Patents

Literature

35results about How to "Not easy to take off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fiber reinforced titanium alloy compound material and preparation method thereof

The invention discloses a carbon fiber reinforced titanium alloy compound material and a preparation method thereof. The preparation method comprises the steps as follows: 1, preprocessing a carbon fiber; 2, conducting chemical copper plating on the surface of the carbon fiber, namely coating copper onto the surface of the carbon fiber by utilizing a chemical plating method; 3, conducting chemical vapor phase deposition on pure tungsten, namely conducting chemical vapor phase deposition on the surface of the copper-coated carbon fiber to obtain a tungsten deposition layer; 4, cutting according to the design requirement to obtain the carbon fiber with the proper length; and 5, mixing powder according to the design requirement of titanium alloy content, placing a mixture and the carbon fiber into a pressing mould for hot-press forming, and sintering to obtain the carbon fiber reinforced titanium alloy compound material in the required shape at last. According to the carbon fiber reinforced titanium alloy compound material prepared by the method, the compositionality is good, the titanium alloy content is adjustable, the carbon fiber distribution is controllable, and the carbon fiber is not decarburized. The carbon fiber reinforced titanium alloy compound material is high in specific modulus, low in density, high in specific strength and impact toughness and good in adiabatic shear failure resistance, and is a high-performance structural material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

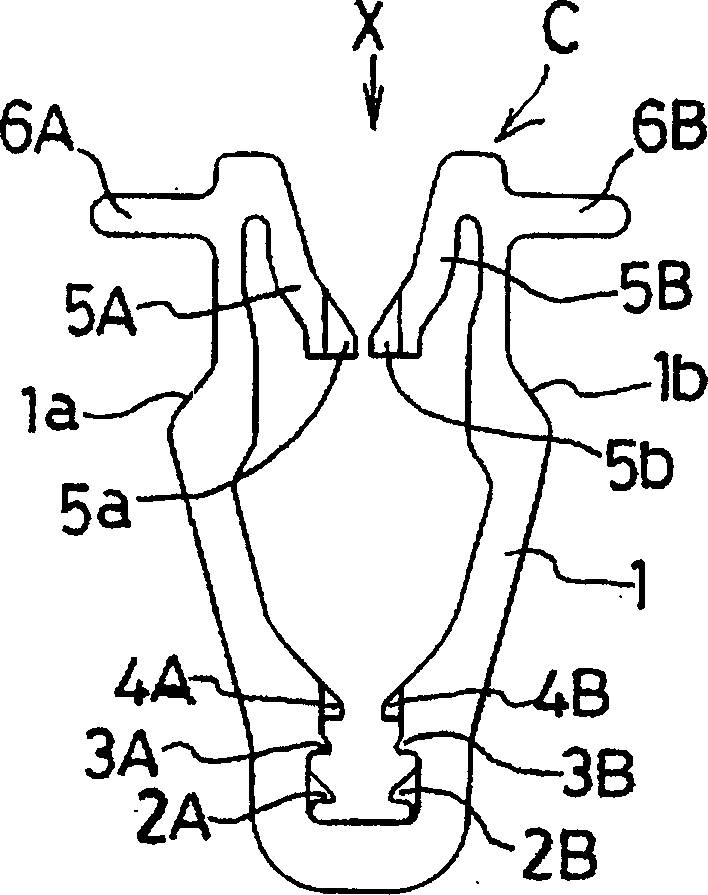

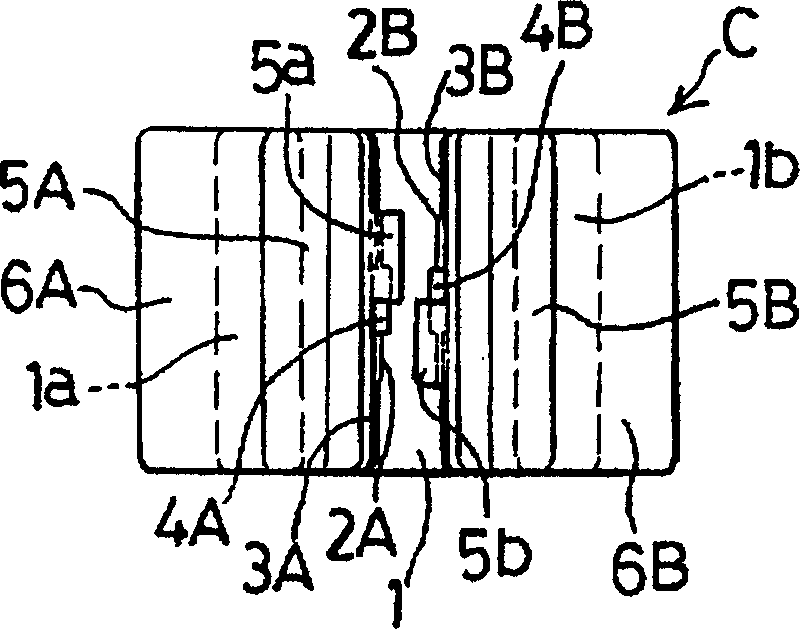

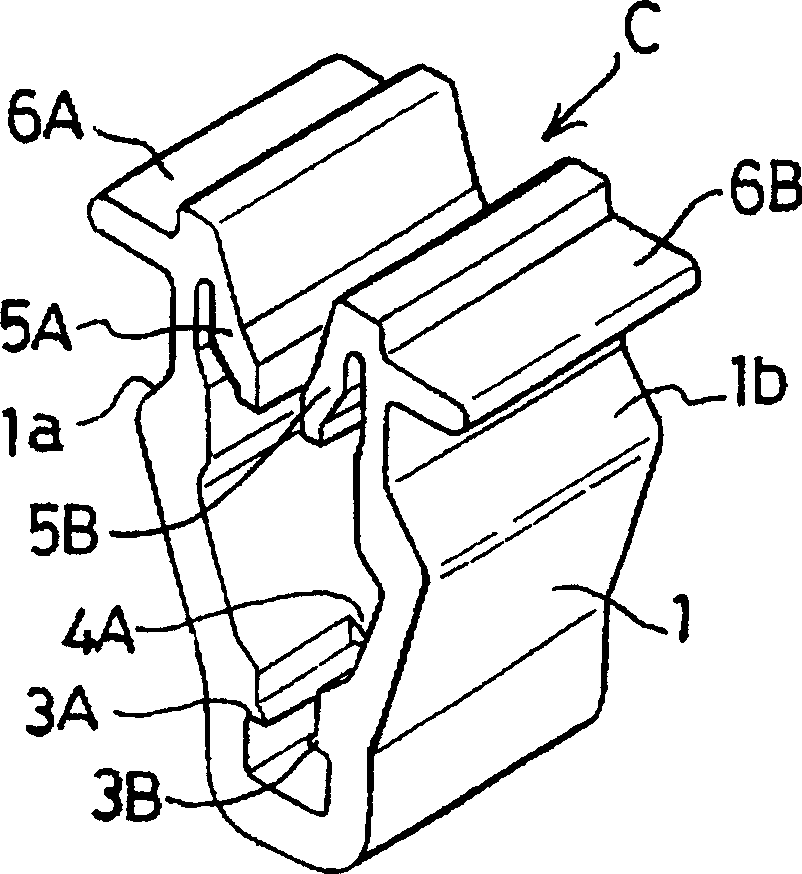

Clip

InactiveCN1417491ANot easy to take offSnap-action fastenersInstrument arrangements/adaptationsEngineering

Owner:NIFCO INC

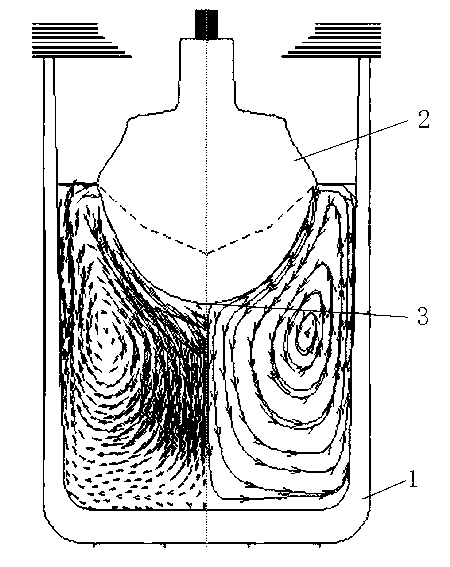

Rotary shoulder technique for growing sapphire crystal by kyropoulos method

InactiveCN103014842AQuality improvementIncrease profitPolycrystalline material growthUsing seed in meltEngineeringCrystal growth

The invention discloses a rotary shoulder technique for growing sapphire crystal by a kyropoulos method. In the sapphire growth process employing the kyropoulos method, the power is reduced to enter the shoulder stage after seeding of the crystal is finished; the crystal is kept in a rotary state at this stage, and meanwhile, the withdrawal rate of the crystal is kept; the diameter of the crystal is gradually enlarged along with an upward pulling process; rotation of the crystal is stopped when the growth weight achieves 8-10% of inventory; and the crystal enters an equant growth stage in a vertical pulling state. By adopting the rotary shoulder technique disclosed by the invention, vortex rotating along with the crystal is formed by flux on a solid-liquid interface along with rotation of the crystal; and an air bubble gathered on the solid-liquid interface is gradually discharged along with flow of the flux. Therefore, the content of the air bubble can be effectively reduced; the quality and the utilization rate of the crystal are improved; crystal sticking on crucible caused by over-quick crystal growth in one direction and uneven temperature field also can be effectively avoided; molding of the appearance of the crystal is facilitated; subsequent crystal manufacturing procedures are facilitated; the stick cutting rate can be improved; and the product usage is also improved.

Owner:江苏国晶光电科技有限公司

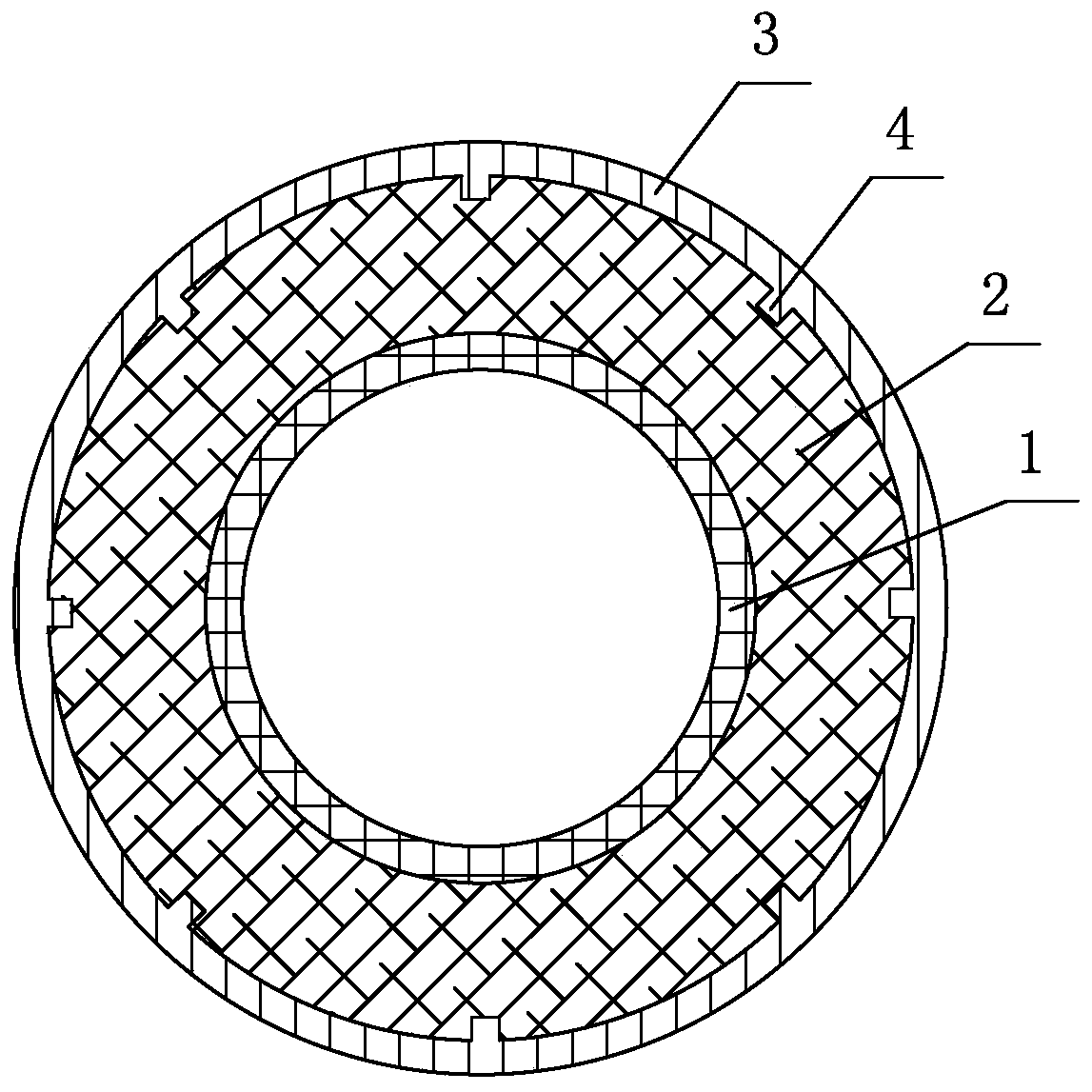

Carbon fiber cloth-aluminum alloy compound material and preparation method thereof

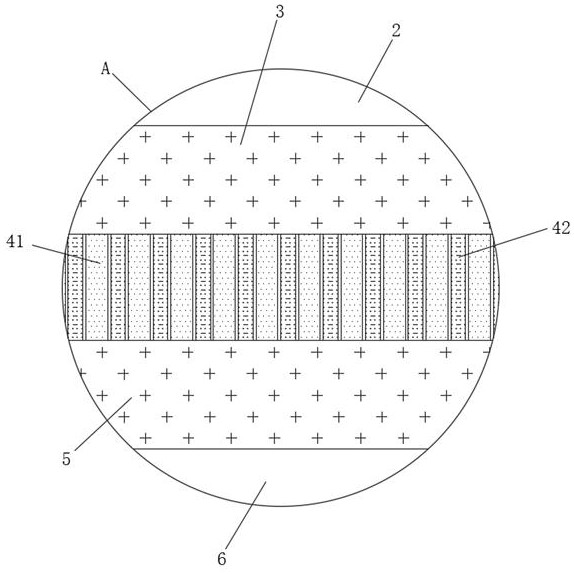

InactiveCN102642011AWell combinedNot easy to take offCarbon fibresFoundry mouldsChemical platingSpecific modulus

The invention discloses a carbon fiber cloth-aluminum alloy compound material and a preparation method thereof. The carbon fiber cloth-aluminum alloy compound material is obtained by cladding carbon fiber cloth with copper and then casting aluminum alloy. The preparation method comprises the following steps: 1) pre-treating the carbon fiber cloth; 2) cladding the carbon fiber cloth with copper: cladding the surface of the carbon fiber cloth with the copper according to a chemical plating or electroplating method; 3) preparing a casting mould,wherein the casting mould is prepared according to the demand on the arrangement of the carbon fiber cloth in the aluminum alloy; and 4) smelting the aluminum alloy and casting, thereby lastly obtaining the carbon fiber cloth-aluminum alloy compound material in required shape. The carbon fiber cloth-aluminum alloy compound material prepared according to the preparation method is excellently compounded; the components of the aluminum alloy are adjustable; the distribution of the carbon fiber cloth is controllable; and the compound material has higher specific modulus, low density and high specific strength, and is suitable for the building field and the protecting field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

