Patents

Literature

181results about How to "Reduce overall weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

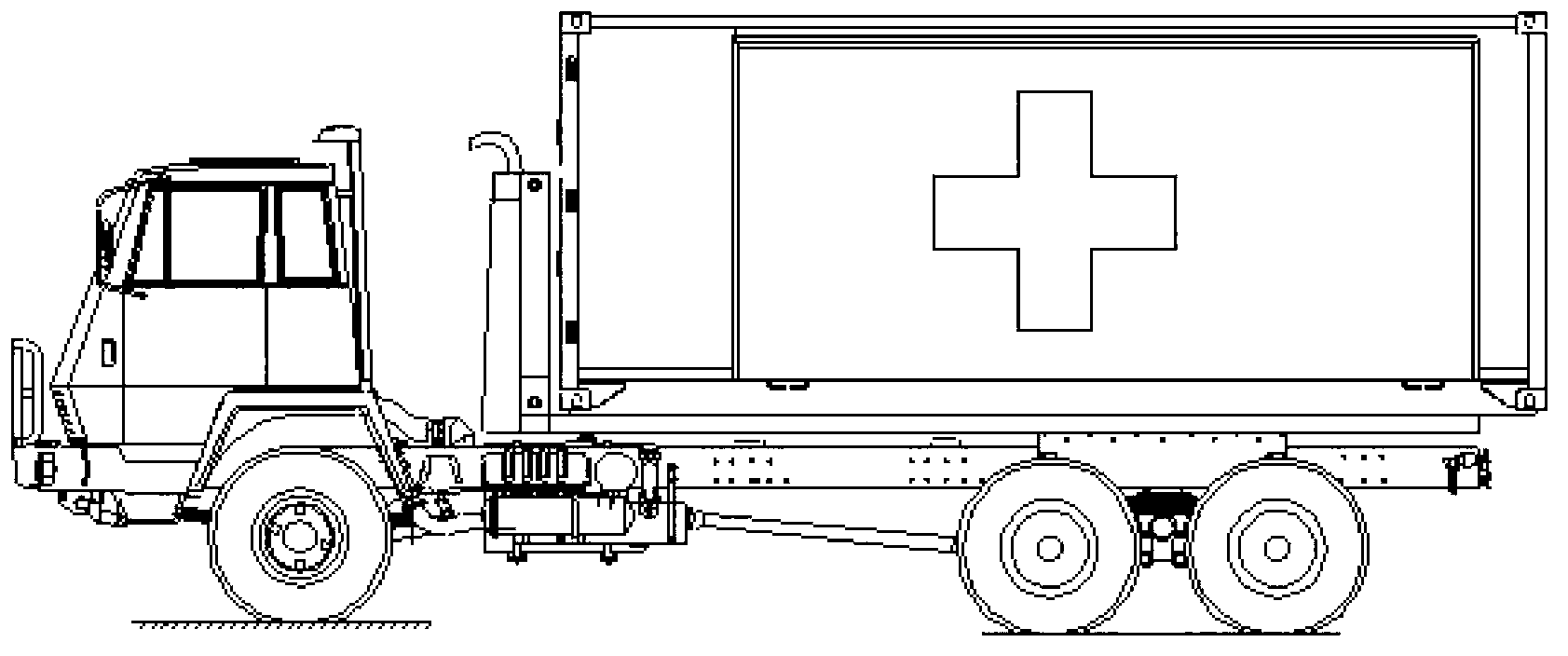

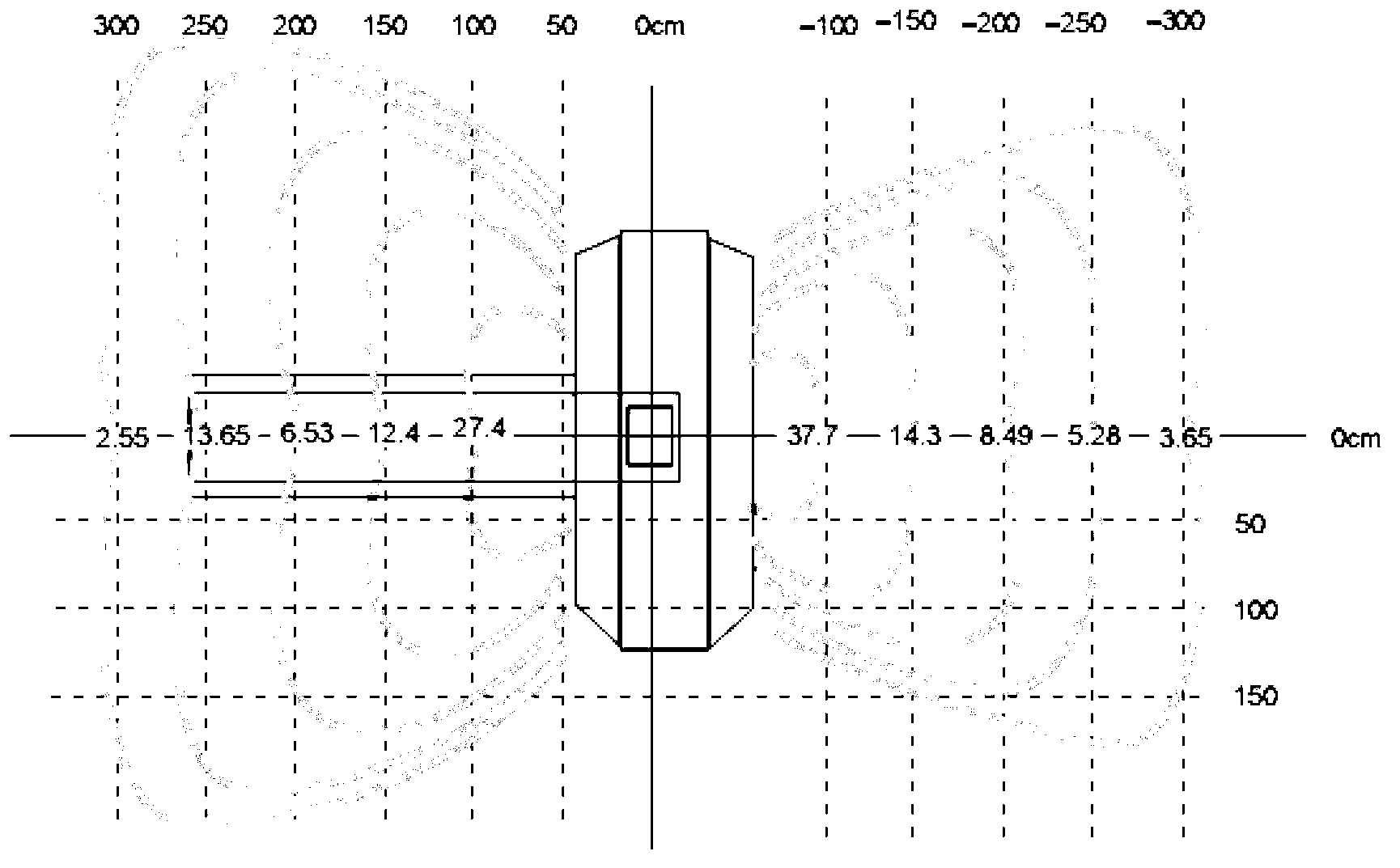

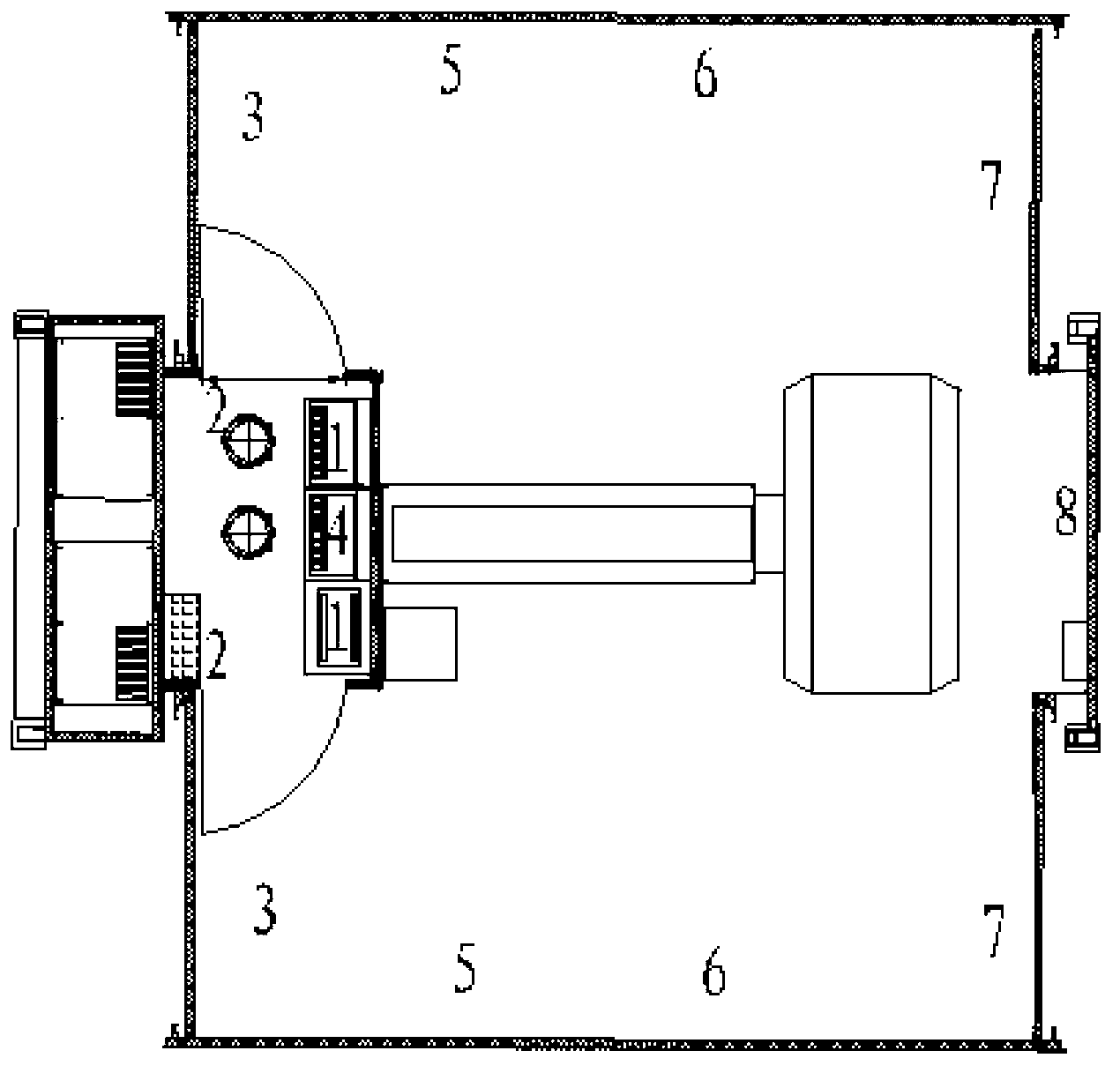

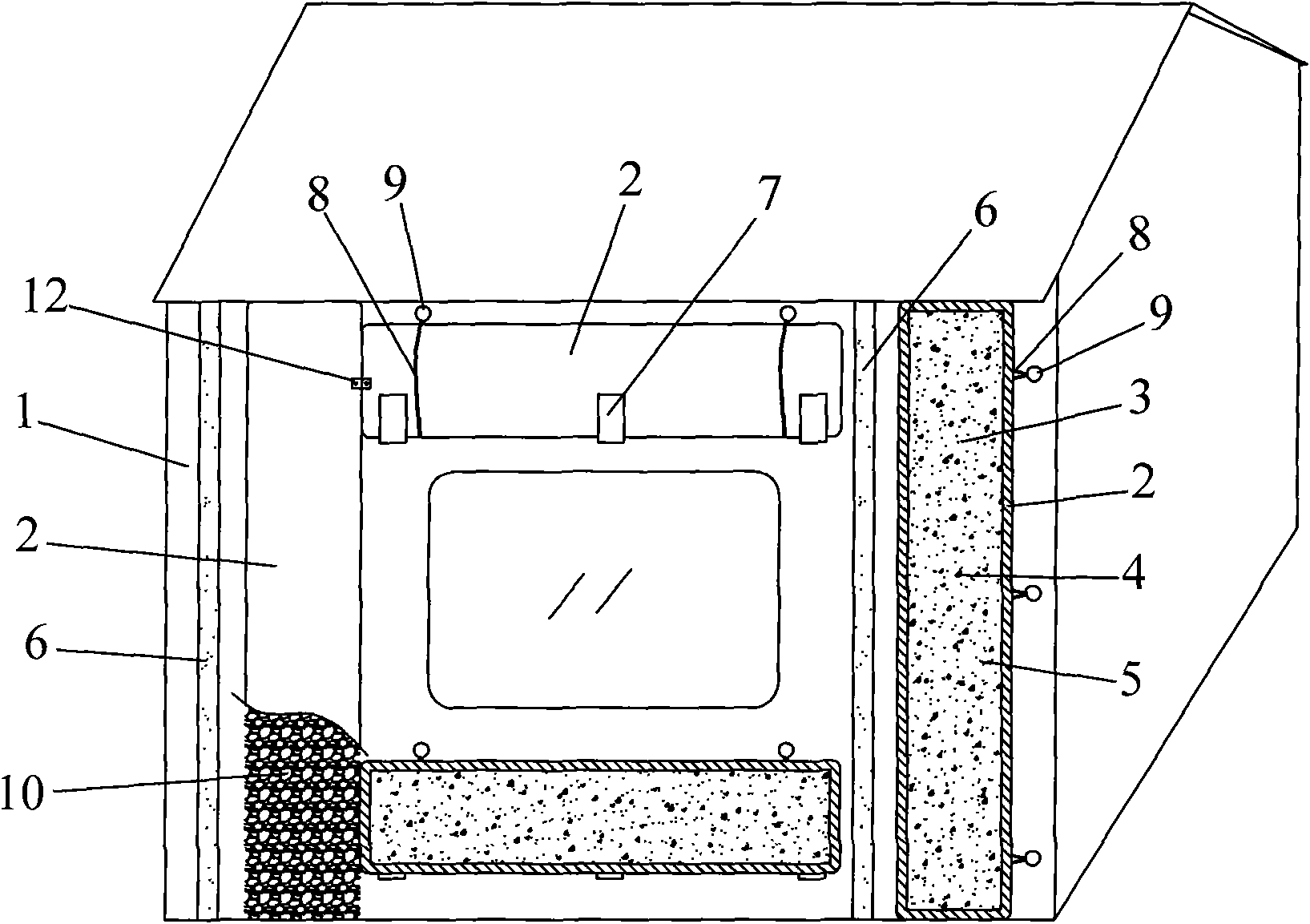

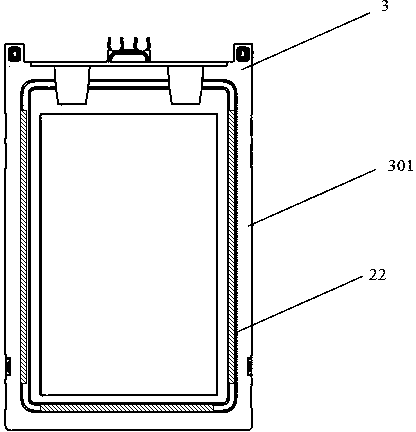

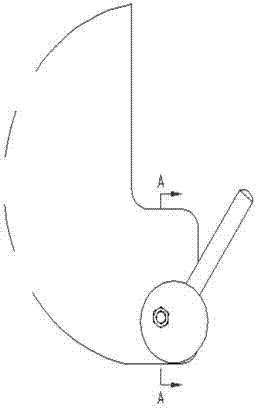

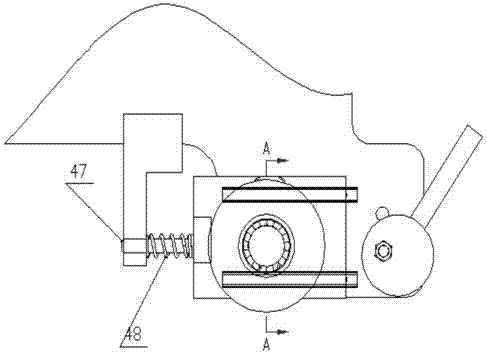

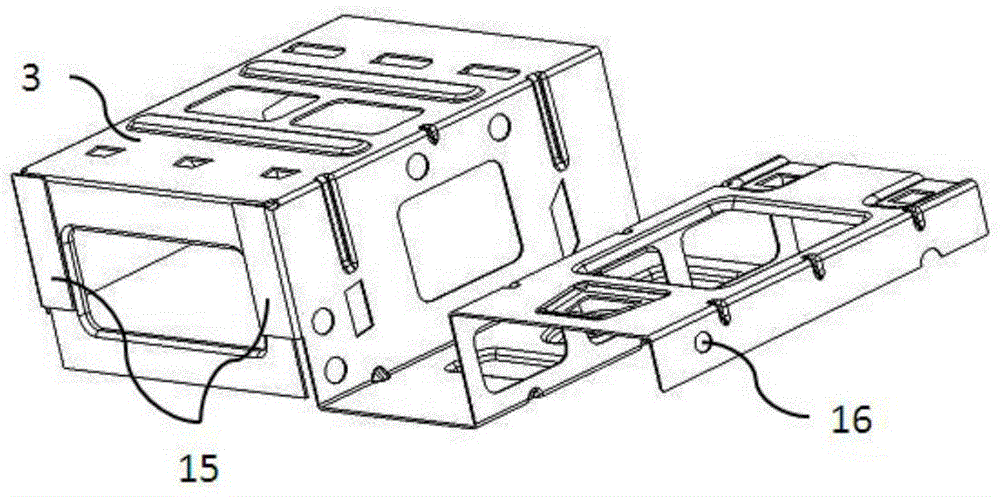

Vehicular shelter with damping system for field environment

ActiveCN103300985AReduce overall weightHigh medical service capacityBreathing protectionTreatment roomsTomographyBuilt environment

