Patents

Literature

213 results about "Heat not burn" patented technology

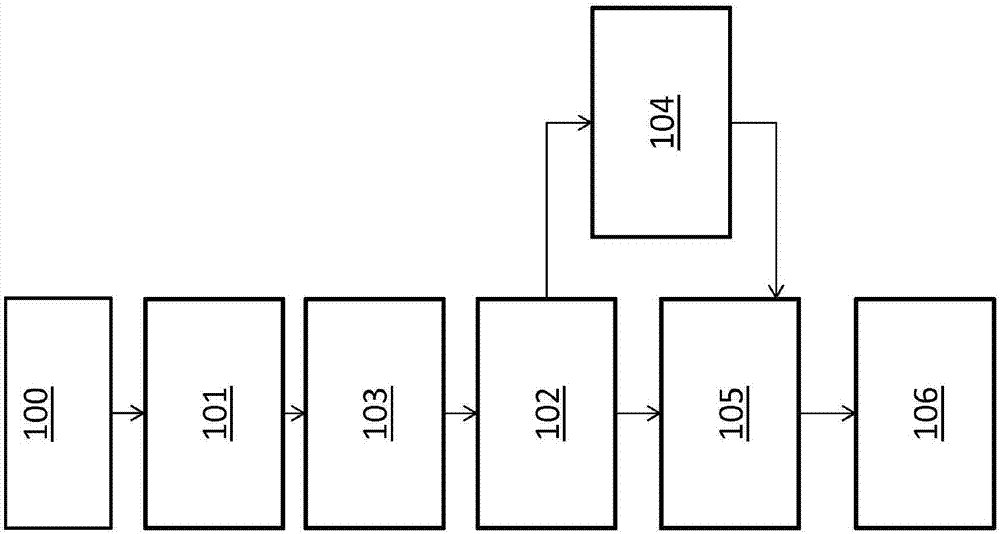

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat Not Burn works exactly as the name suggests. Instead of burning tobacco, HNB devices heat tobacco, creating a vapour that contains nicotine. As we know that the harm from smoking is not from the nicotine but the combustion caused when you burn tobacco, it should be much safer than smoking.

Heat-not-burn cigarette smoke cooling material and application thereof

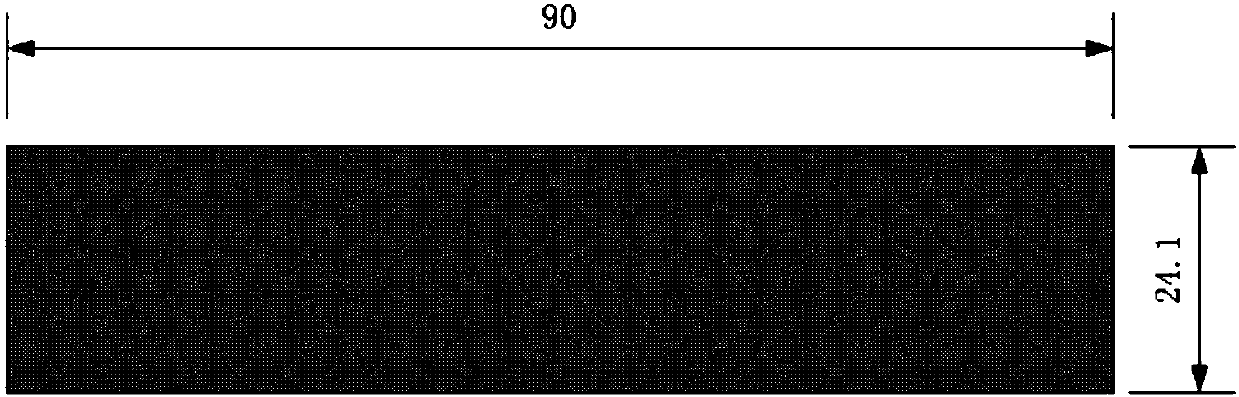

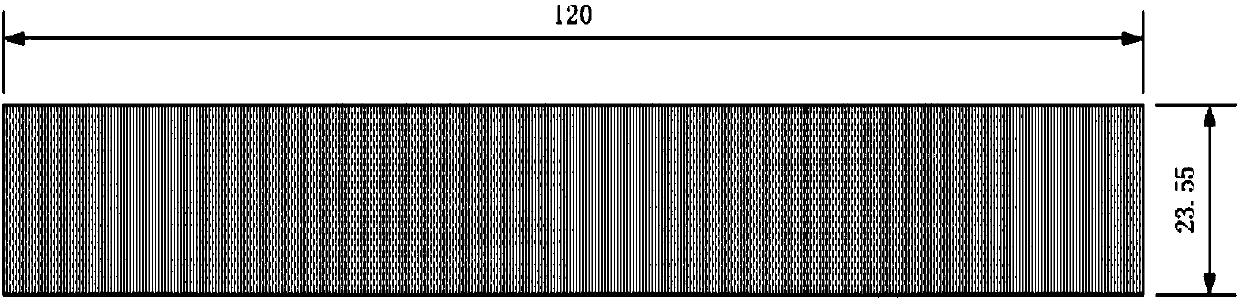

ActiveCN108143004AAvoid heat shrinkage defectsExcellent heat shrinkage resistanceTobacco devicesCooling effectHeat not burn

The invention discloses a heat-not-burn cigarette smoke cooling material and application thereof. The heat-not-burn cigarette smoke cooling material is prepared from, by mass, polymer 50-75%, layerednano material 5-15%, fibrous nano material 4-15%, phase change material 5-10% and metal powder 3-10% by adopting screw extrusion processing. The heat-not-burn cigarette smoke cooling material has highheat resistant shrinkage by means of addition of the layered nano material and the fibrous nano material, and the defect that a polylactic acid cooling material shrinks due to heat is avoided; the exogenous phase change material is added, so that the heat-not-burn cigarette smoke cooling material has a better cooling effect; in addition, the heat-not-burn cigarette smoke cooling material has a low interception rate of smoke, and the suction experience is not affected basically.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Preparation method of heat-not-burn reconstituted tobacco through roll-in method and application thereof

InactiveCN108065448AIncrease contentHigh in fiberTobacco preparationCigar manufactureFiberFood grade

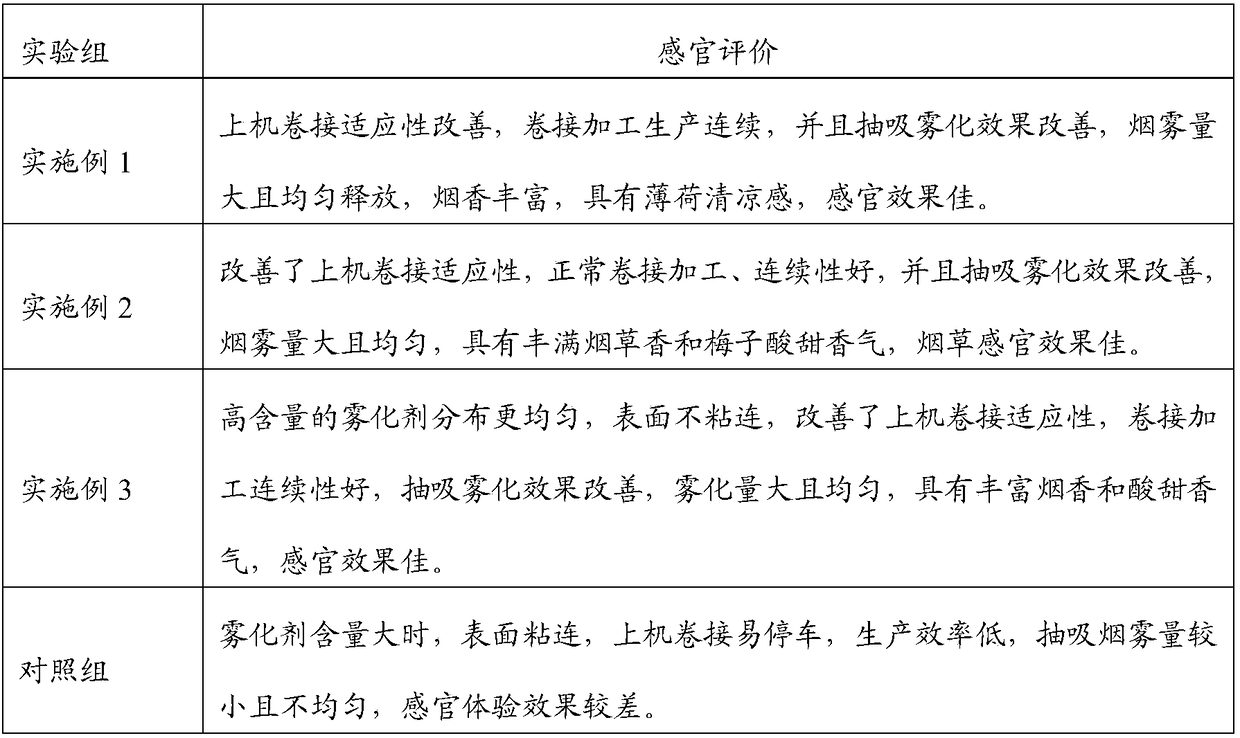

The invention discloses a preparation method of heat-not-burn reconstituted tobacco through a roll-in method and application thereof. On the basis of a roll-in method technology, a technical method isimproved, the heat-not-burn reconstituted tobacco is prepared, the problem of high-proportion addition of a fogging agent is solved, and a food-grade adhesive is used for evenly dispersing and solidifying the fogging agent into a tobacco material; the content of the fogging agent of the prepared heat-not-burn reconstituted tobacco is increased, the heat-not-burn reconstituted tobacco is evenly distributed at the same time, the surface is not sticky, the fiber content is increased, the tensile strength is improved, the machining resistance is good, smoke is evenly released during smoking, thesensory effect is good, and the simulated feeling of cigarette smoking is good.

Owner:HUBEI CHINA TOBACCO IND

Heat-not-burn reconstituted tobacco with high heat transfer performance and preparation method of heat-not-burn reconstituted tobacco

InactiveCN110150722AHigh densityImprove heat transfer performanceTobacco preparationTobacco treatmentHigh densityHeat transmission

The invention belongs to the field of novel tobacco manufacturing products, and particularly relates to a heat-not-burn reconstituted tobacco with the high heat transfer performance and a preparationmethod of the heat-not-burn reconstituted tobacco. The heat-not-burn reconstituted tobacco with the high heat transfer performance comprises the following raw materials: plant fibres, cigarettes and tobacco raw materials, heat conduction materials, a smoke agent, accessories, perfume raw materials and moisture; according to the heat-not-burn reconstituted tobacco, cigarette core materials used fora heat-not-burn cigarette are prepared and obtained, due to the characteristics of high heat conduction materials and the high density core materials uniformly distributed in the core materials, thehigh heat transfer performance is provided, the problems that when the heat-not-burn reconstituted tobacco is prepared by a traditional paper-making method, nonuniform heat transmission is caused by the poor heat transfer performance of proximate materials, smoke releasing and fragrance releasing are little, the number of suction mouth is few, and the quality of suction is poor are solved, strongcigarette fragrance, sufficient smoke quantity, the excellent physical processing performance and the good suction quality are given to the heat-not-burn cigarette.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

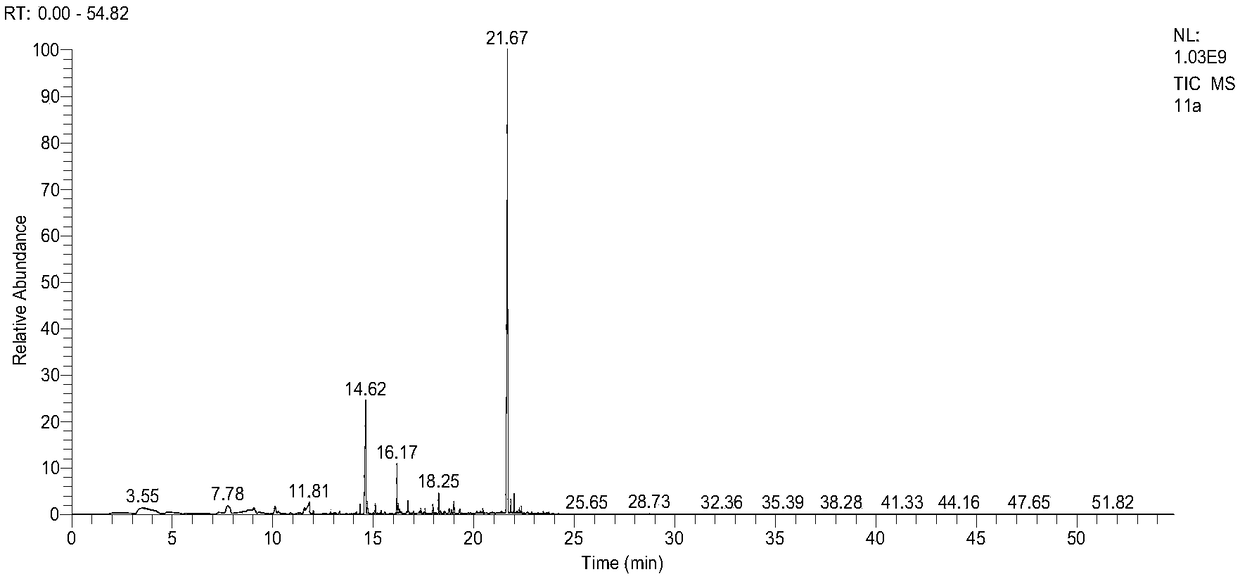

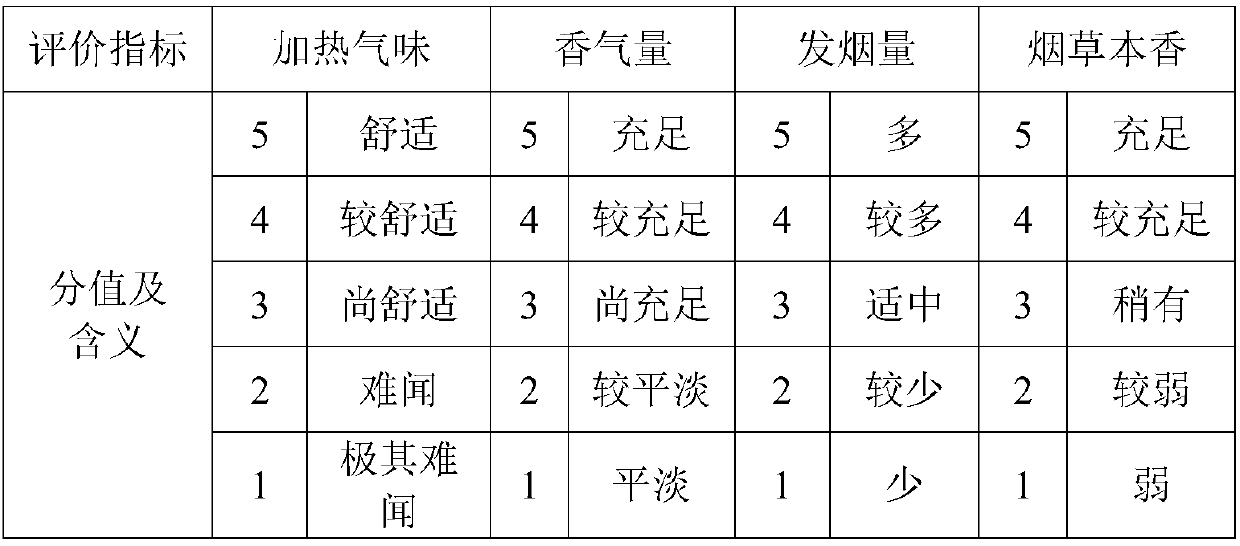

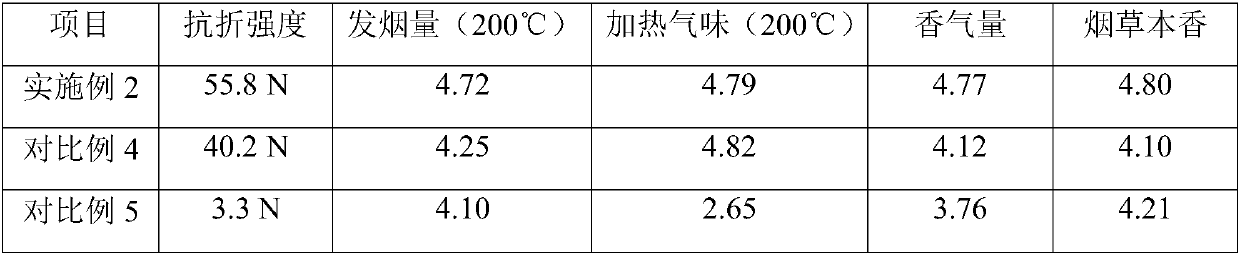

Fuming product and preparation method and application thereof

InactiveCN107616540AEffective bondingEasy to put inTobacco treatmentHeat not burnUltimate tensile strength

The invention discloses a fuming product and a preparation method and application thereof, and belongs to the technical field of tobaccos. The fuming product comprises an inorganic binder, an inorganic adsorbing material, the tobaccos, a fogging agent, water and essence. After extrusion forming, the fuming product prepared by using the method is of an integrated structure, the bending strength ishigh, and the structure is not prone to damage; when the fuming product is applied to a heat-not-burn tobacco product, a heat-not-burn device is easy to place and take out, no powder or particles aregenerated, and convenience is brought to cleaning; a lot of smoke and aroma matter can be generated, the smoking feeling of a customer is improved; the tobacco content can be precisely controlled, thearoma matter in the tobacco raw materials is extracted under an thermal action, and nicotine is released; the preparation method and the forming technology are simple.

Owner:SHANGHAI TOBACCO GRP CO LTD

Tobacco substrate suitable for heat-not-burn effect and preparation method thereof

ActiveCN107319628AImprove uniformityImprove heat transfer efficiencyTobacco preparationFiberAdhesive

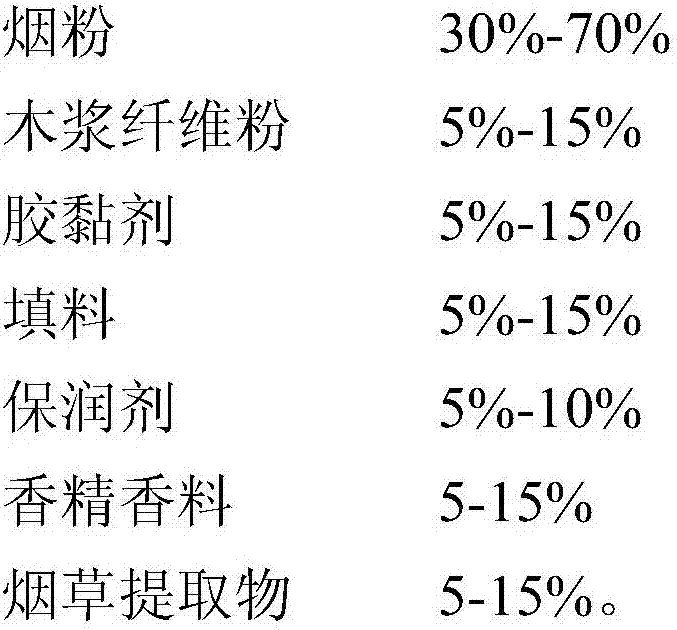

The invention discloses a tobacco substrate suitable for a heat-not-burn effect and a preparation method thereof. The method comprises the following steps of 1, obtaining tobacco powder with particle size distribution of 60-200 mesh after tobacco raw materials are ground into powder and sieved, and obtaining wood pulp fiber powder with size distribution of 60-200 mesh after wood pulp fibers are ground into powder and sieved; 2, mixing the tobacco powder, the wood pulp fiber powder, adhesives, filler, moisturizing agents, flavors, fragrances and tobacco extracts according to a ratio to obtain mixed slurry, then adding water in the mixed slurry for stirring, and conducting uniform mixing to obtain loose granular slurry; 3, pressing the granular slurry into sheets, and conducting drying after sheet pressing to obtain the sheet-shaped heat-not-burn tobacco substrate. In the preparation process of the substrate, the step is taken into consideration that the tobacco raw materials are ground into powder at first, and the structures of the fibers are destroyed, so that the specific surface area of the raw materials is increased; meanwhile, the strength problem in the molding process is taken into consideration, partial long wood pulp fibers are adopted to be ground into powder to improve the strength of the substrate, and the powder is mixed with the tobacco extracts more uniformly during preparation.