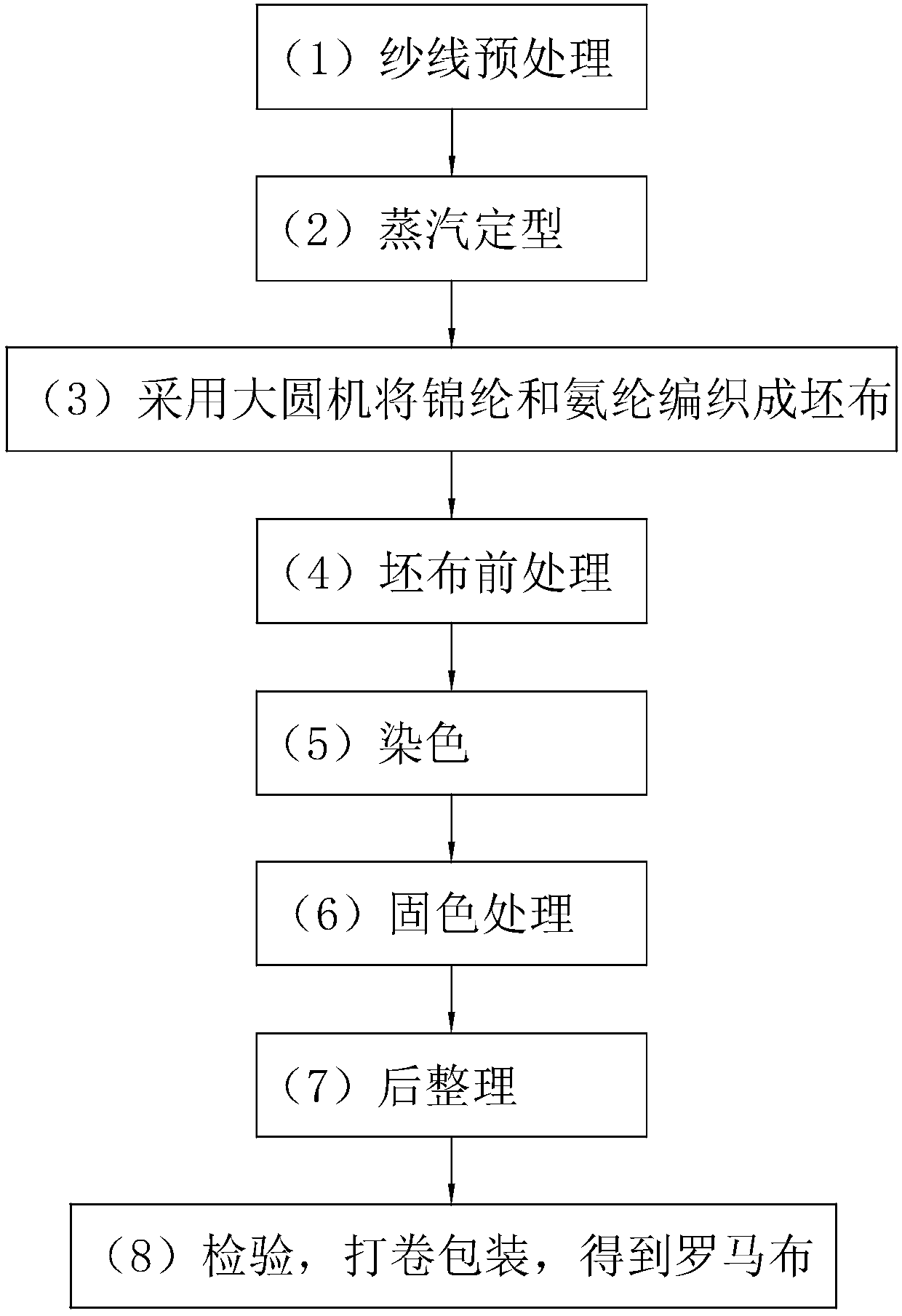

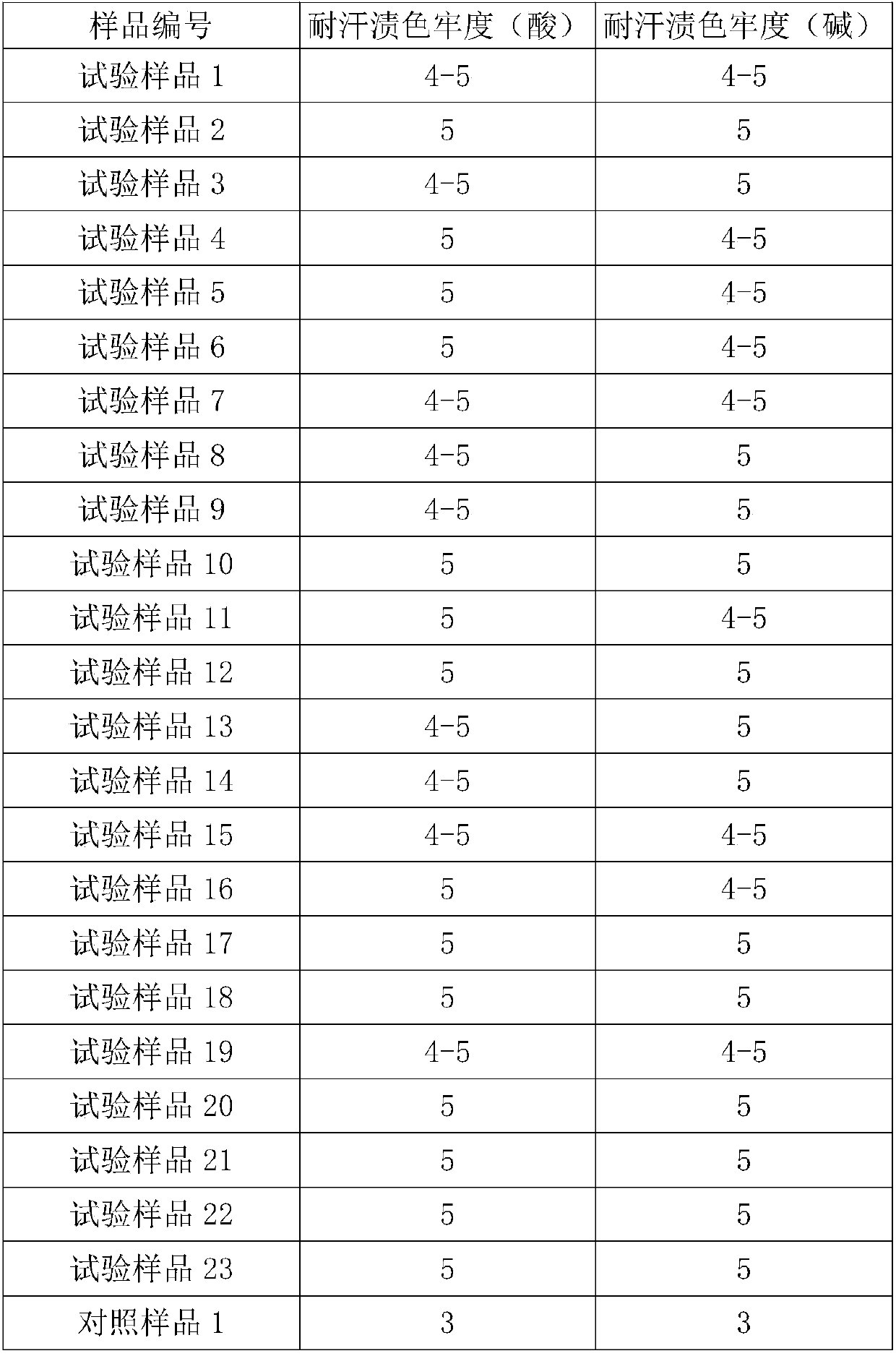

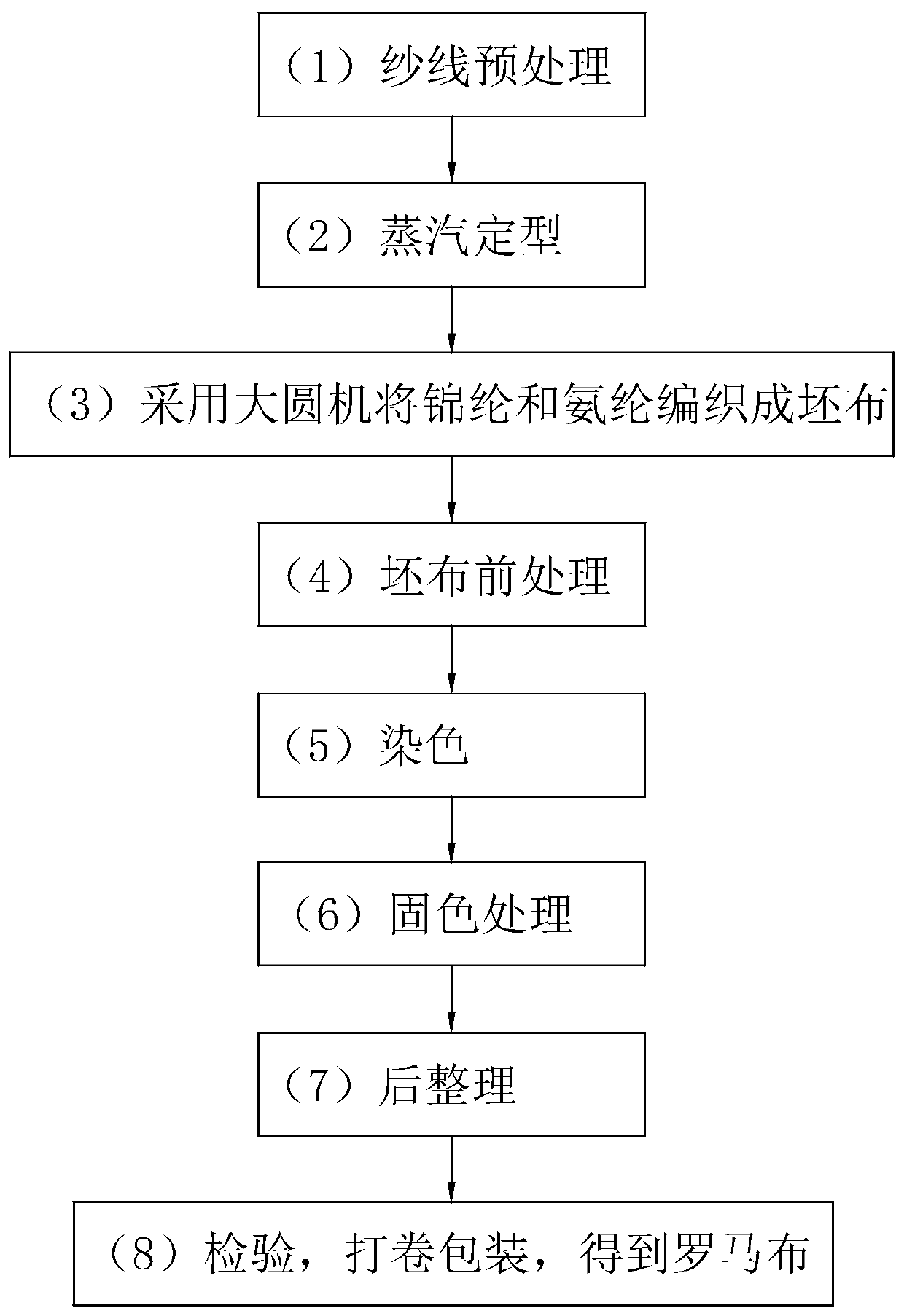

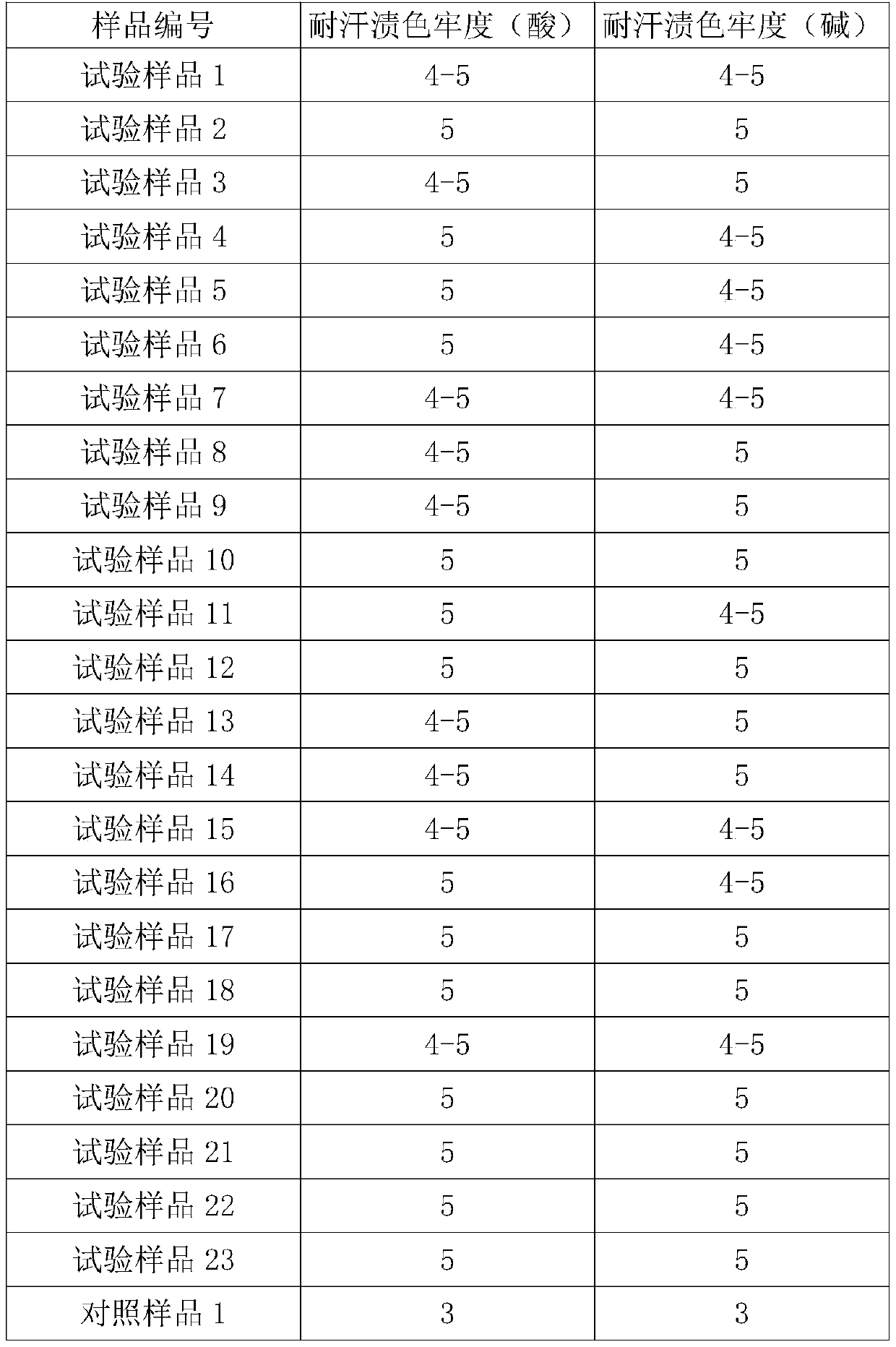

Preparing method of Roma cloth

The invention discloses a preparing method of Roma cloth, and relates to the technical field of textile preparation. The problem that Roma cloth is prone to color fading under rubbing and perspirationis solved. The method includes the following steps of firstly, preprocessing yarns; secondly, conducting vapor sizing; thirdly, weaving chinlon and spandex into a gray fabric through a circular knitting machine; fourthly, postprocessing the gray fabric; fifthly, conducting dyeing; sixthly, conducting color fixing treatment; seventhly, conducting after finishing; eighthly, conducting inspecting, rolling and packaging to obtain the Roma cloth. Through twice alkali boiling, batched dye adding and color fixing treatment, the color firmness to rubbing and the color fastness to perspiration of theRoma cloth are improved.

