Patents

Literature

1039results about How to "Reduce retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

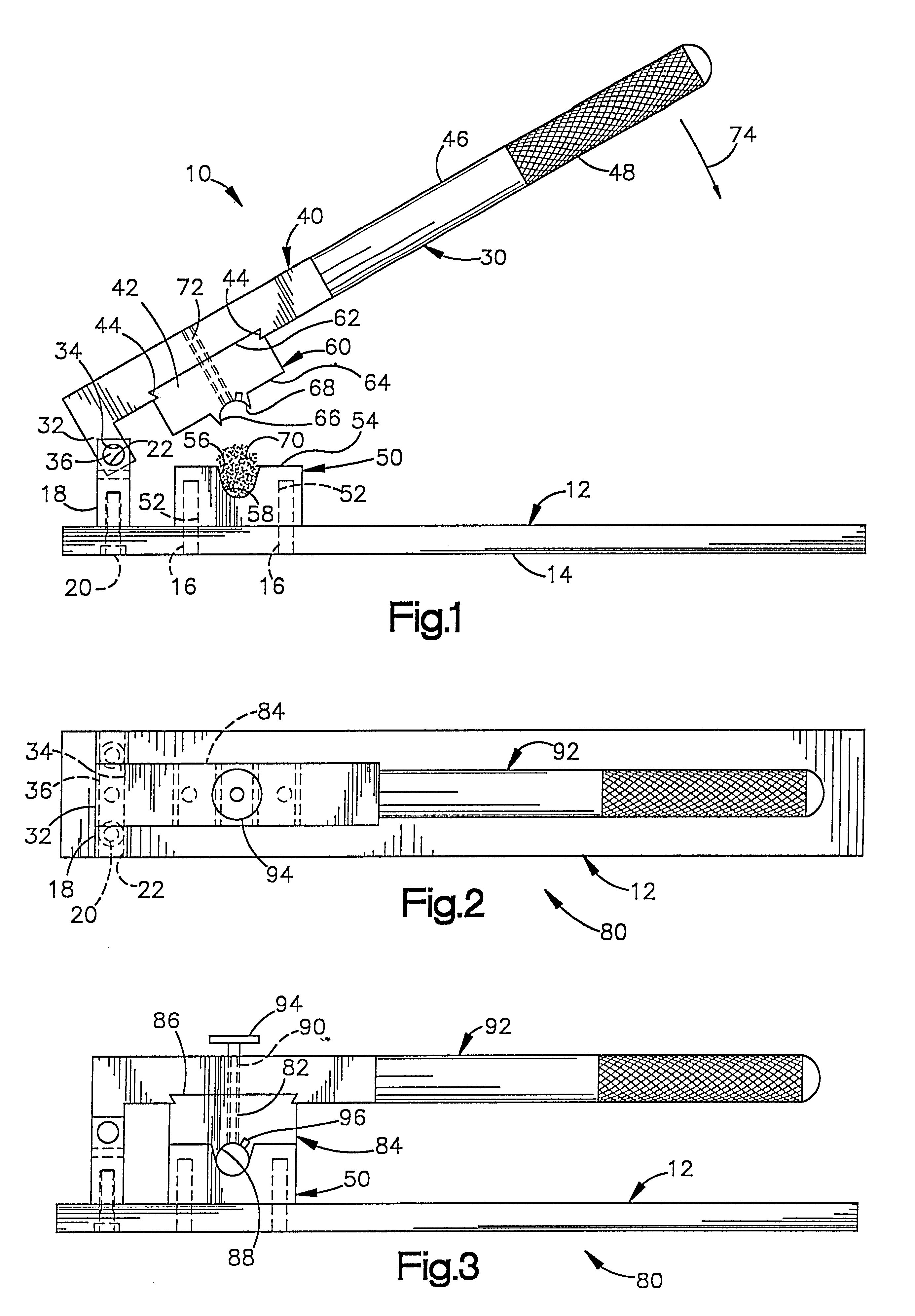

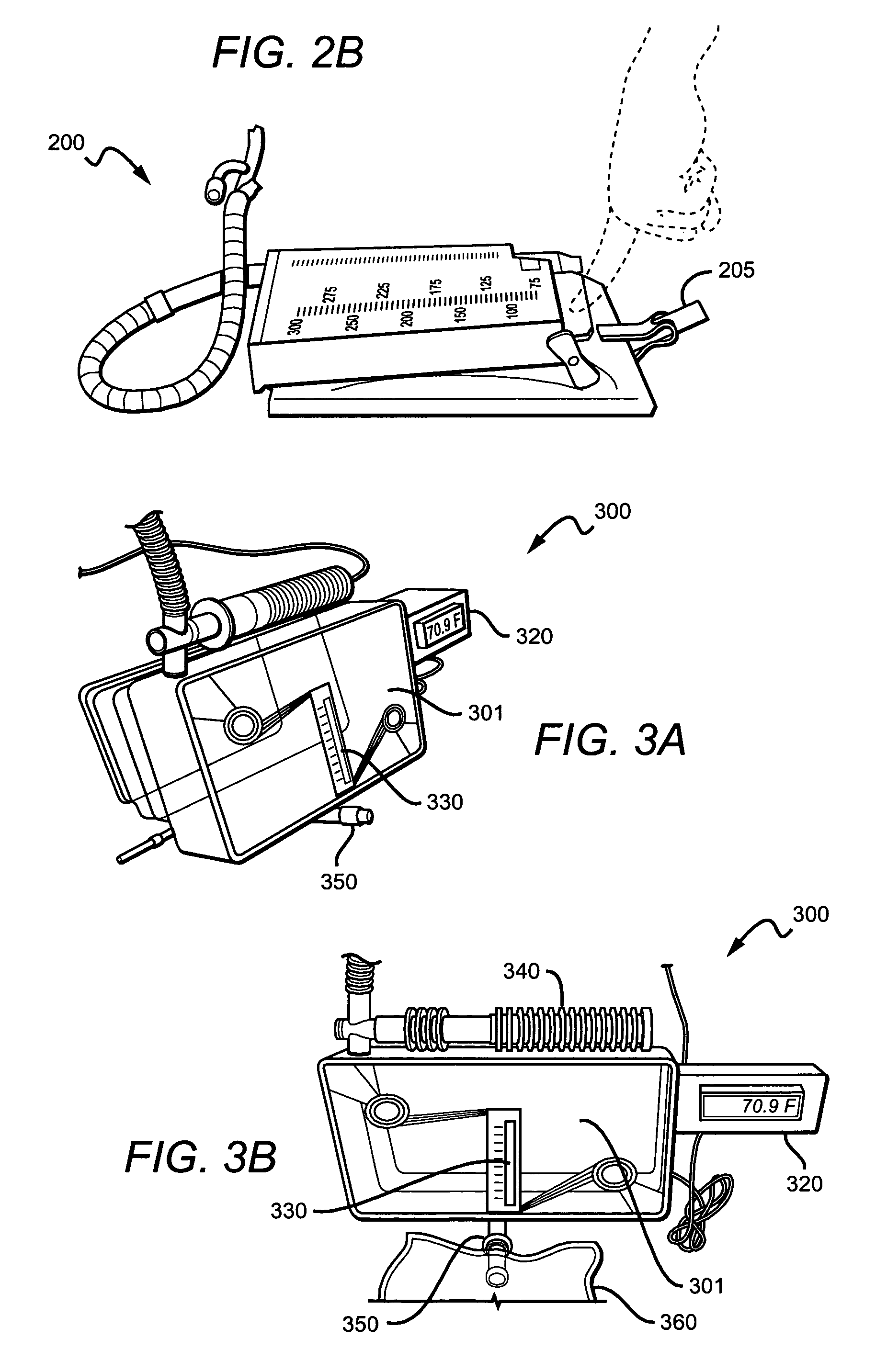

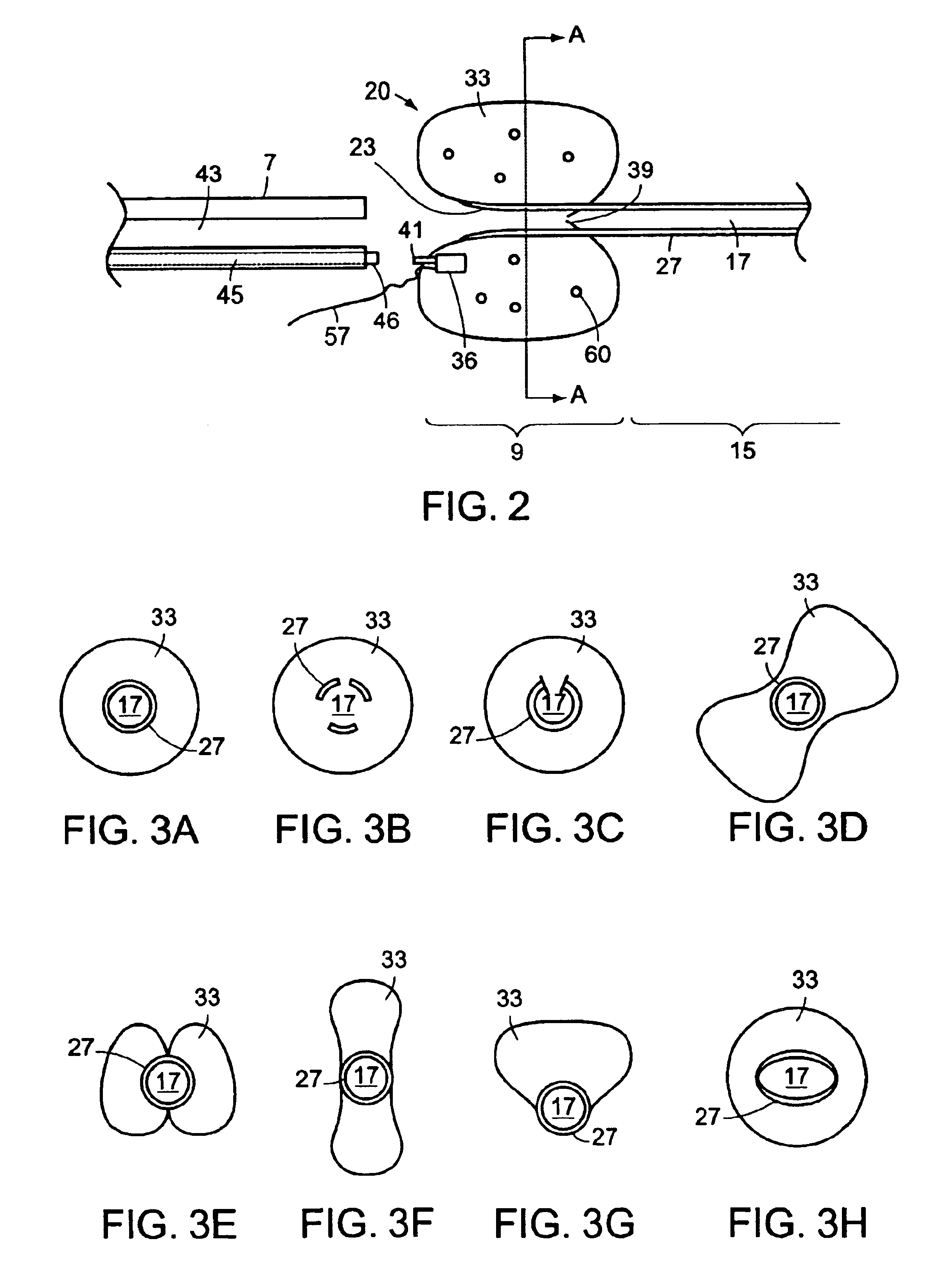

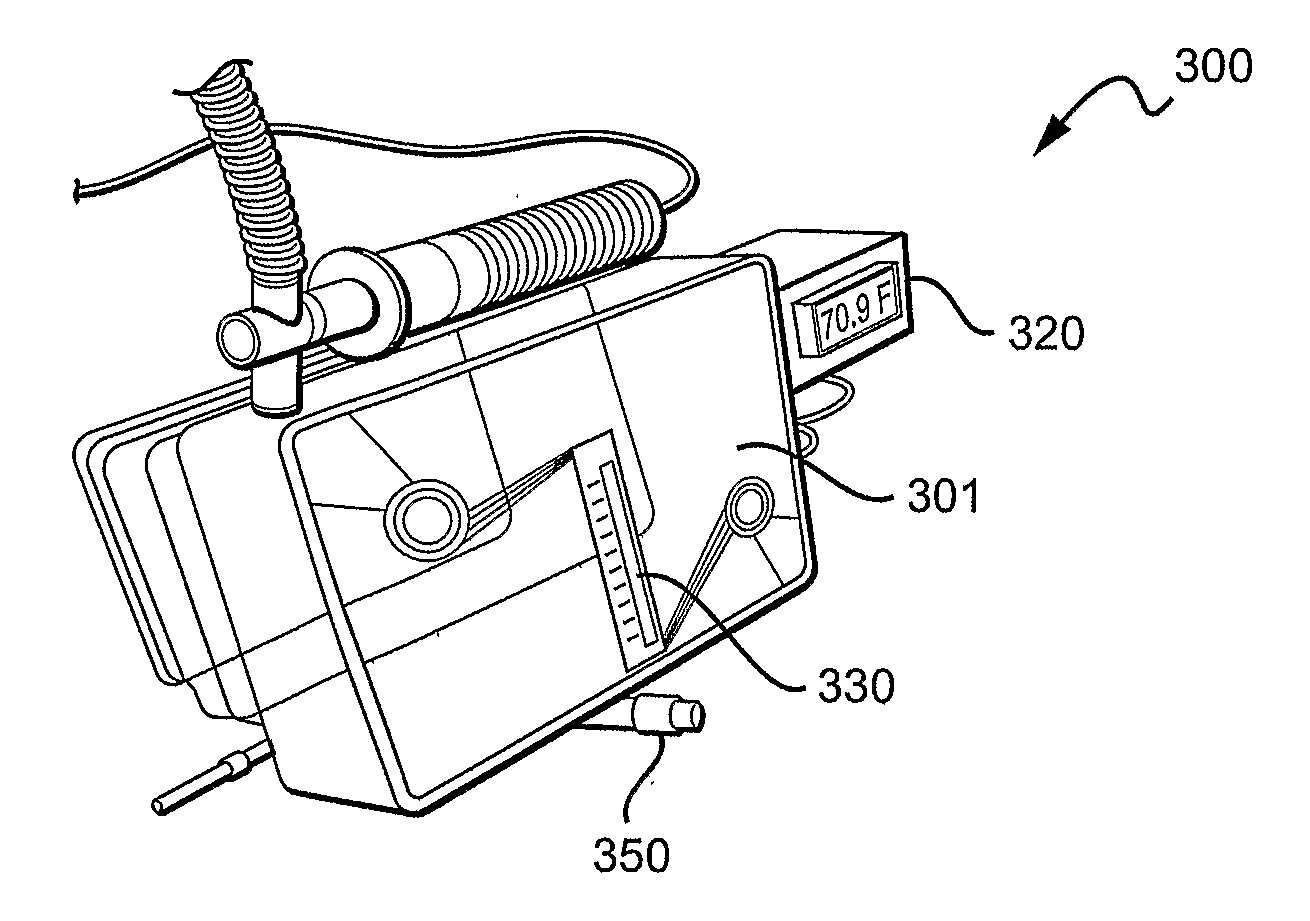

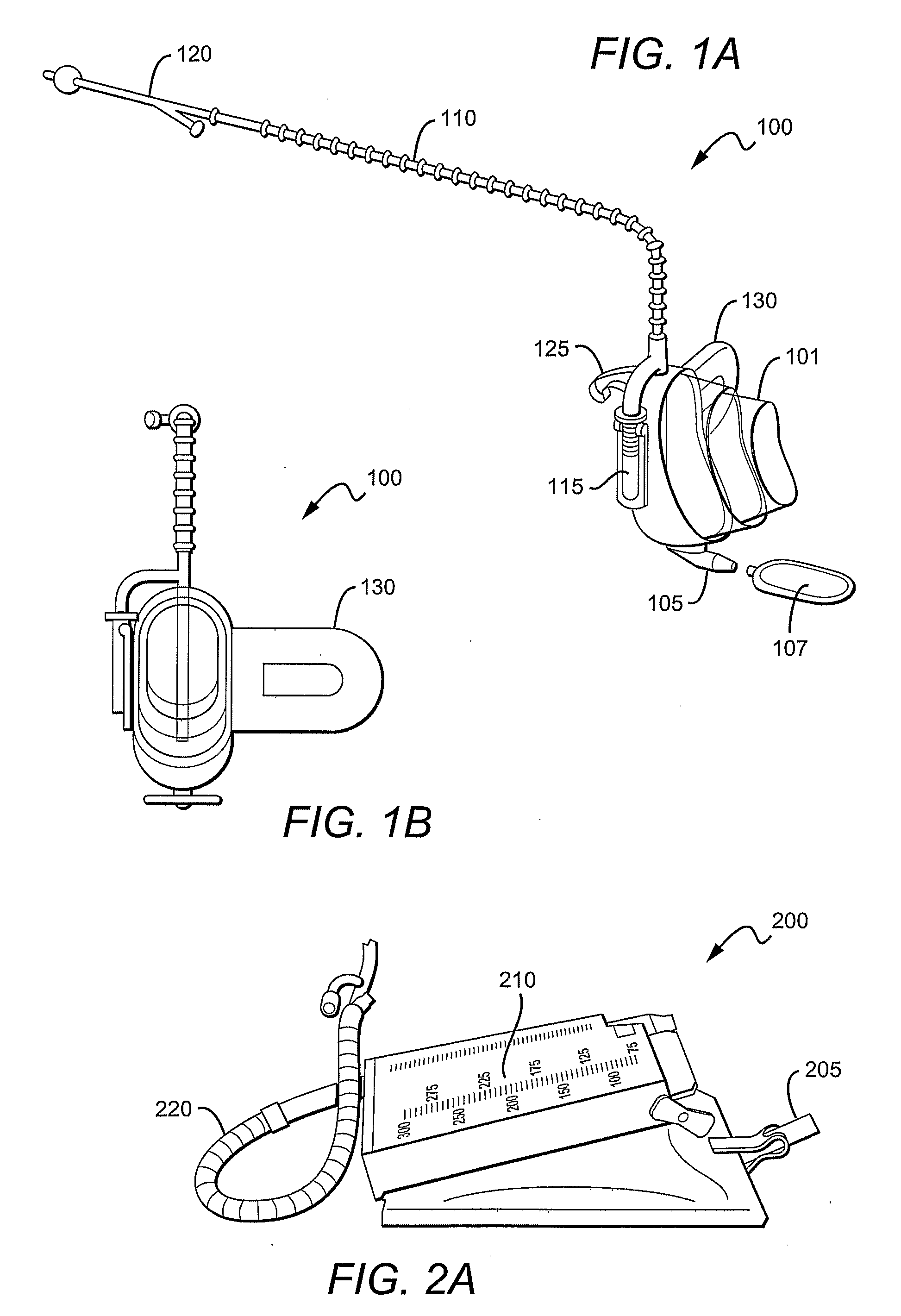

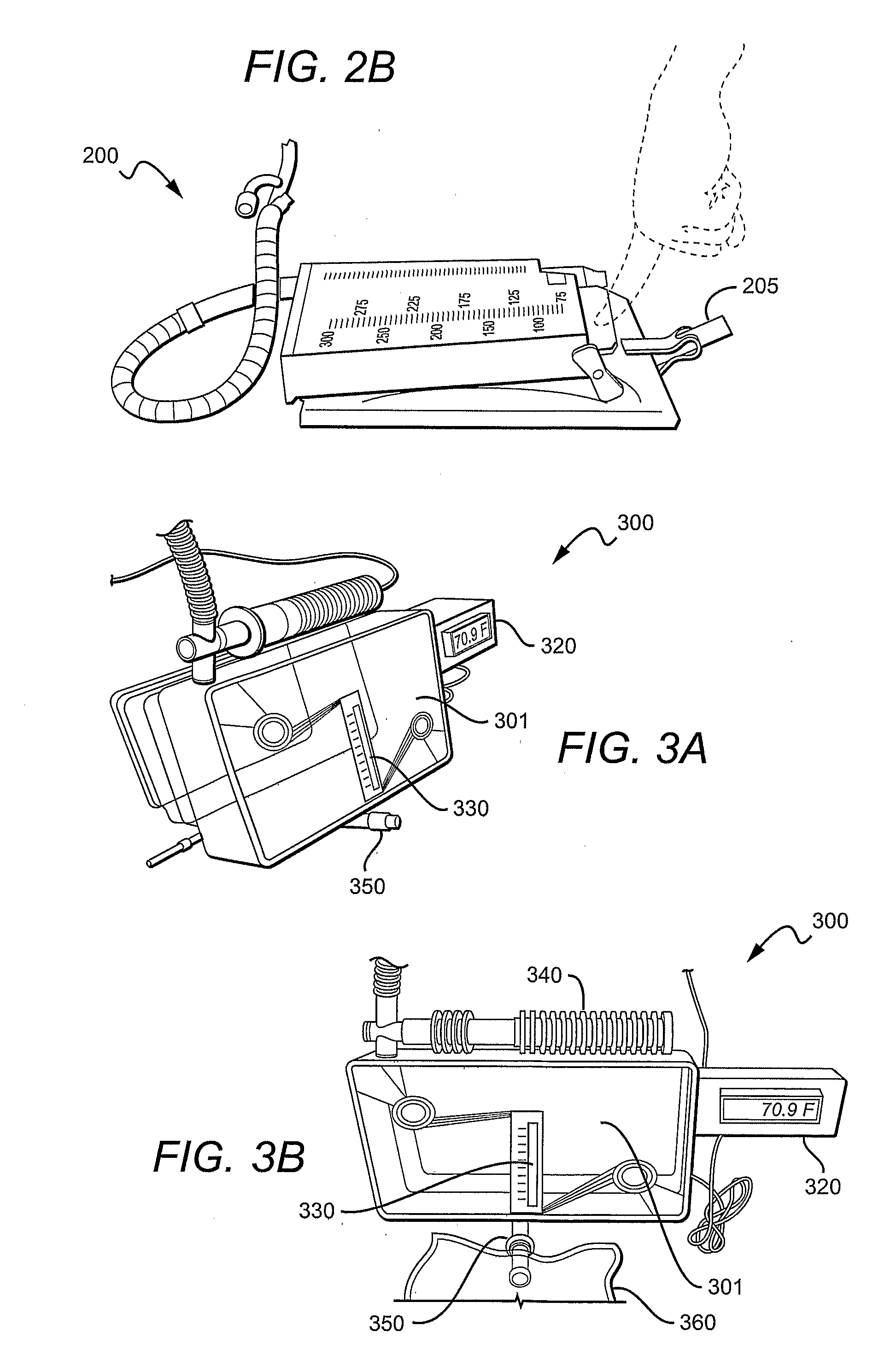

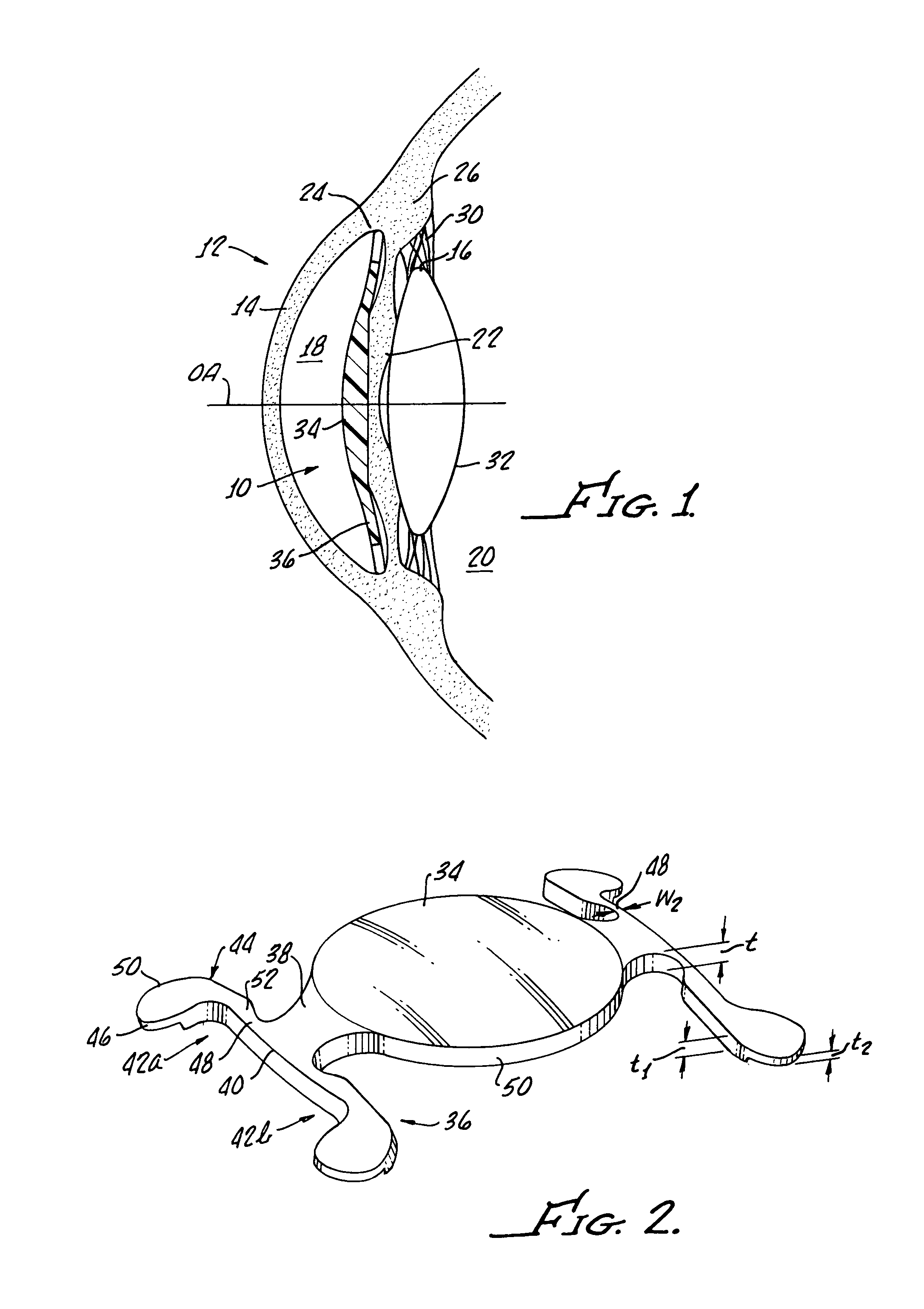

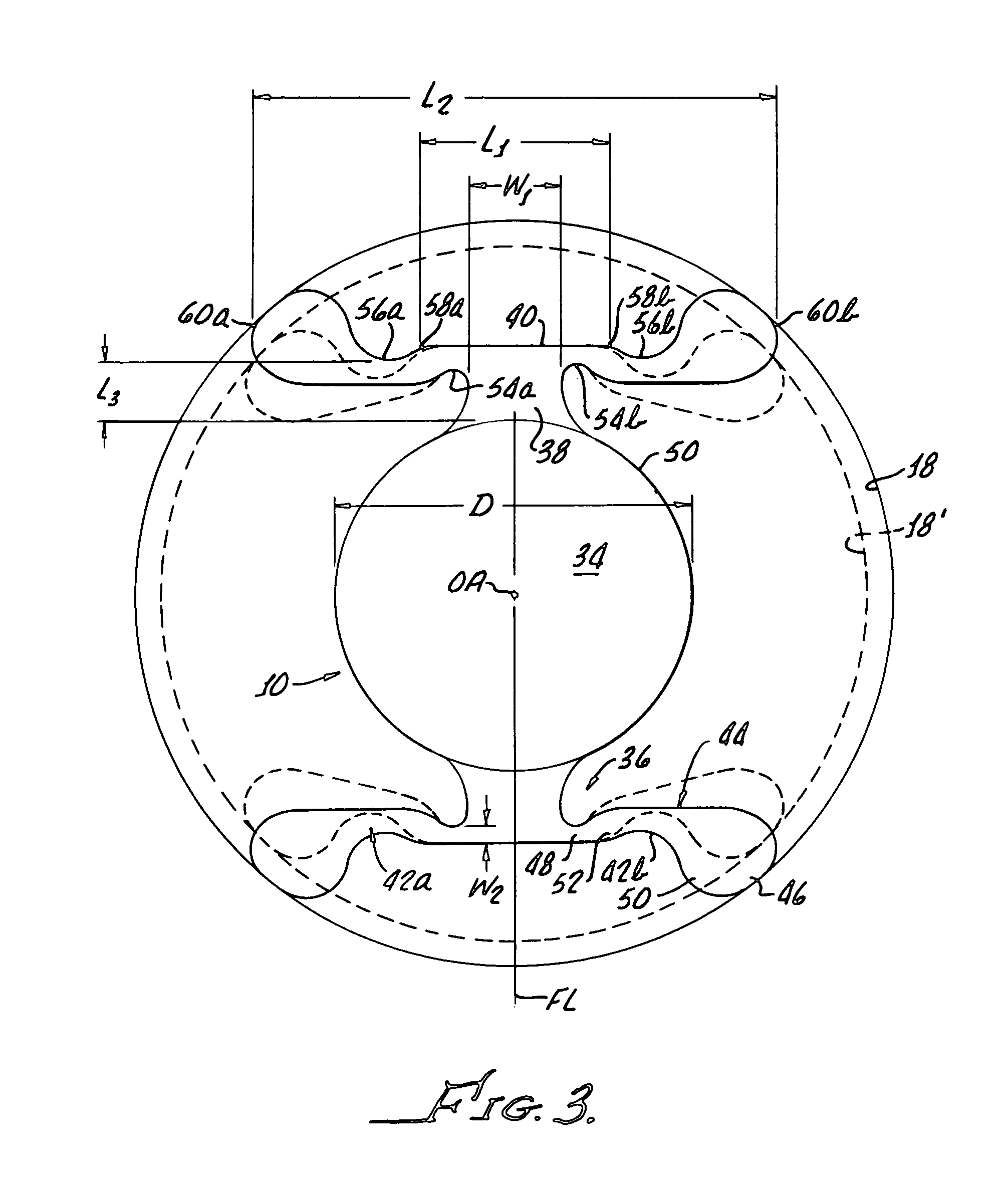

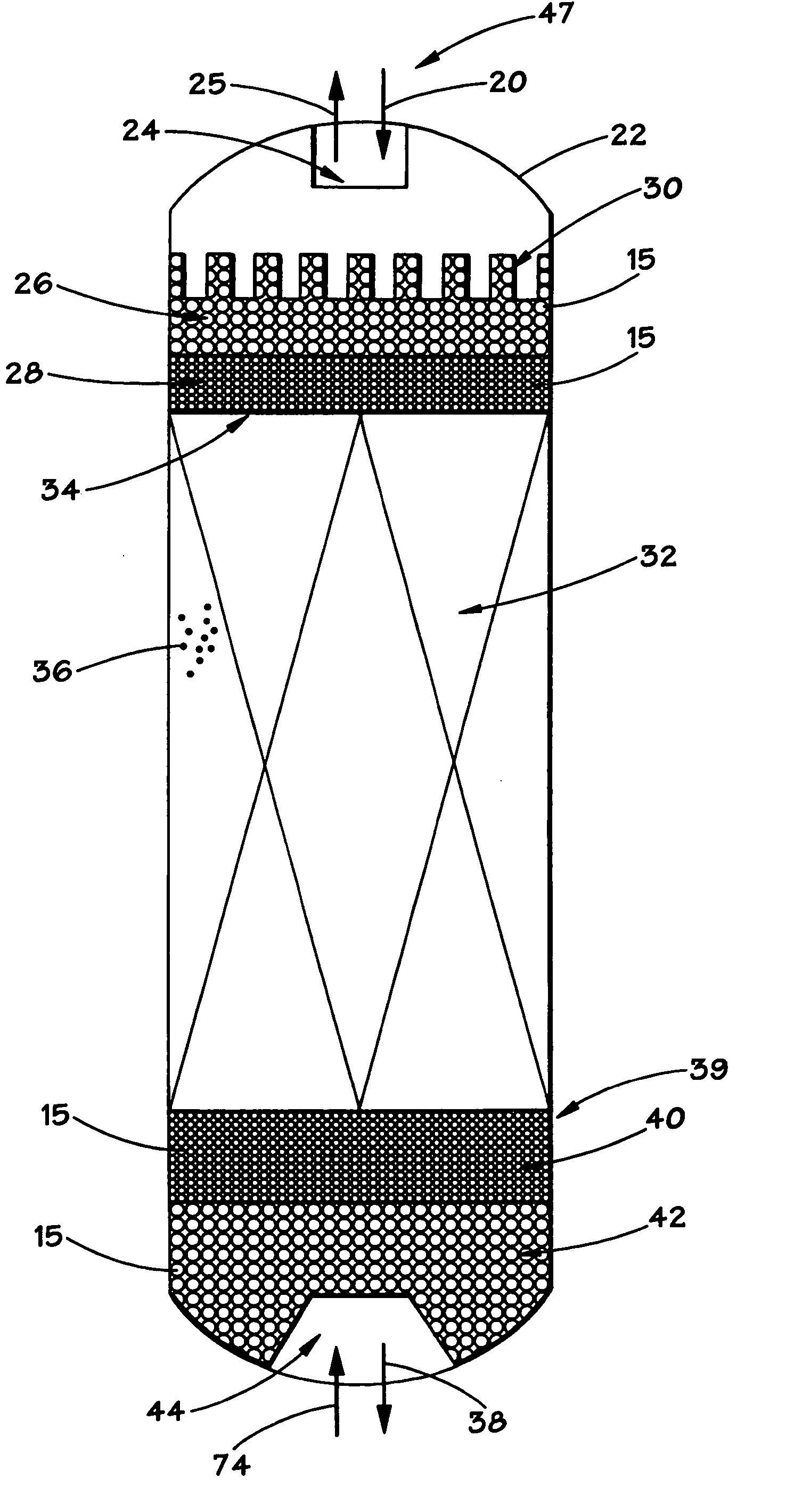

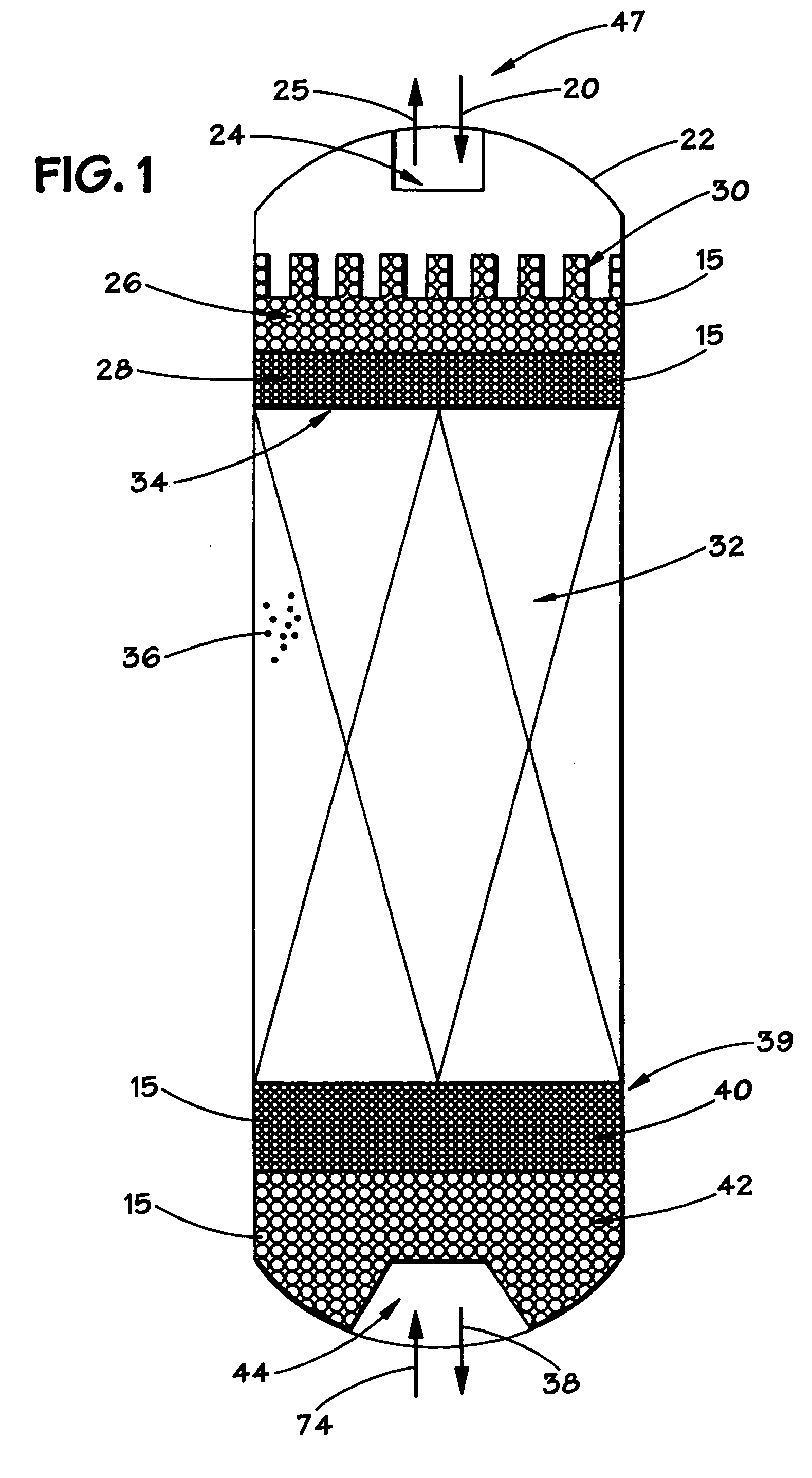

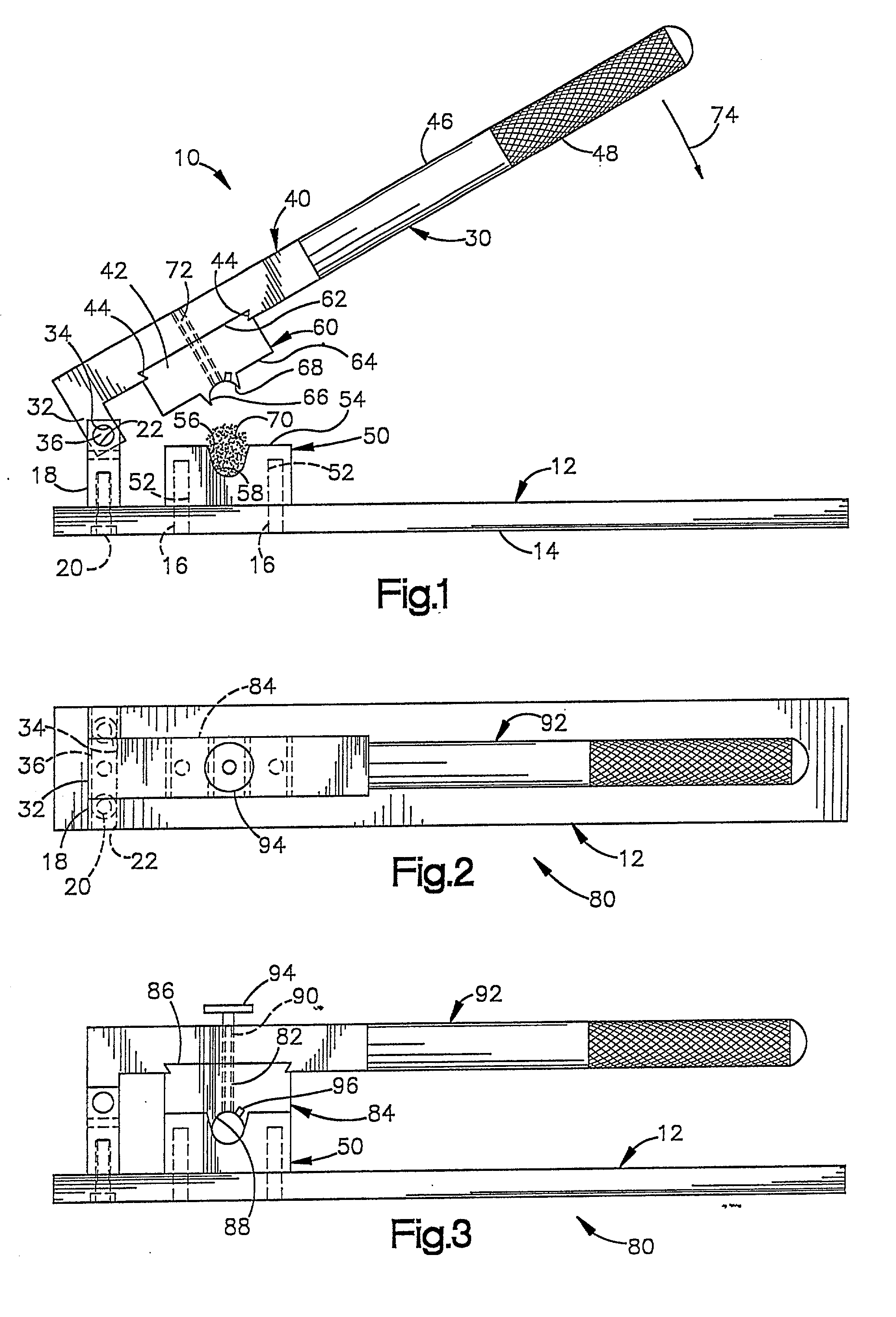

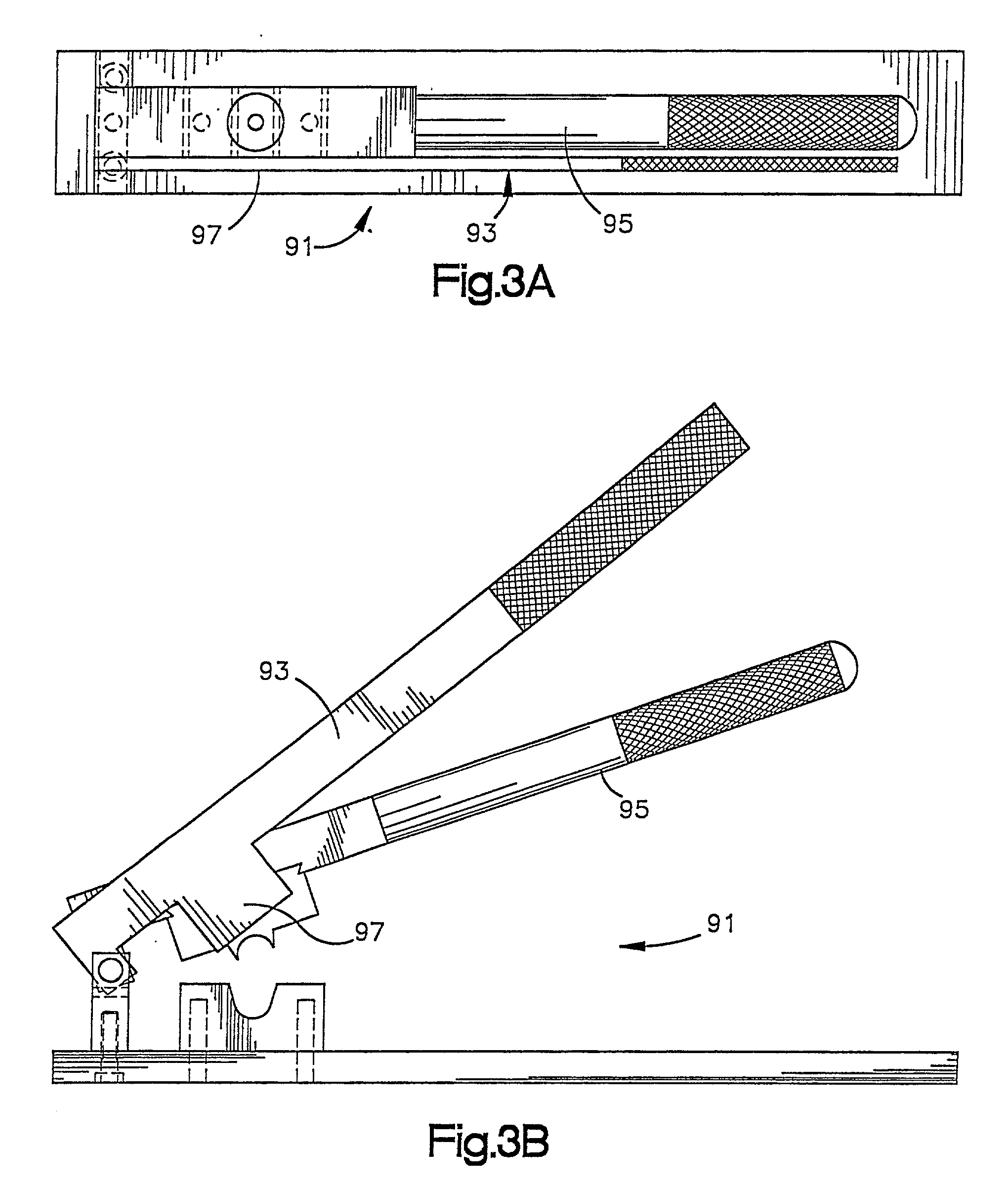

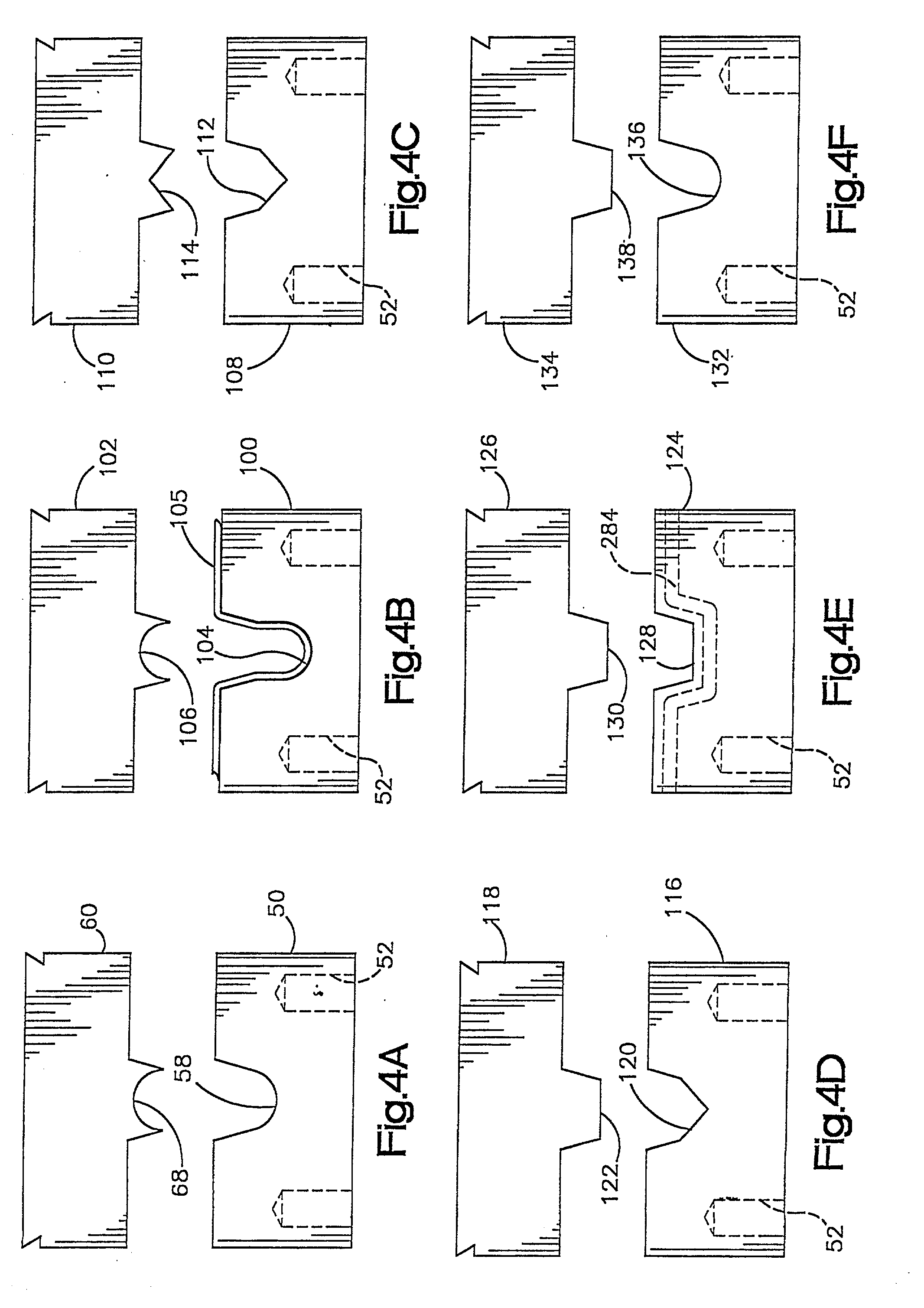

Tissue press and system

InactiveUS6132472AReduce retentionReduce capacitySuture equipmentsInternal osteosythesisTissue GraftEngineering

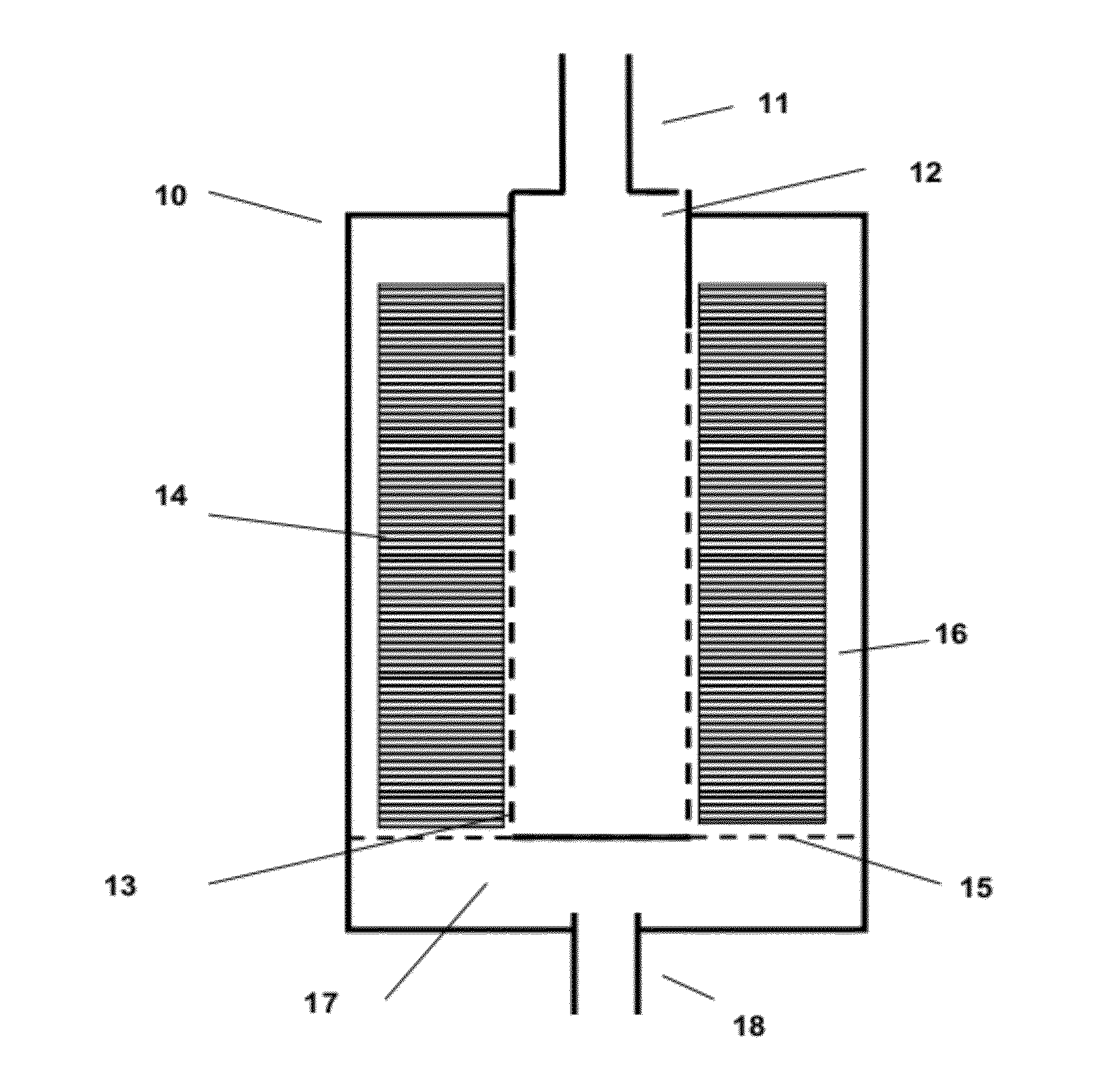

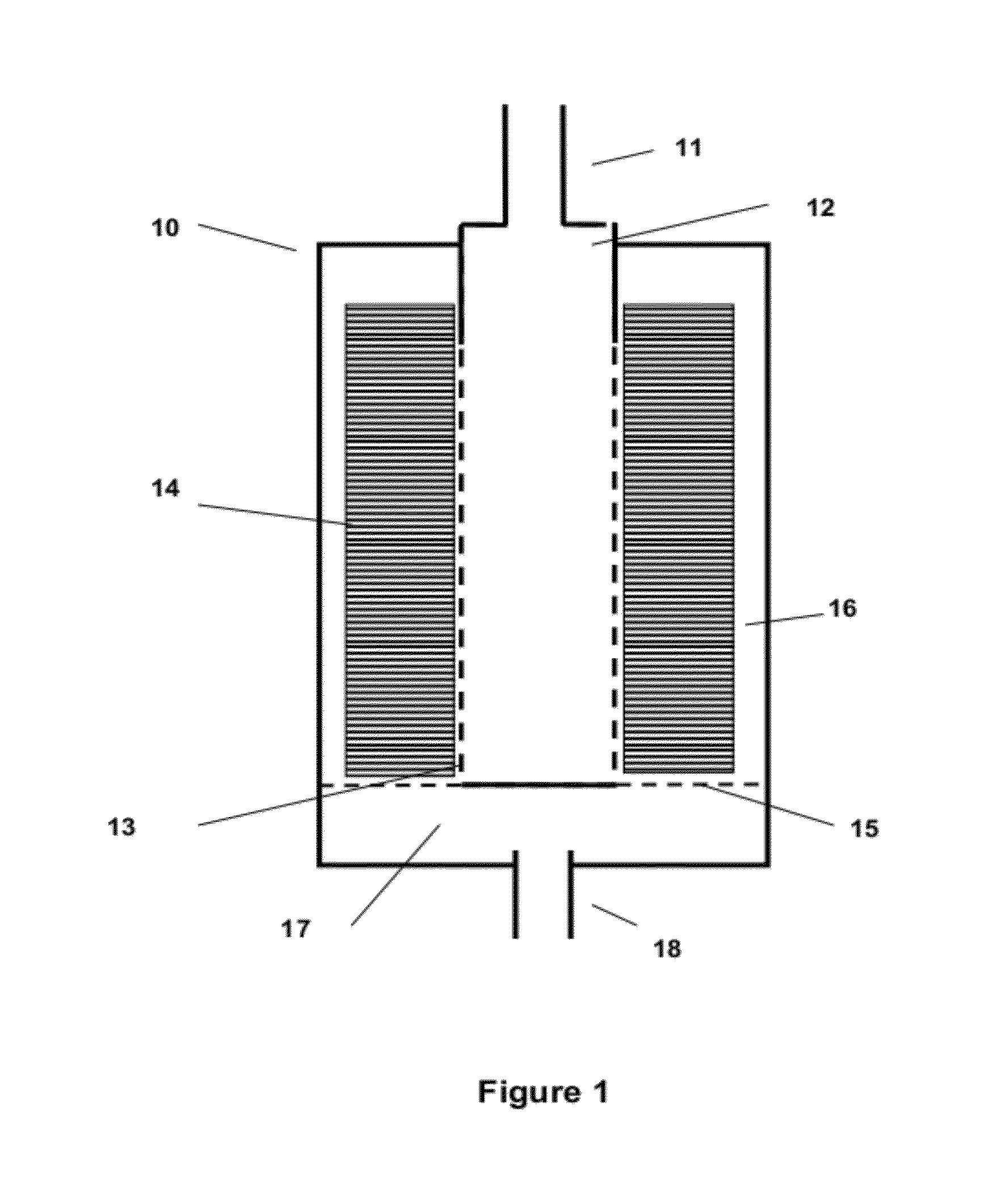

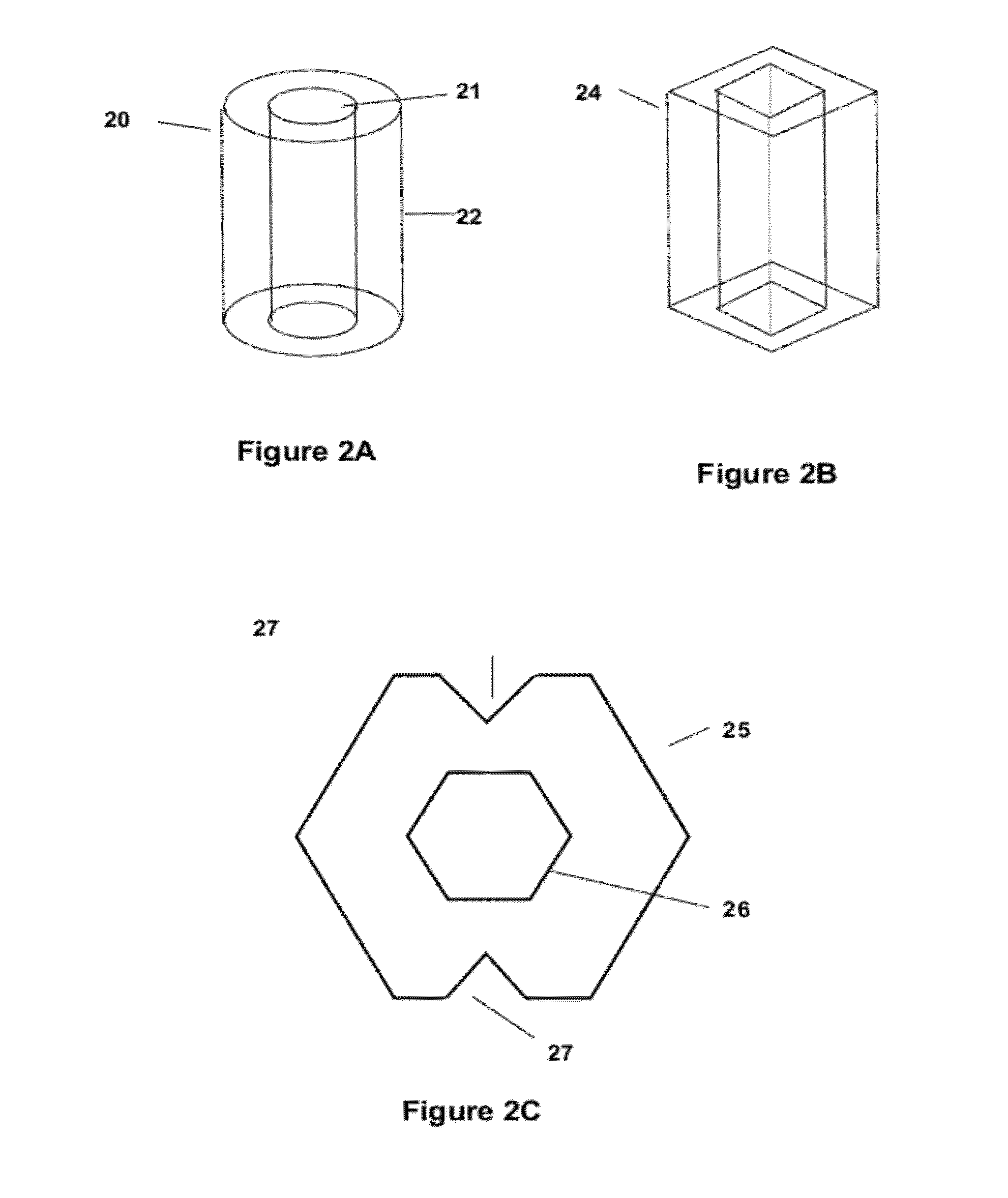

A tissue press and method for shaping or compressing a piece of tissue comprises first and second members movable relative to each other. A first forming element of a predetermined shape is selectively engageable on the first member. A second forming element of predetermined shape is selectively engageable on the second member. The first and second forming elements are positionable on opposite sides of the piece of tissue. The first and second members are relatively movable between a first spaced apart condition and a second condition in which the piece of tissue is held between the first and second forming elements. Means are preferably provided for monitoring and controlling the amount of pressure applied to the piece of tissue, in order to maintain the tissue in a viable living condition. Means may also be provided for draining off fluid from compressed tissue, so that the tissue can be implanted in a compressed state and imbibe fluid from the host site. A retainer, which may be expandable, can be used to maintain the tissue graft in a compressed condition.

