Patents

Literature

121results about How to "High peeling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for peeling almond or peach seed by freezing

The invention relates to a method for peeling an almond or a peach seed by freezing. The method comprises the following steps of: cleaning the almond or the peach seed; removing dust on the surface; soaking the almond or the peach seed in water to freeze at the lower temperature; quickly placing the frozen almond or peach seed into boiling water for heating; and taking the almond or the peach seed out, and quickly peeling the almond or the peach seed by using a machine to obtain the peeled almond or peach seed. In the method for peeling the almond or the peach seed by freezing, seed coats of the almond or the peach seed are peeled by a mechanical method and compared with the conventional technology, the method for peeling the almond or the peach seed by freezing improves peeling rate, the obtained almond or peach seed has better quality, and all the components are unmodified; and the method has the advantages of contributing to energy saving and environmental protection, satisfying the principle of sustainable development, along with no pollution, low energy consumption, and easy processing.

Owner:SHAANXI UNIV OF SCI & TECH

Walnut kernel peeling method

The present invention relates to a method for removing walnut kernel seed cover under the condition of normal temperature after the walnut kernel is frozen at low-temperature. It is characterized by that for dried walnut kernel the walnut kernel is soaked in the water with 0-10deg.C, after the walnut kernel is reconstituted, the walnut kernel is frozen; for fresh walnut kernel whose water content is greater than or equal to 45% it has no need of reconstitution, can be directly frozen; its freeze temperature is -5 - -25deg.C; after a lyer of ice cover is formed on the walnut kernel surface, the walnut kernel can be taken out and can be placed at normal temperature or into water with 30-60deg.C to melt the ice cover, then a manual method or mechanical method can be adopted to strip seed cover of walnut kernel. Its technological process includes the following steps: reconstitution, freezing, melting, stripping seed cover so as to obtain finished product.