Owner:绍兴柯桥杰坝针纺科技有限公司

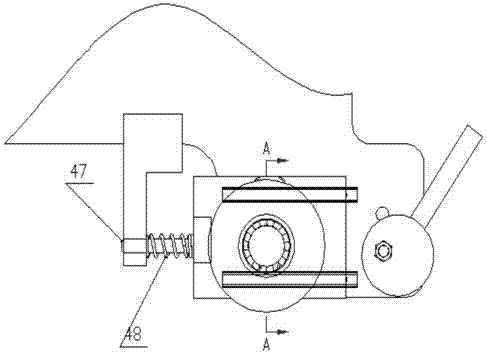

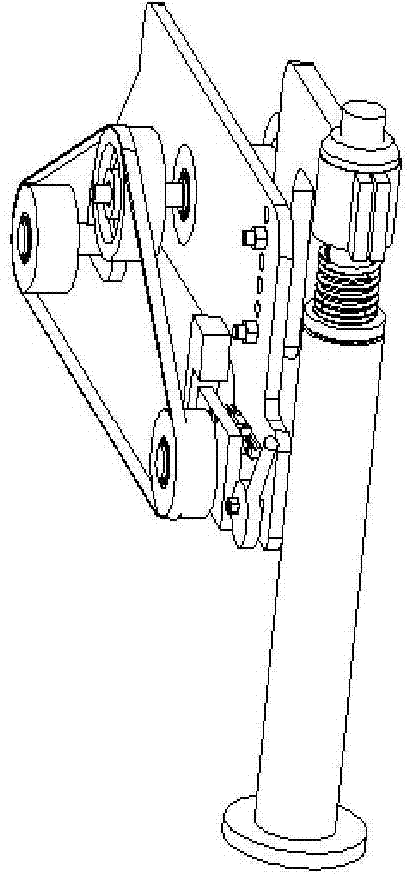

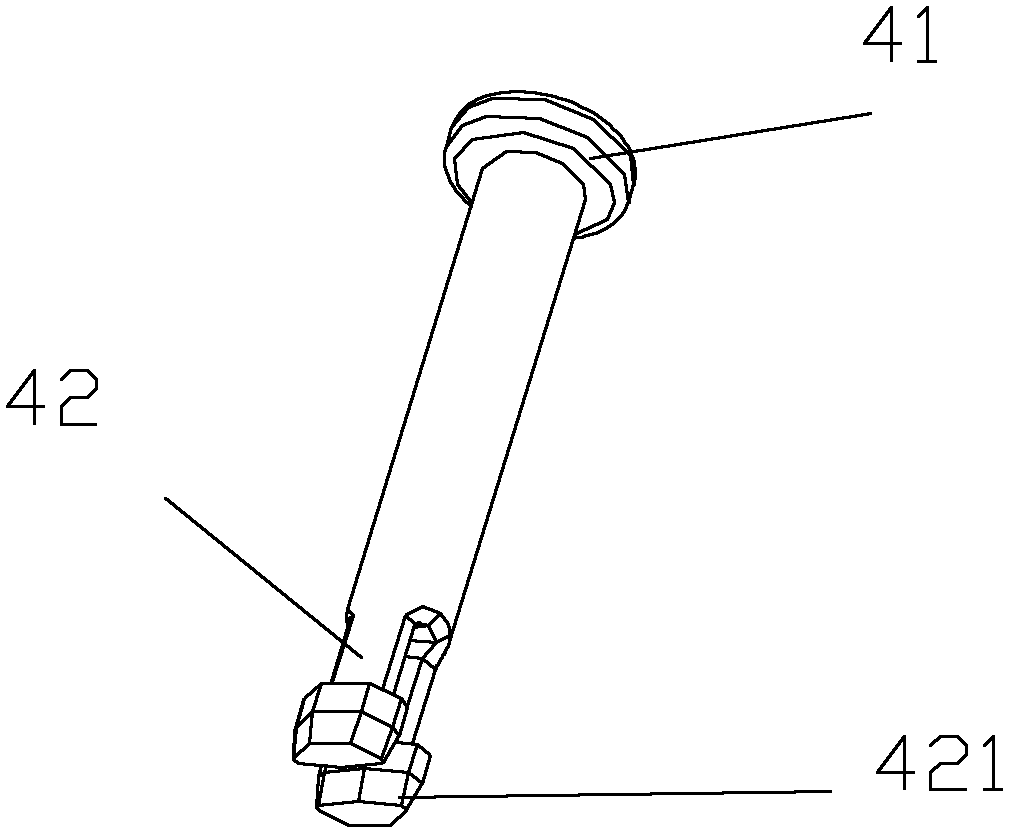

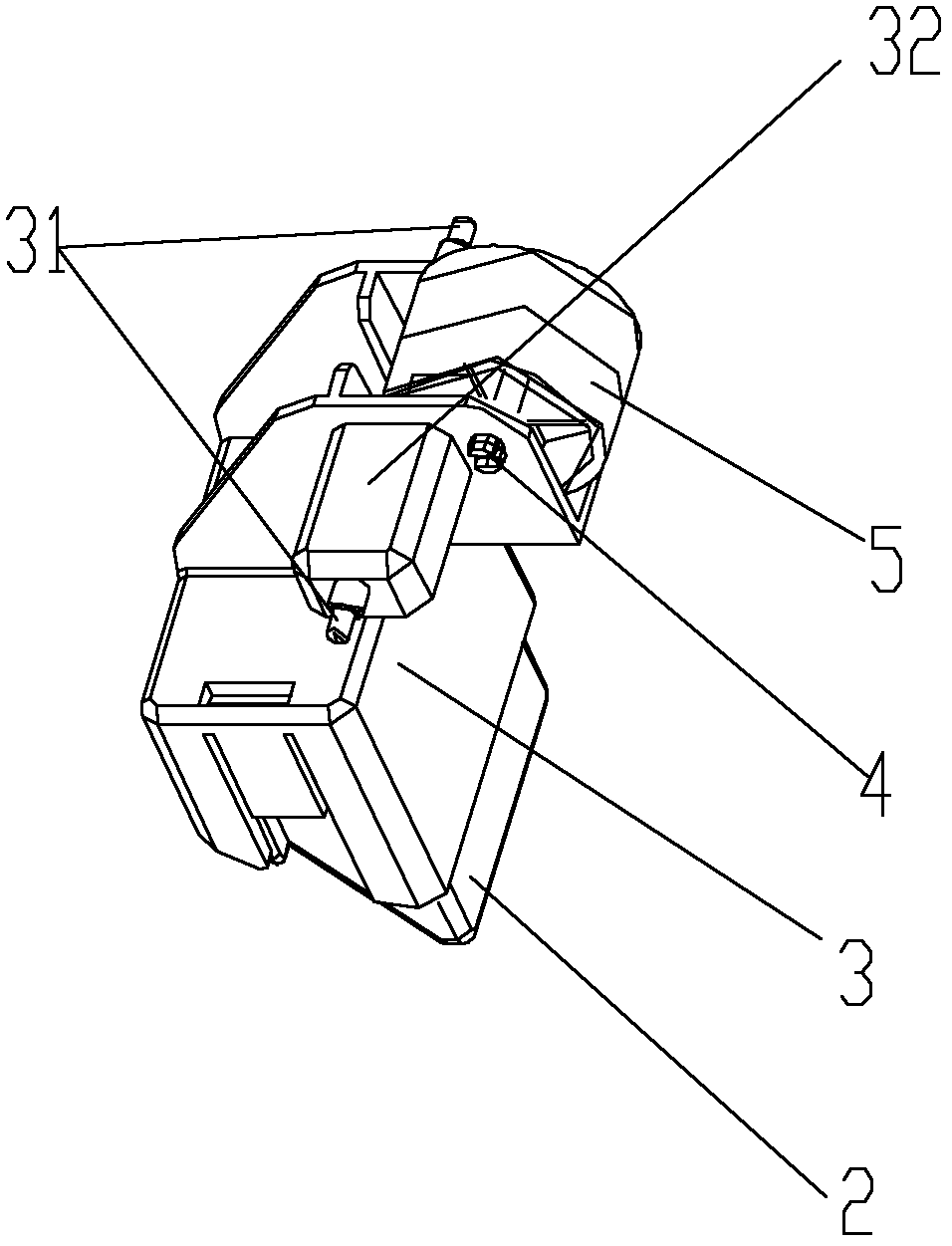

Automatic traveling polishing apparatus of rotor polishing machine tool and application method of automatic traveling polishing apparatus

InactiveCN104742001ASimple processing technologyReduce overall weightBelt grinding machinesElectric machineryEngineering

The invention discloses an automatic traveling polishing apparatus of a rotor polishing machine tool and an application method of the automatic traveling polishing apparatus. The automatic traveling polishing apparatus comprises a polishing mechanism; the polishing mechanism comprises an upright assembly, a movable arm and a main body cover; the main body is connected with the upright assembly by use of the movable arm. The application method comprises the steps of firstly adjusting an eccentric wheel assembly, mounting an abrasive belt on a driving wheel, a driven wheel and a tensioning wheel and adjusting the height of the movable arm on the upright assembly by use of a hold-down nut, adjusting the rotating angle of the main body cover by adjusting the movable arm, starting a servo motor to drive the driving wheel to rotate, thereby driving the abrasion belt to rotate, and then completing the polishing process. According to the automatic traveling polishing apparatus, the labor hours are greatly shortened in the process of machining workpieces, the application of manpower resources is reduced and the production cost is reduced.

Owner:QINGDAO JIANGHAN PETROLEUM MACHINERY

Floater component and water tank and dehumidifier comprising same

ActiveCN103375885AEasy to assemble and disassembleLock firmlySpace heating and ventilation safety systemsLighting and heating apparatusToxic materialPulp and paper industry

The invention provides a floater component and a water tank and a dehumidifier comprising the same. The floater component comprises a buoy, a floater, a roller and a connecting rod. The buoy is provided with pivotal shafts, a first side of the buoy is provided with a floater mounting portion, a second side of the buoy is provided with a roller mounting portion, and two first connecting rod mounting holes are formed in two side walls of the roller mounting portion respectively. The floater is mounted inside the floater mounting portion, a second connecting rod mounting hole is formed in an axis of the roller, the connecting rod penetrates the two first connecting rod mounting holes and the second connecting rod mounting hole to arrange the roller in the roller mounting portion, a flange is arranged at a first end of the connecting rod, a plurality of elastic sections are arranged at the second end of the connecting rod at intervals, and a boss extending outwards is arranged at the end of each elastic section. The floater component is convenient to mount and demount, and the technical problems of wiredrawing, burned black and production of pungent smell and toxic substances due to the fact that the connecting rod needs to be connected via welding in the floater component assembling process in the prior art are solved.

Owner:GREE ELECTRIC APPLIANCES INC

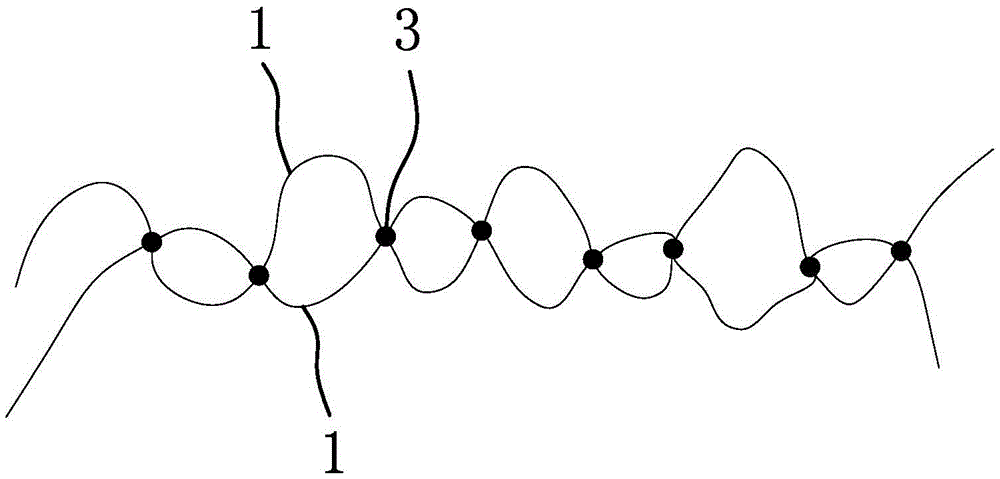

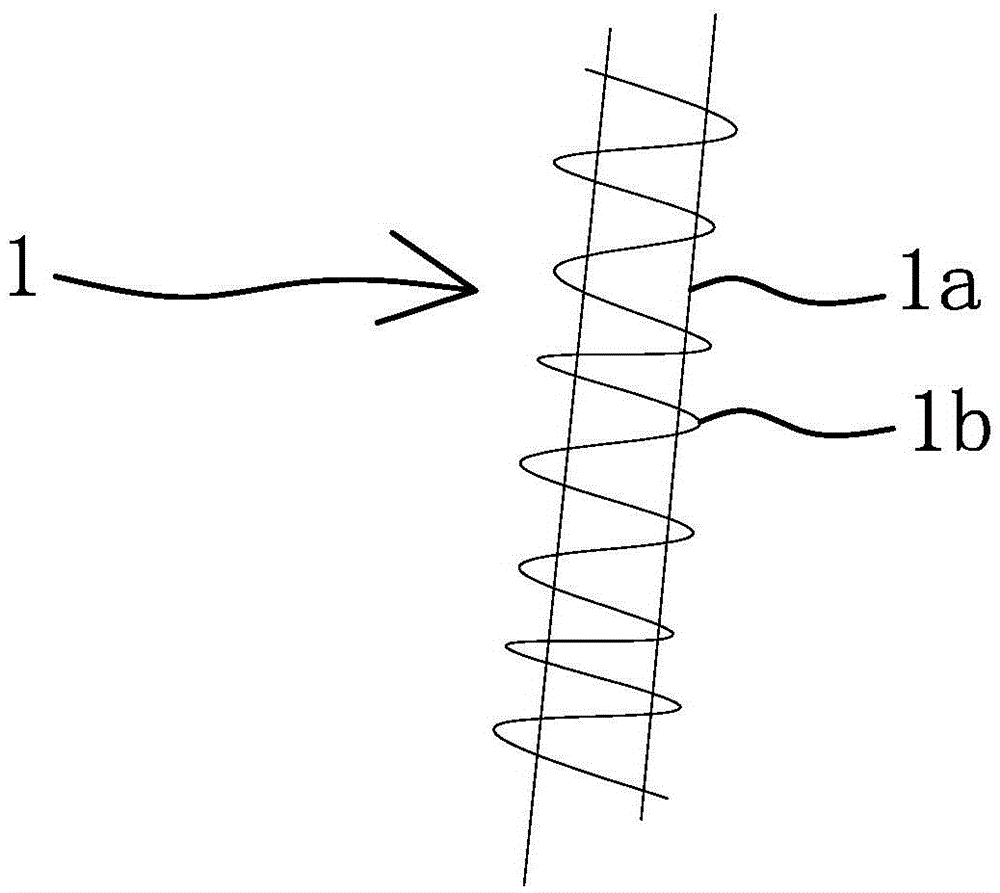

Poking-proof knitted socks and production process of poking-proof knitted socks

The invention provides a pair of poking-proof knitted socks and a production process of the poking-proof knitted socks, aiming at solving the problem of the design in the prior art that socks are easy to run and the like. The production process of the poking-proof knitted socks comprises the following steps: A, knitting a sock body: knitting by using core-spun yarns containing fusible spandex on a stocking frame to form the sock body; B, pretreating: pre-shrinking the sock body and carrying out softening treatment for the first time; C, molding: putting the sock body at a heating and pressurizing state to fuse and separate out parts containing the fusible spandex in the core-spun yarns at mutual crossed parts of the core-spun yarns of the sock body so that the core-spun yarns are mutually fused at the mutual crossed parts to form mesh nodes and the like. The poking-proof knitted socks and the production process of the poking-proof knitted socks have the advantages that the production process is simple and easy to operate; a produced product is reasonable in design and simple in structure; a mesh node structure is adopted so that the binding fastness between the yarns is enhanced and the socks are not easy to run.

Owner:ZHEJIANG DONGFANGYUAN KNITTING

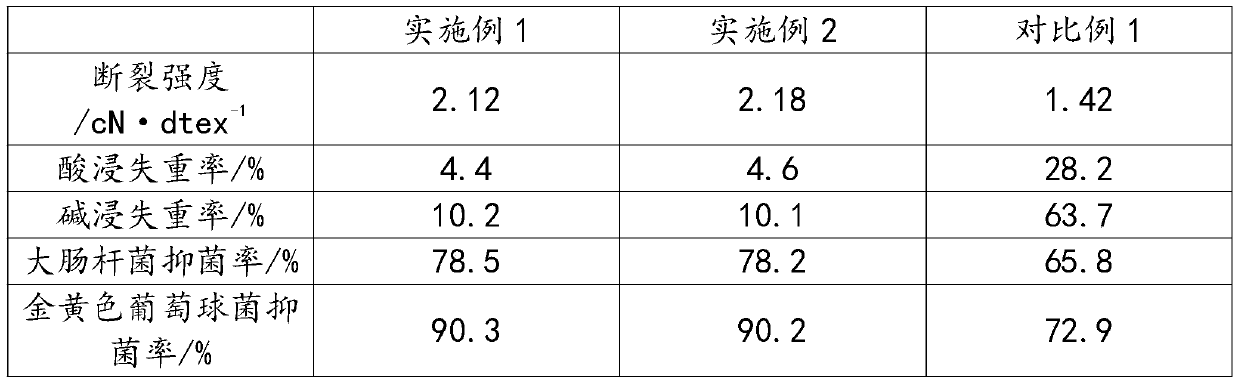

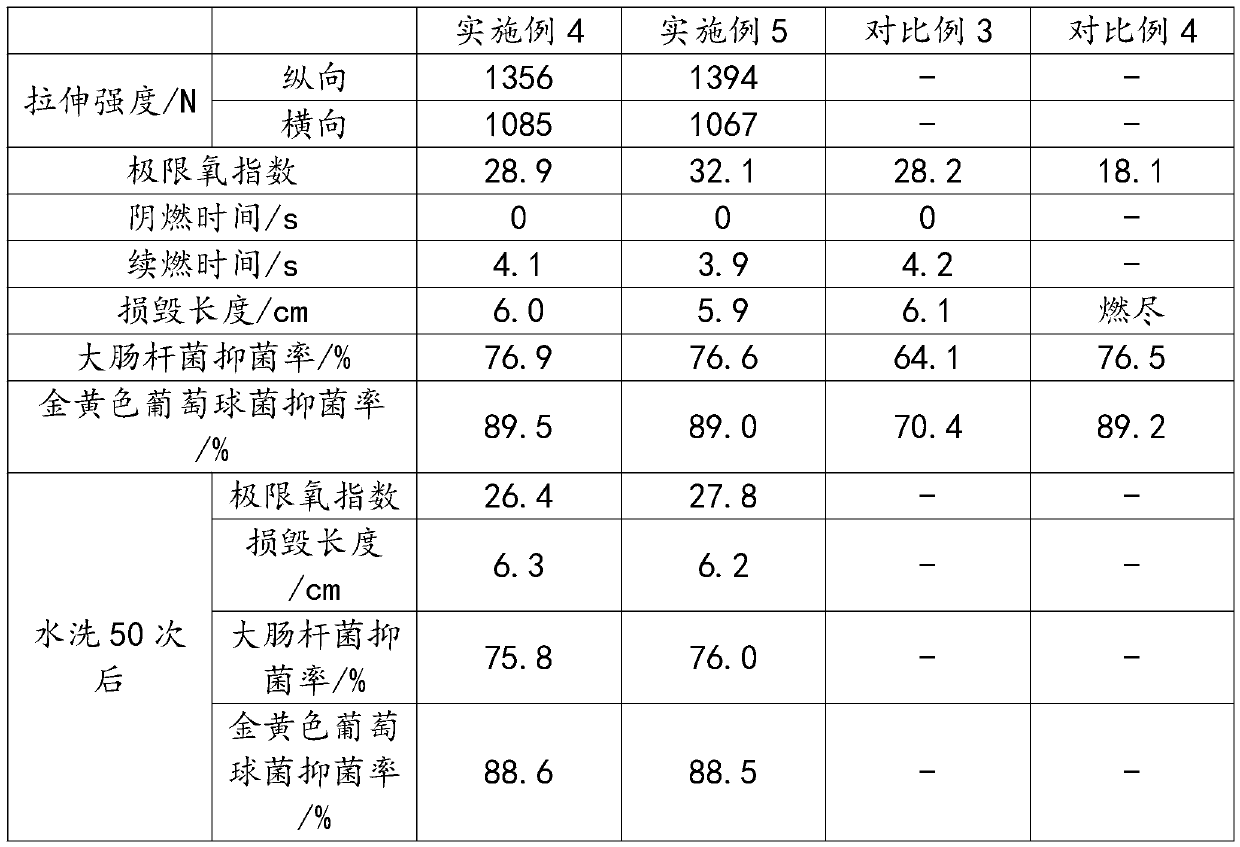

Environment-friendly flame-retardant textile fabric

InactiveCN110341263AGood antibacterial propertiesImprove regularityCellulosic plastic layered productsHeat resistant fibresPolyesterYarn

The invention discloses environment-friendly flame-retardant textile fabric. The environment-friendly flame-retardant textile fabric is double-layer fabric, wherein the inner layer fabric is formed byweaving mulberry bark / antibacterial fiber blended yarn, the outer layer fabric is formed by weaving linen / flame-retardant fiber blended yarn, and the inner layer fabric and the outer layer fabric areconnected through polyester drawn textured yarn; and the fabric is formed by weaving the mulberry bark / antibacterial fiber blended yarn, the linen / flame-retardant fiber blended yarn and the polyesterdrawn textured yarn through a double-sided circular knitting machine. The environment-friendly flame-retardant textile fabric adopts the double-layer fabric, the inner layer fabric is breathable andmoisture-permeable and has an antibacterial function, the outer layer fabric has a flame-retardant effect, and the polyester drawn textured yarn plays the role of connection; antibacterial fiber is cellulose acetate fiber modified by the chemical grafting of sorbic acid chloride and has good antibacterial properties, flame-retardant fiber is viscose fiber which is chemically grafted with ethyl dichlorophosphate molecules and amino-terminated polysiloxane and has good flame retardant properties and mechanical properties, and the bonding form of chemical bonding is firm, and high washable performance is achieved; and the environment-friendly flame-retardant textile fabric has good breathability and moisture permeability and a wide application range.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Mercerized plush carpet and its weaving method

InactiveCN1776069AColorful and brightLess difficult to cut fleeceTufting apparatusDyeing processYarnEngineering

This invention relates to a mercerized shag carpet and weaving method, which contains twisting 50-120 strand of 120-450D bright viscose fiber into 18-30 twist number 1-10 plied viscose fiber yarn, after dyeing making 5-35 count 1-10 plied viscose fiber yarn into shag carpet with 3-15cm hair height of viscose fiber plied yarn and 1-10cm hair height of acrylic plied yarn.