Owner:BONUTTI 2003 TRUST A THE +1

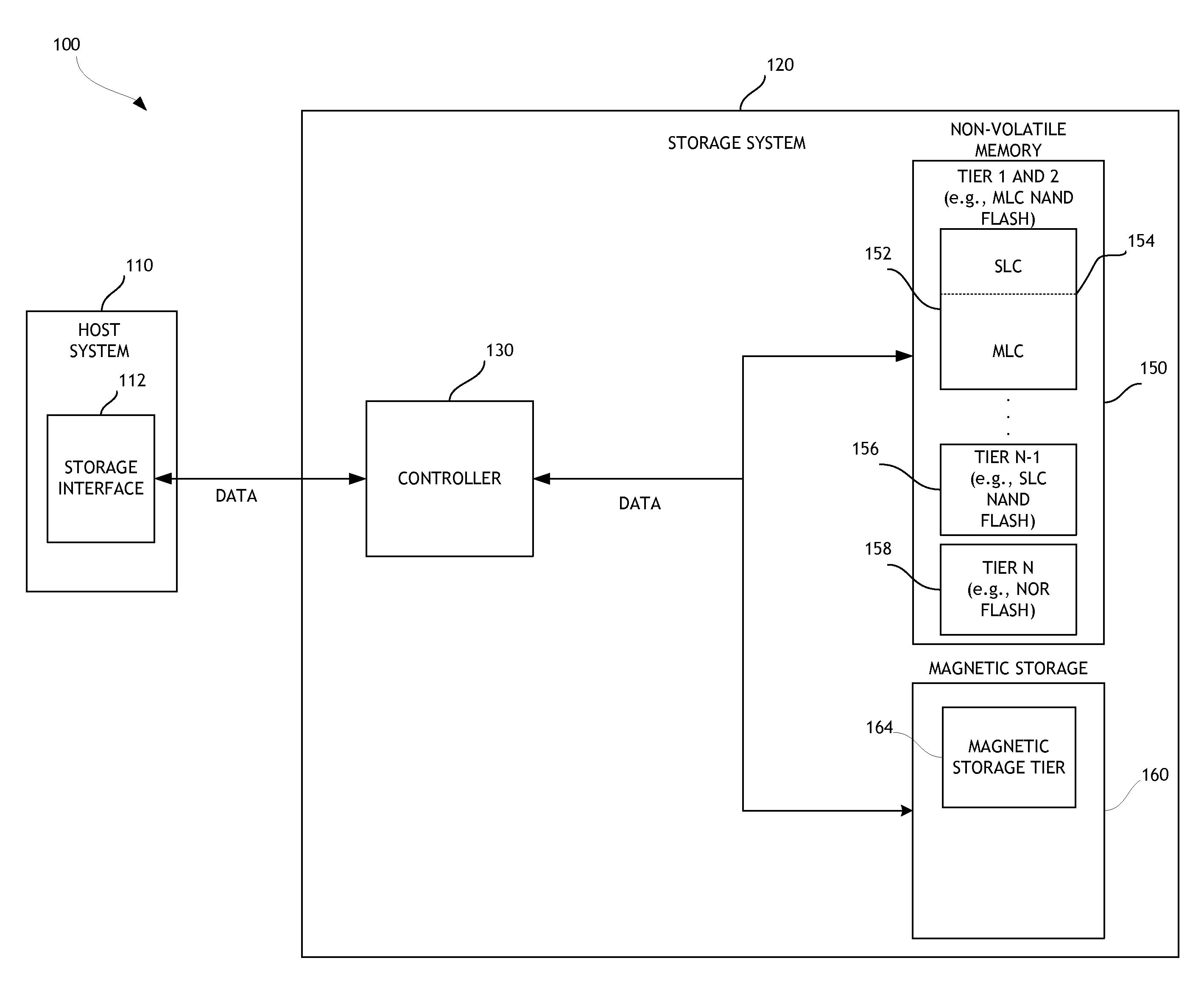

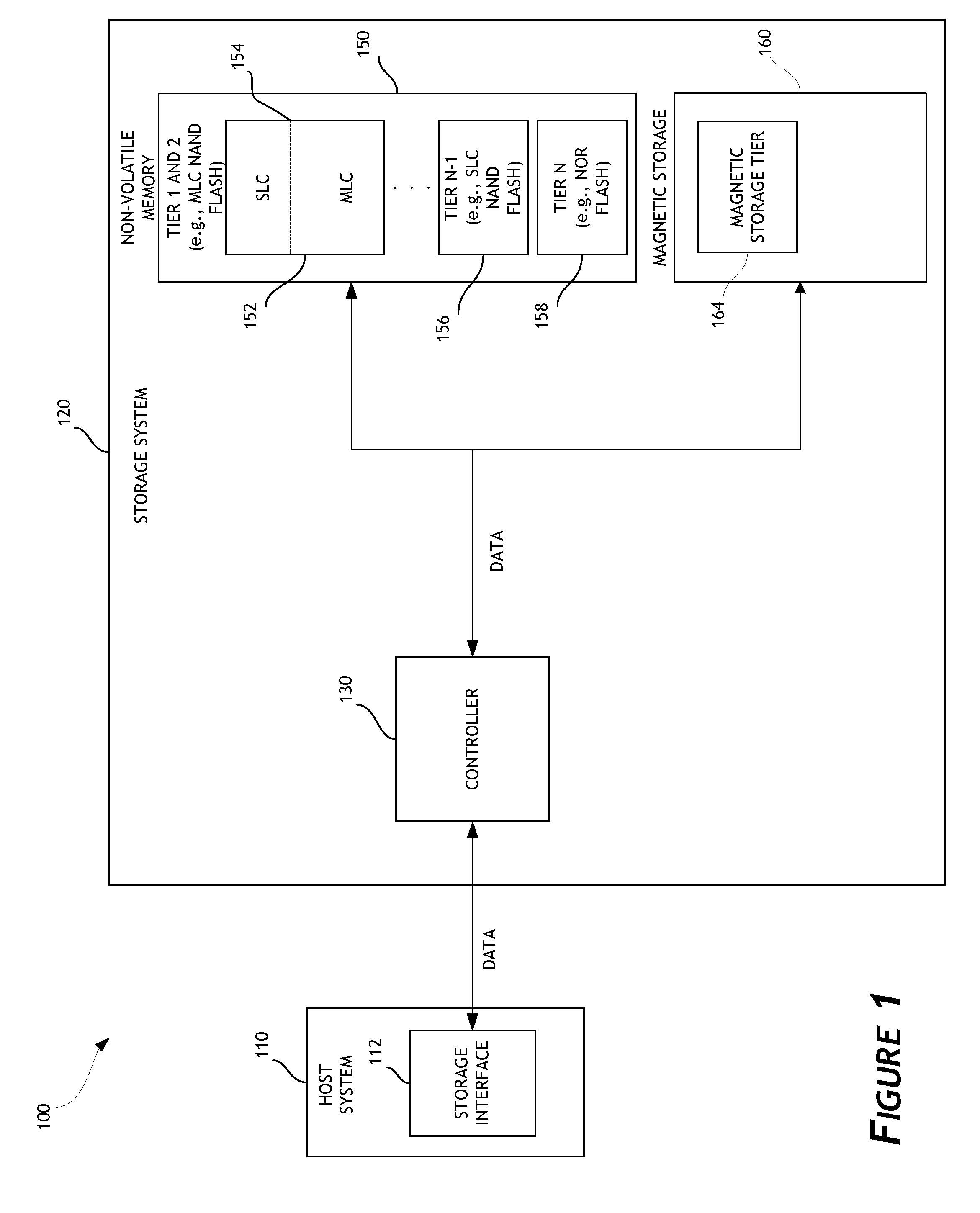

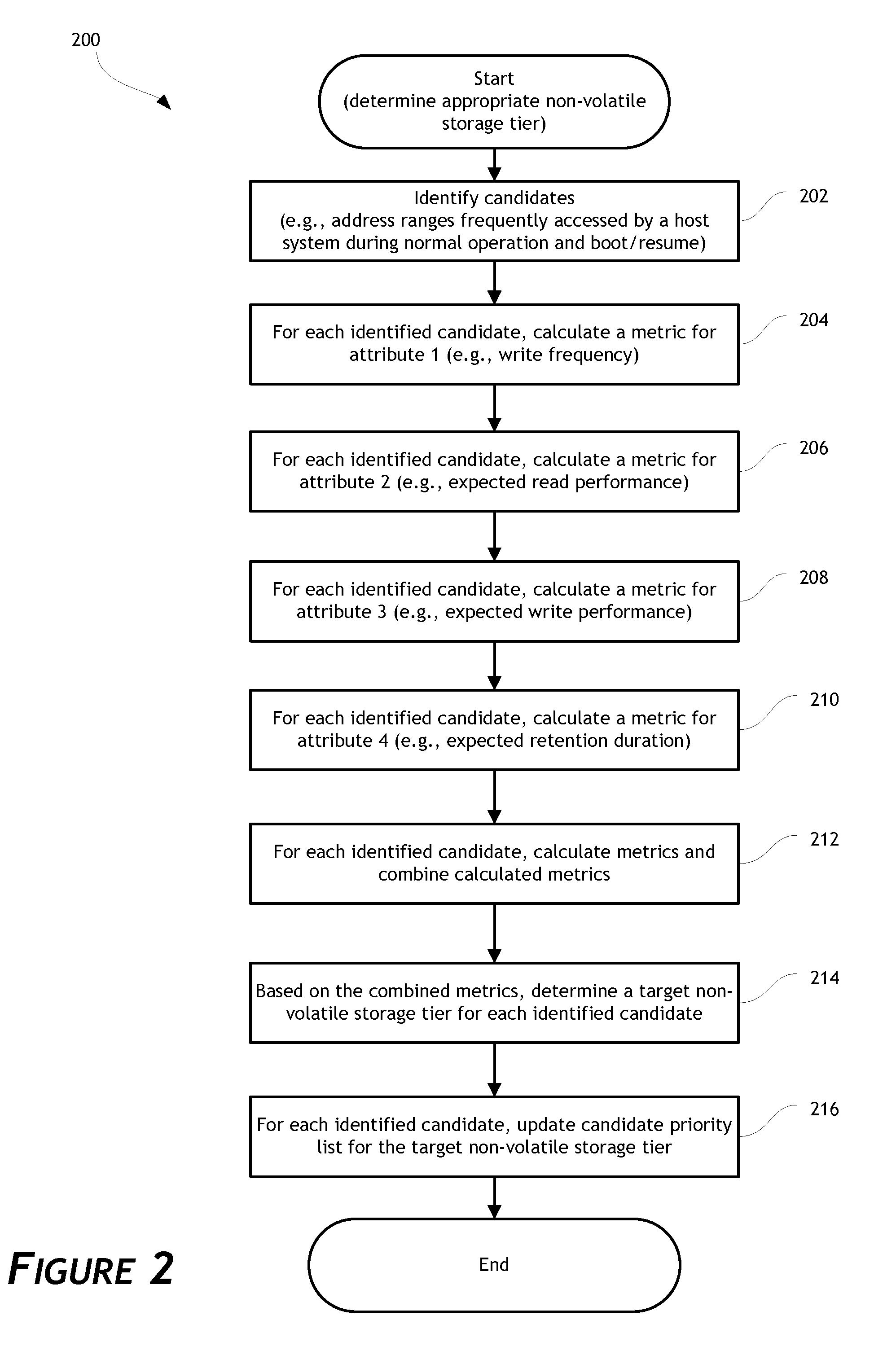

Disk drive data caching using a multi-tiered memory

ActiveUS20130132638A1Limit usable lifeReduce dataMemory architecture accessing/allocationEnergy efficient ICTSingle levelComputer science

A disk drive is disclosed that utilizes multi-tiered solid state memory for caching data received from a host. Data can be stored in a memory tier that can provide the required performance at a low cost. For example, multi-level cell (MLC) memory can be used to store data that is frequently read but infrequently written. As another example, single-level cell (SLC) memory can be used to store data that is frequently written. Improved performance, reduced costs, and improved power consumption can thereby be attained.

Owner:WESTERN DIGITAL TECH INC

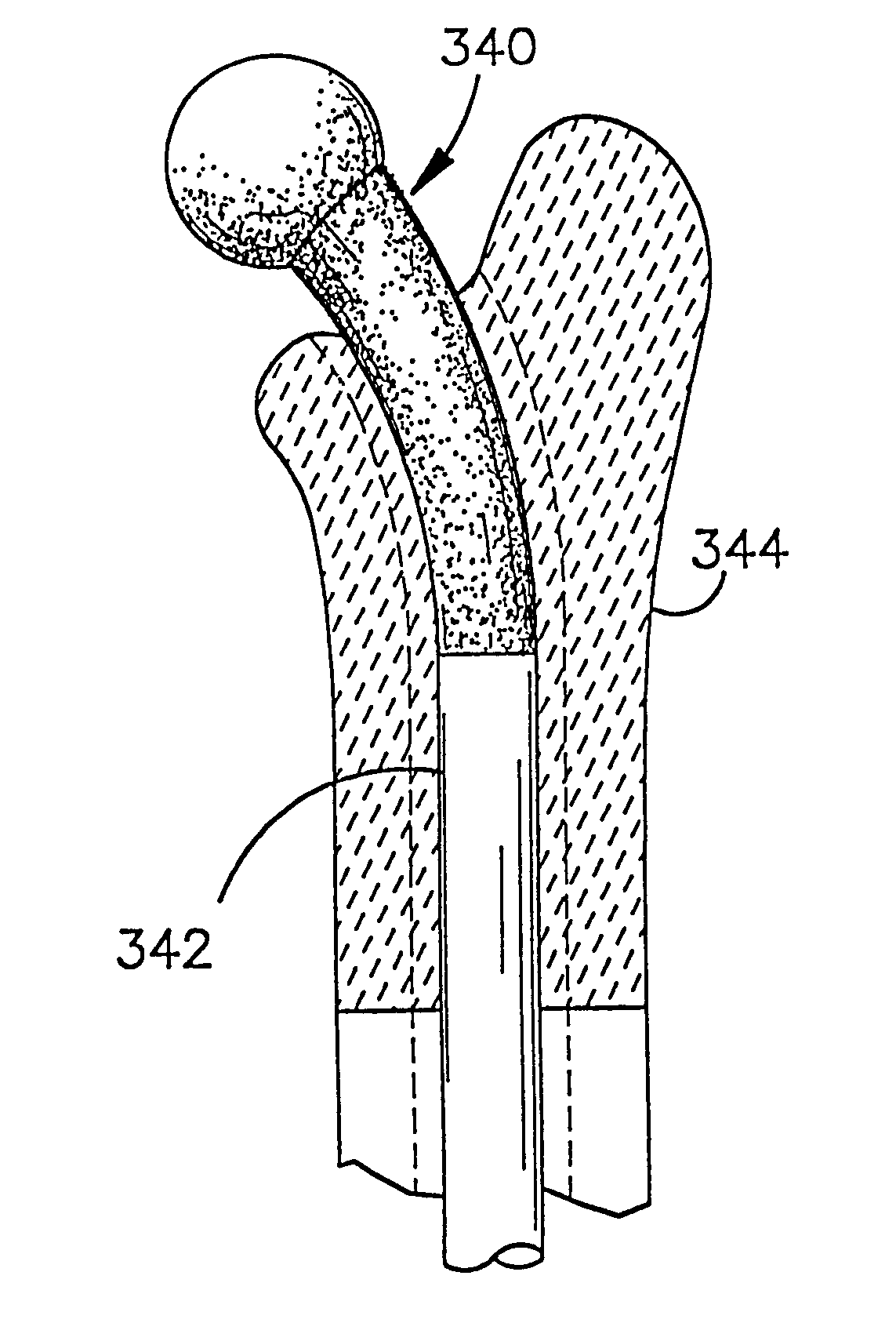

Expandable hip implant

InactiveUS6361565B1Reduce retentionReduce capacitySuture equipmentsInternal osteosythesisProsthesisBody fluid

An implant is formed of an expandable material. An opening is formed in a bone in a patient's body. At least a portion of the implant is positioned in the opening in the bone in the patient's body. The implant is retained against movement relative to the bone in the patient's body by absorbing body fluid with the implant and expanding the implant while the implant is disposed in the opening in the bone in the patient's body. The implant may be a hip replacement member.

Owner:BONUTTI 2003 TRUST A THE +1

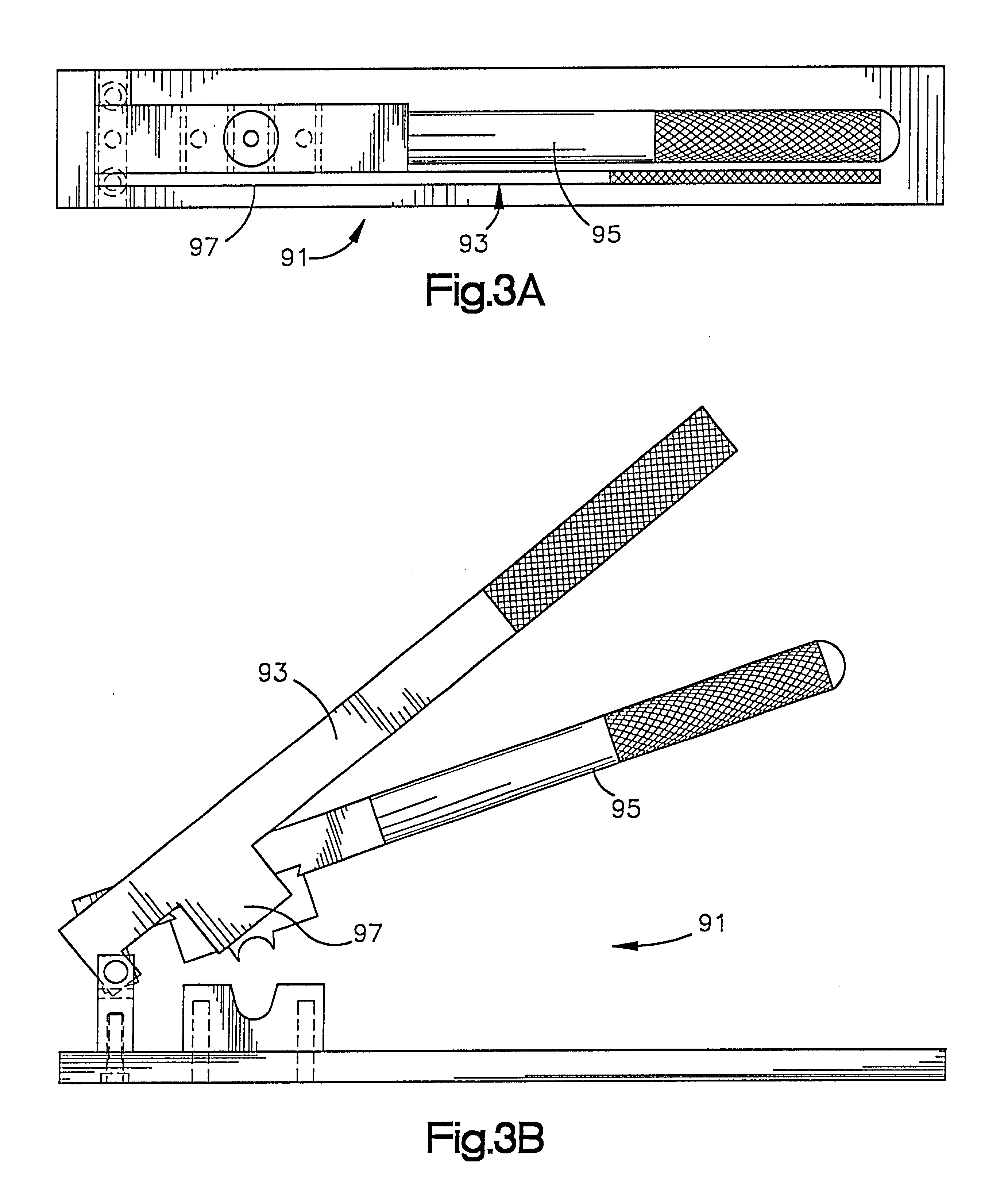

Multi-functional and modular urine collection system

ActiveUS7931630B2Reduce retentionImprove wettabilityWound drainsMedical devicesCollection systemUrine collection device

Multi-functional urine collection devices, embodiments of which can include a self-expanding container having a receptacle for receiving urine from the tubing, a pump for moving urine through the tubing and into a receptacle, extendable tubing that may be shortened and / or lengthened, and / or one or more meters for monitoring, measuring, transmitting or storing a characteristic from the urine.

Owner:CR BARD INC

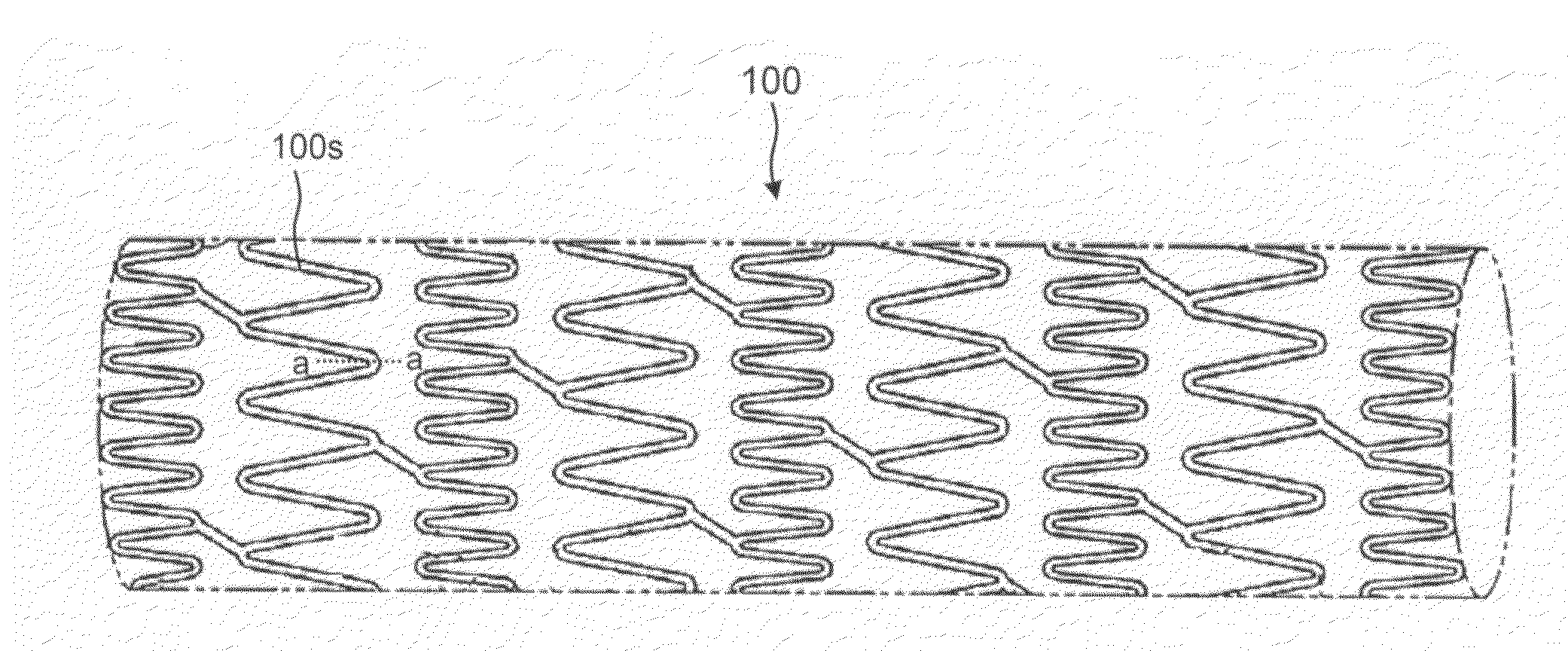

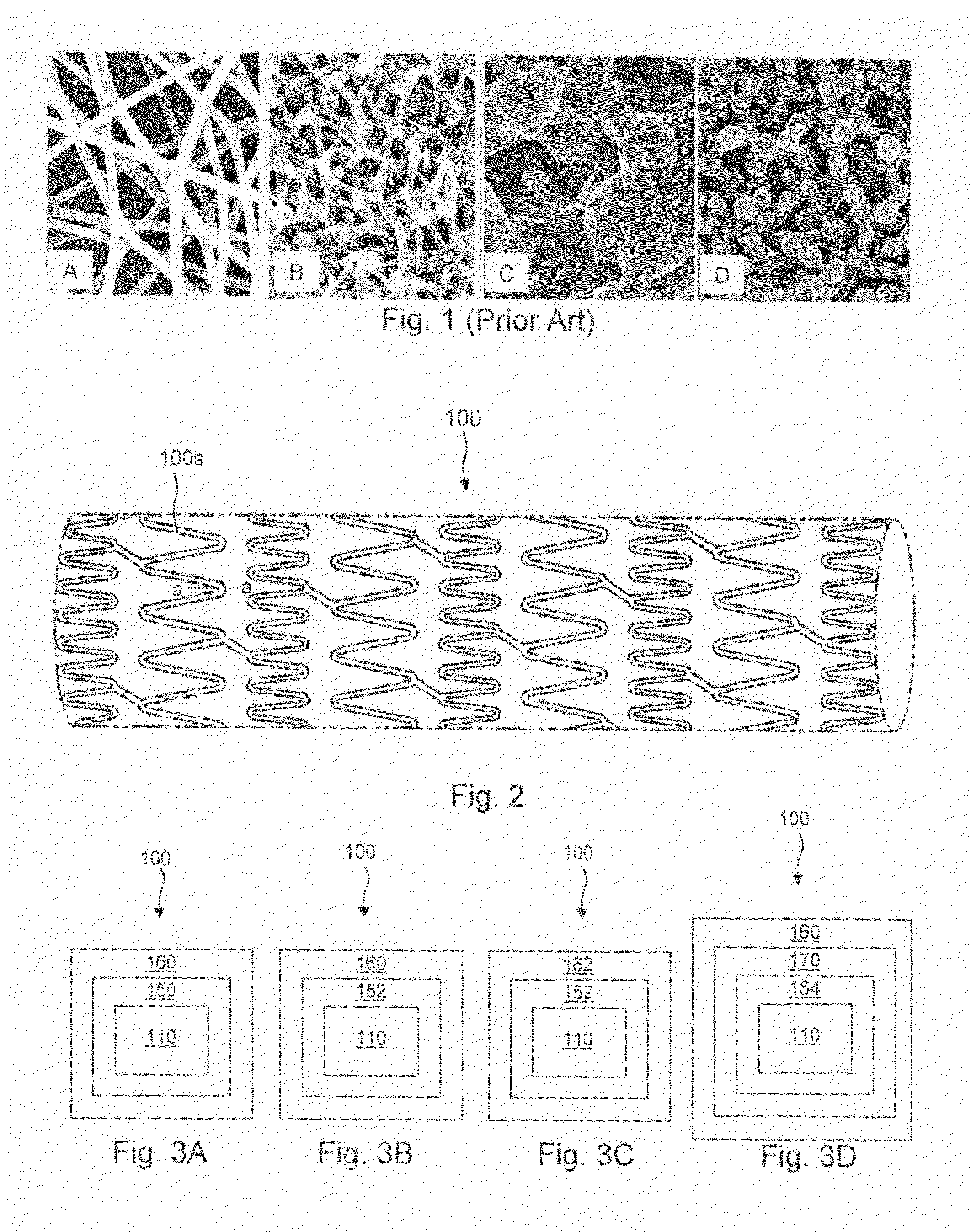

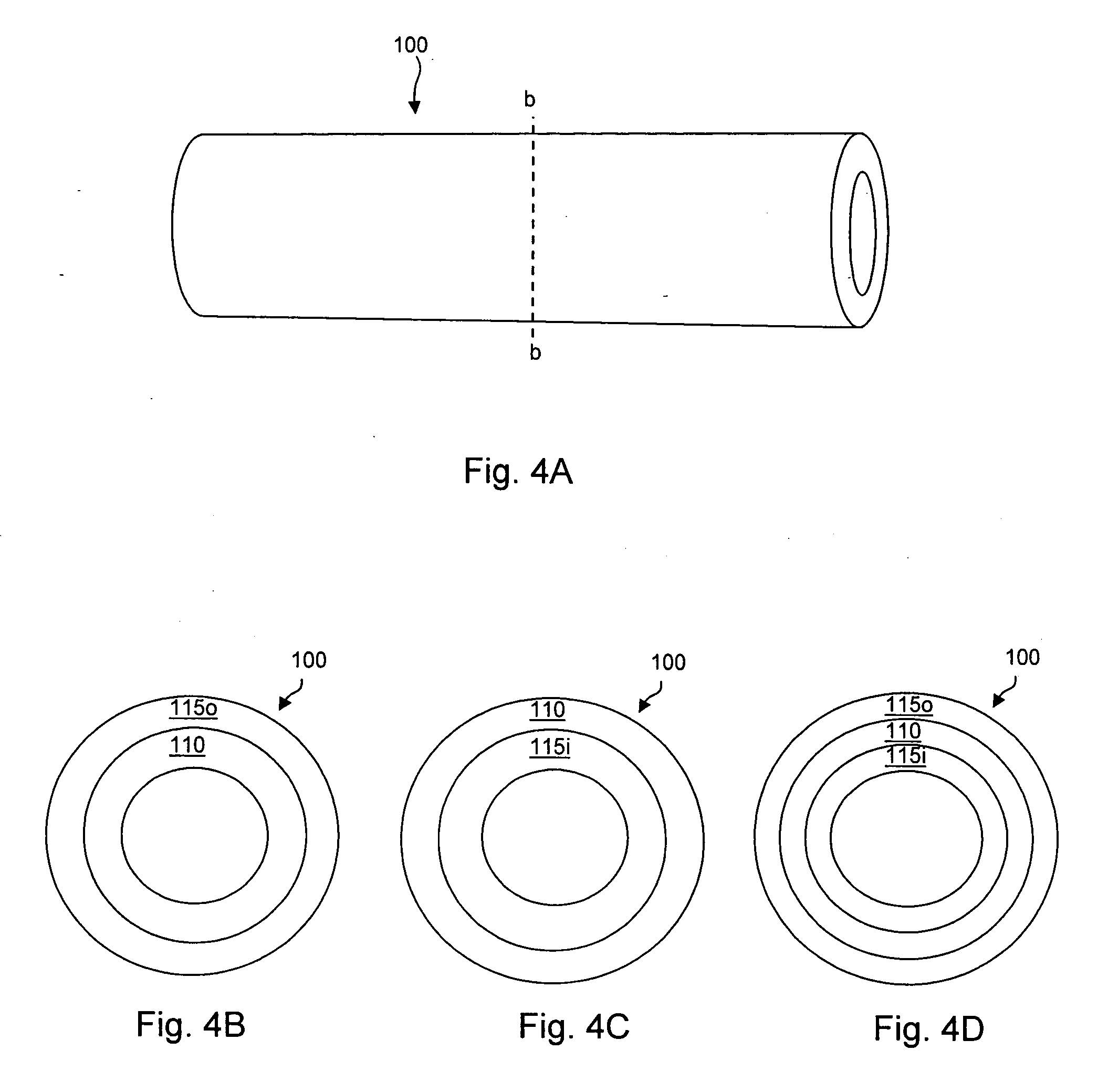

Medical devices comprising porous layers for the release of therapeutic agents

InactiveUS20080051881A1Reduce retentionImprove cell adhesionSuture equipmentsStentsMedical deviceBiomedical engineering

In accordance with an aspect of the invention, implantable or insertable medical devices are provided in which a porous layer is disposed over a therapeutic-agent-containing region. In accordance with another aspect of the invention, medical devices are fabricated by a method in which a porous layer is deposited over a therapeutic-agent-containing region using a field-injection-based electrospray technique.

Owner:BOSTON SCI SCIMED INC

Reservoir barrier layer systems and methods

ActiveUS20090259183A1Reduce retentionAmpoule syringesSynthetic resin layered productsCyclic olefin copolymerBiomedical engineering

A reservoir and a plunger head contained within may be configured to move relative to each other in response to at least one of the reservoir being detached from a base, the base and / or the reservoir being removed from a packaging, and the base and / or the reservoir being moved relative to each other. A first layer may be configured to define a reservoir, the first layer, which may be made of a material compatible with fluidic media in the reservoir, may be adjacent a second layer for inhibiting a diffusion through the second layer. A first layer that may be less than 0.3 mm and made of a cyclic olefin copolymer may be configured to define a reservoir. A reservoir may be defined by a wall made of a cyclic olefin copolymer and the wall may be for substantially preventing light from passing through the reservoir.

Owner:MEDTRONIC MIMIMED INC

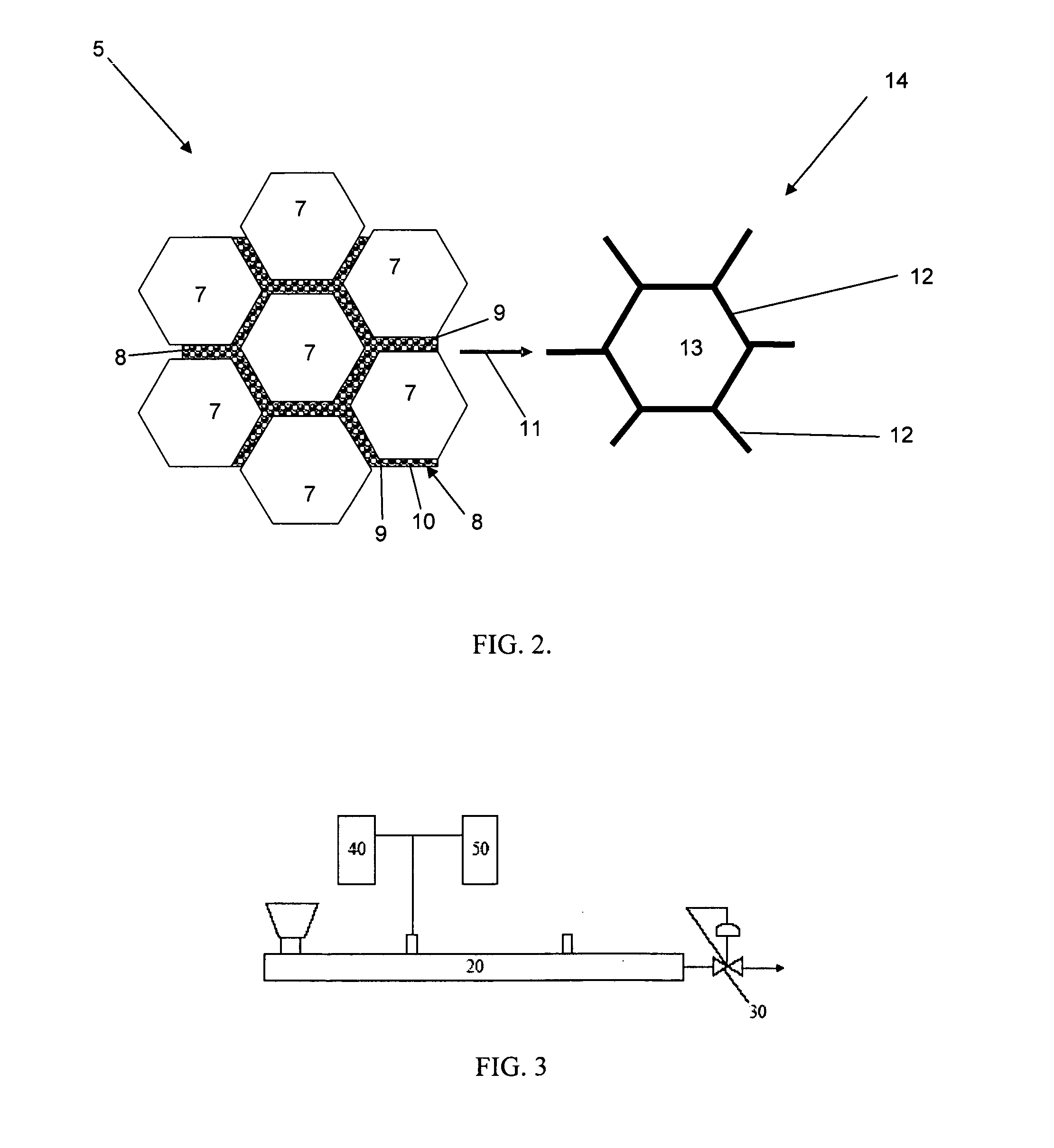

Gas Purification Process Utilizing Engineered Small Particle Adsorbents

ActiveUS20120222555A1Great diffusion rateLower Level RequirementsCarbon compoundsSulfur compoundsParticulatesSorbent

A gas separation process uses a structured particulate bed of adsorbent coated shapes / particles laid down in the bed in an ordered manner to simulate a monolith by providing longitudinally extensive gas passages by which the gas mixture to be separated can access the adsorbent material along the length of the particles. The particles can be laid down either directly in the bed or in locally structured packages / bundles which themselves are similarly oriented such that the bed particles behave similarly to a monolith but without at least some disadvantages. The adsorbent particles can be formed with a solid, non-porous core with the adsorbent formed as a thin, adherent coating on the exposed exterior surface. Particles may be formed as cylinders / hollow shapes to provide ready access to the adsorbent. The separation may be operated as a kinetic or equilibrium controlled process.