Owner:CHINA TOBACCO ZHEJIANG IND

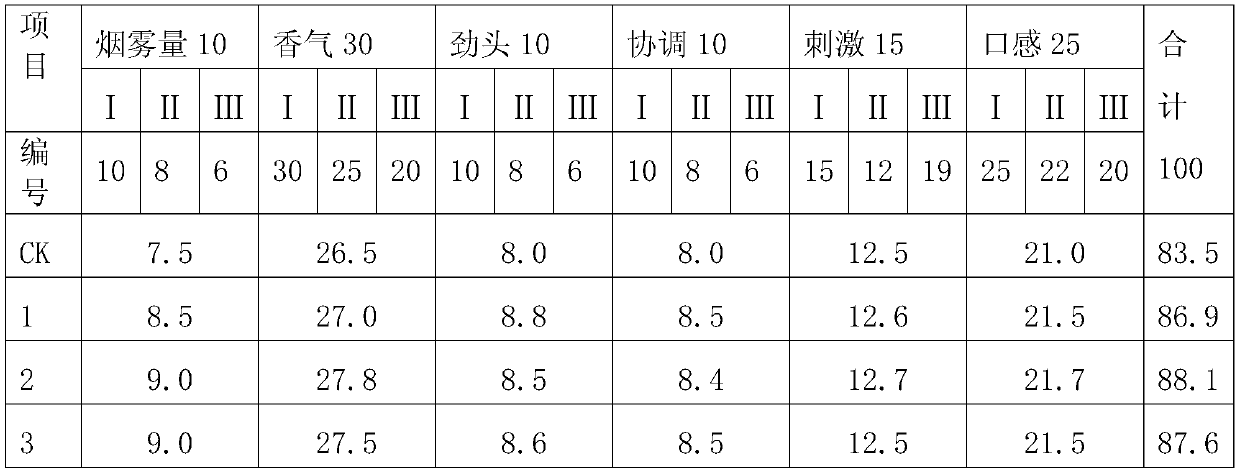

Method for preparing heat-not-burn tobacco bases containing active carbon

ActiveCN105747264AReduce the impactIncrease loadTobacco preparationTobacco treatmentActivated carbonFlavor

The invention discloses a method for preparing heat-not-burn tobacco bases containing active carbon.The method comprises the following steps that active carbon is weighed and mixed with water, defibering and pulping are conducted, and active carbon pulp is obtained; tobacco raw materials are weighed, soaked, filtered and pulped so that tobacco pulp can be obtained; by weight, 50-80 parts of tobacco pulp, 8-25 parts of wood pulp, 10-30 parts of active carbon pulp and 4-8 parts of adhesive are weighed and evenly mixed; the mixture is formed and dried so that the tobacco bases are obtained; by weight, 1-40 parts of tobacco essential oil, 2-20 parts of tobacco flavor material and 40-80 parts of atomization agent are weighed and evenly mixed so that coating liquid can be obtained; the coating liquid is sprayed to the tobacco bases, standing is conducted for 40-48 h under the constant-temperature and constant-humidity conditions, and finally the heat-not-burn tobacco bases containing active carbon are obtained.Cigarettes prepared from the tobacco bases are put in a smoking set to be used, good satisfaction can be brought to consumers, the amount of smoke is large, the fragrance concentration is high, and the quality of heat-not-burn cigarettes is improved better.

Owner:CHINA TOBACCO GUIZHOU IND

Low-temperature cigarette processing method and application thereof

InactiveCN108477668AEvenly distributedIncrease contentTobacco preparationTobacco treatmentMicrowaveChemical reaction

The invention aims to provide a low-temperature cigarette processing method and application thereof. On the basis of thick pulp and roll-pressing reconstituted tobacco processes, ultrasonic waves areused for stirring and mixing materials evenly, so that an atomizing agent in higher proportion is uniformly distributed in heat-not-burn reconstituted tobaccos, the bonding is good, there is no adhesion on the surfaces, the strength of the reconstituted tobaccos is good, the rolling adaptability of the heat-not-burn reconstituted tobaccos on a machine is improved, an existing rolling unit can conduct normal rolling, the production continuity is good, the production efficiency is high, chemical reaction occurs in the heating and drying process, bubble pores are internally formed, the internal surface area is increased, the distribution of the high-content atomizing agent is more uniform, and the suction and atomization effects of the rolled low-temperature cigarette are improved, the cigarette fragrance is rich, and the sensory effect is good.

Owner:HUBEI CHINA TOBACCO IND +1

Ultra-micro powder plant slice and preparation method thereof

The invention relates to an ultra-micro powder plant slice and a preparation method thereof. The preparation method comprises the steps that ultra-micro plant powder, outer margin fibers, an adhesiveand other additives are homogenized to form adhesive colloidal fluid, the adhesive colloidal fluid is extruded to form a slice shape, and drying formation is conducted. The plant slice is suitable fora heat-not-burn flavor-producing section, the plant slice is large in smoke formation amount, rich in fragrance and high in physiological satisfiability, the smoke flavor is close to natural plant fragrance, the product density and the filling value are close to those of natural plant leaves, the machining performance is high, and the amount of water required during production is small; no wastewater is generated, the raw material utilization rate is high, the plant slice meets the requirements for energy conservation and environment protection, the production technology is simple, and the preparation method is suitable for industrial production.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

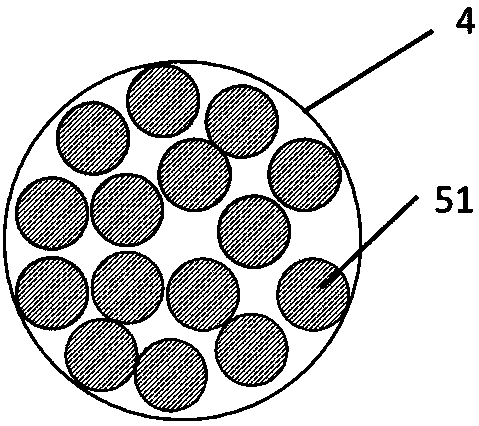

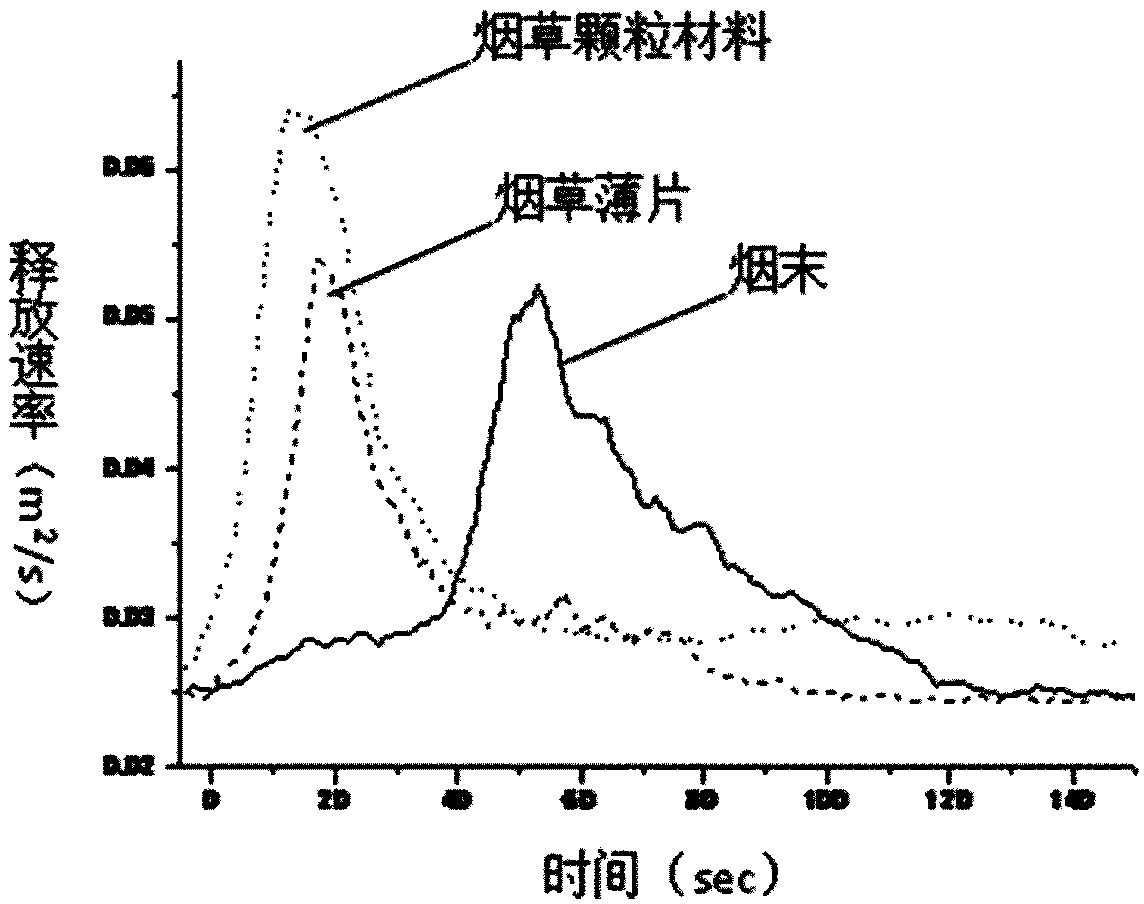

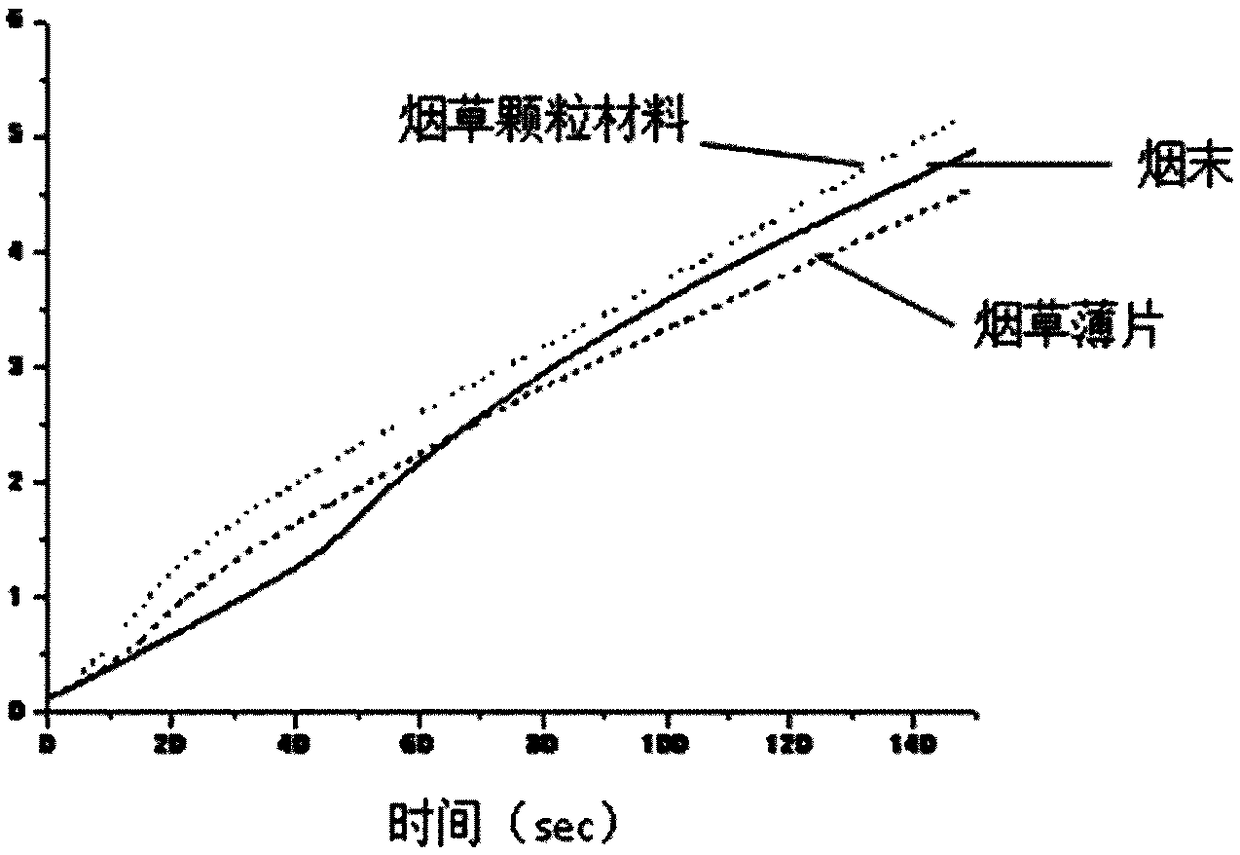

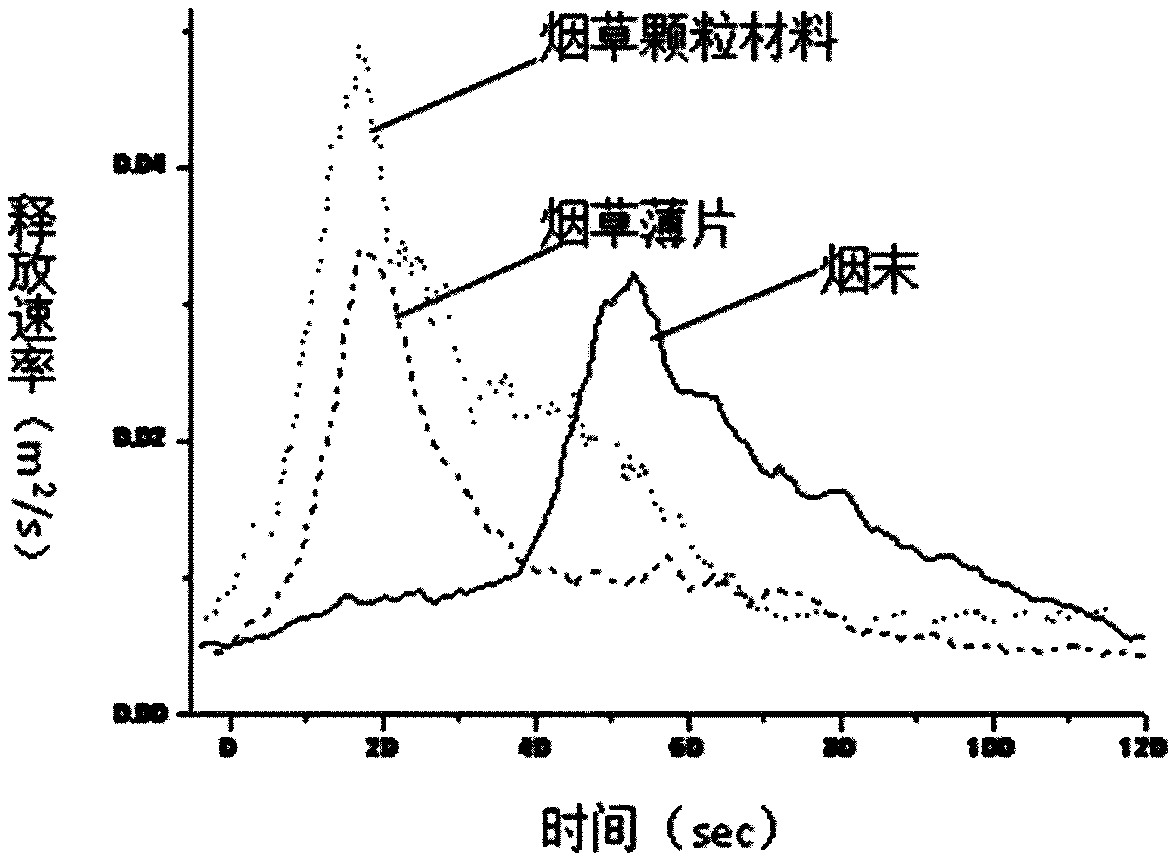

Smoke-releasing granular material suitable for heat-not-burn tobacco producTS and preparation method thereof

The invention discloses a smoke-releasing granular material suitable for heat-not-burn tobacco producTS and a preparation method thereof. The smoke-releasing granular material is prepared from, by mass, 40%-60% of tobacco ultrafine powder, 0-10% of other biomass powder, 5-10% of tobacco dry distillate, 20-40% of atomizing agent, 1-5% of binder and the balance tobacco essences and flavors. The smoke-releasing granular material is uniform in granularity, the addition amount of the atomizing agent can be adjusted arbitrarily according to demands, the amount of released smoke is large, and the similar smoking satisfaction can be provided for consumers in the heat-not-burn state. Through the addition of the tobacco dry distillate, the sensory quality of the smoke can be significantly improved,so that the smoke has excellent uniformity, aroma, concentration and strength; through the cooperative use of the other biomass powder, the smoke is endowed with a unique flavor and mouthfeel.