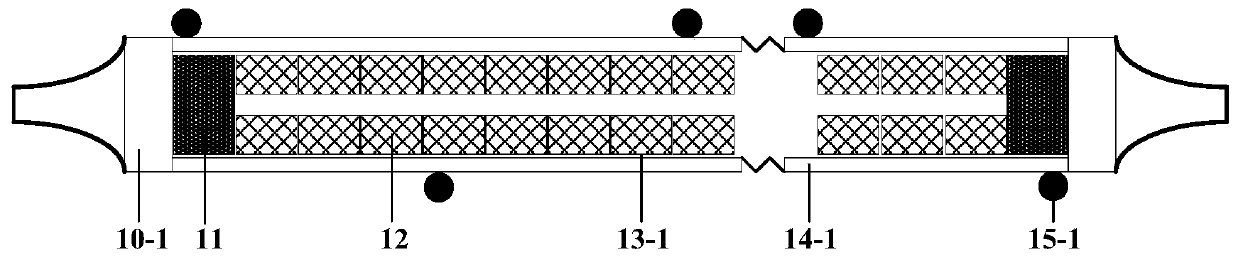

Disclosed is a vehicular shelter with a damping system for a field environment. A conformal radiation grading protection system is arranged on the side wall of the vehicular shelter and comprises a plurality of lead plates with different thicknesses, a patient table of a CT (computerized tomography) device is fixed onto a shelter bottom plate, the damping system comprises a force bearing support and a metal damper, a scanning frame of the CT device is mounted on the force bearing support, the force bearing support is separably fixed onto the shelter bottom plate through the metal damper, a balancing adjustor is further arranged on the scanning frame of the CT device and is separated from the shelter bottom plate in a conveying state, and the metal damper is loaded. In an operating state, the scanning frame of the CT device is rigidly connected with the shelter bottom plate through the balancing adjustor, and the metal damper is unloaded. The overall weight of the vehicular shelter is greatly reduced on the premise of safety radiation protection, medical service capacity is high, maneuverability is fine, cost is reduced, and the vehicular shelter has fine damping effects.