Owner:SHANDONG INST OF POMOLOGY

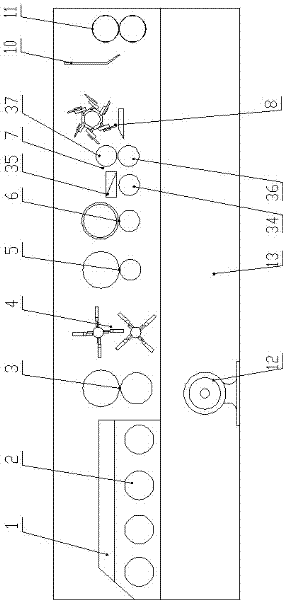

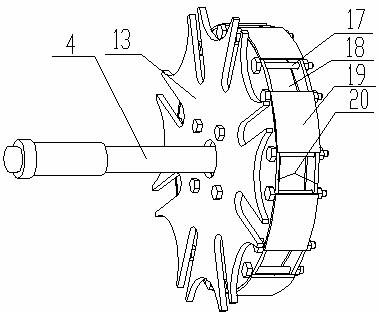

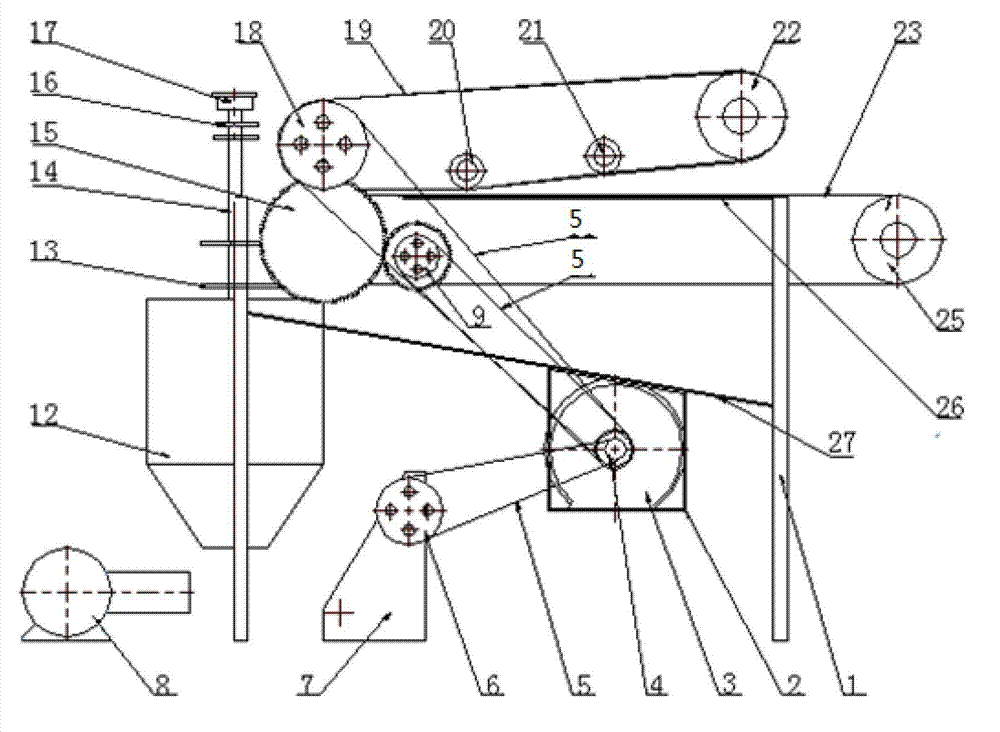

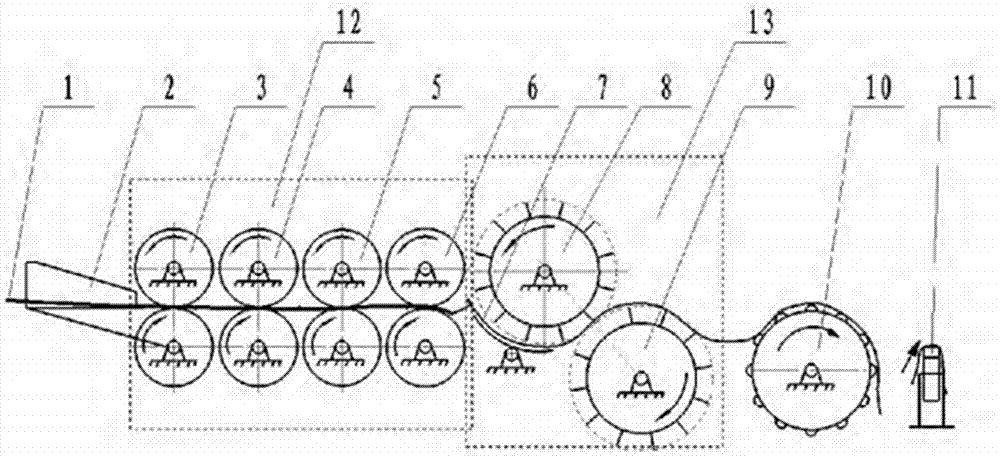

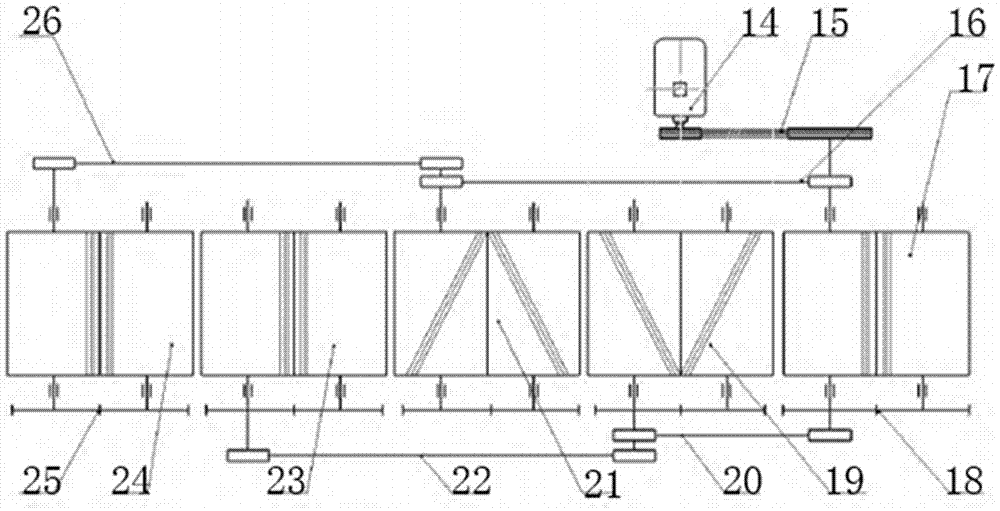

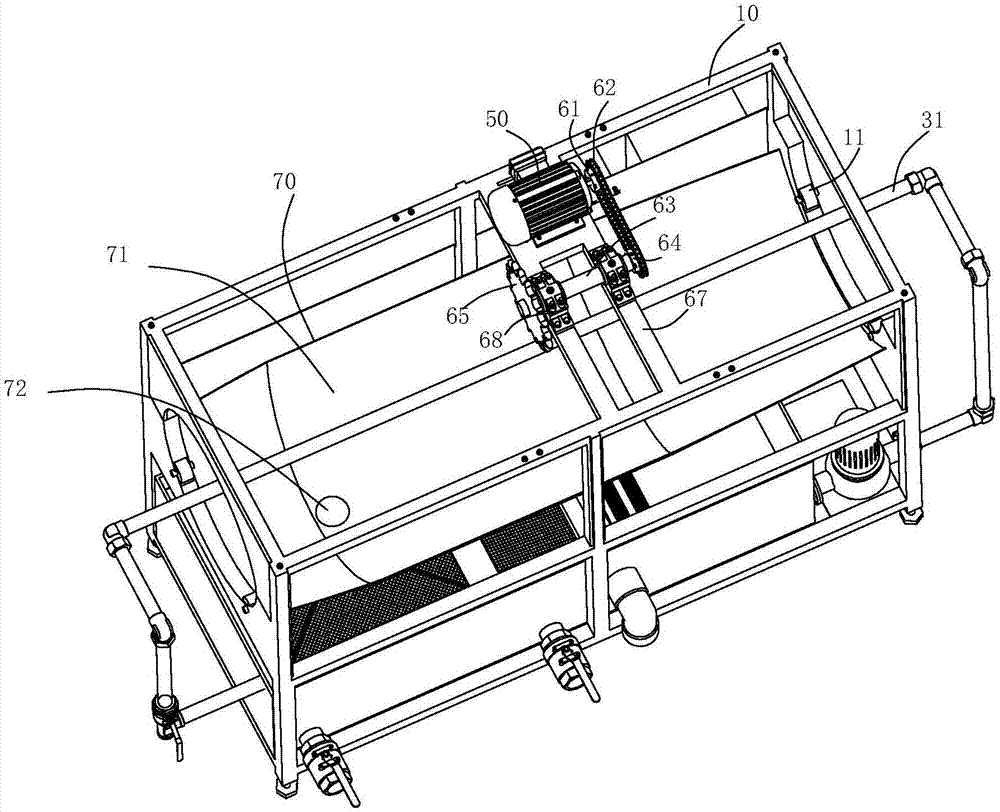

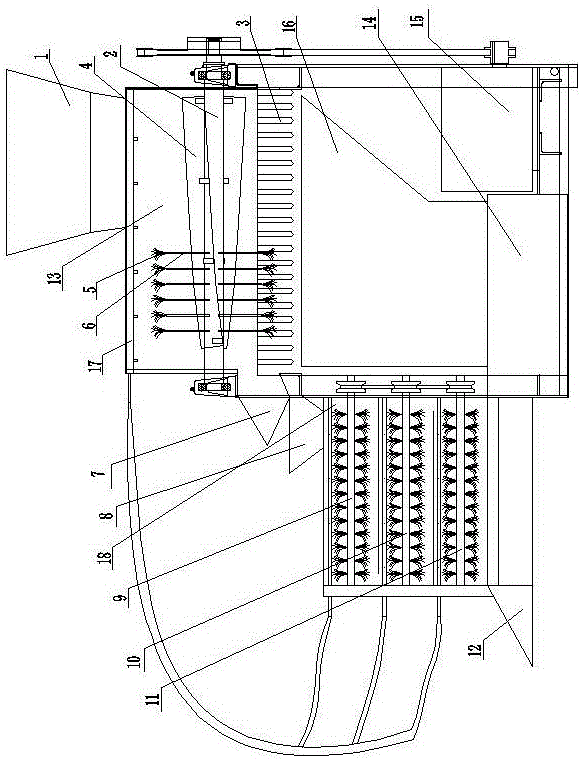

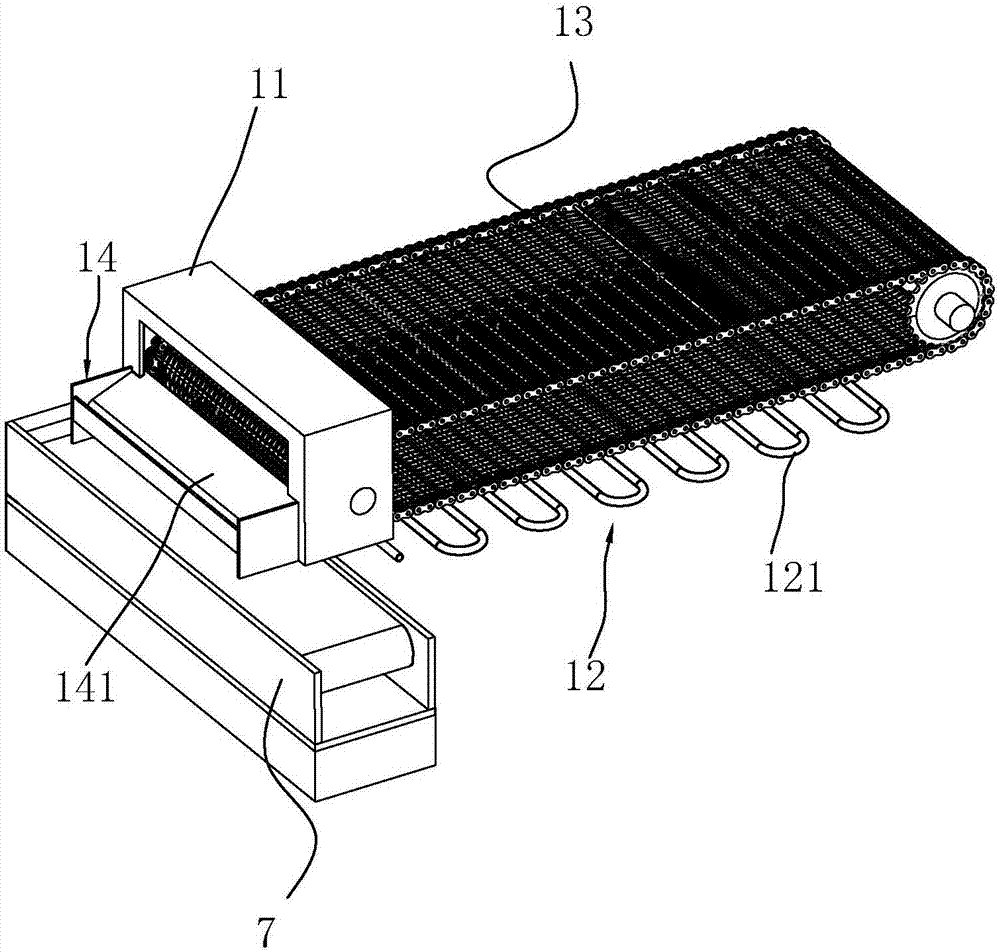

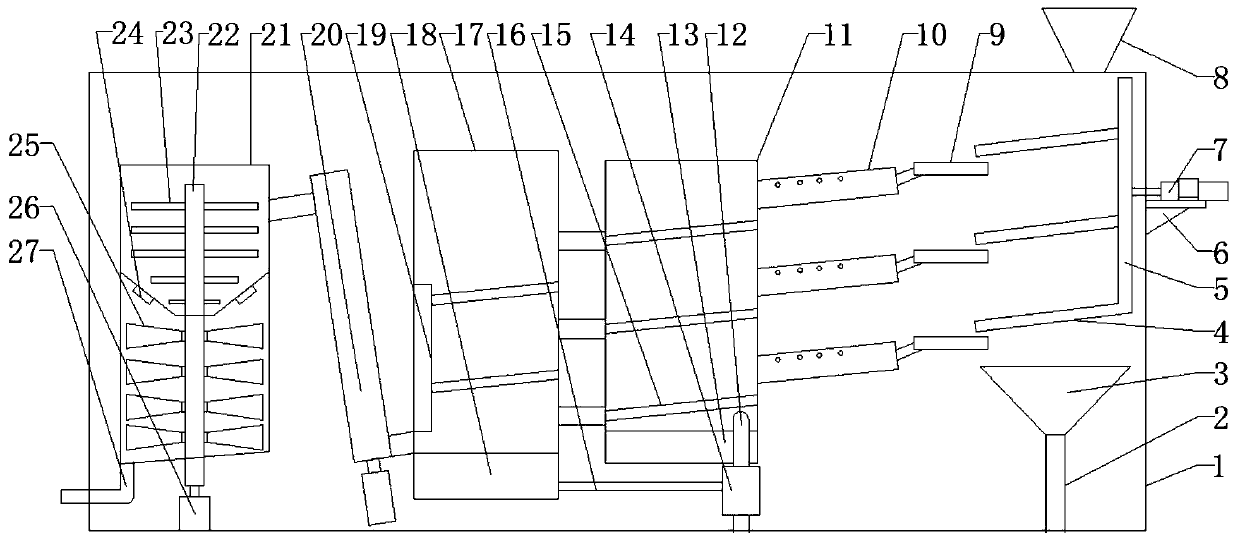

Peel-pith-leaf separator of maize straw

InactiveCN102528865AAchieve separationTake advantage ofCane mechanical workingEngineeringEnergy consumption

The invention discloses a peel-pith-leaf separator of a maize straw. The separator comprises a rack (13) and a power mechanism (12) arranged on the rack and is characterized in that a guiding conveying mechanism, a leaf removing mechanism, a peel-stripping mechanism and an output mechanism are arranged on the rack (13) from front to back and are all in transmission connection with the power mechanism (12). The separator disclosed by the invention specially aims at leaf-removing and pith-stripping works so as to realize the function of peel-pith-leaf thorough separation, and further the peel, the pith and the leaf of the maize straw can be respectively and effectively utilized; besides, the separator disclosed by the invention has the advantages of small mechanical vibration, low noise, less energy consumption, strong practicability, good market prospect and worthy of popularization and application.

Owner:HENAN AGRICULTURAL UNIVERSITY

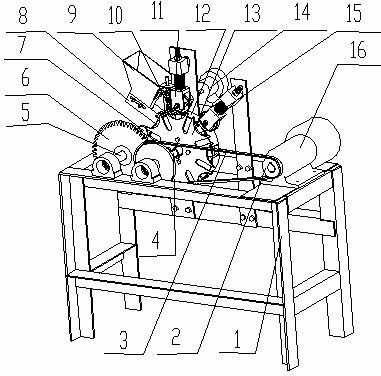

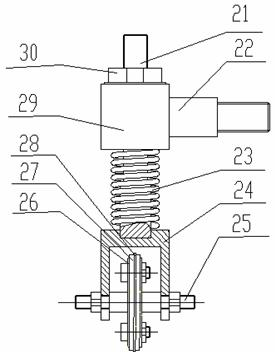

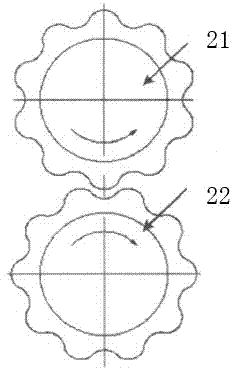

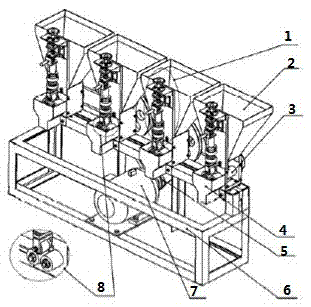

Hobbing type lotus seed shucker

The invention relates to a hobbing type lotus seed shucker, which is composed of a frame, a feeding mechanism, a conveying mechanism, a cutting mechanism, an uncoating mechanism, a motor and the like, wherein the conveying mechanism is driven by a grooved pulley, and step performing of lotus seed shucking and uncoating is realized by the intermittent movement of a grooved pulley mechanism, so that the shucking is more thorough and more effective; and spring adjustment systems are respectively installed on the shucking mechanism and the uncoating mechanism, and the springs can automatically adjust the distance between a cutting blade and an uncoating roller as well as a rubbing roller according to the lotus seed size, so that the shucking of lotus seeds with different sizes is adapted. The shucker has the characteristics of high shucking rate and low breakage rate in the shucking process, and has the characteristics of simple structure, small volume, low manufacturing cost, stability in operation and the like in the equipment performance.

Owner:NANCHANG UNIV

Walnut shelling and picking device

The invention discloses a walnut shelling and picking device which comprises a rack, wherein a case is arranged on the rack; a compression grinding device is arranged in the case; the discharge port of the compression grinding device is provided with a stirring device; the discharge port of the stirring device is provided with a sorting unit; a power device is fixed on the lower wall of the case, and is respectively connected with the sorting unit and the compression grinding device through a V-shaped belt; and the compression grinding device is firstly used for cracking the walnut, then through the hammering of the stirring device and the wind force separation, velvet strip adhesion and other functions of a separating device, the kernel is shelled out, so the automatic kernel-husk separation is realized. A height-adjustable device is adopted, the device can be adaptive to treatment of different types of walnuts, thus the walnut shelling and picking device can be used for mass production, so the labor time is shortened, the labor is saved, the processing cost is lowered, and the problems that the walnut is difficult to shell and depends on manual shelling are better solved; and moreover, the shelling rate and kernel yield are improved, so efficient low-consumption low-cost green and clean production is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Rapeseed peeling method used for making oil through cold pressing

ActiveCN104877756AEasy to peelHigh peeling rateFatty-oils/fats productionProcess engineeringRapeseed

The invention provides a rapeseed peeling method for making oil through cold pressing and belongs to front-end procedures in a rapeseed oil making method. The rapeseed peeling method provided by the invention comprises the following steps: (1), rapeseed pre-processing, (2), microwave pre-processing, (3), crushing and peeling; (4) hull and kernel separating, (5), color sorting and peeling, and (6), oil making through cold pressing. The process is relatively simple, the investment is less, the microwave pre-processing is conducive to rapeseed crushing and peeling, hull and kernel adhesion is effectively reduced after crushing, moreover, a drying effect is played, the rapeseed peeling rate can reach 95 percent or above, and the shelling rate and the color sorting rate are both higher than 95 percent. Low temperature pressed crude oil obtained through low temperature pressing to the rapeseed kernel obtained after microwave treatment is light in color, more reasonable in nutrient substance composition, can be high-quality rapreseed oil without need of complex refining process, and meets the requirements of current consumers to green and healthy oil.

Owner:HEFEI UNIV OF TECH

Hulling separation method for rapeseeds and special separation device

InactiveCN103555414AImprove separation efficiencyNo stickingSievingScreeningVegetationMetal impurities

The invention discloses a hulling separation method for rapeseeds. The hulling separation method comprises the following steps of cleaning rapeseed raw materials to remove sand and vegetation impurities to enable the impurity content to be less than or equal to 2 percent; then performing drying at the drying temperature of 160 DEG C, wherein the water content of the dried rapeseeds is 5-8 percent; cooling the rapeseeds to normal temperature, performing magnetic separation to remove metal impurities, conveying the rapeseeds into a rapeseed huller for shearing, grinding and extruding to obtain hull and kernel mixtures, and then conveying the mixtures into a separation sieve in a special separation device, wherein under the joint action of a vibration sieve and a fan, the upper layer of hulls with small density are removed through the fan, and the lower layer of seeds with large density are discharged through a front port of the special separation device and are collected. The hulling separation method has the advantages that the hulling rate is high, the primary hulling separation rate can be up to 98 percent, and the hulling effect is good; the proportion of naturally split half kernels to integrated kernels is up to about 75 percent; the powder rate is lower than 3 percent; the kernel and hull separation efficiency is high; the phenomenon that the kernels and the hulls are adhered is avoided.

Owner:HENAN YIFENG EDIBLE OILS +1

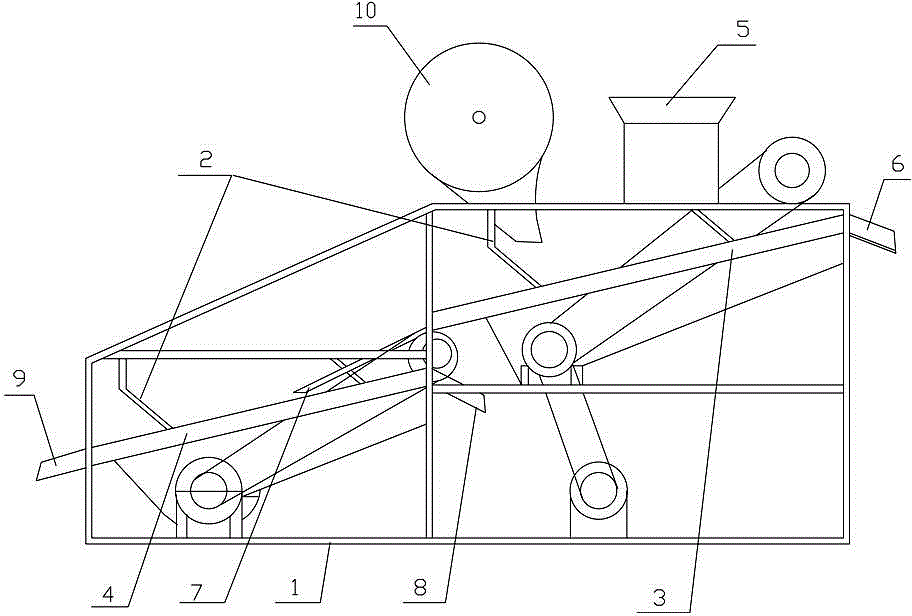

Peanut sheller

The invention relates to a peanut sheller, belonging to the technical field of agricultural machinery. The peanut sheller follows the principle of hand shelling, has lower crushing and damage rates and can maintain the original color and luster of the shelled peanuts so as to meet the requirements of the shelled peanuts used as seeds or for export. The peanut sheller mainly comprises a support and a conveying device, wherein shelling devices are arranged above the support; a cleaning device is arranged below the support; the conveying device comprises a feeding hopper and a conveying pipeline; a conveying fan is arranged on the conveying pipeline below the feeding hopper; the cleaning device comprises a shell discharge pipe, a screen box and a cleaning fan; the shell discharge pipe is arranged on the support above the screen box; screens are installed at the top of the screen box; discharge holes are arranged at the bottom of the screen box; the cleaning fan is fixed on the support above one side of the screens; the shelling devices comprise separating hoppers, rubber rollers and upright rubber plates; and the separating hoppers and the upright rubber plates are fixed on the support. The peanut sheller is mainly used for shelling the peanuts used as seeds or for export.

