Passivating agent and repairing method for in situ repairing of heavy metal cadmium in soil

An in-situ remediation and heavy metal technology, applied in the restoration of contaminated soil, chemical instruments and methods, soil conditioning materials, etc., can solve the problems of environmental pollution in the production process, unsuitable for factory production, and limited passivation effect of heavy metal ions , to achieve the effect of increasing crop yield, significant immobilization, and good passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

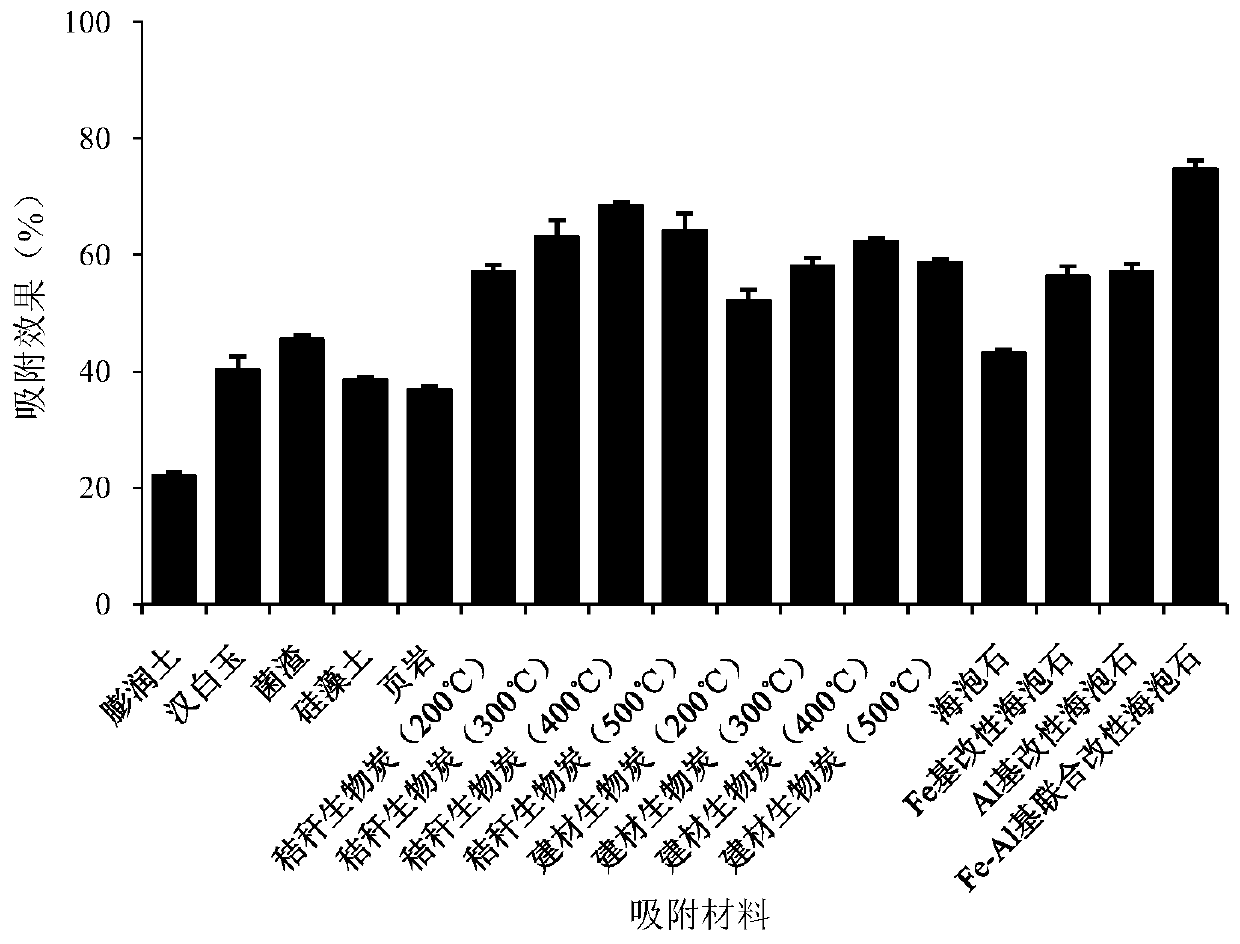

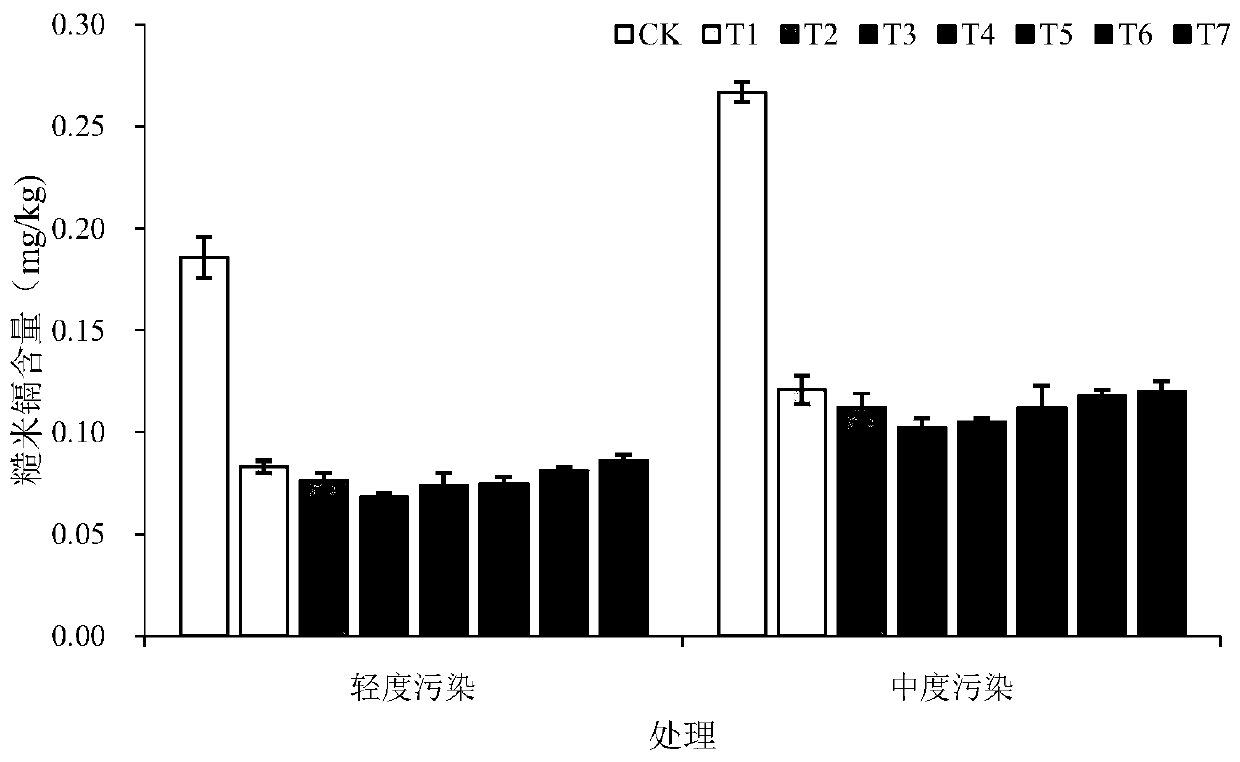

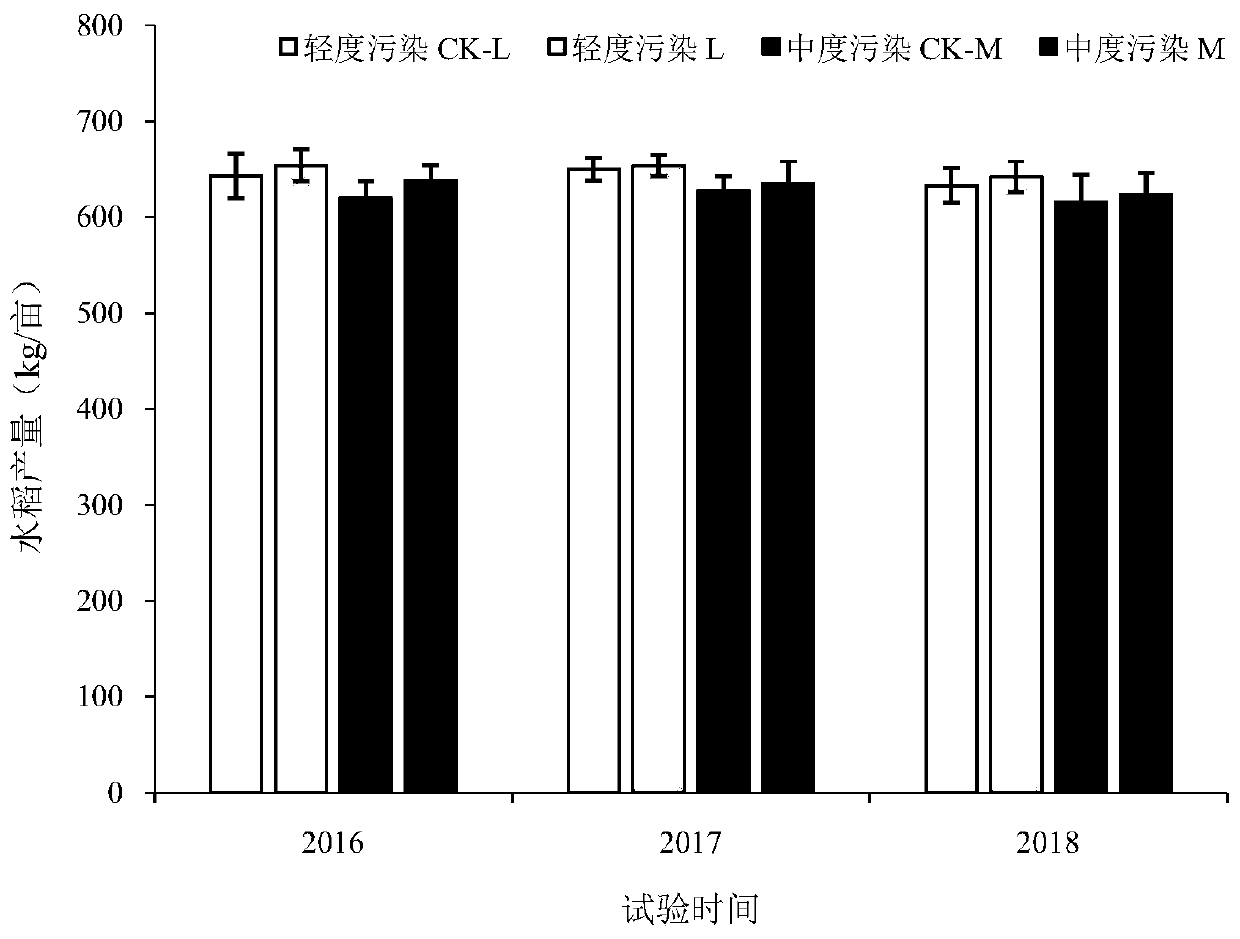

Method used

Image

Examples

Embodiment 1

[0050] A preferred embodiment of the present invention provides a passivator for in-situ remediation of heavy metal cadmium in soil.

[0051] The passivator for in-situ remediation of heavy metal cadmium in soil is prepared by mixing the following raw materials in parts by weight:

[0052] 1 part of biochar, 3 parts of treated fungus residue and 5 parts of modified sepiolite.