Owner:CHINA TOBACCO ANHUI IND CO LTD

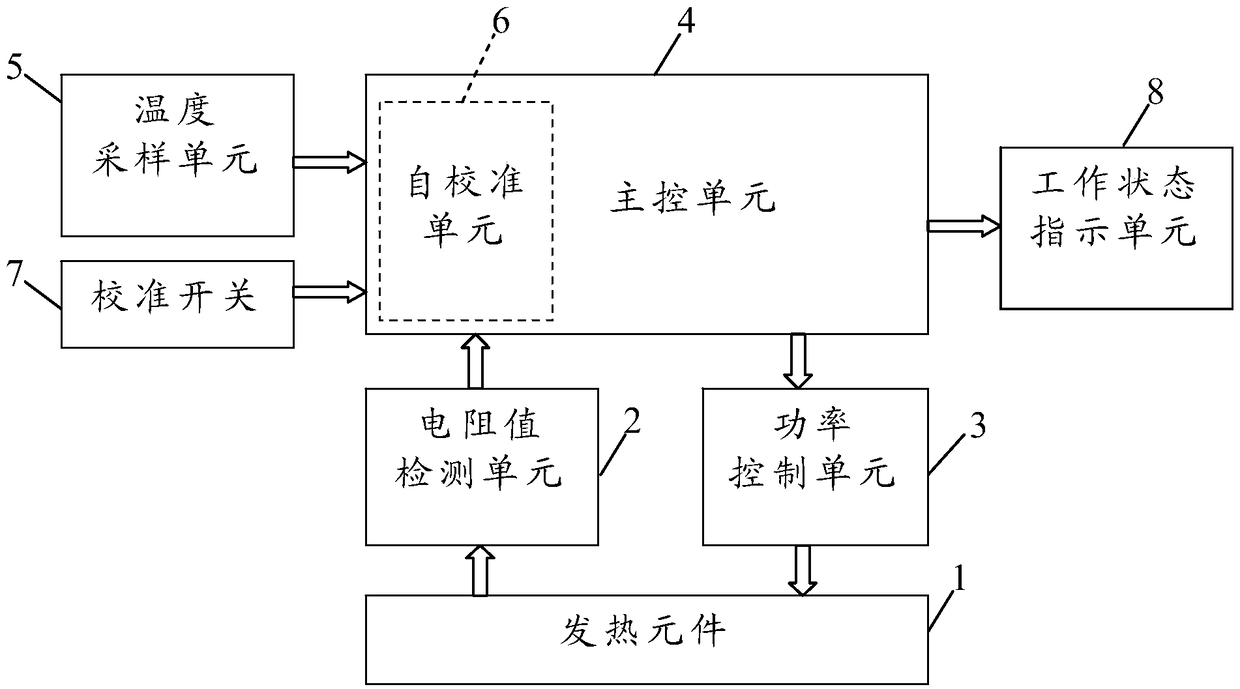

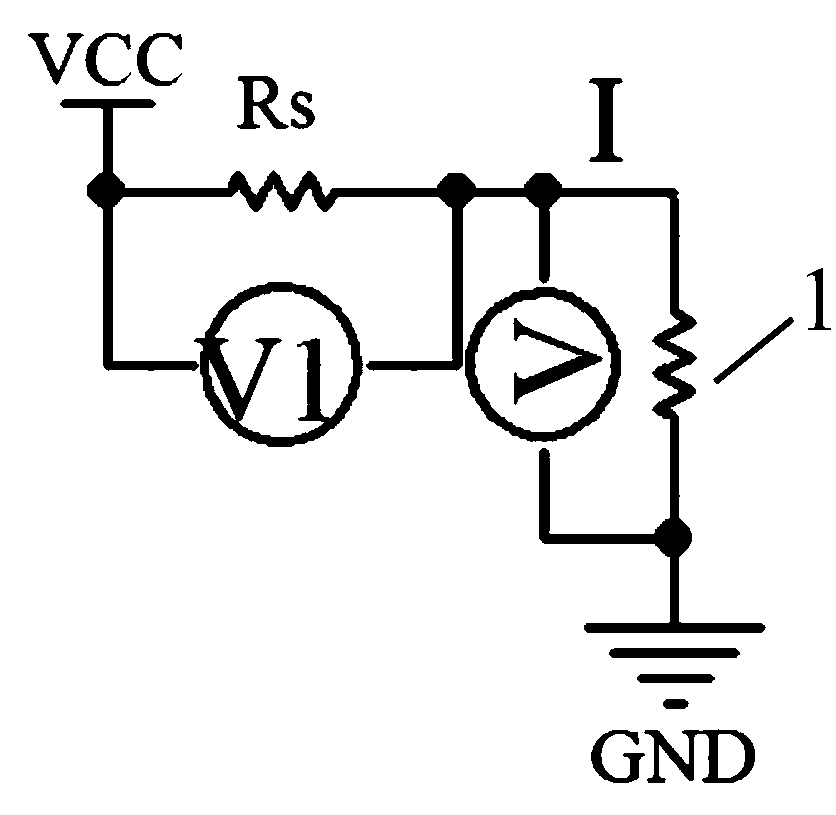

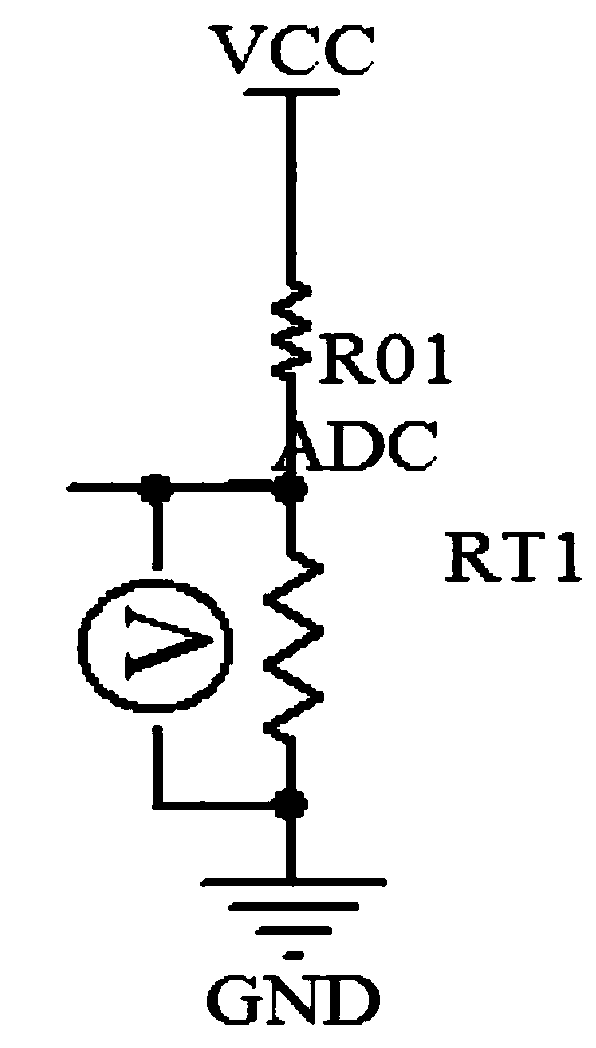

Electrical-heat-not-burn smoking set and temperature control device thereof

ActiveCN109043675AEasy to replacePrecise temperature controlTobacco devicesElectricityElectrical resistance and conductance

The invention discloses an electrical-heat-not-burn smoking set and a temperature control device thereof. The temperature control device comprises a heating element, a power control unit, a resistancevalue detection unit, a main control unit connected with the power control unit and the resistance value detection unit, a temperature sampling unit which is connected with the main control unit is in physical contact with the heating element and is used for sampling the standard temperature of the heating element, a self-calibration unit for calibrating the temperature-resistance relationship ofthe heating element through the standard temperature and a calibration switch, wherein the power control unit and the main control unit are connected with the heating element. The electrical-heat-not-burn smoking set comprises the temperature control device. After the self-calibration unit, the temperature sampling unit and the self-calibration switch are arranged, the temperature-resistance relationship of the heating element can be automatically calibrated, temperature controlling of the smoking set is more accurate, later-period heating element replacement is convenient, the smoking set isnot required to be manually calibrated in production, the production process is simplified, and the production efficiency is improved.

