Method for using partial homogeneous charge compression ignition in a diesel internal combustion engine for NOx trap regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

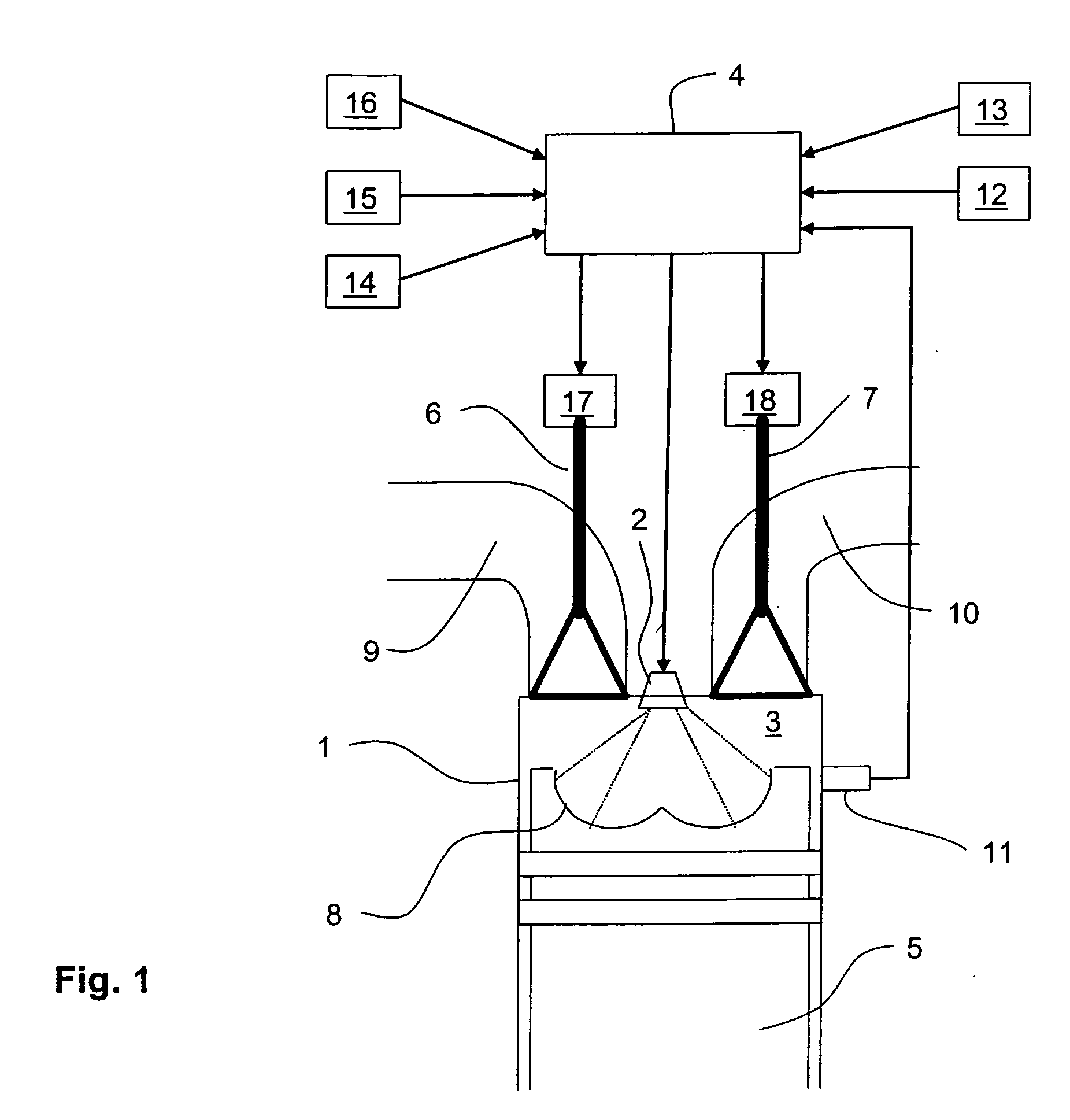

[0023]FIG. 1 shows a schematic illustration of a cylinder of an internal combustion engine according to the invention. The engine is provided with at least one cylinder 1 and comprises a fuel injector 2, through which fuel is injected into a combustion chamber 3, for each cylinder. A fuel injection control unit 4 controls the timing and quantity of fuel injected through each fuel injector during a combustion cycle. A piston 5 in the engine cylinder has a compression action that causes a mixture of air and fuel within the combustion chamber to be ignited by compression ignition. The cylinder is provided with at least one inlet valve 6 for admitting gas, the so called combustion gas, which includes fresh air into said cylinder and at least one exhaust valve 7 for exhaust gases from said cylinder. The piston is further provided with a piston bowl cavity 8. Combustion gas is supplied through an intake conduit 9 connected to an intake manifold, while exhaust gas is exhausted through an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com