Owner:烟台市农业机械科学研究所

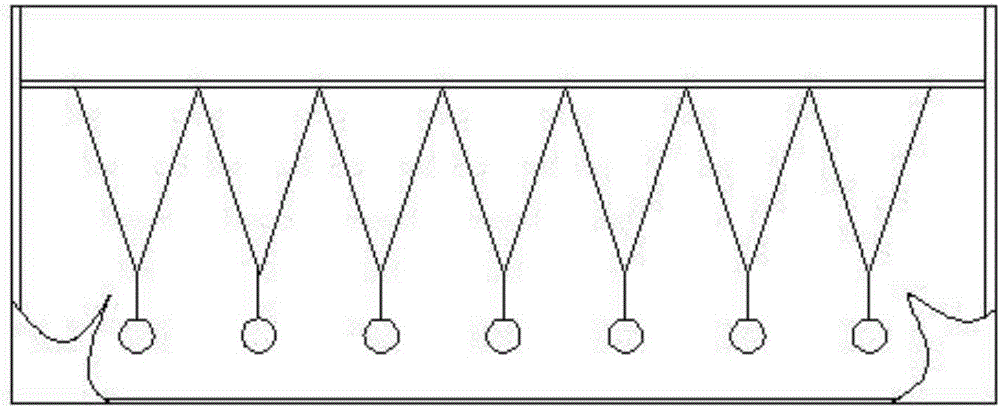

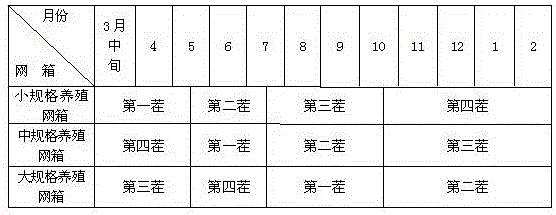

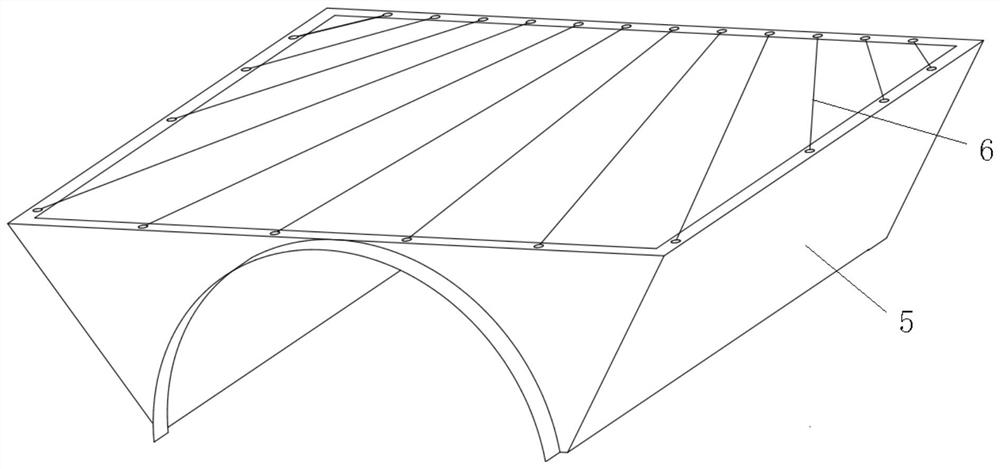

A winter pond net cage intermediate culture method for stichopus japonicus larvae

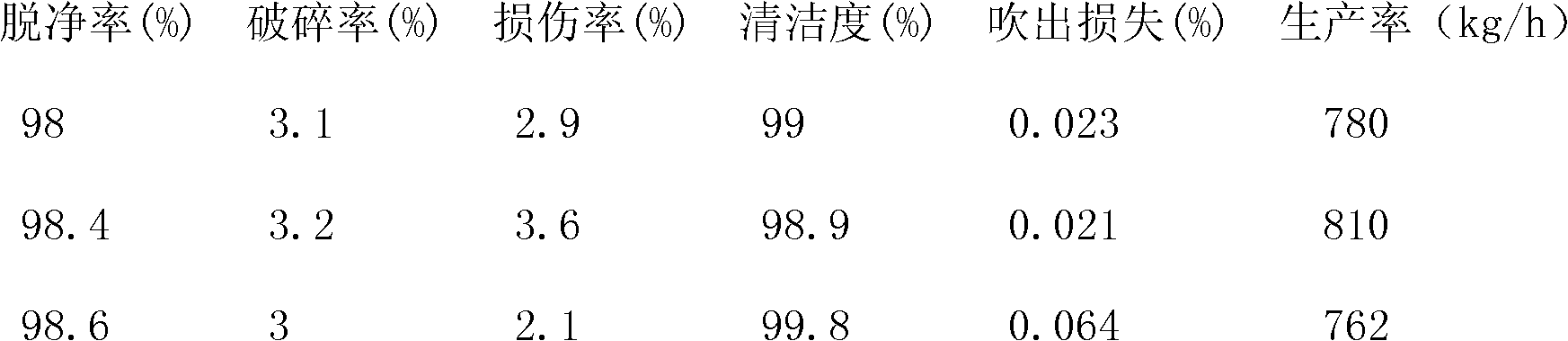

InactiveCN106386596AExpand the breeding spaceReduce resistanceClimate change adaptationPisciculture and aquariaStichopusProduction rate

The invention provides a winter pond net cage intermediate culture method for stichopus japonicus larvae. The method comprises the steps of selecting a culture pond with a water depth of 1.8m-2m; erecting net cages, with the top surfaces of the net cages being 5cm-10cm lower than a water surface; making W-type adhering substances with 6 mesh-10 mesh polyethylene nets and distributing the adhering substances in the net cages uniformly; performing daily management of adjusting the water quality of pond water, and putting larvae in the pond at the end of October or at the beginning of November, with the stocking density being 0.5Kg per net cage to 0.7Kg per net cage; increasing light illumination in an icebound period in winter and monitoring under-ice water quality indexes; after ice melts, starting an oxygenation apparatus to promote vertical flow of water and improve the water quality environment; when larvae in the cages reach 250 / kg-300 / kg at the end of April, selling the larvae as commercial larvae for culture. The method can increase the culture space after the water is icebound, create the optimal environment for overwintering of sea cucumbers, greatly increase the effective usage area of adhering substances, reduce the production cost of larvae, basically guarantee all-weather production all year round, increase the culture survival rate and body wall production rate, and guarantee the quality of adult sea cucumbers.

Owner:锦州市水产技术推广站

Rapeseed peeling method suitable for cold pressing oil preparation

InactiveCN104293480AHigh peeling rateReasonable compositionFatty-oils/fats productionProcess engineeringRapeseed

The invention provides a rapeseed peeling method suitable for cold pressing oil preparation, belonging to a front procedure in a rapeseed oil preparation method. The rapeseed peeling method comprises the following steps: (1) rapeseed pretreatment, (2) ultrasonic wave treatment, (3) drying, (4) breaking and peeling, and (5) skin and kernel separation. The method is simple and low in investment, the drying time is greatly shortened by the ultrasonic wave treatment, the rapeseed peeling rate is more than 95%, and the peeling rate is high. The peeled rapeseeds obtained by adopting the method is particularly suitable for processing of low-temperature pressed rapeseeds, and low-temperature pressed rapeseed oil is good in color and high in quality and meets the requirement of current customers for green and healthy oil.

Owner:HEFEI UNIV OF TECH

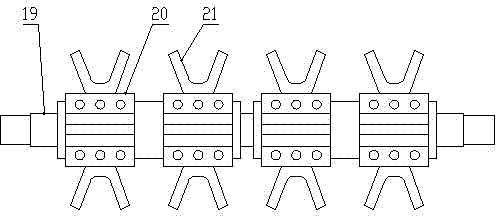

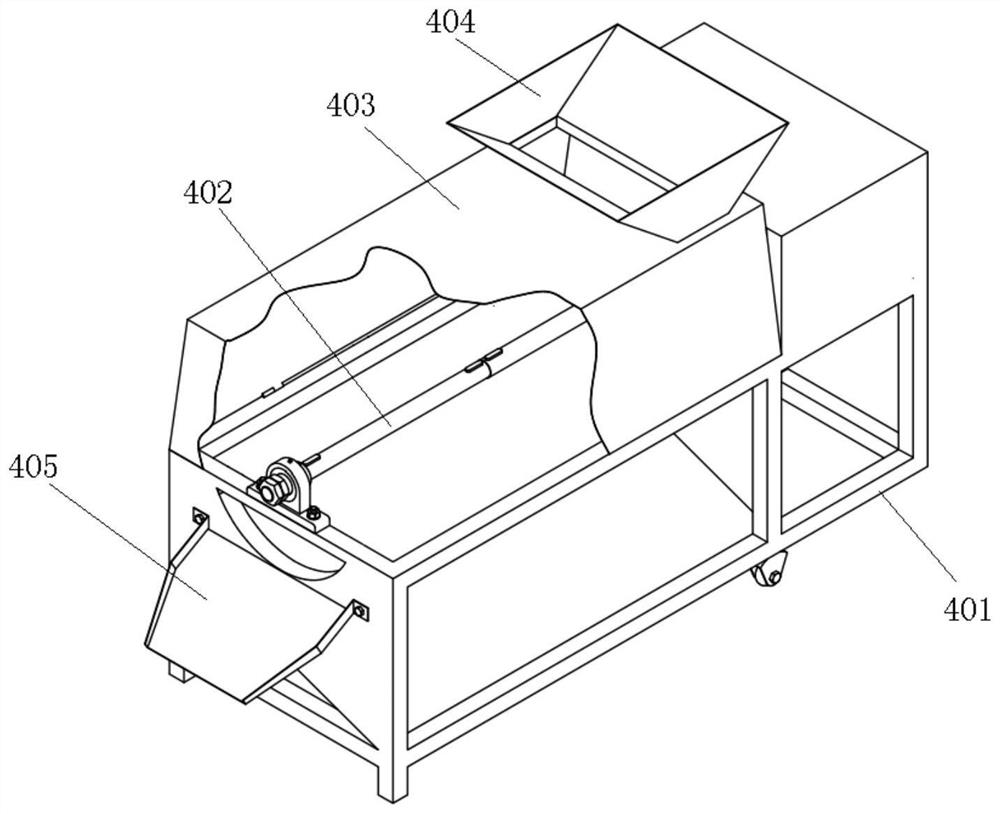

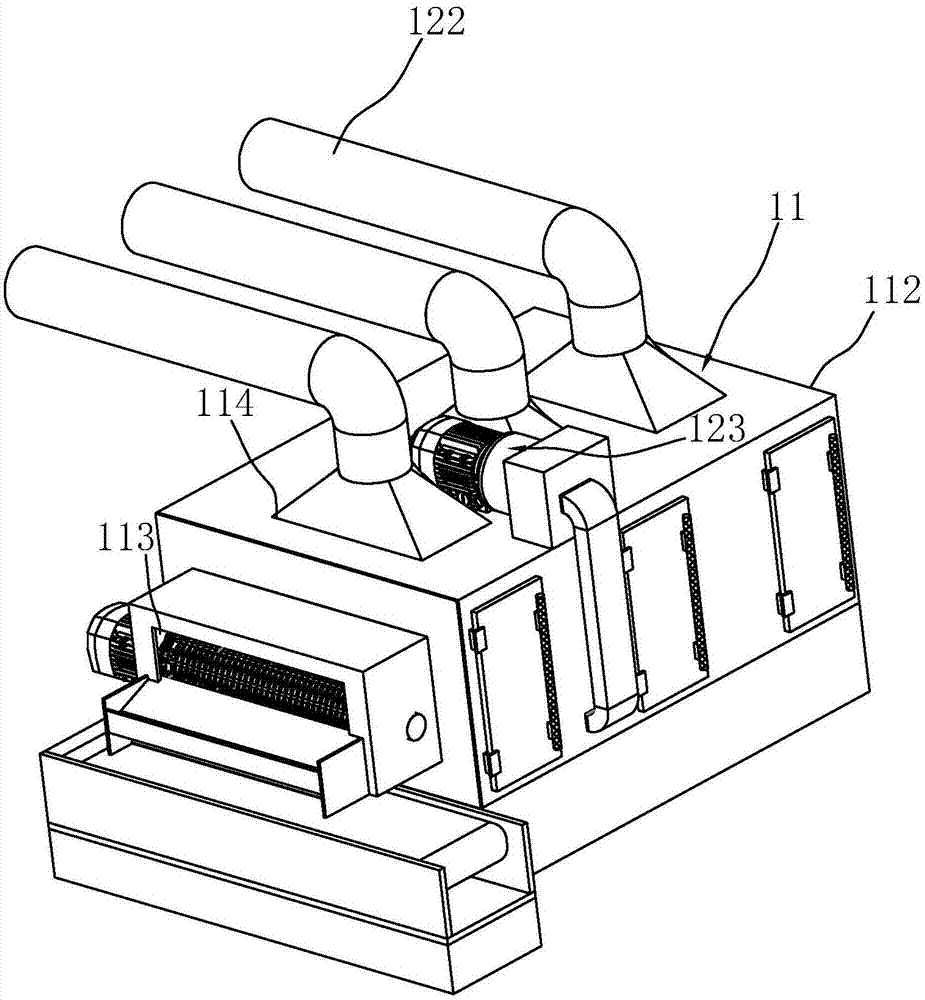

Industrial hemp peeling machine

The industrial hemp peeling machine of the present invention mainly includes a stalk, a feeding hopper, a first pair of crushed stem rollers, a second pair of crushed stem rollers, a third pair of crushed stem rollers, a fourth pair of crushed stem rollers, and a hemp peeling concave plate. Upper peeling roller, lower peeling roller, hemp receiving roller, hemp receiving device, stalk rubbing part, fiber combing part, in which the hemp is fed into the stalk rubbing mechanism through the feeding hopper, and the straight-toothed stem crushing roller crushes and bends the hemp, The skin and bone of the stem are initially separated; then the fresh cannabis stem enters the stem rubbing mechanism, and the cannabis is rolled vertically, and it also has a horizontal rubbing effect, so that the skin and bone of the cannabis are separated more thoroughly, and then the skin and bone enter the combing and separating mechanism, The bone fragments leak out of the concave plate, and the fresh skin is collected by the hemp collecting device; the industrial hemp peeling machine has a high fresh stem peeling rate, a high peeling rate, high production efficiency, low labor intensity, compact structure, and easy to move. Strong bone separation ability and so on.

Owner:田佳聪

Processing method for directly cold-pressing oil from rapeseeds

InactiveCN107312623AQuality improvementHigh peeling rateFatty-oils/fats productionOil and greaseRapeseed

The invention discloses a processing method for directly cold-pressing oil from rapeseeds, which includes the following steps: (S1) drying and cleaning: rapeseeds, the production date is May or June, are collected, and the rapeseeds are screened by a vibrating screen and a filter screen; (S2) rapeseed preprocessing: the screened rapeseeds are stir-fried under the stir-frying temperature of 40 DEG C to 60 DEG C until the moisture in the rapeseeds are removed, ensuring that the moisture content in the rapeseeds is 2 to 5 percent; (S3) grinding and shelling: the dried rapeseeds are put into a shelling and separating machine, and are ground and shelled; (S4) shell and kernel separation: the material in S3 is put into a winnower, and the shells of the rapeseeds are removed by the method of separation; (S5) milling: the material in S4 is put into an automatic mill and milled; (S6) low-temperature pressing. The invention provides a high-nutritional value and health-care rapeseed oil production method which is simple, convenient and reasonable in process, and the processing method can provide technical support for the small-scale production of special oil, and is suitable for being popularized in the technical field of edible oil production.