Owner:钟桥云

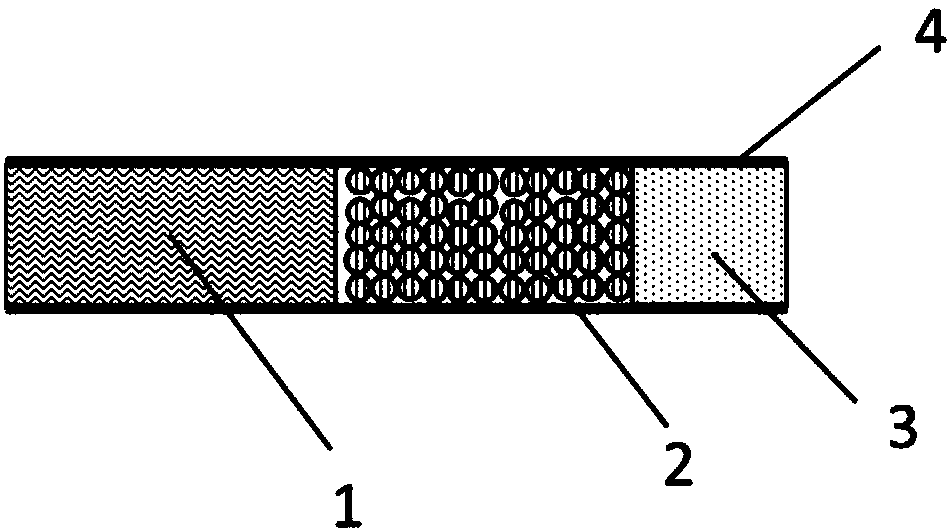

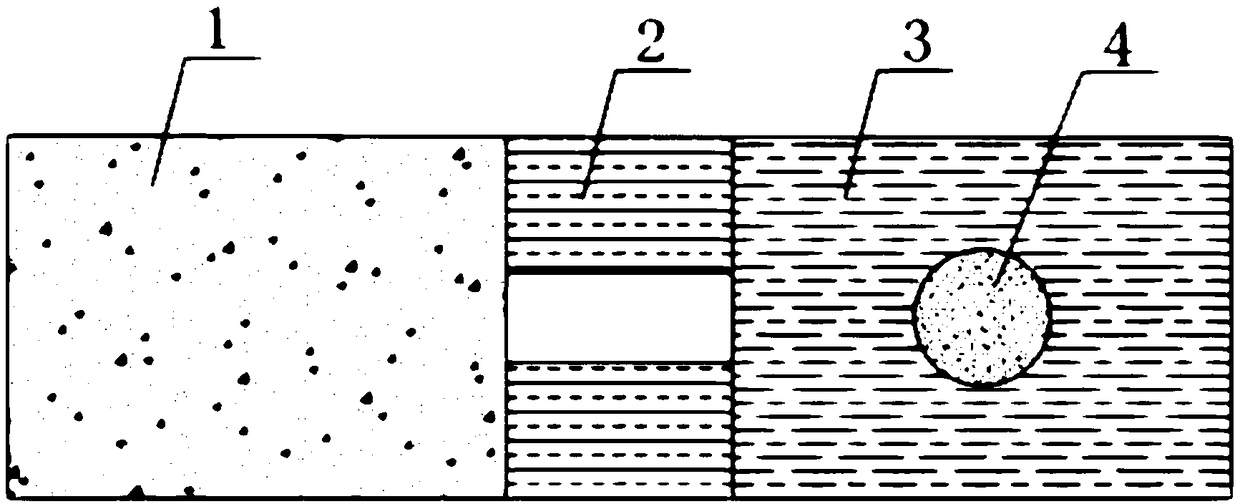

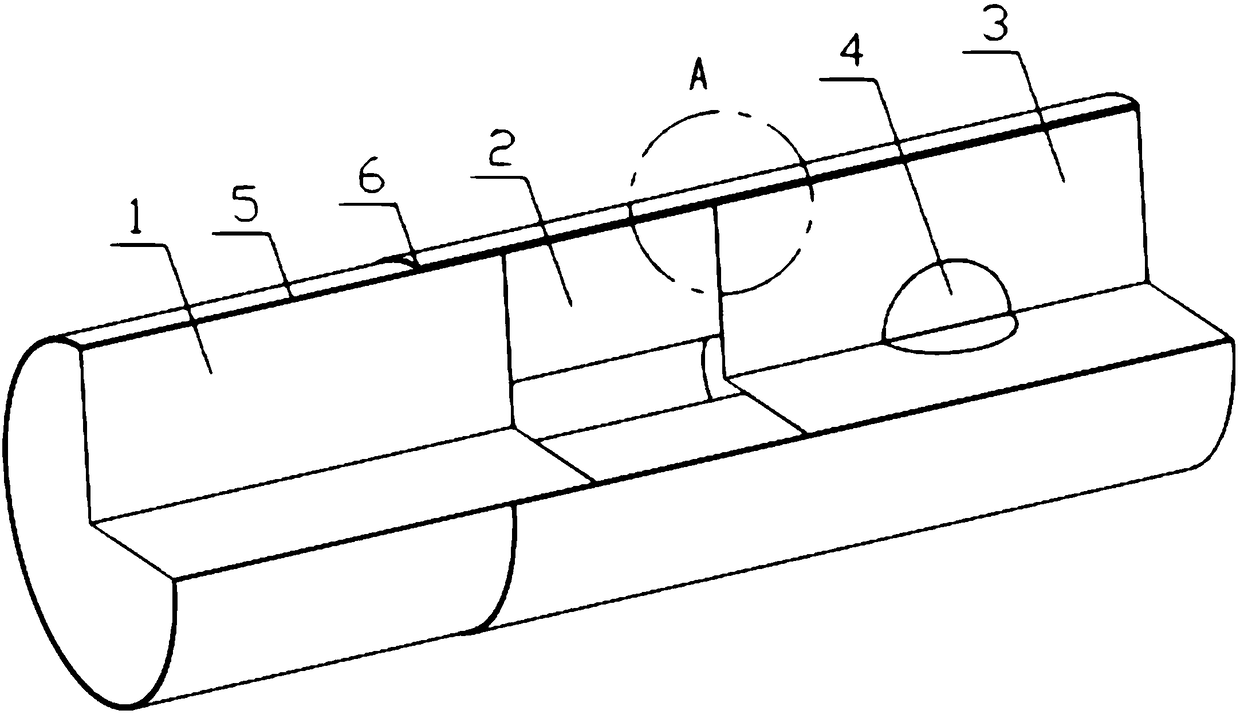

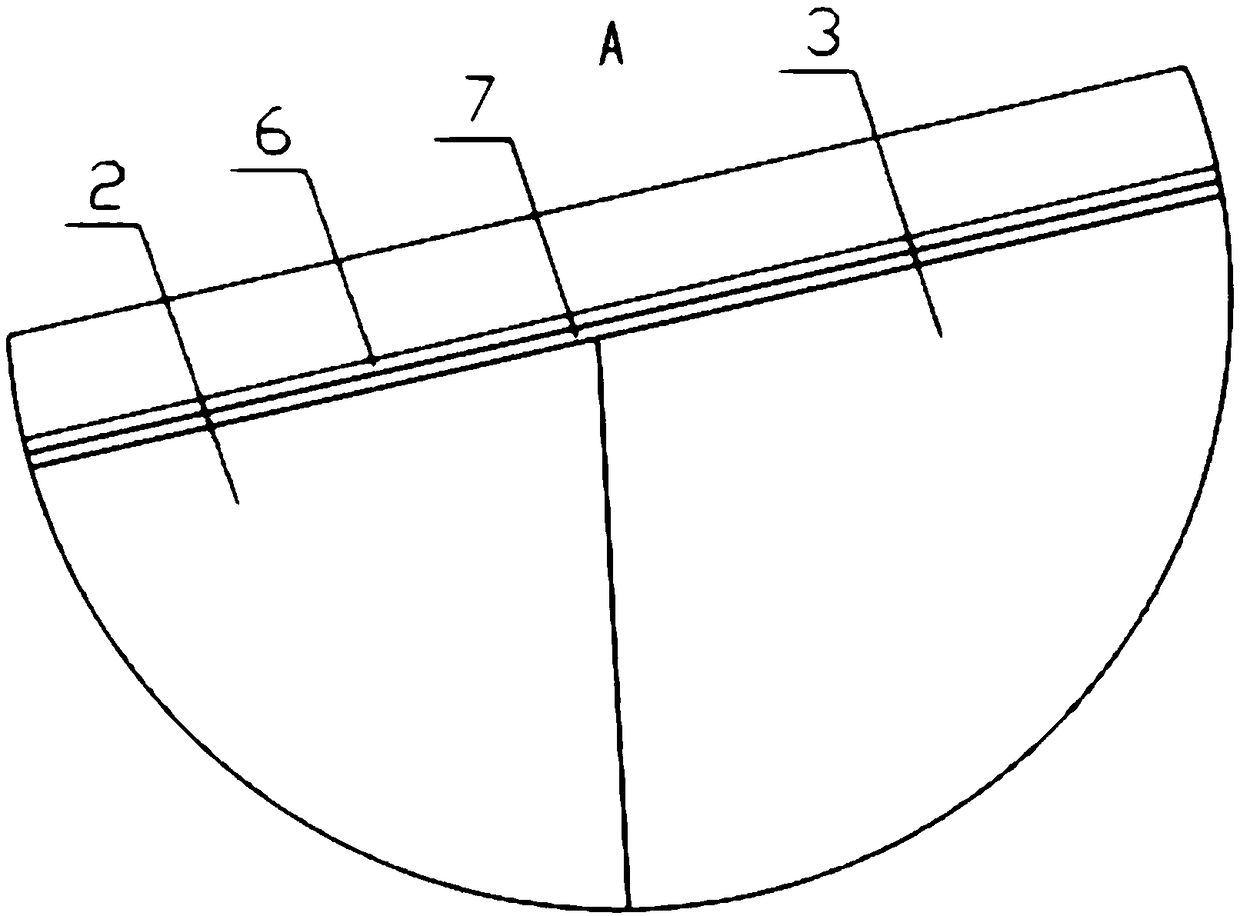

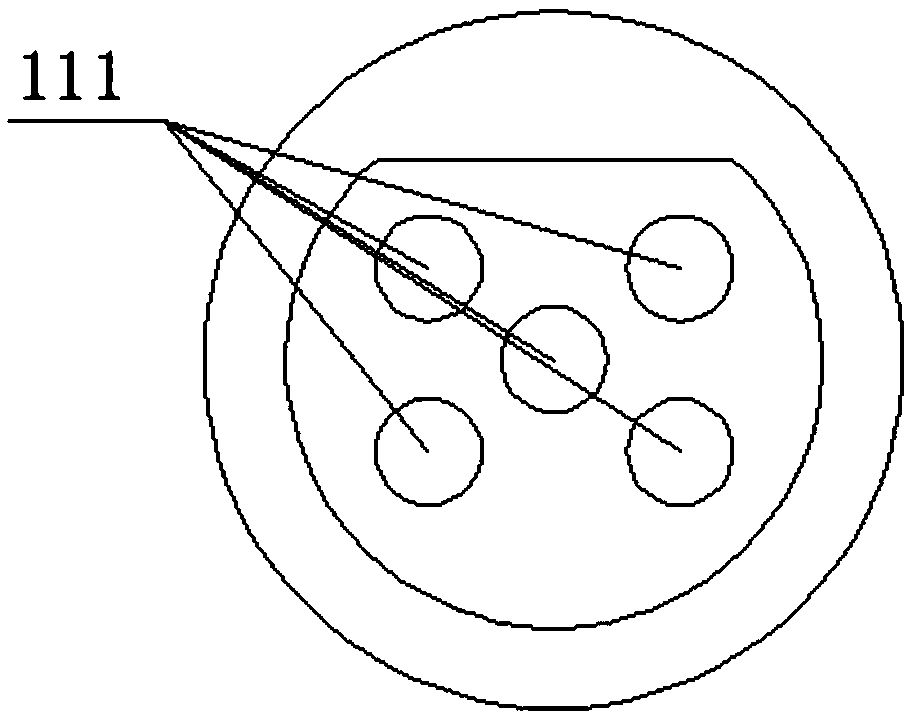

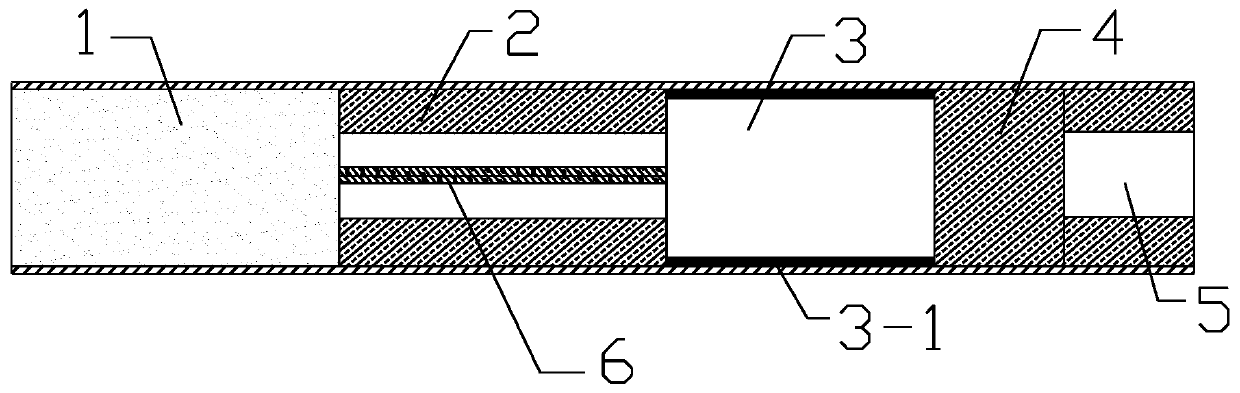

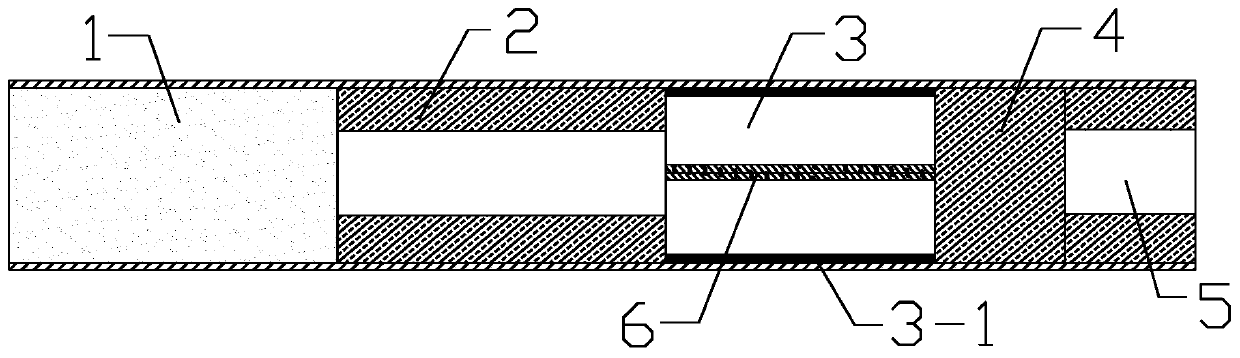

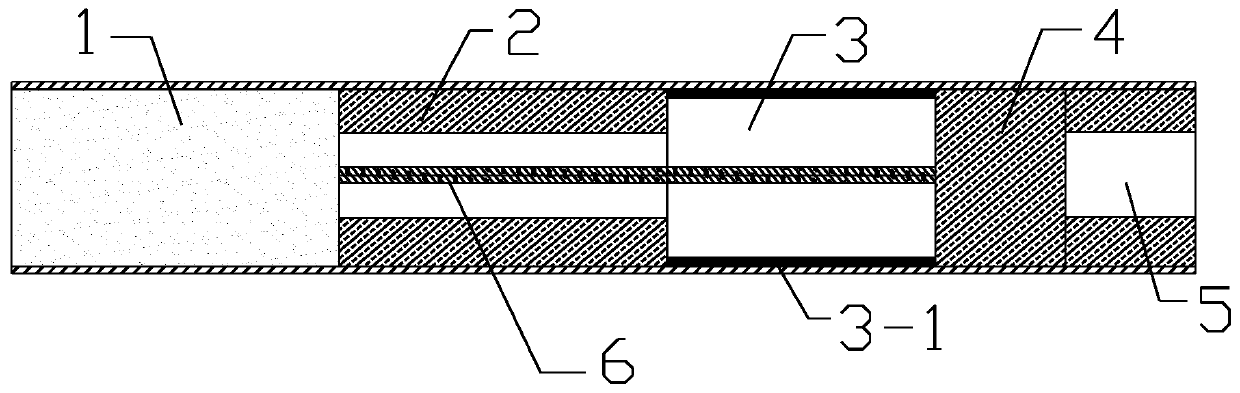

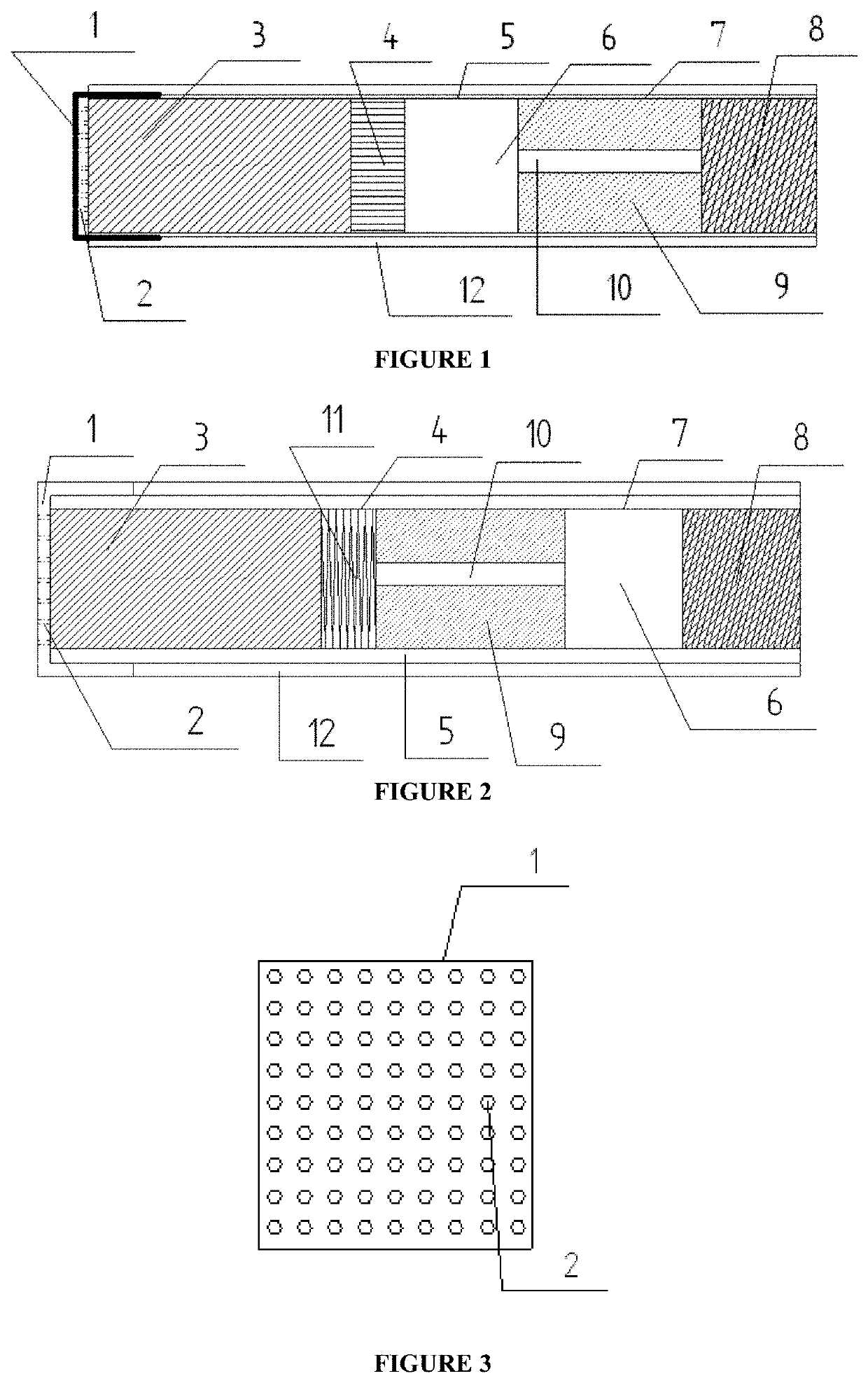

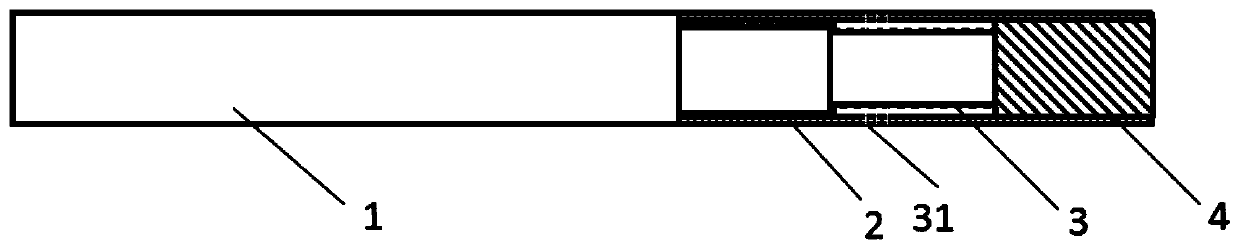

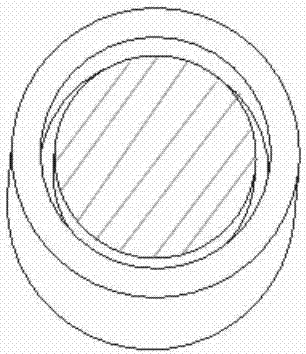

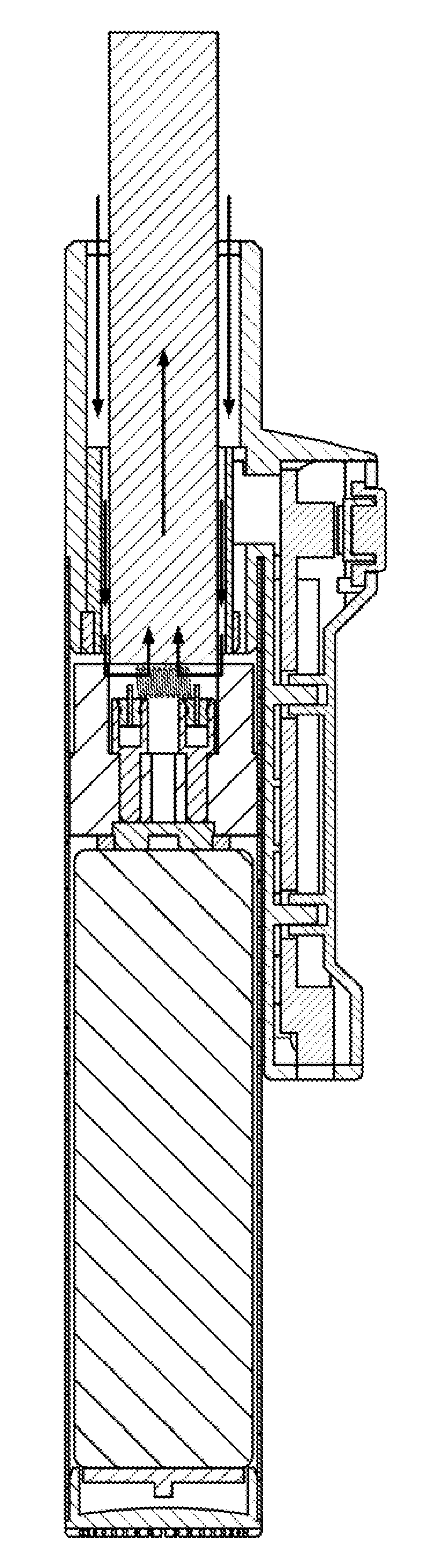

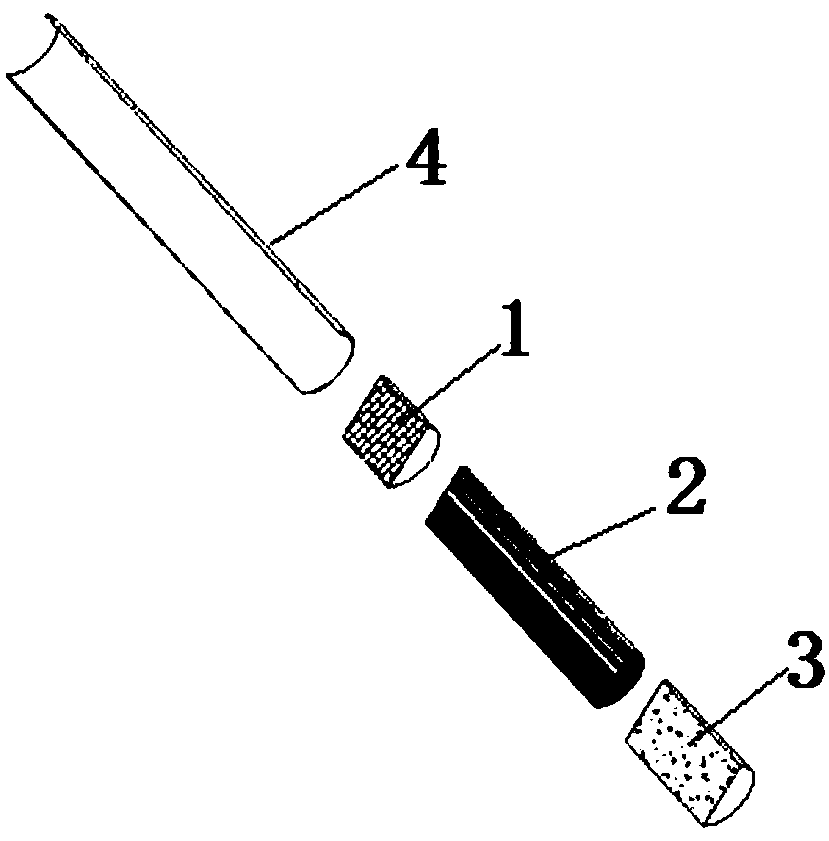

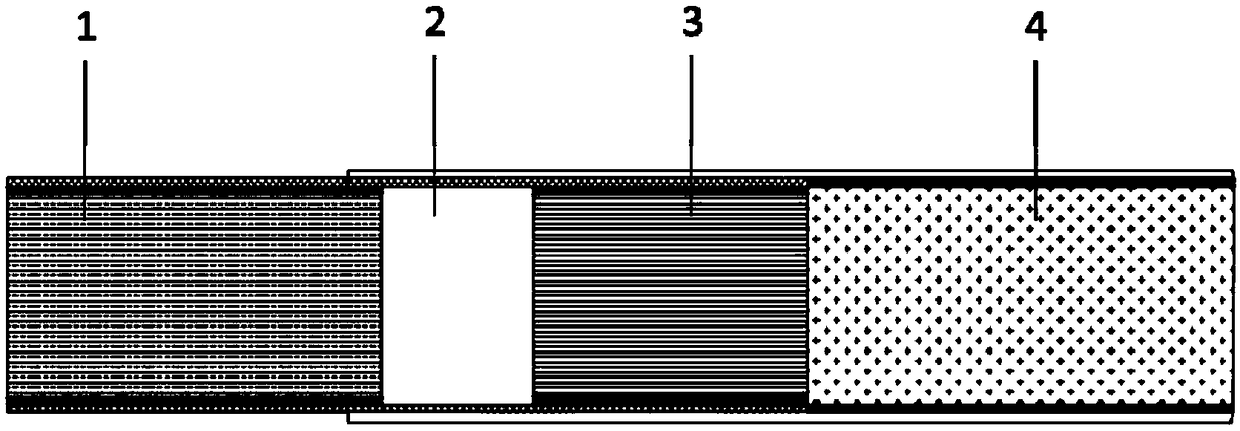

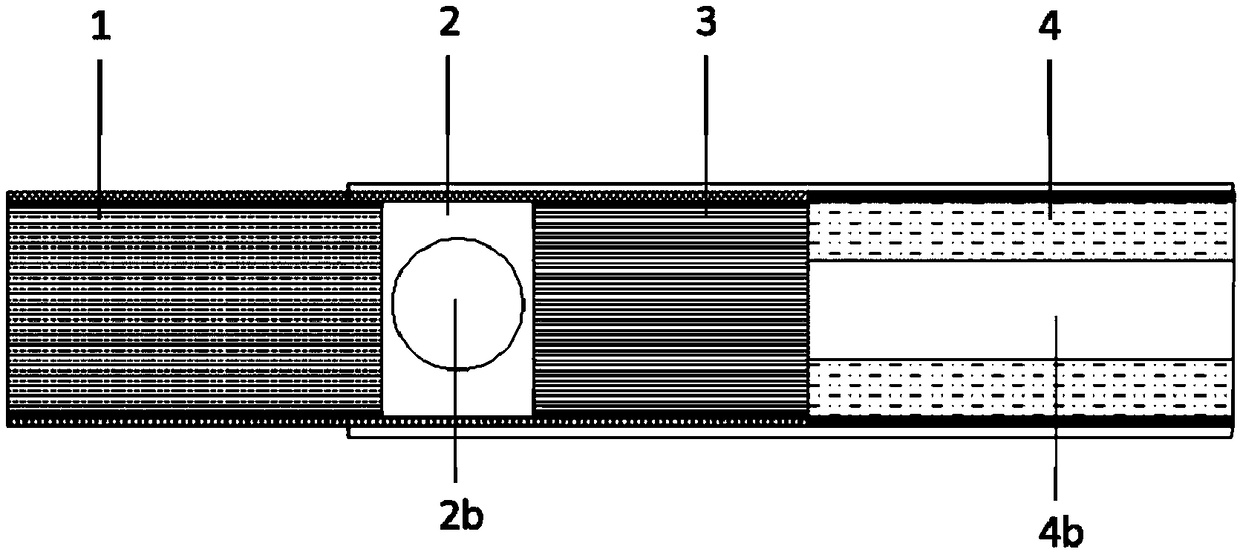

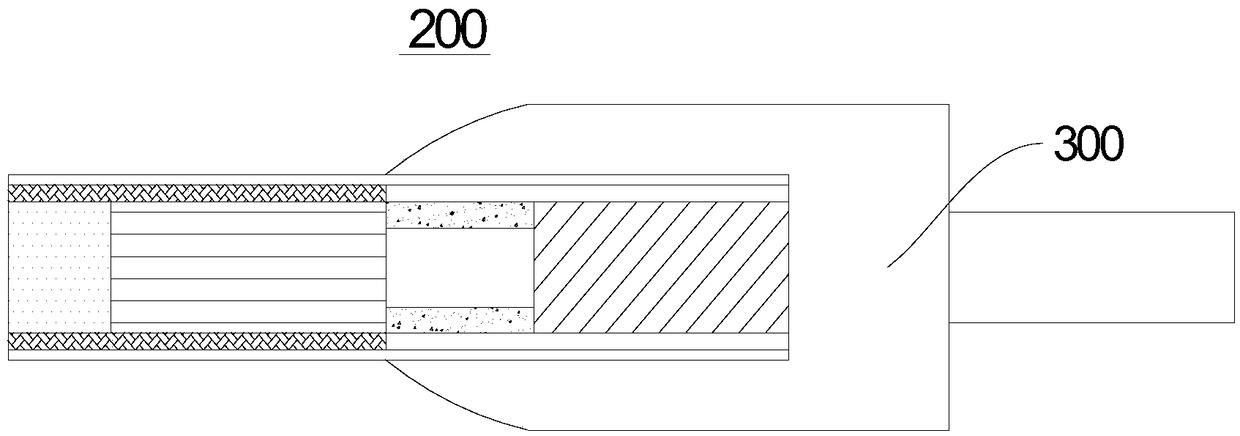

Heat-not-burn cigarette and assembly thereof

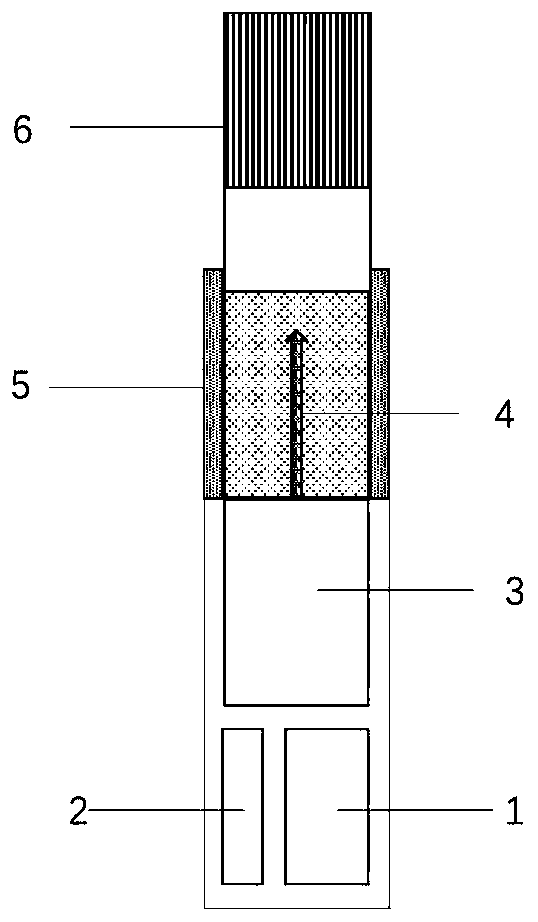

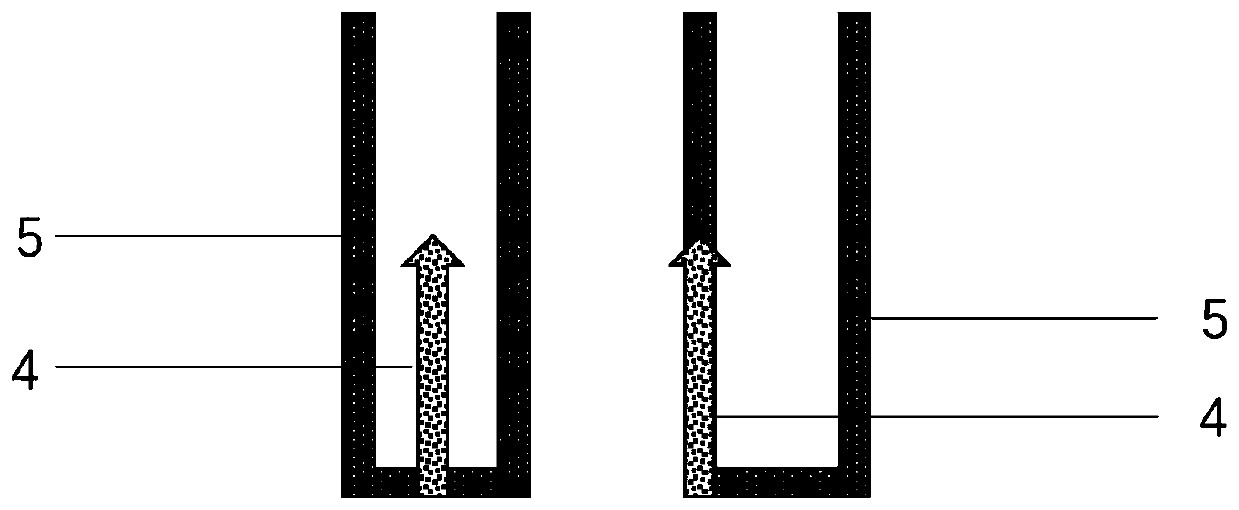

PendingCN109043654AFully volatileImprove filtering effectCigar manufactureTobacco devicesFiberHeat not burn