Owner:FIRST HOSPITAL AFFILIATED TO GENERAL HOSPITAL OF PLA +1

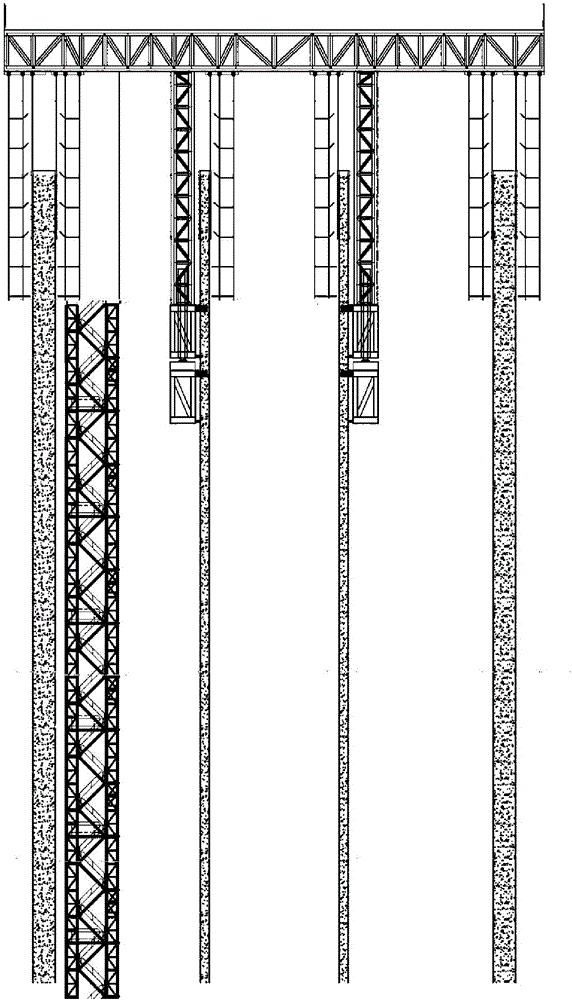

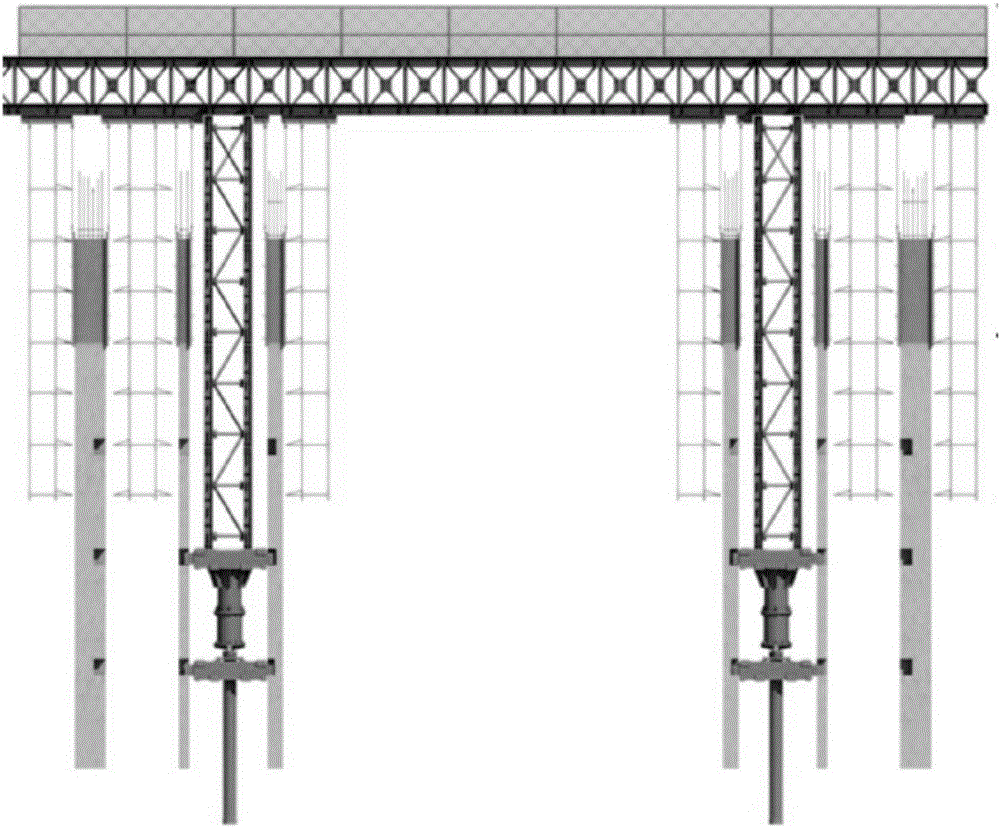

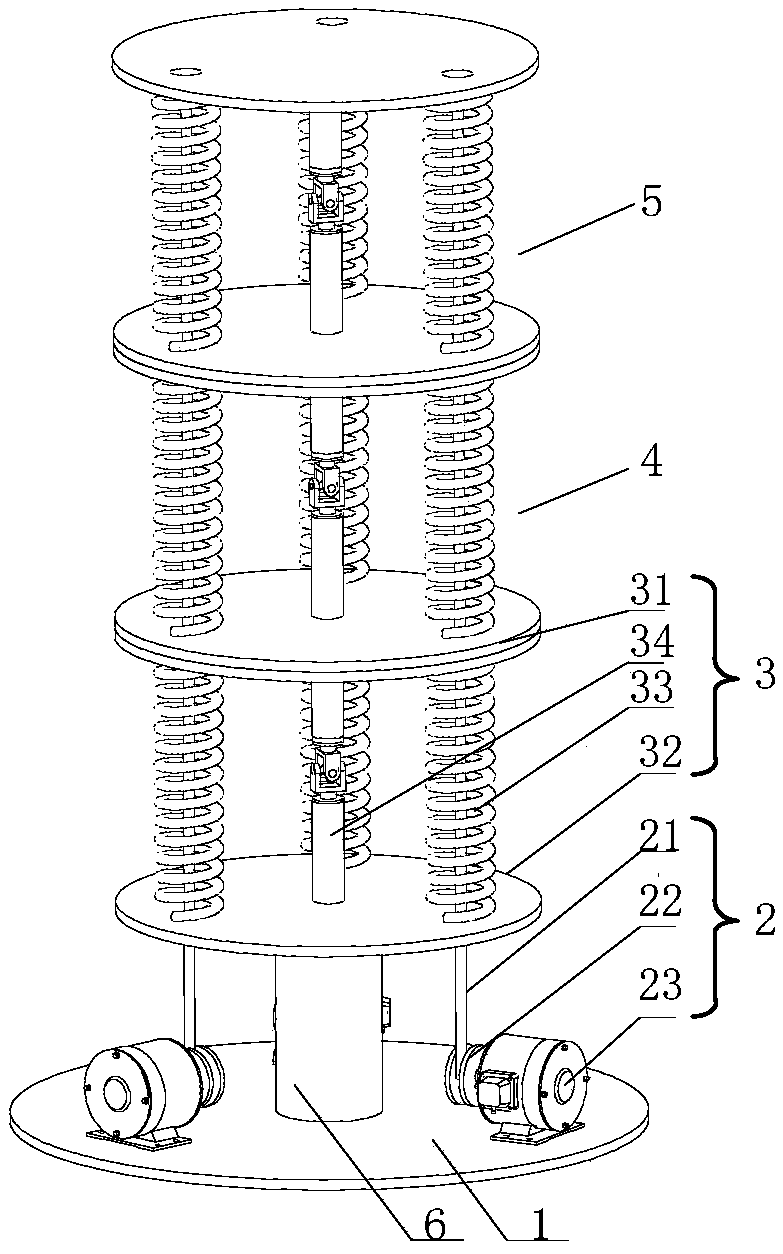

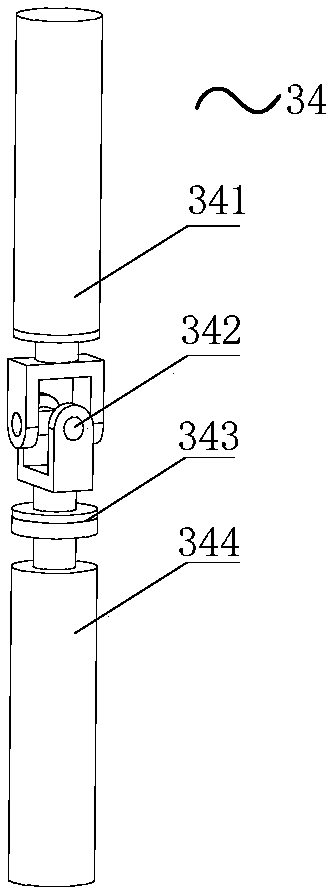

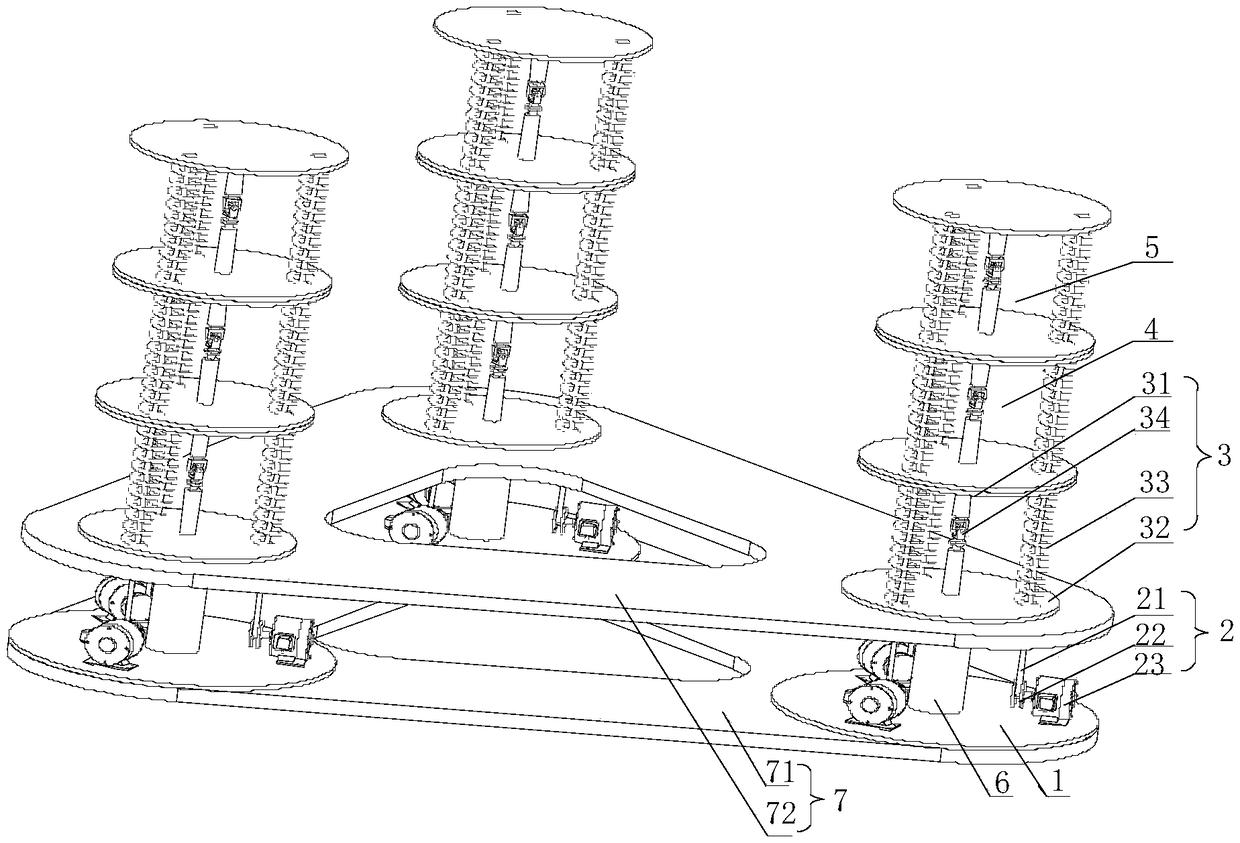

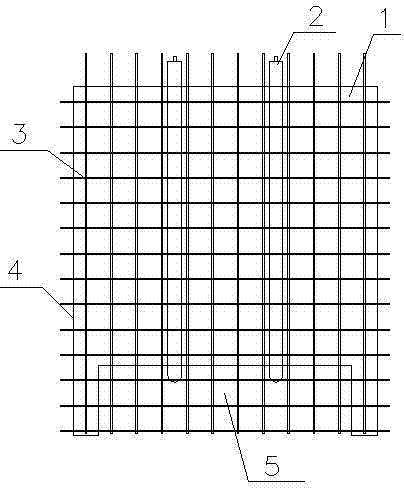

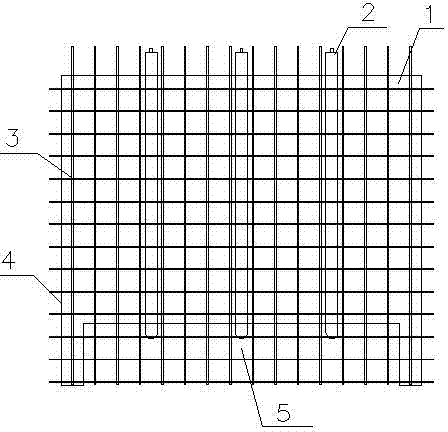

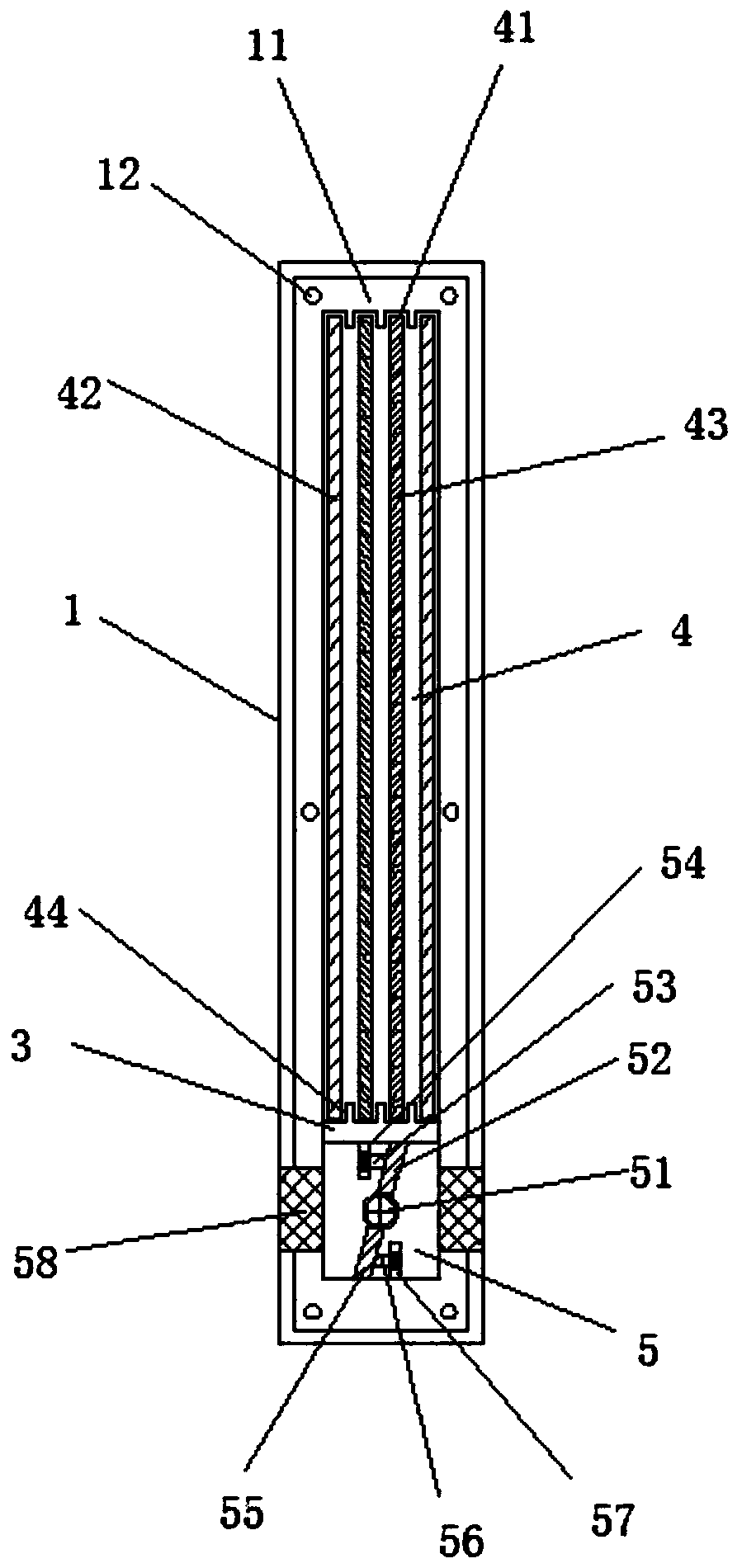

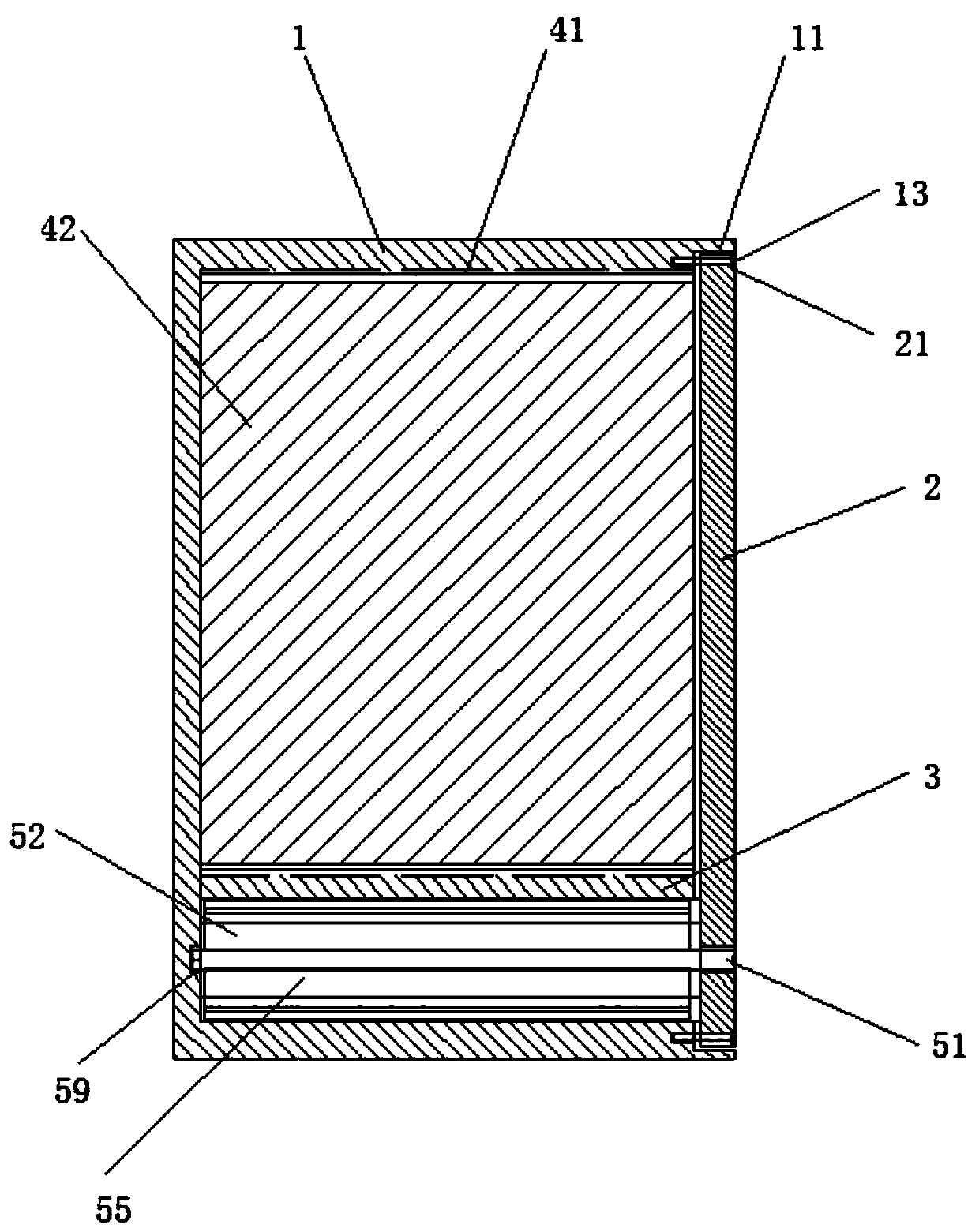

Synchronous construction method for horizontal and vertical structures of super high-rise building

ActiveCN106400951AReduce overall weightReduce the burden onForms/shuttering/falseworksRebarBuilding construction

The invention discloses a synchronous construction method for horizontal and vertical structures of a super high-rise building. According to the synchronous construction method, a hydraulic creeping formwork system is adopted on the outer wall of the super high-rise building, and a jacking platform system is adopted between two building walls on the inner side of the super high-rise building; when being operated at the same time, the two systems can replace a conventional overall jacking construction platform as a construction platform, thereby reducing the overall weight of a construction platform and the burden of a hydraulic jacking system, achieving higher flexibility, and improving the construction speed; as the light-weight jacking platform system is configured, a small-sized oil cylinder can be adopted; accordingly, no horizontal supporting steel beam is needed, oil cylinder climbing can be achieved as long as wall-attached embedded parts are mounted on the building walls, the total height of the construction platform and a supporting frame body can be reduced, the construction gap between the vertical and horizontal structures can be narrowed, and the construction of the horizontal structure can be prevented from being influenced by a hydraulic climbing system; and the jacking platform system adopted on the inner wall of the super high-rise building is prevented from penetrating through the building walls, and the gap between the construction platform and a reinforcing bar colligation operation surface is equal to the height of one floor, thereby achieving convenient reinforcing bar transfer and colligation.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +2

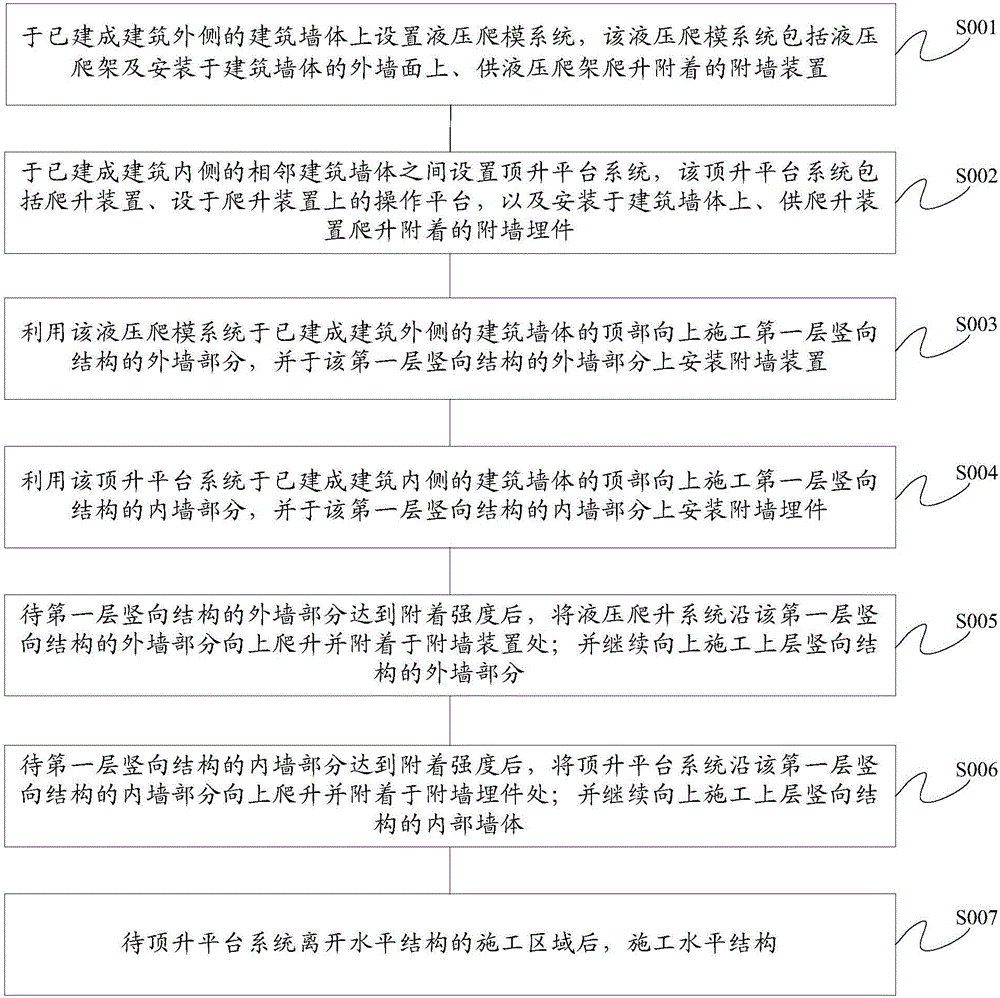

Open grid type gas-cooled space nuclear reactor core

ActiveCN110232979AReduce weightReduce overall weightNuclear energy generationCooling arrangementNuclear reactorElectric energy

The invention discloses an open grid type gas-cooled space nuclear reactor core, belonging to the technical field of nuclear reactors. The reactor core comprises a core activity zone, a core barrel, radial reflection layers and control rods, wherein the core activity zone is located in the core barrel and is composed of a plurality of fuel rods; the radial reflection layers are of a hollow cylindrical structure, are composed of an inner layer and an outer layer, are wrapped around the outer side of the core barrel and have the same height as the core barrel; the fuel rods and the control rodsare distributed in the core activity zone; the fuel rods and the control rods are positioned by upper and lower grid plates and winding wires wound around the jackets of the rods; the interior of eachfuel rod is composed of hollow cylindrical fuel pellets and filled with helium gas; the inner two ends of the fuel rod are provided with axial reflection blocks; and the reactor core and the reflection layers are cooled by a helium-xenon gas mixture. The reactor core of the invention can provide megawatt high-power electric energy for space tasks, and has the advantages of light weight and compact structure.

Owner:XI AN JIAOTONG UNIV

Method and device of virtual space stereo imaging

InactiveCN101650906AReduce overall weightEasy to transportMirrorsAdvertisingStereo imagingVirtual image