[0053] The biochar is prepared by the following method: cut the dried straw into small pieces, carry out anaerobic carbonization at 400°C for 8 hours, cool to room temperature and then pulverize, and pass through a 18-mesh sieve to obtain the primary product of biochar. Add water to the mixture, stir thoroughly and then filter, collect the filtrate for later use, collect the residue and dry it to obtain biochar.

[0054] Modified sepiolite is prepared by the following method: heat the filtrate at a constant temperature of 60 °C, slowly add Al(NO 3 ) 3 -Fe(NO 3 ) 3 mixed solution of Al(NO 3 ) 3 an...

Embodiment 2

[0057] A preferred embodiment of the present invention provides a passivator for in-situ remediation of heavy metal cadmium in soil.

[0058] The passivator for in-situ remediation of heavy metal cadmium in soil is prepared by mixing the following raw materials in parts by weight:

[0059] 2 parts of biochar, 3 parts of treated fungus residue and 4 parts of modified sepiolite.

[0060] The biochar is prepared by the following method: cut the dried straw into small pieces, carry out anaerobic carbonization at 400°C for 8 hours, cool to room temperature and then pulverize, and pass through a 18-mesh sieve to obtain the primary product of biochar. Add water to the mixture, stir thoroughly and then filter, collect the filtrate for later use, collect the residue and dry it to obtain biochar.

[0061] Modified sepiolite is prepared by the following method: heat the filtrate at a constant temperature of 60 °C, slowly add Al(NO 3 ) 3 -Fe(NO 3 ) 3 mixed solution of Al(NO 3 ) 3 a...

Embodiment 3

[0064] A preferred embodiment of the present invention provides a passivator for in-situ remediation of heavy metal cadmium in soil.

[0065] The passivator for in-situ remediation of heavy metal cadmium in soil is prepared by mixing the following raw materials in parts by weight:

[0066] 3 parts of biochar, 3 parts of treated fungus residue and 3 parts of modified sepiolite.

[0067] The biochar is prepared by the following method: cut the dried straw into small pieces, carry out anaerobic carbonization at 400°C for 8 hours, cool to room temperature and then pulverize, and pass through a 18-mesh sieve to obtain the primary product of biochar. Add water to the mixture, stir thoroughly and then filter, collect the filtrate for later use, collect the residue and dry it to obtain biochar.

[0068] Modified sepiolite is prepared by the following method: heat the filtrate at a constant temperature of 60 °C, slowly add Al(NO 3 ) 3 -Fe(NO 3 ) 3 mixed solution of Al(NO 3 ) 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com