Owner:望谟县布依王油脂有限公司

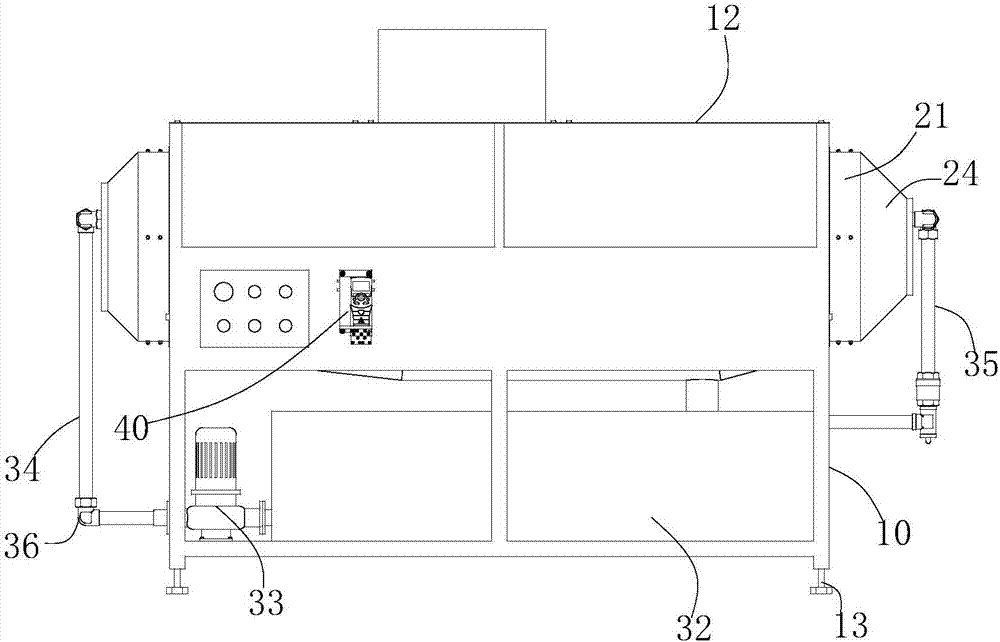

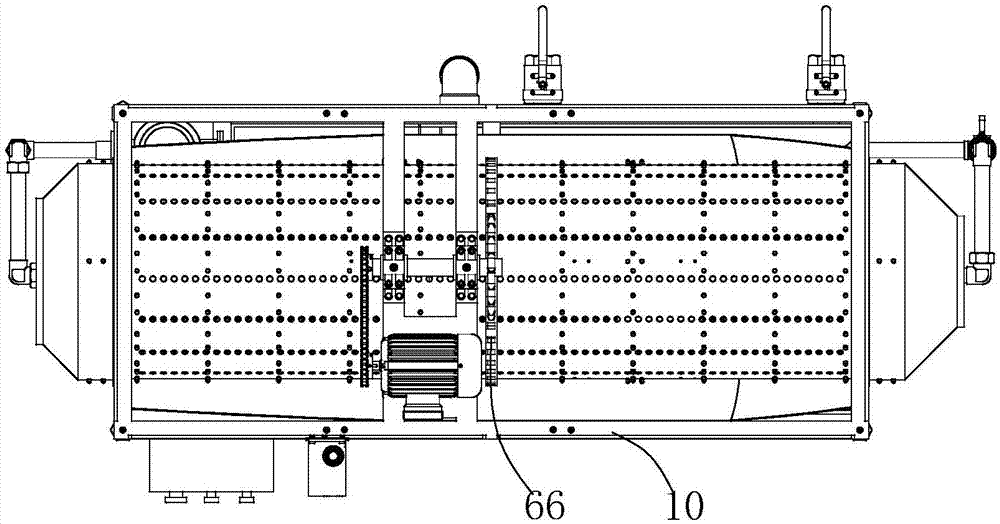

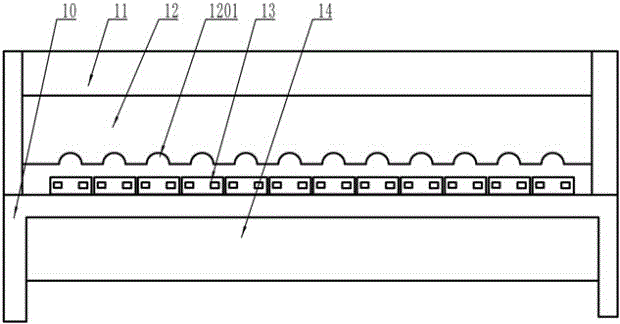

Continuous potato cleaning and peeling integrated machine

PendingCN107296288AImprove efficiencyAccurate speed regulation and easy operationClimate change adaptationMechanical energy handlingSlagFrequency changer

The invention discloses a continuous potato cleaning and peeling integrated machine. The continuous potato cleaning and peeling integrated machine comprises a rack, a peeling mechanism, a cleaning mechanism and a power mechanism, wherein the peeling mechanism, the cleaning mechanism and the power mechanism are installed on the rack. The peeling mechanism comprises a roller, a cavity is formed in the roller, and a spiral brush is arranged on the inner wall of the roller. The cleaning mechanism comprises a spraying pipe installed in the cavity. The power mechanism comprises a frequency converter, a motor and a drive mechanism. A triple filtering water circulating mechanism is further arranged and comprises a trapezoidal filter net, a slope type filter net, a filter sponge and a filter clamping plate. The rotating speed of the motor can be adjusted, then the rotating speed of the whole roller can be regulated and controlled, impact loads caused when the motor is started are avoided, the advantages of continuous cleaning and peeling and slag water triple filtering water circulating are achieved, water can be effectively saved, the cost is reduced, operation is convenient and easy, the peeling effect and efficiency of potatoes are improved, the loss rate is reduced, the added value of the potatoes is increased, and the peeling mode and the peeling structure are convenient to apply and popularize.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Ultrasonic garlic clove peeling device and method

InactiveCN107006878APeeling achievedImprove peeling efficiencyFood treatmentMechanical engineeringUltrasonic generator

The invention provides an ultrasonic garlic clove peeling device and method. The device comprises a container, a conveying belt penetrates into the container and installed on a driving device, a feed inlet is connected with one end of the conveying belt, a discharge opening is connected with the other end of the conveying belt, and an ultrasonic generator is arranged on the inner wall of the container. The device has the advantages of being simple in structure, capable of achieving peeling through ultrasound, high in peeling efficiency, high in peeling rate, low in bruise rate and the like.

Owner:SHANDONG MARIA MACHINERY

Mango peeling and washing machine based on drum screen

InactiveCN107836728AEvenly heatedEasy to separateVegetable peelingFood treatmentCombustionPulp and paper industry

The invention provides a mango peeling and washing machine based on a drum screen, and belongs to the field of processing of fruits. The mango peeling and washing machine based on the drum screen comprises a combustion engine, wherein a flame is arranged at one end of the combustion engine; a flame stirrer is arranged on the flame; the drum screen is arranged above the flame stirrer; a feeding endof the drum screen is connected with a vibrating feeding hopper; a discharging end of the drum screen is connected with a brush winding cage; a gas collecting hood is arranged above the drum screen,and is connected with an exhaust fan; one end of the exhaust fan is connected with a cyclone separator, and the other end of the cyclone separator is connected with a tube array type separator; and the upper end of the tube array type separator is connected with atmosphere, and the lower end of the tube array type separator is connected with the combustion engine. According to the mango peeling and washing machine disclosed by the invention, the combustion engine is mounted, so that the purpose that the surface of a mango is heated can be achieved, and the crust of the mango is carbonized; theflame stirrer is mounted, so that a flame cup can be uniformly stirred, the heating of the mango is uniform; pulp of the mango cannot be damaged due to too high temperature of the surface, so that good mouth feel is maintained; and the operating equipment has the advantages of being simple in operation, high in peeling rate, energy-saving and environmentally-friendly and low in cost.

Owner:金华市川璞农业科技有限公司

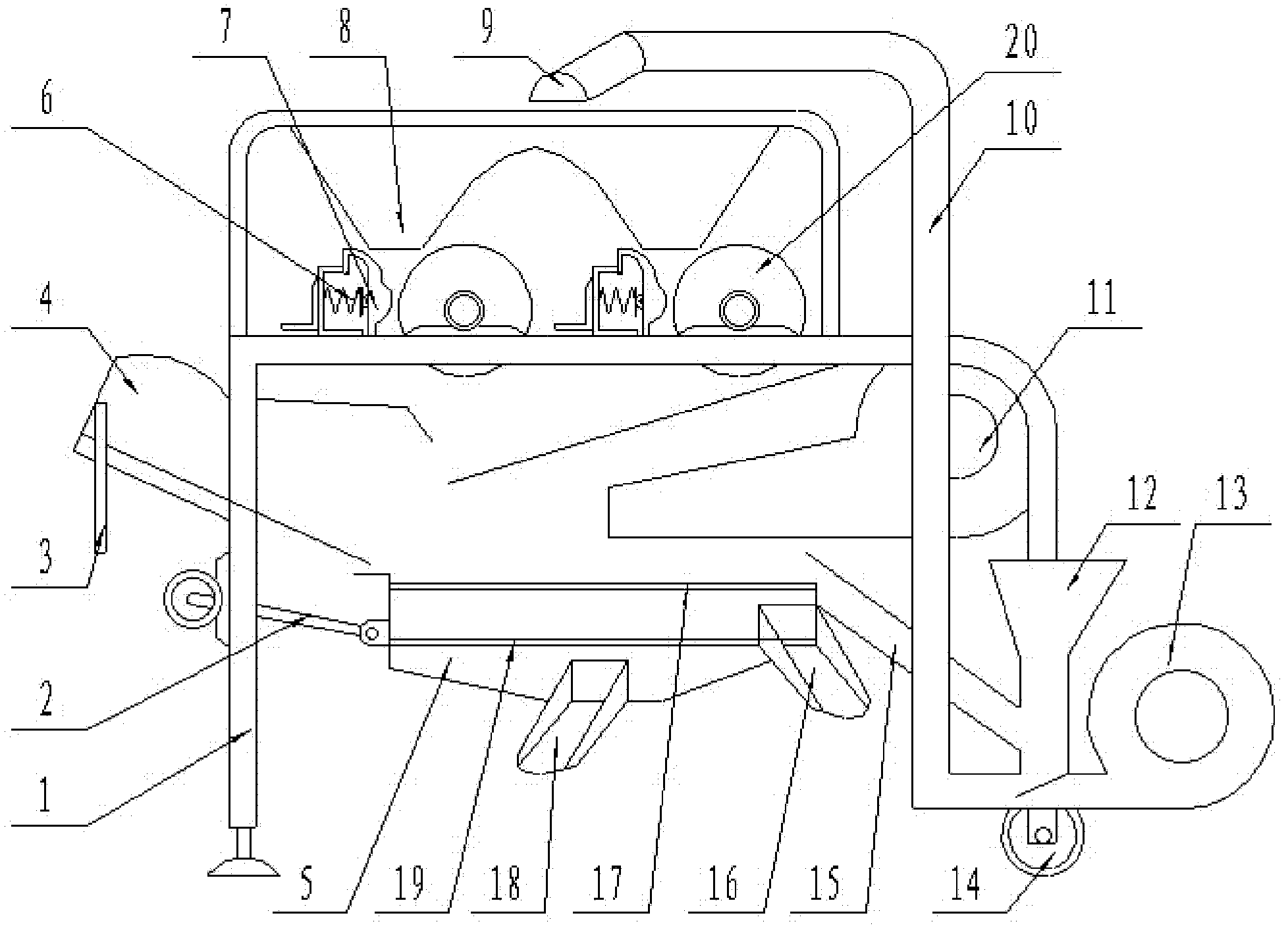

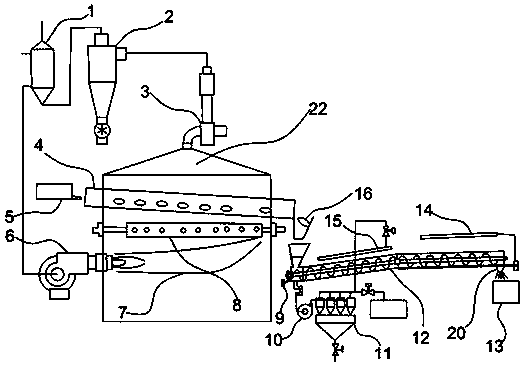

High temperature steam seed huller

InactiveCN110026263AHigh peeling rateAvoid damageGrain huskingGrain polishingEngineeringBreakage rate

The invention discloses a high temperature steam seed huller and is intended to provide the high temperature steam seed huller, high in hulling rate, low in exterior damage rate, low in breakage rate,low in cost and high in efficiency. The high temperature steam seed huller comprises a housing, a hulling device, a vibratory feeding device, a steam system, a winnowing system, a partition, an exhaust fan, a germ box, and a kernel box. The partition is arranged inside the housing and divides the housing into a vibratory feeding chamber on the left and a hulling chamber on the right; the vibratory feeding device and the steam system are arranged inside the vibratory feeding chamber; the steam system is positioned below the vibratory feeding device; the hulling device is arranged in the hulling chamber; the kernel box and the germ box are arranged below a lower outlet of the hulling device sequentially from left to right. The winnowing system is arranged on the outer side of a sidewall plate of the hulling chamber and is communicated with an air suction port. The high temperature steam seed huller is suitable for hulling for corn, soybean, peanut and other seeds.

