Preparation method of heat-not-burning cigarette sheet

A heat-not-burn and thin-sheet technology, which is applied in the preparation of tobacco, tobacco, and tobacco treatment, can solve the problems of not satisfying consumers' smoking experience and limited chemical content, and achieve a small crushing rate and uniform aroma release , the effect of a large amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

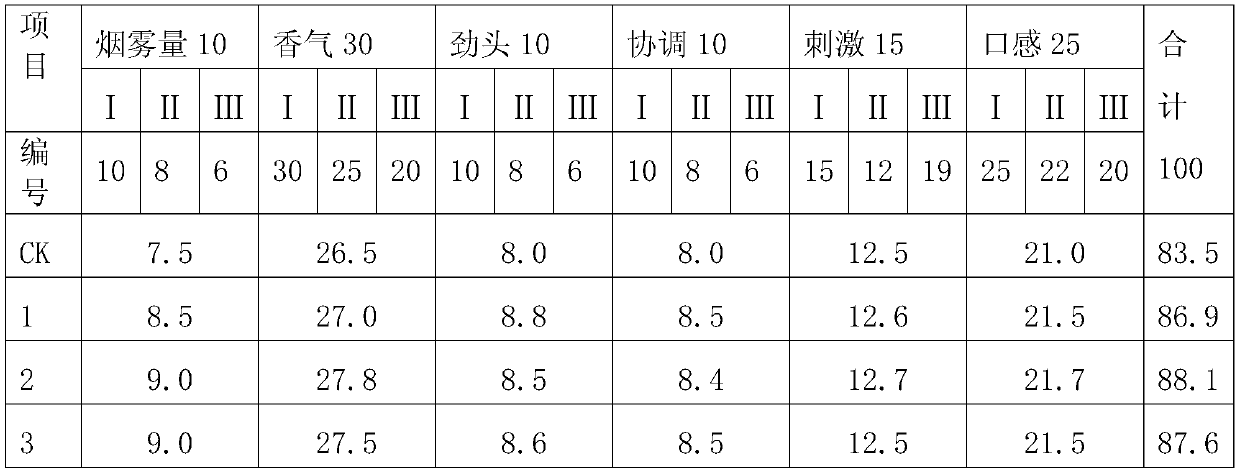

Examples

Embodiment 1

[0040] The bacterial cellulose heat-not-burn sheet provided in this embodiment, the preparation method comprises the following steps:

[0041] 1) Bacterial cellulose membrane treatment: the bacterial cellulose membrane obtained is sterilized and adjusted to neutrality. The bacterial cellulose membrane is a purchased finished bacterial cellulose membrane with a thickness of 4mm and a moisture content of 98%.

[0042] Sterilize and adjust to neutrality, specifically refer to the following operations: boil the bacterial cellulose membrane with 1mol / L NaOH solution for 1 hour to sterilize, and then wash it repeatedly with water until it is neutral.

[0043] 2) Adjust the content of the bacterial cellulose film, soak the treated bacterial cellulose film in the tobacco extract solution, let it stand for 2 hours, dry it to a moisture content of 15%, coat the surface of the cellulose film with a coating solution, and let it stand for 2 hours. Set for 1h, dry to 6% moisture.

[0044]...

Embodiment 2

[0051] 1) Bacterial cellulose membrane treatment: the bacterial cellulose membrane obtained is sterilized and adjusted to neutrality.

[0052] Bacterial cellulose membrane is a cellulose membrane made by fermentation and growth of bacteria in the laboratory, with a thickness of 5mm and a moisture content of 95%.

[0053] Sterilize and adjust to neutrality, specifically refer to the following operations: boil the bacterial cellulose membrane with 1mol / L NaOH solution for 1 hour to sterilize, and then wash it repeatedly with water until it is neutral.

[0054] 2) Adjust the content of the bacterial cellulose film, soak the treated bacterial cellulose film in the tobacco extract solution, let it stand for 2 hours, dry it at 80°C to a moisture content of 18%, and coat it with a coating solution On the surface of the cellulose film, let stand for 1 hour, and dry to 8% moisture.

[0055] The tobacco extract solution is tobacco water extract extracted from tobacco dust and water at a ...

Embodiment 3

[0061] 1) Bacterial cellulose membrane treatment: the bacterial cellulose membrane obtained is sterilized and adjusted to neutrality. The bacterial cellulose membrane is a cellulose membrane grown by fermentation in the laboratory, with a thickness of 5mm and a moisture content of 95%. Sterilize and adjust to neutrality, specifically refer to the following operations: boil the bacterial cellulose membrane with 1mol / L NaOH solution for 1 hour to sterilize, and then wash it repeatedly with water until it is neutral.

[0062] 2) Adjust the content of the bacterial cellulose film, soak the treated bacterial cellulose film in the tobacco extract solution, let it stand for 2 hours, dry it at 110°C until the water content is 20%, and coat it with the coating solution On the surface of the cellulose film, let stand for 1 hour, and dry to 8% moisture.

[0063] The tobacco extract solution is tobacco water extract extracted from tobacco dust and water at a ratio of 1:1, and the quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com