Combined spunlace non-woven fabric for personal hygiene nursing product water absorption surface layer and preparation method of non-woven fabric

A technology of spunlace non-woven fabrics and hygiene care, which is applied in the direction of non-woven fabrics, textiles, papermaking, and paper machines. Conducive to the growth of bacteria and the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

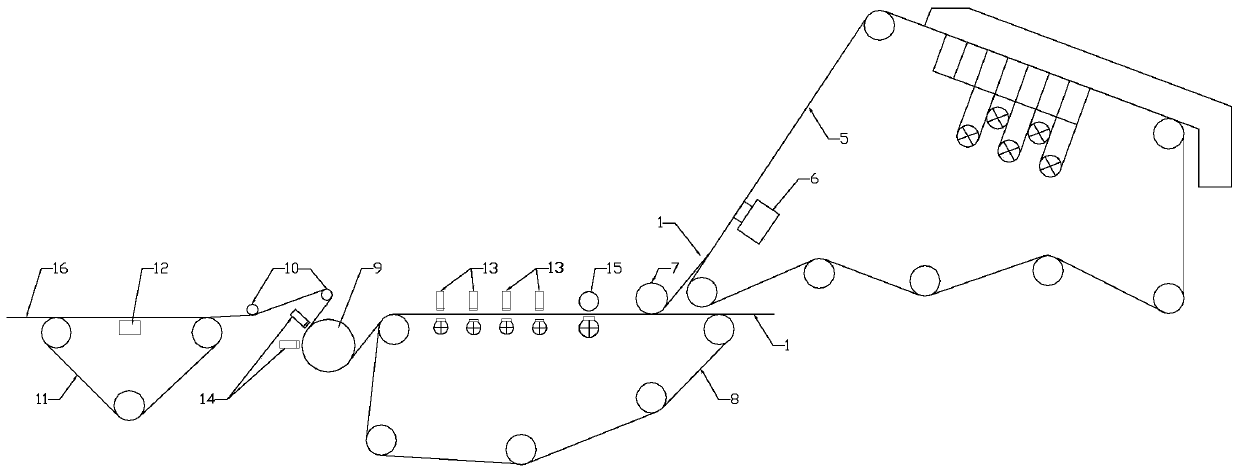

[0086] A method for preparing a combined spunlace nonwoven fabric, comprising the following steps:

[0087] 1) Send the raw materials of the second fiber layer into the unloading tank in proportion to disperse the fibers to make a fiber slurry with a concentration of 0.1-1wt%; remove impurities and fiber clusters, so that the fibers in the fiber slurry are in a single fiber state .

[0088] 2) After the fiber slurry is stirred and diluted, it is sent to the inclined wire former through the slurry pump, and the second fiber layer is made after being netted, formed and dehydrated; the second fiber layer is placed on the forming wire.

[0089] 3) After the raw materials of the first fiber layer are fed in proportion, the first fiber layer is made through the processes of opening, mixing and carding in sequence.

[0090] 4) The first fiber layer is introduced onto the hydroentangled screen, and then the second fiber layer is peeled off from the forming net and transferred to the ...