Owner:张金伟

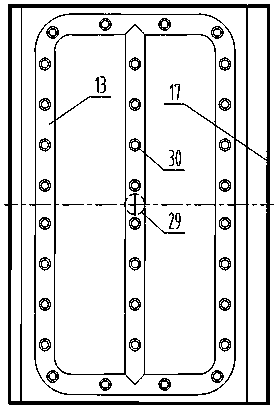

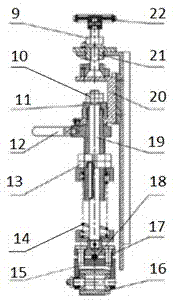

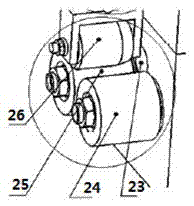

Peeling device for green husk walnuts

InactiveCN106360753AImprove efficiency and cleanlinessEasy to separateHuskingHullingBrush deviceEngineering

A peeling device for green husk walnuts comprises a barrel cavity I (13) for placing green husk walnuts in, a barrel cavity II (18) communicated with the barrel cavity I (13), a skinning device arranged in the barrel cavity I (13) and generating rubbing force on husks of the green husk walnuts, a roller brush device arranged in the barrel cavity II (18) and used for cleaning the husks of the green husk walnuts and a motor (15) for providing power for the skinning device and the roller brush device. In the barrel cavity I (13), the husks of the green husk walnuts are stripped through the skinning device; in the barrel cavity II (18), the husks and remaining husks of the green husk walnuts are cleaned through the roller brush device, the green husk walnuts are no longer peeled manually, and thus green husk walnut peeling efficiency and cleanness are improved.

Owner:TAIAN INST OF AGRI MACHINERY SCI SHANDONG PROV

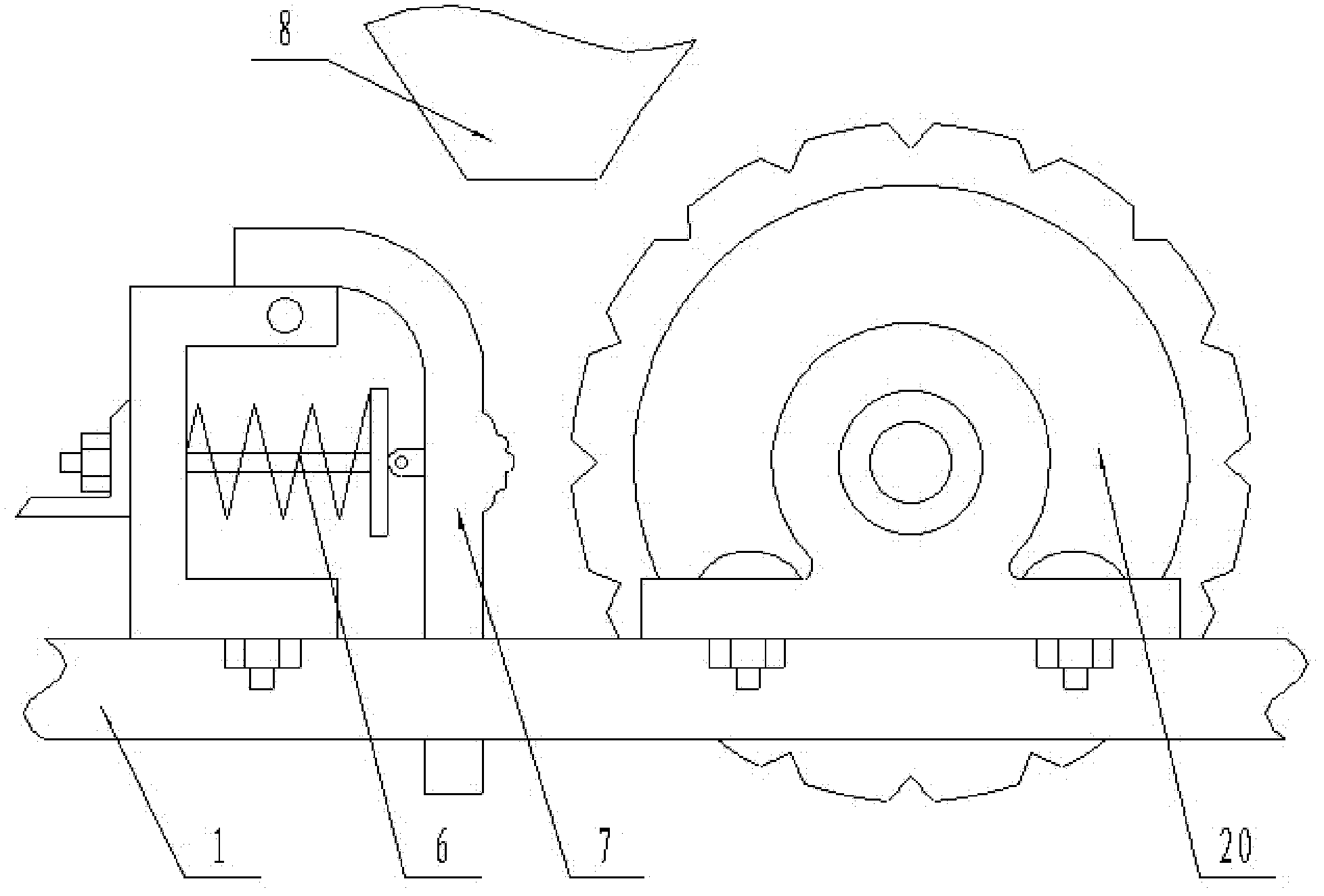

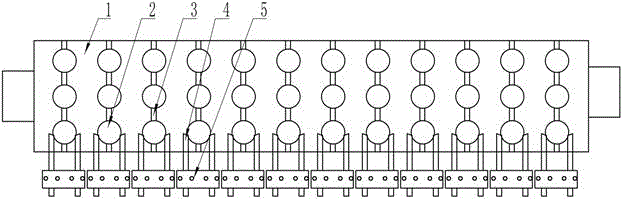

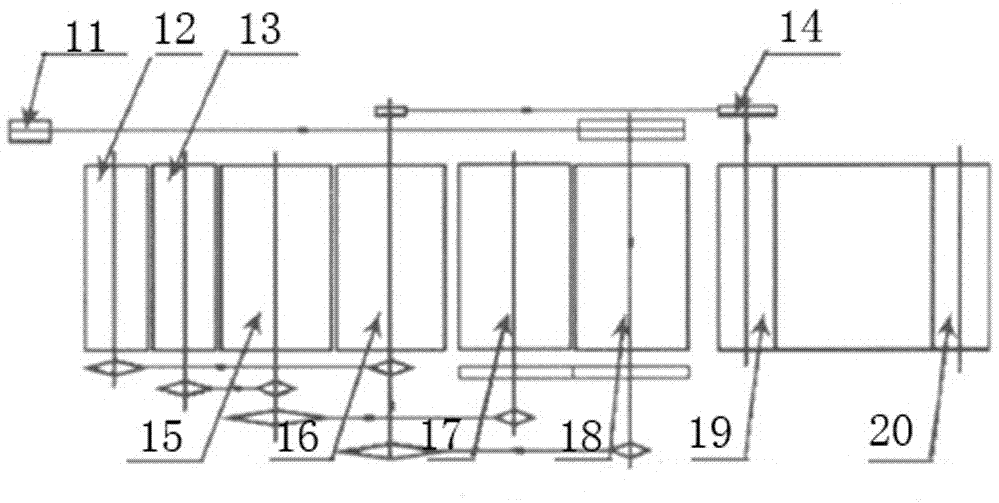

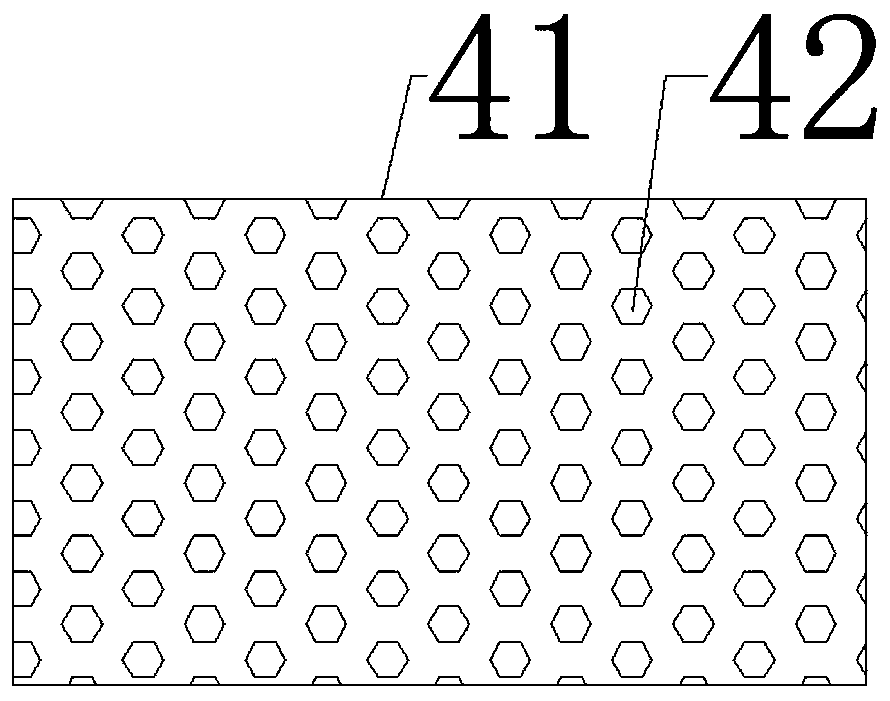

Gordon euryale seed husking mechanisms and gordon euryale seed husking machine

InactiveCN105410952AImprove work efficiencyHigh peeling rateHuskingHullingEngineeringMechanical engineering

The invention relates to gordon euryale seed husking mechanisms and a gordon euryale seed husking machine. Each gordon euryale seed husking mechanism comprises multiple pits and two husking knives, wherein the multiple pits are formed in the side face of a cylindrical roller in the circumferential direction at intervals, the two husking knives are arranged at the two sides of the corresponding pits respectively, and the roller rotates toward knife points of the husking knives. The gordon euryale seed husking machine comprises a rack, the rack is provided with a hopper, a feed mechanism, the cylindrical roller, the husking mechanisms, a material aggregation mechanism and a power mechanism, the power mechanism drives the roller to rotate, the hopper and the feed mechanism are arranged above the roller, the material aggregation mechanism is arranged below the roller, the multiple husking mechanisms are arranged along the axis of the roller, each husking mechanism comprises the multiple pits and the two husking knives, wherein the multiple pits are formed in the side face of the cylindrical roller in the circumferential direction at intervals, the two husking knives are arranged at the two sides of the corresponding pits respectively, and the roller rotates toward the knife points of the husking knives. The hopper is arranged above the feed mechanism, the feed mechanism is a vertically-through box body, multiple seed passing holes are formed in the lower edge of a front panel of the box body, and the seed passing holes are formed above the pits. The gordon euryale seed husking mechanisms and the gordon euryale seed husking machine have the advantages of being high in work efficiency and high in husking rate.

