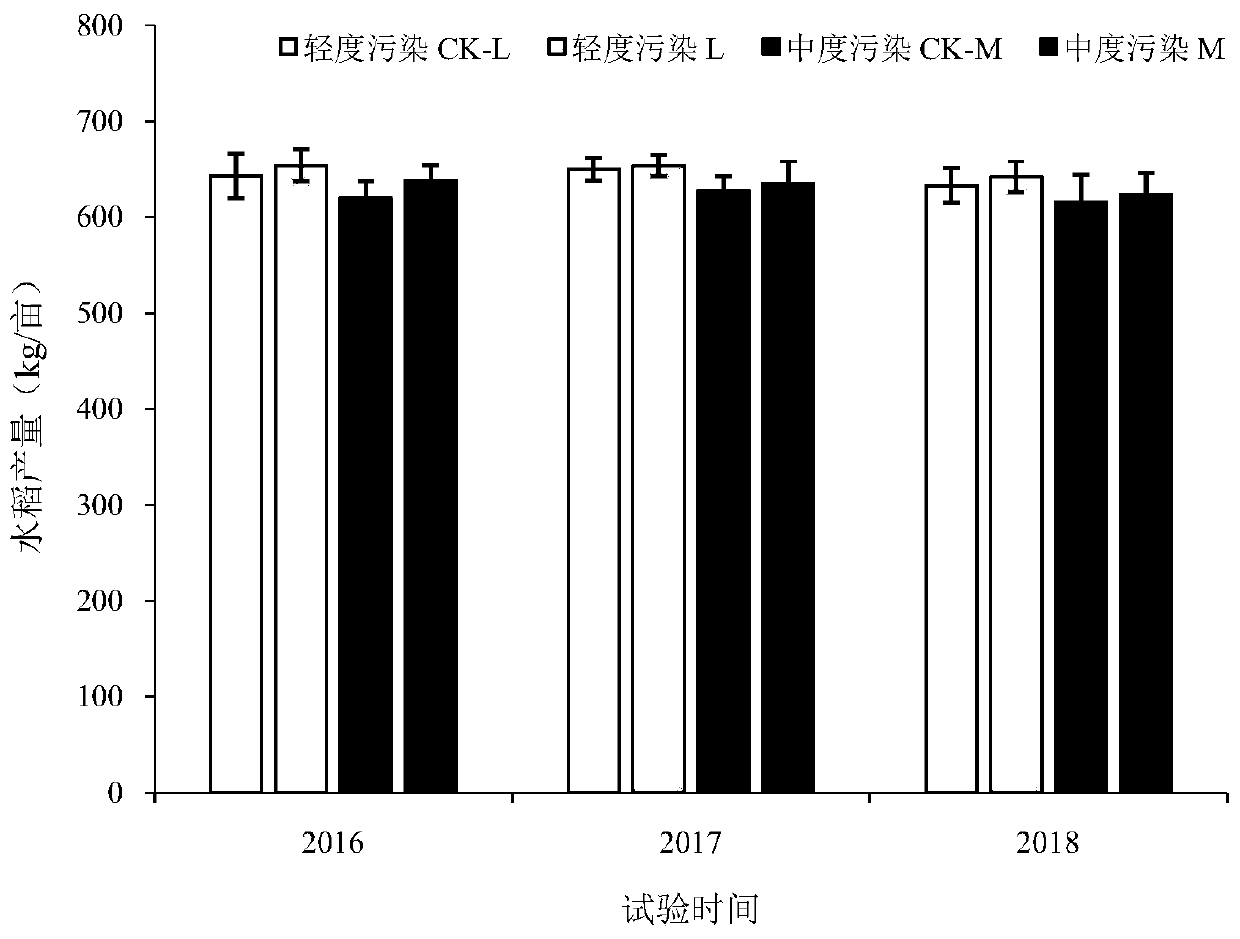

Passivating agent and repairing method for in situ repairing of heavy metal cadmium in soil

ActiveCN110283596AGood effectModified structureAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsBiochar

The invention discloses a passivating agent and a repairing method for in situ repairing of heavy metal cadmium in soil. The raw materials of the passivating agent comprise biochar, treated bacterium residues and modified sepiolite. The raw materials of the passivating agent have sufficient sources, and the process flow meets production requirements of enterprises, so preparation of a large amount of the passivating agent can be ensured. The passivating agent can significantly inhibit the activity of heavy metal cadmium in farmland soil and reduce the content of heavy metal cadmium in the edible parts of agricultural products, can be applied to the in situ passivation repairing of medium-light cadmium polluted farmlands at a large scale, and has a broad application prospect in the field of improvement of the safety productivity of medium-light cadmium polluted farmlands s.