Owner:天津恒盛纺织品有限公司

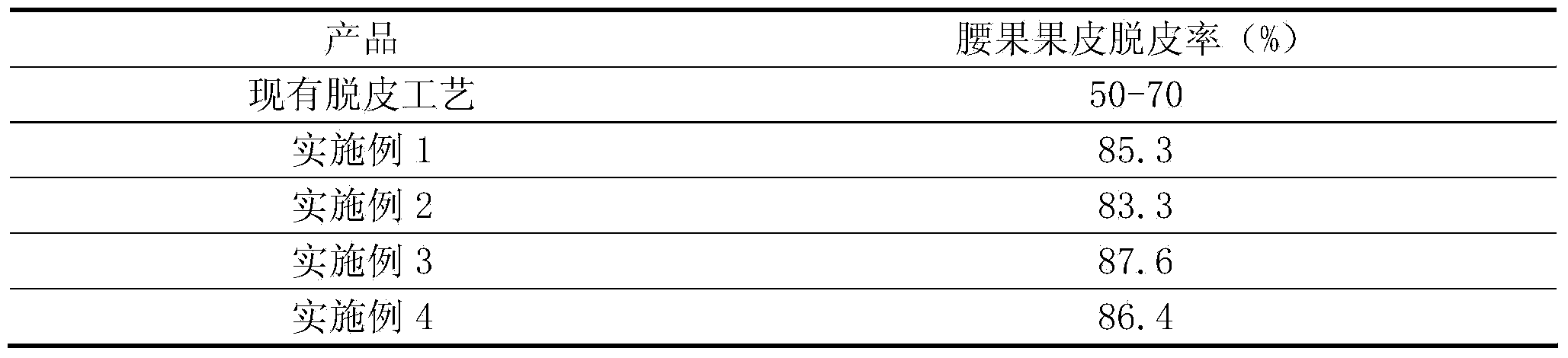

Method for peeling anacardium occidentale kernels

The invention provides a method for peeling anacardium occidentale kernels. The method for peeling the anacardium occidentale kernels comprises the following steps that (1) gradient hot-air drying is conducted on the hulled kernels with peels; (2) cold treatment is conducted on the anacardium occidentale kernels dried in the step (1); (3) water mist humidifying treatment is conducted on the anacardium occidentale kernels processed in a cold treatment mode; (4) secondary hot-air drying is conducted on the humidified anacardium occidentale kernels; (5) mechanical scraping and air current impact are adopted for removing the peels of the anacardium occidentale kernels processed in a secondary hot-air drying mode, scraps are collected through negative pressure, and coarse products are obtained; (6) third drying is conducted on the peeled and scrap-removed anacardium occidentale kernels so as to obtain finished products.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

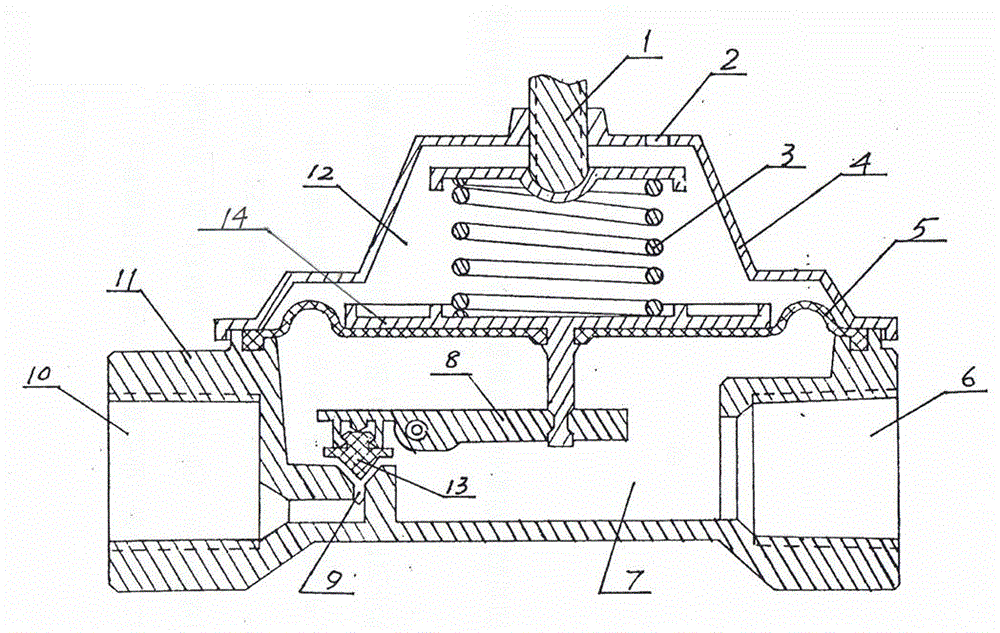

Reinforced type protective cover for pressure regulating valve

InactiveCN103557359AEliminate potential safety hazardsExtend working lifeValve housingsEngineeringAtmosphere

The invention provides a reinforced type protective cover for a pressure regulating valve. The reinforced type protective cover comprises a cover body and a skirt edge, wherein the skirt edge is matched and connected with the upper valve deck of the pressure regulating valve and the outer outline of a valve seat bonding part; at least one vertical convex rib or groove is formed in the inner wall of the skirt edge; an upper valve deck and a gap are arranged in the cavity of the cover body; at least one inward lug boss and / or at least one reinforced rib are / is arranged on the inner wall of the upper top part of the cover body and near corresponding upper valve deck blowhole(s); at least one convex button is arranged at the lower part of the inner wall of the skirt edge. With adoption of the reinforced type protective cover disclosed by the invention, the situation that the blowholes in the upper valve deck of the pressure regulating valve are communicated with the atmosphere in any bad weather and environment is ensured, so that the service life of the pressure regulating valve is prolonged and the working reliability of the pressure regulating valve is improved.

Owner:罗达健

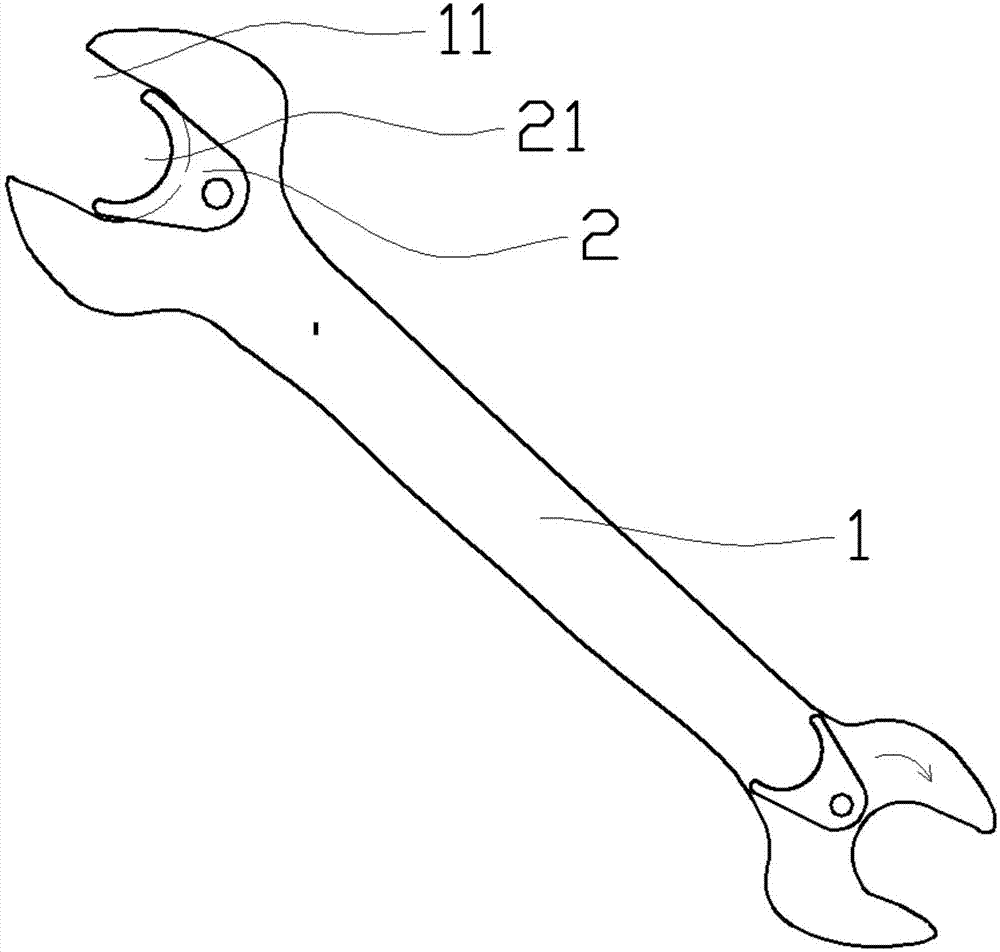

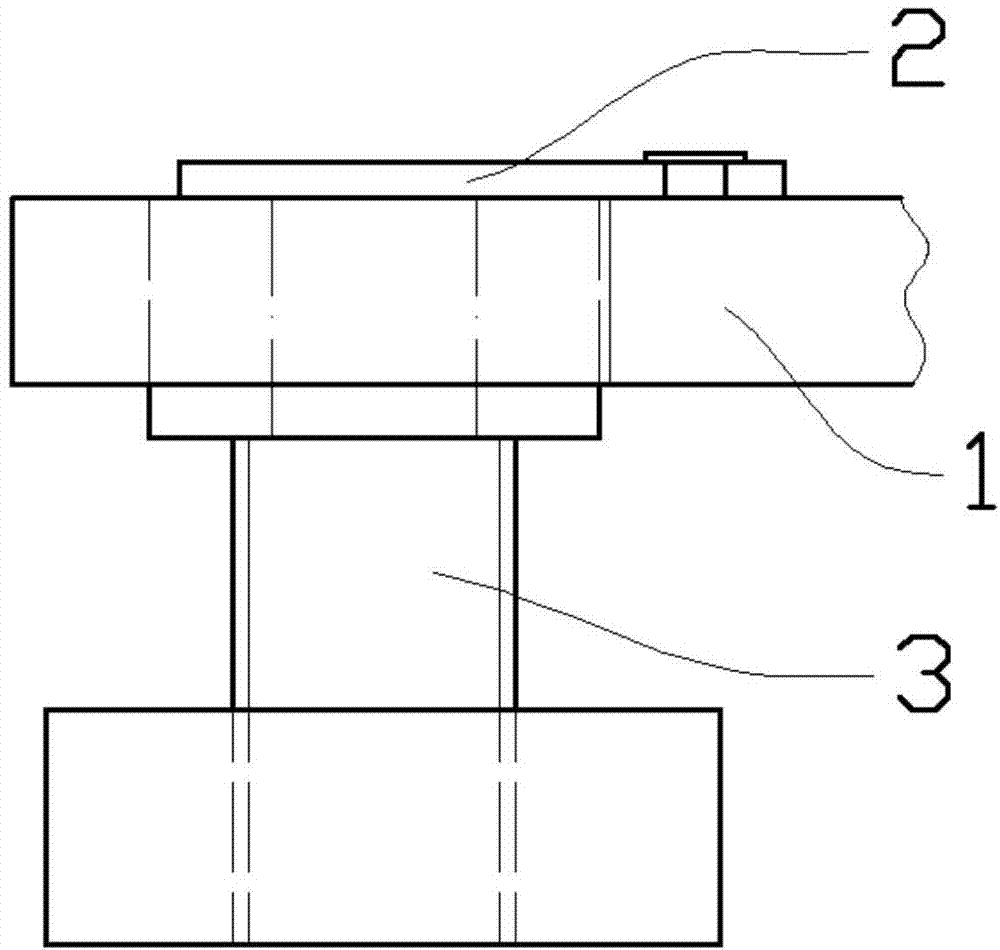

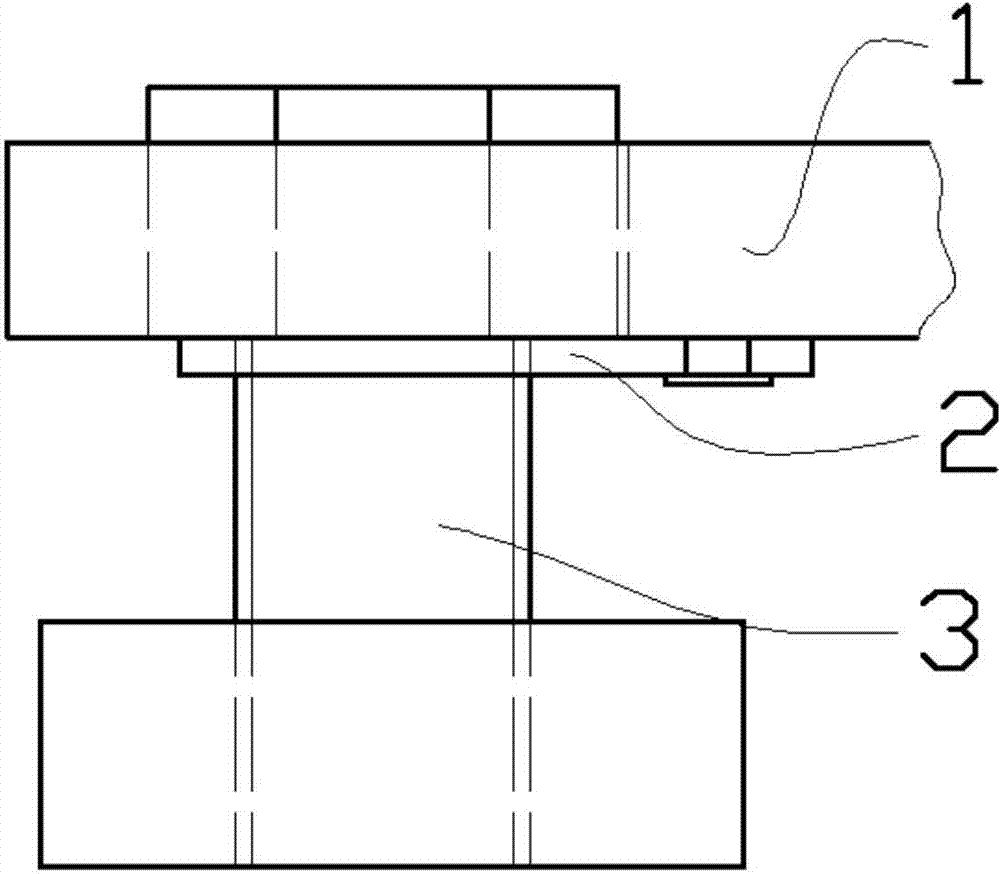

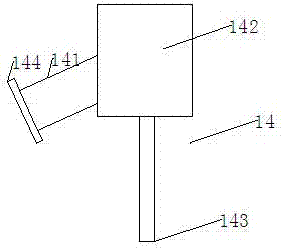

Fall-prevention wrench

The invention provides a fall-prevention wrench which comprises a wrench body and a clamping plate. The head part of the wrench body is designed to be provided with a bayonet structure. An arc side is designed to be arranged on the bayonet structure. A semi-circle groove is designed to be formed in the clamping plate. The clamping plate adheres to the head part of the wrench body. The semi-circle groove of the clamping plate is concentric with the arc of the bayonet structure. The directions of the openings of the clamping plate and the bayonet structure correspond to each other. The fall-prevention wrench is simple in structure, convenient to use, not prone to falling when being used for screwing, higher in assembling efficiency and capable of being supported by the clamping plate when a bolt or a nut is detached and preventing the bolt or the nut from falling.