Owner:EXXON RES & ENG CO

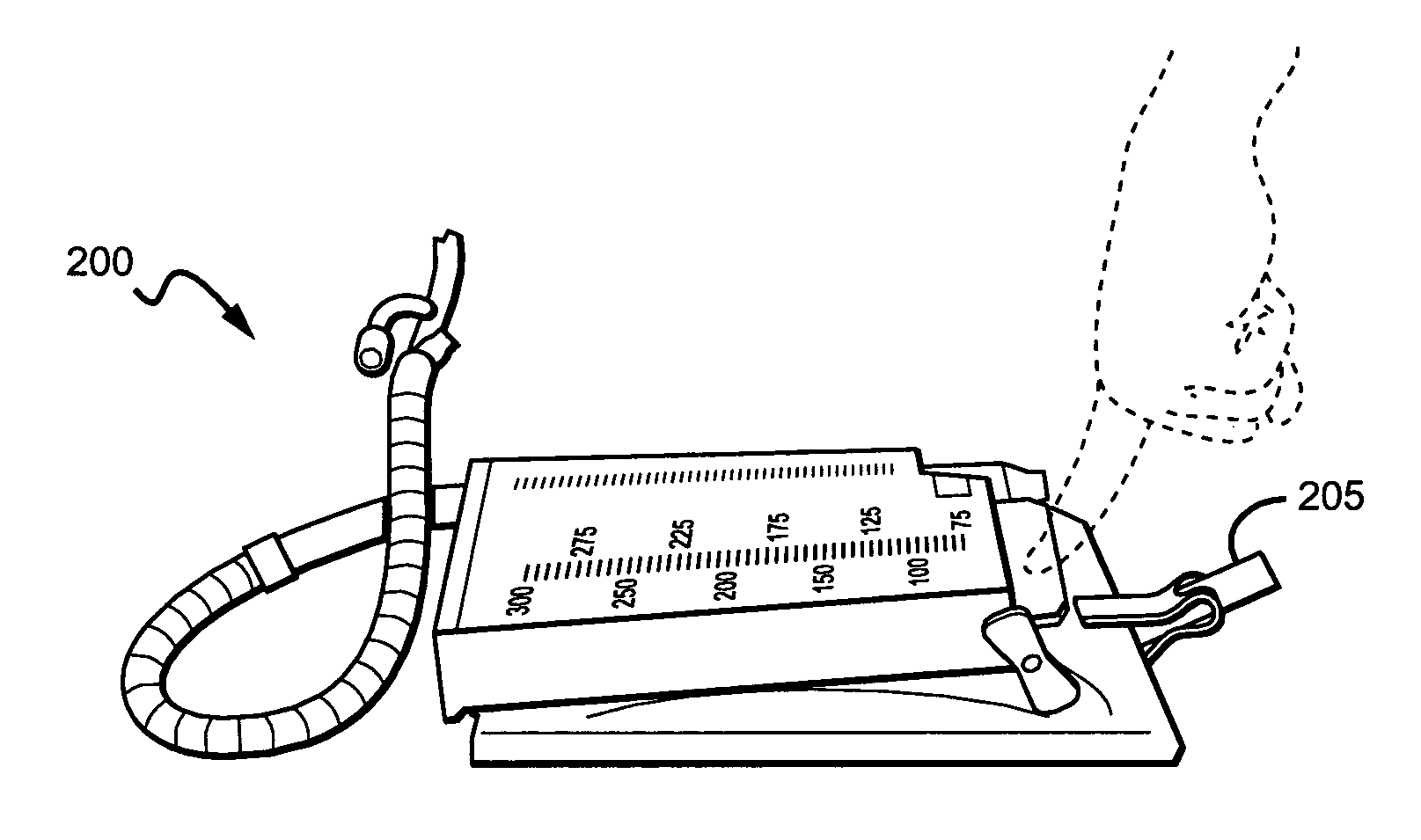

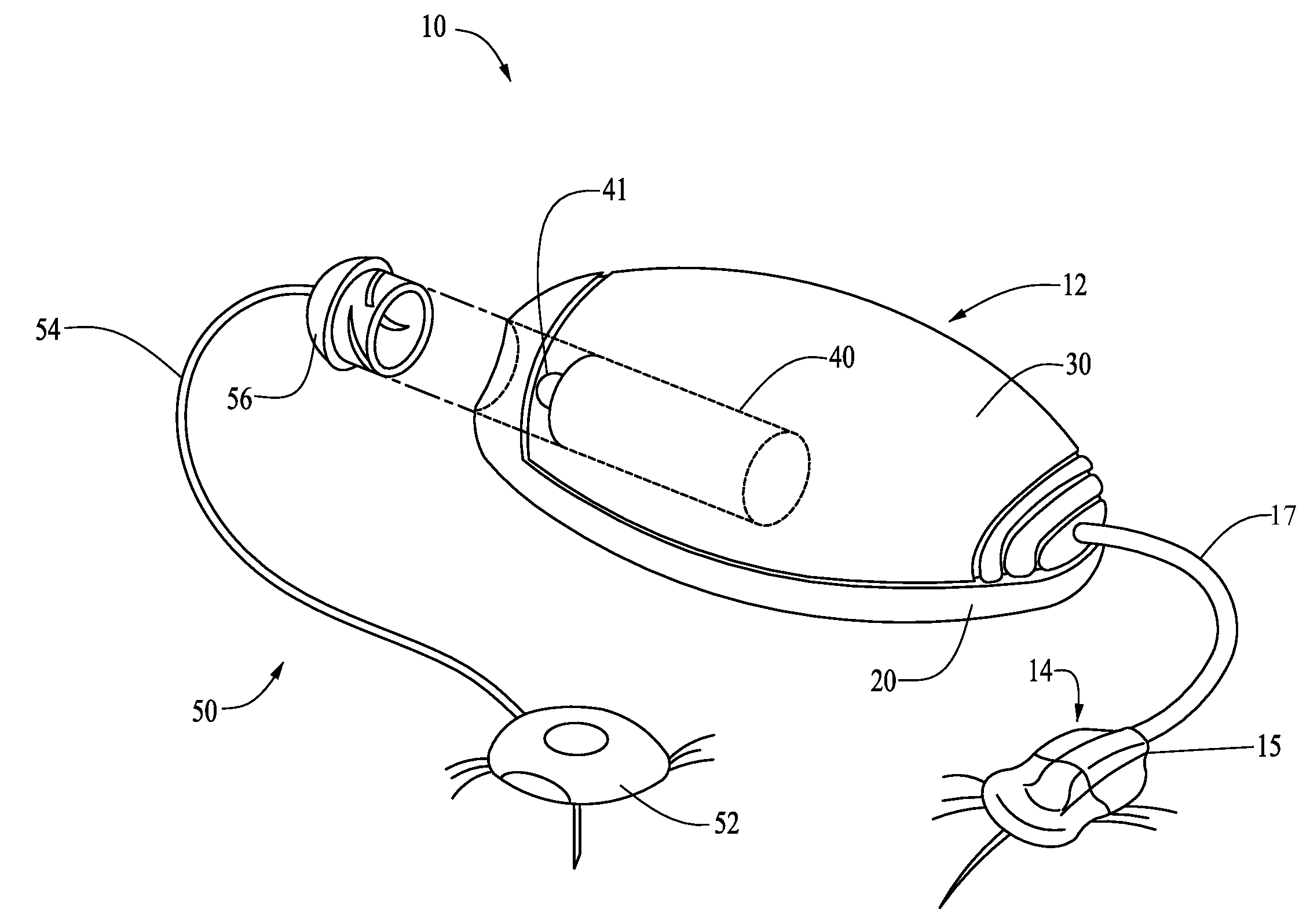

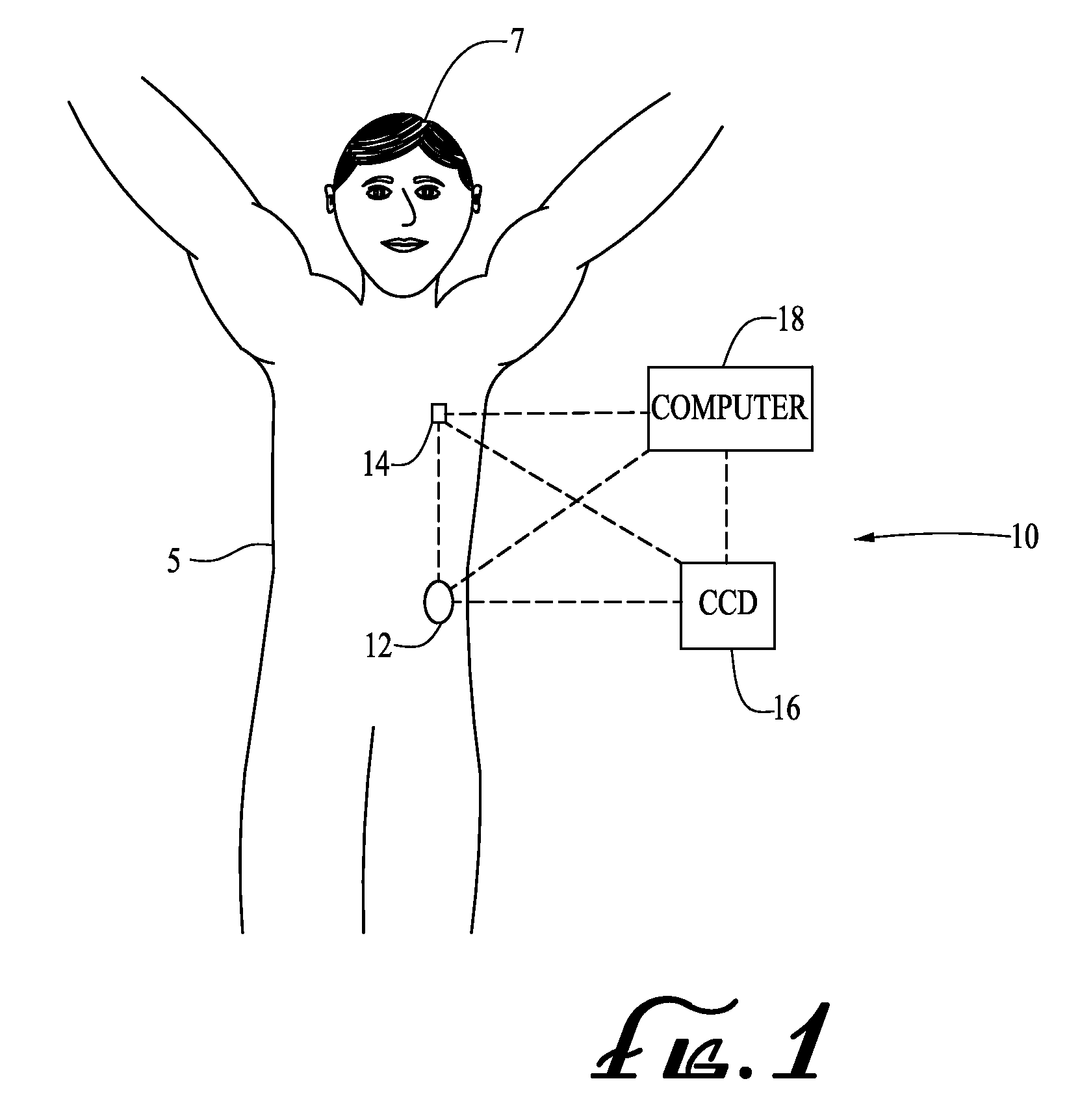

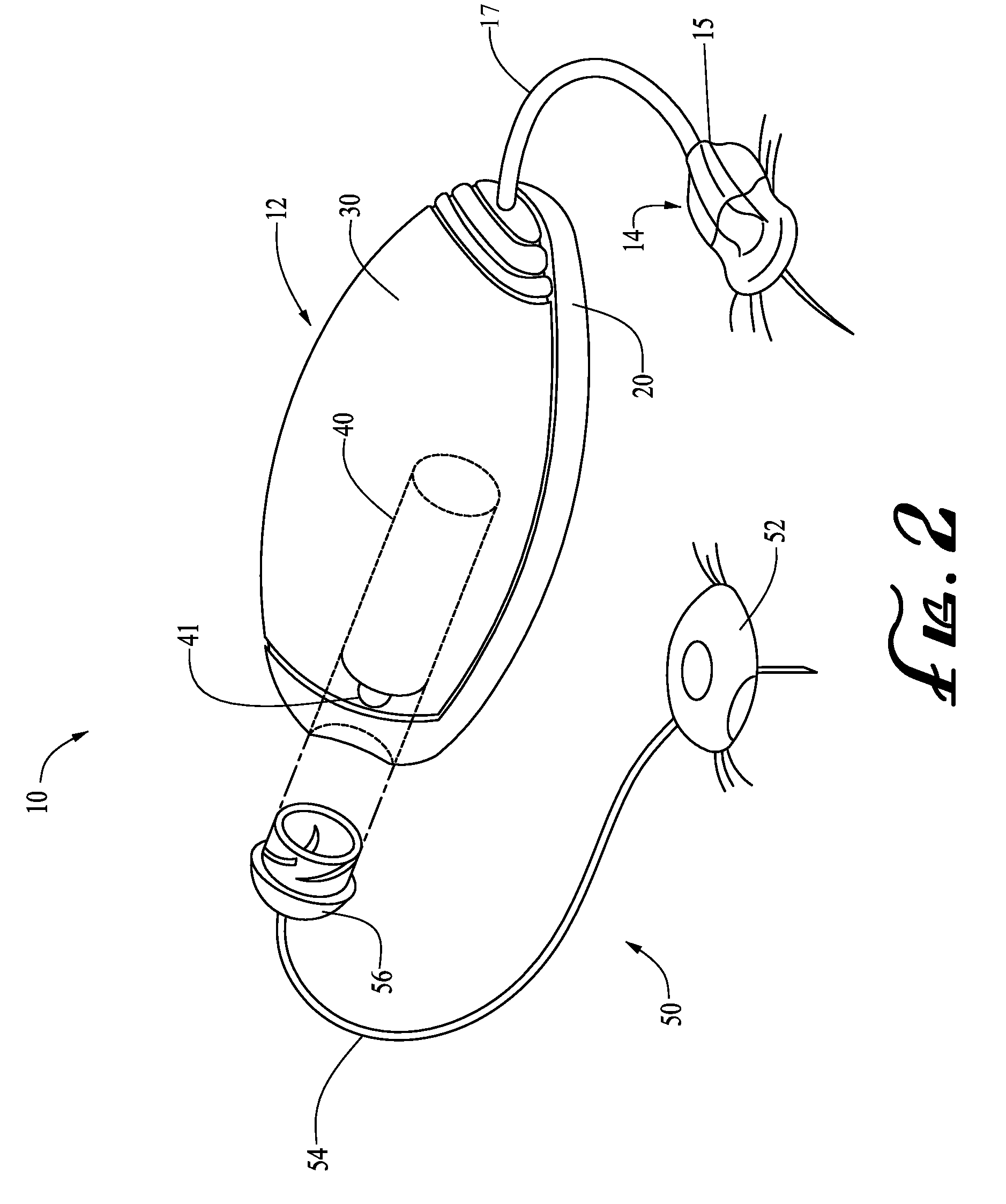

Ureteral stent with end-effector and related methods

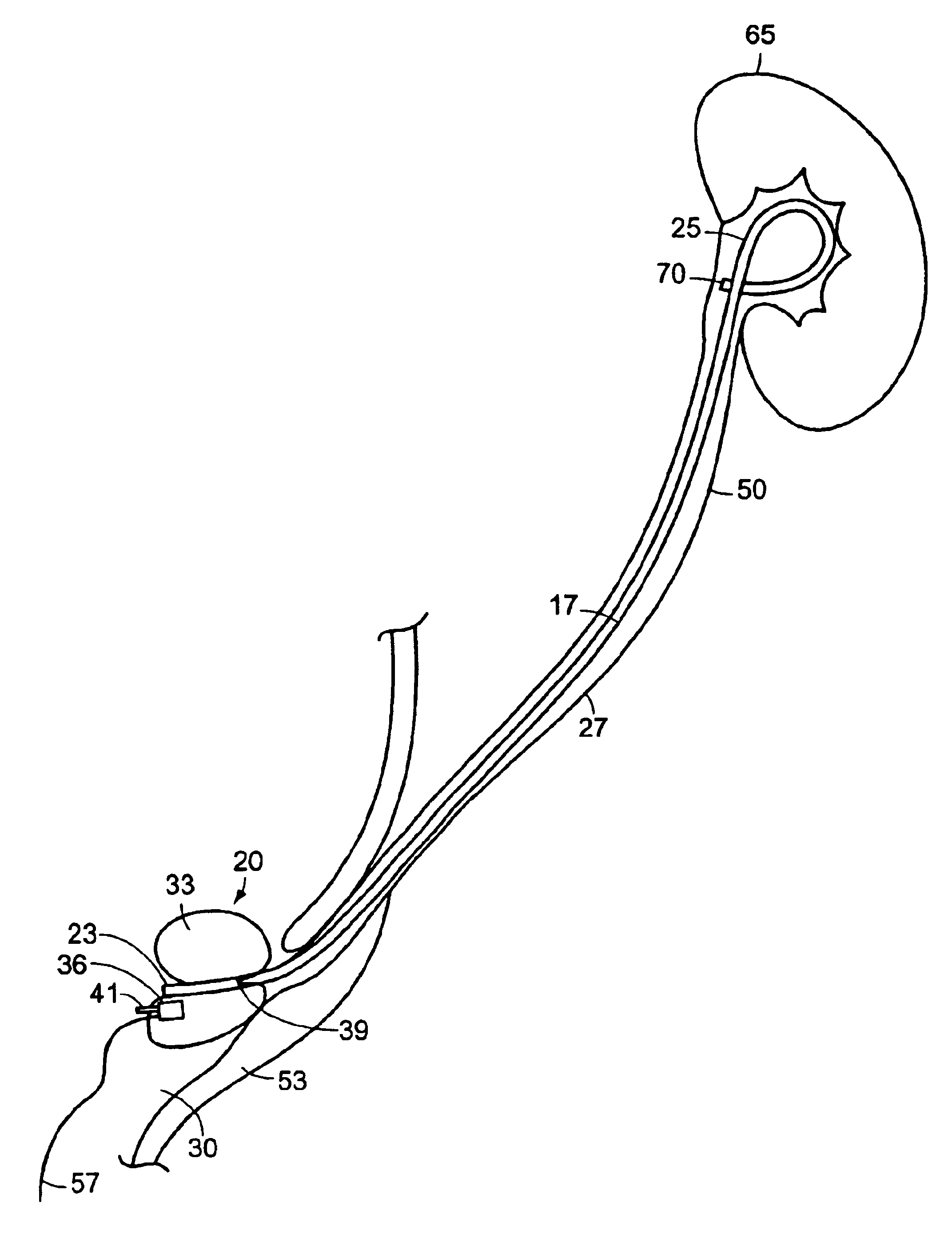

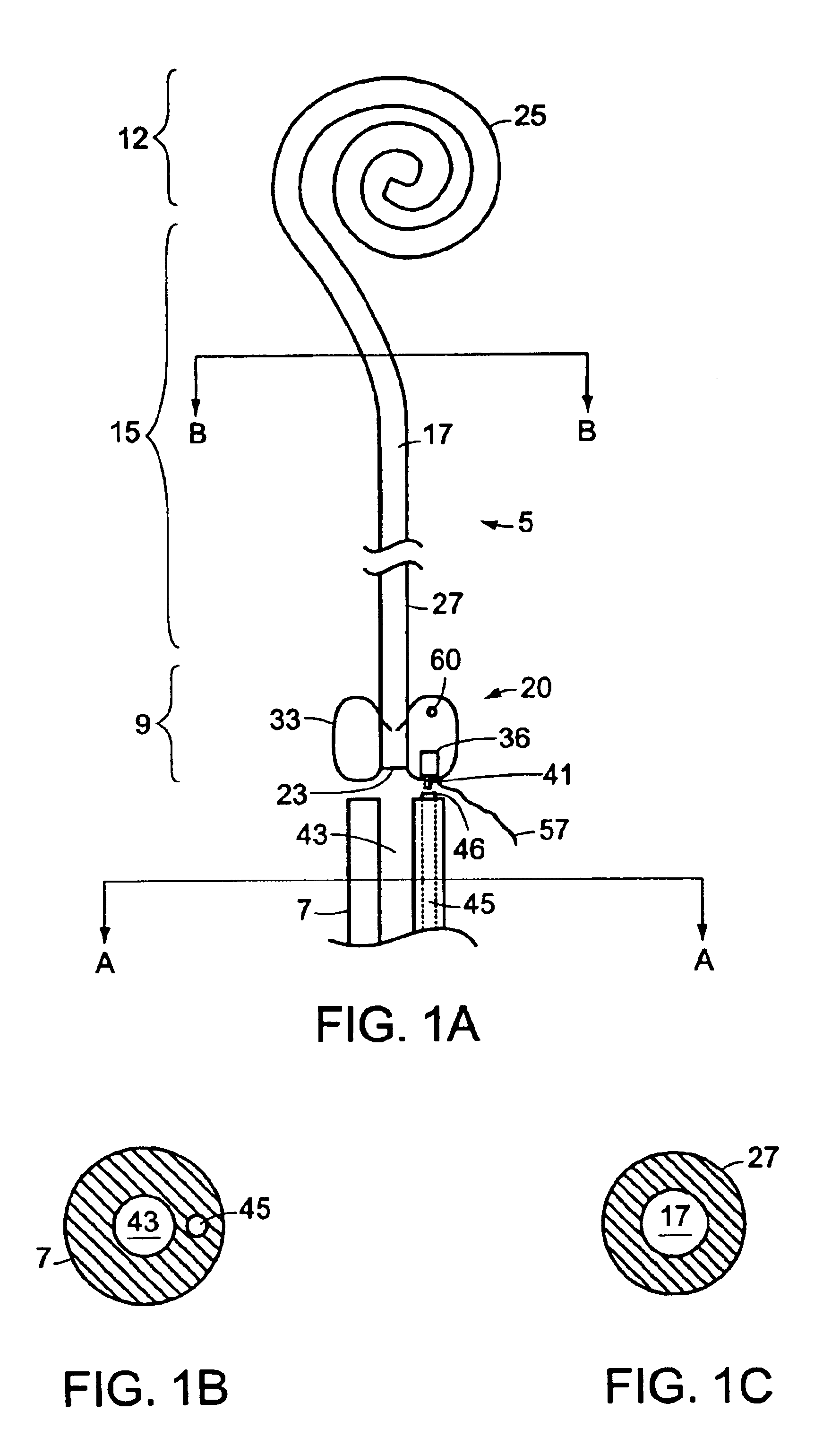

InactiveUS6949125B2Decreased fluid retentionMinimizing patient discomfortBalloon catheterSurgeryUrethraControl release

A system and related methods for maintaining the patentcy of the ureter comprising a pusher tube having a pusher tube lumen and an inflate lumen disposed within a wall of the pusher tube and a urinary stent having a proximal and distal portions with an elongated body portion therebetween configured to fit the ureter of the patient and defining a lumen. The system further includes an end-effector that may comprise an inflatable balloon positioned at the proximal portion of the urinary stent for retaining the proximal portion in the urinary bladder. At the distal portion, a retention end-piece is positioned for retaining the distal portion of the stent in the renal pelvis. The end-effector and the retention end-piece of the stent maintain the elongated body portion in situ. The end-effector may also include an inflatable balloon and may contain pharmaceutical or biologic agents for controlled release into the bladder.

Owner:BOSTON SCI SCIMED INC

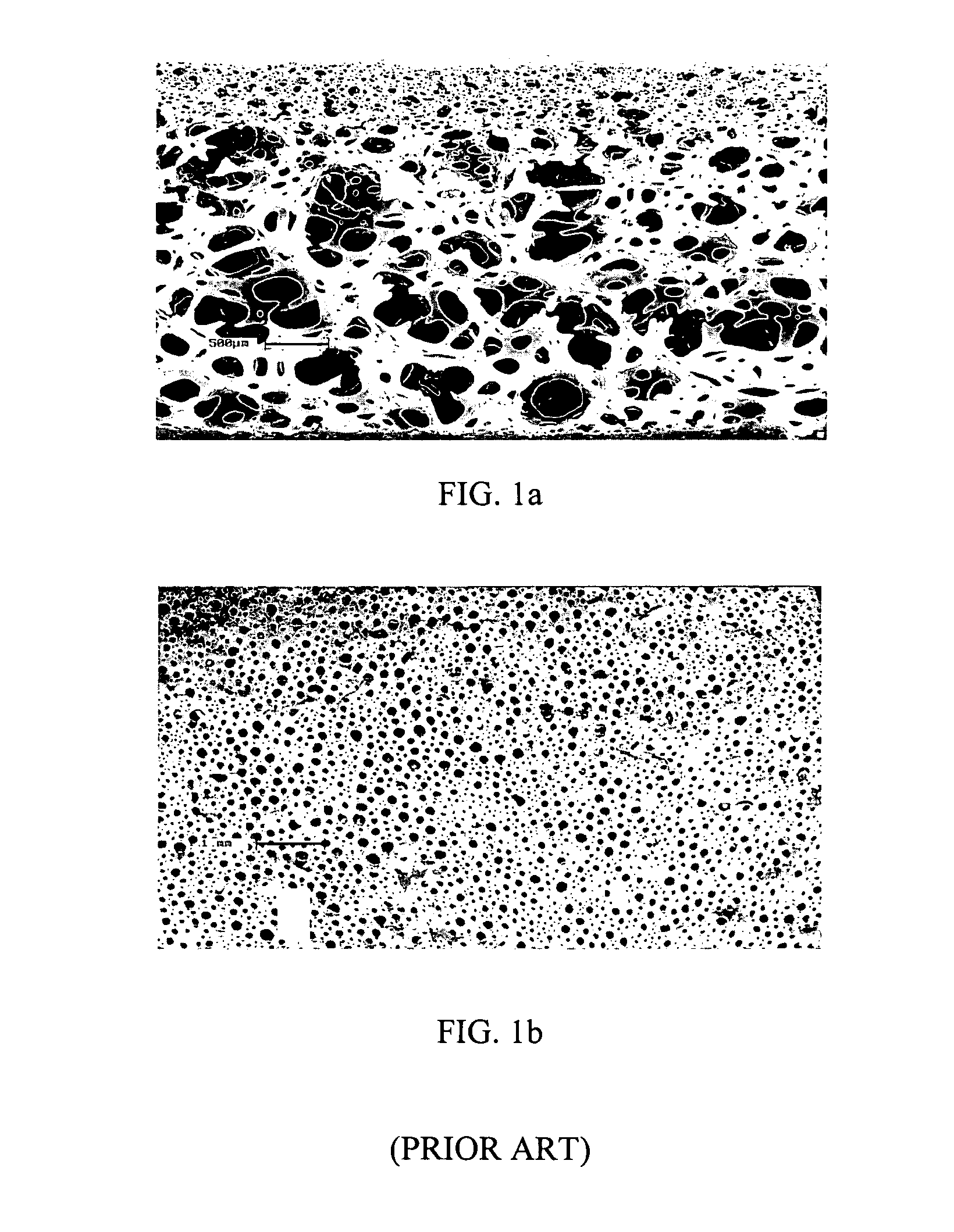

Fibrillated polyolefin foam

ActiveUS20080076844A1Improve heat resistanceLow compression setAbsorbent padsBandagesThermoplasticFiber

A method for generating a thermoplastic foam from an aqueous dispersion, the aqueous dispersion comprising a thermoplastic resin, water, and a dispersion stabilizing agent, the method including: adding at least one froth stabilizing surfactant to the aqueous dispersion to form a mixture; adding a fiber to the mixture; and frothing the mixture to create a froth, removing at least a portion of the water in the froth to create a foam, wherein the foam generated has a non-cellular fibrillated morphology. In another aspect, embodiments disclosed herein relate to a foam having a thermoplastic-based, fibrillated, non-cellular structure, wherein the foam has an average density of about 0.02 g / cm3 to about 0.07 g / cm3. In certain embodiments, the foam may be used in an absorbent article.

Owner:DOW GLOBAL TECH LLC

Hydrophobic coating compositions, articles coated with said compositions, and processes for manufacturing same

InactiveUS7268179B2Low costReduce solvent lossAnalysis material containersSpecial surfacesAlkoxy groupChemistry

Hydrophobic coating compositions are provided as are processes to coat articles with the compositions. Extremely hydrophobic coatings are provided by the compositions. Durable, weatherable and scratch-resistant coatings are provided by compositions comprising a fluorinated component and an adhesion promoter compound. The adhesion promoter compound can include an alkoxy group, a furfuryl-containing ring structure, and a reactive group.

Owner:CYTONIX

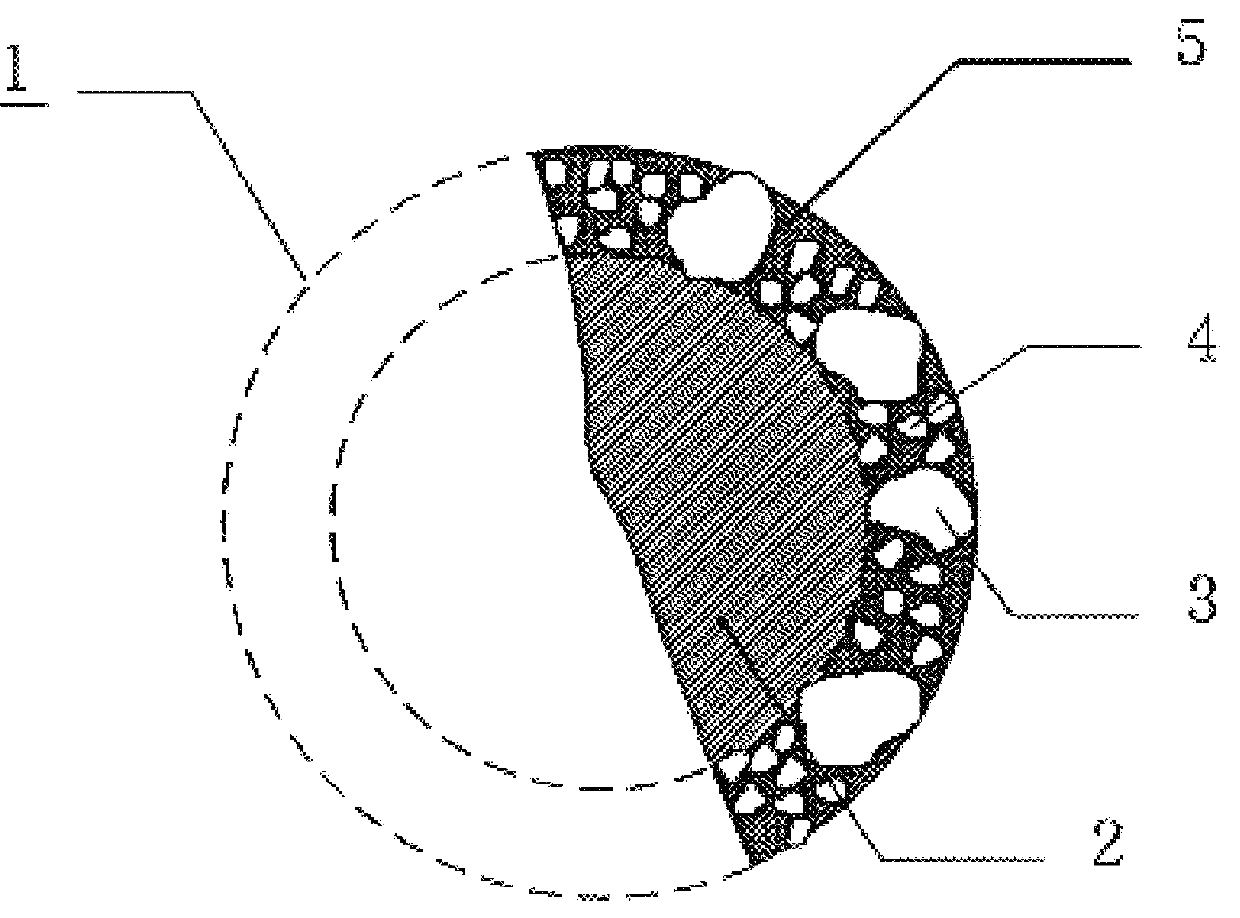

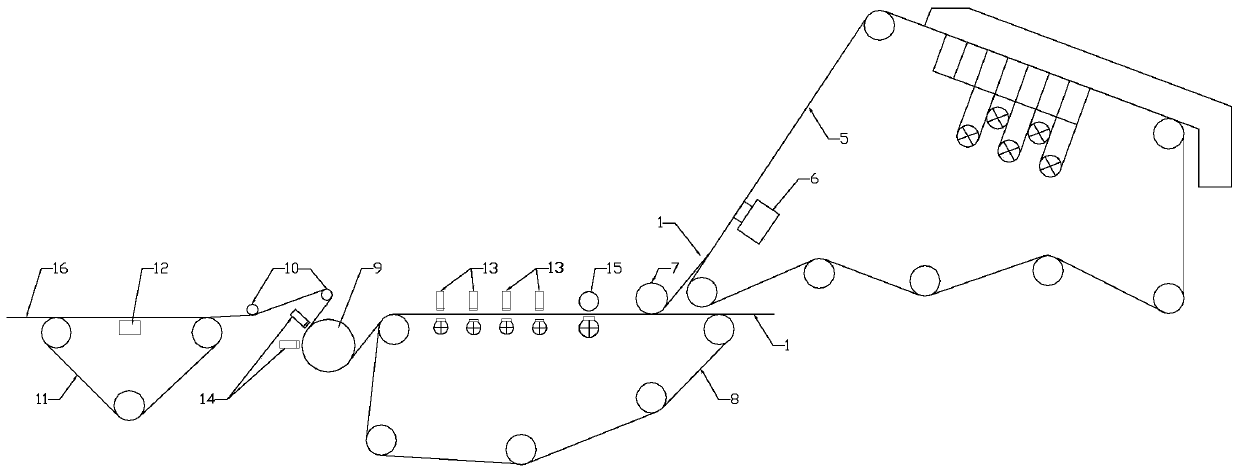

Wire-saw and its manufacturing method

InactiveUS6070570AReadily worked and finishedImprove homogeneityMetal sawing toolsGrinding devicesEngineeringElectronic materials

PCT No. PCT / JP98 / 00532 Sec. 371 Date Mar. 9, 1999 Sec. 102(e) Date Mar. 9, 1999 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35784 PCT Pub. Date Aug. 20, 1998The present invention provides a wire saw for use in cutting works of electronics materials or optical materials and a method for manufacturing the same, said wire saw having the following characteristic features. Namely, onto a high-strength core wire 2, abrasive grains 3 having a grain size not smaller than two-thirds the thickness of a layer of resin bond 4 on said core wire 2 but not exceeding a half the diameter of said core wire are fixed with said resin bond, said resin bond containing a filler having a grain size smaller than two-thirds the thickness of said resin bond layer. The thus structured and arranged wire saw has an improved efficiency and precision in cutting. The wire saw can be manufactured readily by using an enamelling oven.