Owner:SICHUAN AGRI UNIV +1

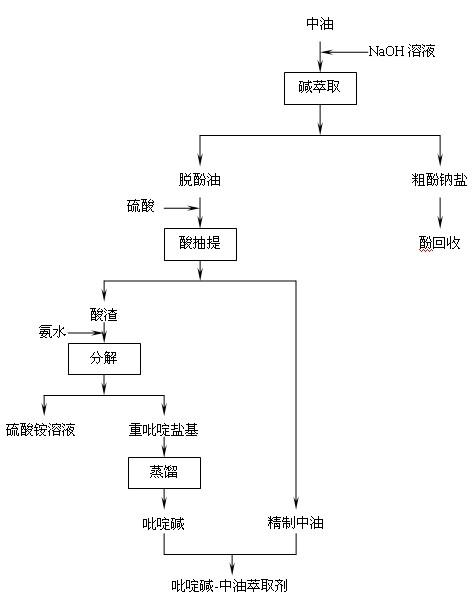

Oil dephenolizing extractant in brown coal tar, and preparation method and application thereof

InactiveCN102351270AReduce lossMeet the requirements of industrial recyclingWater contaminantsLiquid solutions solvent extractionHigh concentrationLiquid waste

The invention discloses a preparation method of an oil dephenolizing extractant in brown coal tar, which not only can realize recycling comprehensive utilization of oil in the brown coal tar, but also can recover phenolic materials to provide basic production raw materials for organic chemical industry production. The method comprises the following steps of: carrying out alkali wash refining and acid wash refining on oil in the brown coal tar by using an NaOH solution and sulfuric acid to generate refined medium oil, and then carrying out chemical decomposition on acid sludge subjected to acid washing by using an ammonia water solution to separate out crude pyridine liquor; distilling the crude pyridine liquor to obtain pyridine base; and at last, adding pyridine base fraction into the refined medium oil according to proportion to obtain the oil dephenolizing extractant in brown coal tar. The oil dephenolizing extractant is used for processing high concentration waste water containing phenol, wherein the dephenolizing efficiency reaches 95% and the dephenolized extractant is carried out with reextraction for regenerating by using the NaOH solution with the regeneration efficiency of higher than 99%, and cycle use of the extractant can be realized. The dephenolizing extractant disclosed by the invention has low preparation cost, simple operation process, no waste liquor discharge in the preparation process of the extractant, and little extractant loss in waste water processing procedure, and is capable of realizing industrial continuous operation.

Owner:KUNMING UNIV OF SCI & TECH

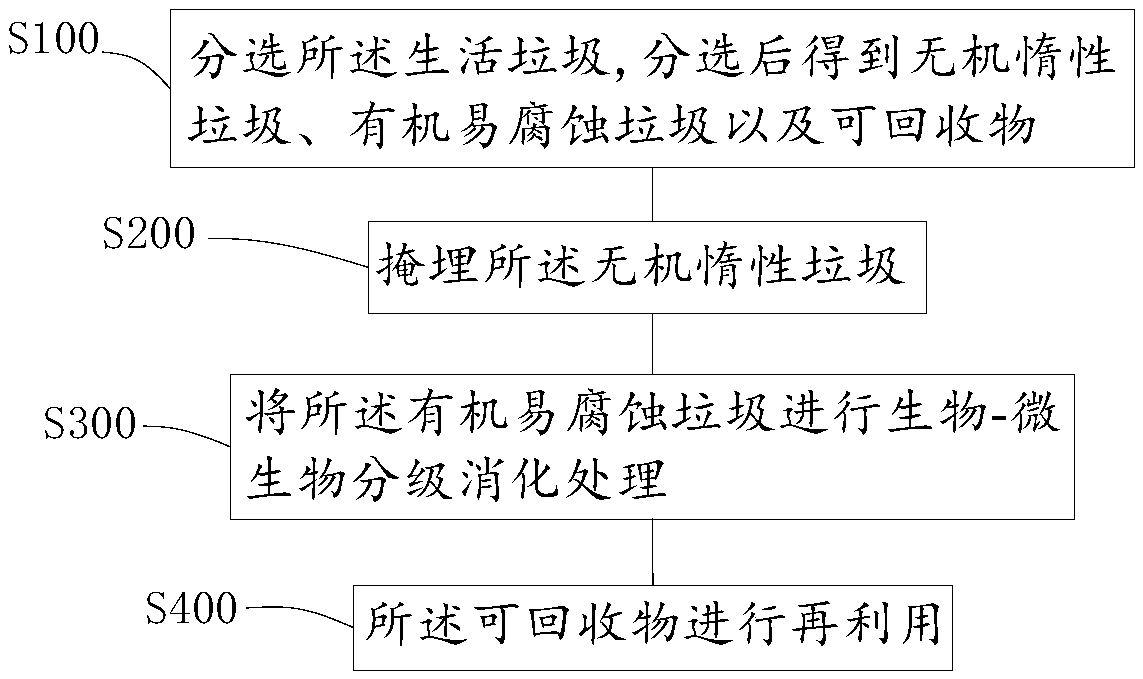

Centralized domestic garbage classified treatment process

InactiveCN109047299AIncrease valueOvercome expensiveBio-organic fraction processingWaste processingDigestion TreatmentRenewable resource