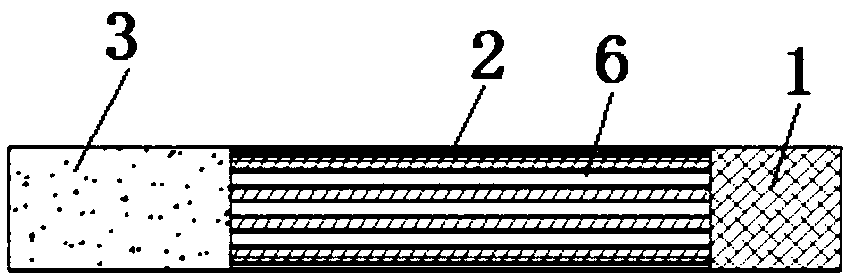

The invention discloses a heat-not-burn cigarette and its assembly. The heat-not-burn cigarette comprises a tobacco section (1), a cooling section (2), a filtering section (3), a first wrapping paper(5), a tipping paper (6) and a second wrapping paper (7). The end of the tobacco section (1) is connected with the front end of the cooling section (2), and the end of the cooling section (2) is connected with the front end of the filtering section (3). The first wrapping paper (5) wraps the tobacco section (1) to form cigarettes; the second wrapping paper (7) wraps the cooling section (2) and thefiltering section (3) to form an integrated filter rod. The tipping paper (6) rolls the cigarette and the integrated filter rod together. The cooling section (2) is a hollow filter rod, and the filtering section (3) is a solid filter rod that is made of polylactic acid fiber. The assembly includes the heat-not-burn cigarette and a low temperature heating cigarette set. The heat-not-burn cigaretteis applicable to electric heating, which has a sufficient filtering effect. The inlet temperature is reduced while reducing the inhalation of cigarette harmful substances and the taste of the cigarette is maintained as well.

Owner:POWERTHINK (BEIJING) TECH CO LTD +1

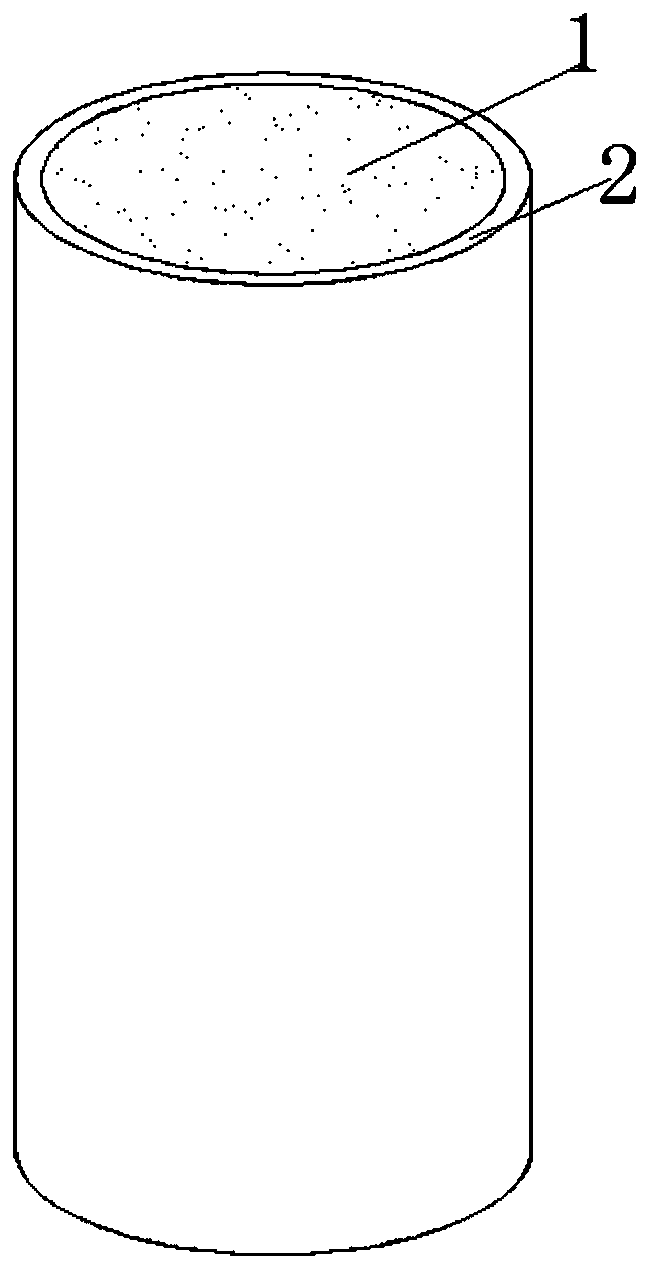

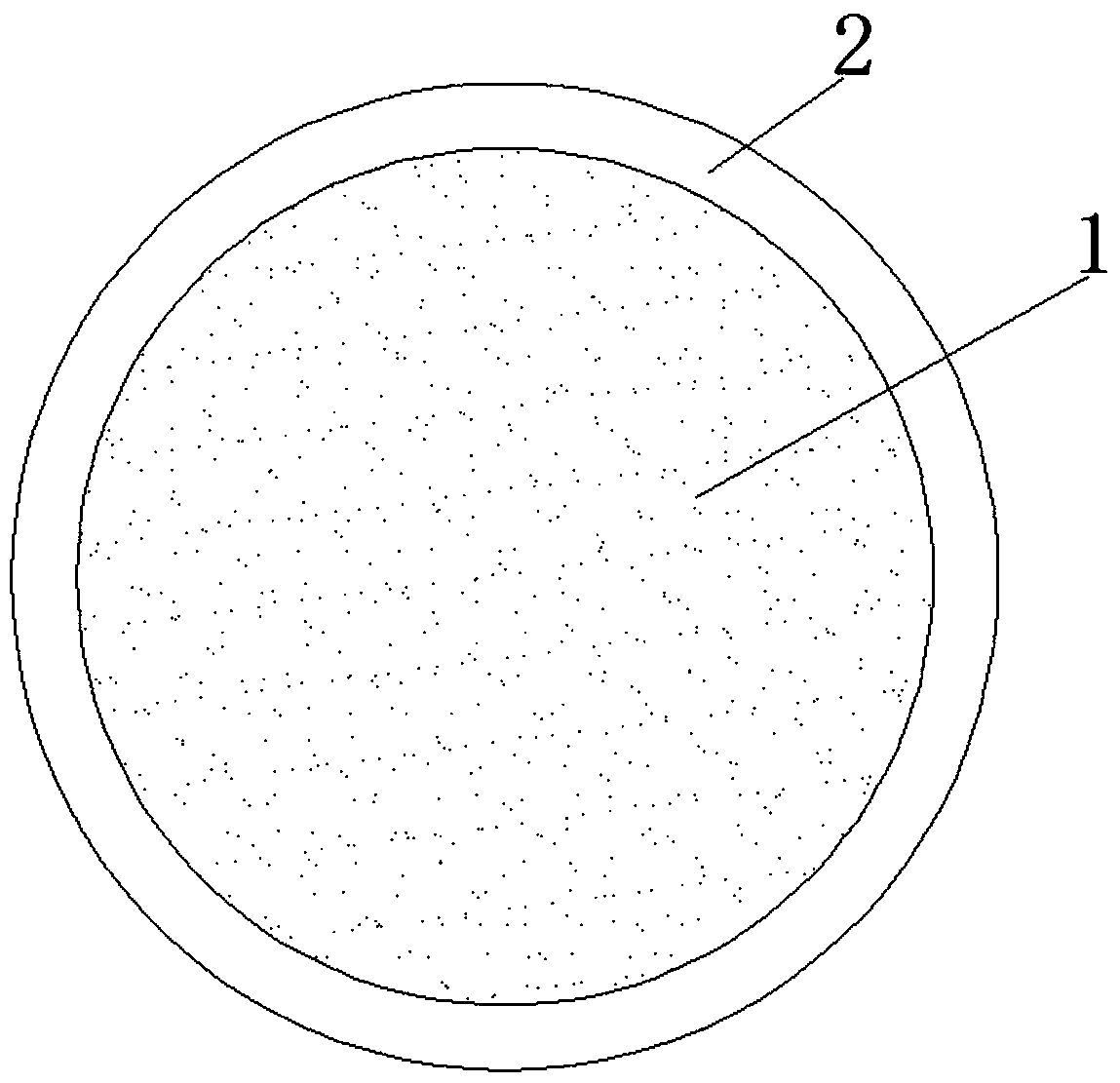

Cooling unit for holder of heat-not-burn fuming product and preparation method of cooling unit

ActiveCN108783588AReduce the temperatureReduce burnTobacco smoke filtersPolyethylene glycolCooling effect

The invention discloses a cooling unit for a holder of a heat-not-burn fuming product. The cooling unit comprises a cylindrical cooling inner core, wherein the cooling inner core is produced from polylactic acid and a compound, and the compound contains one or more of polyethylene glycol, aluminum hydroxide, magnesium hydrate and nano-silica. All the materials adopted in the cooling unit are efficient heat-absorbing and cooling materials, the prepared structural style is novel, and the airflow path can be effectively prolonged, so that the cooling effect is further improved; and the temperature of smoke can be remarkably reduced, and the firing and hot feels when the smoke entering an oral cavity are reduced, so that the smoking experience is improved.

Owner:YUNNAN XIKE TECH CO LTD

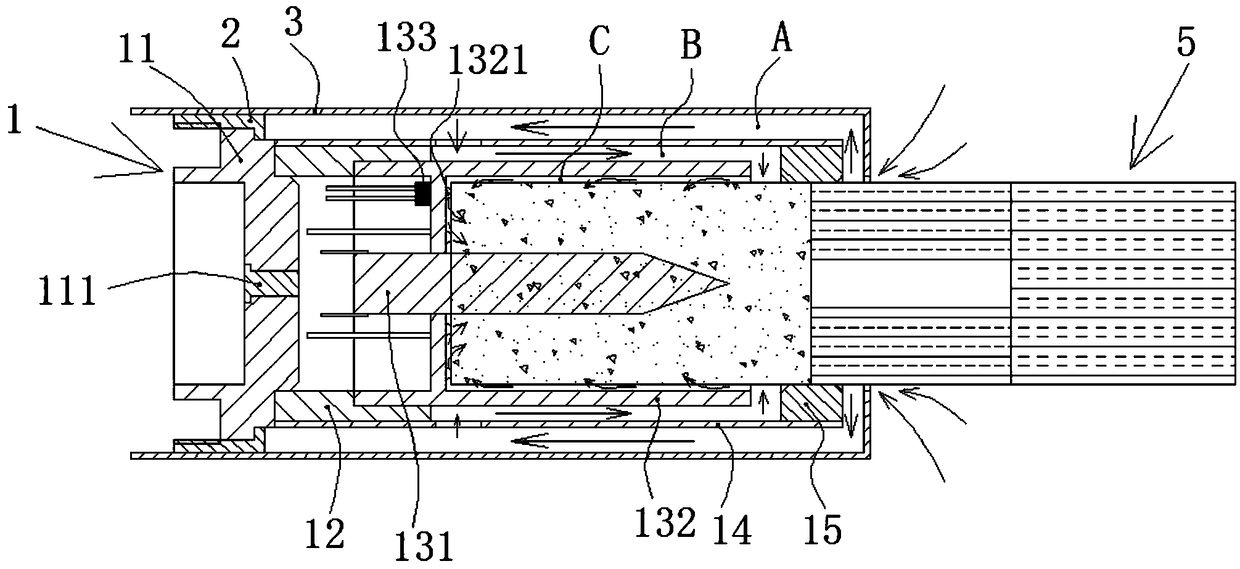

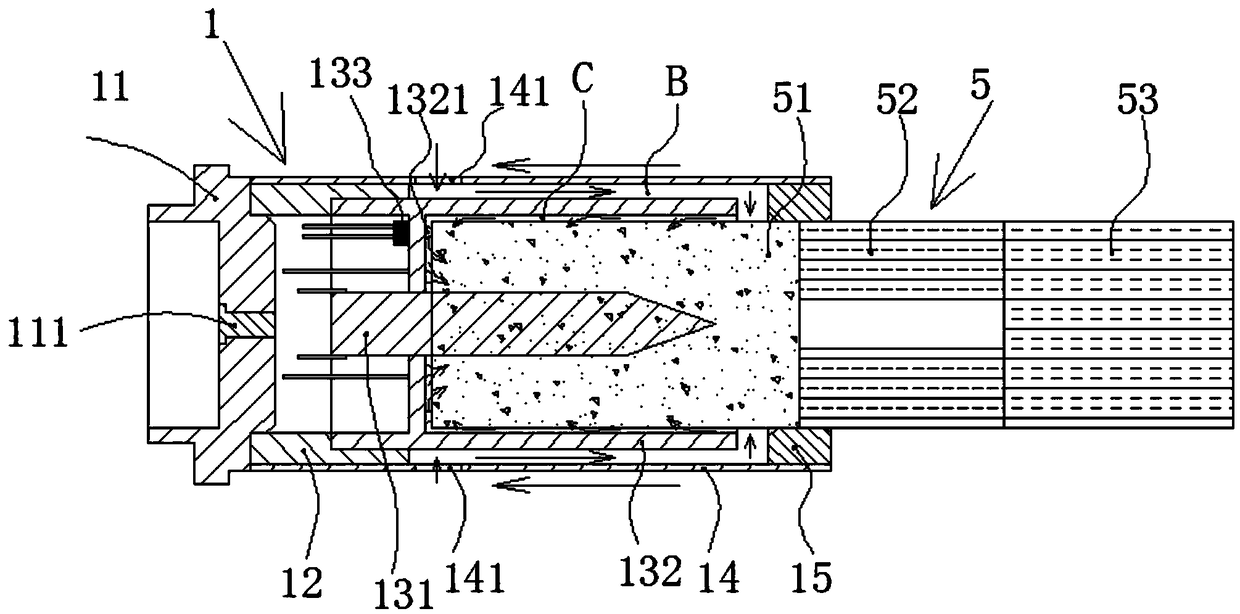

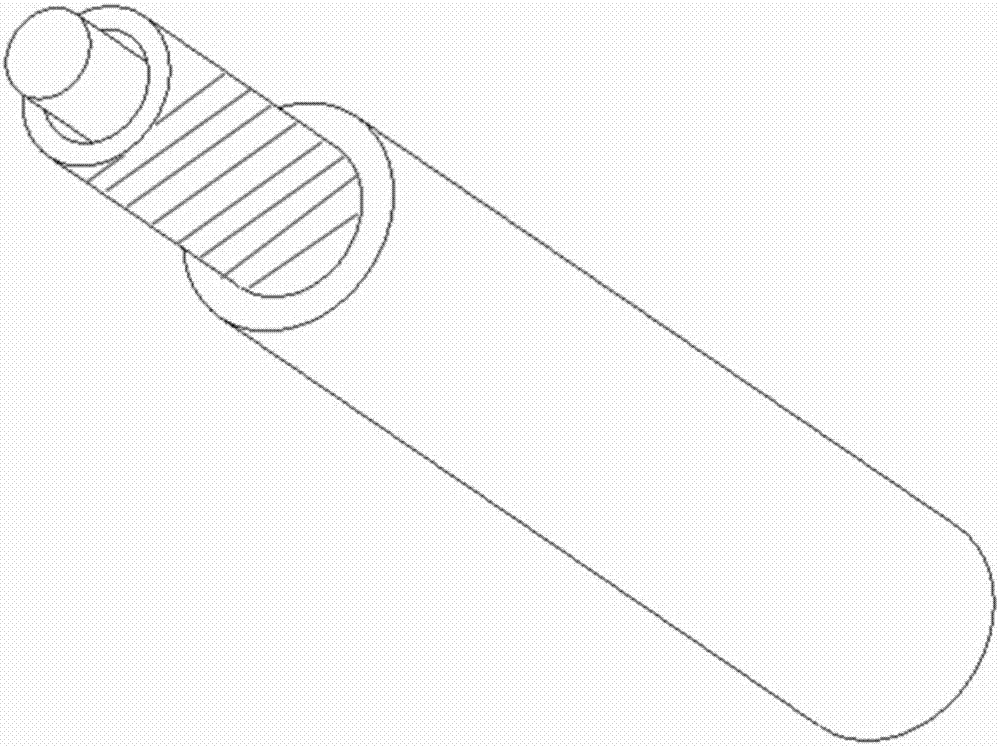

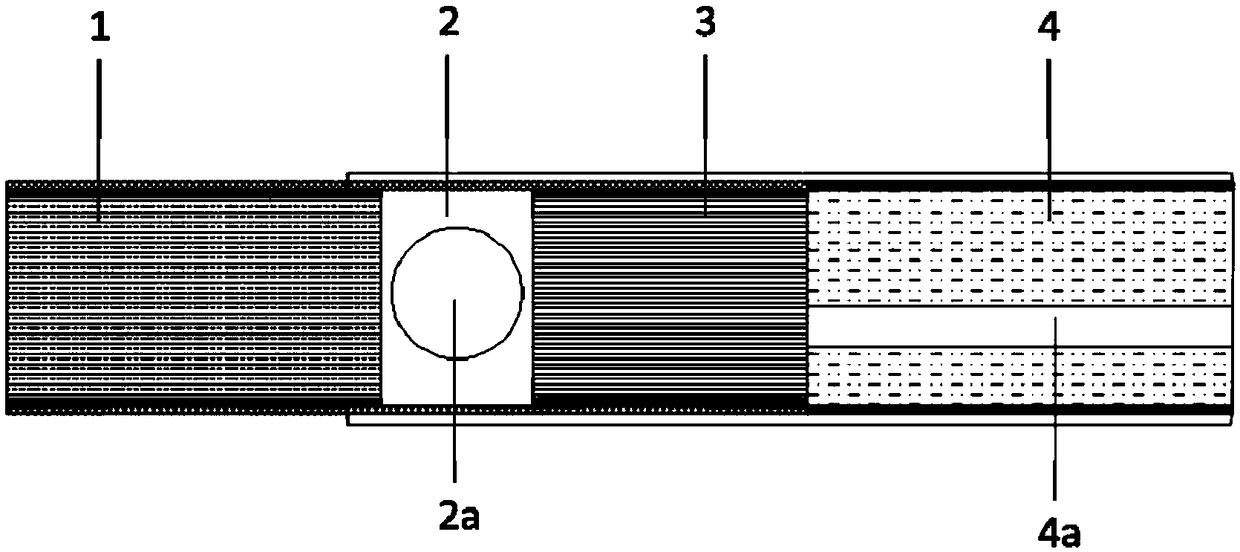

Smart three-dimensional soaking device of heat-not-burn cigarette, kit and heating method thereof

PendingCN109315838AAchieve convection heatingHarm reductionCigar manufactureElectric heatingTwo temperatureProcess engineering

The invention discloses a smart three-dimensional soaking device of a heat-not-burn cigarette, a kit and a heating method thereof. The smart three-dimensional soaking device comprises a heating assembly (1) and an exterior cigarette set shell (3); a first heating cavity (A) is formed in the portion between the cigarette set shell (3) and the heating assembly (1); a second heating cavity (B) is formed in the portion between a heating assembly shell and a combined heater (13) in the heating assembly shell; an inner cavity of a heating cylinder (132) in the combined heater (13) is a third heatingcavity (C); a heating stick (131) with a tip is arranged in the heating cylinder (132); air flow communication is achieved among the three heating cavities; the heating cylinder and the heating stickare both provided with heating circuits, the heating assembly is connected with a control circuit which comprises two temperature control loops, the heating cylinder and the heating stick are regarded as heating objects respectively for independent regulation and control, and heat energy is intelligently distributed. A three-dimensional soaking technology provides all-directional combined even heating of the circumferential surface and the core part for the heat-not-burn cigarette, so that the taste of the cigarette is close to that of a traditional cigarette, and harm is also reduced.