Owner:王传代

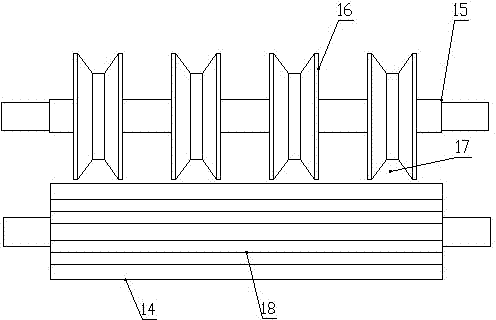

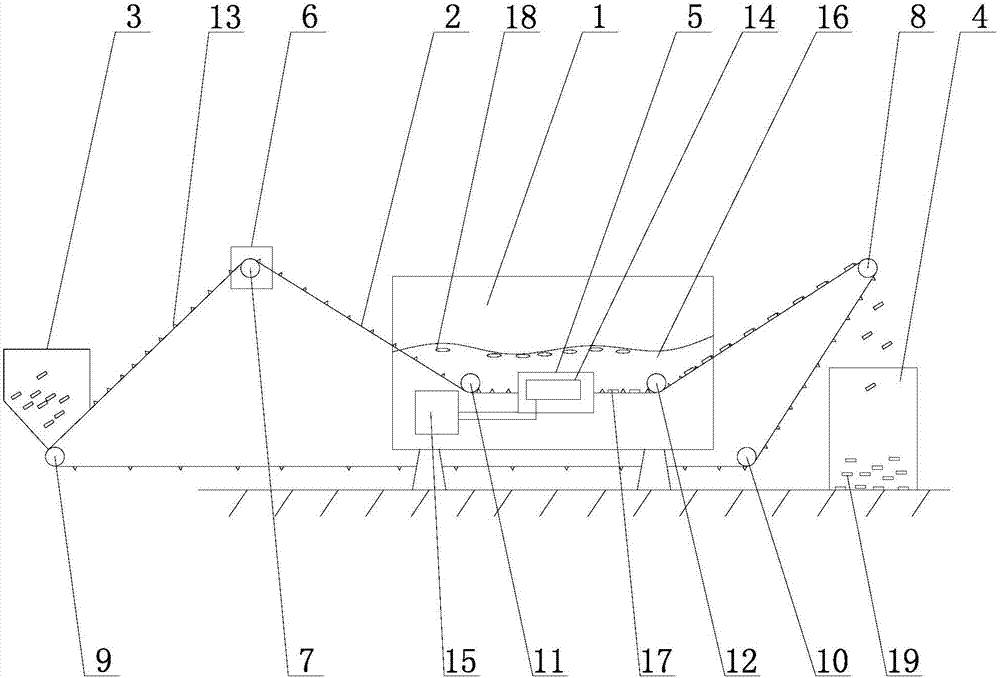

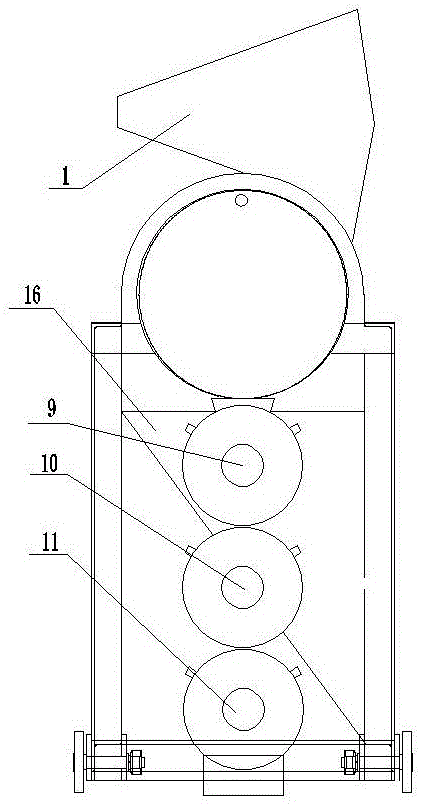

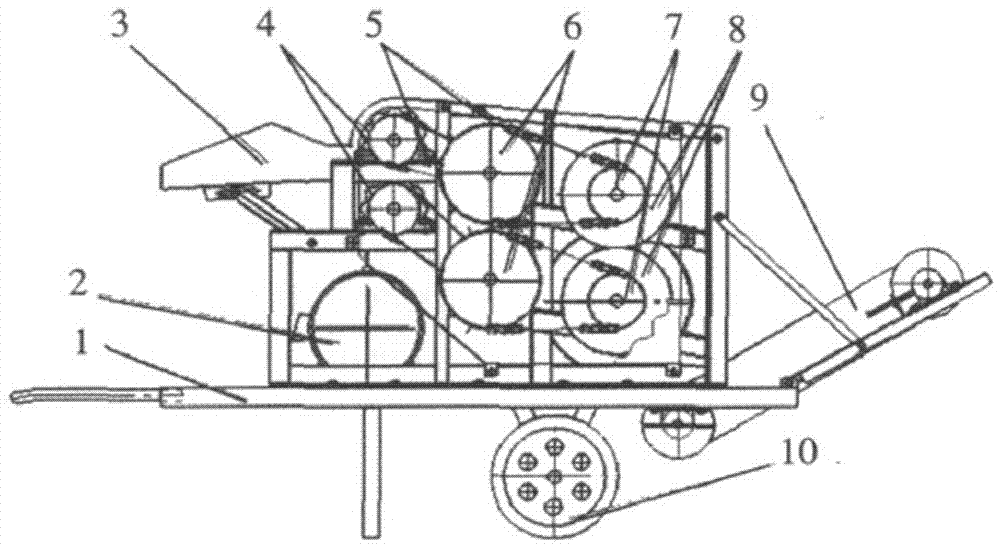

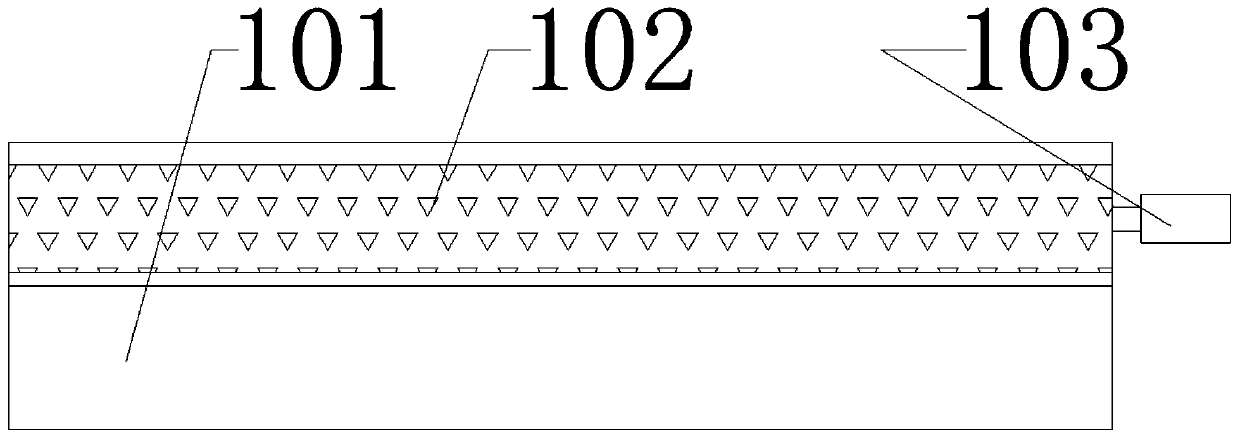

Peeling machine of hibiscus cannabinus and jute

InactiveCN106868601AHigh peeling rateHigh stripping rateMechanical fibre separationHibiscusEngineering

The invention discloses a kenaf jute peeling machine capable of peeling kenaf jute. The device mainly includes a frame assembly, a motor, a feeding hopper, a pressing roller group, a chain, a first pair of peeling rollers, and a sprocket wheel. , the second pair of peeling rollers, the hemp skin output device, and the walking wheel, in which the kenaf jute is fed into the roller group through the feeding hopper, and each hemp stalk is crushed by the pressure roller to realize the preliminary separation of the skin and bone of the stem; the preliminary separation The final kenaf jute enters the first pair of peeling rollers and the second pair of peeling rollers respectively for kneading, and the skin and bone of the jute and kenaf stems are completely separated. Output device output, the kenaf jute peeling machine has the characteristics of high fresh stem peeling rate, high peeling rate, high production efficiency, low labor intensity, compact structure, convenient movement, and strong skin and bone separation ability.

Owner:邢筱丹

Seed peeling method

The invention relates to the field of food industry, in particular to a seed peeling method. According to the seed peeling method provided by the invention, seeds are peeled in a mechanical friction manner after being refrigerated and heated. Compared with the prior art, the seed peeling method has the following advantages: (1) the peeling rate is high, that is, the peeling rate can be kept 90-95%; (2) kernels obtained after peeling are high in quality and good in completeness; (3) the seed peeling method is good in practicability, free of environment pollution, simple to operate, low in cost and applicable to industrial production.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

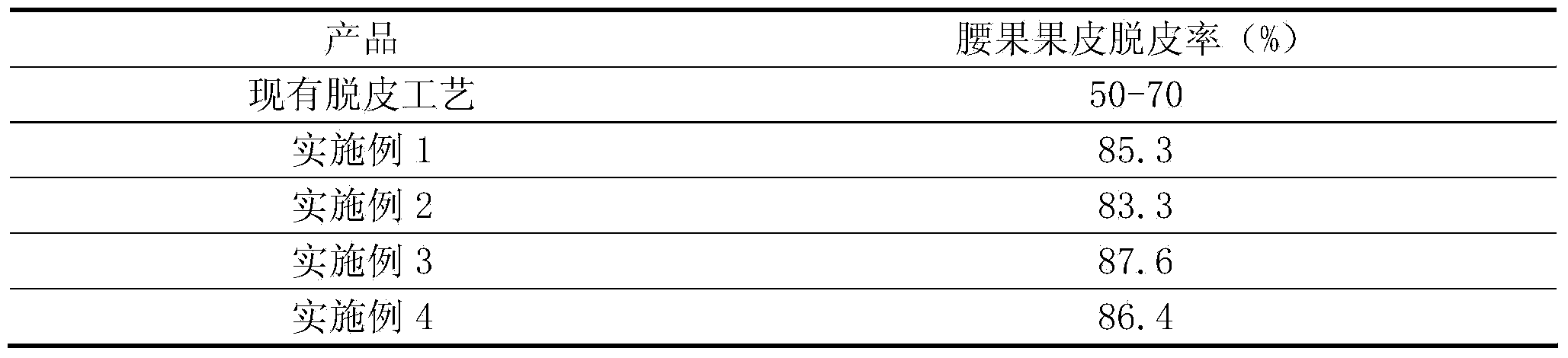

Method for peeling anacardium occidentale kernels

The invention provides a method for peeling anacardium occidentale kernels. The method for peeling the anacardium occidentale kernels comprises the following steps that (1) gradient hot-air drying is conducted on the hulled kernels with peels; (2) cold treatment is conducted on the anacardium occidentale kernels dried in the step (1); (3) water mist humidifying treatment is conducted on the anacardium occidentale kernels processed in a cold treatment mode; (4) secondary hot-air drying is conducted on the humidified anacardium occidentale kernels; (5) mechanical scraping and air current impact are adopted for removing the peels of the anacardium occidentale kernels processed in a secondary hot-air drying mode, scraps are collected through negative pressure, and coarse products are obtained; (6) third drying is conducted on the peeled and scrap-removed anacardium occidentale kernels so as to obtain finished products.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

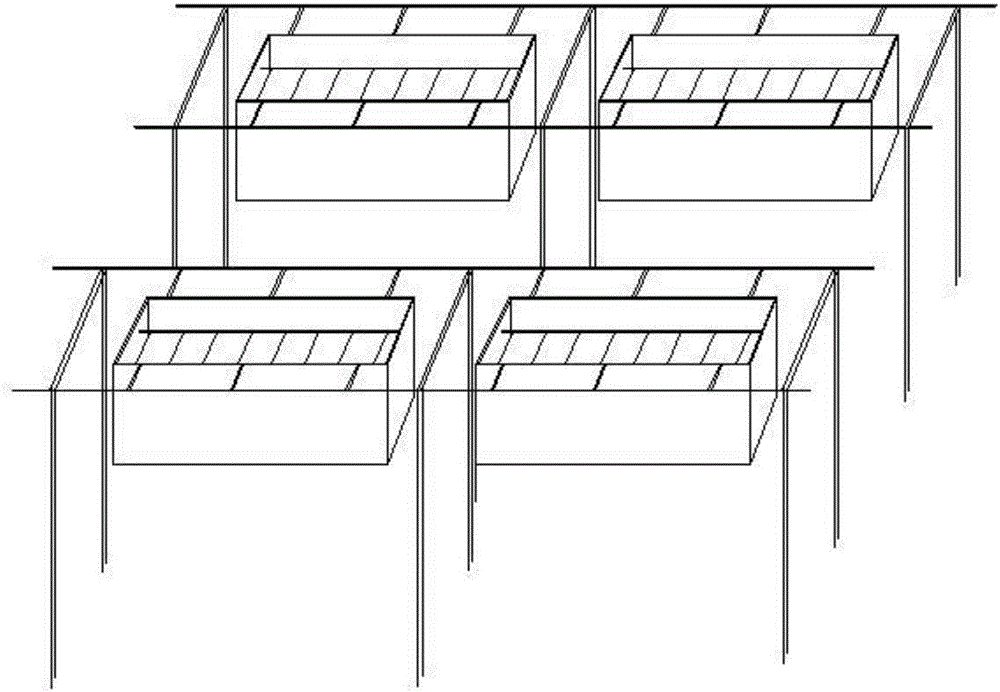

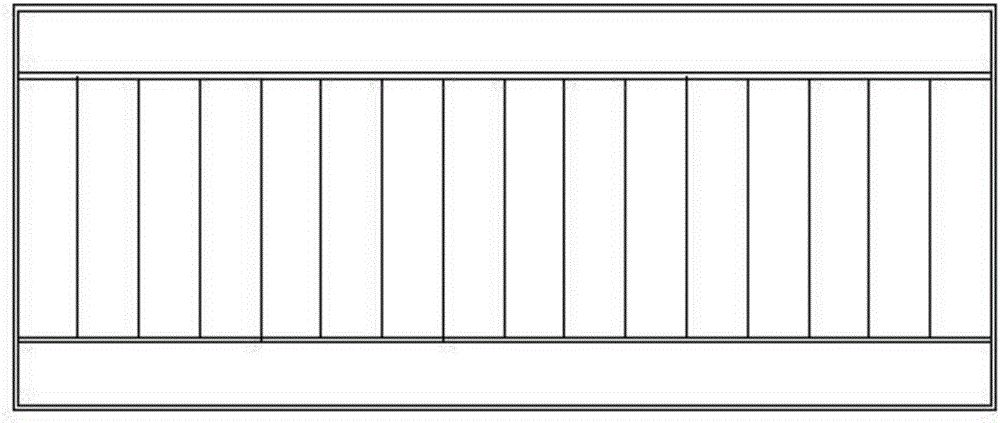

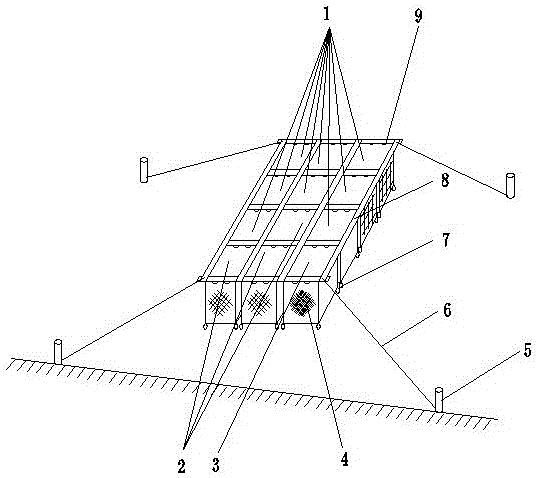

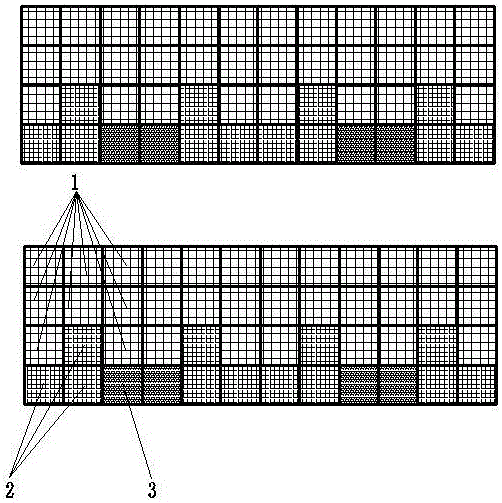

Shallow sea cage apostichopus japonicus recirculating aquacultural facility and aquacultural method

ActiveCN105660494ASafe sheltered habitatIncrease attachment spaceClimate change adaptationPisciculture and aquariaShallow seaEngineering

The invention provides a shallow sea cage apostichopus japonicus recirculating aquacultural facility and an aquacultural method. The shallow sea cage apostichopus japonicus recirculating aquacultural facility comprises a plurality of cages. The shallow sea cage apostichopus japonicus recirculating aquacultural facility is characterized in that the plurality of cages comprise small, medium and large aquacultural cages which are respectively used for aquaculture of small, medium and large juvenile apostichopus japonicus, the small, medium and large aquacultural cages are connected in proportional allocation that quantity of the small aquacultural cages is lower than quantity of the medium aquacultural cages and the quantity of the medium aquacultural cages is lower than quantity of the large aquacultural cages to form aquacultural units, and the aquacultural units are connected and then are fixed under the sea through piling. In March, April and May every year, the small, medium and large juvenile apostichopus japonicus are put into the cages to be cultivated according to specific density, and cultivation in each stage can provide enough juvenile apostichopus japonicus for the next stage; and then the small juvenile apostichopus japonicus are continuously supplemented and put into the cages, and the process is repeated, so that ecological efficient continuous product is realized. Aqucultural facility utilization rate is greatly improved, production cost is greatly reduced, growth rate of the juvenile apostichopus japonicus is improved, survival rate of the juvenile apostichopus japonicus is greatly improved, operation management is convenient, and comprehensive benefits are obviously improved.