The invention provides a centralized domestic garbage classified treatment process. The centralized domestic garbage classified treatment process comprises the steps that domestic garbage is sorted firstly, and inorganic inert garbage, organic easy-to-corrode garbage and recyclable materials are obtained after sorting; the inorganic inert garbage is transported to a burial site to be buried; the organic easy-to-corrode garbage is subjected to organism-microorganism grading digestion treatment; and the recyclable materials are reutilized. According to the centralized domestic garbage classifiedtreatment process, the domestic garbage can be divided into the three types of the inorganic inert garbage, the organic easy-to-corrode garbage and the recyclable materials; and the organic easy-to-corrode garbage in kitchens and the like are treated through a resource utilization technology with organism-microorganism grading digestion, the high-valued recyclable materials are in butt joint witha downstream renewable resource recycling enterprise, and the inorganic inert garbage enters a sanitary landfill to be treated finally.

Owner:GUANGDONG XIFU ENVIRONMENTAL PROTECTION TECH

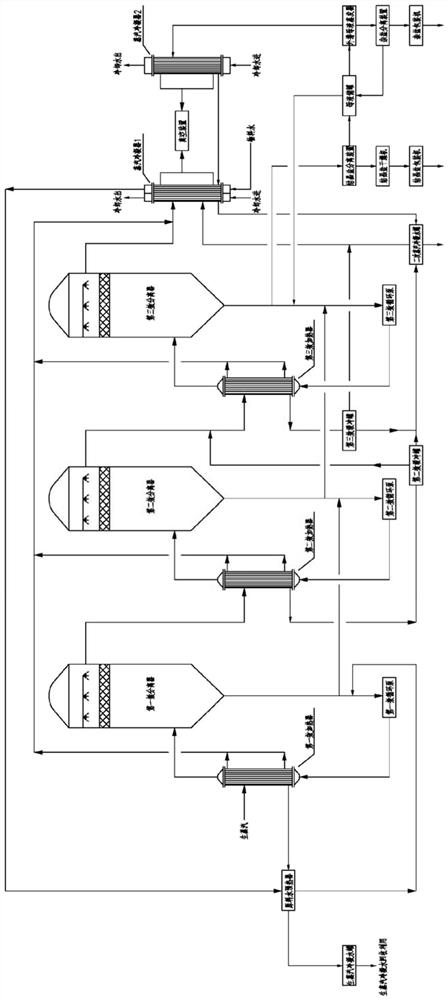

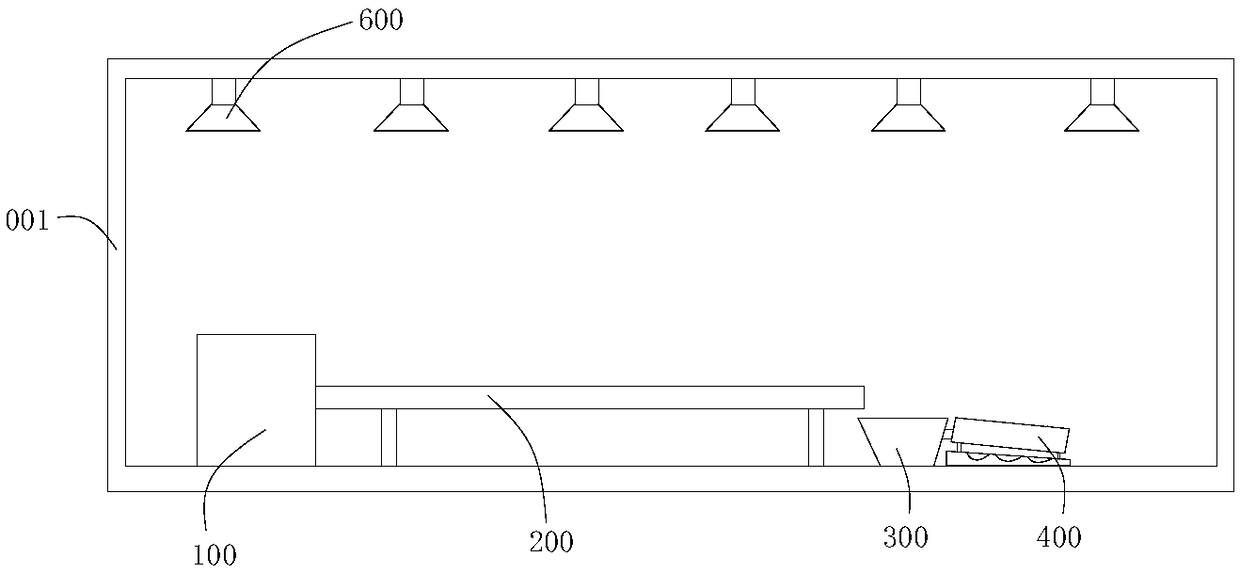

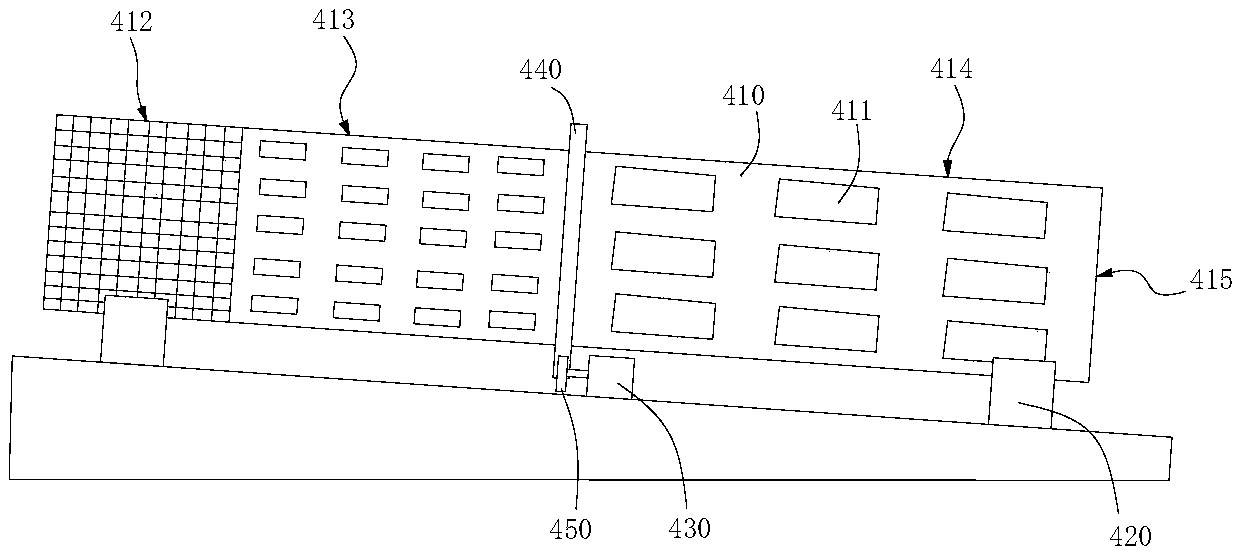

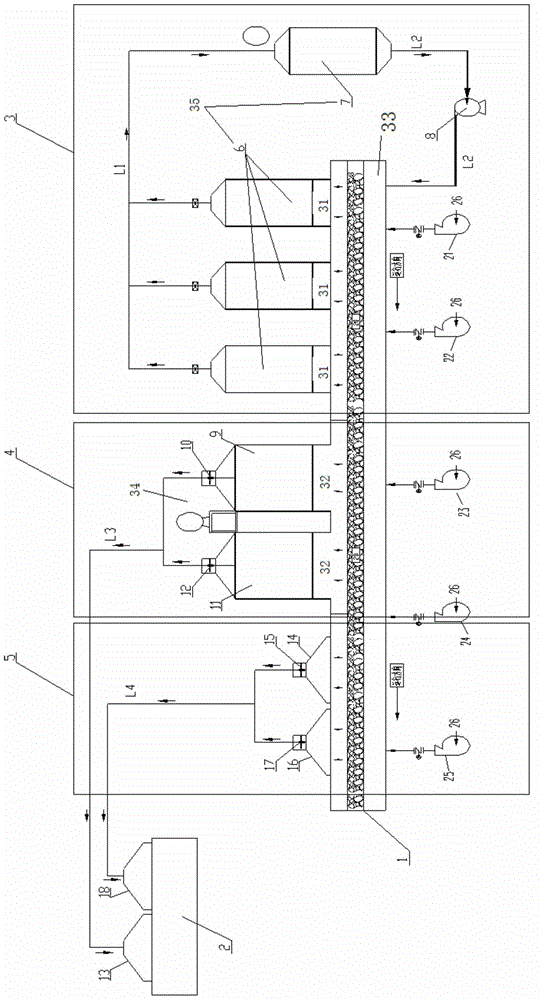

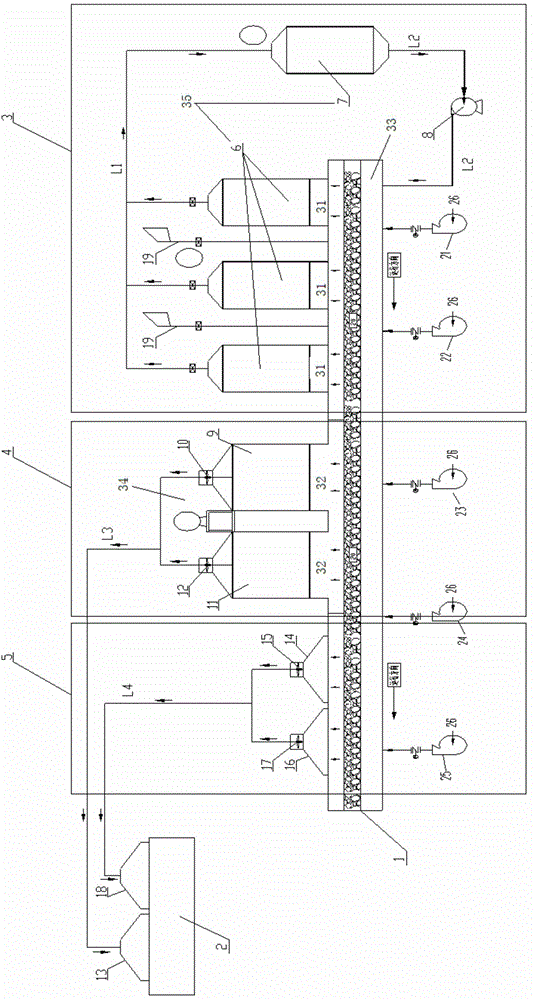