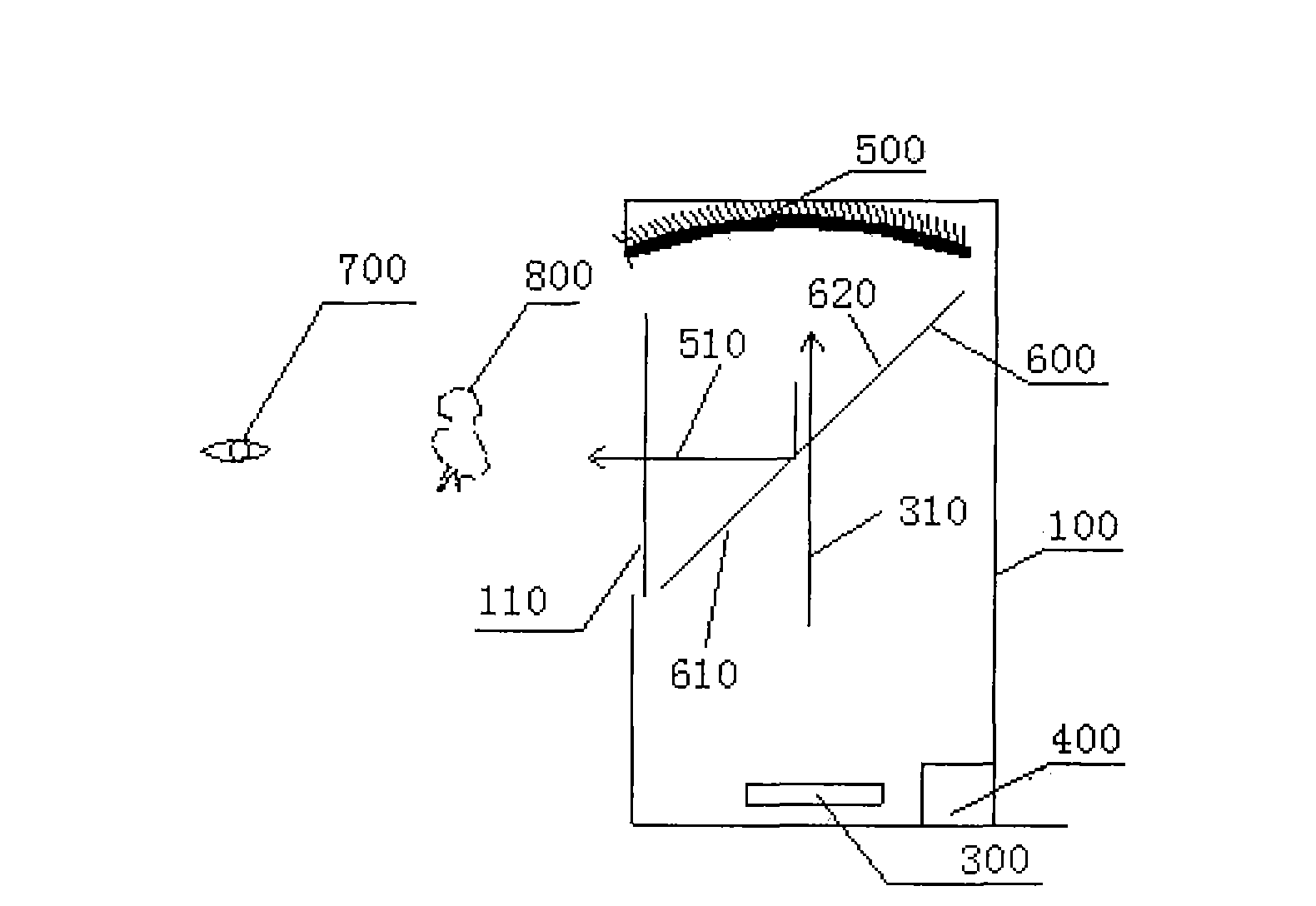

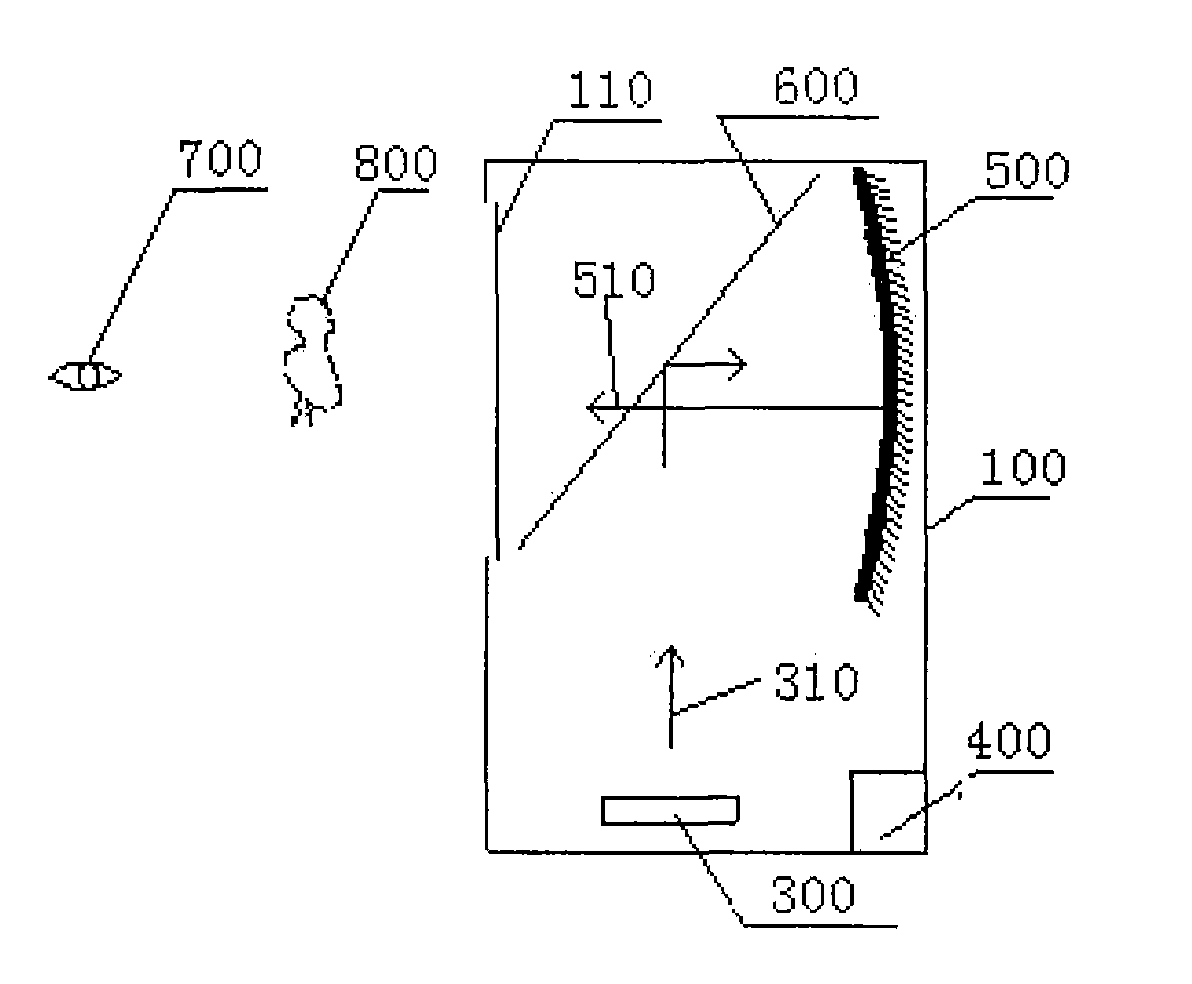

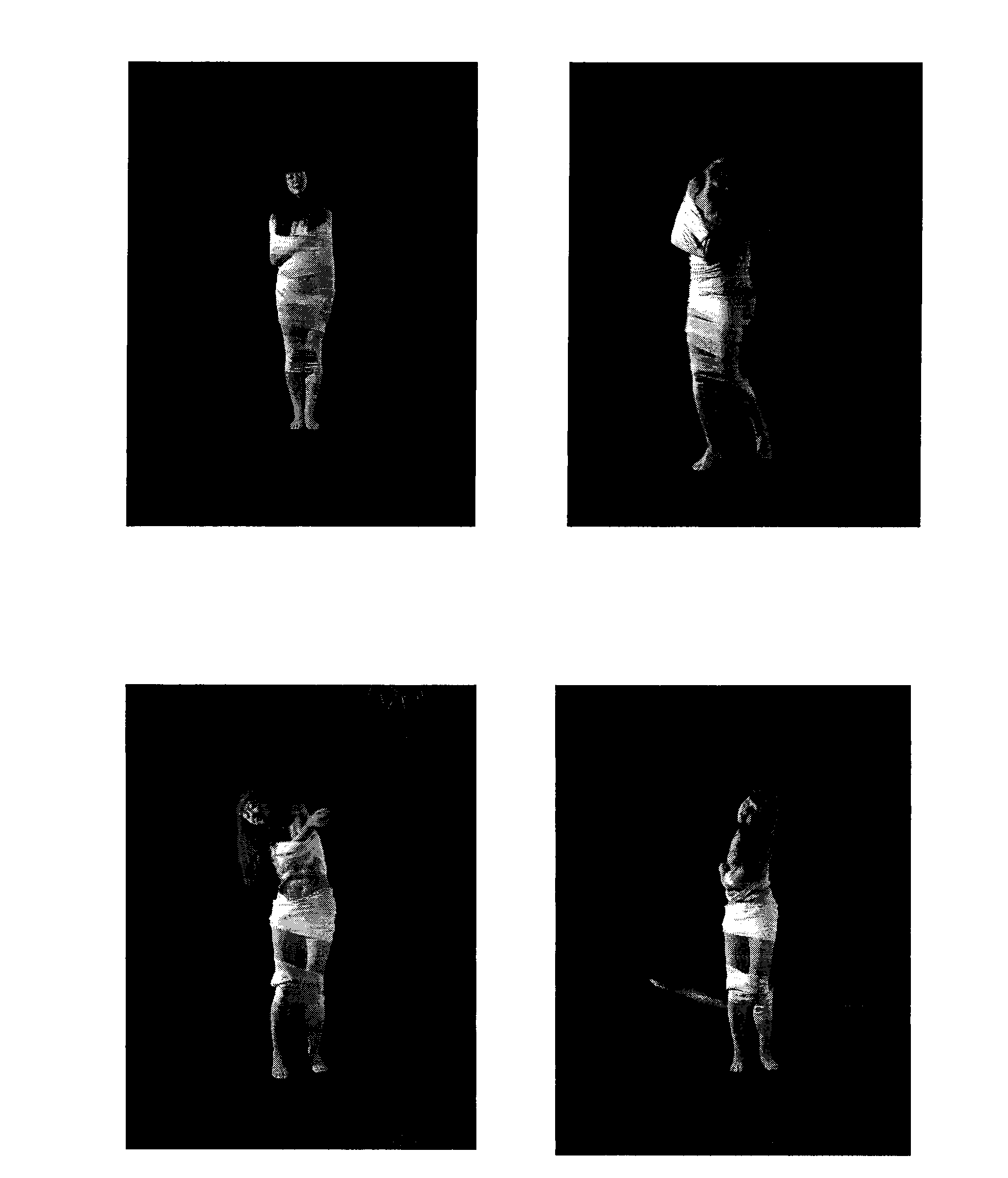

The invention discloses a method of virtual space stereo imaging, comprising the following steps: 1. displaying a three-dimensional image by a display device arranged outside the focus of a sphericalconcave mirror and within the sphere center thereof; 2. irradiating the three-dimensional image into the spherical concave mirror by a beam splitter; and 3. reflecting the three-dimensional image outby the spherical concave mirror so as to form a dangling three-dimensional image in the space of people visual angle. The invention also discloses a device of realizing virtual space stereo imaging. The invention combines computer technology, three-dimensional image manufacture, modelling art and optical imaging technology as a whole, and can show a lifelike virtual image suspending in the air andhaving stereoscopic impression right ahead the device; and the visual image can be seen but can not be touched and provides new, attractive and intriguing visual enjoyment.

Owner:上海杰派展示有限公司

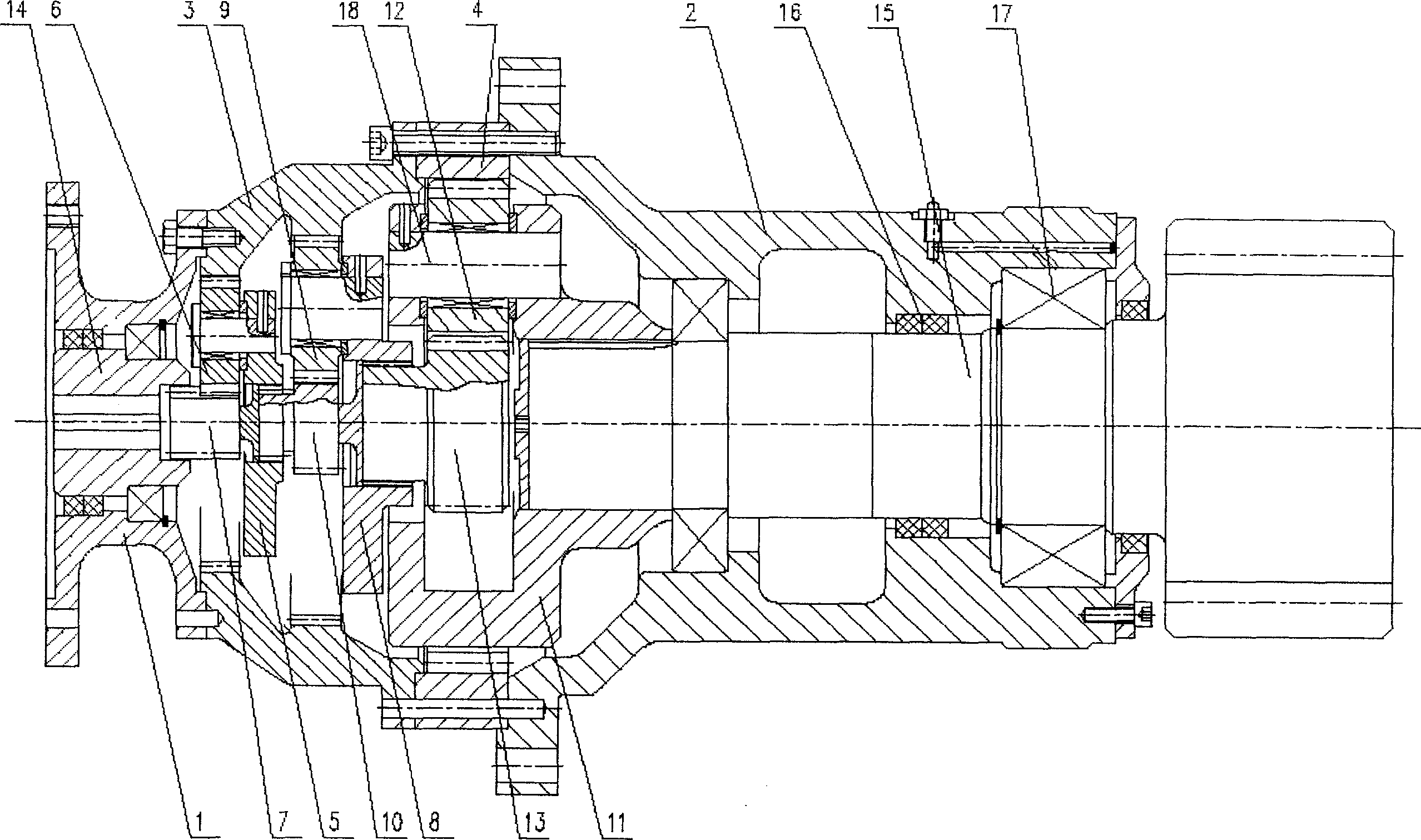

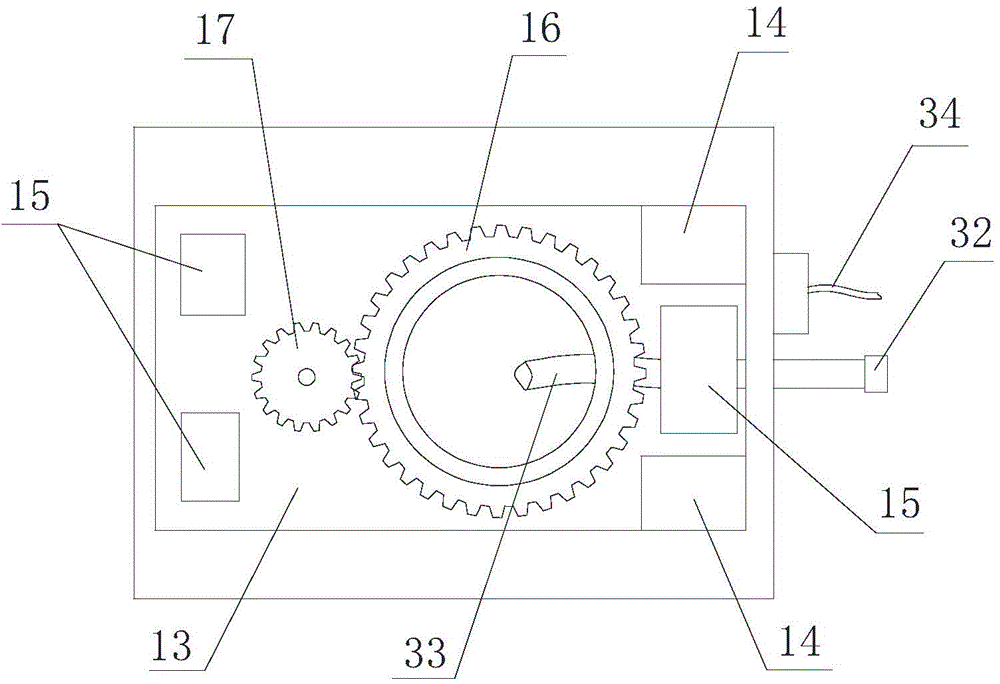

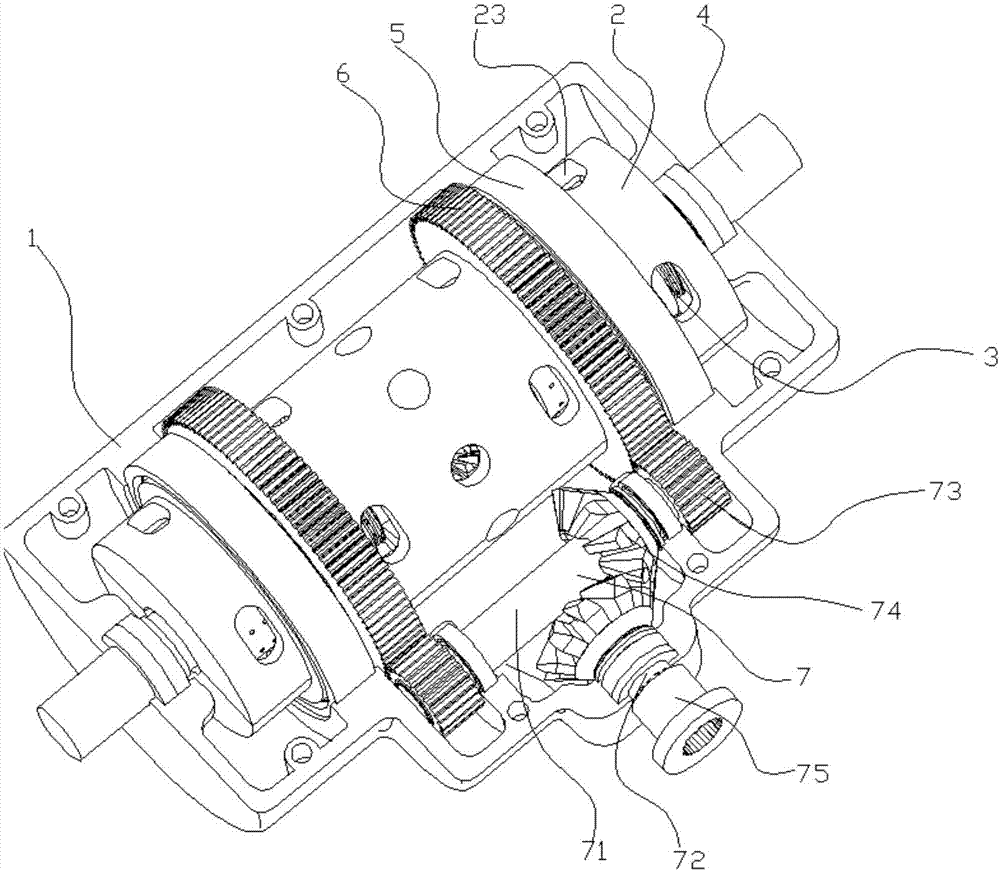

Variable propeller gearbox of wind power generator

ActiveCN1587682ACompact structureReduce overall weightToothed gearingsWind motor combinationsWind drivenPropeller

The invention relates to a kind of oar-exchanging bear box of wind-driven generator. The box body includes flange, gear circle, and the back box body. Between the flange and the back box body there are the first-grade and the second-grade inner gear cluster, and the third-grade inner gear circle, input shaft, planet frames and solar wheels at all levels, output gear shaft axis, the input shaft is connected to the first-grade solar wheel, the planet frame at all levels are connected to the next grade solar wheel, the third-grade planet frame is connected with the output gear shaft, the output gear shaft is fixed on the back box body by the bearing. Each-grade planet frame has planet wheel, between the input shaft and flange, between output gear shaft and back box body, there is oil-sealing. Advantages of the invention: take the first and second inner gear circle cluster as a component and make the structure compact; take the inner gear circle cluster and the inner gear circles at all levels, as a part of the box, reduce the weight, and it is easy to process, convenient to dismantle and fix. The planet wheel usnig needle bearing, can increase the bearng capacity, and reduce installing room.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

Spatial greening structure of wall surface

The invention relates to a spatial greening structure of a wall surface. The wall surface is fixedly provided with a plurality of breathable and non-watertight object containing bags vertically or transversely, plant growth material is filled in the object containing bags, then the object containing bags containing the plant growth material are fixedly arranged on the wall surface directly, and people can implant plants or spray plant seeds or the like on the object containing bags according to requirements. The plant growth material in the object containing bags supplies nutrition to the plants, enables the plants to grow in the object containing bags, so that the purpose of greening the wall surface is achieved, and the effect on the heat insulation of the wall surface and the like are achieved. The invention has simple structure, low cost and strong practicality and is favorable to market popularization.