Owner:POWERTHINK (BEIJING) TECH CO LTD

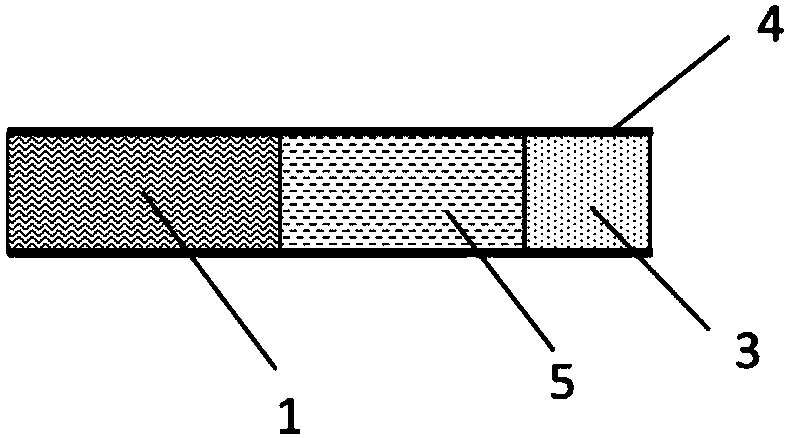

Novel fragrant heat-not-burn cigarette and preparation method thereof

PendingCN109793274AReduce the temperatureEnhance sensory experienceTobacco smoke filtersFiberCellulose diacetate

The invention provides a novel fragrant heat-not-burn cigarette and a preparation method thereof. The novel fragrant heat-not-burn cigarette comprises a tobacco material segment, a tobacco shred end hollow filter rod segment, a cooling segment, a fiber tow filter segment and a hollow segment. The cooling segment is a hollow chamber composed of a paper tube and a polylactic acid sheet layer wound on the inner wall of the paper tube; fragrant fiber tows are arranged in the tobacco shred end hollow filter rod segment, in the cooling segment or in both the tobacco shred end hollow filter rod segment and the cooling segment; the fragrant fiber tows are made by mixing fragrance-containing capsules and cellulose diacetate in a ratio of (0.1-0.2):1, dissolving the mixture in a solvent to obtain aspinning solution with mass percent of 15-25%, and coagulating the spinning solution in a coagulating bath which is made with a solvent and water through a dry-wet process spinning machine. The fragrant fiber tows are added to the tobacco shred end hollow filter rod through a filter rod former; high-temperature smoke may release fragrant odor when passing by; therefore, the fragrant odor of the heat-not-burn cigarette can last long, the temperature of the smoke is reduced, and a user can gain better sensory experience.

Owner:HUBEI CHINA TOBACCO IND

Heat-not-burn cigarettes

The invention pertains to the technical field of novel tobacco, and in particular relates to a cigarette structure for heat-not-burn cigarettes. A heat-not-burn cigarette comprising: an envelope that is cylindrical and hollow, a cleaning isolation sleeve disposed at a front end of the envelope, and a smoking article zone and a cooling and filtration zone sequentially disposed in the envelope. With the cleaning isolation sleeve, the invention prevents the tobacco shreds from dropping out when a user inserts the heating body into the cigarette, and prevents fine part in the smoking article from falling into the heater during heating, thereby ensuring cleanness of the heater.

Owner:ZHAO XUE

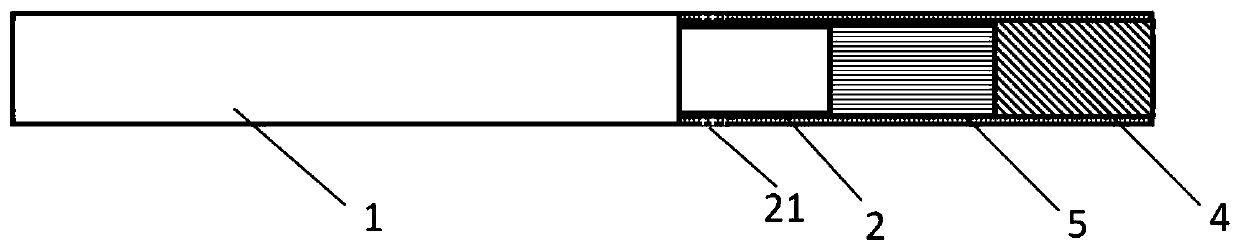

Dual-purpose smoking product

PendingCN110403235AGuaranteed smoke productionRaise the ratioTobacco treatmentCigar manufactureFlavorMass ratio

The invention discloses a dual-purpose smoking product which is suitable for being smoked after being ignited and smoked in a heat-not-burn mode at the same time. The dual-purpose smoking product comprises a cigarette core section (1), a supporting section (2) and a filtering section (4) which are sequentially connected; the supporting section (2) and the filtering section (4) are wrapped by forming paper to form a filter tip rod; the cigarette core section (1) and the filter tip rod form the smoking product through tipping paper; a cigarette core base material of the cigarette core section (1) comprises reconstituted tobacco and cut tobacco, and the mass ratio of the reconstituted tobacco to the cut tobacco is 1:1 to 7:3; the reconstituted tobacco comprises a first aroma-increasing substance with a boiling point greater than or equal to 200 DEG C and a second aroma-increasing substance with the boiling point being less than 200 DEG C. According to the structure of the smoking product,cooling and smoke filtering can be both achieved, the comfortable and fast smoking feeling is provided, flavors and fragrances with different boiling points are added to meet the smoking taste requirements of different conditions, the cigarette core section (1) can meet the requirements of consumers on nicotine, and the smoking amount can be ensured in the heat-not-burn state.

Owner:CHINA TOBACCO YUNNAN IND

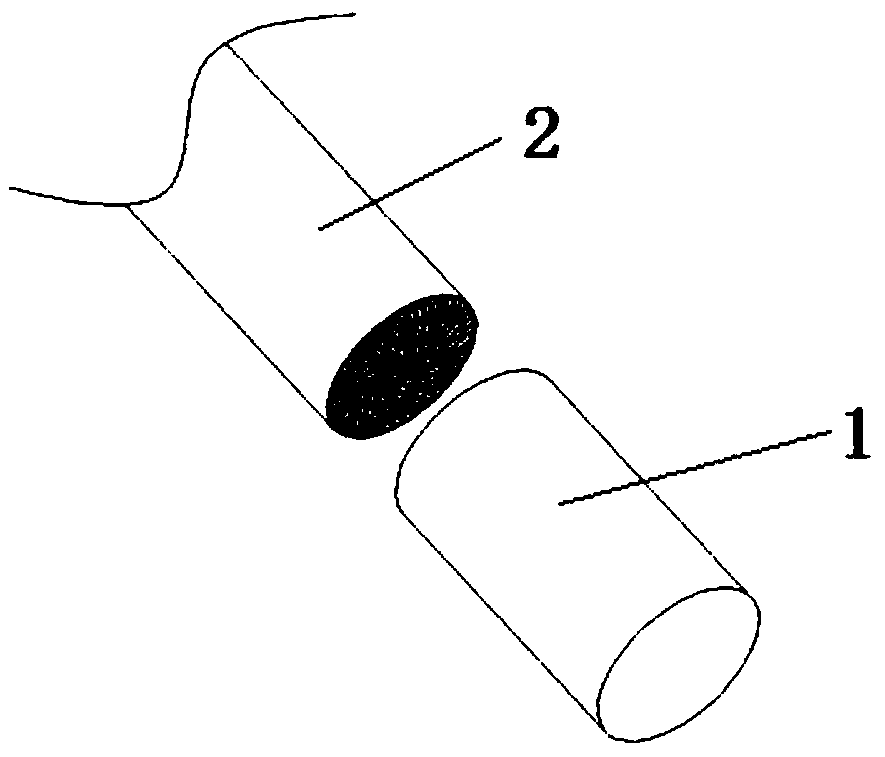

Tobacco material smoke generator for heat-not-burn tobacco products and preparation method and application of tobacco material smoke generator

InactiveCN107319641AWell mixedImprove stabilityTobacco treatmentCigarette manufactureHigh intensityHeat not burn

The invention provides a tobacco material smoke generator. The tobacco material smoke generator comprises a dry smoke generating material and an atomizing agent and is applied to heat-not-burn tobacco products, uniform in mixing of tobacco materials and the atomizing agent and high in stability. In addition, technical simplicity in formation, high hardness and strength and less proneness to structural damages are realized; tobacco content can be accurately controlled, and aroma substances in tobacco materials are extracted under thermal action while nicotine is released; simplicity and easiness in operation and suitableness for serving as smoke generator consumables for heat-not-burn cigarettes are realized.

Owner:SHANGHAI TOBACCO GRP CO LTD

Novel low-temperature heat-not-burn cigarette with functions of temperature reduction and aroma conservation

PendingCN108041680ARich and diverse structureRich and diversified composition materialsTobacco smoke filtersEngineeringElectronic cigarette

The invention discloses a novel low-temperature heat-not-burn cigarette with functions of temperature reduction and aroma conservation. The cigarette specifically comprises six parts of a big hollow filter stick, a temperature reduction filter stick section, a small hollow filter stick, a tobacco stick, an inner wrapping layer and an external wrapping layer, the cigarette is a novel cigarette witha quaternary compound structure; wherein the inner wrapping layer is respectively wrapped on the tobacco stick, the hollow filter stick and the temperature reduction filter stick section, the external wrapping layer is wrapped on the inner wrapping layer and a quaternary compound stick section; according to the novel low-temperature heat-not-burn cigarette, by the organic combination of materialswith different stick shapes and structures, the novel low-temperature heat-not-burn cigarette is formed, the structure overall design efficiently reduces the smoking temperature of the cigarette, thepurpose of keeping the tobacco fragrance is kept, at the same time, the novel cigarette has the sense of smoking and satisfaction brought by a traditional cigarette, and overcomes the existing shortcomings and defects of an existing electronic cigarette.

Owner:HONGTA TOBACCO GRP

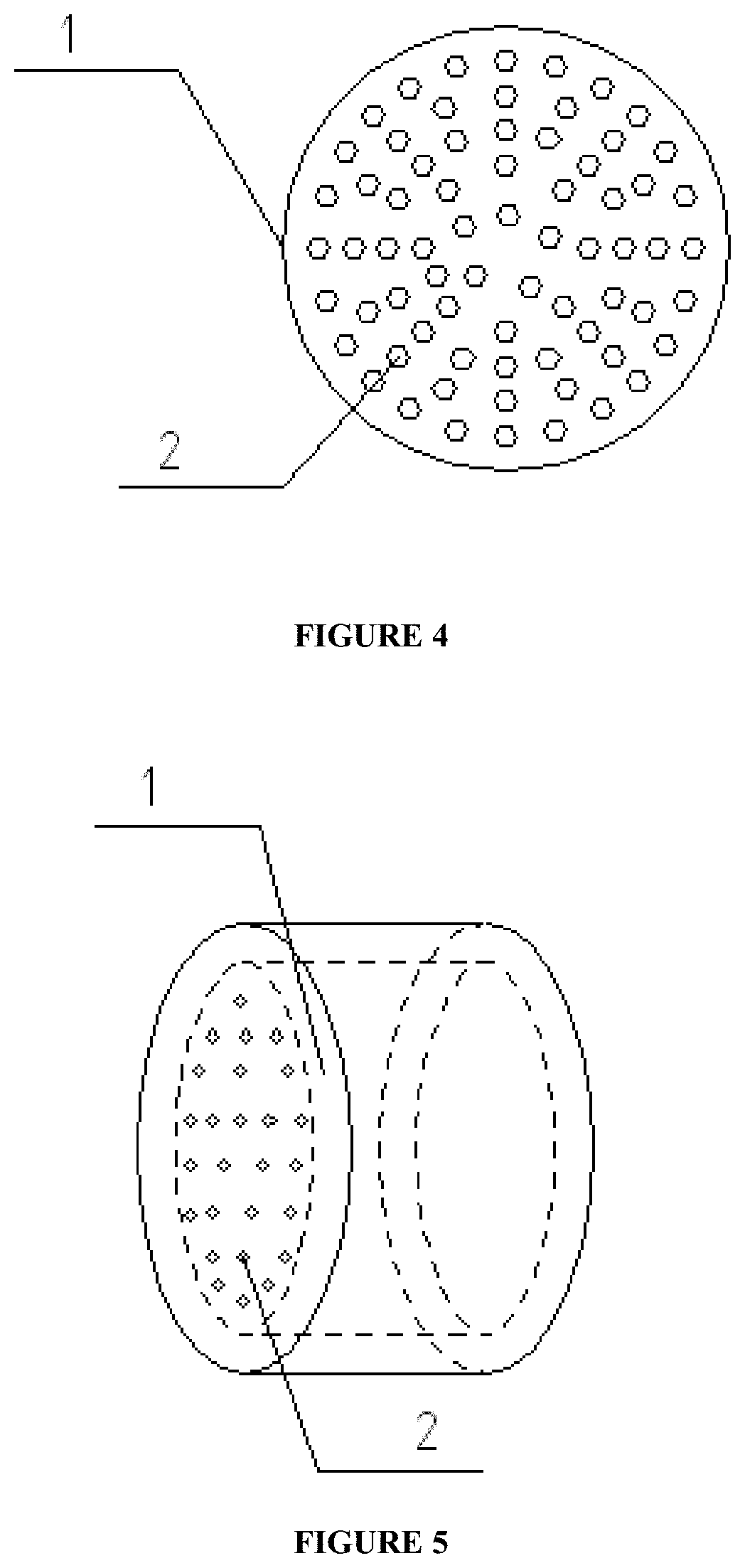

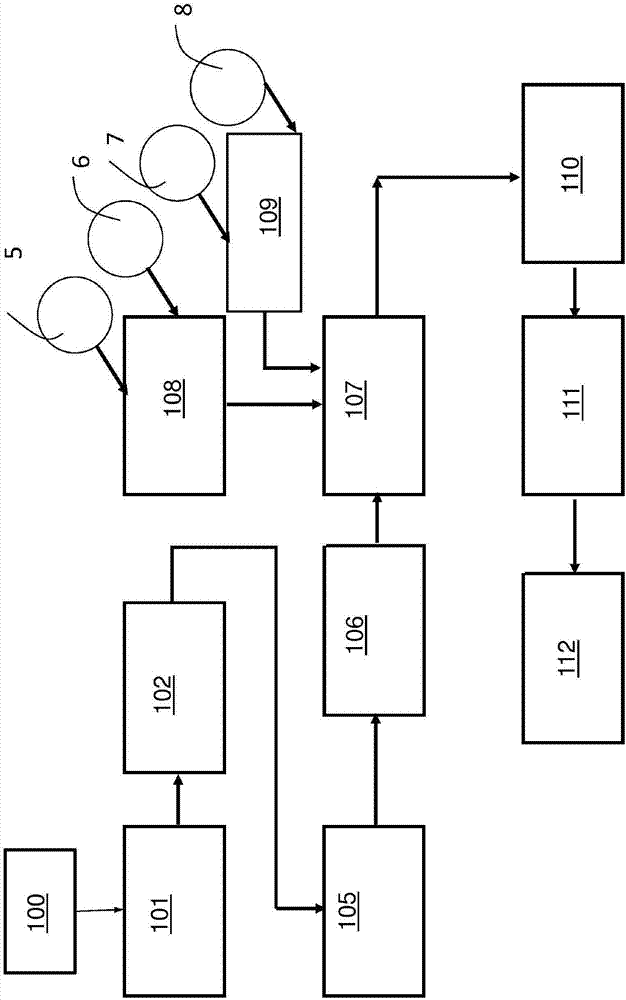

Microwave-heat-not-burn smoking set

The invention relates to a microwave-heat-not-burn smoking set, which is composed of a power supply (1), a solid microwave source (3), a control system (4), a heating cavity (5) and an inner conductor (4) located in the heating cavity. The inner conductor is simple in structure, the loss of microwaves in the transmitting process is effectively reduced, and energy consumption of a system is lowered; because of the inner conductor, heat energy generated by the microwaves is only generated in a smoke formation substrate, heat is brought away by the smoke formation substrate and does not remain in the microwave-heat-not-burn smoking set, and thus the problem of overheating of a shell of the microwave-heat-not-burn smoking set is avoided; and the microwaves in the microwave-heat-not-burn smoking set are transmitted to the smoke formation substrate by the inner conductor and output from inside to outside gradually so as to penetrate through the substrate, the uniformity degree of heating of the smoke formation substrate is increased, and the microwaves are prevented from leaking and then causing harm to human bodies through structural design.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Fragrance module formula, fragrance for heat-not-burn cigarette and preparation method of heat-not-burn cigarette

InactiveCN110522066AFit closelySimple methodTobacco preparationTobacco treatmentHeat not burnSolvent

The invention discloses a fragrance module formula, fragrance for a heat-not-burn cigarette and a preparation method of the heat-not-burn cigarette, and relates to the technical field of heat-not-burn cigarettes. The fragrance module formula comprises 10-90 parts of a fragrance production main body, 10-90 parts of a solvent, 2-50 parts of a tobacco extract, 0.5-70 parts of a flavor enhancer and0.1-50 parts of a flavoring agent, wherein the fragrance production main body is selected from at least one of herbal main aroma, fruity beverage main aroma and floral main aroma. According to the preparation method of the fragrance , the fragrance is prepared by taking the fragrance module formula as a raw material through simple mixing; the preparation method of the heat-not-burn cigarette comprises the steps that the fragrance prepared through the method is loaded into the heat-not-burn cigarette, and the prepared heat-not-burn cigarette has unique fragrance characteristics, does not contain unpleasant offensive odor and is very ideal in smoking taste.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