Owner:ALLIED MATERIAL +1

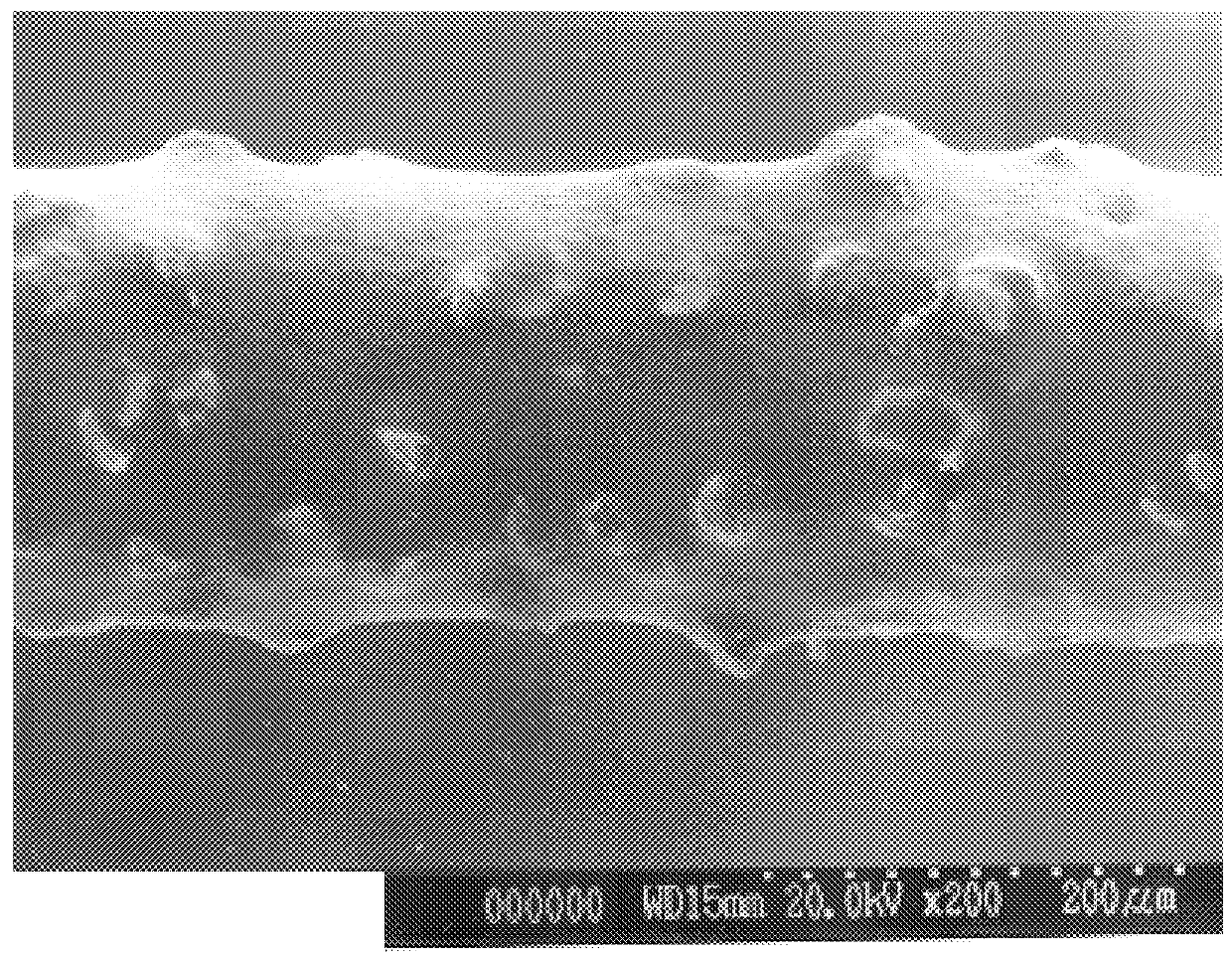

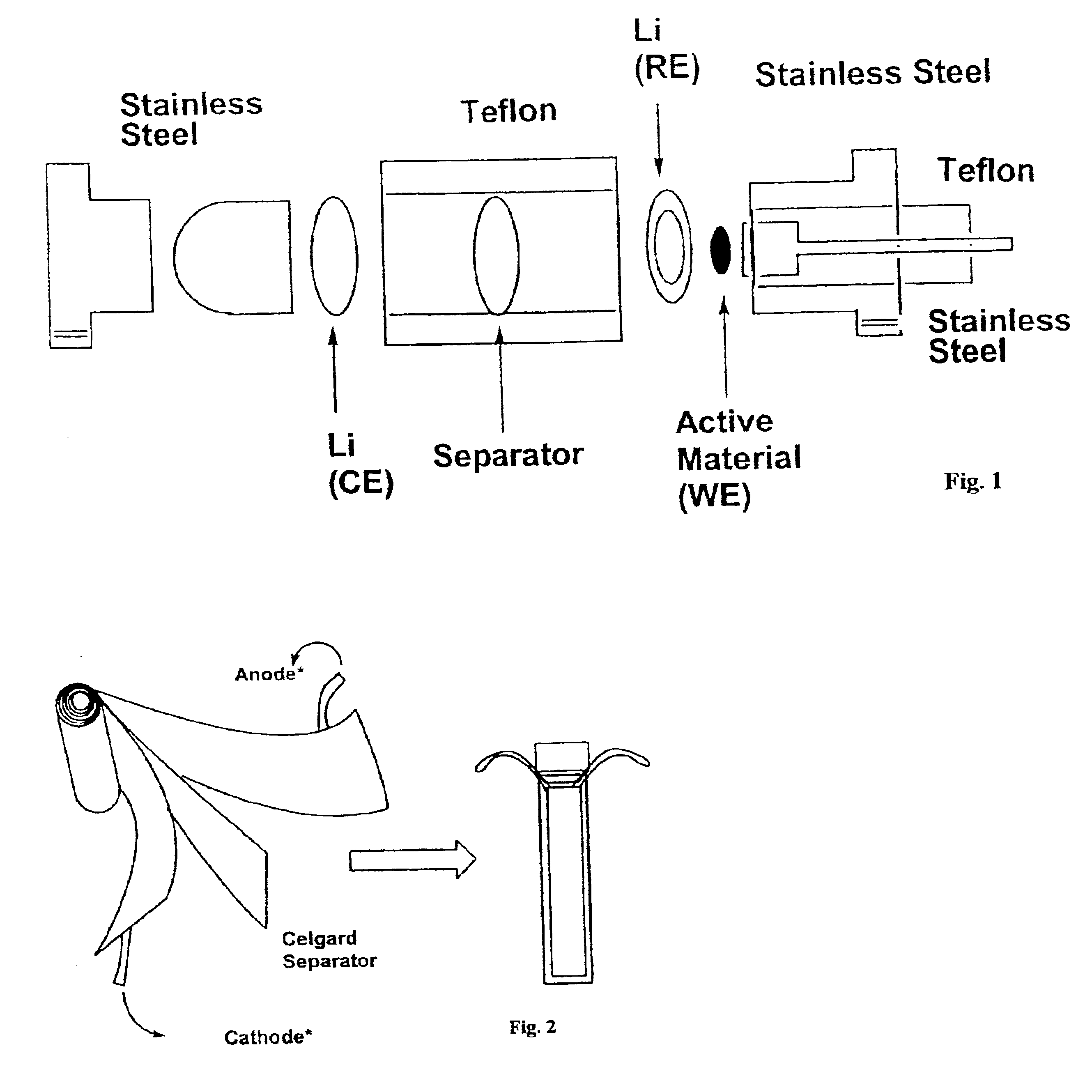

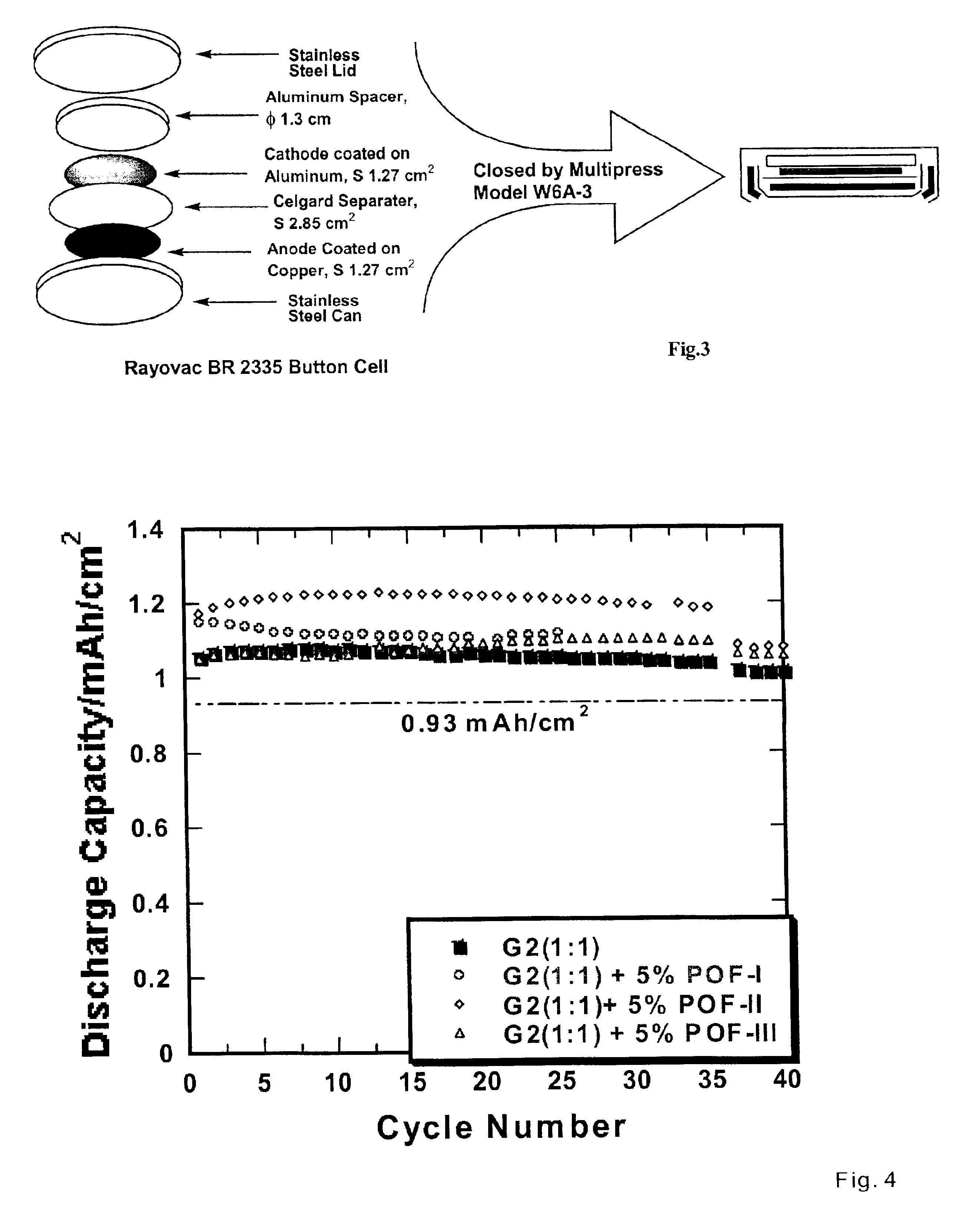

Nonflammable non-aqueous electrolyte and non-aqueous electrolyte cells comprising the same

InactiveUS6924061B1Improve rate performanceEffective and stableElectrolytic capacitorsOrganic electrolyte cellsPhysical chemistryCarbonate

A non-aqueous electrolyte to be used in a Li-ion battery includes a lithium salt, a cyclic carbonate, a linear carbonate and an alkyl fluorinated phosphate, of the following general formula wherein R1, R2 and R3, independently, are selected from the group consisting of straight and branched alkyl groups having 1-5 carbon atoms, and at least one of said alkyl groups is fluorinated, with the locations of said fluorination being at least β-positioned away from the phosphorous of said phosphate, such that said alkyl phosphate has a F / H ratio of at least 0.25, and said electrolyte solution is non-flammable.

Owner:ARMY US SEC THE

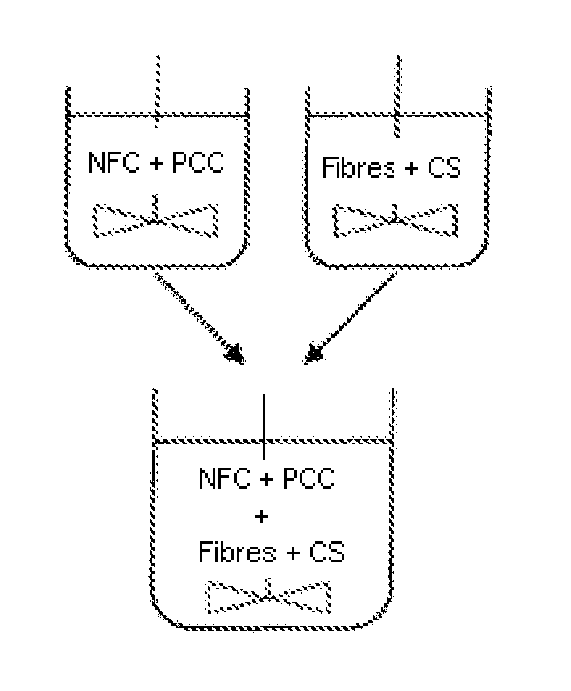

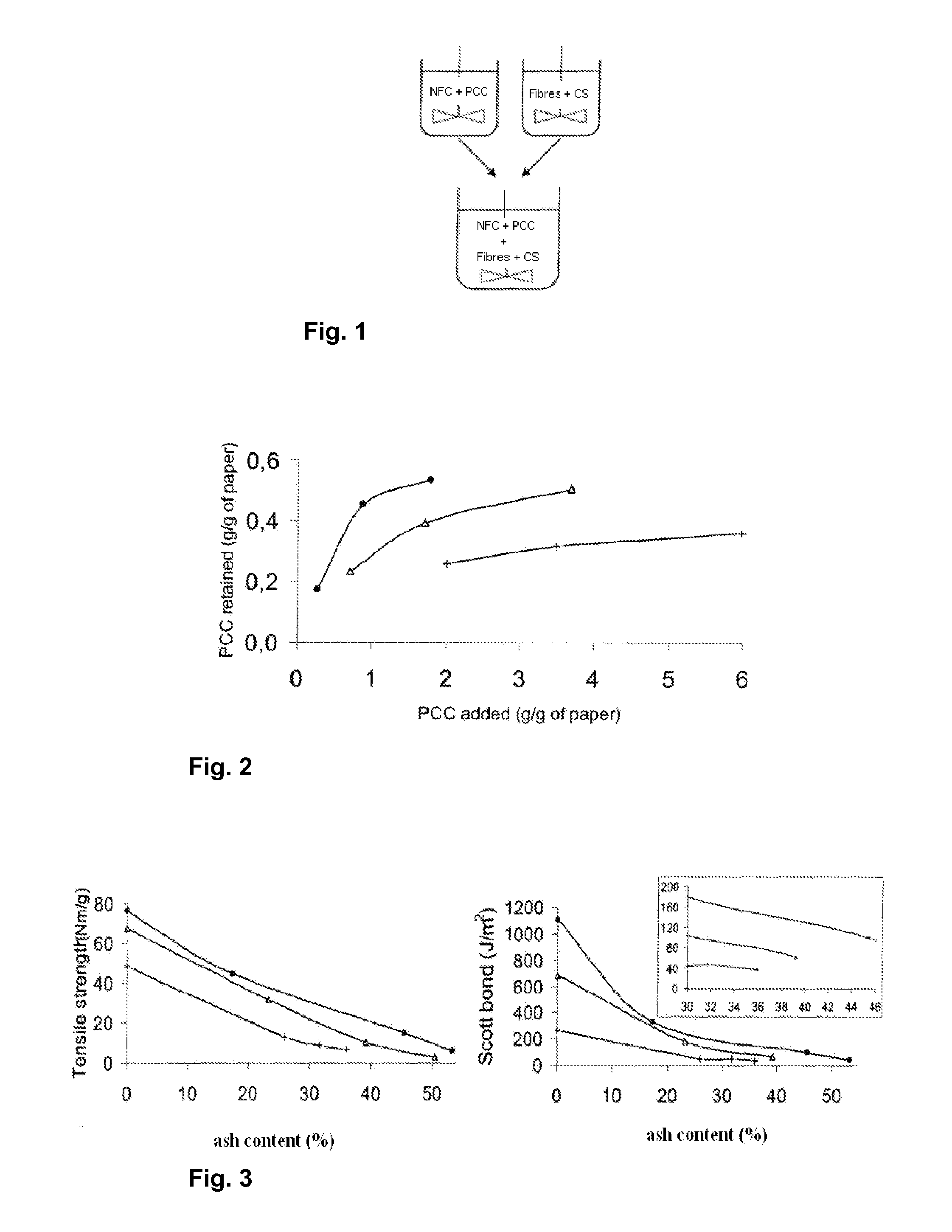

Method for producing furnish, furnish and paper

ActiveUS20120132383A1High filler loadingHigh mechanical strengthSpecial paperPaper after-treatmentCelluloseCardboard

A method for preparing aqueous furnish to be used in paper or paper board manufacturing. Filler and / or fibers are treated with cationic polyelectrolyte and nanofibrillated cellulose. A furnish and a paper or a paper board.

Owner:UPM-KYMMENE OYJ

Heat-not-burn cigarette smoke cooling material and application thereof

ActiveCN108143004AAvoid heat shrinkage defectsExcellent heat shrinkage resistanceTobacco devicesCooling effectHeat not burn

The invention discloses a heat-not-burn cigarette smoke cooling material and application thereof. The heat-not-burn cigarette smoke cooling material is prepared from, by mass, polymer 50-75%, layerednano material 5-15%, fibrous nano material 4-15%, phase change material 5-10% and metal powder 3-10% by adopting screw extrusion processing. The heat-not-burn cigarette smoke cooling material has highheat resistant shrinkage by means of addition of the layered nano material and the fibrous nano material, and the defect that a polylactic acid cooling material shrinks due to heat is avoided; the exogenous phase change material is added, so that the heat-not-burn cigarette smoke cooling material has a better cooling effect; in addition, the heat-not-burn cigarette smoke cooling material has a low interception rate of smoke, and the suction experience is not affected basically.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Multi-Functional and Modular Urine Collection System

InactiveUS20080312550A1Reduce retentionImprove wettabilityWound drainsMedical devicesModularityCollection system

Multi-functional urine collection devices, embodiments of which can include a self-expanding container having a receptacle for receiving urine from the tubing, a pump for moving urine through the tubing and into a receptacle, extendable tubing that may be shortened and / or lengthened, and / or one or more meters for monitoring, measuring, transmitting or storing a characteristic from the urine. Embodiments can also include a display kit having a transmitting device in the form of a cable or wireless transmitter and a display module. The display module may include an LCD and may be configured for attachment to a urine receptacle.

Owner:CR BARD INC

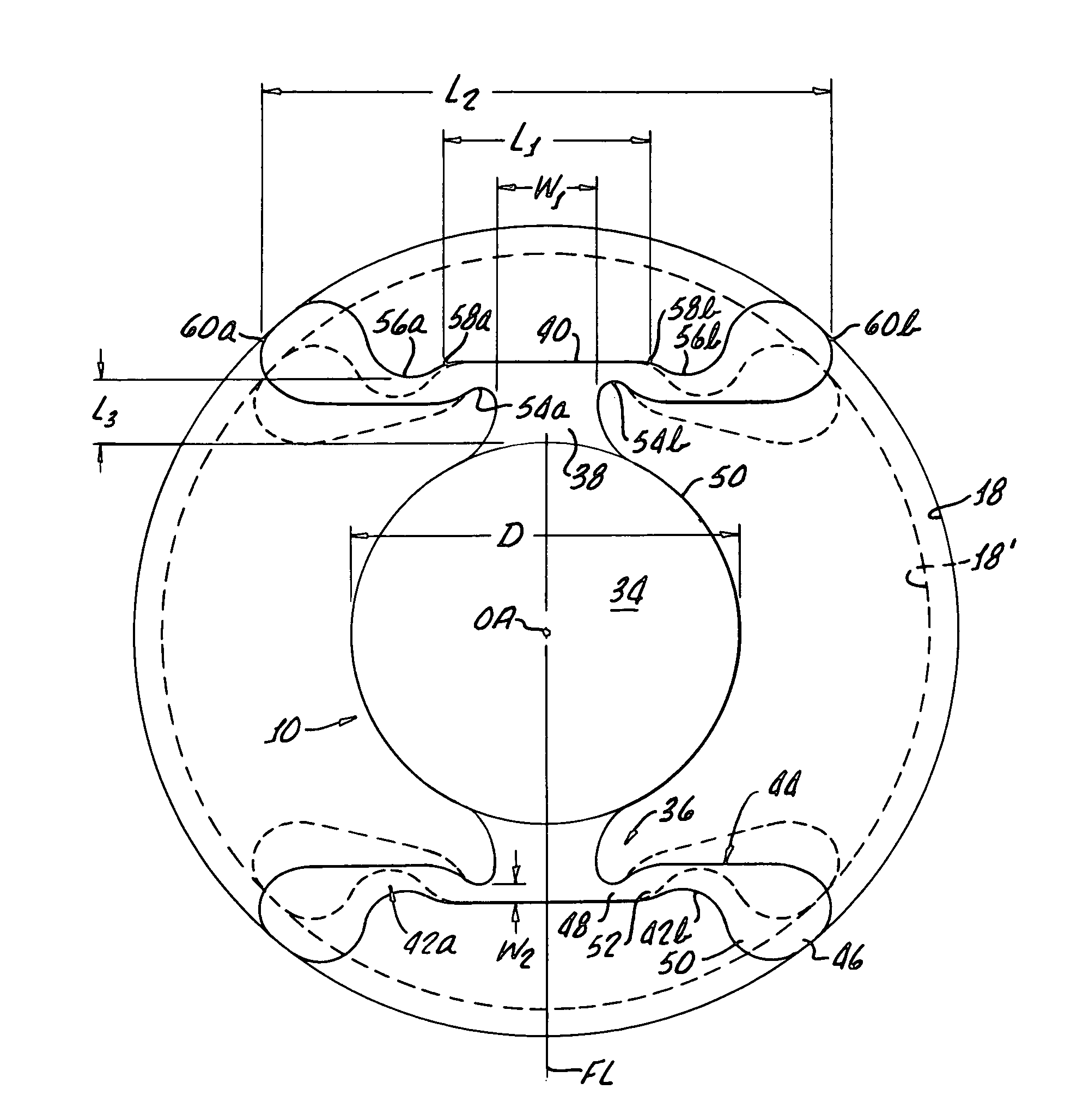

Foldable angle-fixated intraocular lens

InactiveUS7303582B2Reduce morbidityFoldability safe and controlledIntraocular lensIntraocular lensOptometry

A foldable intraocular lens (IOL) includes an optic and at least one fixation member for supporting the optic in the anterior chamber of an eye. The fixation member includes an intermediate portion that extends a first direction away from the optic, and a leg portion that intersects with an outer end of the intermediate portion and extends a second direction, different from the first direction, away from the outer end. The leg portion preferably includes a reduced width region near the intersection with the intermediate portion. The reduced width region acts essentially as a hinge allowing the leg portion to flex about the intermediate portion in responsive to compressive forces, while the intermediate portion and optic remain stable.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Delayed-tack adhesive composition

InactiveUS6080480AIncrease stickinessImprove the immunityNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesPolymer sciencePlasticizer

PCT No. PCT / JP96 / 02685 Sec. 371 Date Mar. 25, 1998 Sec. 102(e) Date Mar. 25, 1998 PCT Filed Sep. 18, 1996 PCT Pub. No. WO97 / 12010 PCT Pub. Date Apr. 3, 1997A delayed-tack adhesive composition exhibiting a high tack strength even for adherends made of non-polar materials such as polyethylene and polypropylene, which comprises a (co)polymer prepared by the use of a radical-polymerizable monomer having a straight-chain or branched alkyl group having 9 to 18 carbon atoms and a plasticizer being solid at ordinary temperatures.