Sinter cooler waste gas afterheat gradient utilization method and device thereof

InactiveCN104833216ANo effluxNo pollution in the processIncreasing energy efficiencyWaste heat treatmentCombustionProcess engineering

The invention discloses a sinter cooler waste gas afterheat gradient utilization zero-emission device and an operation method thereof. The device is that a cooling section of a sinter cooler is divided into a high temperature area, a medium temperature area and a low temperature area; waste gas of the high temperature area of the cooler is generated to steam with high pressure and low pressure for electricity generation or production through a double-pressure type afterheat boiler; the waste gas exhausted by the double-pressure type afterheat boiler is returned to the cooler by a circulating fan; waste gas of the medium temperature area of the cooler is generated to steam for dragging or production through a single-pressure type afterheat boiler; the waste gas exhausted by the single-pressure type afterheat boiler is fed to a sintering machine by an axial flow fan; and the waste gas of the medium and low temperature areas of the cooler is directly provided to the sintering machine for combustion to replace normal temperature air. The waste gas afterheat of the sinter cooler is totally used; and no waste gas is exhausted to pollute the air.

Owner:HUNAN ZHONGYE CHANGTIAN ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Method for recycling tin from tin alkali solution

The invention relates to a method for recycling tin from a tin alkali solution. The method comprises the following steps: stirring the tin alkali solution at a rotation speed of 300-800r / min; adding an additive and metal zinc powder, and reacting for 0.5-2 hours at a temperature of 15-95 DEG C, wherein the adding amount of the additive is 0.01%-2% the adding amount of the metal zinc powder, the adding amount of the metal zinc powder is 1-4 times the molar weight of tin in the tin alkali solution; after the reaction is ended, stopping stirring, filtering, reducing concentration of tin in filtrate to be lower than 100mg / L, and directly electrolyzing the filtrate to produce metal zinc powder, wherein filter slag is coarse tin with content being greater than or equal to 85%; using the metal zinc powder obtained by electrolyzing to replace tin in the next-batch tin alkali solution, so that the production cost is reduced, and the electrolysis waste liquor is recycled for leaching tin-containing materials to prepare the tin alkali solution, and no waste liquor is exhausted. The method is simple in replacement reaction condition, is not high in temperature, is quick in replacement, and the obtained tin is great in purity, is great in value; and the additive is wide in source, is cheap and easily available, and is less in dosage.