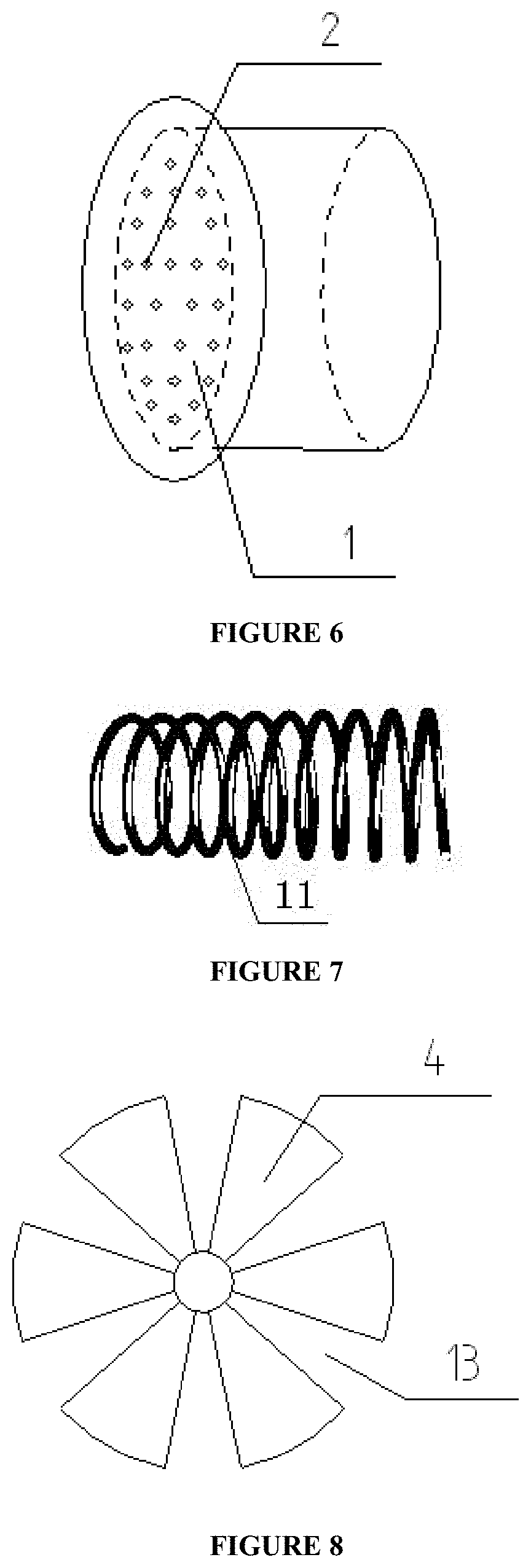

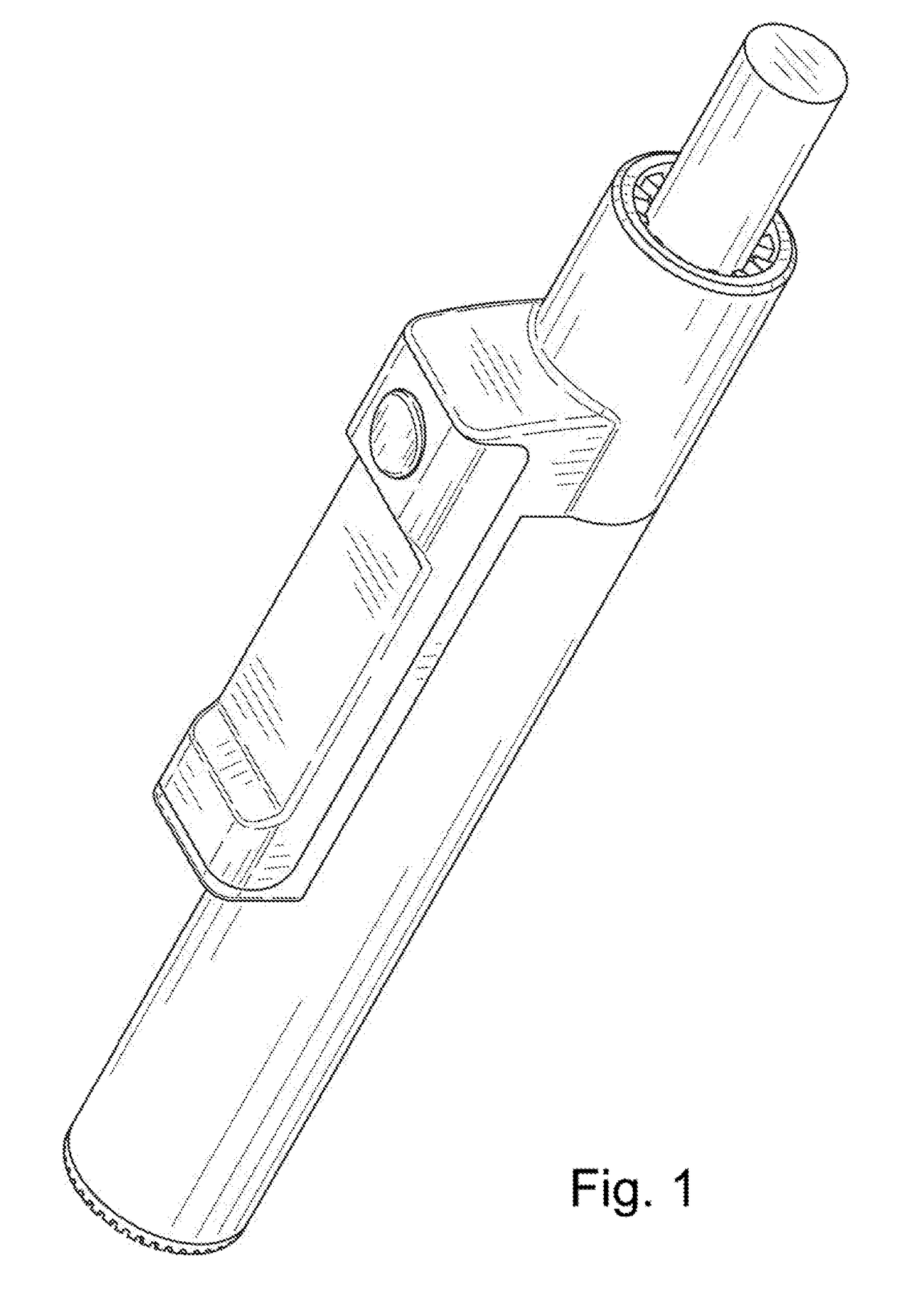

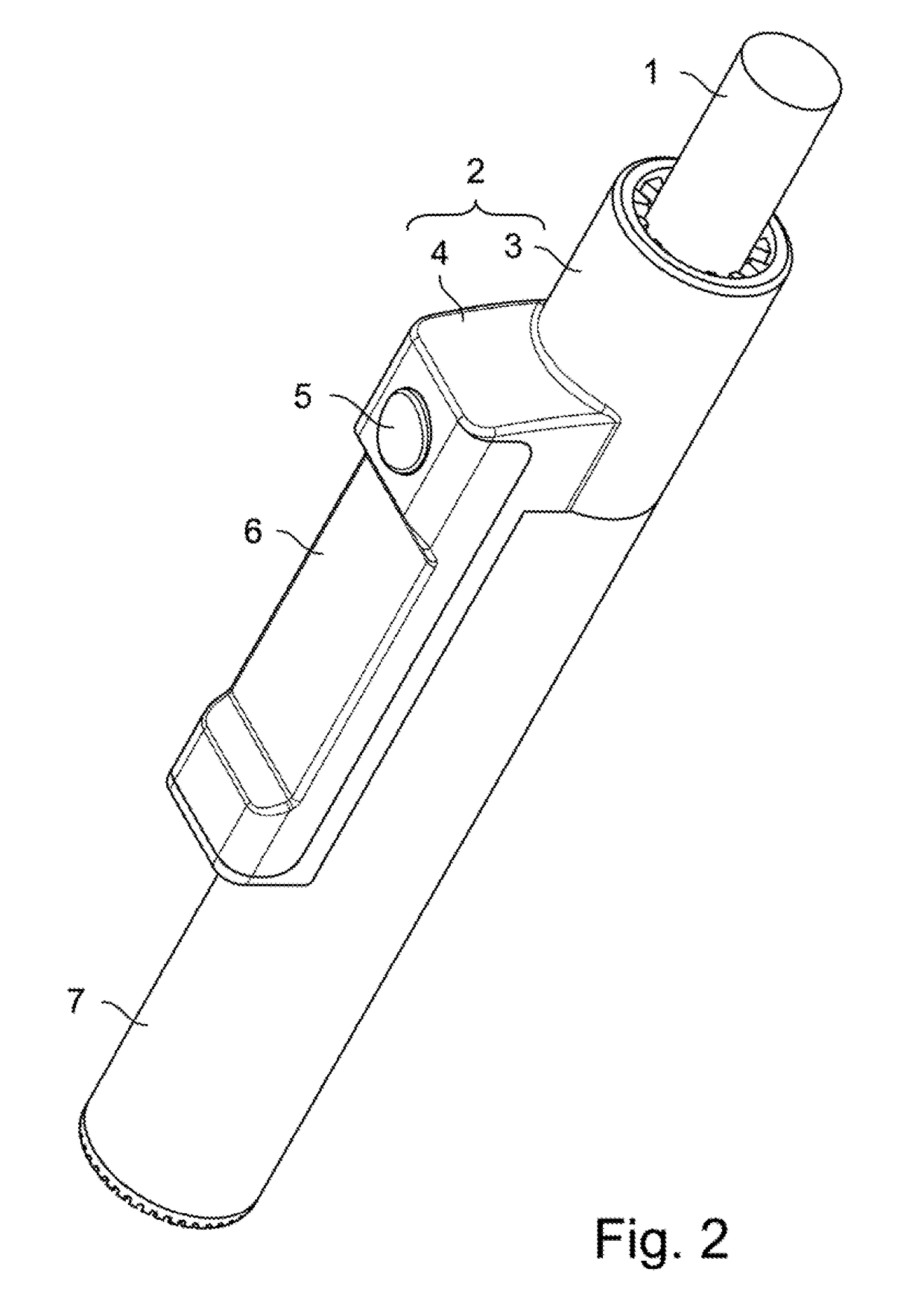

Low temperature heat not burn electronic cigarette

ActiveUS20180153216A1Significant energy lossSmall volumeTobacco devicesHeating element shapesElectrical batteryHeat not burn

The present invention relates to a low-temperature heat-not-burn electronic cigarette comprised of the first holder including a pipe and to mounting plate with the mounting plate connected to the external wall of the pipe. The mounting plate and the second holder are connected to form an inner cavity with a control plate fixed in the inner cavity and the second holder having a key linked to the buttons on the control plate with the buffer pads. The pipe has a corrugated internal wall and a moveable cigarette cartridge. The pipe is inserted into an outer pipe. The outer pipe has an insulation retaining bracket and a battery in it with the insulation retaining bracket having an installation slot facing the cigarette cartridge and the heating coil on the installation slot.

Owner:SHANGHAI GREEN VAPER TECH CO LTD

Control of puff profile

ActiveUS8893724B2Tobacco treatmentCigar manufactureHeat not burnElectrical and Electronics engineering

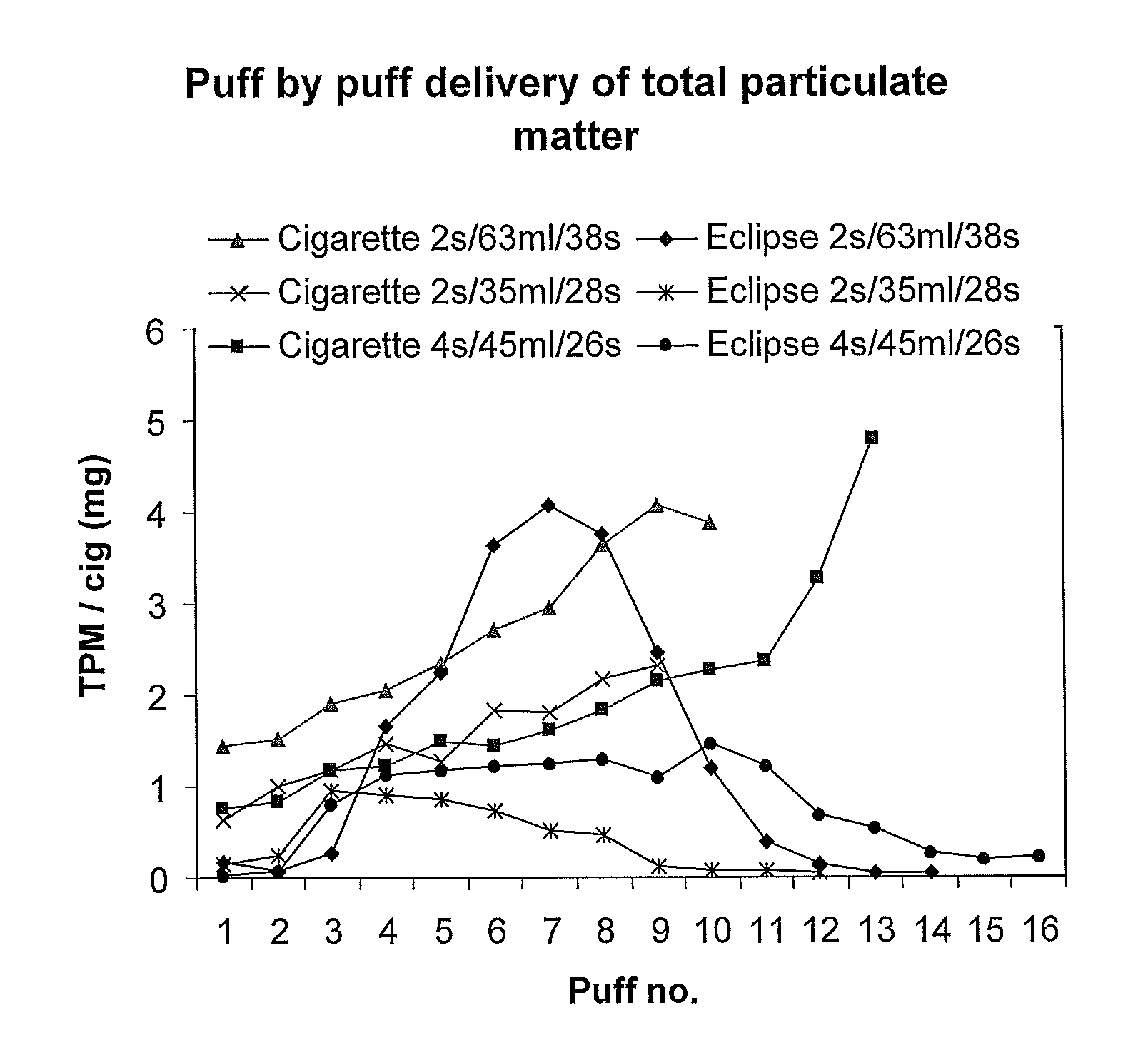

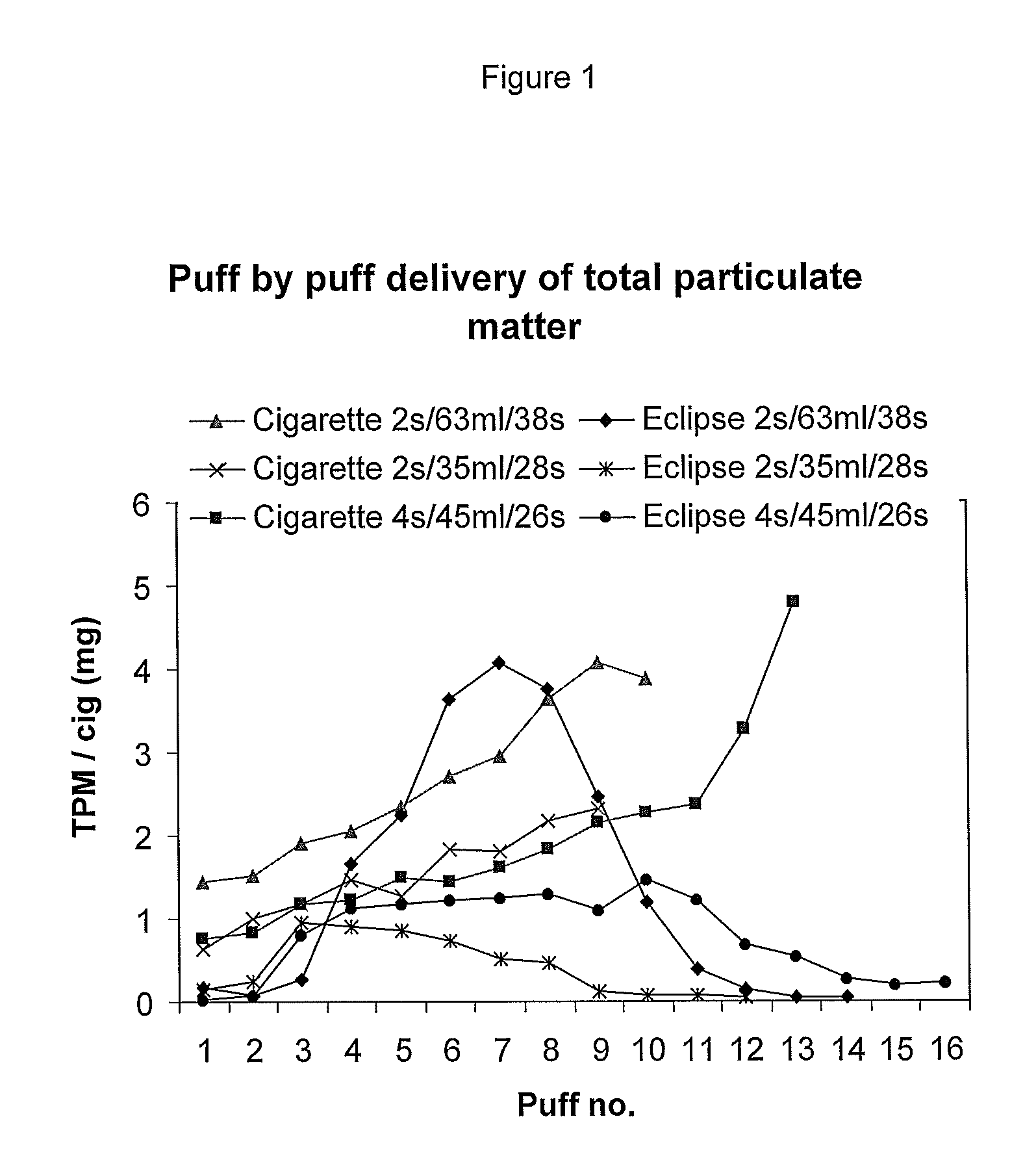

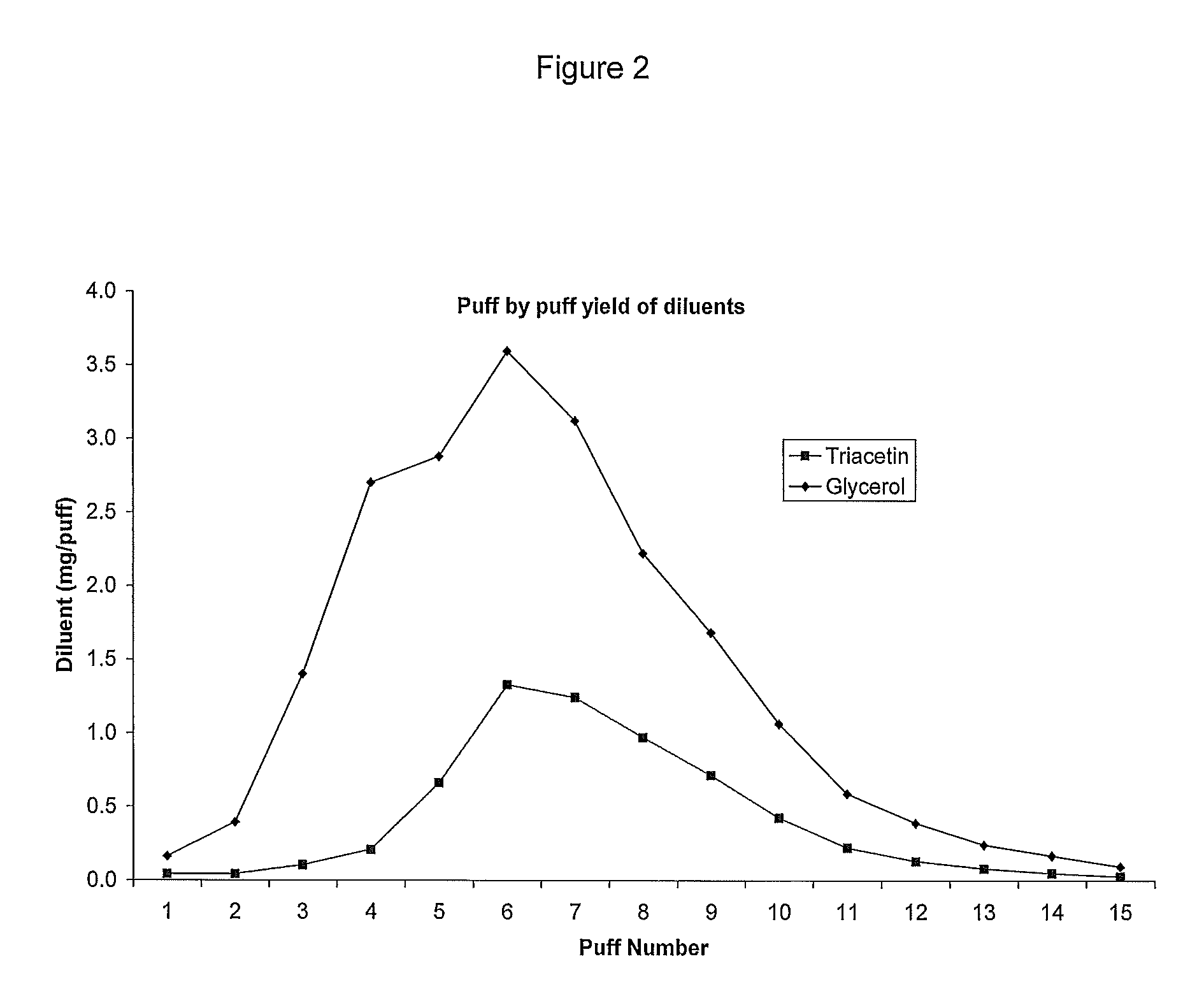

The invention relates to heat not burn products comprising an encapsulated aerosol generating agent, the encapsulation having the effect of controlling the release of the agent during use of the heat not burn product. The encapsulation will control the timing of the release of the aerosol generating agent during the use of the heat not burn product, to allow greater control of the puff yield. In the case of some aerosol generating agents, the encapsulation may also increase the stability of the agent and / or prevent its migration within the product.