Owner:TOYO INK SC HOLD CO LTD

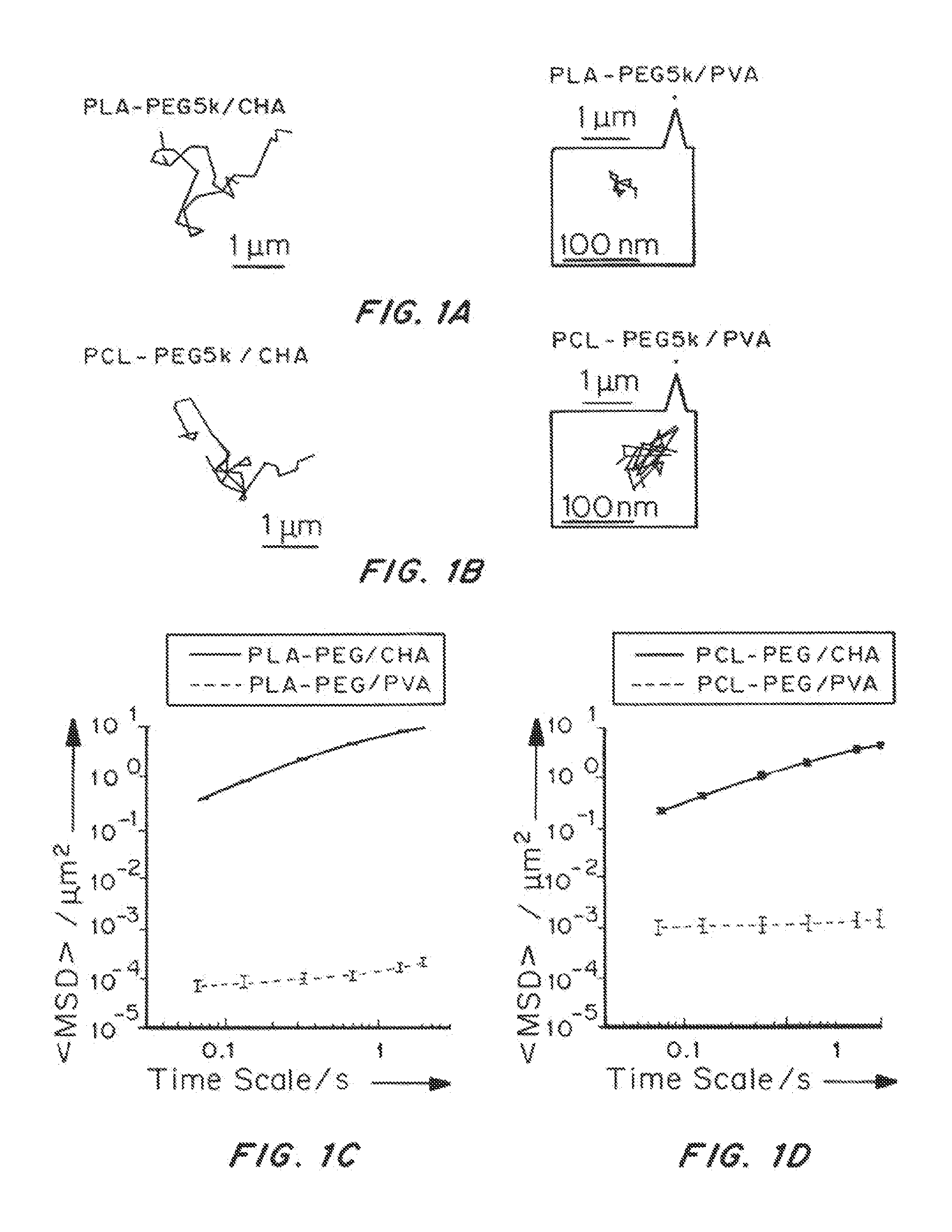

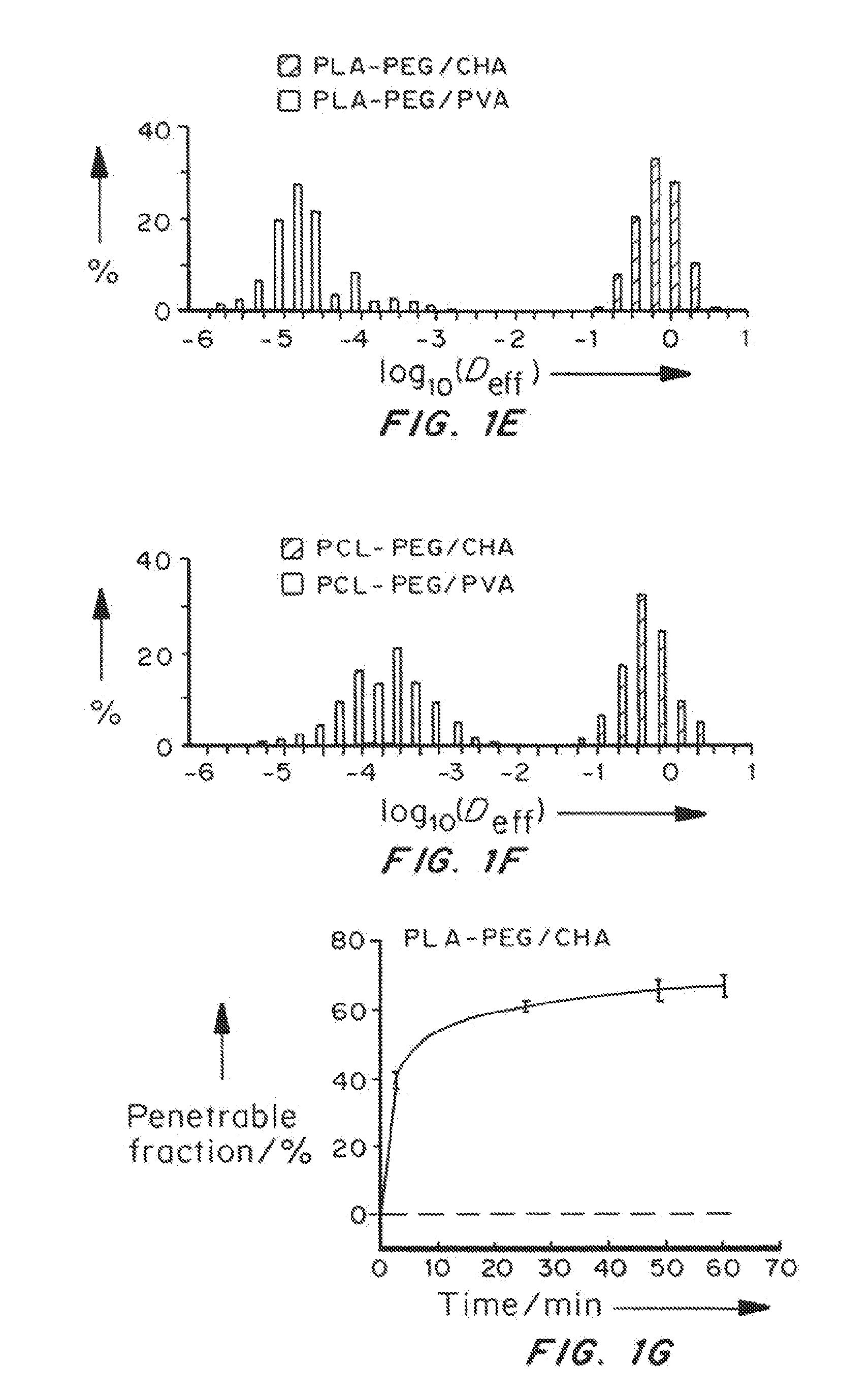

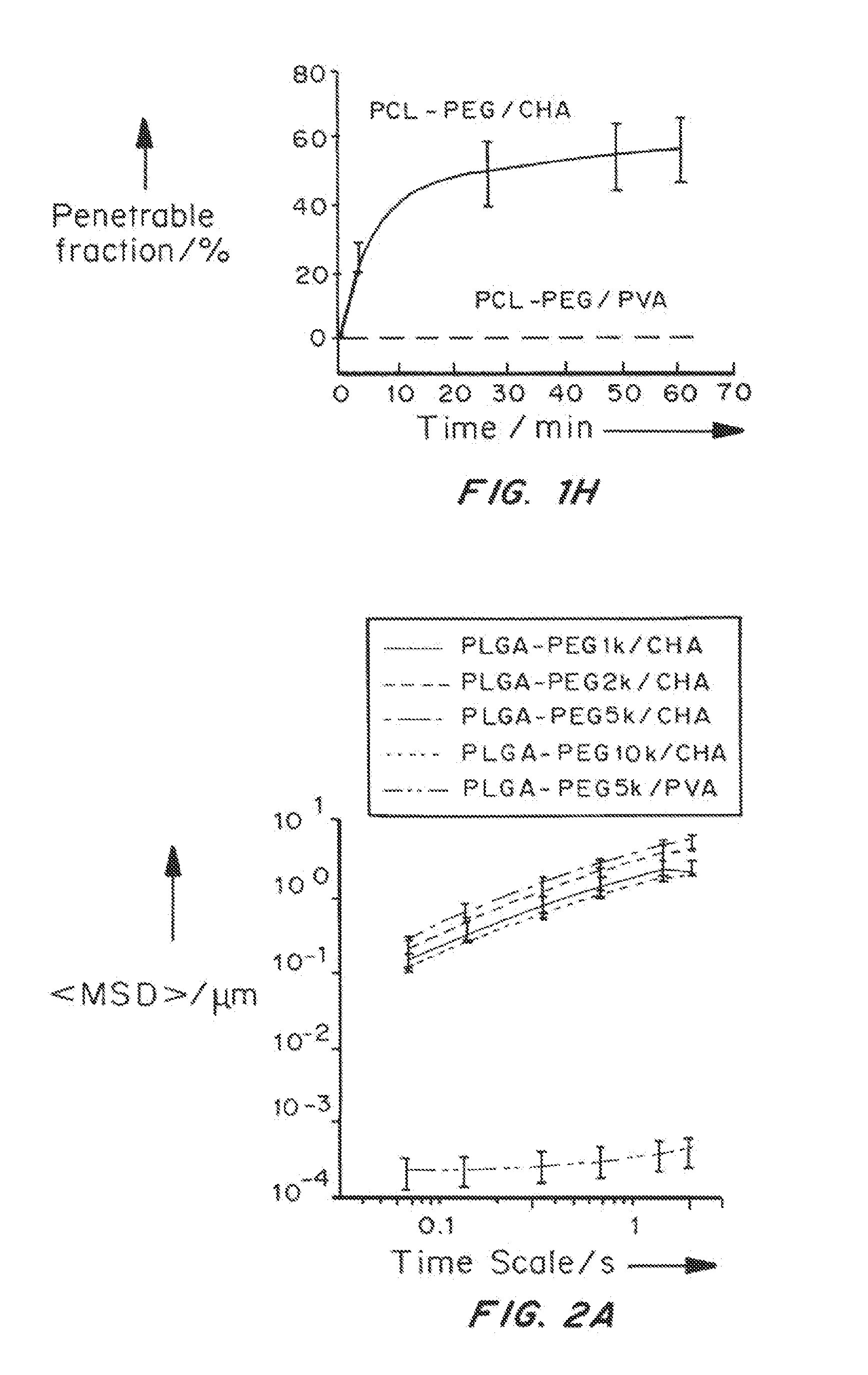

Nanoparticle formulations with enhanced mucosal penetration

ActiveUS20150297531A1Optimize allocationImprove the effectiveness of treatmentBiocideNanotechHigh osmolalityNanoparticle

Hypotonic formulations were evaluated for delivering water-soluble drugs and for drug delivery with muco-inert (that is, non-adhesive) mucus-penetrating nanoparticles (MPP). Hypotonic formulations markedly increased the rate at which drugs and MPP reached the epithelial surface, including deep into the vaginal folds. Minimally hypotonic formulations, preferably ranging from 20-220 mOsm / kg, provided rapid and uniform delivery of MPP to the entire vaginal surface, with minimal risk of epithelial toxicity. Data also show that there is a higher osmolality in the colon, such that vehicles with an osmolality above that of blood plasma (generally considered isotonic at ˜300 mOsm / kg), still lead to improvements in distribution in the colon due to rapid, osmotically-induced fluid absorption. The range for improved colon distribution with a hypotonic vehicle in the colon is ˜20 mOsm / kg-450 mOsm / kg.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

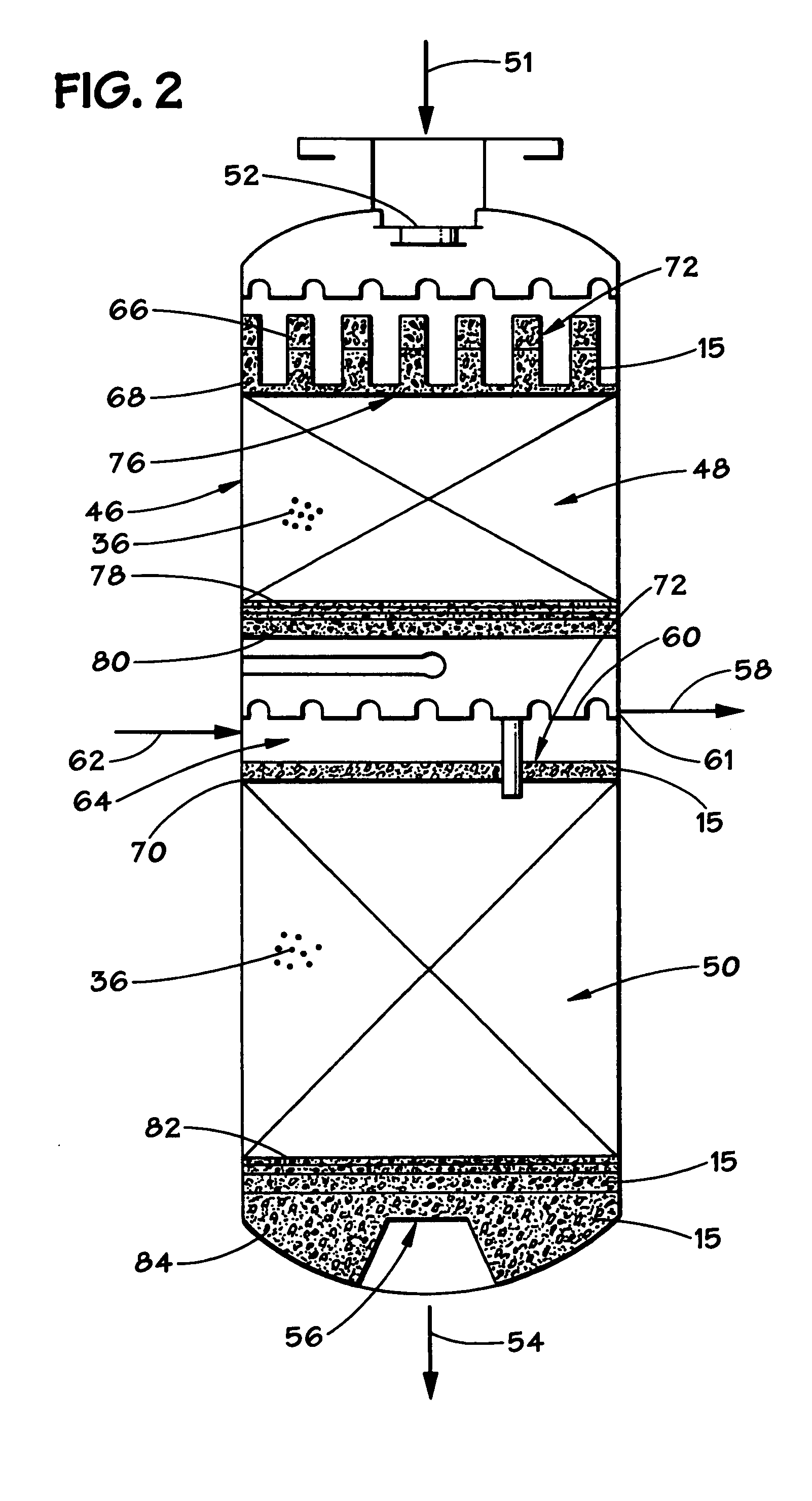

Filtration, flow distribution and catalytic method for process streams

ActiveUS20040192862A1Increased operating lifeExtended run timeDispersed particle filtrationMembrane filtersProcess equipmentCatalytic method

A method for removing contaminants from an process stream that includes the use of reticulated material to filter the process stream. The reticulated material also facilitate process stream flow distribution in process units. The reticulated material can be packed with a void space between a substantial number of the reticulated material that can be varied to enhance filtration and flow distribution. The method of filtering also provides a method of removing contaminants leaving process equipment. The methods can be used on a variety of process streams and process equipment. The reticulated material can include ceramics, metallic materials, and chemical vapor deposition elements. The reticulated material can be of various shapes and sizes, and can also be catalytically active.

Owner:CRYSTAPHASE PRODS

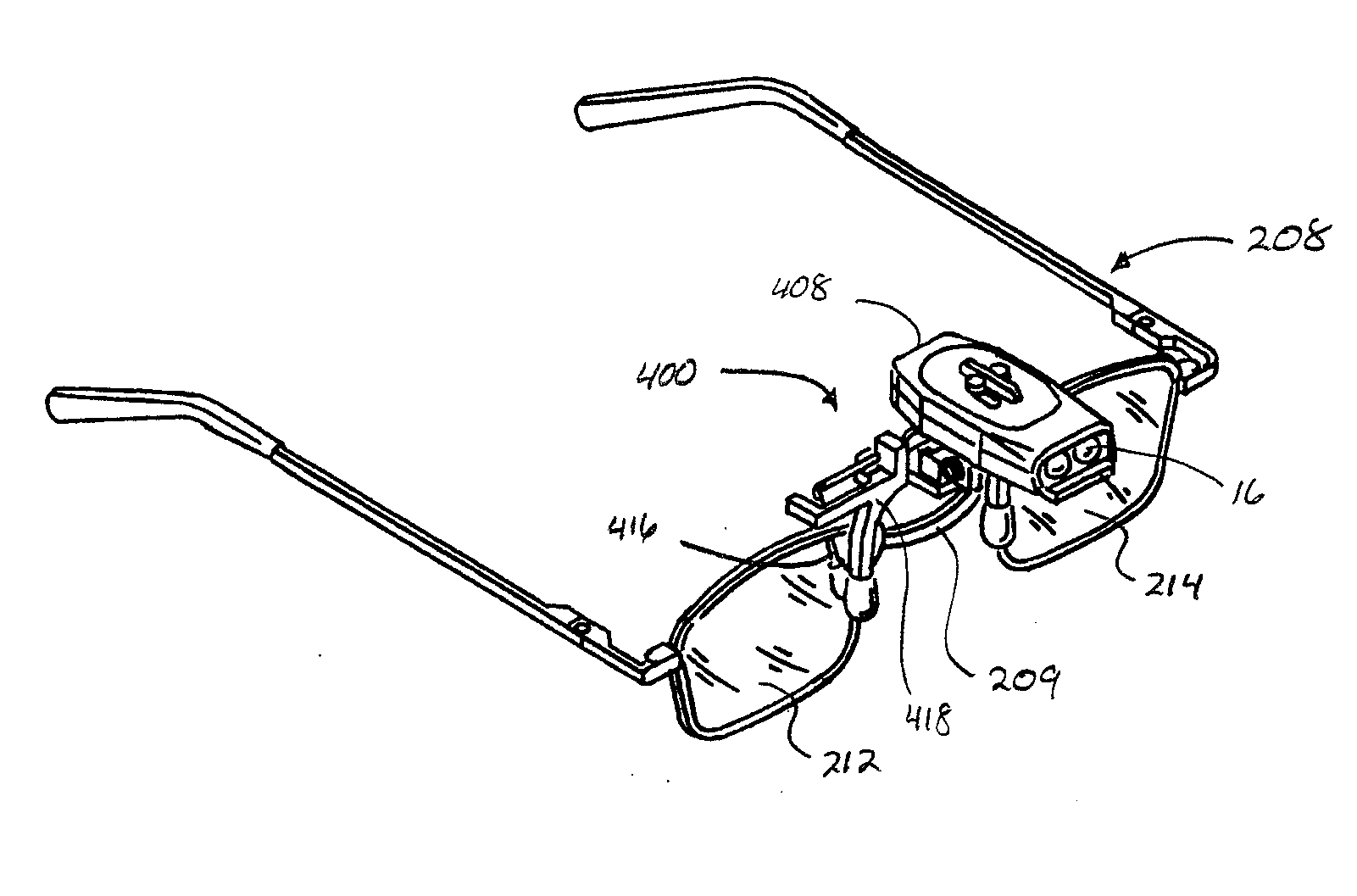

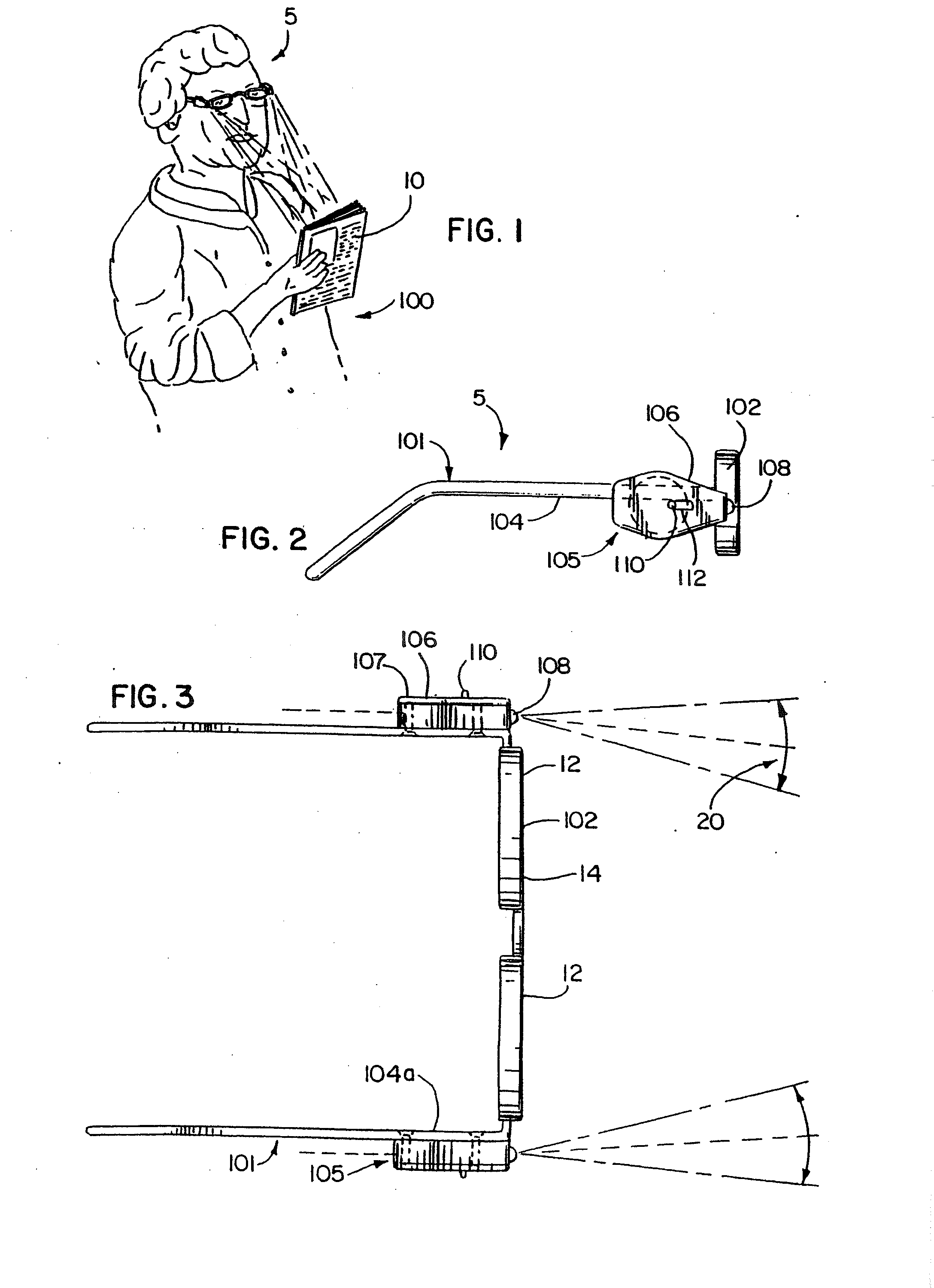

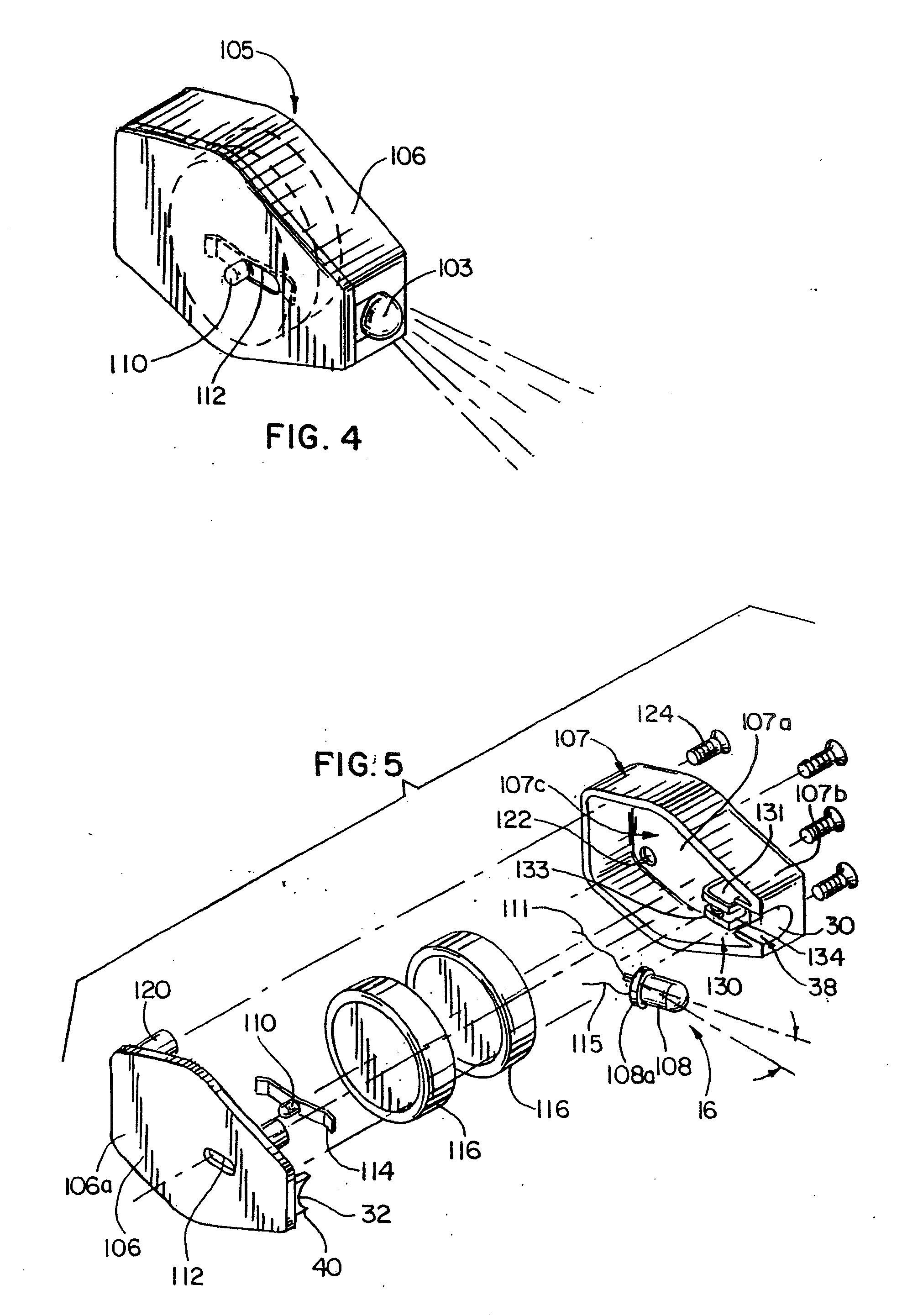

Clip-On Light Apparatus

InactiveUS20070127250A1Great freedomMore versatileLighting support devicesNon-optical adjunctsLight equipmentCoupling

A clip-on light apparatus is provided having a polyaxial coupling joint between a light module and frame to permit the light module to be pivoted about a plurality of axes relative to the frame for directing light in a plurality of directions. The polyaxial coupling joint preferably permits pivoting of the light module about at least two orthogonal axes. In one form, the light module is mounted to a pivot shaft about which the module can be turned with the pivot shaft itself being pivoted along one of the two orthogonal pivot axes.

Owner:WATERS

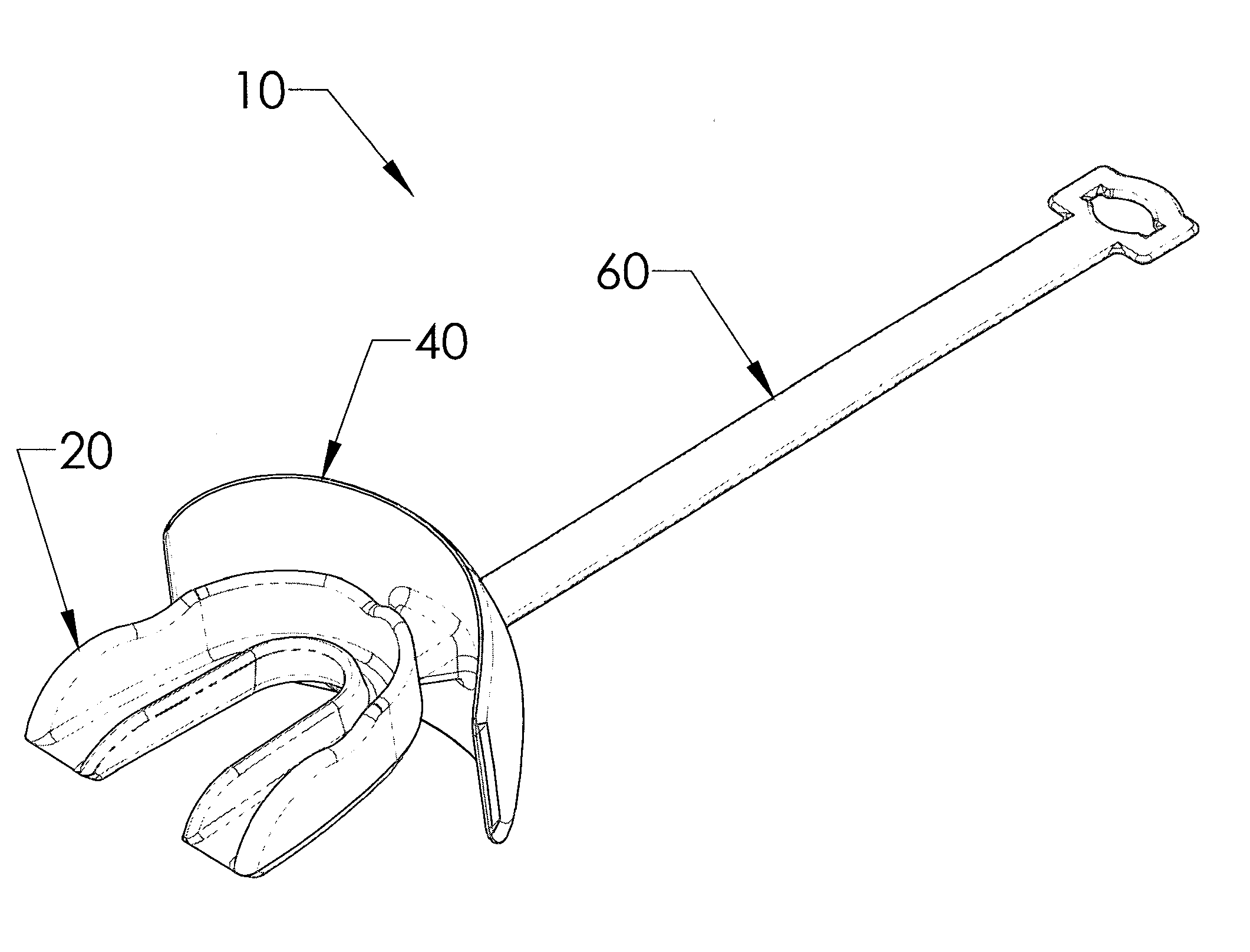

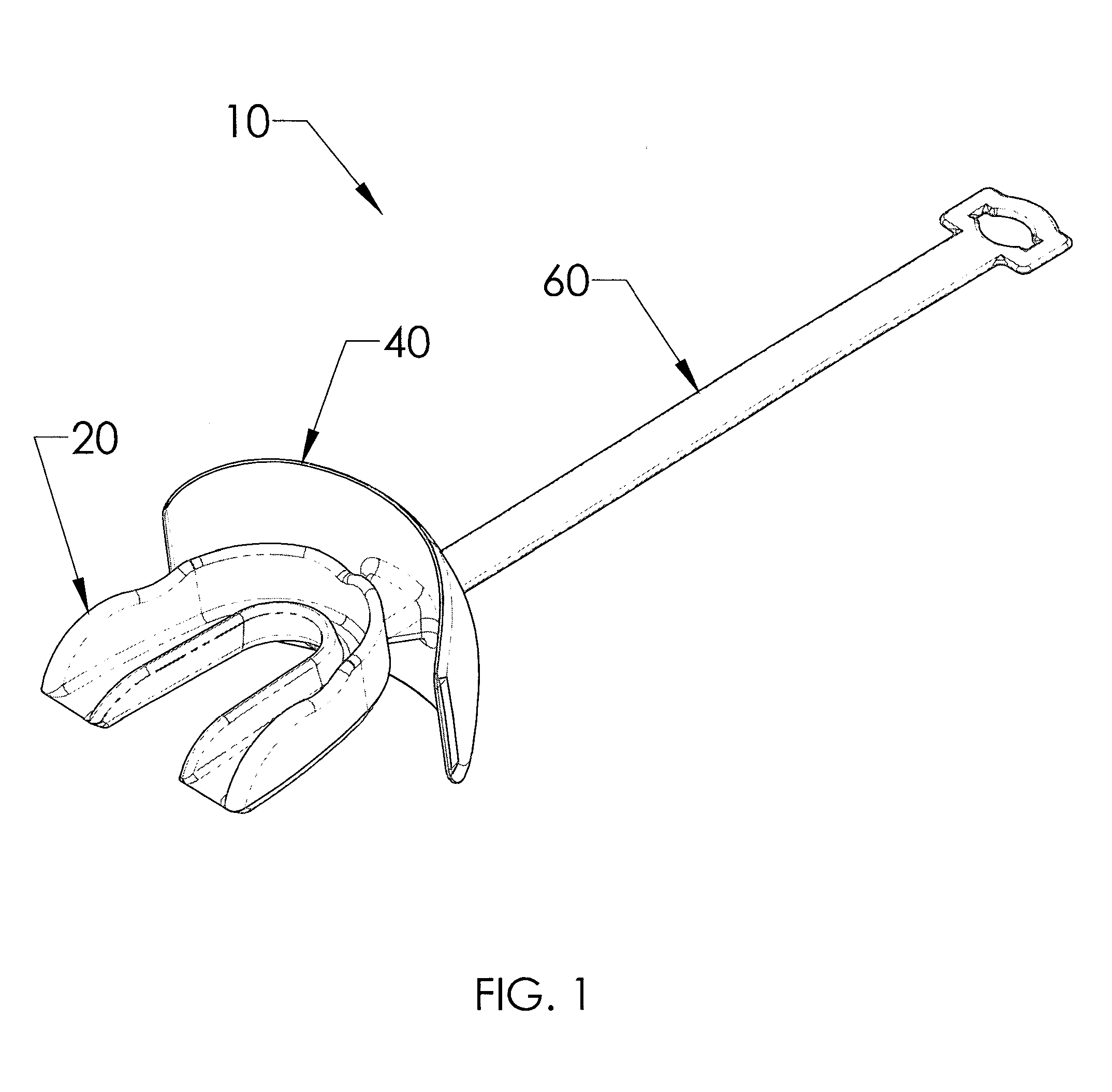

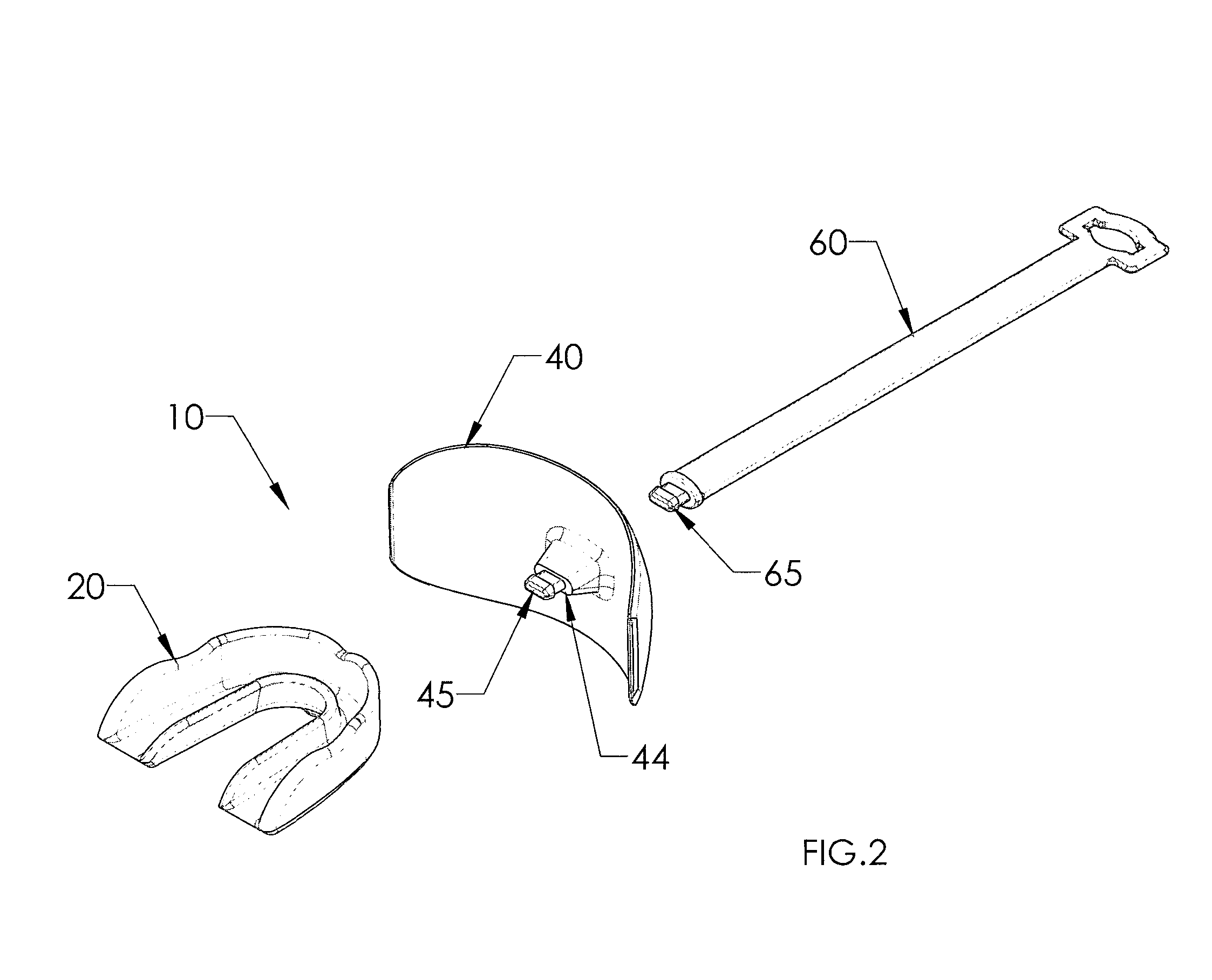

Mouthguard and lipguard assembly

A protective assembly having a mouthguard adapted to protect a user's teeth, a lipguard for protecting the user's lips releasably connectable to the mouthguard, and a tether strap releasably connectable to the lipguard and having an additional portion connectable to a point of the user's equipment, for example a facemask of a helmet. The mouthguard can have a standard form or be manufactured as a custom-fitted molding.