Owner:MARINE BIOLOGY INST OF SHANDONG PROVINCE

Efficient ecological complete formula feed for culture of stichopus japonicus as well as preparation and application of efficient ecological complete formula feed

InactiveCN105211548AComprehensive and balanced nutritional supplyIncrease growth rateAnimal feeding stuffOysterAdditive ingredient

The invention relates to the field of aquatic feed, in particular to efficient ecological complete formula feed for culture of stichopus japonicus. The complete formula feed comprises ingredients and dry matters in percentage as follows: 20%-25% of sargassum pallidum powder, 12%-15% of sargassum thunbergii powder, 8%-10% of ulva pertusa powder, 2%-3% of spiral seaweed powder, 8%-12% of ophiopholis mirabilis powder, 2%-3% of whitefish powder, 4%-6% of scallop leftover powder, 2%-3% of shrimp powder, 3%-6% of soyabean protein powder, 1%-2% of oyster shell powder, 1%-2% of seashell powder, 2%-4% of marine red yeast, 0.3%-0.4% of multi-vitamins, 0.6%-0.7% of composite mineral salt, 15%-20% of sea mud powder and 4%-8% of yellow mud powder. The holothurian feed can supply comprehensive and balanced nutrition to cultured animals through scientific formula proportioning, and other nutritional substances are not required to be supplemented during use; the feed has high feeding attraction, good palatability and high utilization ratio and can remarkably increase the growth rate and the husk ratio during culture of stichopus japonicus. The feed is high-quality complete artificial formula feed for holothurian culture.

Owner:YANCHENG TEACHERS UNIV

Method for processing all-germ naked oat

The invention provides a method for processing all-germ naked oat. The method comprises the steps that impurities are removed, foreign grains in oat are removed through two times of color sorting, crude bran on the surface layers of the oat is removed through a peeling machine, secondary skin breaking and peeling are carried out on the oat through the peeling machine, and after screening, cooling, drying and weighing, the oat is packaged through aluminum foil vacuum bags. By means of the secondary peeling method, the peeling rate of the oat reaches up to about 30%, the cooking time of the deeply peeled oat is greatly shortened, the oat can be suitable for infants, young adults and the aged through oat braising, porridge cooking, oat milk and paste pulping and other eating methods, and the problem that digestion is hard after the oat is eaten by children and the aged is solved. The oat is packaged through the multilayer composite aluminum foil vacuum bags with quite good photopathy and oxygen resistance, and the expiration date of the oat can be prolonged to 18 months. It is avoided that oat grains are treated through steam, boiler firing is not needed, energy consumption is reduced, and environmental protection is promoted.

Owner:张丽娥

Intelligent separation equipment and separation method for peanut kernels and peanut skin

The invention discloses intelligent separation equipment and separation method for peanut kernels and peanut skin. The equipment includes a gas explosion device, a shifting device, a drying device anda negative pressure adsorption device; the gas explosion device receives conveyed peanut materials with skin to be removed, and through the infiltration of supersaturated steam and a rapid pressure relief method, the materials are subjected to gas explosion under the effect of pressure difference to complete the initial separation of the peanut kernels and the peanut skin; the shifting device shifts the initially separated peanut kernels and peanut skin to enter the drying device; the drying device compresses the outside air for heating, and transfers heat through hot air to heat and dry theinitially separated peanut kernels and peanut skin, so that the peanut skin and the peanut kernels are fully separated; and the negative pressure adsorption device collects the fully separated peanutkernels and peanut skin with different densities and masses through the negative pressure adsorption manner, respectively. The technical solution provided by the present disclosure realizes the intelligent separation of the peanut kernels and peanut skin through the gas explosion method to minimize the impact on the quality of the peanut kernels and the peanut skin.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