Owner:WUJIANG SAINA ELECTRONICS TECH

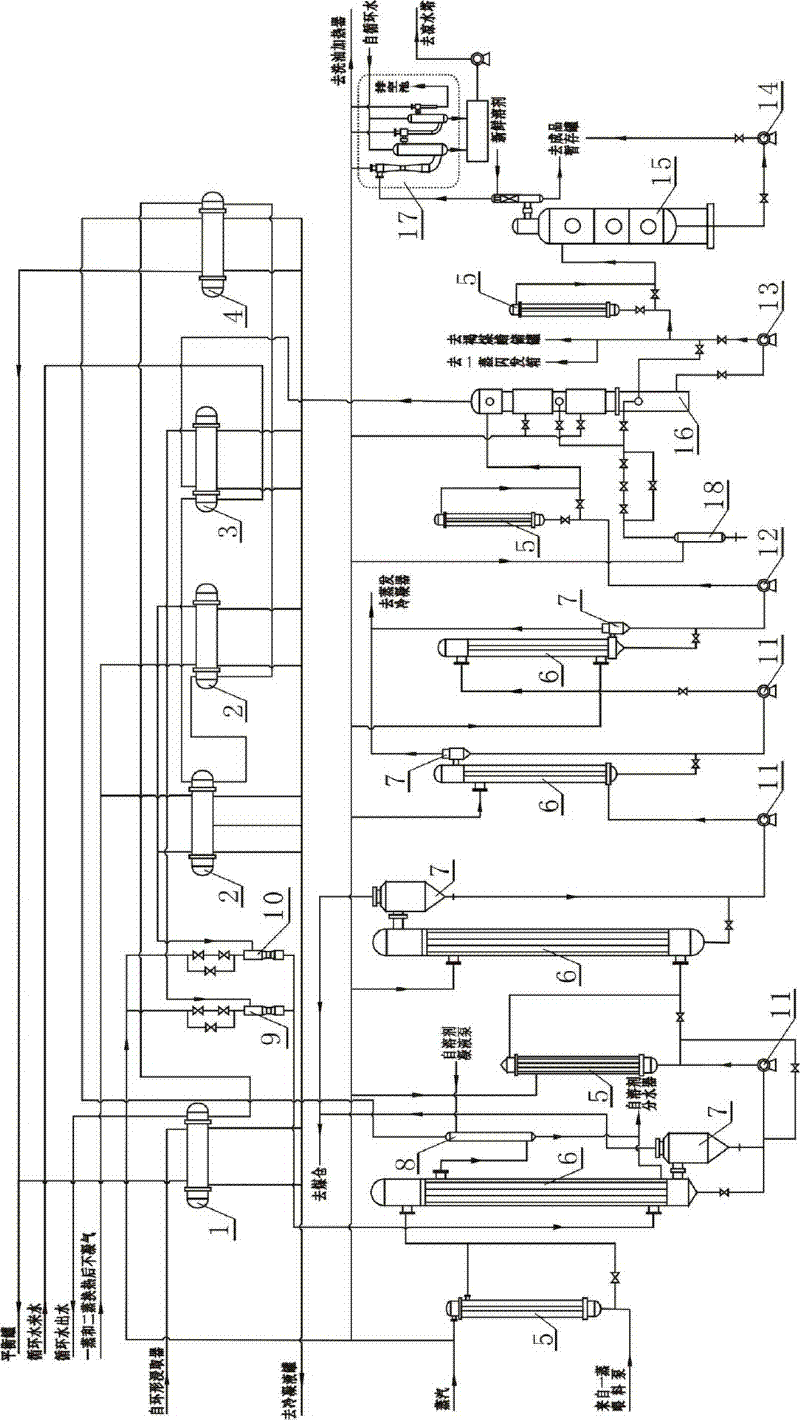

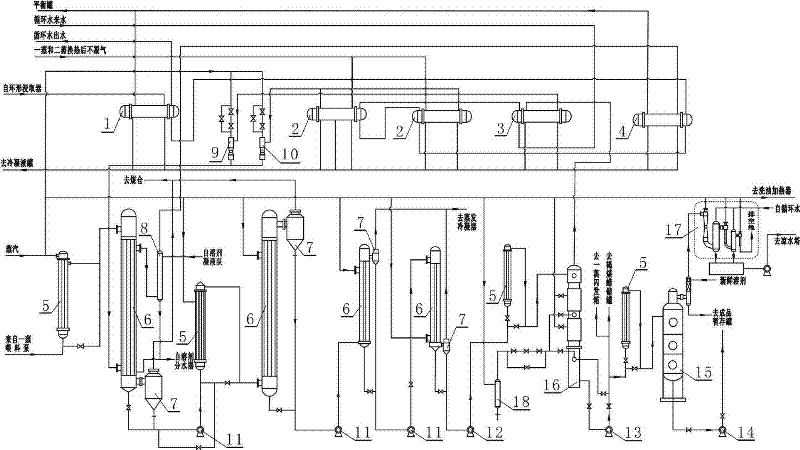

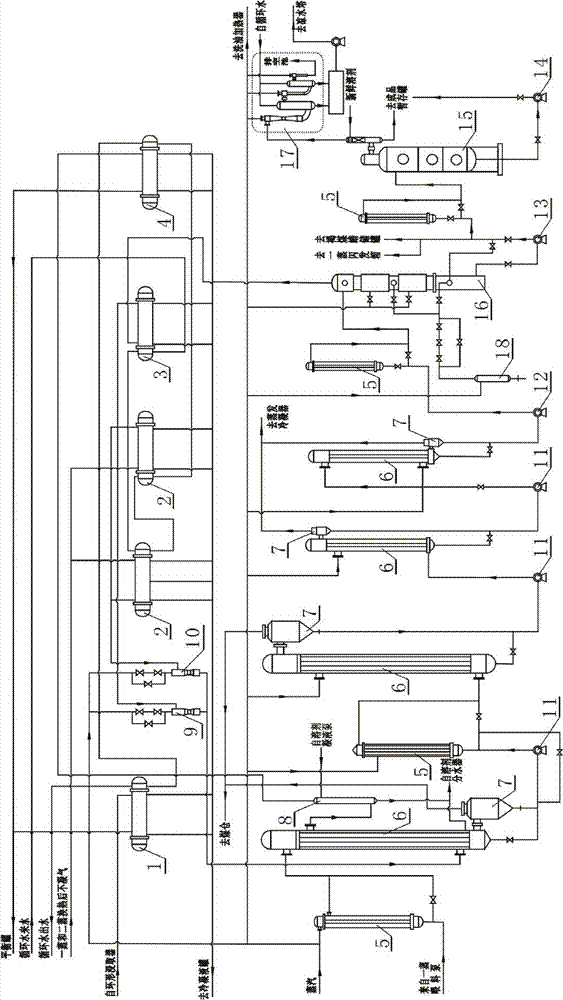

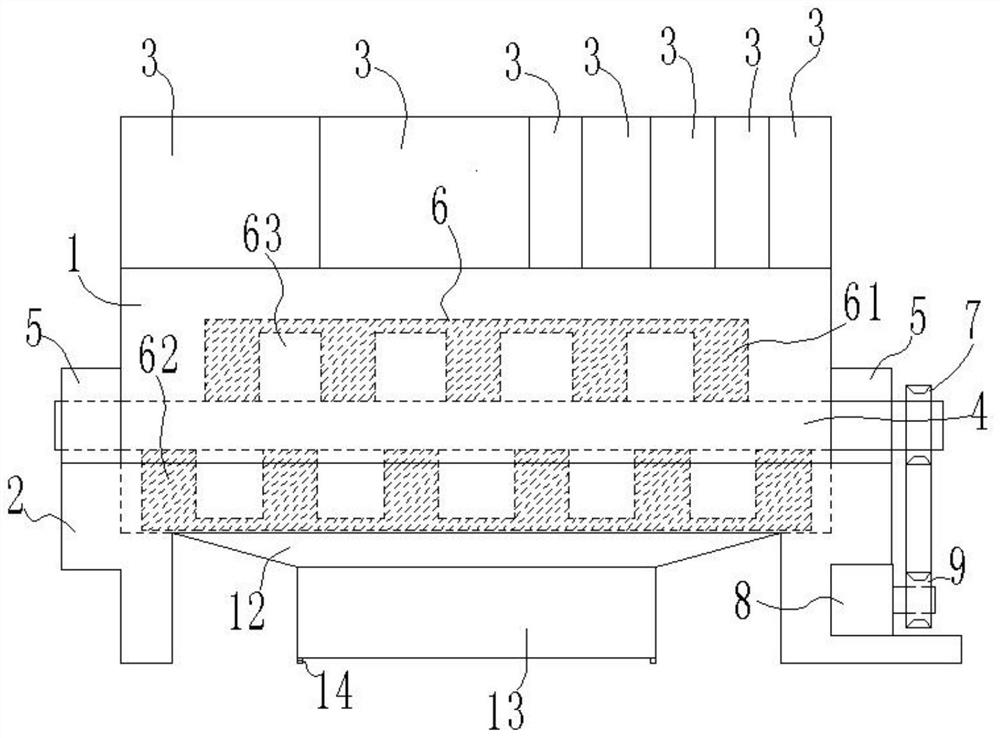

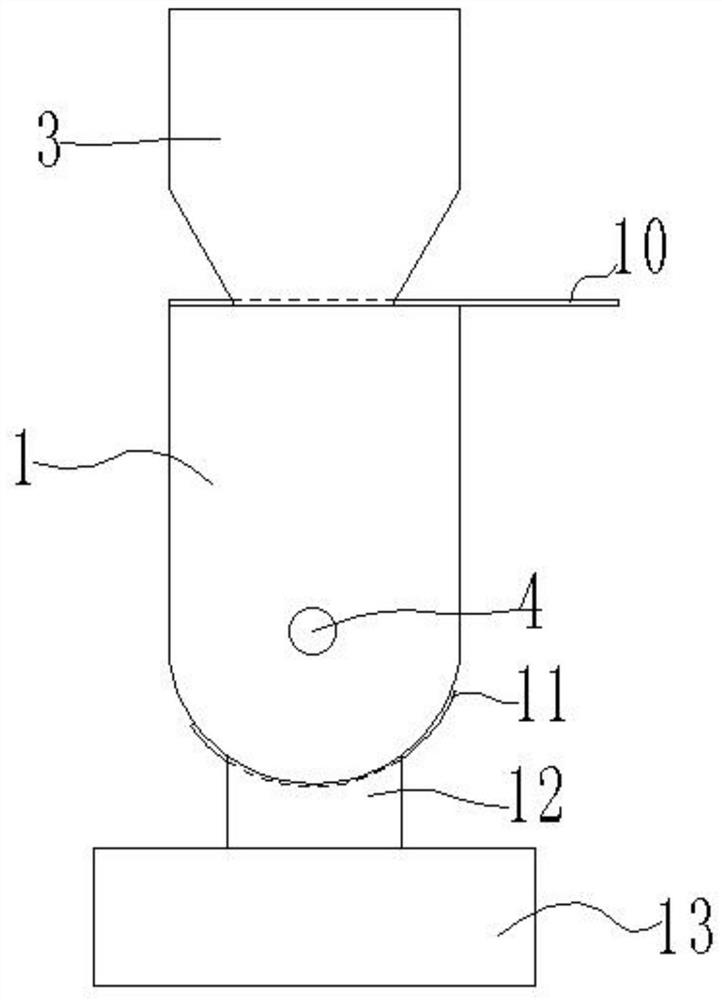

Method and device for high-efficiency energy-saving desolvation of fossilized animal/plant wax-containing solution

ActiveCN102492555ANot easy to take offImprove desolvation efficiencyFatty substance recovery/refiningFatty substance recoveryWaxProcess engineering

The invention discloses a method and a device for high-efficiency energy-saving desolvation of a fossilized animal / plant wax-containing solution. The method provided by the invention comprises the following steps of continuous four-stage evaporation, continuous steam stripping and continuous steaming, wherein the steps are carried out under negative pressure conditions, and realizes recovery of asolvent in non-condensable gas and comprehensive utilization of energy. The device provided by the invention comprises a four-stage evaporator, a stripping tower, a desolvation tower, an auxiliary feed pump, a heater, an economizer and a condenser, wherein the four-stage evaporator, the stripping tower and the desolvation tower are connected to a negative pressure system. The method and the device have the advantages that under negative pressure conditions, the steps of continuous four-stage evaporation, continuous steam stripping and continuous steaming are adopted and waste heat produced bythe steps is utilized fully so that desolvation efficiency is high; a wax heating temperature is low so that improvement of a wax acid value and a wax saponification value is promoted; and multipath recovery of a solvent and non-condensable gas is realized and thorough solvent recovery is realized so that a production cost is reduced greatly.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

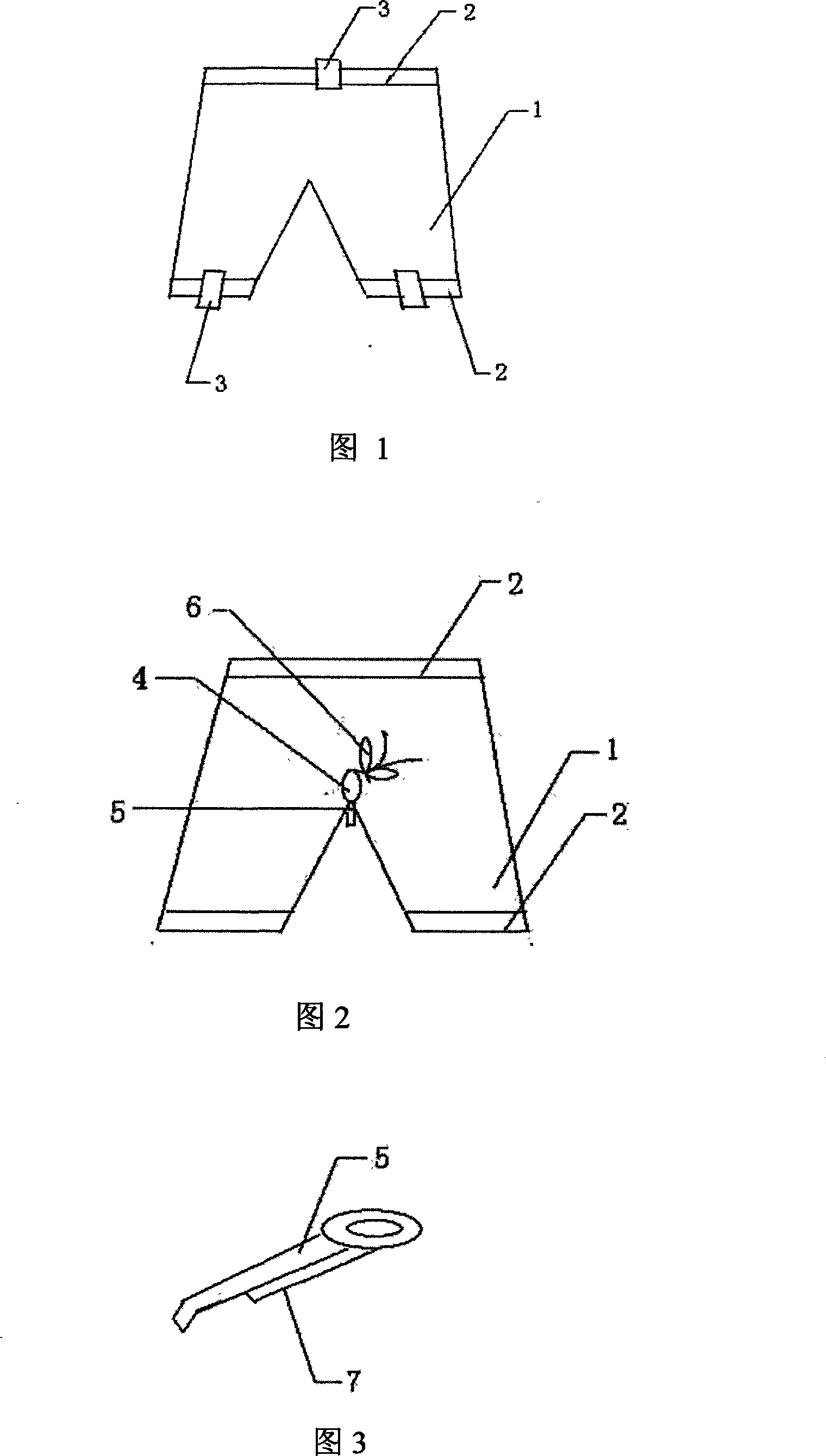

Defence underpants

The invention relates to prevention underwear, including elastic plastic weight loss underwear which is characterized in that a waist port and a trouser leg port of the elastic plastic weight loss underwear are respectively equipped with an inelastic blended belt. The butting point of the blended belts is equipped with a lock. A defecation port is arranged on a position on the elastic plastic weight loss underwear, corresponding to the anus port. Line holes are arranged along the periphery of the defecation port. A tying line is arranged in the line holes. An urination catheter which is induced out of the underwear is arranged on a relative human urethra port. Because the waist port and the trouser leg port of the elastic plastic weight loss underwear are respectively equipped with the inelastic blended belt which is butted through the lock, the underwear can not be taken off when a person meets an adverse malicious violation, and the prevention can be implemented effectively. The defecation port is arranged on the position on the elastic plastic weight loss underwear, corresponding to the anus port. The line holes are arranged along the periphery of the defecation port. One tying line is arranged in the line holes. The defecation can be implemented as long as the tying line is loosened. Because the urination catheter which is induced out of the underwear is arranged on the relative human urethra port, the urination is convenient without taking off the underwear.

Owner:王教乐

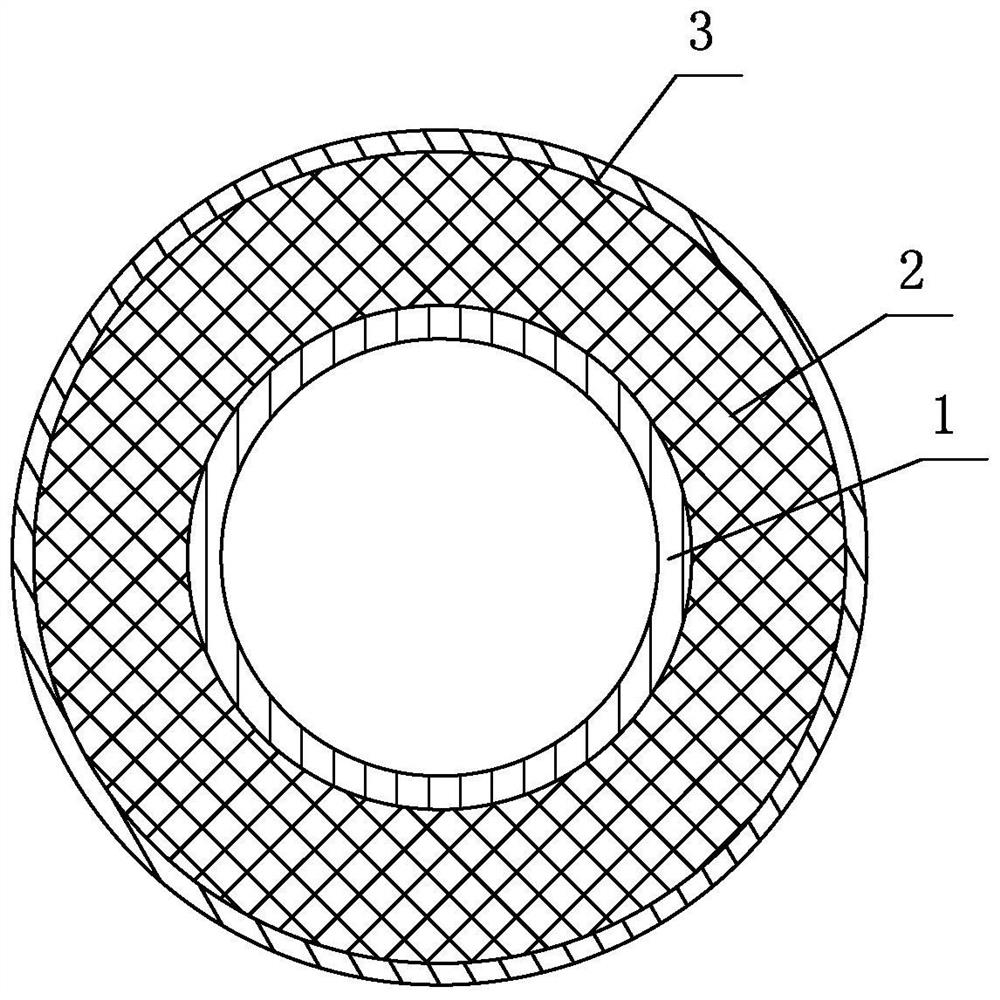

Novel plasti- steel composite cable pipeline, and production equipment and production process thereof

PendingCN112769086ANot easy to take offAvoid scratchesSynthetic resin layered productsCable installations in underground tubesFiberElectric cables

The invention relates to a novel waterproof plastic-steel composite cable pipeline, and production equipment and a production process thereof. The cable pipeline comprises: a woven wear-resistant layer which is formed by weaving dry fibers, wherein the interior of the woven wear-resistant layer is used for laying a cable; a structure reinforcing layer formed by weaving and winding dry cellosilk in a multi-layer mixing mode, wherein the structure reinforcing layer is fixedly laid and compounded on the outer surface of the woven wear-resisting layer, and glue is injected into the surface of the structure reinforcing layer and permeates into the structure reinforcing layer; and a gel coat resin protection layer firmly arranged on the outer surface of the structure reinforcing layer. The gel coat resin protection layer forms a protective layer, the outer wall is smooth and free of burrs, the situation that fibers are prone to being damaged and burrs are generated to prick hands of workers is avoided, and installation and carrying are convenient; and the gel coat resin protection layer and the structure reinforcing layer are made of thermosetting materials, and the gel coat resin protection layer and the structure reinforcing layer can be really bonded and tightly connected during compounding and are not prone to slipping off.