Owner:SPORTSGUARD LAB

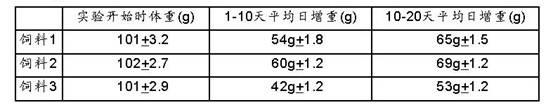

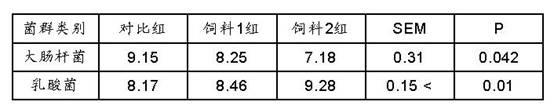

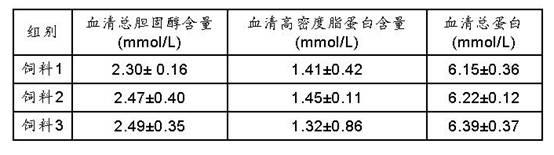

Feed for 22 to 42-day meat ducks and preparation method thereof

ActiveCN102132796AImprove production performanceImprove survival rateFood processingAnimal feeding stuffCellulaseCrop

The invention discloses feed for 22 to 42-day meat ducks, which comprises a feed carrier and a feed additive, wherein the feed carrier comprises one or more of bran, table salt, corn slag, fish meal, stone powder, rice bran, bean pulp and beef tallow; the feed additive comprises an enzyme composition and a traditional Chinese medicinal additive. The enzyme composition further comprises: xylanase, beta-glucanase, beta-mannase, cellulose, amylase, phytase and protease. The traditional Chinese medicinal additive further comprises: wild buckwheat rhizome, common cnidium fruit, dried orange peel, turmeric, suberect spatholobus stem, selfheal, scutellaria baicalensis, folium isatidis, codonopsis pilosula, Chinese angelica, medical stone, curcuma zedoary, charred triplet, sculellaria barbata, drynaria rhizome and fructus forsythiae. The feed can improve the meat quality of duck body, survival rate and crop. The additive contains rich amino acid, mineral substances, vitamins and other nutritive materials and therefore helps to supply amino acid, mineral substances and vitamins to grains and improve the utilization rate of feed.

Owner:SHANDONG NEW HOPE LIUHE GROUP

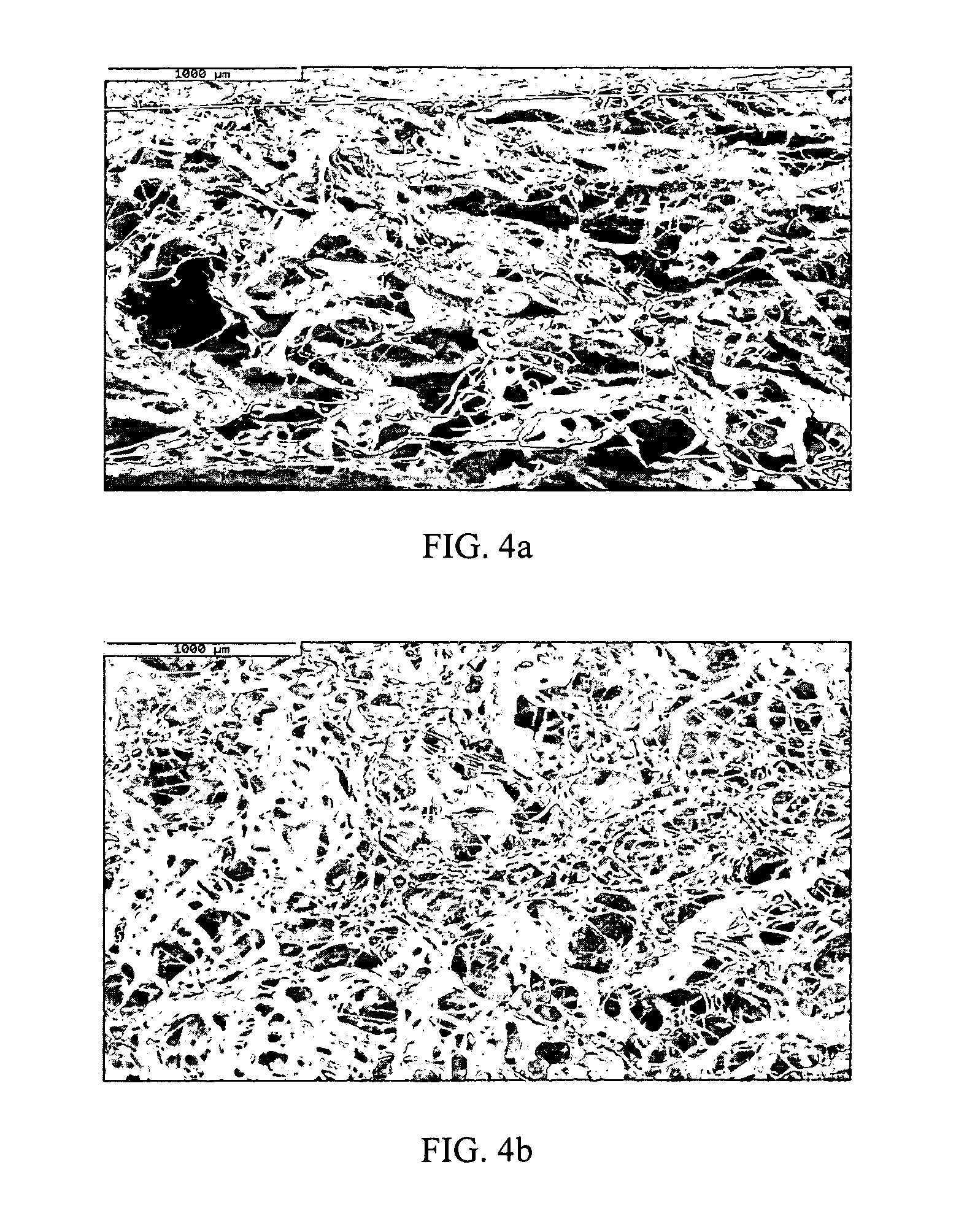

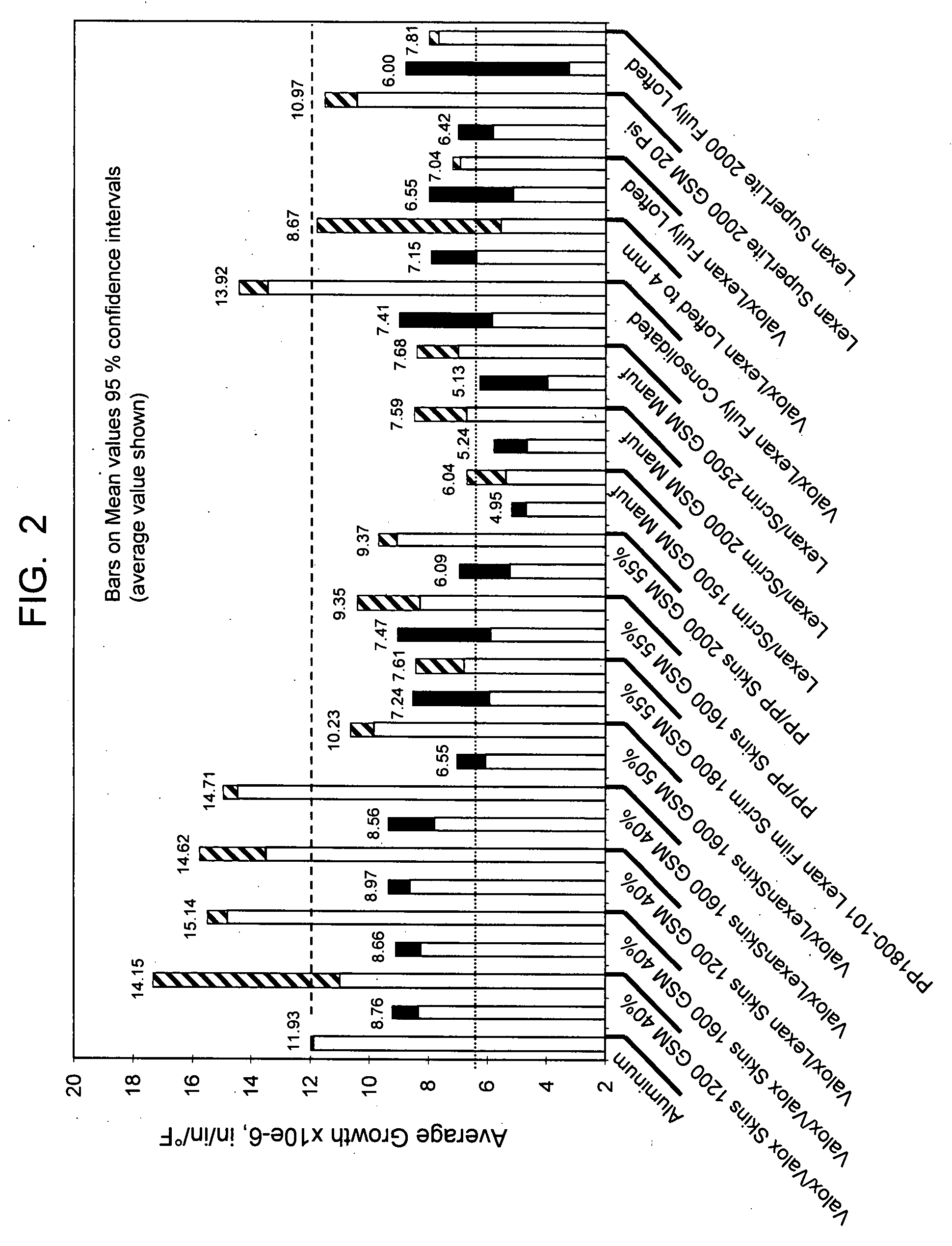

Panel materials for vehicles and enclosures

InactiveUS20080001429A1Reduce basis weightImprove delaminationDomestic articlesFlat articlesPliabilityThermoplastic

A fiber reinforced polymer material having an improved combination of characteristics. The polymer material generally comprises a fiber reinforced polymer resin containing reinforcing fibers and having a porosity between about 0% to about 95% by volume of the polymer material. The fiber reinforced polymer material may form a panel or substrate material that helps resist impact and / or environmental loading. Typically, such a material includes a fiber reinforced thermoplastic or thermoset support layer that has a skin layer on one or both sides, which are joined to one another to form the substrate or panel material. The exterior skin layer typically includes a polymer resin that may also include a support structure, such as reinforcing fibers. The resulting material is typically lightweight and has a reduced basis weight, particularly as compared to current commercial products, in addition to a low thermal expansion such that it provides improved resistance to delamination, improved dimensional stability and flexibility, and decreased water absorption and retention.

Owner:WILLIS CHRISTOPHER D +2

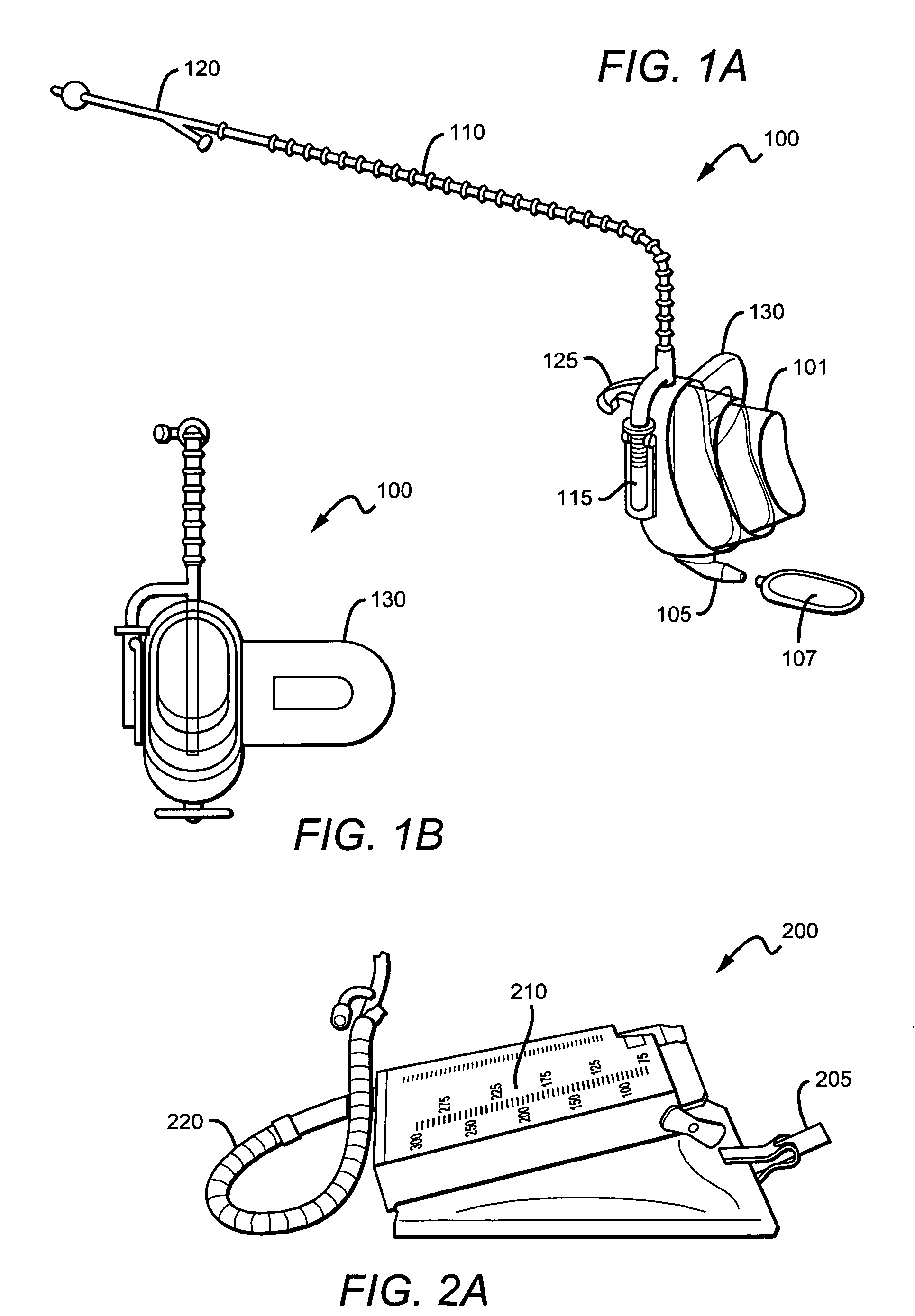

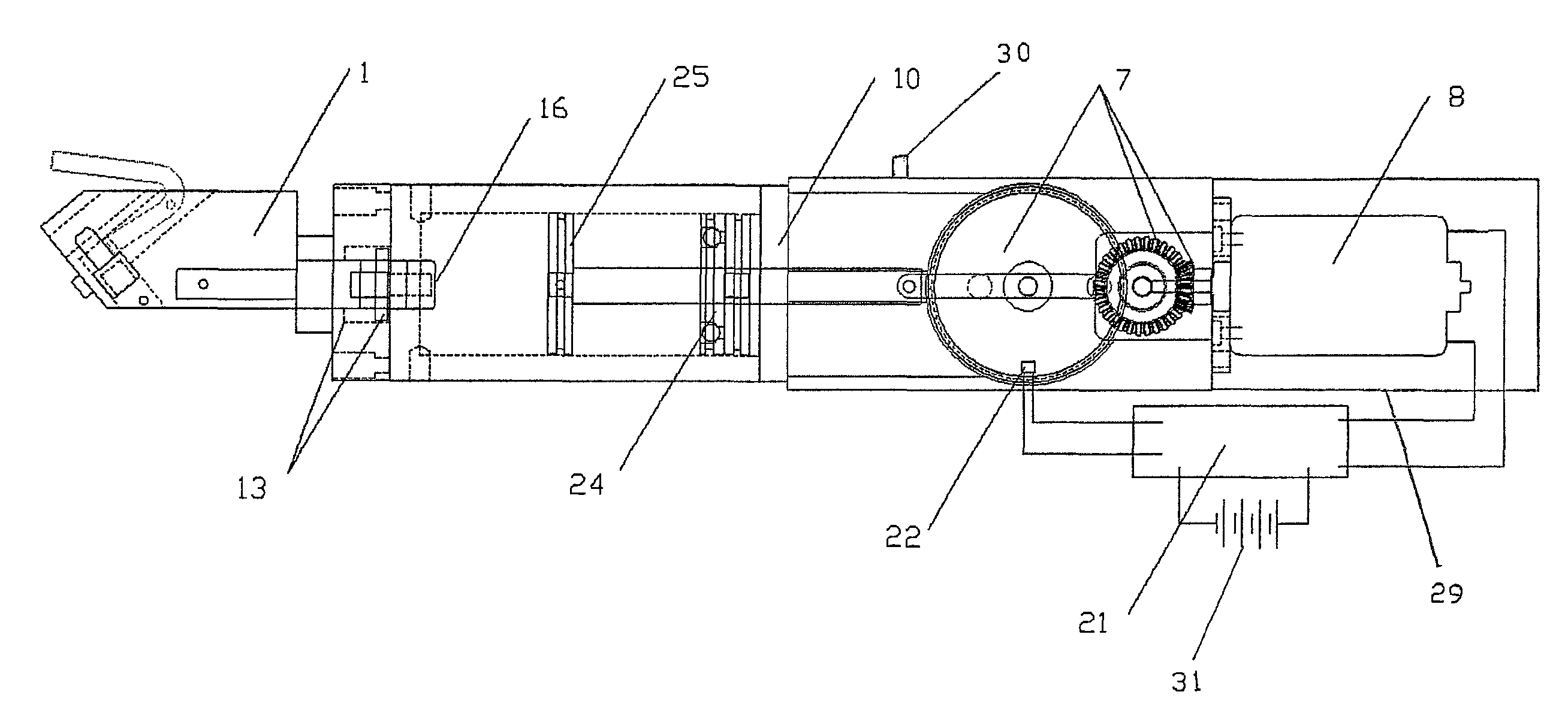

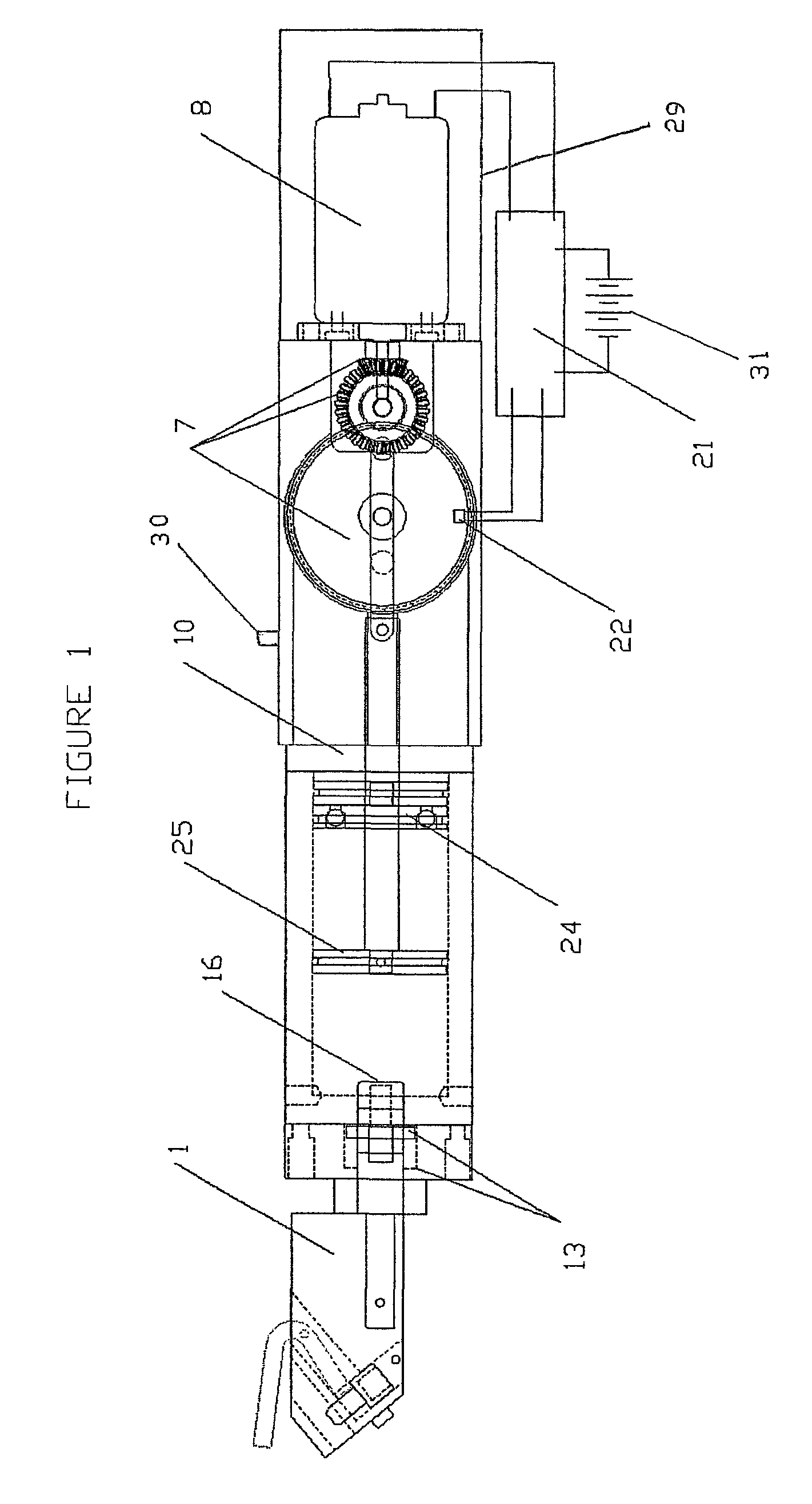

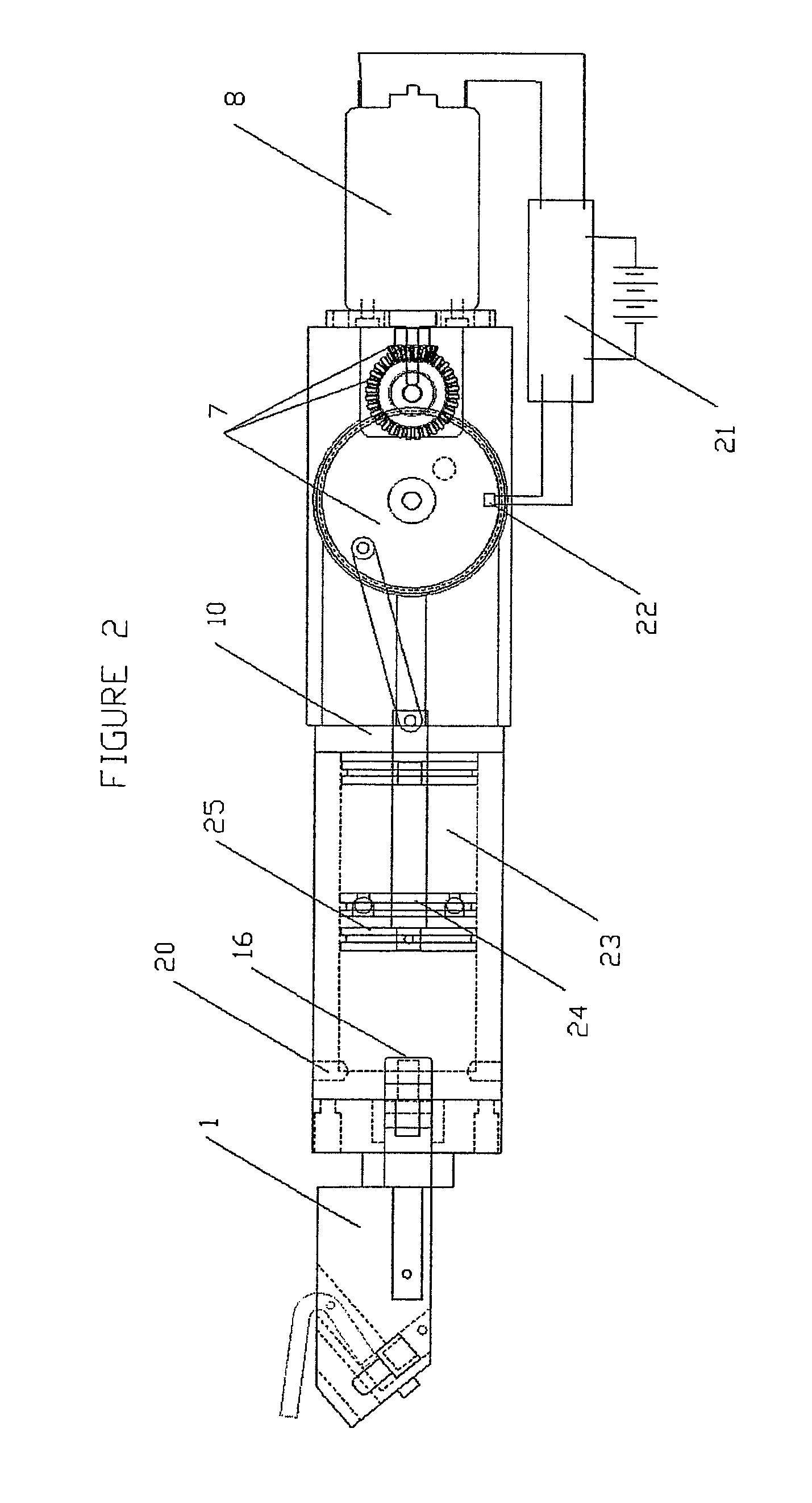

Electric motor driven tool for orthopedic impacting

ActiveUS8936106B2Improve fitAugments the existing surgeon's skill in guiding the instrumentReciprocating drilling machinesConstructionsEnergy regulationEngineering

An orthopedic impacting tool comprises a motor, an energy storage arrangement, a striker, and an anvil. The motor stores energy in the energy arrangement means and then releases it, causing the striker to apply a controlled force on an adapter to create a precise impact for use in a surgical setting. The tool may further comprise a combination anvil and adapter. The tool further allows forward or backward impacting for expanding the size or volume of the opening or for facilitating removal of a broach, implant, or other surgical implement from the opening. An energy adjustment control of the tool allows a surgeon to increase or decrease the impact energy. A light source and hand grips improve ease of operation of the tool.

