System for preparing potassium sulfate from high-salt-content industrial wastewater and technology of system

A technology with high salt content in industrial wastewater, applied in the field of water treatment, can solve the problems of difficulty in salt separation by evaporation and crystallization, low economic value of Glauber's salt, and low quality of crystallized salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

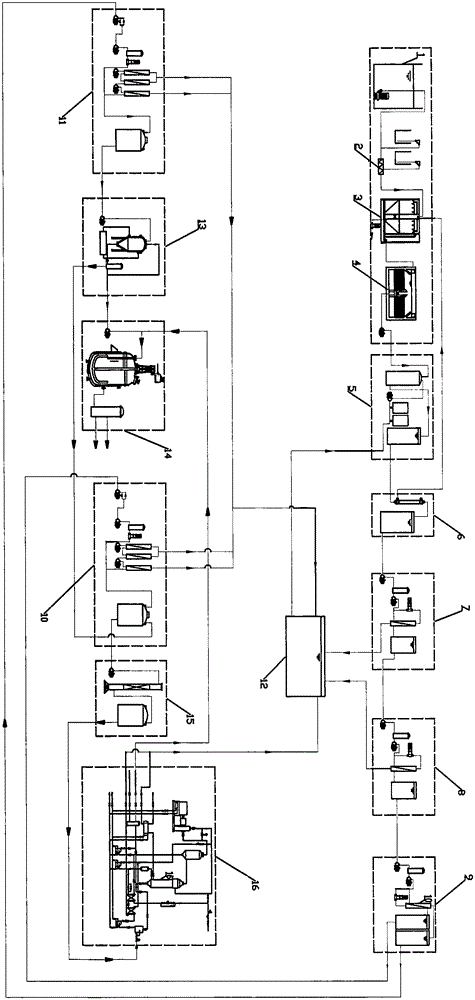

Method used

Image

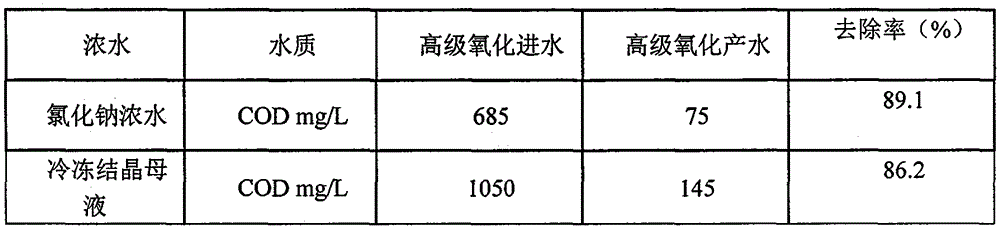

Examples

Embodiment

[0044] Highly salty wastewater discharged from a chemical industry park, the wastewater COD≤90mg / L, TDS≤12000mg / L, NaCI≤3000mg / L, Na 2 SO 4 ≤6000mg / L, total hardness ≤1000mg / L.

[0045] (1) chemical softening

[0046] Chemical softening uses sodium carbonate and sodium hydroxide to remove calcium and magnesium ions in wastewater. After the influent is precipitated by 25% NaOH and 20% sodium carbonate, add 8% to 12% polyferric sulfate (coagulant) and 0.8% PAM (coagulant aid) to coagulate in the sedimentation tank 3 Most of the hardness and calcium and magnesium ions in the concentrated water of precipitation, solid-liquid separation, and a stage of reverse osmosis are removed.

[0047] Table 1

[0048] water quality Chemical softening of incoming water chemical softening water Removal rate (%) Total hardness mg / L 980 39 96

[0049] (2) Resin softening

[0050] The water produced by the sand filter is further softened by ion exchange resin 5 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com