Owner:李世伟 +1

Anti-corrosion galvanized steel sheet and preparation method thereof

InactiveCN113981443AImprove anti-corrosion performanceEasy to makeMetallic material coating processesEpoxyO-Phosphoric Acid

An anti-corrosion galvanized steel sheet comprises a steel sheet and a plating layer. The plating layer comprises a plating layer formed by a zinc plating solution and a passivation plating solution. The zinc plating solution comprises the following components in percentage by weight: (15-20)% of sodium hydroxide, (35-50)% of zinc oxide, (25-40)% of nanoscale zinc powder, (5-20)% of barium sulfate, (1-10)% of talcum powder, (1-10)% of a flatting agent and (1-10)% of calcium borate. The passivation plating solution comprises the following components in percentage by weight: (25-30)% of epoxy resin, (20-40)% of sodium benzoate, (15-30)% of cinnamic acid, (15-30)% of phosphoric acid, (5-30)% of vanadate, (15-20)% of triethanolamine and (5-10)% of a dispersing agent. According to the galvanized steel sheet, two plating layers are formed on the outer surface, so that the corrosion resistance of the steel sheet can be increased in a limited mode; and meanwhile, the preparation is easy, the corrosion-resistant coatings are stable and not prone to being removed, and good economic benefits are achieved.

Owner:安徽荣起安防科技有限公司

High-strength plastic-steel composite cable protection pipe

PendingCN111186197AAvoid scratchesNot easy to take offElectrical apparatusSynthetic resin layered productsYarnFiber

A high-strength plastic-steel composite cable protection pipe comprises an inner layer which is formed by weaving fiber yarn, and the interior of which is used for laying a cable; a middle reinforcinglayer formed by weaving, winding and mixing a plurality of layers of fiber yarn and fixedly compounded on the outer surface of the inner layer; and a thermal shrinkage layer which is shrunk and fixedon the outer surface of the middle reinforcing layer. The inner layer is formed by weaving the fiber yarn, so that friction is resisted, the fiber yarn is not easy to fall off, the cable can pass through easily, the cable is prevented from being scratched when the cable is penetrated by hairs on the inner wall, and the cable penetrating failure caused by loose fibers winding the cable on the inner wall is avoided; the middle reinforcing layer is formed by weaving, winding and mixing the fiber yarn, is high in mechanical strength, can bear heavy load, is not easy to break, and plays a good role in protecting the internal cable; the outer thermal shrinkage layer forms a protective layer, the outer wall is not prone to damage, burrs are avoided, the situation that a glass reinforced plasticpipe is prone to damage and generates burrs to prick the hands of workers is avoided, and installation and carrying are convenient.

Owner:山东土大力管道工程有限公司

Preparation method of carbon fiber reinforced titanium alloy composite material

The invention discloses a preparation method of a carbon fiber reinforced titanium alloy composite material, and belongs to the field of preparation of composite materials. The cleaning, the disinfection, the sterilization and the enzymolysis are performed for spirogyra and ramie stems; the spirogyra and the ramie stems are put in a fermentation tank for fermenting, and are mixed with ethyl acetate and acetic acid for standing; polyacrylamide is added for mixing and extruding to obtain a cake-shaped carbon fiber material; the cake-shaped carbon fiber material is added in extraction liquid, prepared cotton leaves and chlorophytum comosum, for leaching after the yarn extraction, and is spun for mixing with prepared titanium dioxide turbid liquid; and titanium dioxide is loaded on spun yarns, is mixed with metal titanium, is dried by an oven, and is calcined to obtain the carbon fiber reinforced titanium alloy composite material. The preparation method has the following beneficial effects: the method is simple in preparation process; as carbon fibers are treated, the chemical compatibility and the physical compatibility between the carbon fibers and titanium alloy matrixes are improved; and the obtained product is excellent in quality, is high in bonding force, is not easy to be extracted in use, and is high in material stretching resistance and shearing resistance.

Owner:迈克瑞(珠海)复合材料有限公司

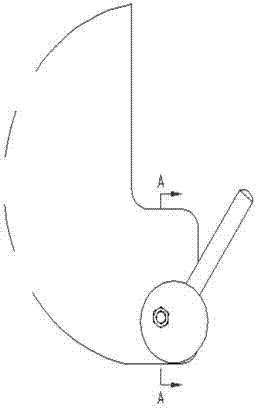

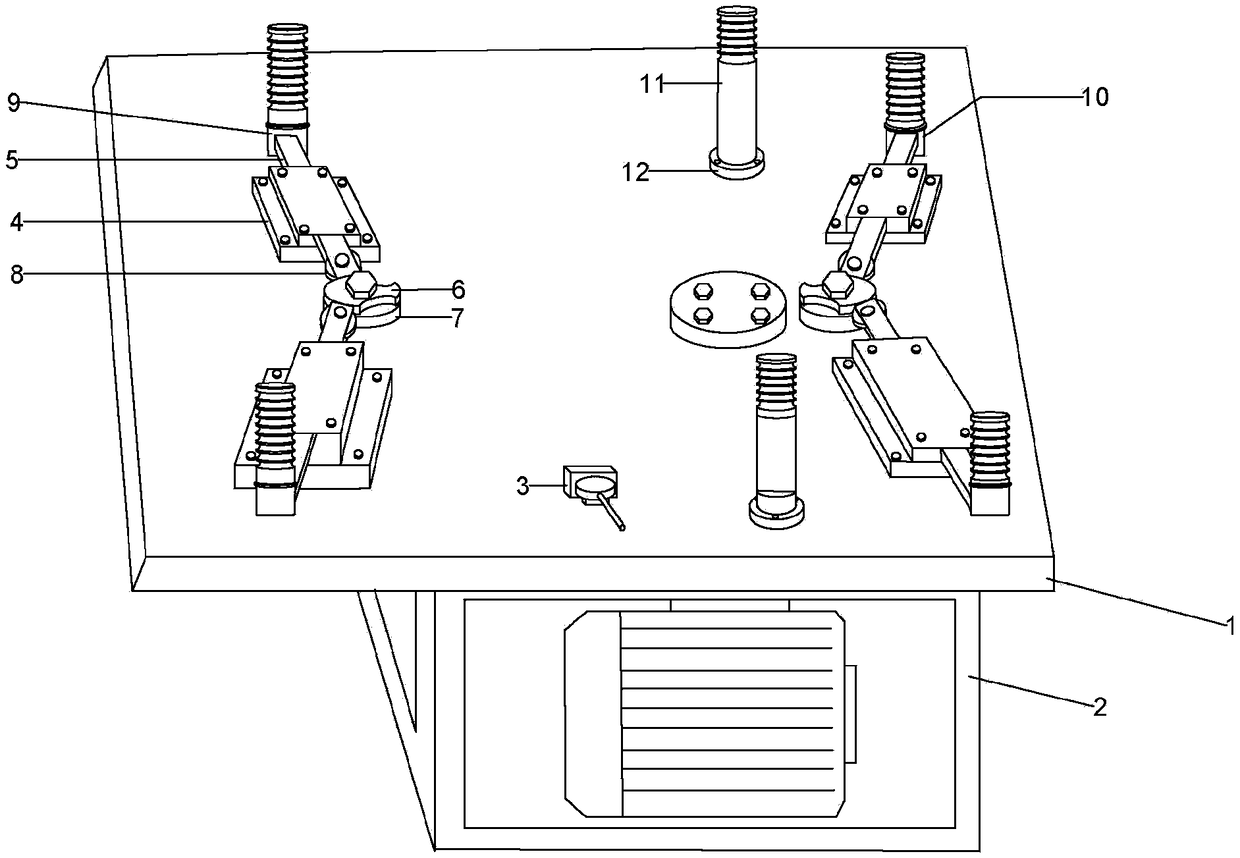

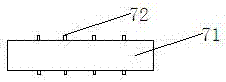

Evaporator coil coiler for refrigerator

The invention discloses an evaporator coil coiler for a refrigerator. The evaporator coil coiler for the refrigerator is characterized in that the evaporator coil coiler comprises a rotatable workbench panel and a base; a pipe fixer and multiple sets of slidable guiding components are arranged on the workbench panel; each set of the guiding components includes a mold column which comprises a plurality of ring grooves and is annularly distributed on the workbench panel; The guiding component comprises the mold column, a fixed seat and a support rod, wherein the fixed seat is fixed on the workbench panel, and the support rod is slidably placed in the middle of the fixed seat; the outer end of the support rod is connected with the mold column, while the outer end of the same leans against a limiting part of the adjustable support rod so that an evaporating coil can be removed by simply sliding the mold column without having to remove a coil component.