Owner:CHINA UNIV OF MINING & TECH

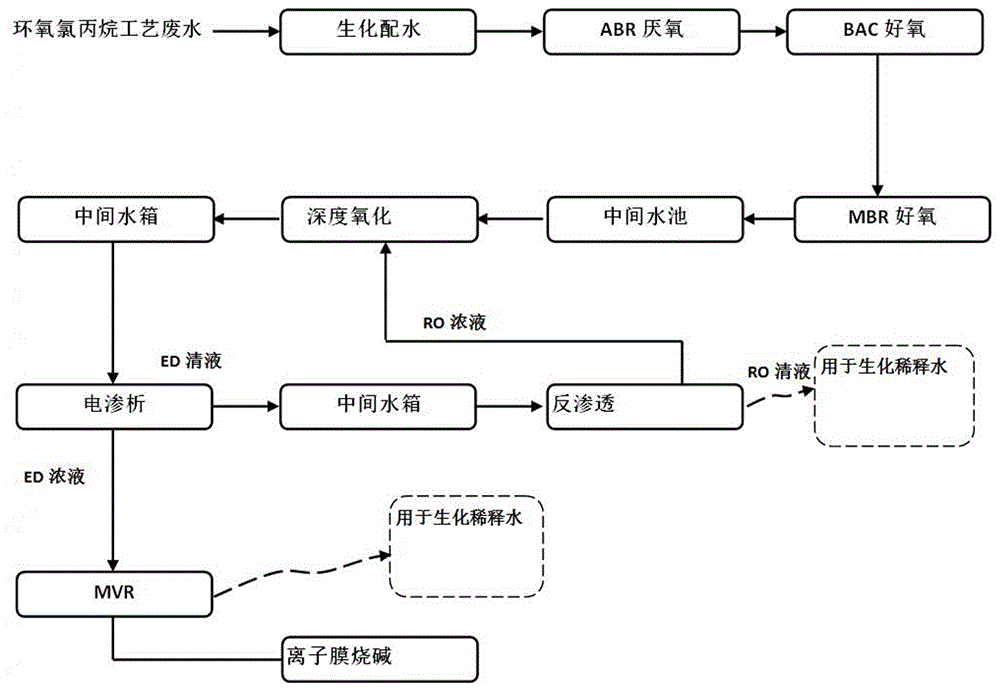

Method for treating epichlorohydrin waste water

InactiveCN106746184AReduce dilutionReduce processTreatment using aerobic processesWater contaminantsResource utilizationReverse osmosis

The invention discloses a method for treating epichlorohydrin waste water. The method comprises the following steps: degrading organic pollutants by adopting ABR anaerobic treatment / BAC aerobic treatment / MBR aerobic treatment; for MBR effluent water, treating surplus organic compounds through combined usage of deep oxidation of an oxidizer and adsorption with activated carbon; for deep oxidation effluent water, performing electrodialysis concentration, performing MVR evaporation concentration on electrodialysis concentration liquid, using MVR condensate as dilution water, enabling an MVR concentrated solution to reach to the standard of ion film caustic soda for recycling; and performing reverse osmosis on electrodialysis light liquid for desalting, using reverse osmosis light liquid as dilution water for recycling, and enabling reverse osmosis strong liquid to return to a deep oxidation technology. Clean water produced in the whole technology of the method disclosed by the invention is completely used as dilution water, inorganic salts in the epichlorohydrin waste water can be completely recycled to be used for an ion film caustic soda technology, the purpose of resource utilization of water and salts is achieved, the whole technology is effective to implement, the operation is flexible and convenient, the resource utilization of the water and the salts for the epichlorohydrin waste water can be achieved, discharge is not needed, and no adverse effect on environment is generated.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

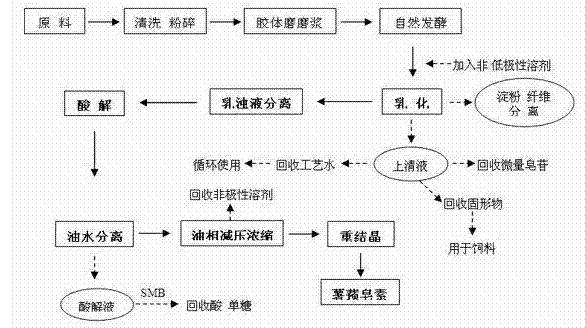

Green process for preparing diosgenin

The invention discloses a green process for preparing diosgenin and belongs to the technical field of natural product extraction. The main procedure of the process comprises the steps of washing, smashing, naturally fermenting, emulsifying, separating fibers, separating starch, separating emulsion, performing acidolysis, separating oil and water, performing reduced-pressure condensing, and recrystallizing to get the product; recovering acid and monosaccharide in the acidolysis solution through a simulated moving bed; and adding a nonpolar solvent into a natural fermentation solution while grinding by a colloid mill, emulsifying the diosgenin to form the emulsion fixed in the water, and separating to get the cellulose, starch, supernate and emulsion after emulsifying. The emulsion is directly acidolysis processed so that the hydrolysis condition is reduced, the diosgenin is free of being damaged, and the quality of the diosgenin is increased; the pollution source is completely eliminated by the acid and the monosaccharide in the acidolysis solution. The process meets the standards of high purity, high yield, low cost and pollution free. The prepared diosgenin content is greater than 98%, the yield is greater than 80%, the recovery rate of the cellulose, the starch and the like is greater than 95%, the production cost is reduced by 30%, the ton cost is reduced by **-** and no pollution is discharged.

