Method for treating epichlorohydrin waste water

A technology for epichlorohydrin and waste water, which is applied in multi-stage water treatment, water/sewage treatment, aerobic process treatment, etc. It can solve the problems of potential safety hazards, low treatment cost, cumbersome treatment process, etc., and reduce the number of sedimentation tanks. process, reduce the amount of dilution, and operate flexibly and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

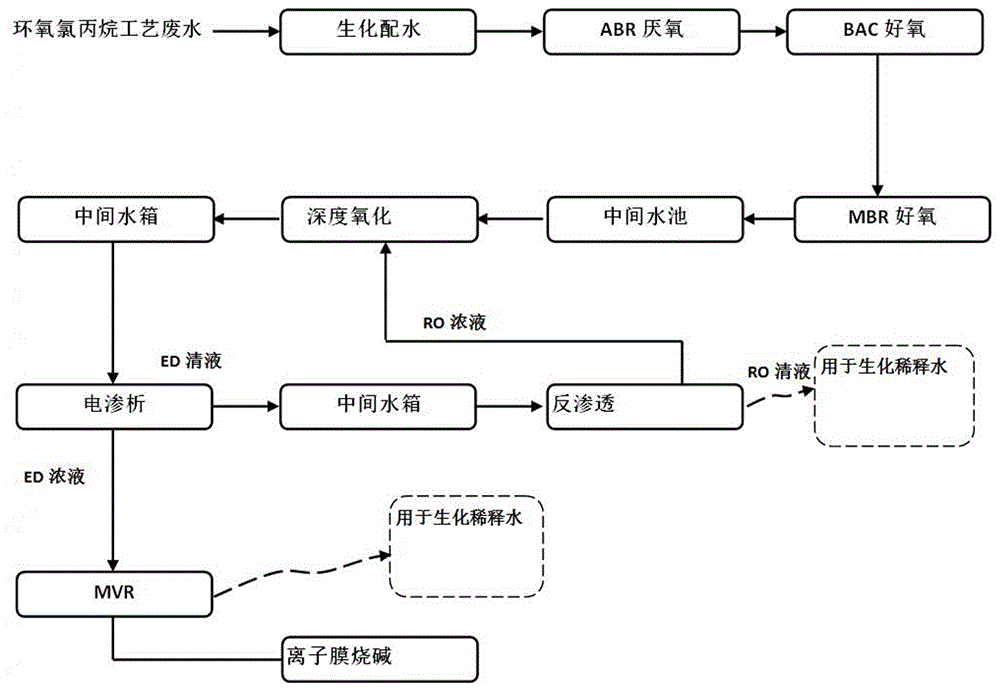

[0036] like figure 1 As shown in the process flow chart, firstly, the epichlorohydrin wastewater is pumped into the biochemical water distribution tank, and 4-6 times of clear water is added for the first time to dilute until the wastewater salt content is 5 wt%. In the process, RO produced water and MVR condensate are added with sodium hydroxide solution to adjust the pH to 7~9; the water temperature is controlled at 25~35℃, and salt-tolerant compound bacteria are added to the water body, and the anaerobic biochemical reaction is carried out for 36 hours to destroy the organic matter in the wastewater. The water body continues to pass into the reaction tank, adjust the pH to 7~9, control the water temperature to 25~35℃, add salt-tolerant compound bacteria, carry out the first-level aerobic reaction for 36 hours, and control the dissolved oxygen in the aerobic tank. It is 2~4mg / L; the aerobic biochemical reaction is 24 hours, and the organic matter in the wastewater is biodegr...

Embodiment 2

[0040]In this embodiment, the concentrated solution after electrodialysis concentration is not evaporated and concentrated by feeding into MVR, but the concentrated solution obtained from the concentrated solution after electrodialysis concentration can be added with technical grade sodium chloride to configure saturated brine as ionic membrane caustic soda raw material. The steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com