Owner:ZHEJIANG JIESHENG LOW TEMP EQUIP CO LTD

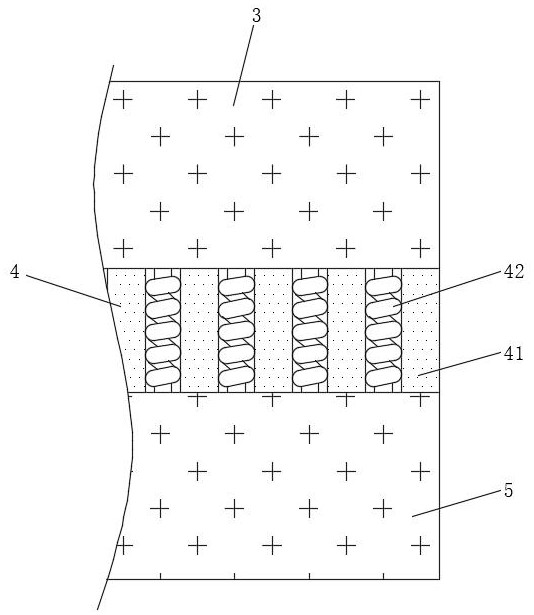

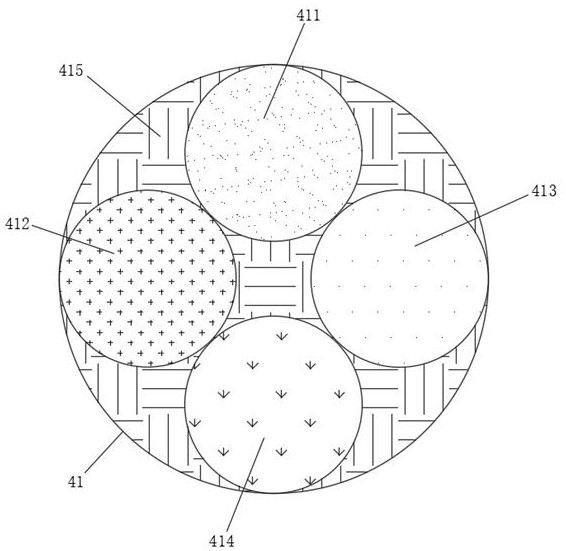

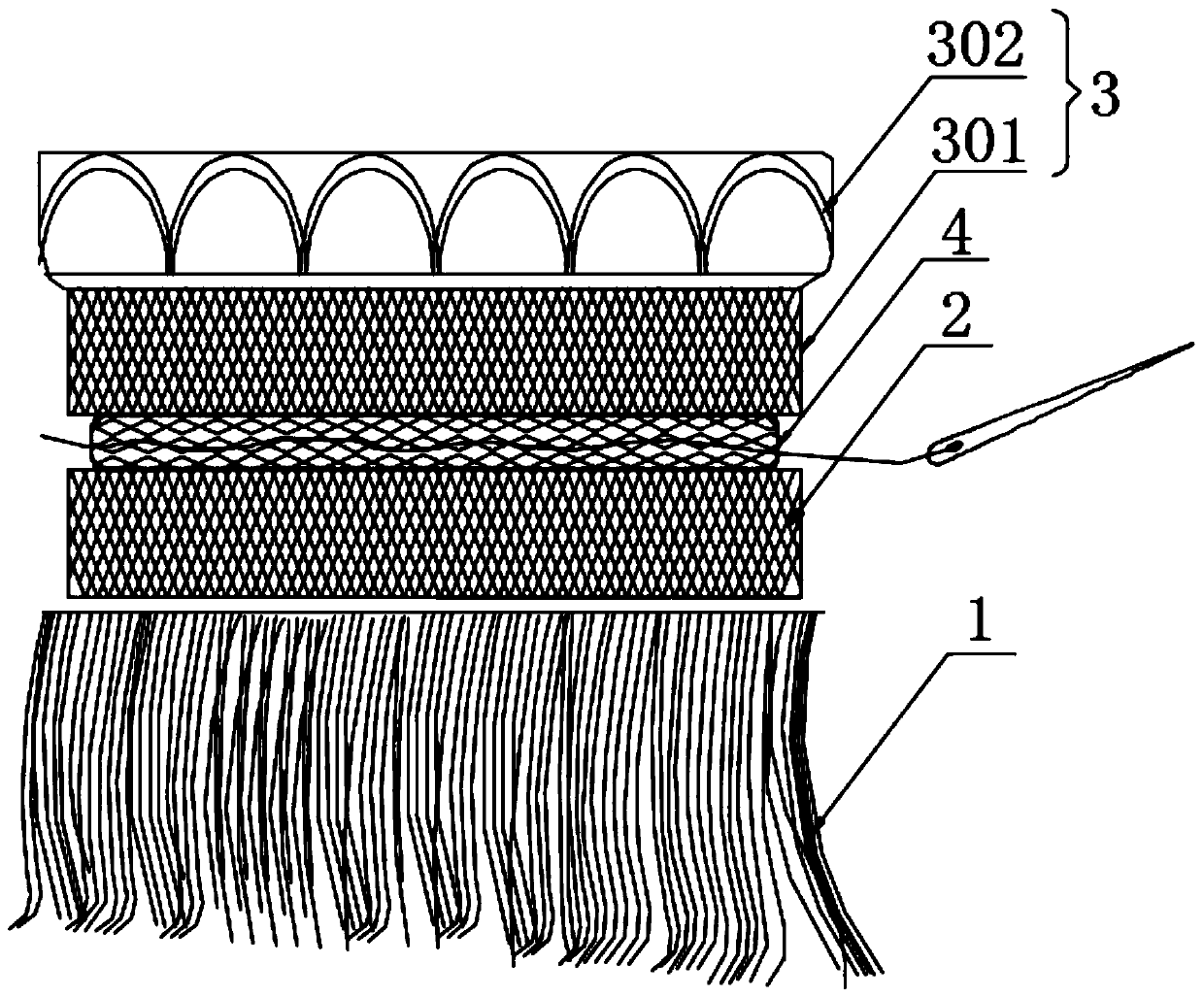

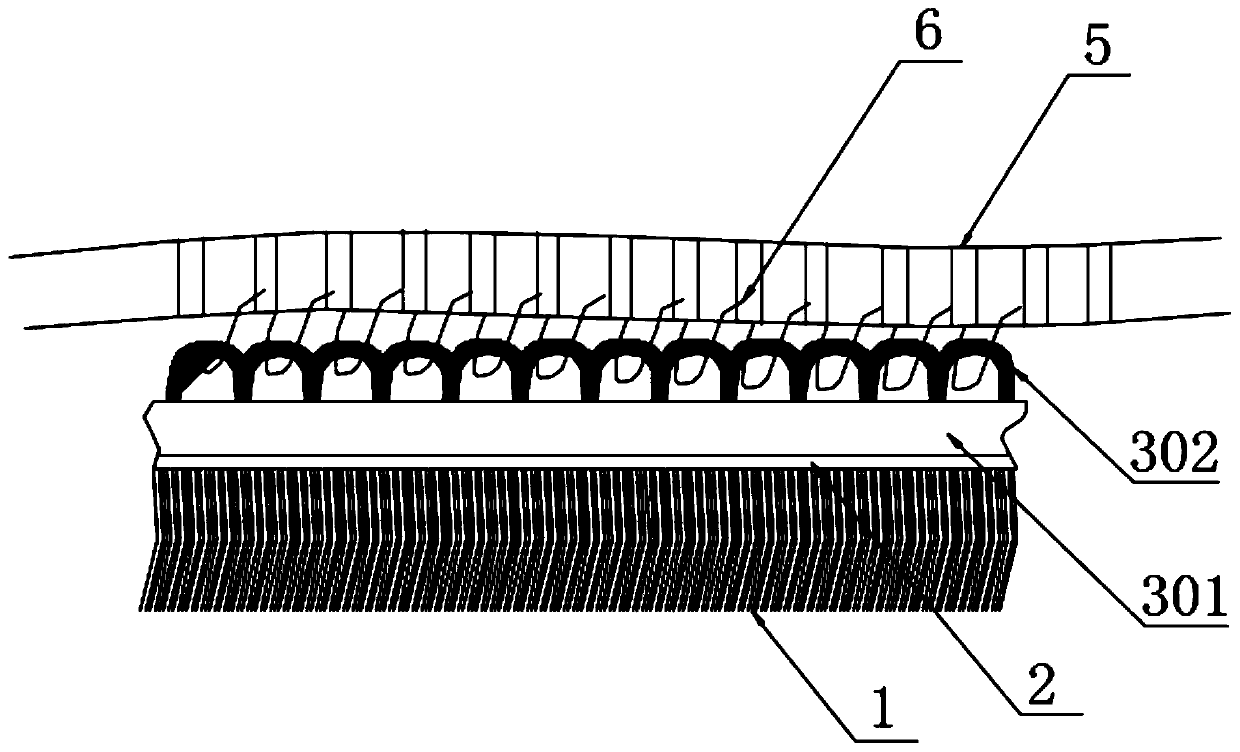

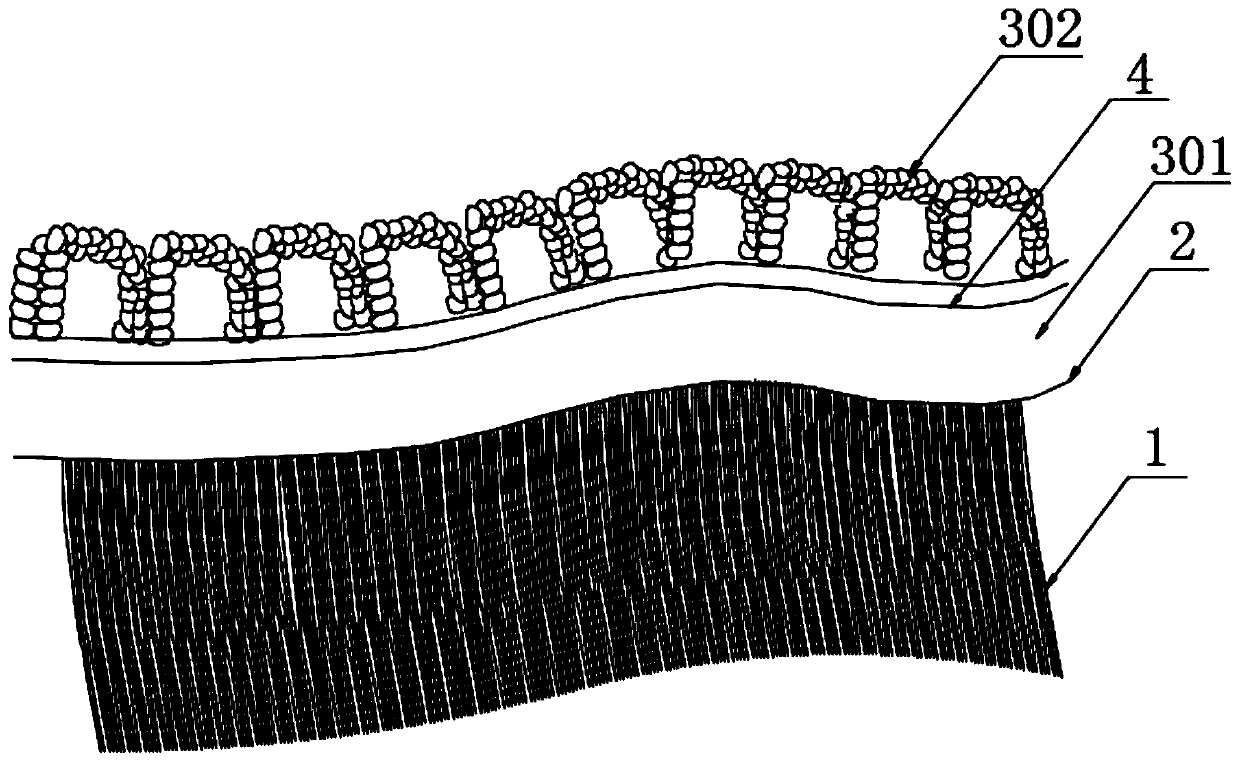

Nest-structure tailored fabric and traceless clothes made prepared from same

ActiveCN113085308ASmall detachmentMeet the needs of useSynthetic resin layered productsCellulosic plastic layered productsFiberEngineering

The invention discloses a nest-structure tailored fabric and traceless clothes prepared from the same. The nest-structure tailored fabric comprises a fabric body, the fabric body comprises a wear-resistant layer, a first magnetic health-care fiber fabric, a warm-keeping layer, a second magnetic health-care fiber fabric and a skin-friendly layer which are sequentially arranged from outside to inside. According to the invention, memory wire harnesses can be pulled into a straight line shape under the action of the repulsive force of the first magnetic health-care fiber fabric and the second magnetic health-care fiber fabric within a specified temperature, so that the warm-keeping wire harnesses on the two sides of each memory wire harness can wrap the memory wire harness for heat preservation. When the temperature is high, the linear memory wire harnesses are recovered to a spiral shape and the warm-keeping wire harnesses on the two sides of the linear memory wire harnesses are expanded, so that hot air can be dissipated from the middle of the spiral memory wire harnesses, and heat dissipation of the fabric body is facilitated. Through mutual cooperation of the memory wire harnesses and the warm-keeping wire harnesses, the fabric body can be kept warm, and and the fabric body can be properly ventilated when the temperature is too high.

Owner:江苏云的科技有限公司

Method and device for high-efficiency energy-saving desolvation of fossilized animal/plant wax-containing solution

ActiveCN102492555BNot easy to take offImprove desolvation efficiencyMineral wax recovery/refiningFatty substance recoveryWaxProcess engineering

The invention discloses a method and a device for high-efficiency energy-saving desolvation of a fossilized animal / plant wax-containing solution. The method provided by the invention comprises the following steps of continuous four-stage evaporation, continuous steam stripping and continuous steaming, wherein the steps are carried out under negative pressure conditions, and realizes recovery of asolvent in non-condensable gas and comprehensive utilization of energy. The device provided by the invention comprises a four-stage evaporator, a stripping tower, a desolvation tower, an auxiliary feed pump, a heater, an economizer and a condenser, wherein the four-stage evaporator, the stripping tower and the desolvation tower are connected to a negative pressure system. The method and the device have the advantages that under negative pressure conditions, the steps of continuous four-stage evaporation, continuous steam stripping and continuous steaming are adopted and waste heat produced bythe steps is utilized fully so that desolvation efficiency is high; a wax heating temperature is low so that improvement of a wax acid value and a wax saponification value is promoted; and multipath recovery of a solvent and non-condensable gas is realized and thorough solvent recovery is realized so that a production cost is reduced greatly.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

A kind of preparation method of carbon fiber reinforced titanium alloy composite material