Owner:DALIAN POLYTECHNIC UNIVERSITY

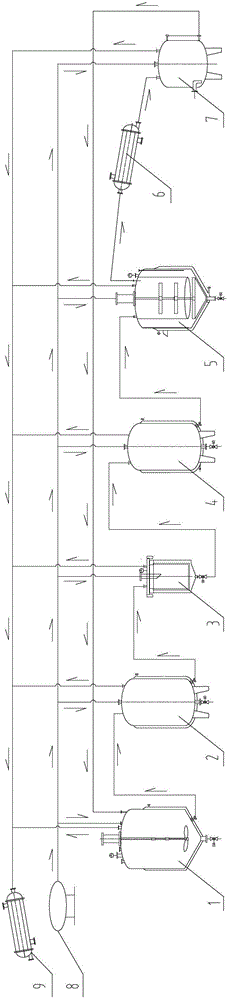

Complete set of equipment and method for separating high-temperature coal tar components via low-temperature rapid extraction method

ActiveCN103194252BHigh recovery rateOptimize the marketTar working-up by distillationTar working-up by solvent extractionThermodynamicsWastewater

The invention relates to a complete set of equipment and a method for separating high-temperature coal tar components via a low-temperature rapid extraction method, and belongs to the complete set of separation equipment and the method for extracting the high-temperature coal tar. The complete set of equipment comprises two kettles and four jars: a coal tar extraction kettle, a light oil solution buffering jar, a filtering jar, refined light oil solution buffering jar, a distillation kettle and a solvent storing jar. The method comprises the following steps: extracting the coal tar to obtain heavy asphalt; filtering a refined light oil solution; and distilling the refined light oil to obtain the refined light oil. The equipment and the method have the advantages that the separation of light and heavy components in the coal tar is realized rapidly; the operation condition is moderate; the separation process is advanced; the separation efficiency is high; and the separation depth and the treatment quantity of the coal tar can be mastered flexibly and controlled selectively by changing an extraction agent, the adding amount of the extraction agent as well as the parameters of the extraction operation. The equipment and the method provided by the invention are simple and convenient to operate, obvious in energy conservation and consumption reduction, high in solvent recovery rate and easy in automatic operation, realize low-carbon clean production and are low in investment cost as well as nearly free of discharging waste residue, waste gas and waste water.

