Feedwater treatment method by pre-ozonation and aerated biological activated carbon

An aerated organism and feedwater treatment technology, which is applied in the field of feedwater treatment and micro-polluted drinking water source purification, can solve the problems of unfavorable stable operation of coagulation and sedimentation units and great influence, and achieve the effect of hindering biochemical action and avoiding the burden of filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The monthly average of the raw water ammonia nitrogen in the dry season of the test raw water is basically 1.5-2.5mg / L.

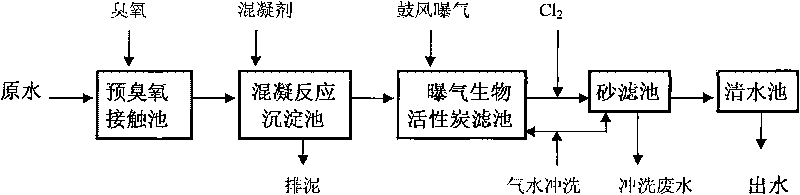

[0031] Such as figure 1 Shown, a kind of pre-ozone and aerated biological activated carbon feedwater treatment method comprises the following steps:

[0032] (1) The raw water first enters the pre-ozone contact tank, and ozone is added to the tank to pre-oxidize the raw water; calculated according to the volume of raw water, the dosage of ozone is 1.0 mg / L, and the contact time is 10 minutes;

[0033](2) Before the effluent of step (1) enters the coagulation reaction tank, dosing coagulant polyaluminum chloride is calculated according to the volume of raw water, and the dosage is 100 mg / L. After fully mixing, coagulation reaction and precipitation are carried out to remove Turbidity substances; an aerated biological activated carbon filter is set after the sedimentation tank of the treatment system, which can biodegrade ammonia nitrogen and organic ...

Embodiment 2

[0039] The monthly average of ammonia nitrogen in raw water during the test is basically 1.0-1.5mg / L.

[0040] Such as figure 1 Shown, a kind of pre-ozone and aerated biological activated carbon feedwater treatment method comprises the following steps:

[0041] (1) The raw water first enters the pre-ozone contact tank, and ozone is added to the tank to pre-oxidize the raw water; calculated according to the volume of raw water, the dosage of ozone is 0.8 mg / L, and the contact time is 10 minutes;

[0042] (2) Before the effluent of step (1) enters the coagulation reaction tank, dosing coagulant polyaluminum chloride is calculated according to the volume of raw water, and the dosage is 100 mg / L. After fully mixing, coagulation reaction and precipitation are carried out to remove Turbidity substances; an aerated biological activated carbon filter is set after the sedimentation tank of the treatment system, which can biodegrade ammonia nitrogen and organic matter, and non-biodegra...

Embodiment 3

[0048] The monthly average of ammonia nitrogen in raw water during the test is generally lower than 1.0mg / L.

[0049] Such as figure 1 Shown, a kind of pre-ozone and aerated biological activated carbon feedwater treatment method comprises the following steps:

[0050] (1) The raw water first enters the pre-ozone contact tank, and ozone is added to the tank to pre-oxidize the raw water; calculated according to the volume of raw water, the dosage of ozone is 0.5 mg / L, and the contact time is 10 minutes;

[0051] (2) Before the effluent of step (1) enters the coagulation reaction tank, dosing coagulant polyaluminum chloride is calculated according to the volume of raw water, and the dosage is 50 mg / L. After fully mixing, coagulation reaction and precipitation are carried out to remove Turbidity substances; an aerated biological activated carbon filter is set after the sedimentation tank of the treatment system, which can biodegrade ammonia nitrogen and organic matter, and non-bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com