Owner:张宇顺

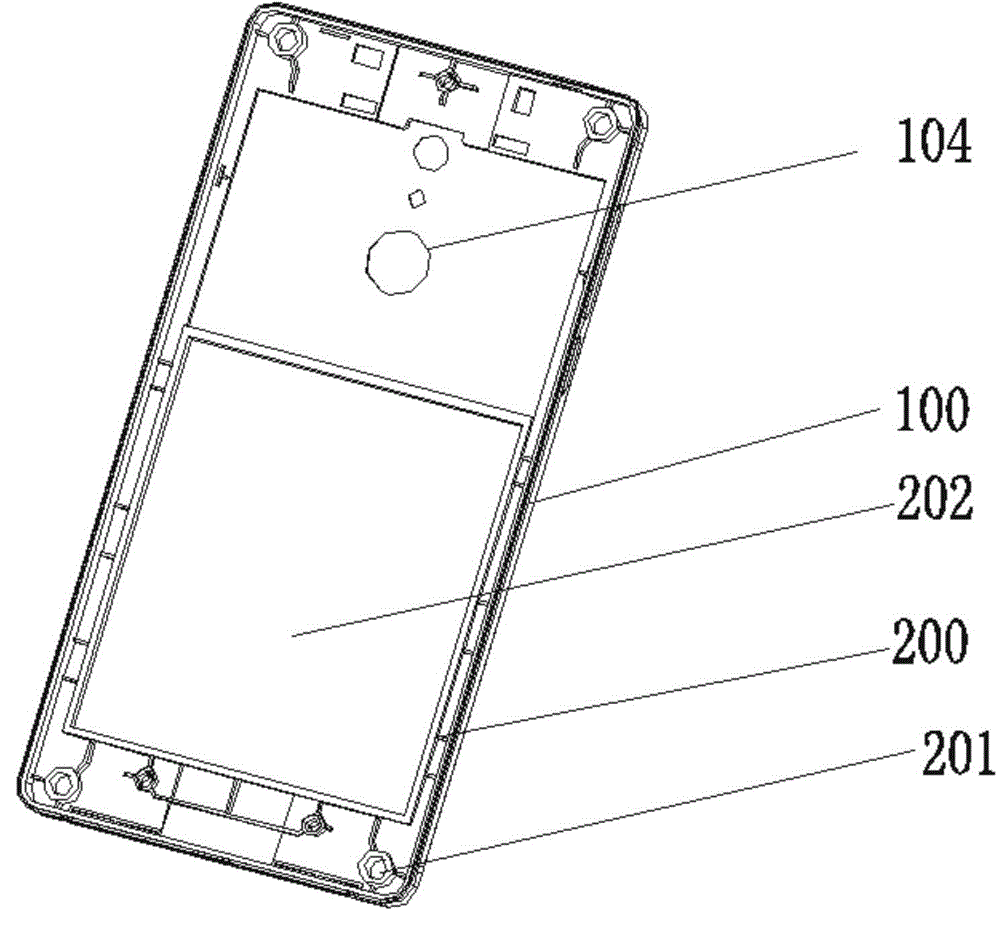

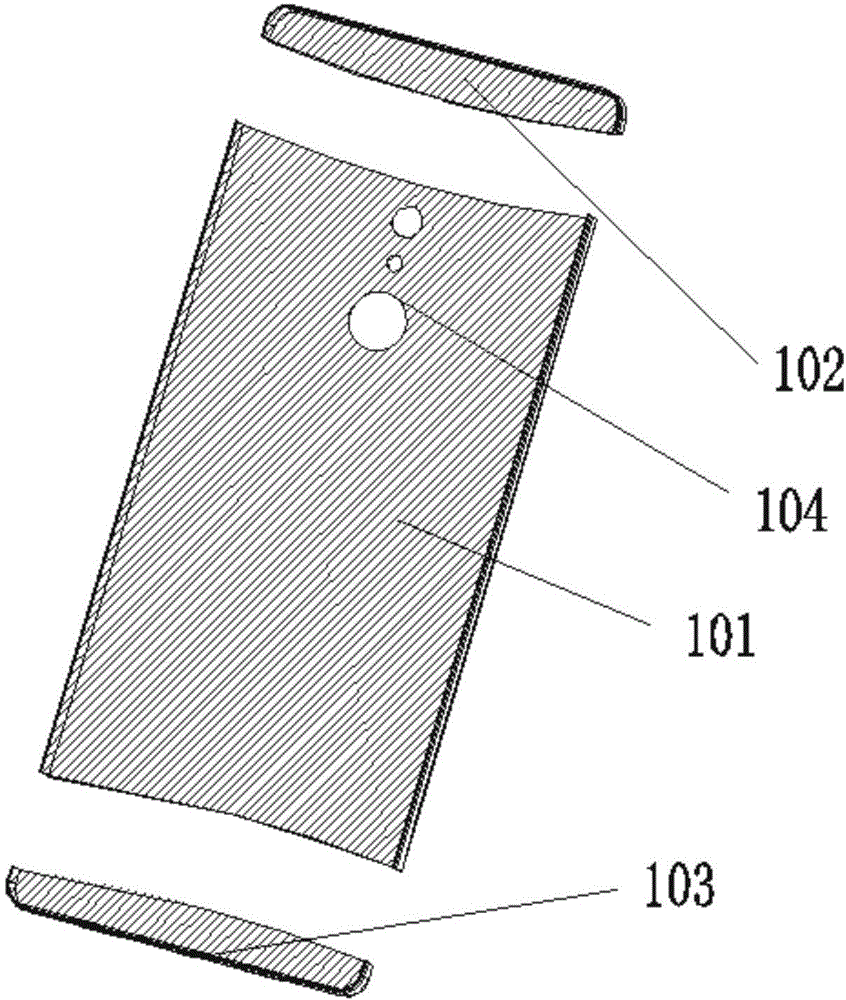

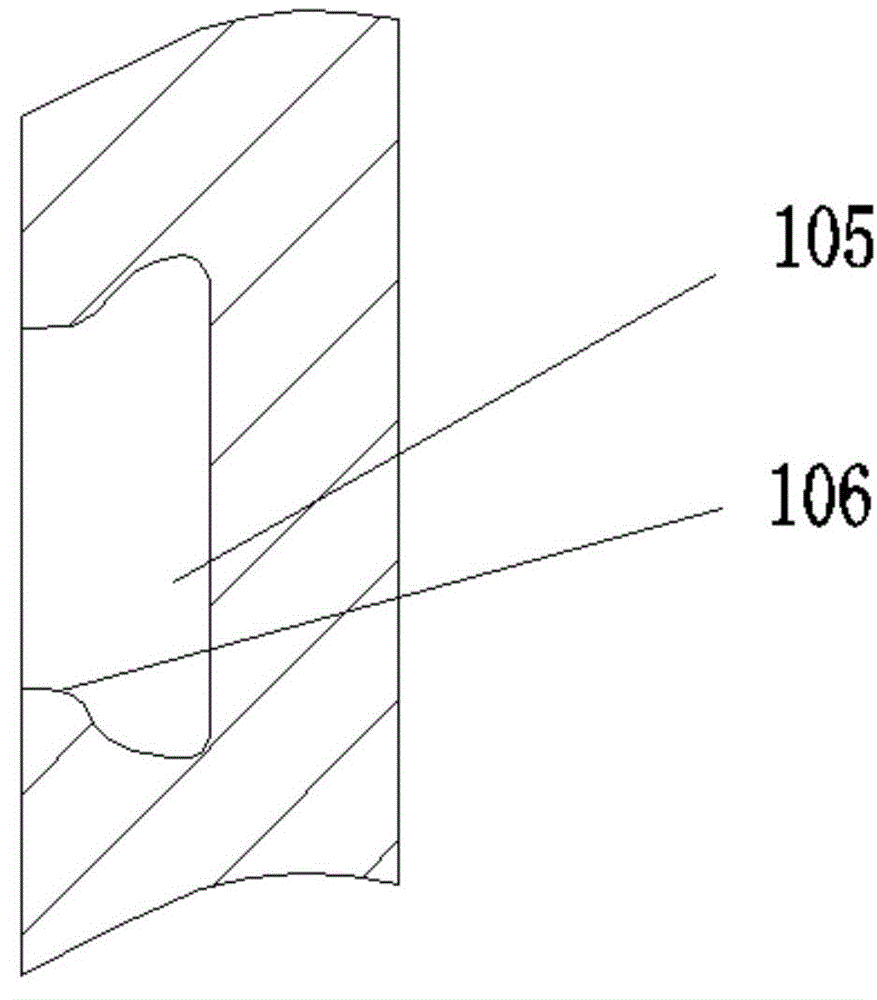

Metal rear cover of mobile electronic product and manufacturing technology thereof

InactiveCN104811513AReduce overall weightFewer machining stepsTelephone set constructionsMobile electronicsManufacturing engineering

The invention relates to the technical field of mobile electronic product shell manufacturing, in particular to a manufacturing technology of a metal rear cover of a mobile electronic product. The manufacturing technology comprises the following steps that a material strip is etched and then is cut to be in the needed length; punching and forming are conducted on the cut material strip to form a rear cover plate, an upper border and a lower border, and then CNC rough machining is conducted on the rear cover plate, the upper border and the lower border; the metal rear cover of the mobile electronic product is formed through injection molding secondary fixation, and a rear cover inner plate is formed through injection molding; the metal rear cover, processed through injection molding, of the mobile electronic product is machined; post-processing is conducted on the metal rear cover of the mobile electronic product. According to the manufacturing technology of the metal rear cover of the mobile electronic product, the number of working procedures of machining can be reduced, or the duration of machining can be shortened, and the appearance of the rear cover of the mobile electronic product can be more attractive. Meanwhile, the invention provides the metal rear cover of the mobile electronic product. The hardness of the metal rear cover of the mobile electronic product is enhanced, and the metal rear cover of the mobile electronic product cannot be easily broken, and is light in weight.