Owner:MEDICAL ENTERPRISES LTD

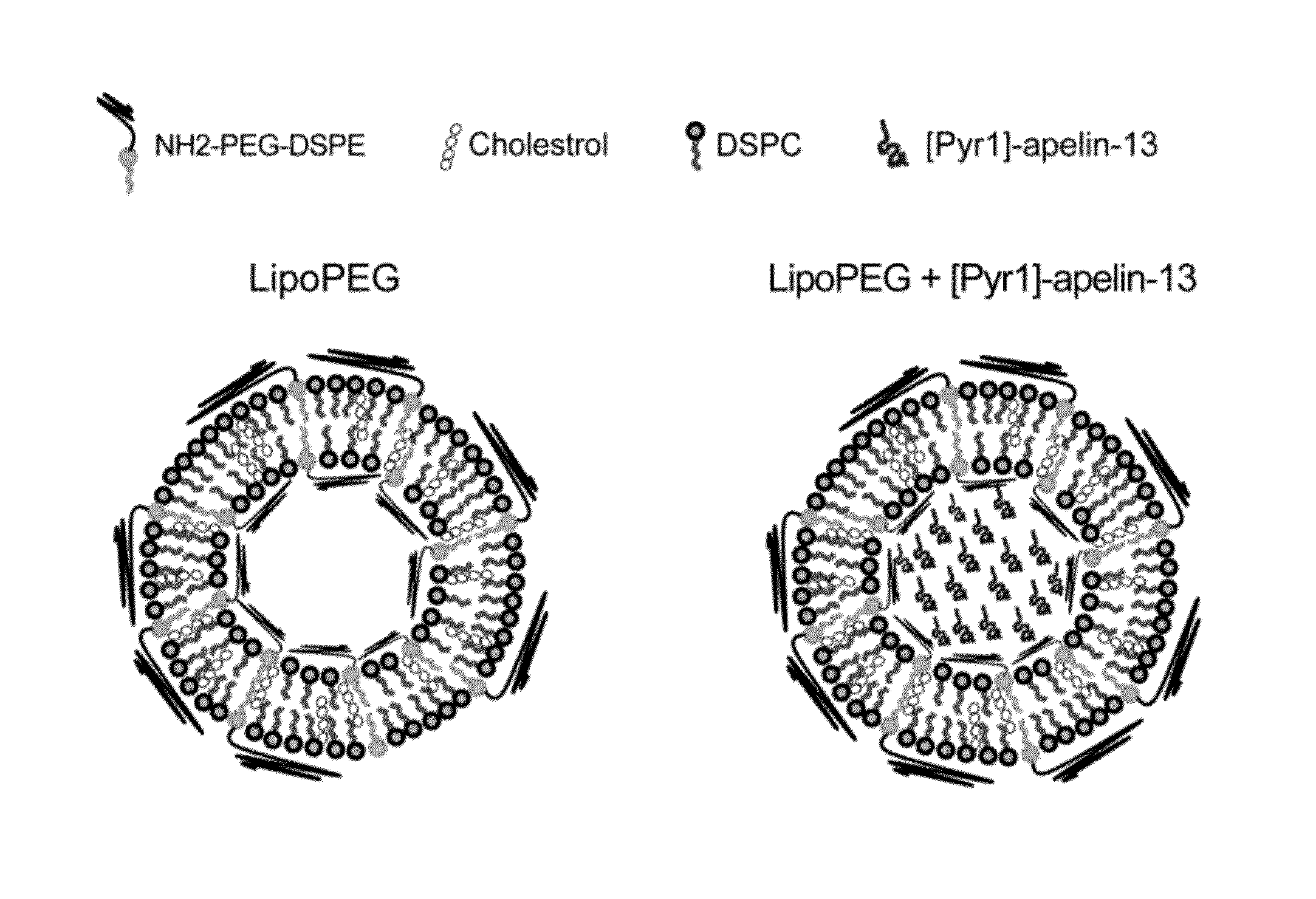

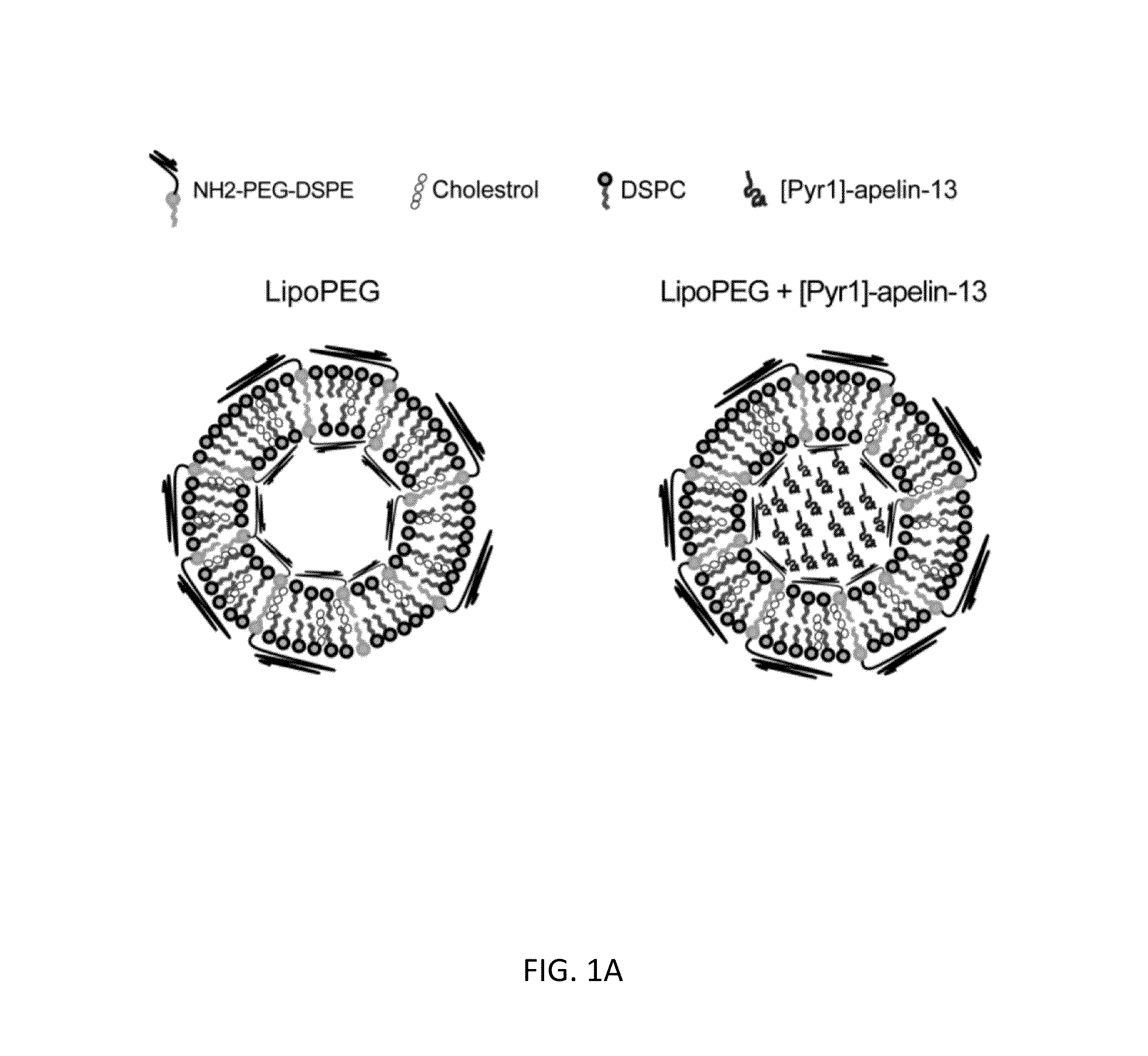

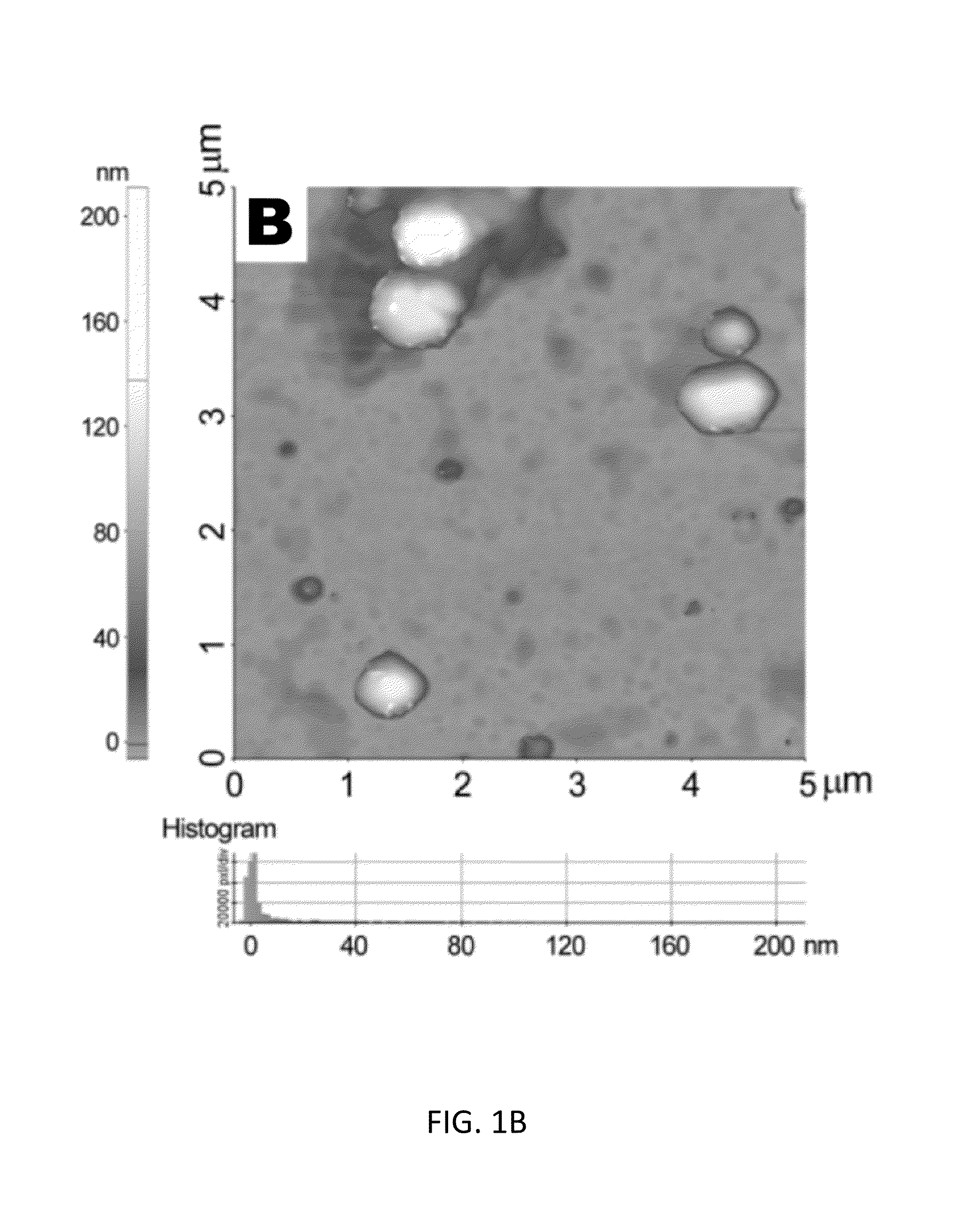

Compositions and methods for treating cardiovascular and pulmonary diseases and disorders with apelin

InactiveUS20160058705A1Improve stabilityPromote recoveryPeptide/protein ingredientsDepsipeptidesDiseaseNanocarriers

Compositions and methods for treating cardiovascular and pulmonary diseases and disorders with apelin are disclosed. In particular, the invention relates to formulations comprising apelin encapsulated in liposome nanocarriers conjugated with polyethylene glycol (PEG) and their use in treatment of cardiovascular and pulmonary diseases and disorders. Encapsulation of apelin in PEG-conjugated liposomes significantly enhances efficacy, improves cellular uptake of apelin, and allows for sustained and extended release of apelin under physiological conditions.

Owner:RAJADAS JAYAKUMAR +2

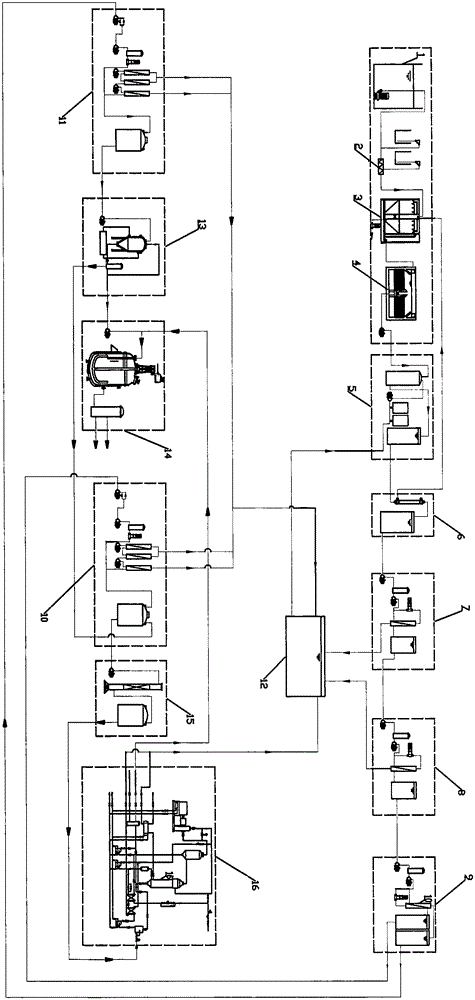

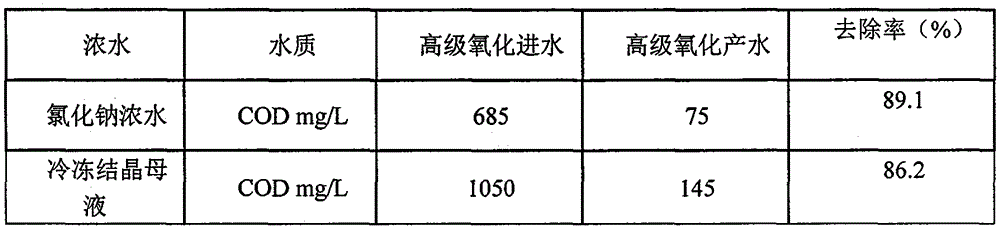

System for preparing potassium sulfate from high-salt-content industrial wastewater and technology of system

ActiveCN105645439AReduce turbidityReduce retentionTreatment involving filtrationWater/sewage treatment by ion-exchangeUltrafiltrationMirabilite

The invention relates to a system for preparing potassium sulfate from high-salt-content industrial wastewater and belongs to the field of water treatment. The high-salt-content industrial wastewater is pretreated through a regulating pool, a pipeline mixer, a high-density precipitate pool, a V-type filter pool, ion exchange resin and an ultrafiltration membrane system and then concentrated through a first section reverse osmosis membrane system and a second section reverse osmosis membrane system and then enters a nanofiltration membrane system for salt separation, nanofiltration produced water and thick water enter a plate-pipe type high-pressure flat sheet membrane system II and a plate-pipe type high-pressure flat sheet membrane system I respectively to be concentrated again, the concentrated thick water enters a freezing crystallization system for crystallization, crystals enter a potassium sulfate preparing system to be converted, freezing mother liquor and the concentrated nanofiltration produced water enter an advanced oxidizing system for oxidation and then enter an evaporative crystallization system for crystallization, and produced sodium sulfate crystal salt enters a potassium sulfate preparing system for conversion. The system has the advantages that the scale of the nanofiltration system is reduced, and investment cost is reduced; salt separation is thorough, and operation cost is low; the purity of the crystallization salt is high; mirabilite and sodium sulfateare converted into potassium sulfate, and the economic value is improved.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

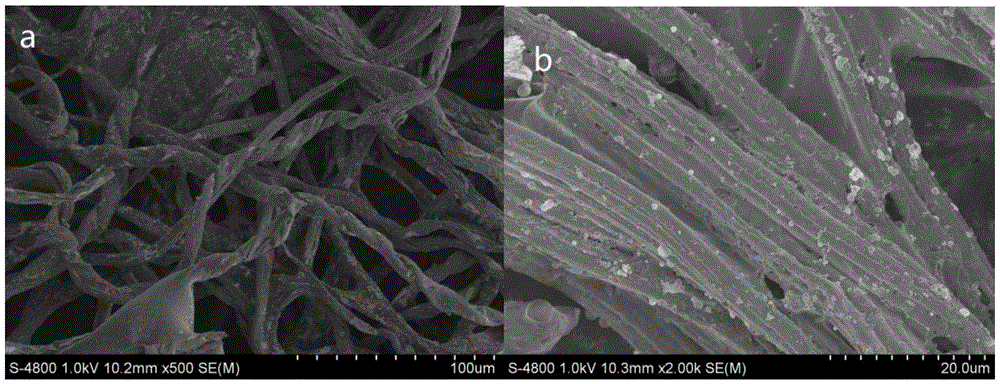

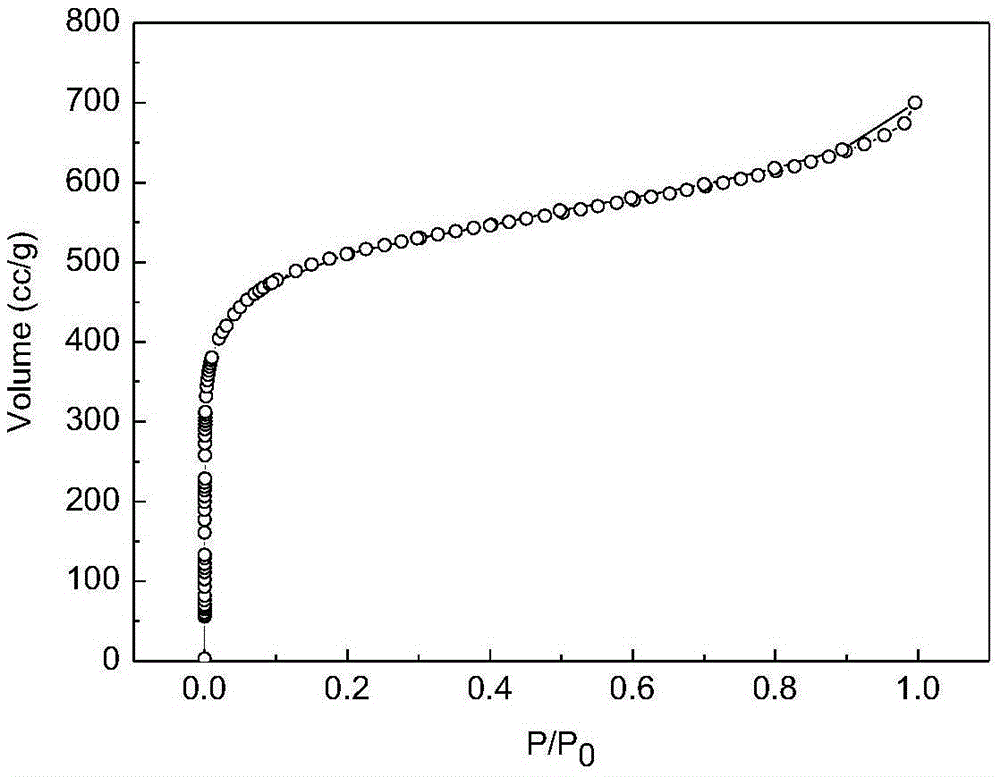

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

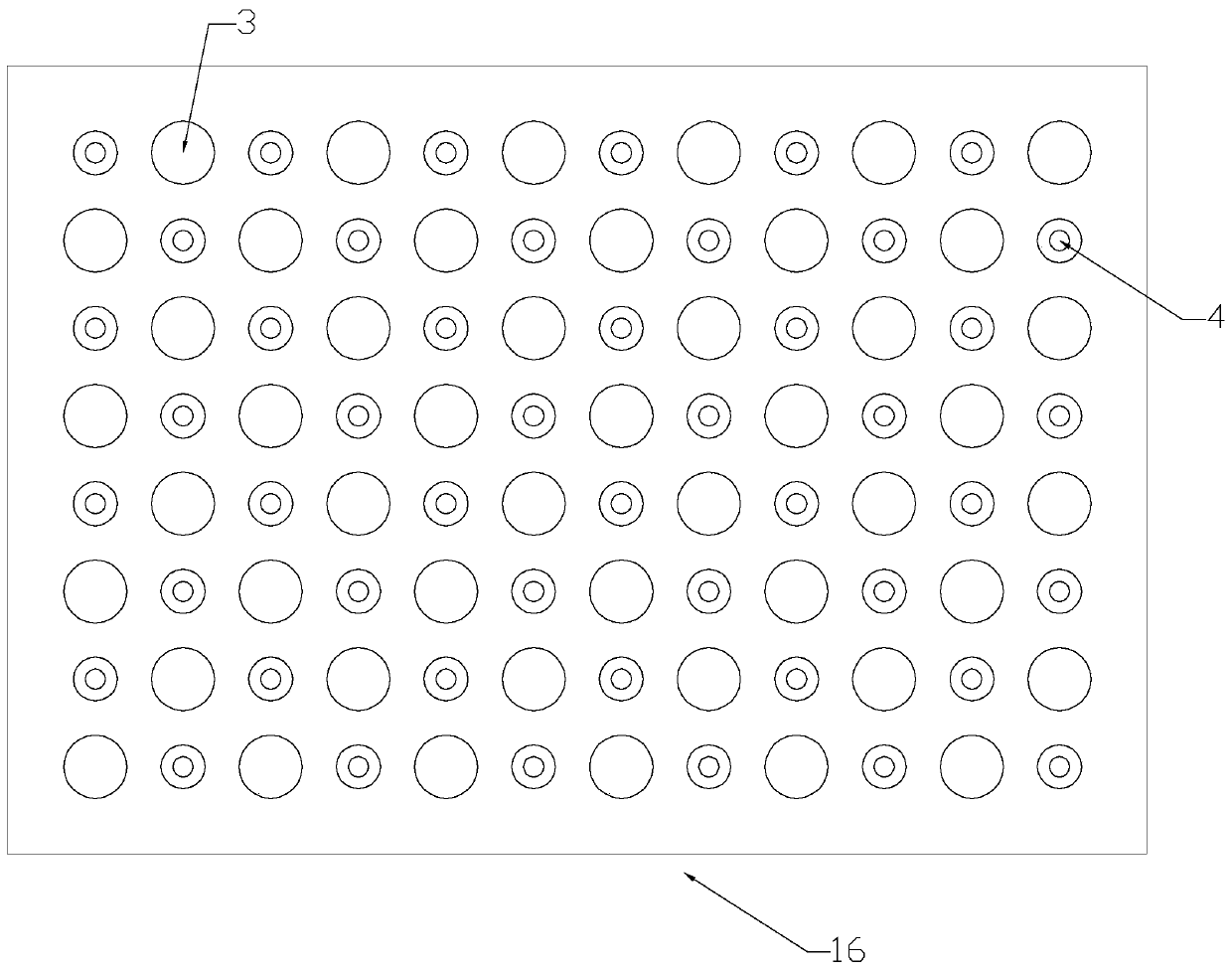

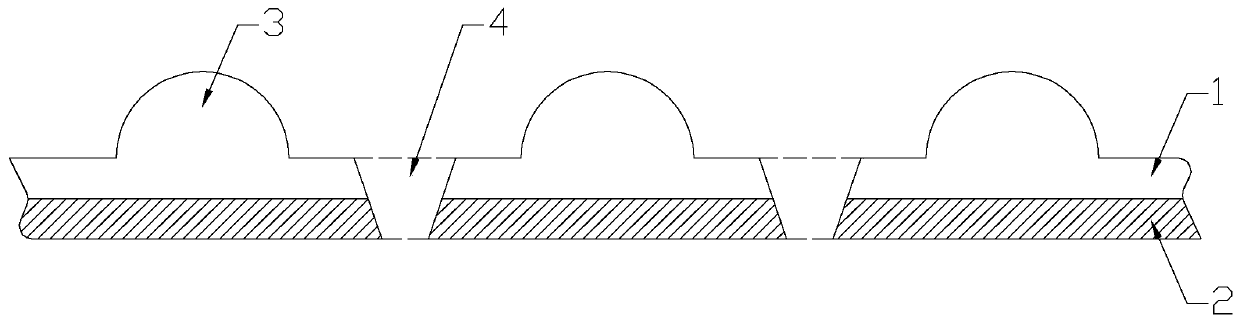

Combined spunlace non-woven fabric for personal hygiene nursing product water absorption surface layer and preparation method of non-woven fabric

PendingCN110344174AImprove comfortReduce retentionNon-woven fabricsMetal working apparatusHuman skinPolymer science

The invention relates to the technical field of spunlace non-woven, and discloses a combined spunlace non-woven fabric for a personal hygiene nursing product water absorption surface layer and a preparation method of the non-woven fabric. The spunlace non-woven fabric comprises a first fiber layer and a second fiber layer, the first fiber layer comprises hydrophilic fibers, the second fiber layercomprises hydrophobic fibers, the fibers in the first fiber layer and the second fiber layer are entangled each other, a plurality of projections and a plurality of through holes are distributed on the surface of the first fiber layer, and the through holes penetrate the second fiber layer. The non-woven fabric comprises double-layer fibers with different solution absorption performances, one surface contacting with human skins has hydrophilicity, softness and skin-friendly performance of the fabric cannot be affected, the other surface without contacting with the human skins has hydrophobicity, so that ratio of hydrophilic fibers can be reduced, liquid storage amount of the surface layer is reduced, liquid absorbed by the first fiber layer can rapidly pass the second fiber layer to entera flow guide layer, and dry and comfortable performances of surface layer materials are improved.

Owner:HANGZHOU NBOND NONWOVENS

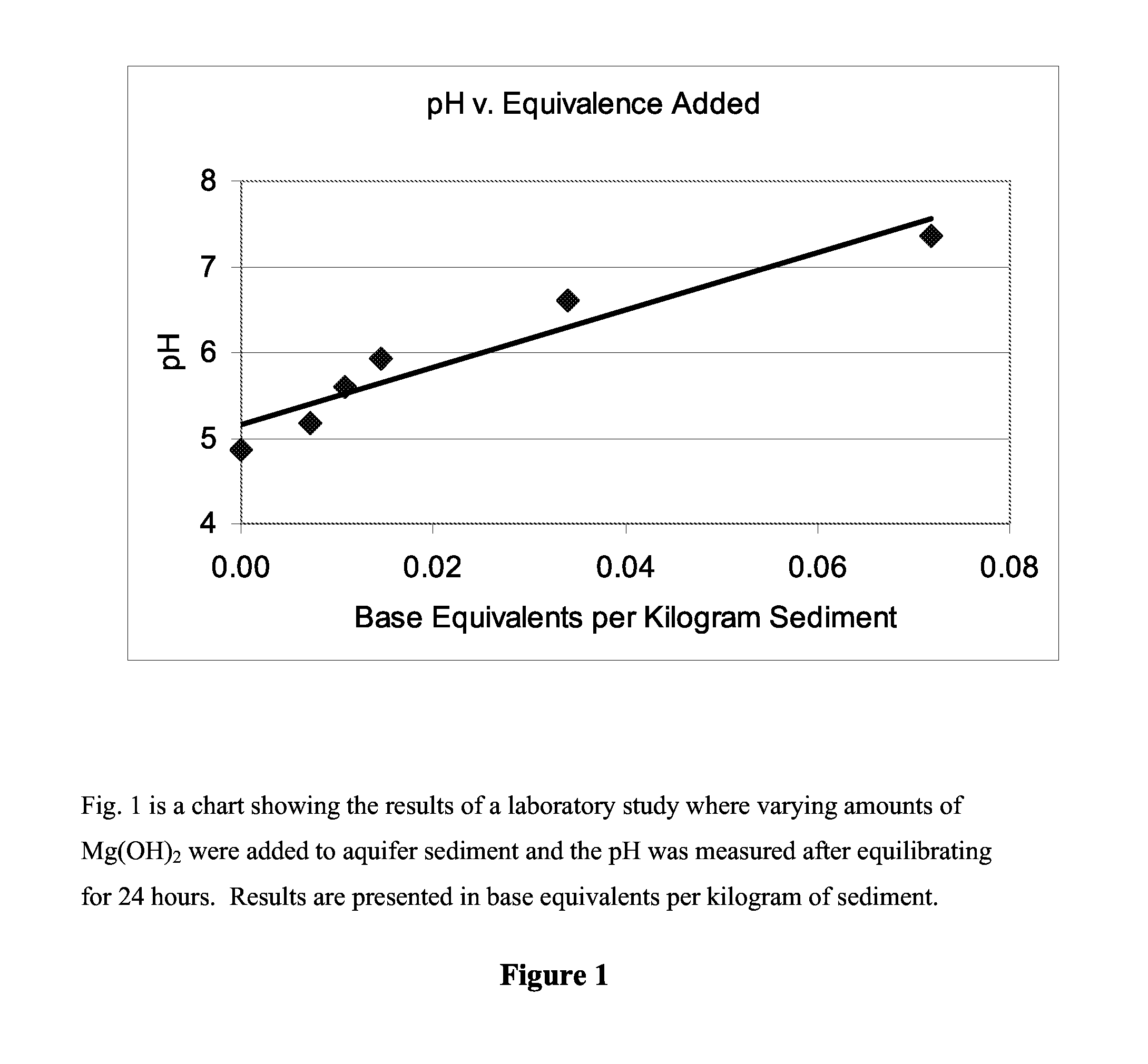

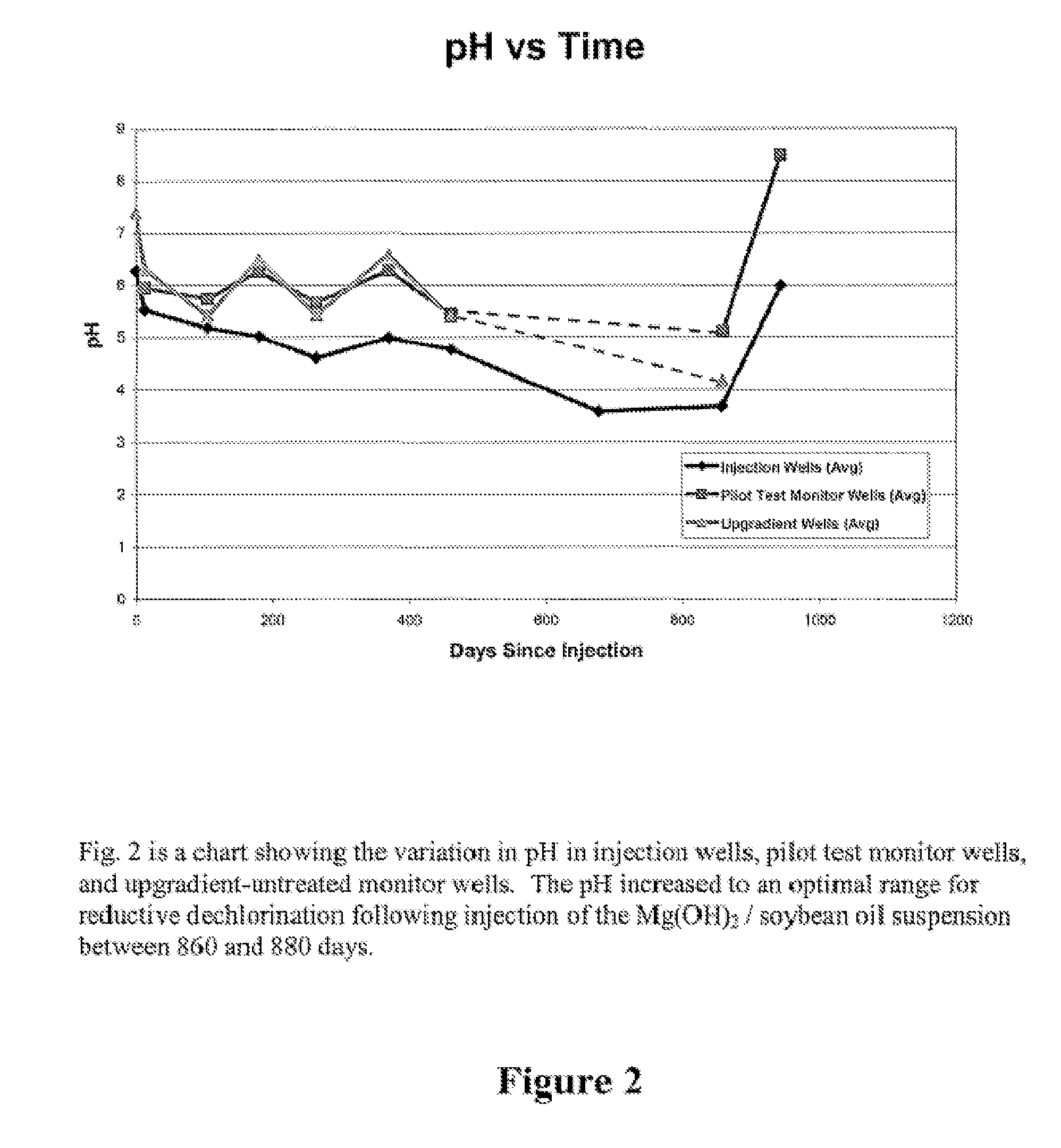

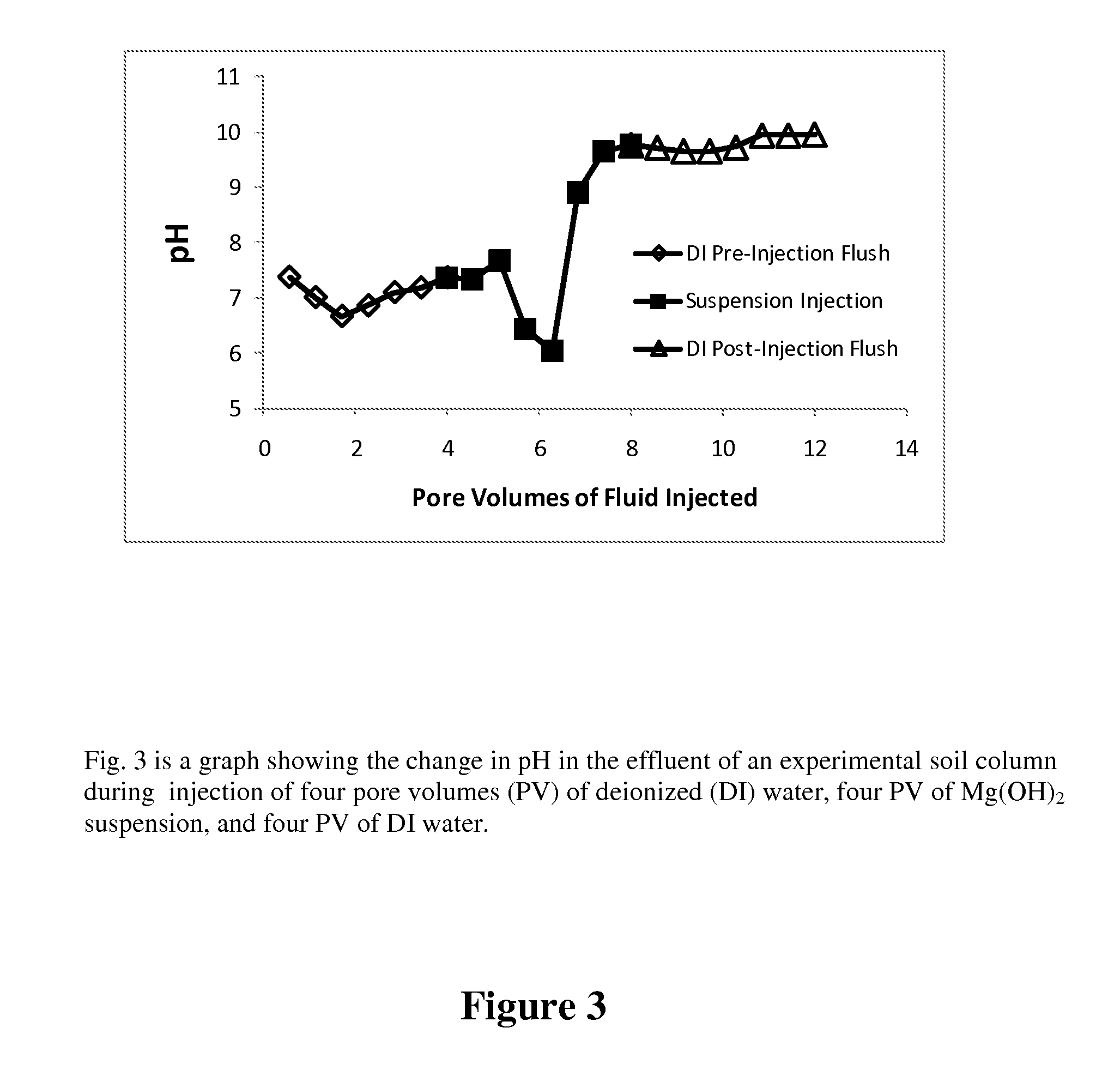

In situ ph adjustment for solid and groundwater remediation

ActiveUS20110139695A1Raise the pHImprove efficiencyWater cleaningContaminated soil reclamationMedicineGroundwater remediation

The present invention provides a safe, low-cost, effective composition and method for the remediation of contaminated subsurface material, the composition comprising solid alkaline material preferably in combination with stabilizing agents, that can be used to increase or maintain the pH of a subsurface zone and improve the performance of in situ treatment processes.

Owner:SOLUTIONS IES

Tissue press and system

InactiveUS20010008979A1Reduce retentionReduce capacitySuture equipmentsBone implantTissue GraftBiomedical engineering

A tissue press for shaping or compressing a piece of tissue comprises first and second members movable relative to each other. A first forming element of a predetermined shape is selectively engageable on the first member. A second forming element of predetermined shape is selectively engageable on the second member. The first and second forming elements are positionable on opposite sides of the piece of tissue. The first and second members are relatively movable between a first spaced apart condition and a second condition in which the piece of tissue is held between the first and second forming elements. Means are preferably provided for monitoring and controlling the amount of pressure applied to the piece of tissue, in order to maintain the tissue in a viable living condition. Means may also be provided for draining off fluid from compressed tissue, so that the tissue can be implanted in a compressed state and imbibe fluid from the host site. A retainer, which may be expandable, can be used to maintain the tissue graft in a compressed condition.

Owner:BONUTTI RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com