Owner:迈克瑞(珠海)复合材料有限公司

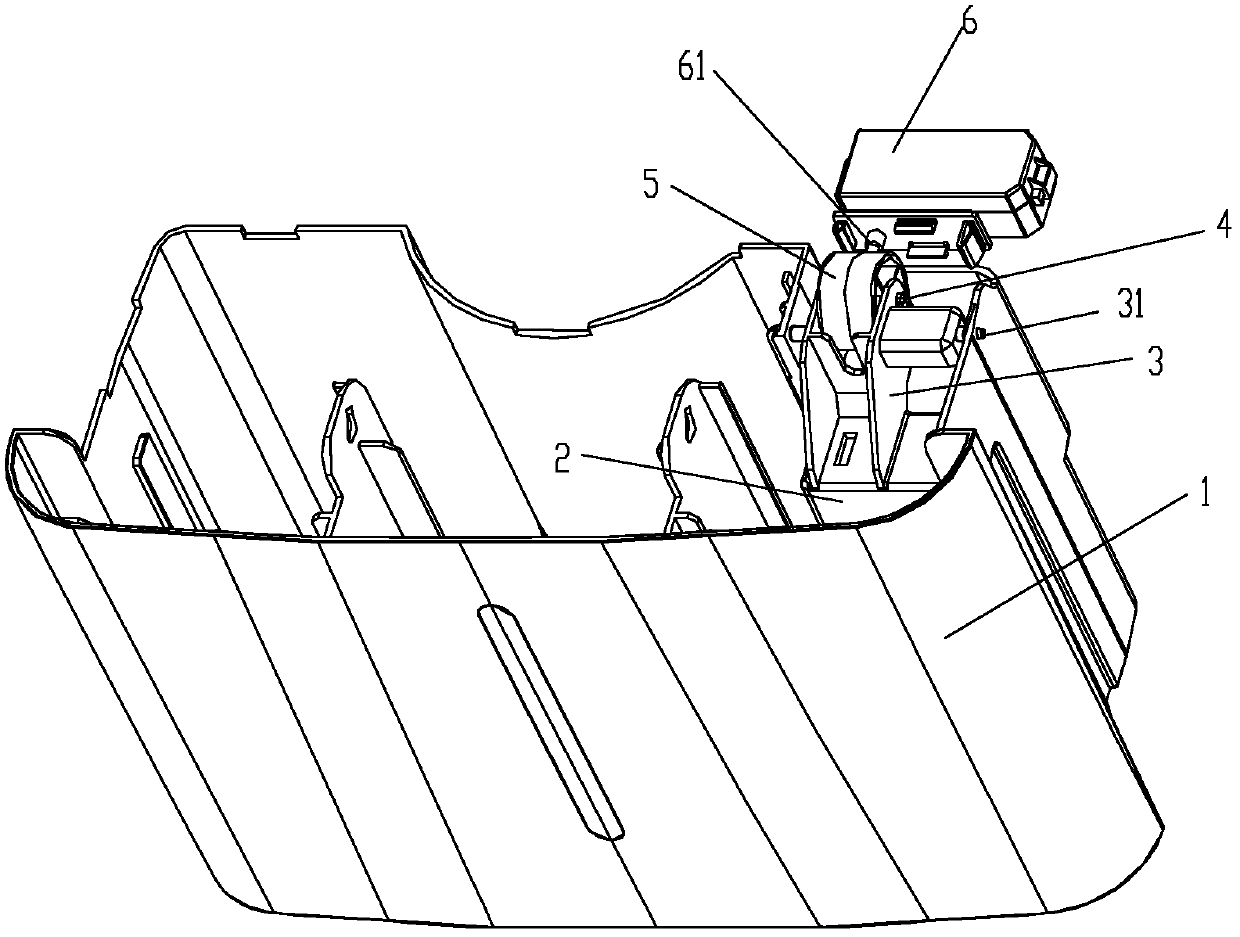

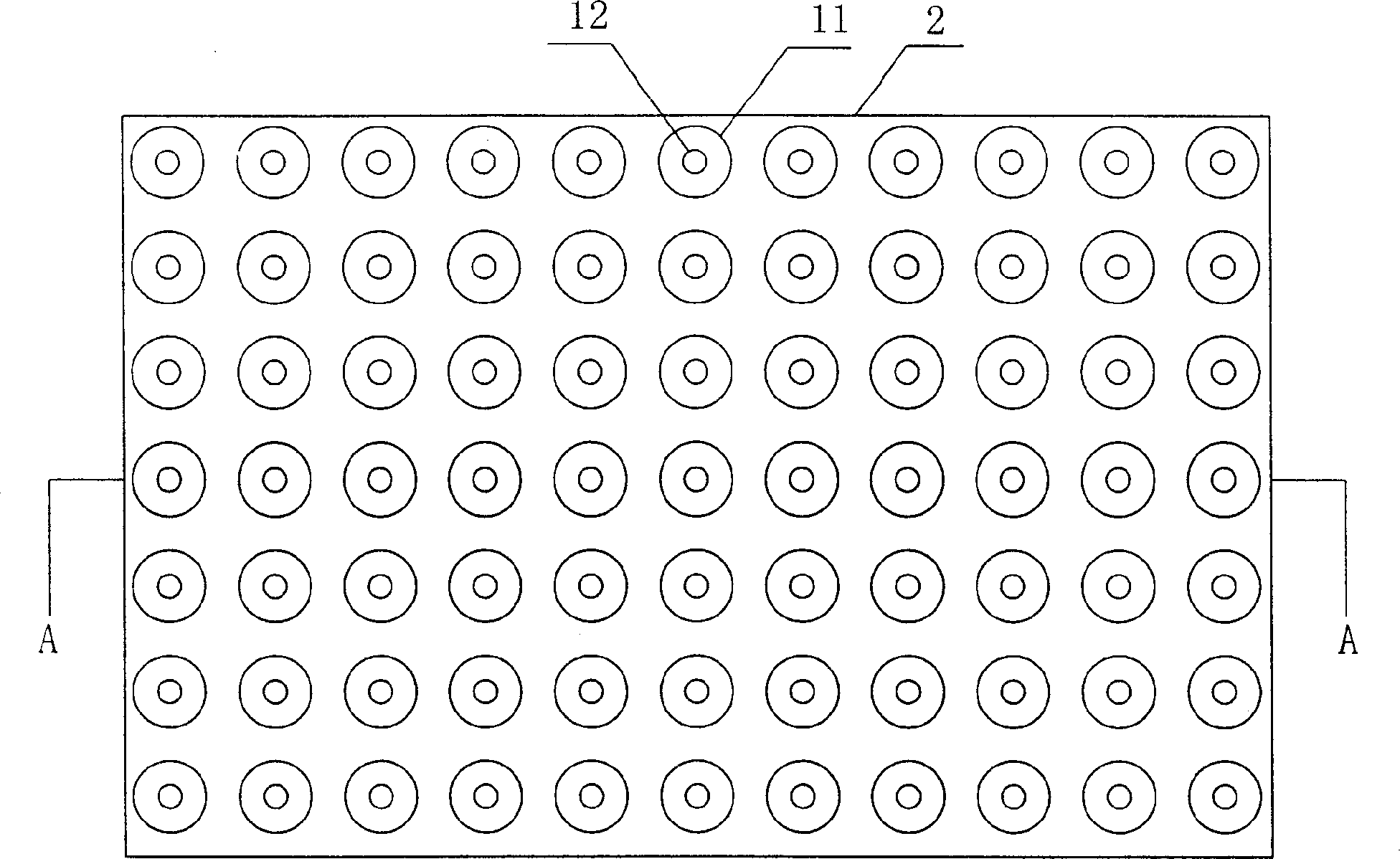

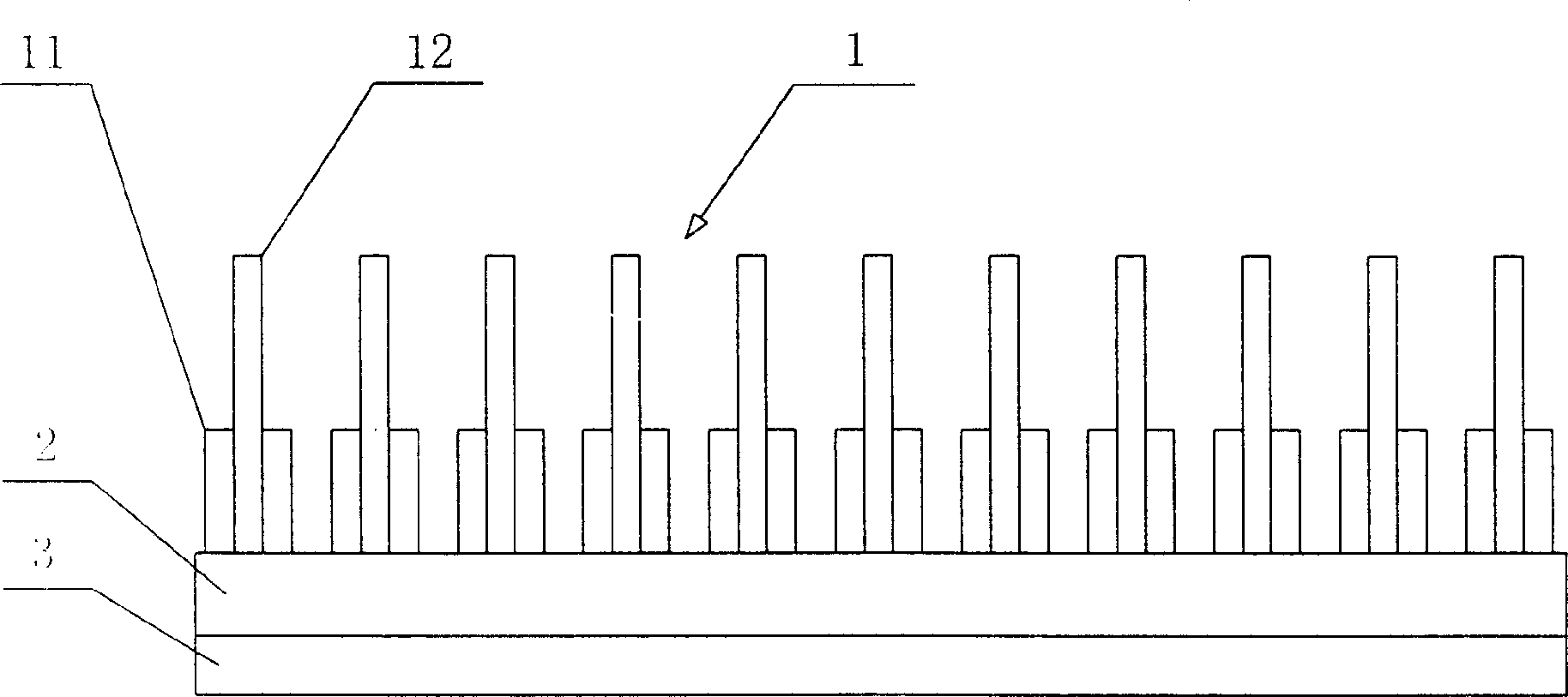

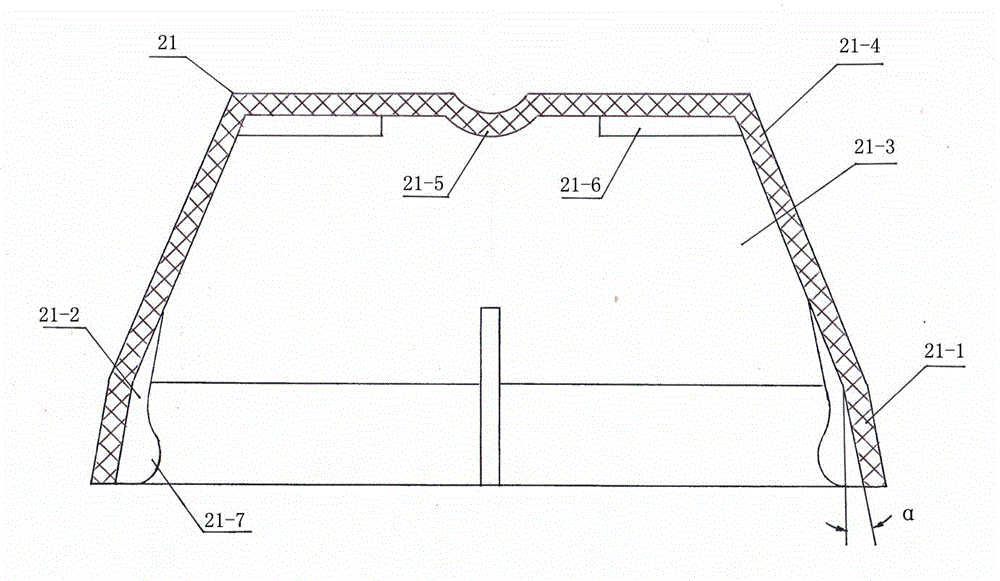

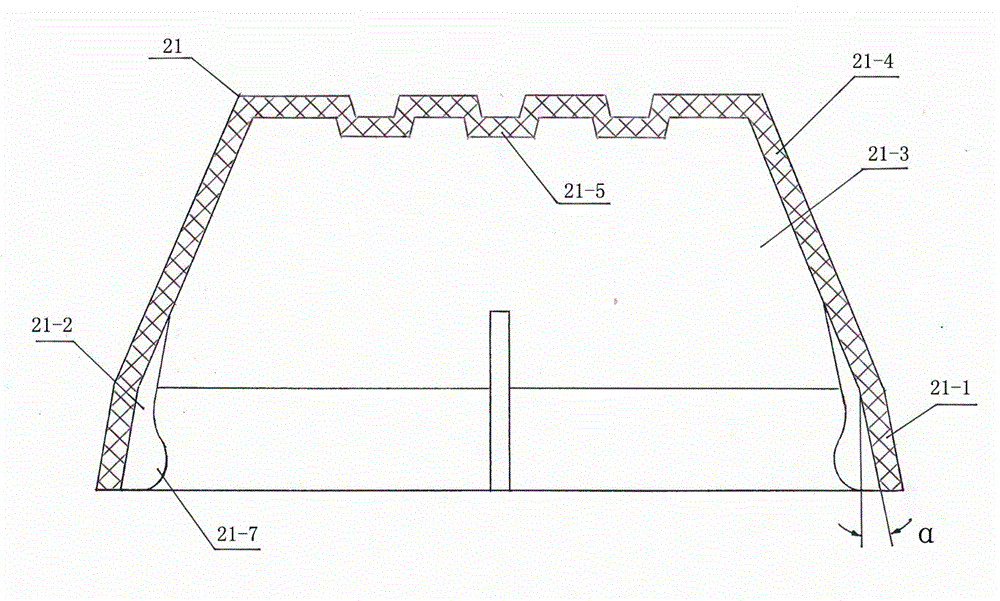

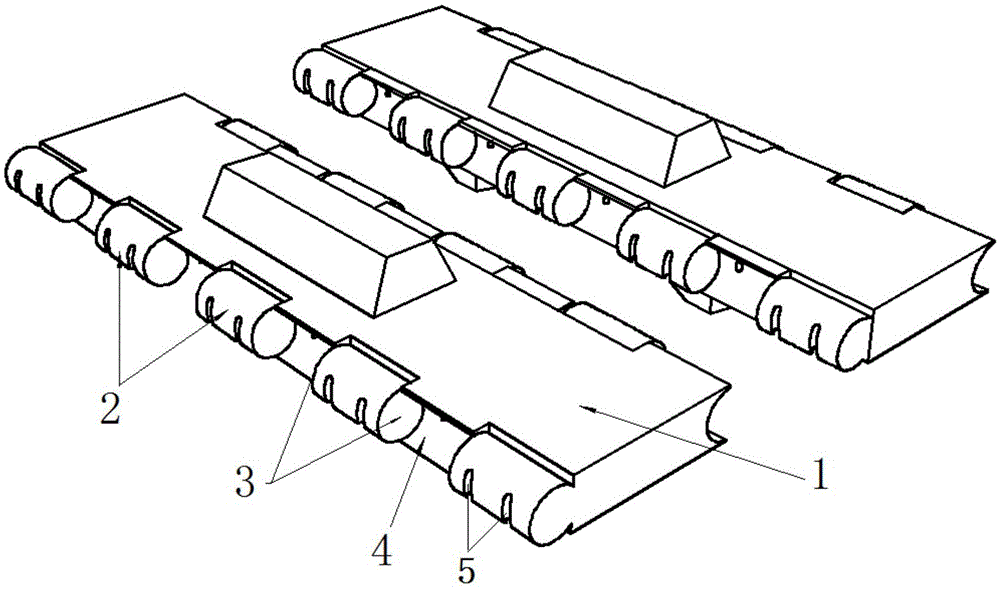

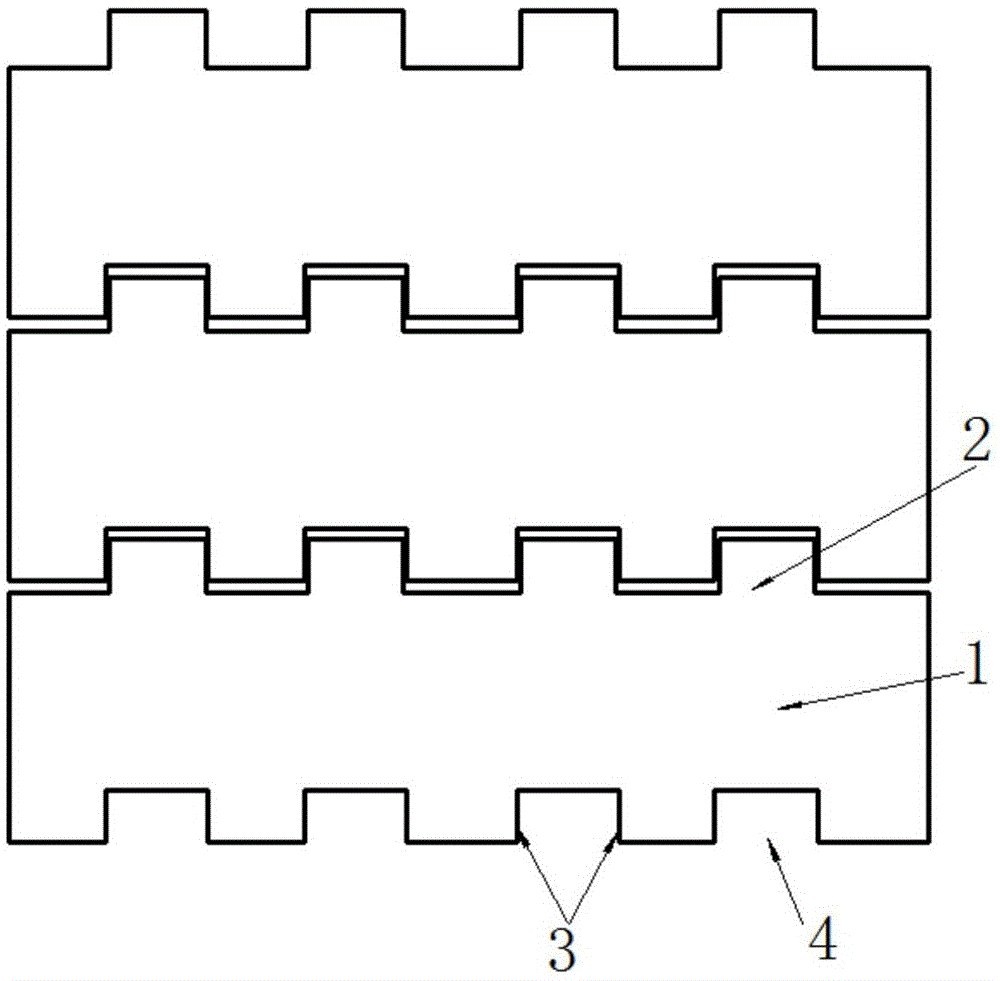

A light crawler lateral positioning structure

ActiveCN103991485BIncrease lateral rigidityImprove walking abilityEndless track vehiclesEngineeringElectrical and Electronics engineering

The invention relates to a transverse positioning structure of a light caterpillar band. The transverse positioning structure mainly comprises three or more positioning protrusions arranged on the two sides of caterpillar band segments in a staggered mode, wherein each positioning protrusion is cylindrical or in the shape of a round tube, stay rope holes used for stay ropes to pass through are formed in the positioning protrusions in the radial direction, and the two end faces of each positioning protrusion serve as positioning faces; a positioning groove is formed between every two adjacent positioning protrusions; after every two caterpillar band segments are combined, the positioning protrusions on one caterpillar band segment are embedded into the positioning grooves in the other caterpillar band segment so as to form complementation; after the two caterpillar band segments are combined, the positioning faces of one caterpillar band segment make contact with the positioning faces of the other caterpillar band segment, and the transverse positions of the caterpillar band segments are limited. The transverse positioning structure of the light caterpillar band has the advantages that the transverse displacement between every two adjacent caterpillar band segments can be limited to the greatest extent, transverse rigidity of the light caterpillar band is improved, the caterpillar band cannot easily fall off in work, and the overall traveling performance of the light caterpillar band is improved.

Owner:杨存俭

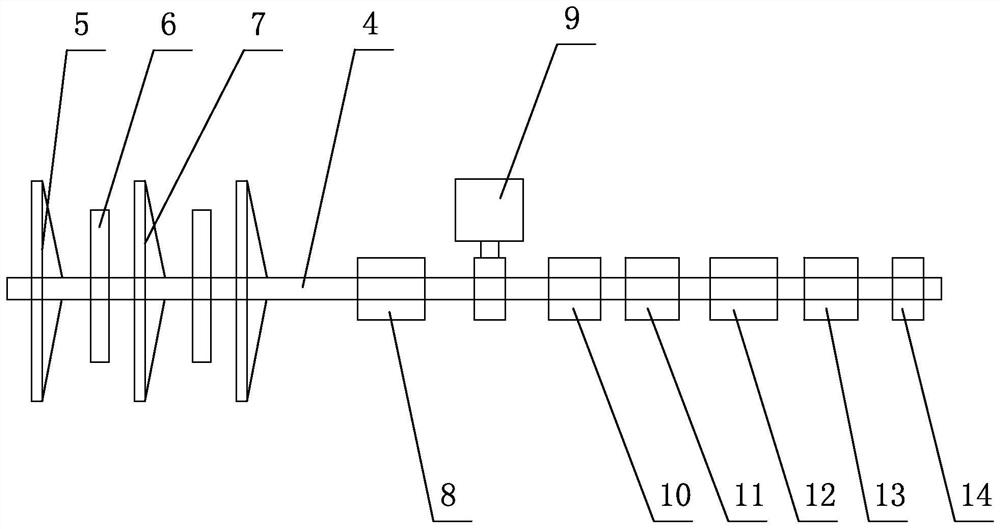

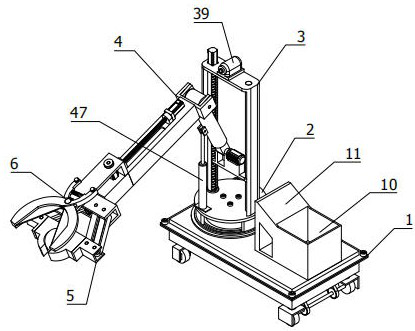

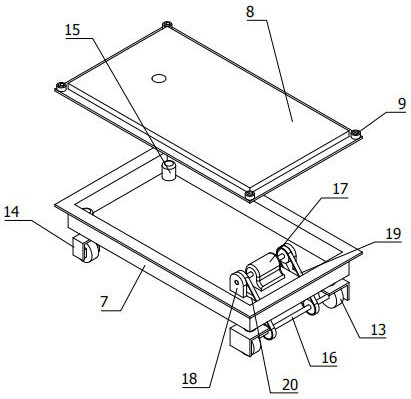

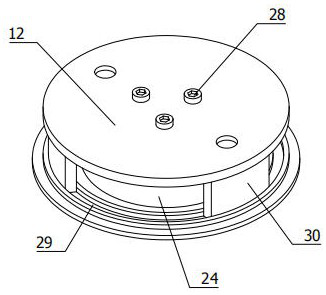

A robot for apple picking

The present invention relates to the field of agricultural robots, in particular to an apple picking robot, which includes a robot housing, a rotating assembly, a lifting assembly, a movable assembly, a grabbing assembly and a cutting assembly. The robot housing includes a base and a top cover. And the four sides between the base and the top cover are respectively fixed by a bolt, the rotating assembly is arranged on the top side of the top cover, the lifting assembly is arranged on the top of the rotating assembly, the movable assembly is arranged on the lifting assembly, and the grabbing assembly is arranged on the movable assembly The end of the cutting assembly is set above the grabbing assembly, a drop box is provided on the top of the top cover and beside the rotating assembly, and a buffer slideway is also provided on the dropping box to prevent apples from being damaged. The rotating assembly includes With a turntable and a gear drive mechanism, the invention solves the problems of large manpower and low picking efficiency for apple picking, improves apple picking efficiency, and reduces manpower labor.

Owner:芜湖挺优机电技术有限公司

High-strength environment-friendly scaffold pedal and preparation method thereof

PendingCN112778786AImprove bindingImproved thermal stability and weather resistanceChemistryPolyamide

The invention discloses a high-strength environment-friendly scaffold pedal and a preparation method thereof, and relates to the technical field of building board production. The high-strength environment-friendly scaffold pedal disclosed by the invention is prepared from polyvinyl chloride, modified plant fibers, polyamide resin, butadiene-styrene copolymer emulsion, metakaolin, silica fume, hexamethylphosphoramide, an ultraviolet light absorber, a heat stabilizer and a lubricant through the steps of PVC-bs-PA blend preparation, blending, granulation and the like. The modified plant fibers are prepared by carrying out surface modification on plant fibers under the action of diacetone alcohol and a silane coupling agent. According to the high-strength environment-friendly scaffold pedal, the raw materials are easy to obtain, the preparation process is simple and easy to operate, the cost is low, the high-strength environment-friendly scaffold pedal has excellent mechanical strength, impact resistance, flame retardance, wear resistance, corrosion resistance and weather resistance, and the service life of the scaffold pedal is prolonged.

Owner:湖南万力工程科技有限公司

A kind of preparation method of Roman cloth

Owner:绍兴柯桥杰坝针纺科技有限公司

Corn thresher

InactiveCN107258242AFine threshingThresher, on the one hand, the design of the present invention is fine as a wholeThreshersEngineeringThreshing

The invention belongs to the technical field of agricultural machinery equipment and provides a corn thresher which comprises a threshing box body. The upper portion of the threshing box body is provided with a feeding port, the lower portion of the threshing box body is provided with a discharging port, the outer surface of the threshing box body is provided with an on-off key, a driving device is arranged in the threshing box body, the four corners of the lower surface of the threshing box body each are provided with a supporting leg, and the on-off key is electrically connected with the driving device. A screening device is correspondingly arranged below a threshing device and is of a tank body structure, the bottom surface of the tank body is provided with screen holes, an axial flow fan is arranged at one end of the tank body in the length direction, the other end of the tank body is open and communicates with the wall of the threshing box body, and a storage bag is arranged at the position of the outside of the threshing box body communicating with the tank body, a storage and transportation device is arranged below the discharging port and comprises a storage tank, rollers arranged at the four corners of the bottom surface of the storage tank and a weight sensor, and the weight sensor is connected with a computer. The corn thresher is reasonable in design, simple in structure, convenient to use and high in working efficiency and saves plenty of labor.

Owner:河南颇文商贸有限公司

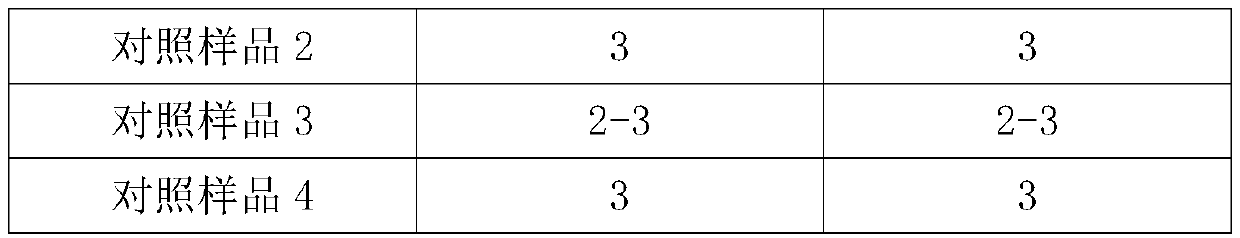

Preparation method of cool polyester washed cloth and special device used in method

PendingCN113373573ANot easy to fadeImprove breathabilityWoven fabricsSpinning solutions preparationPolyesterPolymer science

The invention discloses a preparation method of cool polyester washed cloth and a special device used in the method, and relates to the technical field of washed cloth preparation. The preparation method comprises the steps of S1, raw material mixing, S2, silk making, S3, thread making, S4, weaving, and S5, finishing and dyeing. Cool silk and polyamide are woven, and a woven gray fabric is desized and washed to obtain the washed cloth with the cool feeling; the cool polyester washed cloth has the advantages of cool feeling, washing resistance, difficulty in fading, good air permeability, high fiber strength, soft hand feeling, difficulty in silk falling, good moisture conductivity and elasticity; and a blending machine used in preparation of the cool polyester washed cloth comprises a mixing bin, a base, raw material bins, a stirring shaft and a shaft seat; and the blending machine is provided with seven raw material bins corresponding to seven raw materials in the preparation method of the cool polyester washed cloth, the material mixing effect is good, and the operation is easy and convenient.

Owner:宜兴市伟业印染有限公司

Lace hair weft and production process thereof

The invention discloses a lace hair weft and a production process thereof, and particularly relates to the field of hair products. The lace hair weft comprises a hair; a hair root belt is arranged atone end of the hair; the hair is connected with the hair root belt in a sewed manner; the hair root belt is made of lace; a colored tape is arranged at one end of the hair root belt; and the hair rootbelt is connected with the colored tape in a sewed manner through a sewing thread. The production process comprises the following steps of oppositely placing the hair root belt and a base belt; combining pieces; staggering the hair root belt and the base belt by 1.5cm; a head needle is applied for sewing; enabling the sewing thread to pass through the hair root belt made of the lace fabric and the base belt; and finally connecting and fixing the lace hair weft and a hair weft fixing piece through an annular thread. According to the lace hair weft and the production process, a connecting ringis used as an anchor point of the lace hair weft and the hair weft fixing piece, so that the fixing effect is good, and the service life is long; and the annular thread and the sewing thread are completely separated, and the hair root belt and the base belt are staggered by 1.5cm, so that the damage to the hair weft pieces in the head needle applying process is reduced, the perfect head needle application is achieved, the firmness of the hair is improved, and the service life of the lace hair weft is prolonged.

Owner:蒋泽乾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com