Owner:NICOVENTURES TRADING LTD

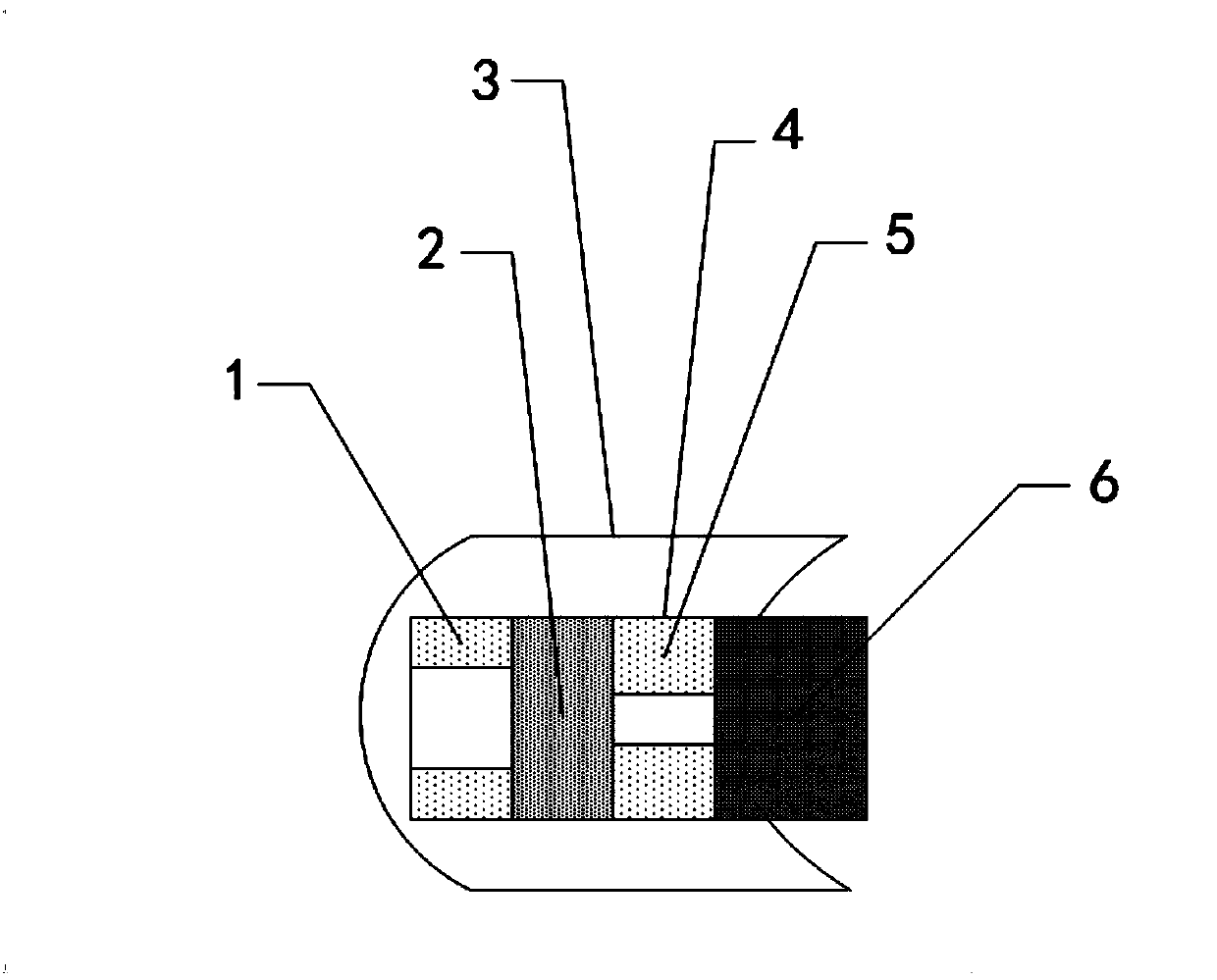

Cooling filter rod, fuming product and application

ActiveCN109588771AGuaranteed amount of smokeEnough smokeCigar manufactureTobacco smoke filtersWater vaporMetallurgy

The invention relates to a cooling filter rod, a fuming product and the application. The cooling filter rod comprises a cooling section; a plurality of passages running through both ends of the cooling section are formed in the cooling section; and the inner surfaces of the passages are coated with a cooling material. The cooling filter rod is characterized in that the cooling material comprises an inorganic phase-change material; and the inorganic phase-change material comprises at least one of Na2HPO4.12H2O, Na2CO3.10H2O, CH3COONa.3H2O, CaCl2.4H2O and Na2SO4.10H2O. The cooling filter rod disclosed by the invention has the advantages of ensuring a smoke volume of fume, reducing a temperature of the fume entering an oral cavity and the like; particularly, the cooling section, by combined design of a cooling rod structure, the type of the cooling material and a use quantity of the cooling material, not only can make the fume easy to rapidly and smoothly flow out of a fuming section, butalso can obviously reduce the temperature of the high-temperature fume before the fume enters the oral cavity; the smoke volume is sufficient and the temperature is proper, so that comfort and satisfaction of smoking are promoted; and problems of excessive water vapor, small smoke volume and bad taste, which are generated when an existing HNB (Heat Not Burning) cigarette is smoked by first threemouths, also can be solved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

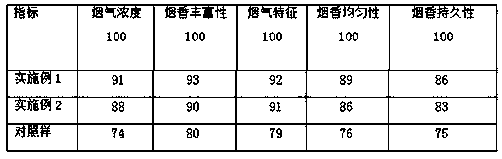

High-aroma heat-not-burn tobacco and preparation method thereof

InactiveCN108703398AIncrease smoke concentrationSmoke features are obviousTobacco preparationTobacco treatmentFlavorAlcohol

The invention belongs to the technical field of cigarettes and particularly relates to high-aroma heat-not-burn tobacco and a preparation method thereof. The preparation method is characterized by including the steps of (1) microwave swelling; (2) tobacco leaf crushing; (3) suspension preparing; (4) spraying; (5) drying and balancing, wherein the step (3) of suspension preparing includes: mixing well a mixture of a polyol, purified water, anhydrous ethyl alcohol, tobacco extract, a tobacco flavor, a binder and a dispersing aid, and leaf particles of the step (2) in a certain mass ratio to obtain homogenous suspension. The tobacco particles and the flavor are made into the suspension that is sprayed to microwave-swelled tobacco stems, and the defects are overcome that, for instance, the traditional heat-not-burn tobacco smoke has low concentration, poor aroma richness, obscure smoke characteristics, non-uniform aroma, and poor duration.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Method for producing a homogenized tobacco material, and homogenized tobacco material

ActiveCN107072286AReduce lossesHigh tensile strengthTobacco preparationTobacco treatmentHeat not burnEngineering

The present invention relates to a method to produce a homogenized tobacco material for use in a heat-not-burn aerosol-generating article, comprising the steps of: - selecting a first target value for a first tobacco characteristic, said first tobacco characteristic being reducing sugars and the first target value being comprised between about (8) percent and about (18) percent in dry weight basis of a total amount of tobacco present within the homogenized tobacco material; - selecting a second target value of a second tobacco characteristic, wherein the second tobacco characteristic is one of total ammonia and total alkaloids; - blending graded tobacco types so as to form the tobacco blend, each graded tobacco type comprising a predetermined amount of the first and second tobacco characteristics, so that the first and second target values of said first and second tobacco characteristics are obtained in said blend within a predetermined tolerance range; - grinding said tobacco blend into a blended tobacco powder; - forming a slurry comprising the blended tobacco powder; and forming a web of homogenous tobacco web from the slurry.

Owner:PHILIP MORRIS PROD SA

Heat-not-burn tobacco sheet and preparation method thereof

InactiveCN107692303AImprove suction qualityHigh tensile strengthTobacco preparationTobacco treatmentPectinaseMaillard reaction

The invention provides a heat-not-burn tobacco sheet and a preparation method thereof. The preparation method comprises: a) biologically treating tobacco under the action of microbes to obtain primarily biologically treated tobacco, wherein the microbes include bacillus and / or yeasts; b) mixing the primarily biologically treated tobacco with dried tangerine peel to obtain a mixture; c) subjectingthe mixture to water extraction and concentration, adding a compound enzyme preparation to perform biological treatment to obtain secondarily biologically treated concentrate, wherein the compound enzyme preparation includes two or more of cellulase, pectinase, proteinase and glucolase; d) mixing the secondarily biologically treated concentrate with a modifying agent to perform Maillard reaction to obtain a coating; 3) applying the coating to the surface of a tobacco sheet base, and drying to obtain the heat-not-burn tobacco sheet. The preparation method may provide improved tensile strength and bulkiness for the heat-not-burn tobacco sheet, adhesion rarely occurs, bad odors such as wood odor are basically removed, and the heat-not-burn tobacco sheet has the aroma of dried tangerine peel.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Cigarette sets applied to heat-not-burn cigarettes

PendingCN109349682AReduce adsorptionIncrease the amount of smokeTobacco devicesMechanical equipmentEngineering

The invention disclose cigarette sets applied to heat-not-burn cigarettes. The cigarette sets comprise smoke formation sections, hollowing sections, cooling sections and junction sections; the right ends of the smoke formation sections are connected with the hollowing sections, and the right ends of the hollowing sections are connected with the cooling sections; the hollowing sections are arrangedbetween the smoke formation sections and the cooling sections, and the right ends of the cooling sections are connected with the junction sections. By means of the hollowing sections of the cigarettesets, adsorption of smoke can be effectively reduced, the smoke amount is increased, and the sensory quality is obviously improved; the cooling process after a supplied material is burst belongs to physical cooling, the use of cooling materials can be reduced, and thus the cost of the materials is reduced; the supplied material can provide a smoke formation agent and part of flavor components which cannot be directly added to a smoke core material, the production technology can be simplified, the problem that currently, it is difficult to add the high-proportion smoke formation agent is solved, and meanwhile the richness of cigarette flavor can be improved; the cigarette sets can be achieved through existing equipment, mechanical equipment does not need to be developed independently, thecost of production equipment is reduced, and the production steps are reduced.

Owner:CHINA TOBACCO YUNNAN IND

Heat-not-burn cigarette additive and preparation method and application thereof

InactiveCN105146731AEnriching the aroma characteristics of heat-not-burn cigarettesFragrance effectTobacco treatmentRespiratory disorderMedicineHeat not burn

The invention discloses a heat-not-burn cigarette additive and a preparation method and application thereof. A component A comprises one or multiple of reed rhizome, dutchmanspipe fruit, root of Chinese Trichosanthes, fructus gardeniae, herba violae and lasiosphaera seu calvatia. A component B comprises one or multiple of climbing groundsel herb, Rabdosia rubescens herb, Radix Sophorae Subprostratae and willowleaf Swallowwort rhizome. A component C comprises one or multiple of Immature fruit of Medicine Terminalia, franchet groundcherry persistent calyx or fruit, Inula flower and kelp. Particles of the three components are enzymatically hydrolyzed via enzyme solution 0.01%-10.00% in mass concentration, then distilling is performed to extract volatile oil, the volatile oil is prepared into the additive, and the additive is added into heating tobacco material according to a weight ratio of 0.0001%-3%. Effective components of natural plants, which have certain effect on relieving harm to the respiratory system, are added to heat-not-burn cigarettes to prepare the heat-not-burn cigarettes effective in relieving the harm of tobacco to the respiratory system, and the fragrance characteristics of the heat-not-burn cigarettes are beneficially enriched.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Preparation method of heat-not-burning cigarette sheet

InactiveCN110432534AHigh Chemical Carrying CapacityReduce breakage rateTobacco preparationTobacco treatmentAdhesiveNanofiber

The invention relates to a preparation method of a heat-not-burning cigarette sheet; the preparation method comprises the following steps of carrying out sterilizing processing on a bacterial cellulose membrane, adjusting the bacterial cellulose membrane to be neutral, soaking the bacterial cellulose membrane in a tobacco extract solution to adjust the contents, coating the surface of the bacterial cellulose membrane with a coating solution to obtain a bacterial cellulose sheet; and coating the bacterial cellulose sheet with a smoke producing agent into a sheet, and preparing the heat-not-burning cigarette sheet. According to the preparation method, the bacterial cellulose membrane is used as a carrier, wherein the bacterial cellulose membrane has nanofibers and a layered space structure,and naturally grows and free of adhesive, so that the bacterial cellulose heat-not-burning sheet is creatively prepared; compared with a traditional tobacco sheet, the sheet has higher chemical substance bearing capacity and a relatively small crushing rate, and the characteristics are favorable for improving the sheet smoke and the fragrance release amount; and the preliminary smoking experimentshows that the prepared sheet does not contain mixed gas of wood, the amount of smoke is large, the fragrance release amount is relatively uniform, and the sensory quality is obviously improved.

Owner:CHINA TOBACCO HENAN IND

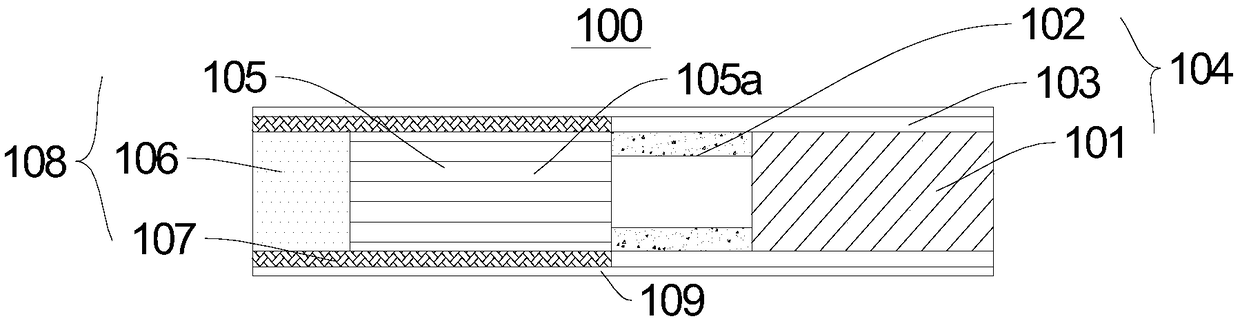

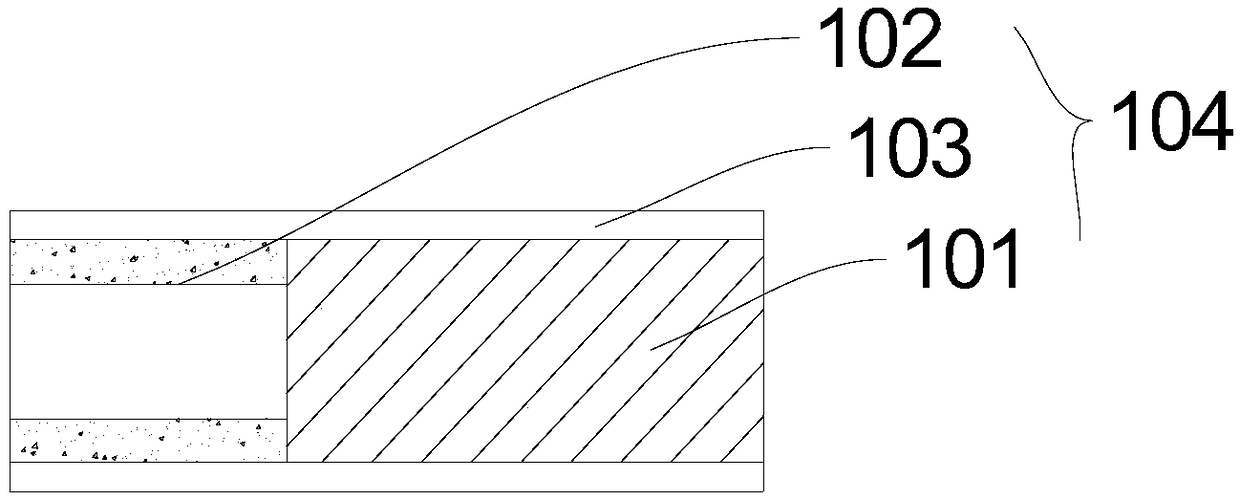

Smoke generating product and electronic cigarette

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a smoke generating product and an electronic cigarette. The smoke generating product comprises a smoke generating section, an isolating section, a flavor blending and cooling section and a cellulose acetate fiber section, wherein the smoke generating section, the isolating section and the flavor blending andcooling section all contain tobacco components; the sum of the tobacco components in the smoke generating section, the isolating section and the flavor blending and cooling section accounts for 30% or above of the total raw material mass of the smoke generating product; the smoke generating section is connected with the isolating section, the isolating section is connected with the flavor blending and cooling section, and the flavor blending and cooling section is connected with the cellulose acetate fiber section; a plurality of gas flowing channels are formed in the flavor blending and cooling section. According to the smoke generating product, the number of smoking can be increased, the user experience is improved, and meanwhile the utilization rate of tobacco raw materials is increased.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com