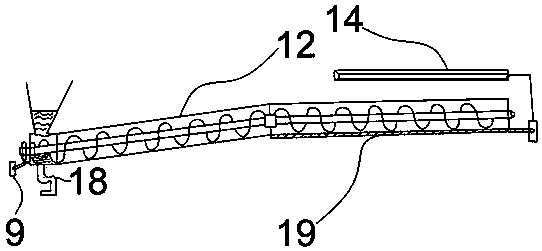

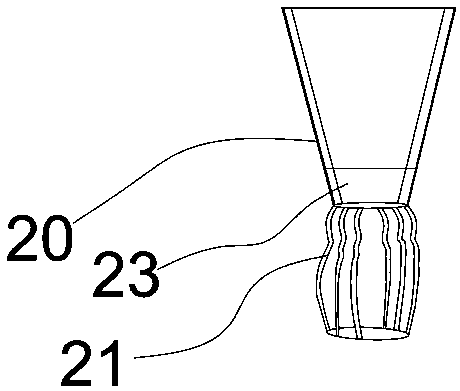

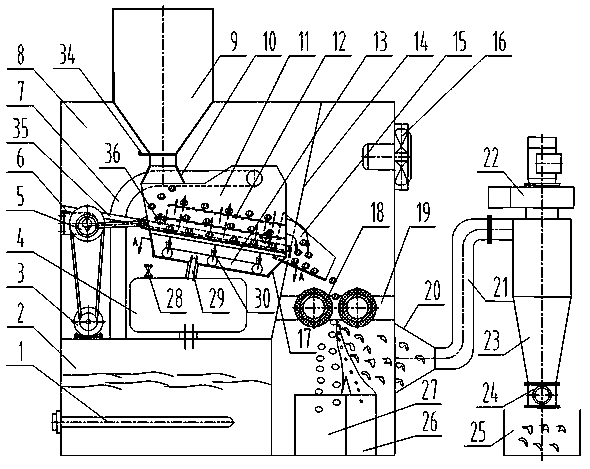

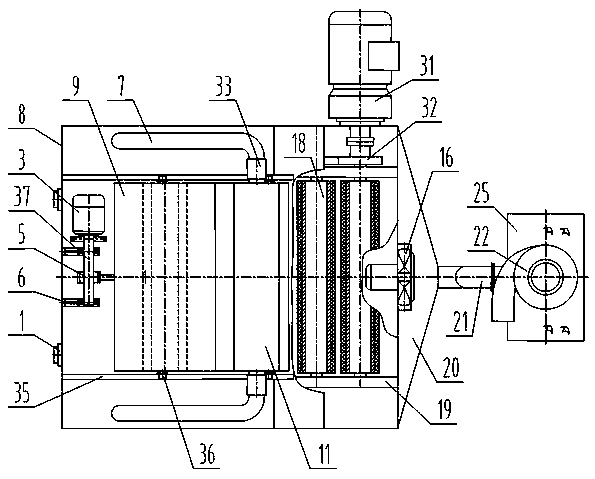

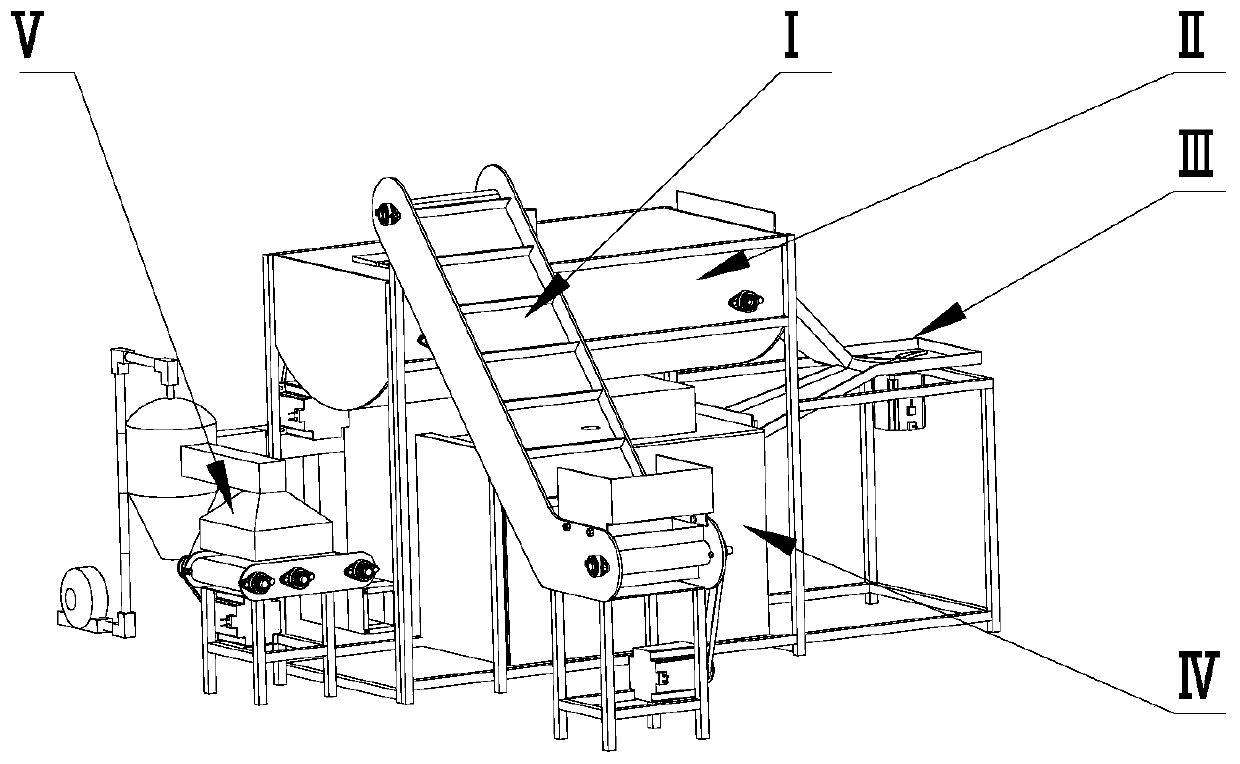

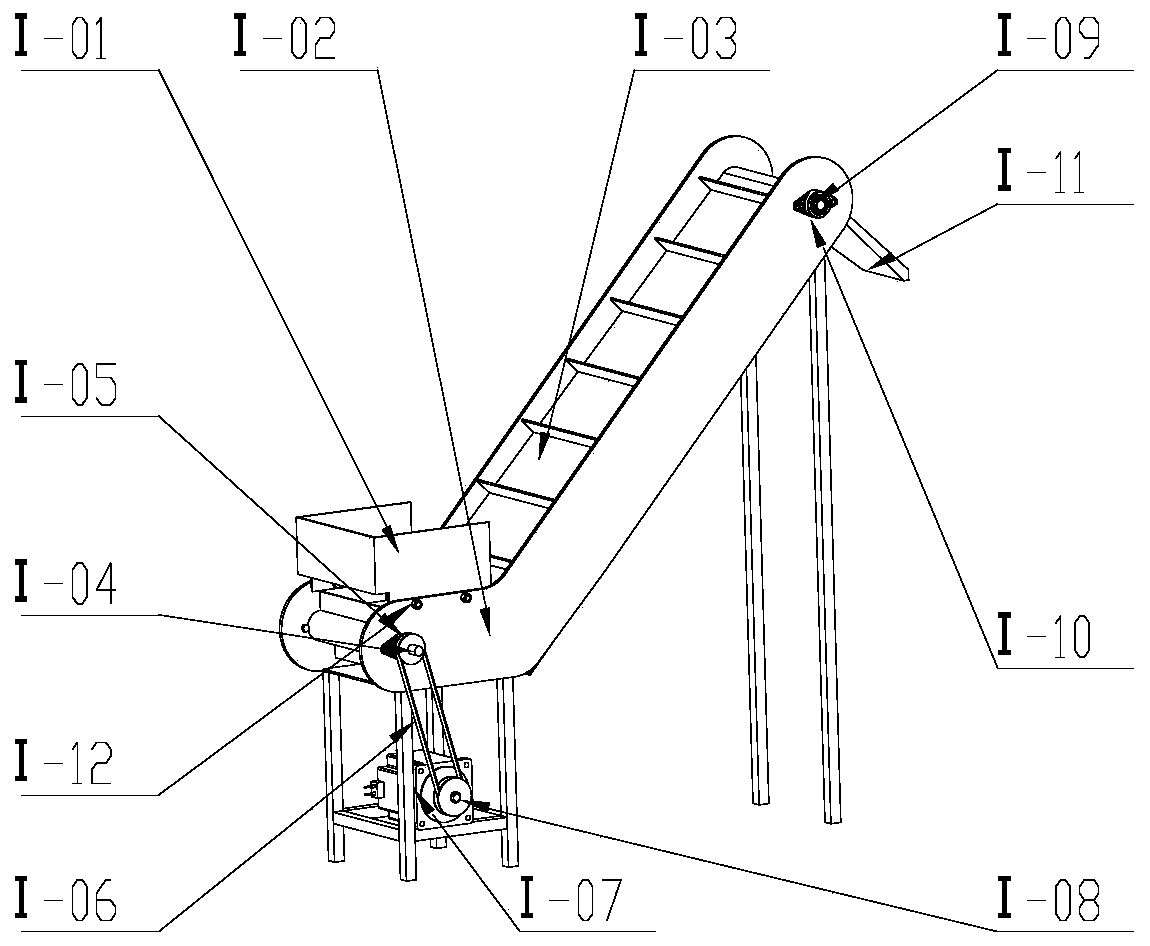

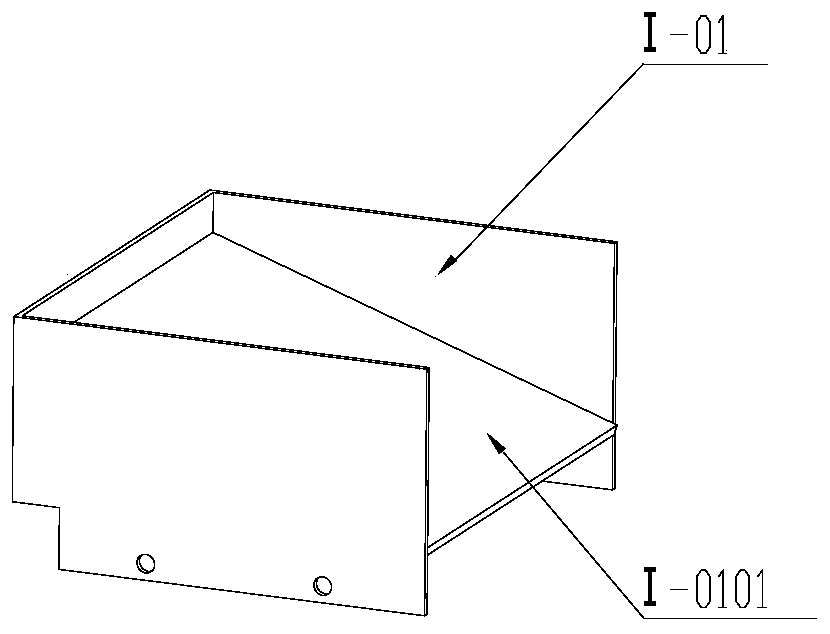

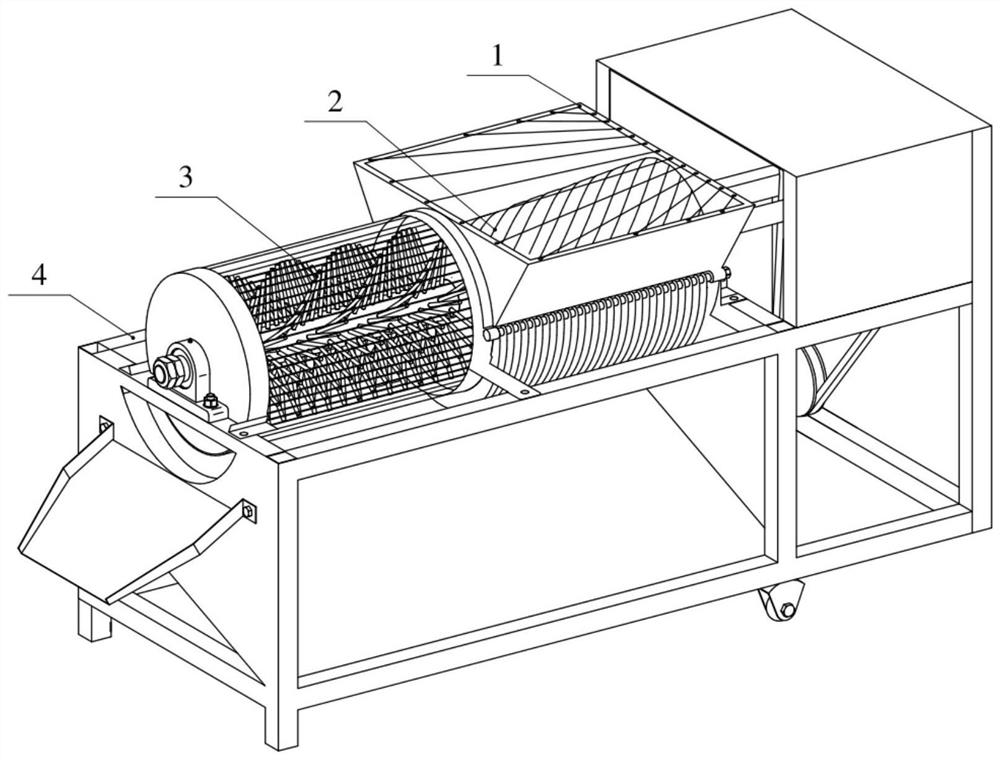

Spiral feeding cutting and scraping type walnut dry-method green husk removing machine

PendingCN112772938AImprove versatilityIncrease productivitySievingScreeningWalnut NutProcess engineering

The invention relates to the technical field of walnut processing, and discloses a spiral feeding cutting and scraping type walnut dry-method green husk removing machine which comprises a rack, a screening mechanism, a cutting and peeling mechanism and a cleaning mechanism, and the screening mechanism, the cutting and peeling mechanism and the cleaning mechanism are installed on the rack; the rack comprises a base, a transmission shaft is arranged on the base, and a transmission shaft drives the cutting and peeling mechanism and the cleaning mechanism to rotate; a feeding hopper used for feeding and a discharging hopper used for discharging are further arranged on the rack; the screening mechanism is used for carrying out size grading on the green walnuts fed by the feeding hopper; the cutting and peeling mechanism is used for performing spiral feeding cutting and scraping type peeling on the graded green walnuts; and the cleaning mechanism is used for cleaning the peeled walnuts to remove residual green husks and discharging the clean walnuts out of the discharging hopper. The green walnut husk removing machine can be used for multiple sizes and multiple varieties, the universality is improved, the whole structure is simple, the function is reliable and easy to achieve, the production efficiency is improved, and the breakage rate is also reduced.

Owner:BEIJING FORESTRY UNIVERSITY

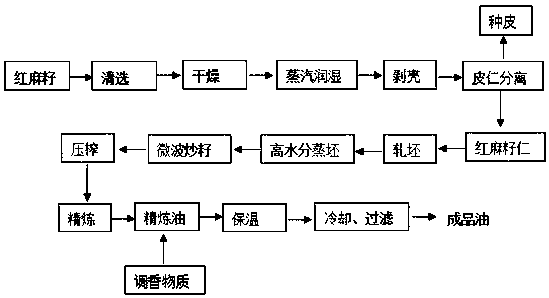

Processing technology for flavored kenaf seed oil with high stability

ActiveCN107904000AHigh peeling rateEasy to separateFatty-oils/fats refiningFatty-oils/fats productionFlavorMicrowave

The invention provides a processing technology for flavored kenaf seed oil with high stability. The processing technology is characterized by comprising the following steps: cleaning kenaf seeds, carrying out drying and steam wetting to realize differentiated adjustment of water contents of seed coats and kernels, and carrying out dehulling in virtue of shearing and rubbing of a dehuller; subjecting the separated kenaf seed kernels to rolling and high-moisture microwave steam-roasting so as to destroy cell structures and passivate bio-enzymes; and subjecting crude kenaf seed oil squeezed by apresser to refining, heating the crude kenaf seed oil to a proper temperature, and adding flavoring substances to adjust the flavor of the kenaf seed oil. Compared with the prior art, the invention has the advantages that the processing technology is scientific and reasonable in process, uses simple equipment and realizes high oil yield; and prepared kenaf seed oil has the characteristics of goodstability in storage and high-temperature resistance, agreeable flavor, safety in eating, etc.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

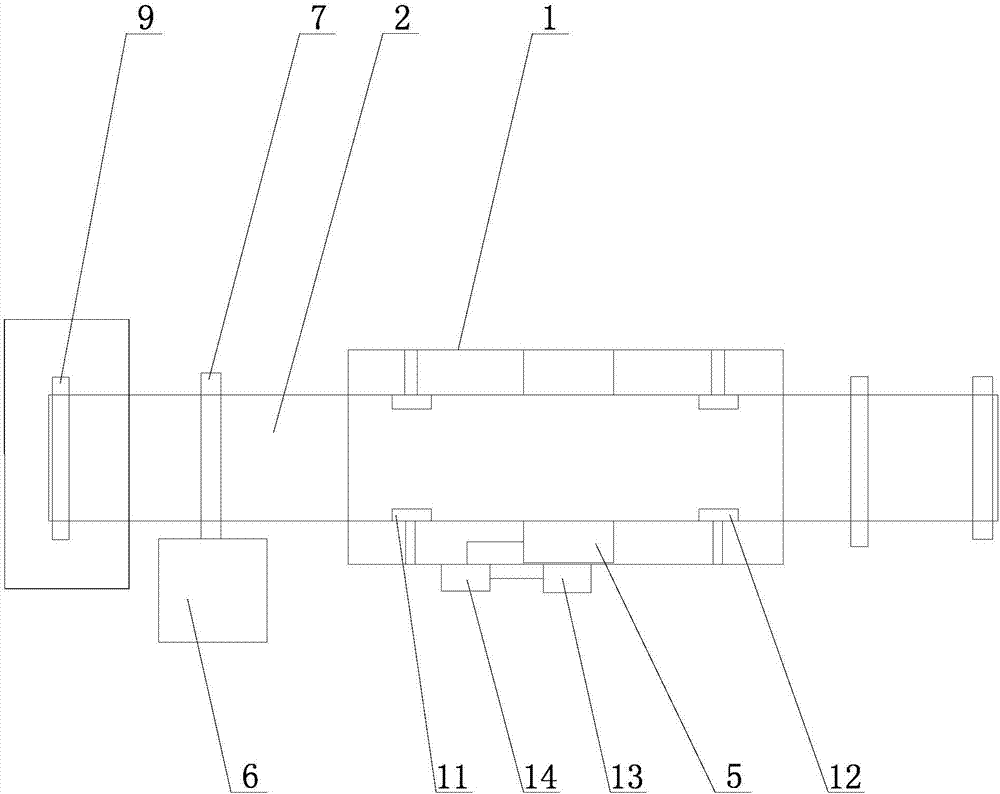

Novel multi-rolling cutter type lotus seed sheller

InactiveCN106858633AMeet the practical needs of mechanized shellingMeet practical needsHuskingHullingElectric machineryEngineering

The invention discloses a novel multi-rolling cutter type lotus seed sheller. The device mainly comprises the parts of a feed hopper, a motor, a transmission system, a classifying feed screw, a shelling head, a lumped regulating mechanism, a discharge opening and a rack, the rolling cutter type lotus seed sheller uses the feed screw to classify and feed shell lotuses, lotus seeds are fed according to a certain configuration rank, a shelling channel comprising double carrier rollers and a shelling roller is used to shell the lotus seed so as to adapt to shelling of different varieties of shell lotuses at different particle sizes, and the lumped regulating mechanism is used in the design of the shller to regulate the main cutting parameters like cutting pressure, cutting depth, inclining and offsetting angles of the space of a spiral rolling cutter. The analysis and test results show that the novel multi-rolling cutter type lotus seed sheller is novel in design, stable in performances, reliable in working and convenient and efficient in regulation and maintenance, and meets the requirements on practicality of mechanical shelling of the lotus seed.

Owner:李福来

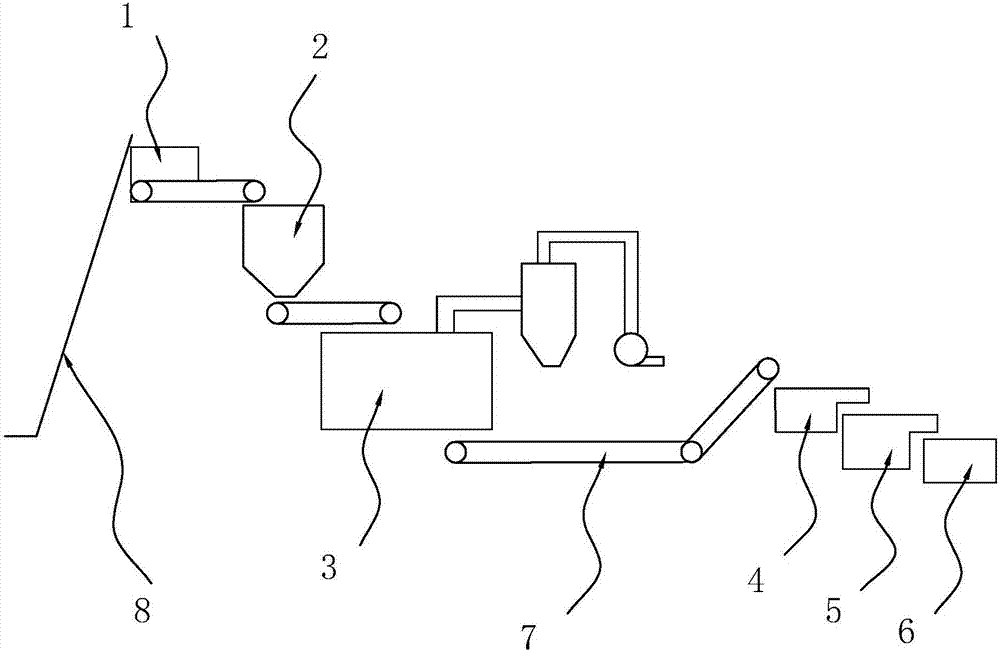

Peanut coat removing production system

InactiveCN107874271AHigh peeling rateImprove pass rateHuskingHullingPulp and paper industryVacuum packing

The invention discloses a peanut coat removing production system. The technical scheme is characterized in that the system comprises a peanut baking machine, a storage bin, a peanut coat removing machine, a peanut color selector, a peanut screening machine and a vacuum packaging machine, wherein a lifting mechanism for lifting peanuts into the baking machine is arranged at the front end of the peanut baking machine, the storage bin is located below the baking machine, the peanut coat removing machine is located below the storage bin, the peanut screening machine is located below the peanut color selector, the vacuum packaging machine is located below a discharging groove of the peanut screening machine, and all the mechanisms convey the peanuts through a conveying belt. The system solves the problem that the content of peanuts with coats in finally obtained peanuts is higher.

Owner:青岛德全食品有限公司

Quick-freezing type Chinese chestnut shelling machine

The present invention discloses a quick-freezing type Chinese chestnut shelling machine. The quick-freezing type Chinese chestnut shelling machine comprises a shell body, a defective product outlet, amaterial collecting hopper, three sieve plates, a connecting plate, a mounting plate, a vibrating cylinder, a material feeding port, three material guiding hoppers, three hole-pricking material feeding machines, a steaming box, a water inlet pipe, a heating plate, a heat exchanger, three steaming plates, a refrigerant connecting pipe, a quick-freezing box, a refrigerator, a material collecting pipe, a lifting auger, a shelling machine, a rotating shaft, batting sticks, on-off valves, material brushes, a rotating motor, a material discharge pipe, screen plate frames, screen holes, a bottom plate, hole-pricking shafts and a driving motor, an upper side of the shell body is provided with the material feeding port, a side wall of the shell body is fixedly connected with the mounting plate, anupper side of the mounting plate is fixedly provided with the vibrating cylinder, a vibrating shaft of the vibrating cylinder passes through the side wall of the shell body and is also connected withone side of the connecting plate, the connecting plate is also provided with the three layers of the screen plates, and the screen plates are located under the material feeding port. The quick-freezing type Chinese chestnut shelling machine is relatively high in peeling rate, can also ensure integrity of fruit pulp and can conduct a quick shelling treatment of Chinese chestnuts.

Owner:ANHUI HE YI FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com