Owner:AOJIE HARDWARE JIANGSU

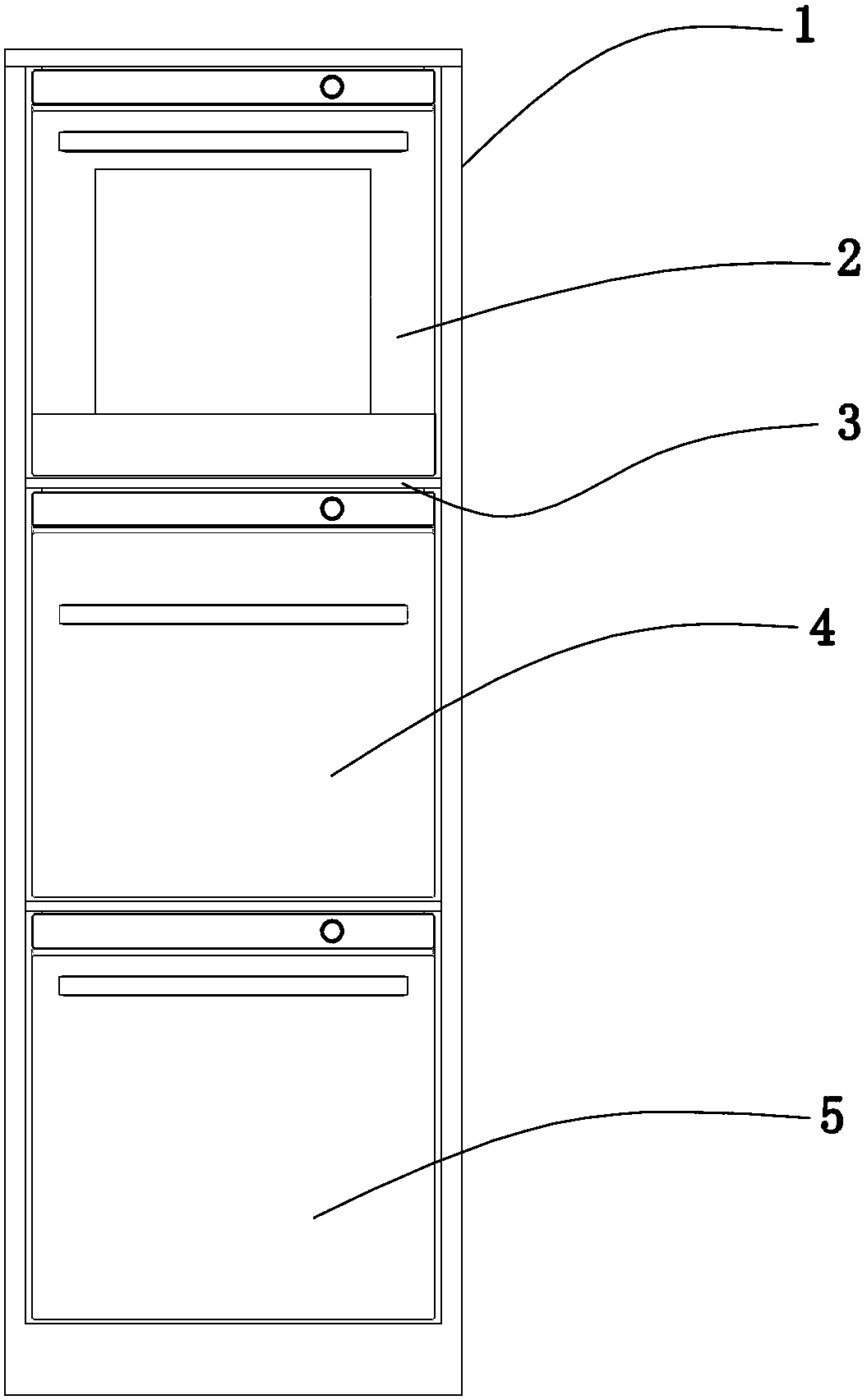

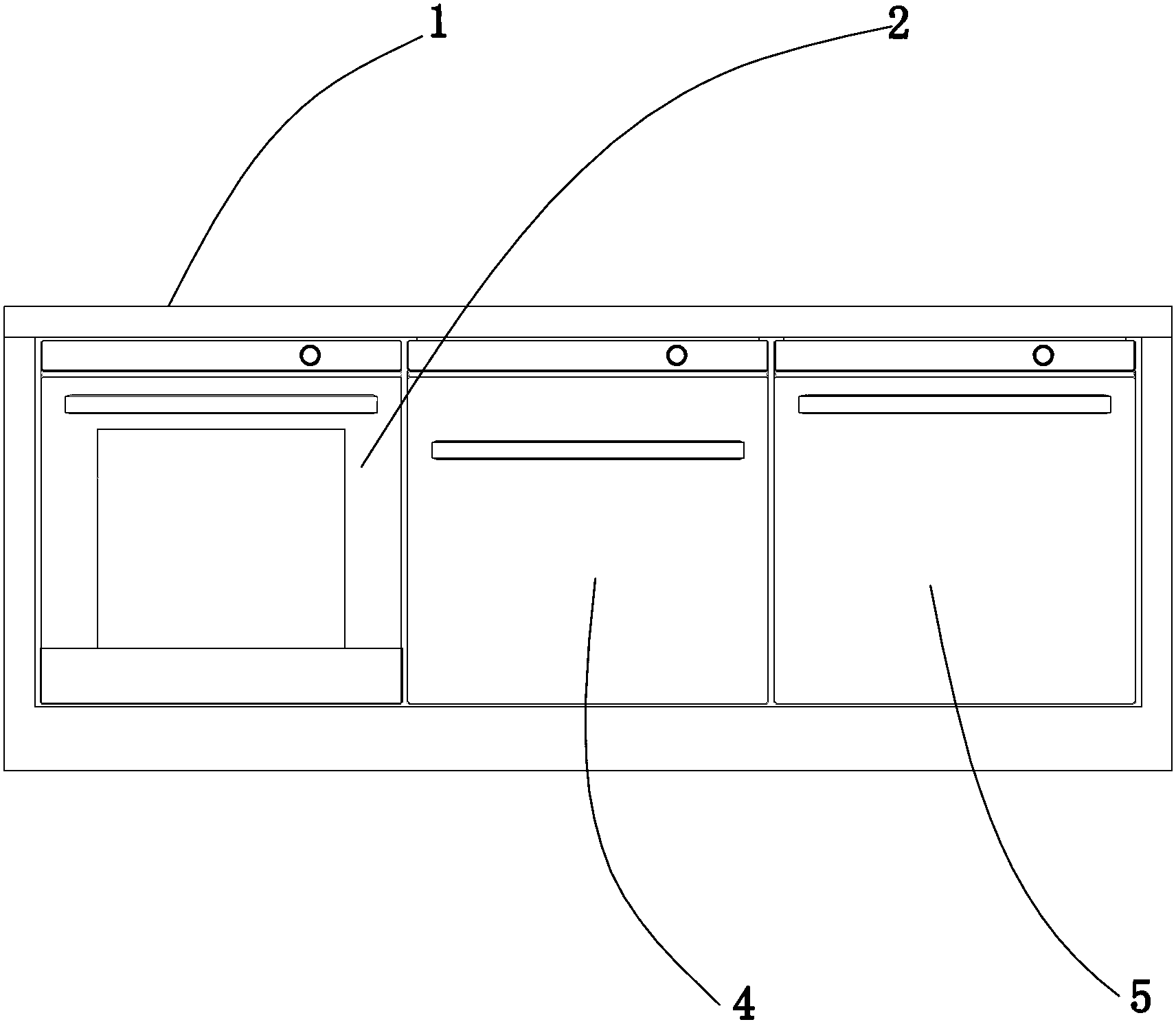

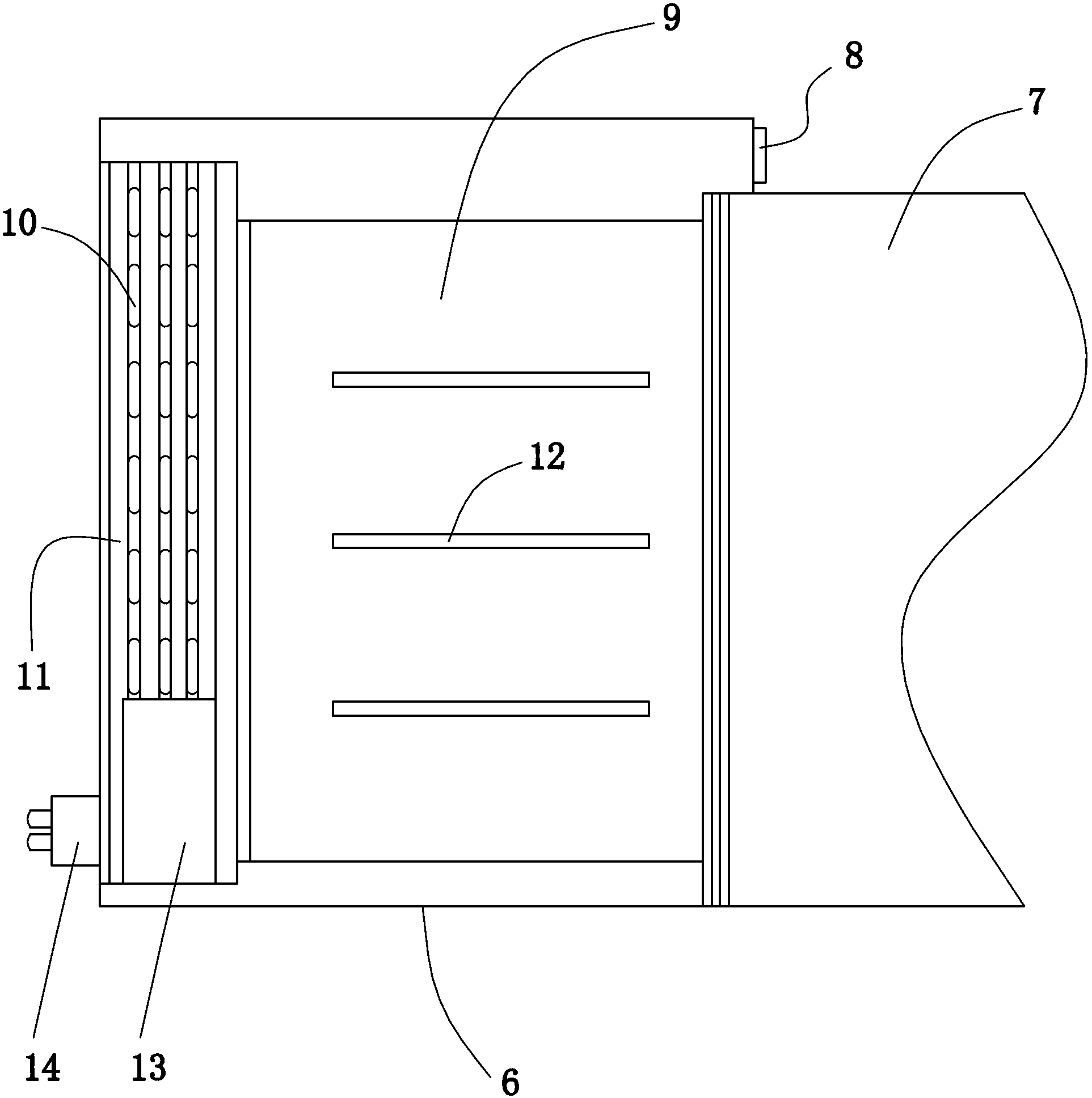

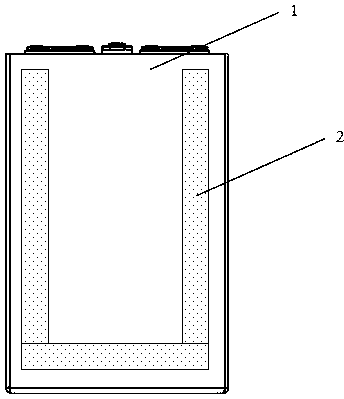

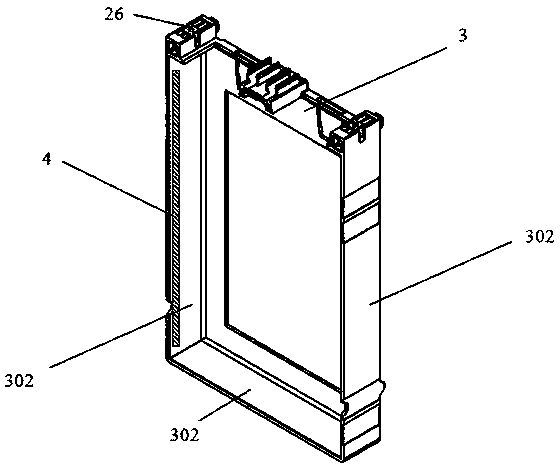

Combination type single box body storage cabinet

ActiveCN102980345AReduce overall weightEasy to carryLighting and heating apparatusRefrigeration devicesFreezing chamberSize matching

The invention relates to a combination type single box body storage cabinet which overcomes the shortcomings that a refrigerating chamber and a freezing chamber of an existing refrigerator cannot share a box body, cannot be transported independently, and need to be transported integrally. The combination type single box body storage cabinet comprises an outer cabinet and at least two single box body storage cabinets arranged in the outer cabinet; the single box body storage cabinets arranged in the outer cabinet are combined in a vertically overlapped mode or in a horizontally parallel mode; the single box body storage cabinets are mutually independent and are respectively provided with a power supply plug; the interior of the outer cabinet is provided with power supply plugs which correspond to each single box body storage cabinet; single box body storage cabinets of the same specification are provided with standard box bodies of the same specification; the standard box bodies of the same specification are identical in appearance size; and the interior of each ingle box body storage cabinet is provided with only one storage inner container. The standard box bodies are used, uniform size of the standard box bodies is formed, and the standard box bodies can be conveniently replaced in one outer cabinet, a problem of size matching does not need to be considered; the independent refrigerating chamber or the independent freezing chamber or an independent fresh-keeping chamber can be arranged in the standard box bodies, overall weight is light, and transportation is facilitated.

Owner:杭州金松优诺电器有限公司

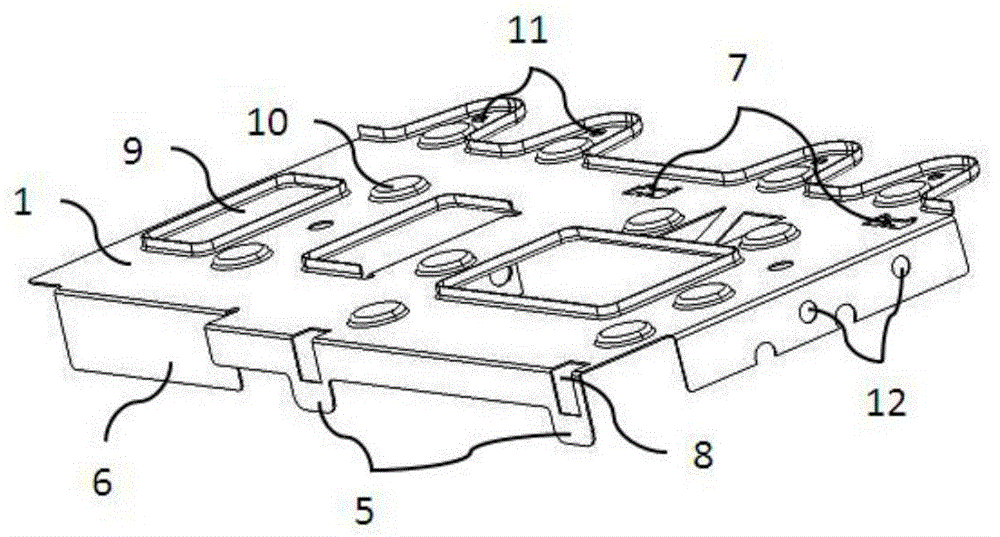

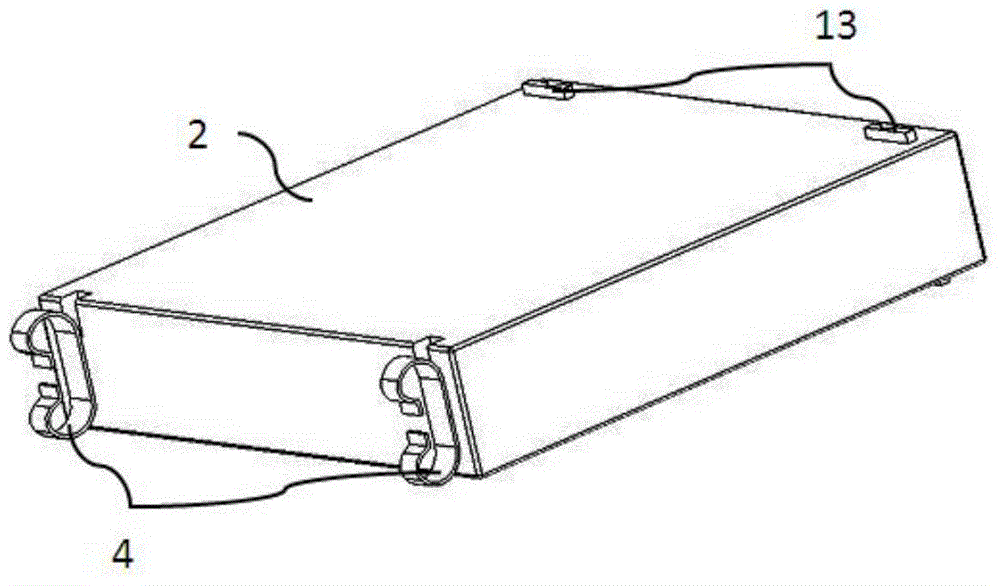

Vehicle lithium ion battery integration module and integration method thereof

ActiveCN104319362AImprove reliabilityReduce overall weightCell component detailsBatteriesElectrical batteryBandage

The invention discloses a vehicle lithium ion battery integration module and an integration method thereof. Single batteries are fixed to a heat conduction frame which has a heat conduction function through the structure glue adhering technology to form a single battery module, a plurality of single battery modules are fixed through the structure glue adhering technology, the module shaping technology and the bandage bundling technology, connection between aluminum strips and battery post terminals is carried out through the laser welding technology, and lastly the wiring harness terminal connecting and inserting technology and the upper cover fixing technology are carried out. According to the vehicle lithium ion battery integration module and the integration method thereof, battery unit splicing is adopted, the post terminals are connected through aluminum strip laser welding, reliability is greatly improved, and compared with the traditional nut locking technology, weight of the whole vehicle lithium ion battery integration module is reduced by about 10 percent to 40 percent.

Owner:SHANGHAI AEROSPACE POWER TECH

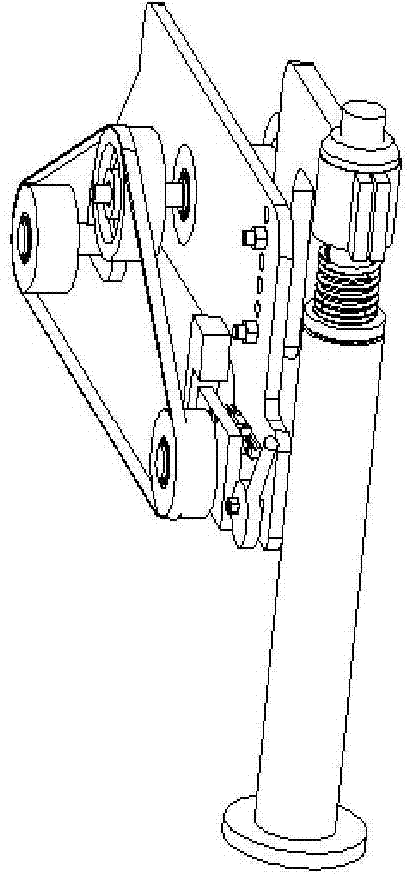

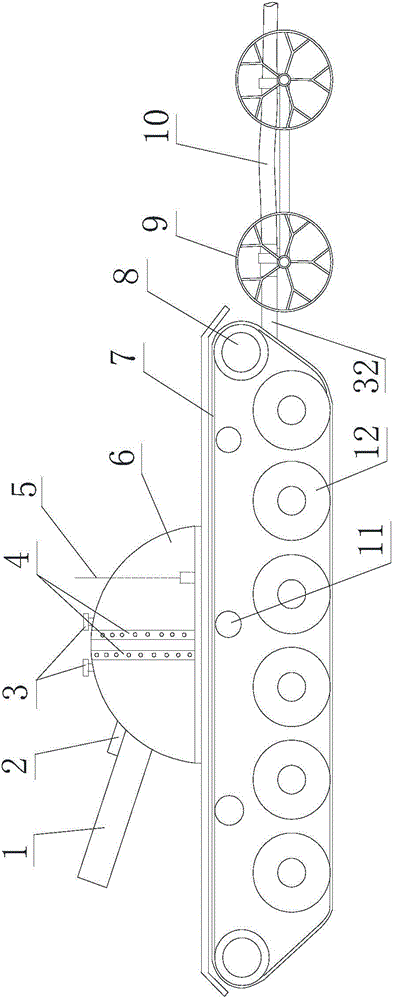

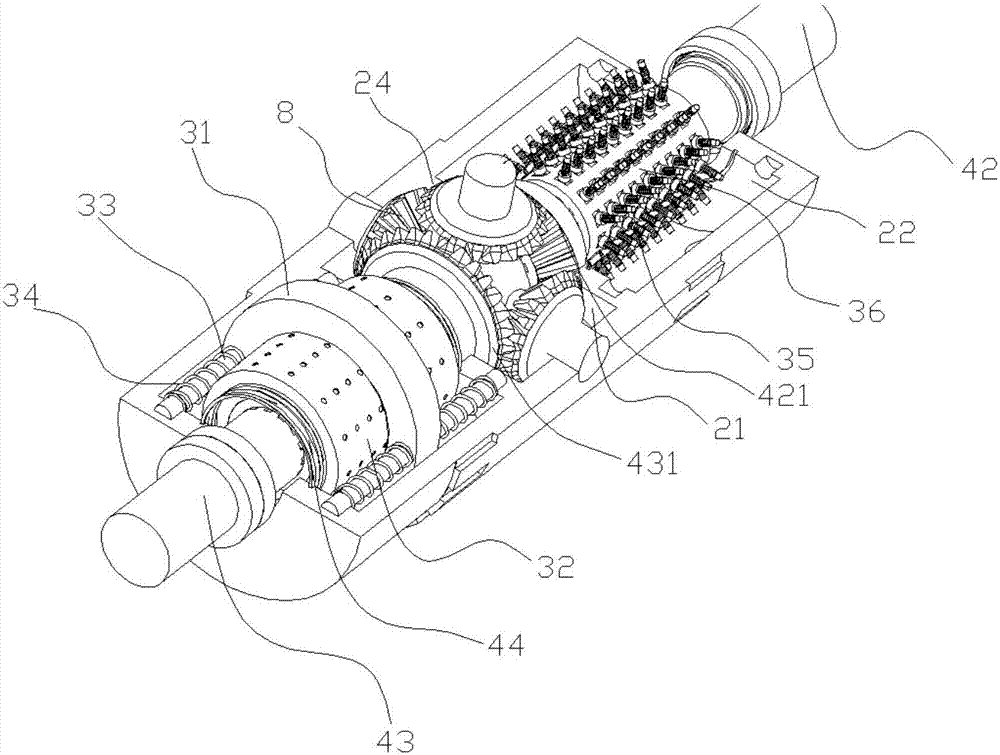

Automatic traveling polishing apparatus of rotor polishing machine tool and application method of automatic traveling polishing apparatus

