Heat transfer unit for internal combustion engine

A technology of heat transfer unit and internal combustion engine, which is applied in the direction of heat transfer modification, heat sink, heat exchanger, etc., and can solve problems such as adjustment and efficiency limitation of heat transfer equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

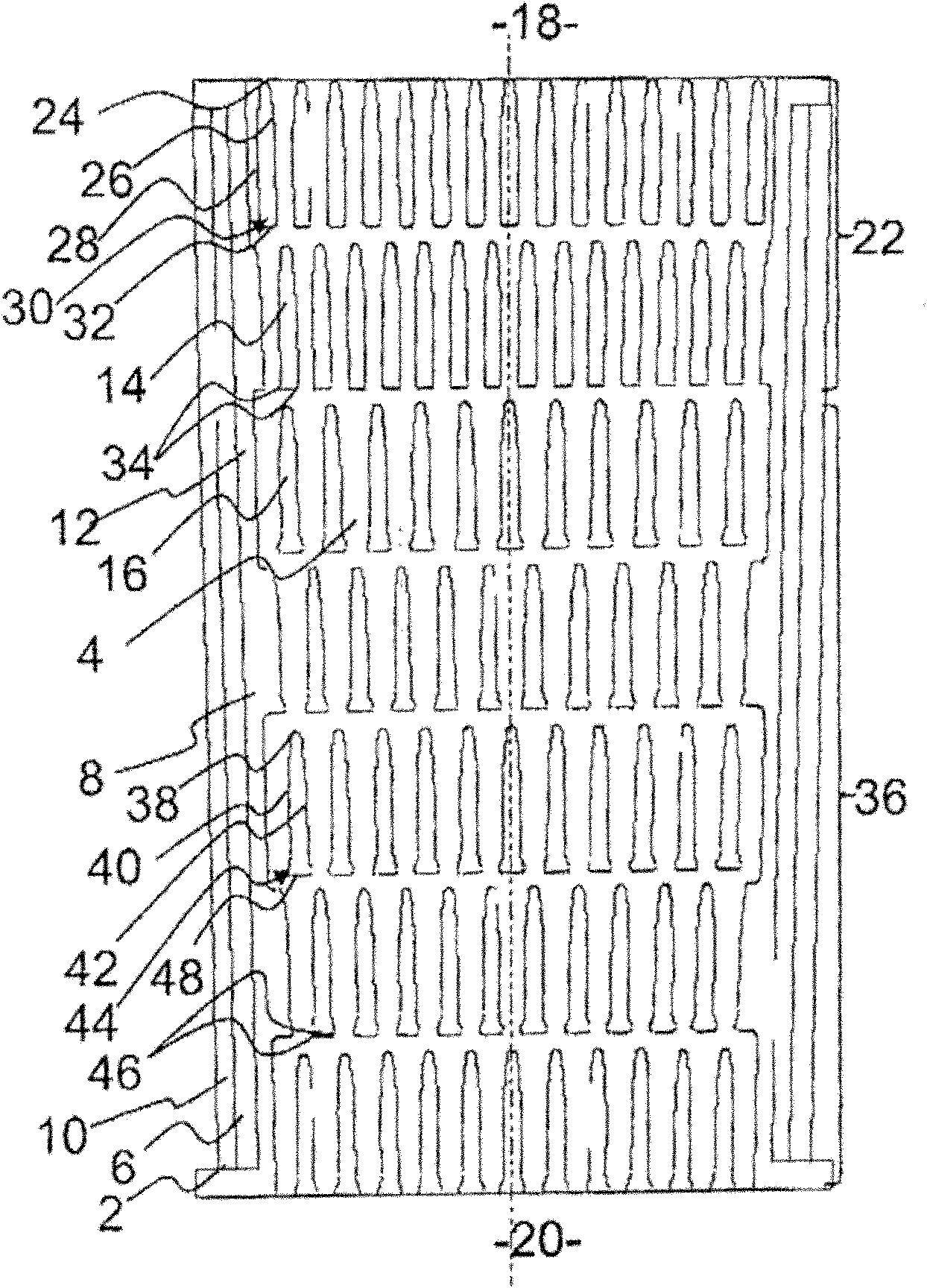

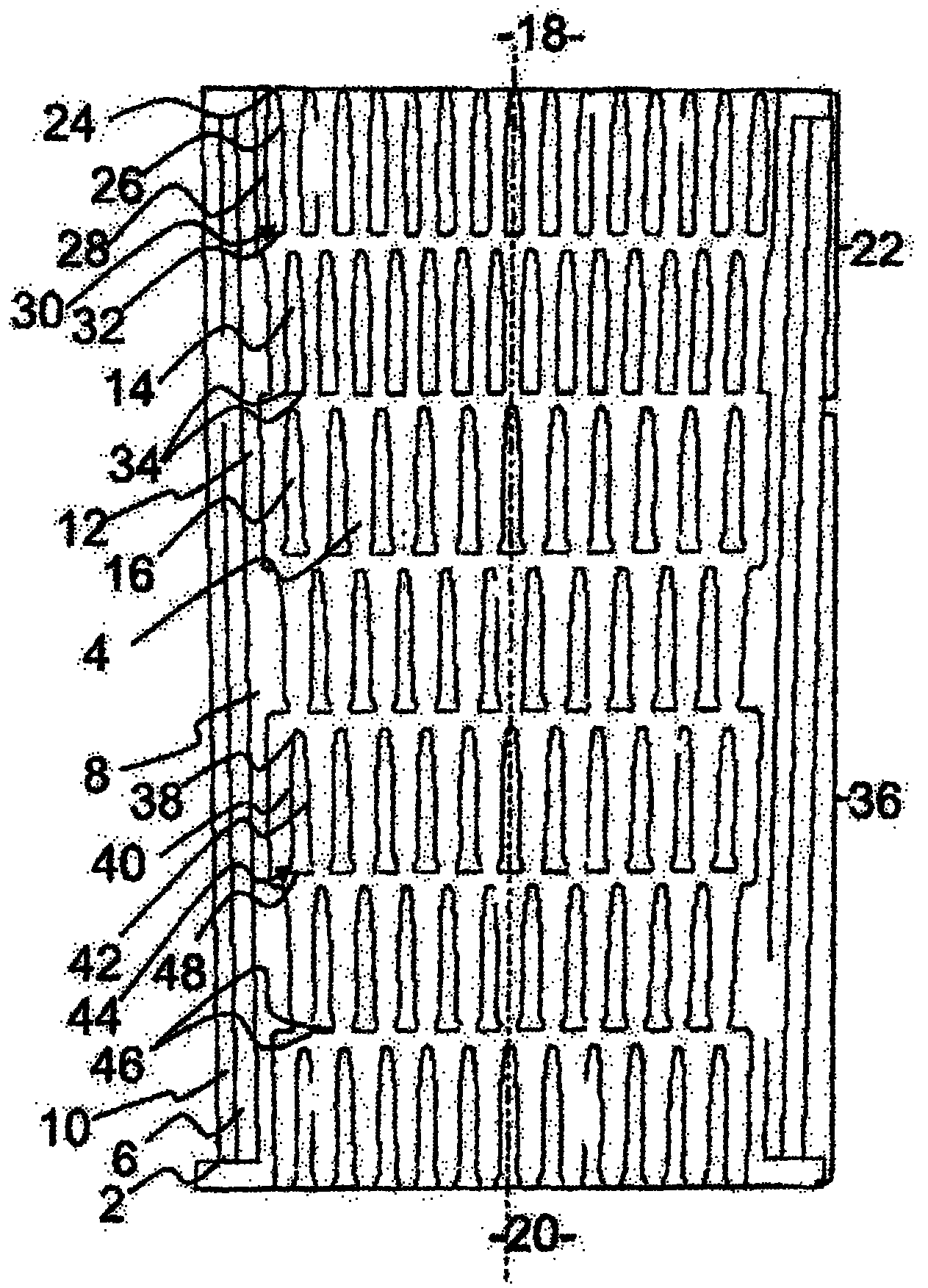

[0015] The heat transfer unit shown in the figure is formed by a housing 2, in which are provided passages 4 through which the fluid to be cooled flows and passages 6 through which the cooling fluid flows. Especially when using this heat transfer unit as an exhaust gas cooler, due to the forced soot into the exhaust gas, the problem of excessive soot formation may arise. For a clearer understanding, the channel 4 through which the fluid to be cooled flows is referred to below as The exhaust gas flows through the channels.

[0016] The housing 2 includes a multi-part inner housing 8 and an outer housing 10 surrounding the inner housing 8 and substantially spaced from the inner housing 8 .

[0017] In this embodiment, the channel 6 through which the coolant flows is arranged between the inner shell 8 and the outer shell 10, thus surrounding the channel 4 through which the fluid to be cooled flows, which is provided by the inner shell The peripheral wall of the body 8 is defined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com