Automatic traveling polishing apparatus of rotor polishing machine tool and application method of automatic traveling polishing apparatus

A technology of automatic walking and polishing mechanism, used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low degree of automation, increased production cost, low polishing accuracy, etc., to reduce production cost and reduce total weight , the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

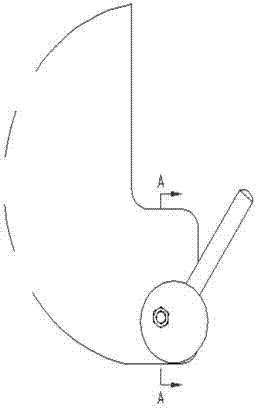

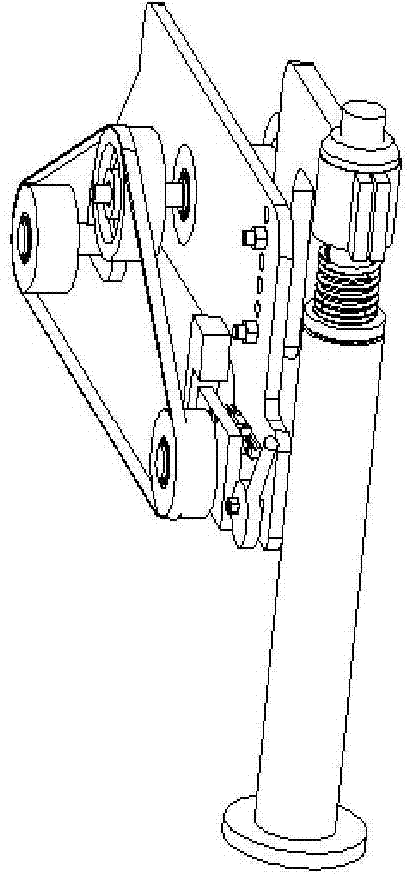

[0035] A self-propelled polishing equipment for a screw drill rotor polishing machine tool of the present invention includes a polishing mechanism. The polishing mechanism includes a column component 1 , a movable arm 2 and a main body cover 4 .

[0036] The column composition 1 includes a column shaft 16, a column tube 17 and a base plate 18 connected in sequence, preferably welded, as attached Figure 5 , the column tube 17 is a hollow structure, the purpose is to reduce the weight of the column composition, to facilitate the operation of the automatic walking polishing mechanism.

[0037] The compression nut 3, the movable arm 2, and the spring 10 are sequentially sleeved on the column shaft 16 of the column composition 1 from top to bottom; The movable arm 2 is provided with screw holes, and is connected with the main body cover 4 through bolts 15 .

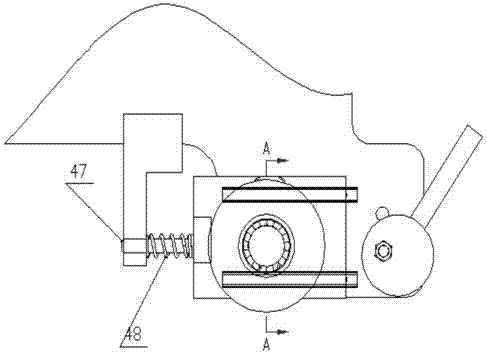

[0038] The main body cover 4 is provided with a driving wheel composition 5, a driven wheel composition 6, and a movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com