InactiveCN104742001ASimple processing technologyReduce overall weightBelt grinding machinesElectric machineryEngineering

The invention discloses an automatic traveling polishing apparatus of a rotor polishing machine tool and an application method of the automatic traveling polishing apparatus. The automatic traveling polishing apparatus comprises a polishing mechanism; the polishing mechanism comprises an upright assembly, a movable arm and a main body cover; the main body is connected with the upright assembly by use of the movable arm. The application method comprises the steps of firstly adjusting an eccentric wheel assembly, mounting an abrasive belt on a driving wheel, a driven wheel and a tensioning wheel and adjusting the height of the movable arm on the upright assembly by use of a hold-down nut, adjusting the rotating angle of the main body cover by adjusting the movable arm, starting a servo motor to drive the driving wheel to rotate, thereby driving the abrasion belt to rotate, and then completing the polishing process. According to the automatic traveling polishing apparatus, the labor hours are greatly shortened in the process of machining workpieces, the application of manpower resources is reduced and the production cost is reduced.

Owner:QINGDAO JIANGHAN PETROLEUM MACHINERY

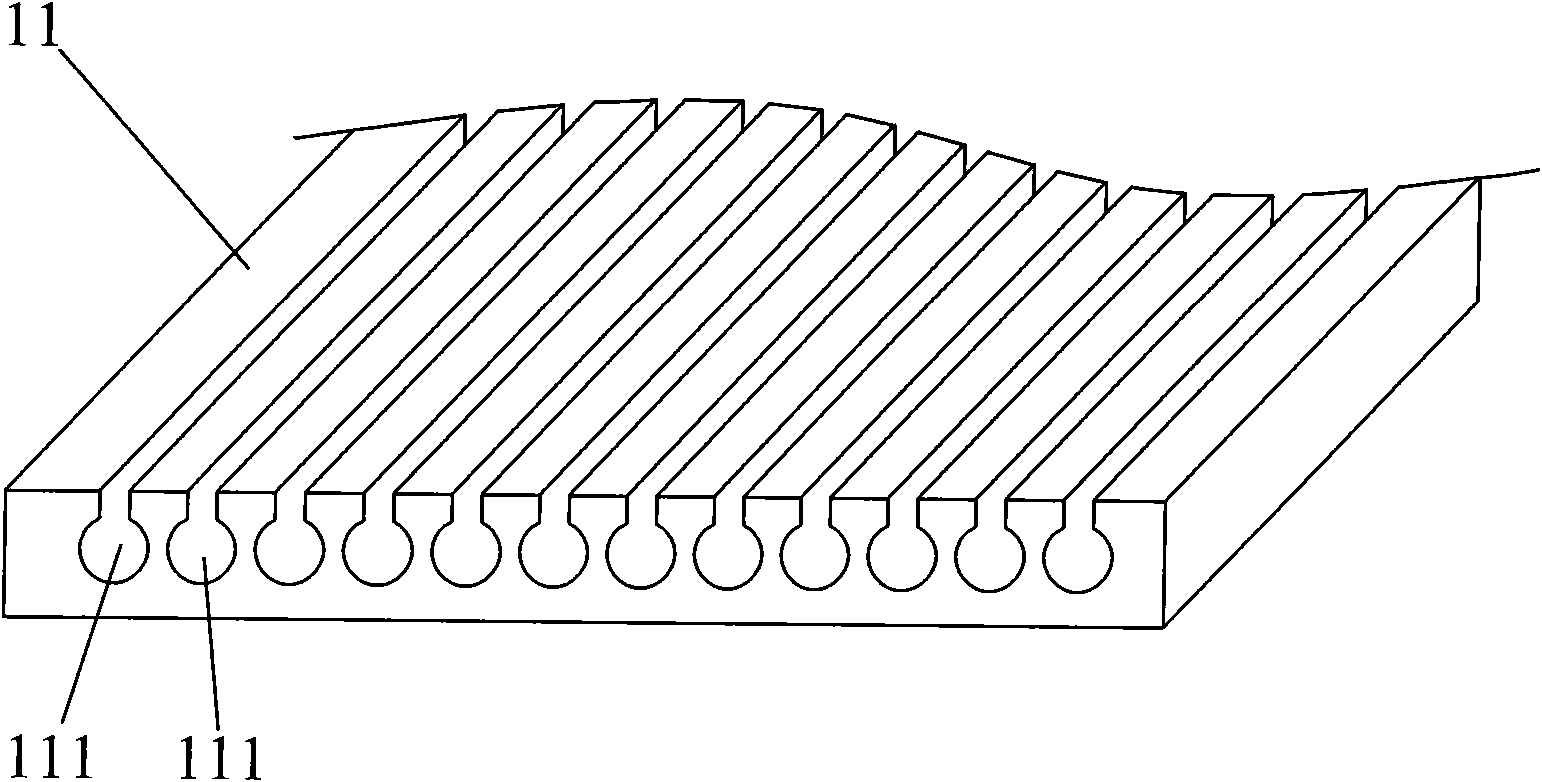

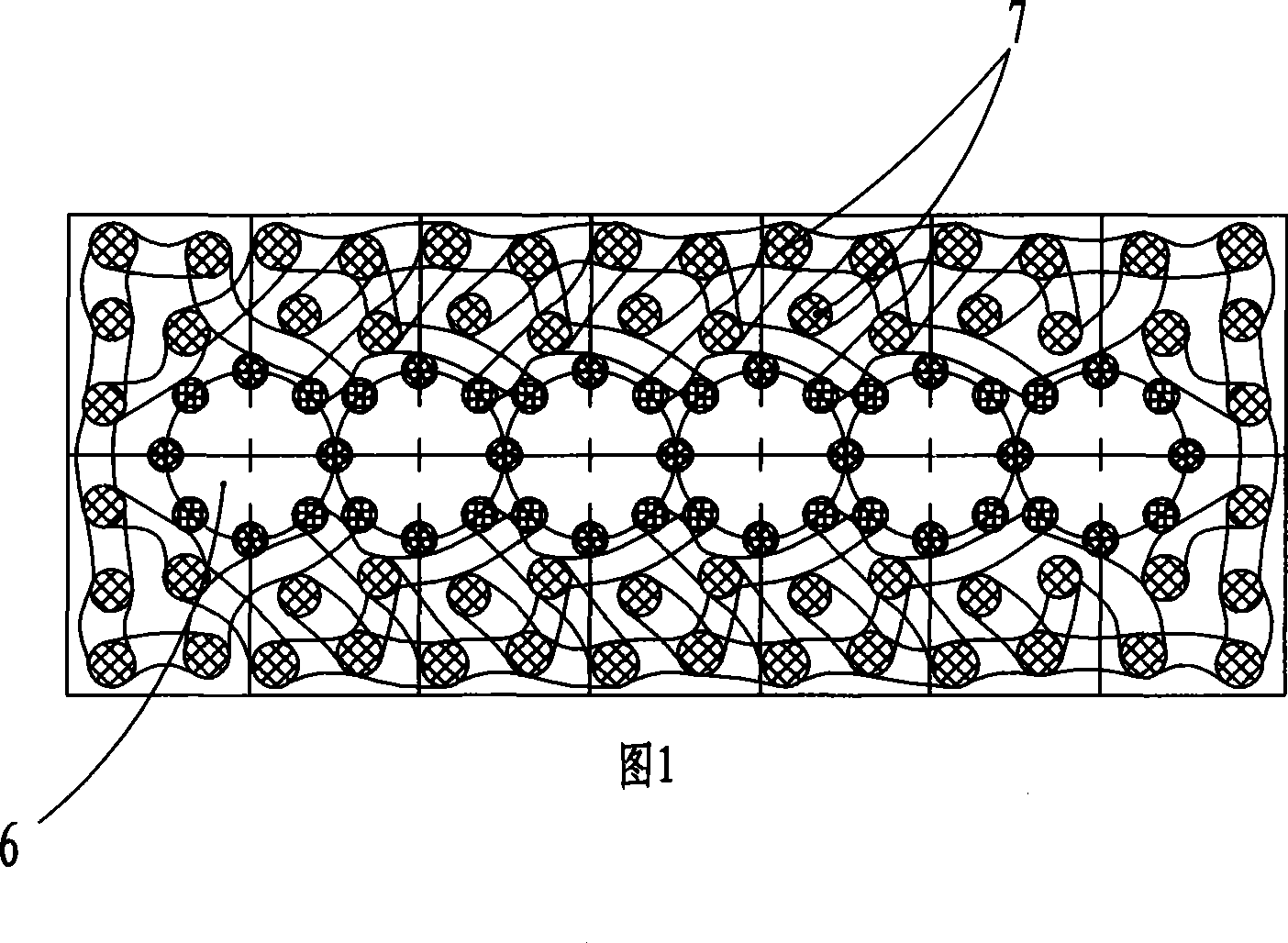

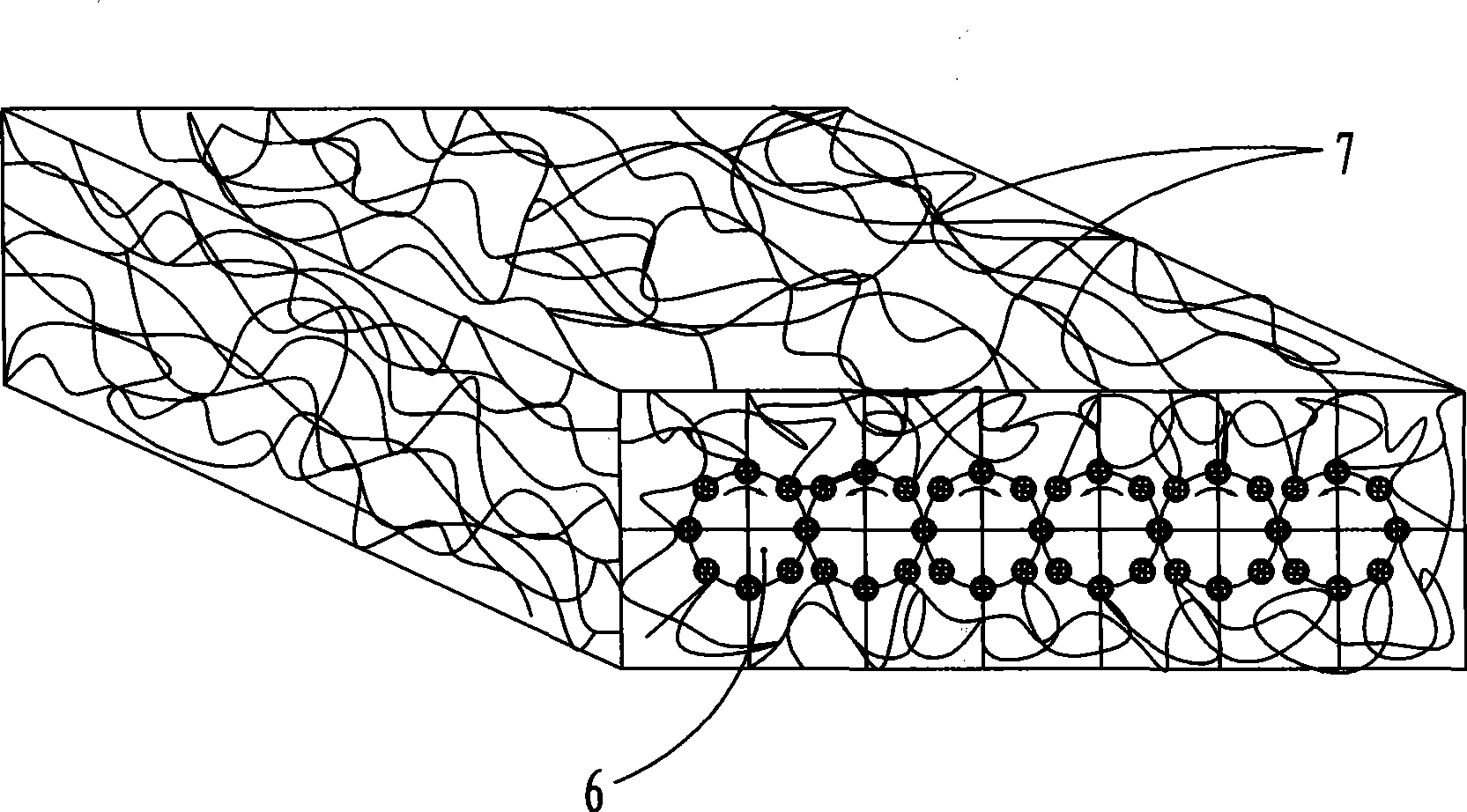

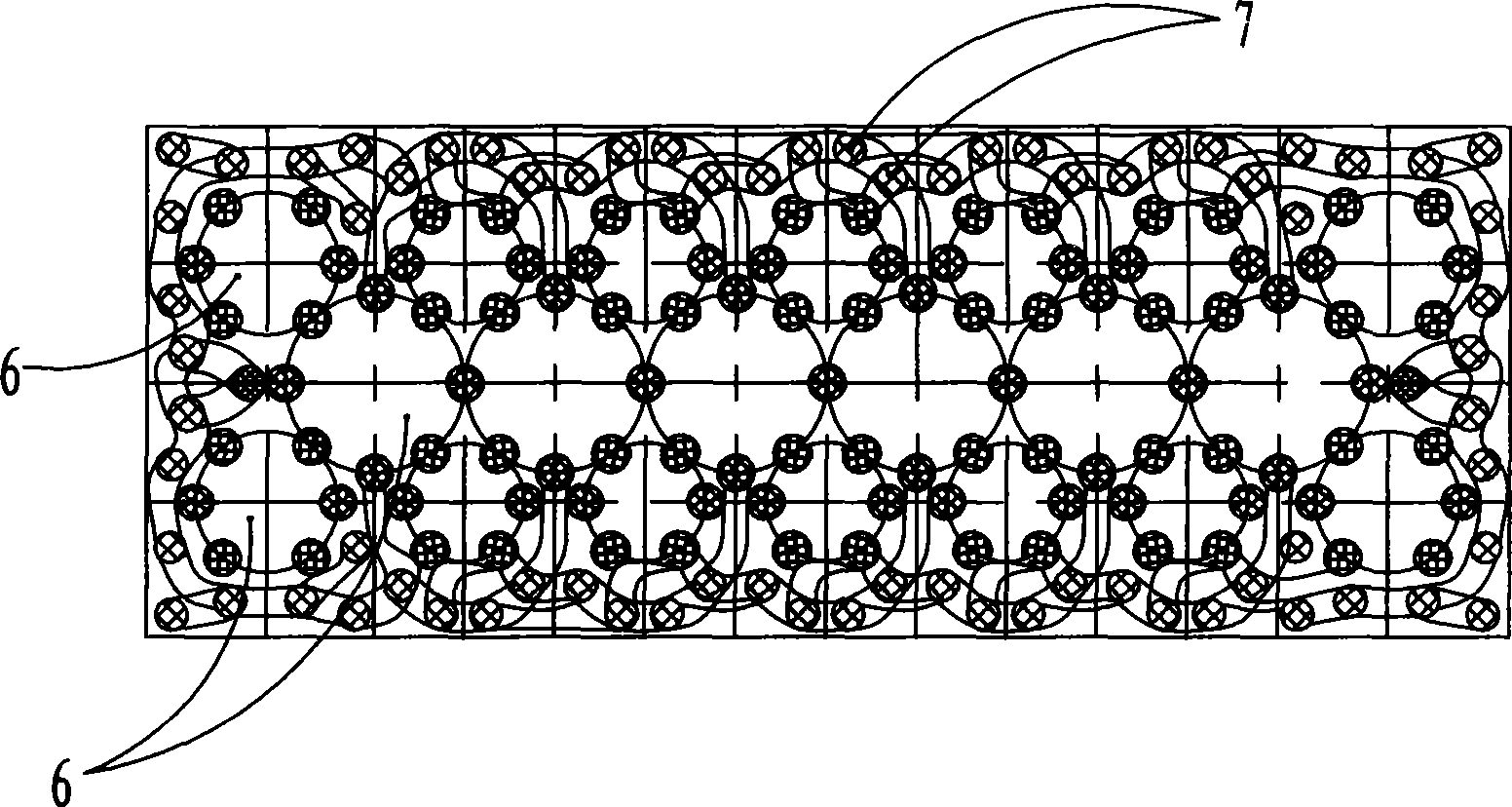

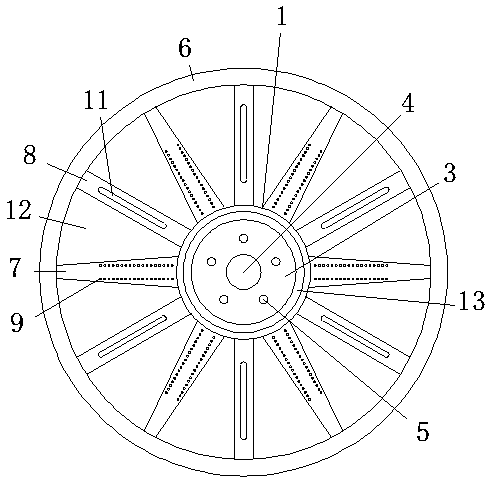

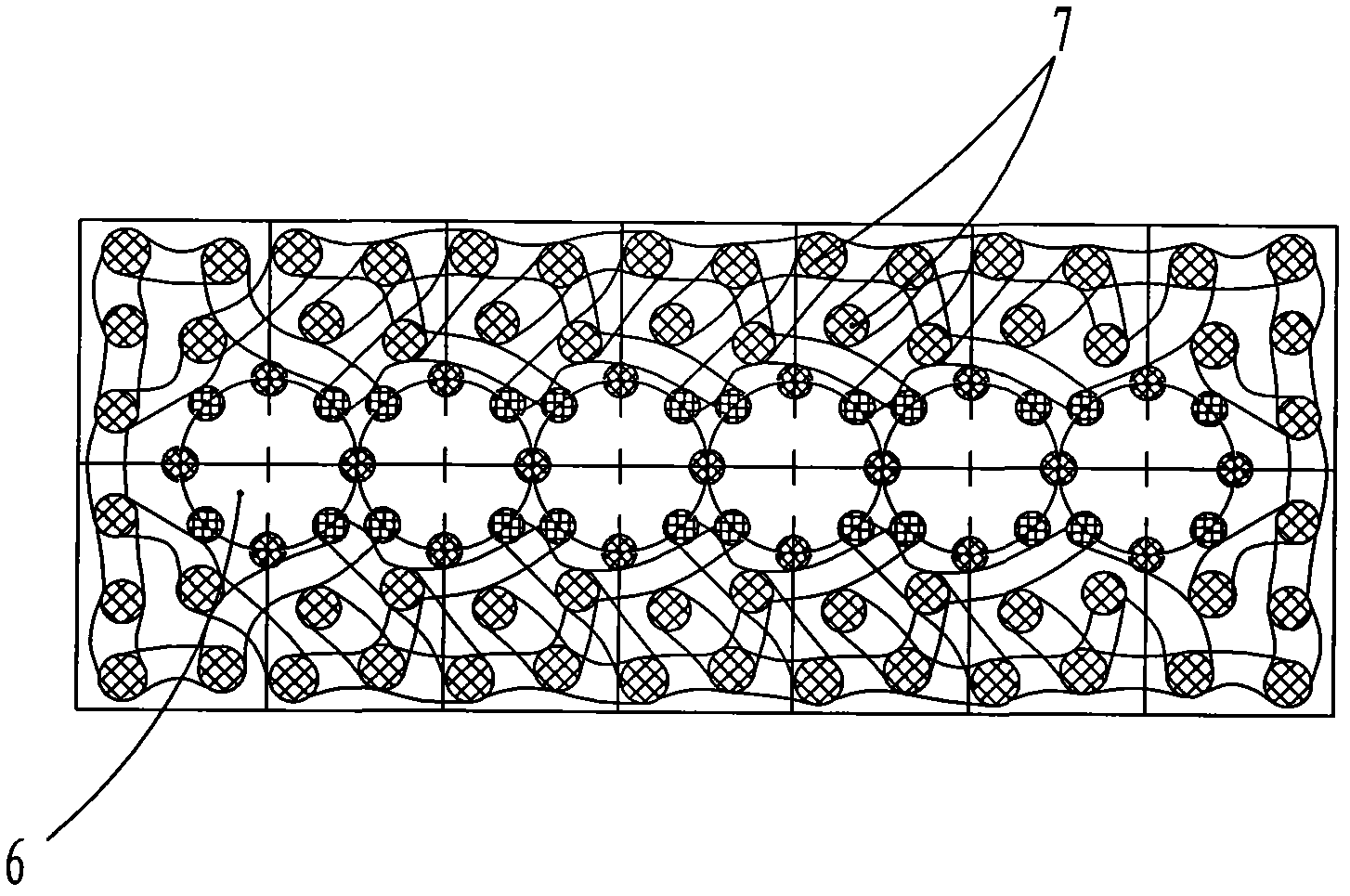

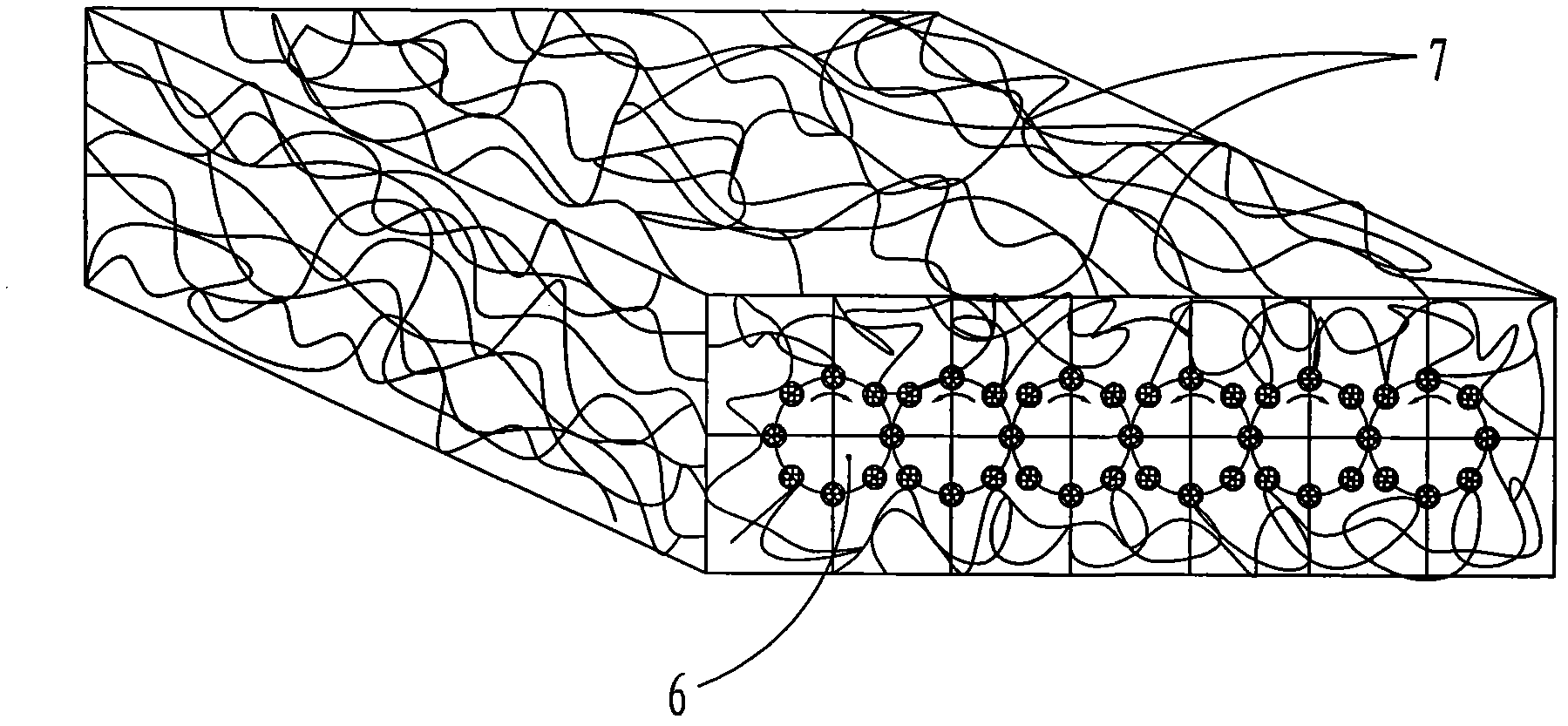

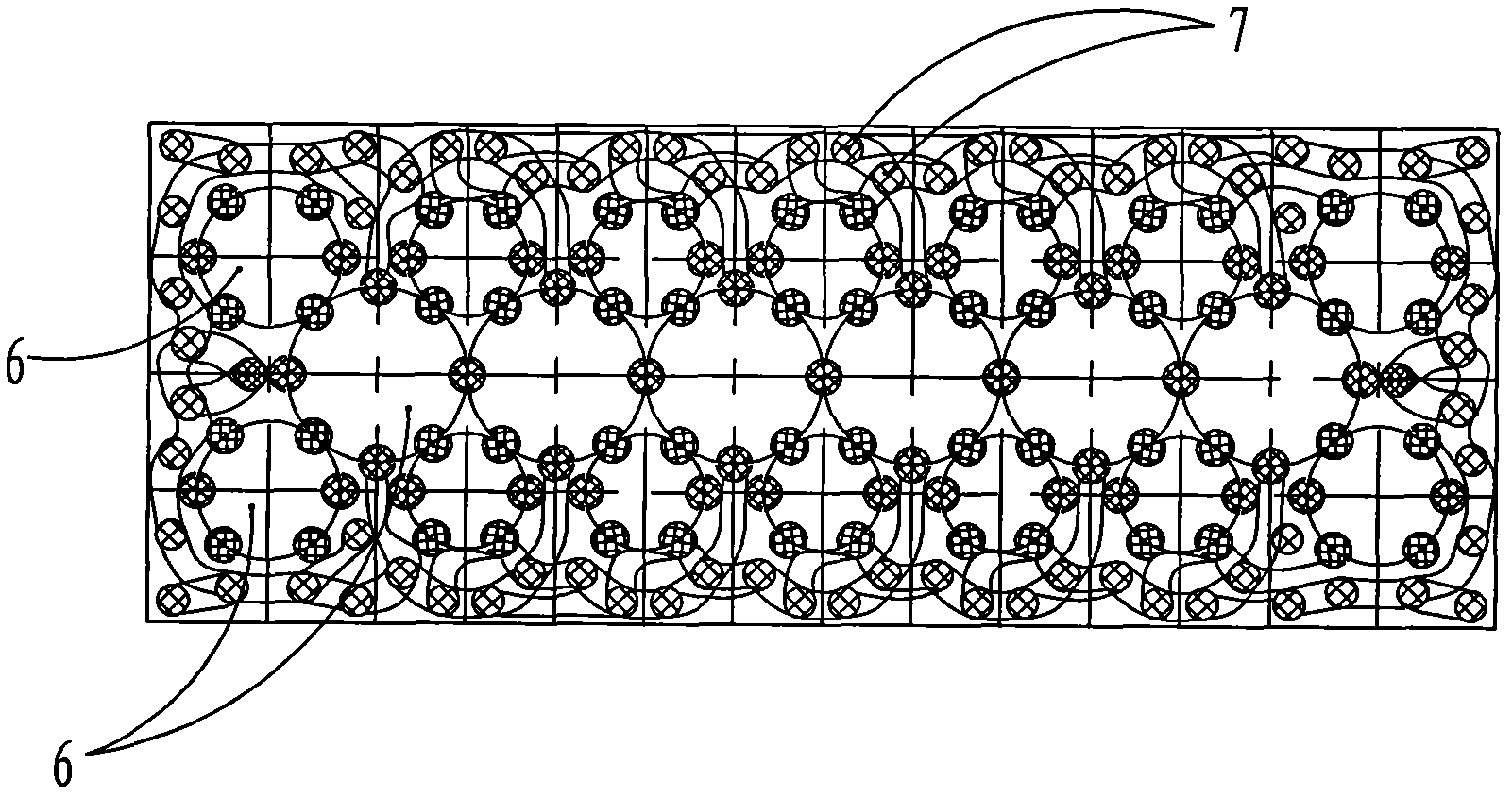

Plastic cushion with pipe network and floss silk and production technique thereof and rotary forming head

ActiveCN101455495AHigh strengthReduce overall weightStuffed mattressesSpring mattressesCushionVolumetric Mass Density

Pipe network and floss coexisting type plastic cushion comprises plastic flosses which are randomly arranged and have connecting points, in which there is a pipe network. The technical steps are: sending raw materials into an extruder to heat and plasticize to form a fusant shape; extruding out via a rotating type forming machine head; plastic threads extruded from a discharge hole of a fixing model downwards running to the random flosses via a forming roller, and forming a