Owner:CHINA UNIV OF MINING & TECH +1

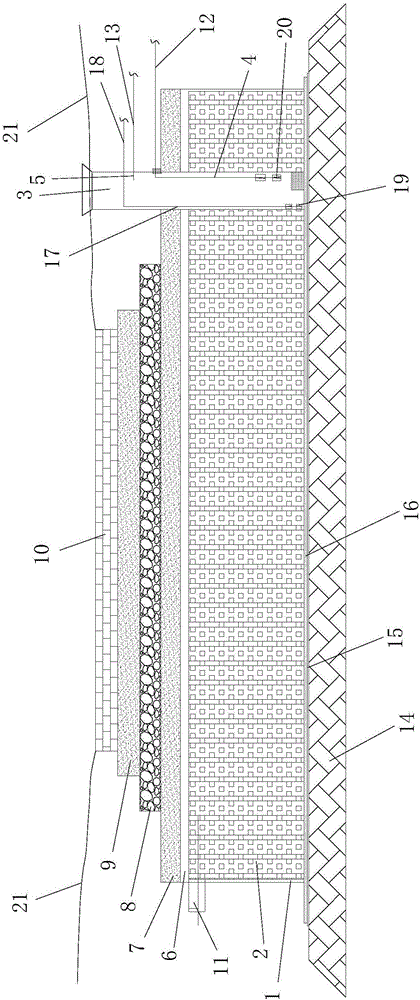

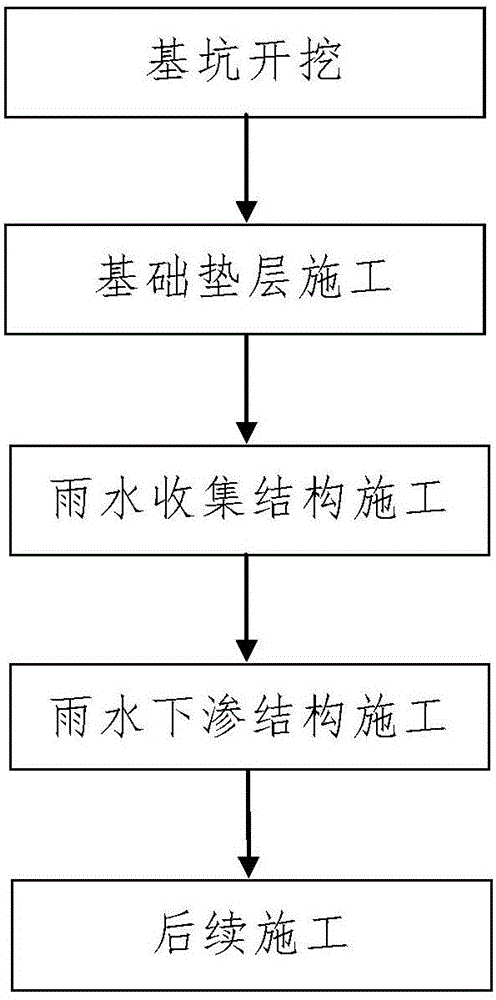

Sunken plaza capable of collecting and recycling rainwater and construction method thereof

ActiveCN106088684ASimple structureReduce construction costsSewerage structuresPublic buildingsVegetationRainwater harvesting

The invention discloses a sunken plaza capable of collecting and recycling rainwater and a construction method thereof. The sunken plaza comprises a foundation pad laid at the bottom of a foundation pit, a rainwater collection structure erected on the foundation pad, and a rainwater infiltration structure laid on the rainwater collection structure. A water outlet well is arranged inside the rainwater collection structure. Vegetation buffer belts are arranged on the outer sides of the periphery of the upper portion of the foundation pit. The rainwater collection structure is formed by splicing a plurality of PP rainwater collection modules, and an overflow pipe is arranged at the upper portion of the rainwater collection structure. The rainwater infiltration structure comprises a filter layer, a medium sand layer, a rubble layer, a coarse sand layer and a filter plate which are distributed from bottom to top. The construction method comprises the steps of 1, foundation pit excavation; 2, foundation pad construction; 3, rainwater collection structure construction; 4, rainwater infiltration structure construction; 5, follow-up construction. The sunken plaza is reasonable in design, easy and convenient to construct, good in using effect and capable of filtering and collecting rainwater, forming integrated rainwater infiltration and collection, effectively solving the problem of water drainage of the sunken plaza.

Owner:陕西昊然海绵城市建设技术有限公司

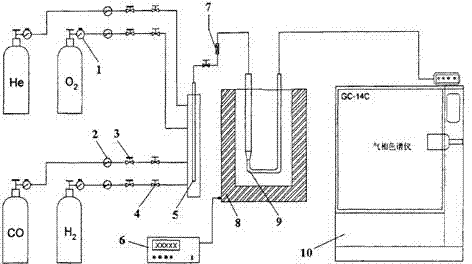

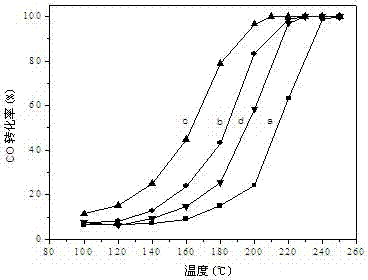

Preparation method and application of Pd/modified bauxite catalyst

InactiveCN102294241ANo effluxEasy to makeCatalyst carriersDispersed particle separationPtru catalystMetallurgy

The invention provides a preparation method and application of a Pd / modified bauxite catalyst. The preparation method comprises the following steps: carrying out hydrothermal treatment on natural bauxite at the temperature of 130-170 DEG C for 48-72 h, then drying at the temperature of 80-110 DEG C for 4 h, and roasting for 2-4 h at the temperature of 550-650 DEG C to obtain a modified bauxite carrier; at room temperature, dipping the modified bauxite carrier in H2PdCl4 solution (0.03 g / ml) with volumetric method, drying with an infrared lamp, and roasting for 2-6 h at the temperature of 450 DEG C to obtain the Pd / modified bauxite catalyst with different Pd loadings. According to the invention, the Pd / modified bauxite catalyst is used as the catalyst of a CO oxidation reaction, so that the invention has creativity. The preparation process is simple without discharging of waste water, and the catalyst can be synthesized in a great lot. The catalyst is applied in the CO oxidation reaction with low load capacity and high catalytic activity. The preparation method can greatly reduce production cost. The invention has a good application prospect.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com