Embodiment 1

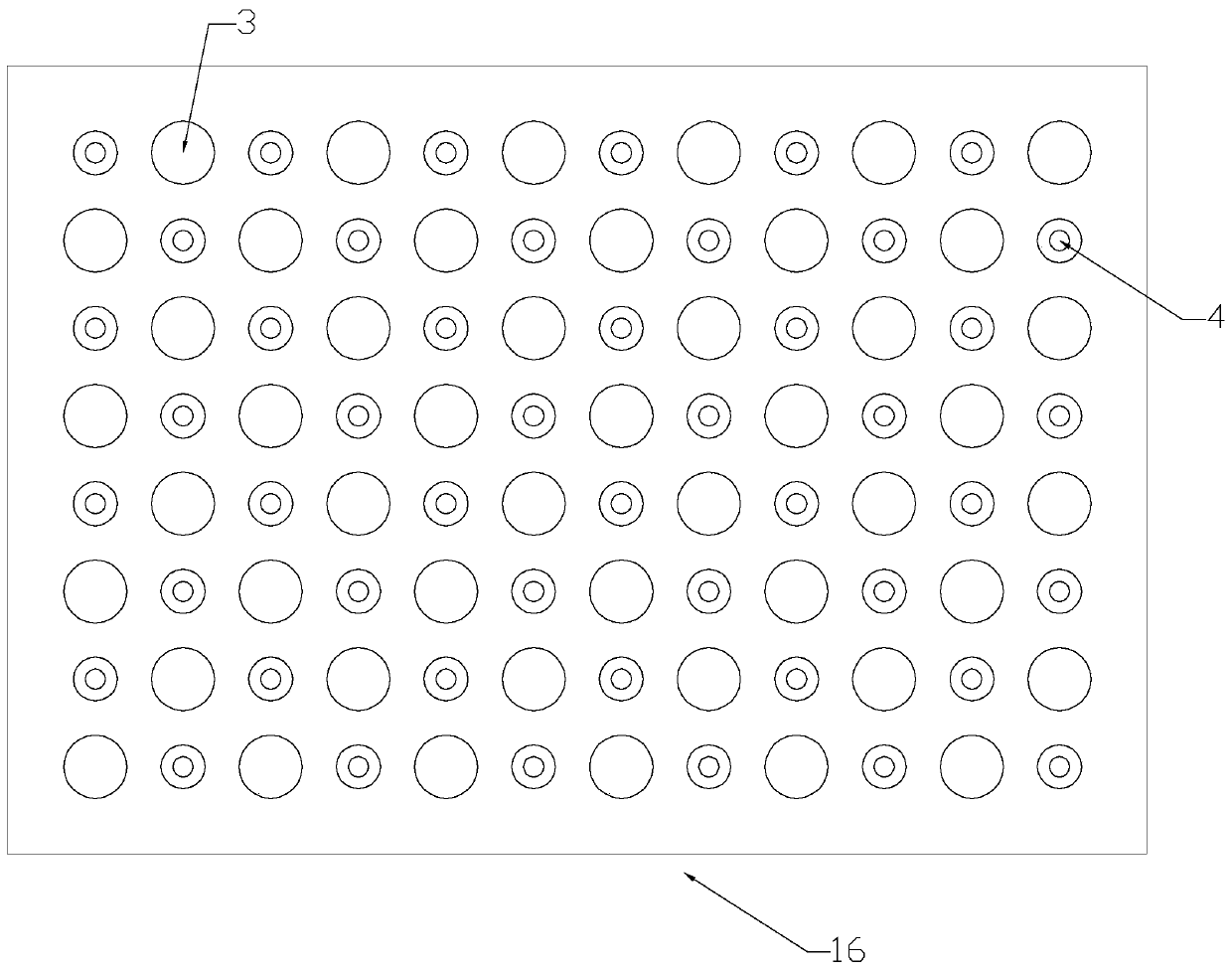

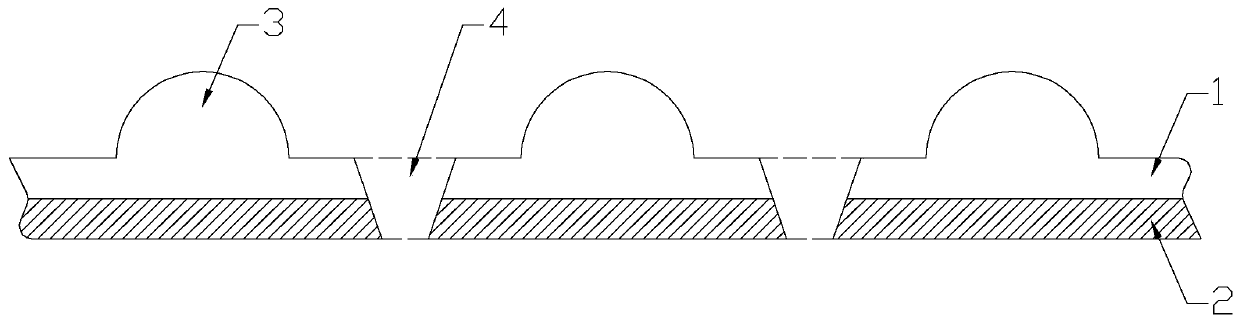

[0099] Such as Figure 1-2 As shown, a combined spunlaced non-woven fabric used for water-absorbing surface layers of personal hygiene products, including the first fiber layer and the second fiber layer connected by upper and lower layers; the first fiber layer contains mass The cotton fiber of percentage 100%; The hydrophobic fiber that contains mass percentage 100% in the described second fiber layer; The fibers in the first fiber layer and the second fiber layer are entangled with each other; The surface distribution of the first fiber layer There are several protrusions and several through holes passing through the second fiber layer; the opening area of the through holes on the top surface of the first fiber layer is larger than the opening area on the bottom surface of the second fiber layer.

[0100] The opening ratio of the through-holes is 35%; the protrusions and the through-holes are alternately arranged and distributed; the conventional moisture regain of the hy...

Embodiment 2

[0116] A combined spunlace non-woven fabric used for the water-absorbing surface layer of personal hygiene care products, including a first fiber layer and a second fiber layer connected by upper and lower layers; the first fiber layer contains 80% by mass Hydrophilic fibers and 20% polyester fibers; the second fiber layer contains 90% by mass percentage of hydrophobic fibers and 10% ultra-short viscose fibers; the first fiber layer, the second fiber layer The fibers of the first fiber layer are entangled with each other; the surface of the first fiber layer is distributed with some protrusions and some through holes that go through the second fiber layer; the opening area of the through holes on the top surface of the first fiber layer is larger than that on the bottom surface of the second fiber layer of the opening area.

[0117] The porosity of the through-holes is 45%; the protrusions and the through-holes are alternately arranged and distributed; the conventional moist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com