connecting point at the mutual connecting point; plastic threads extruded from the peripheral groove of a rotating model in the inner side of the fixing model forming the pipe network shape, having a cavity in the pipe network shape; cooling and typing the extruded formed plastic cushion, whose middle has the pipe network distribution and the periphery has the flosses; drawing out the formed plastic cushion to a cooling machine, and according to the specification to cut. The rotating type forming machine head structure is to mount a rotating model and a processing groove on the fixing model. The rotating model is connected with a rotating mechanism. This technology and the cushion for machine head have proper integral density, proper thread-line connecting point, high firmness degree, and do not need the spraying glue enhancement, without pollution. And this invention can be equipped with the temperature adjusting component.

Owner:DALIAN PLASTICS RES INST CO LTD

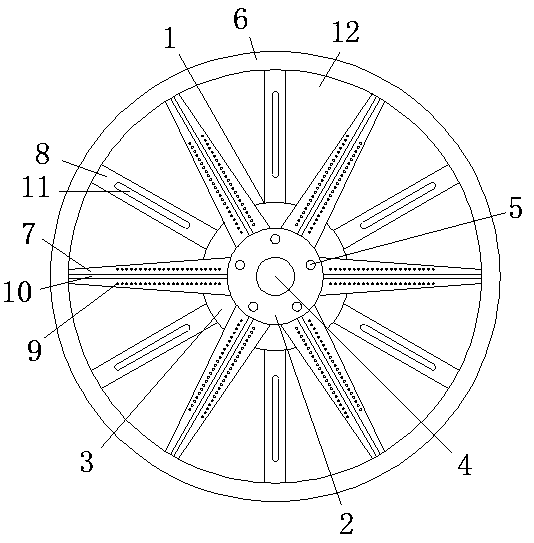

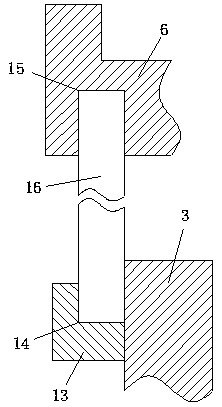

Automobile aluminum alloy hub

The invention discloses an automobile aluminum alloy hub which comprises a hub body. The hub body comprises a wheel disc and a rim. The wheel disc comprises an inner disc and an outer disc. The innerdisc is arranged at the rear end of the outer disc. A shaft hole is formed in the center of the wheel disc. Multiple evenly-distributed main spokes are arranged on the periphery of the inner disc. Theother end of each main spoke is fixed to the rim. Multiple evenly-distributed auxiliary spokes are arranged on the periphery of the outer disc. The other end of each auxiliary spoke is fixed to the rim. The main spokes and the auxiliary spokes are arranged in a staggered mode. Multiple air guide cavities are formed between the main spokes and the auxiliary spokes. A protection device is arrangedat the front end of the hub body. The periphery of the rim is sleeved with a rim ring. The automobile aluminum alloy hub is simple in structure, reasonable in design and beautiful in appearance, the structural strength of the hub is guaranteed, the heat dissipation performance is good, the comfort level of a user in the traveling process is improved through the protection device and buffering devices, and the service life of the hub is prolonged.

Owner:江西瑞一韵承科技有限公司

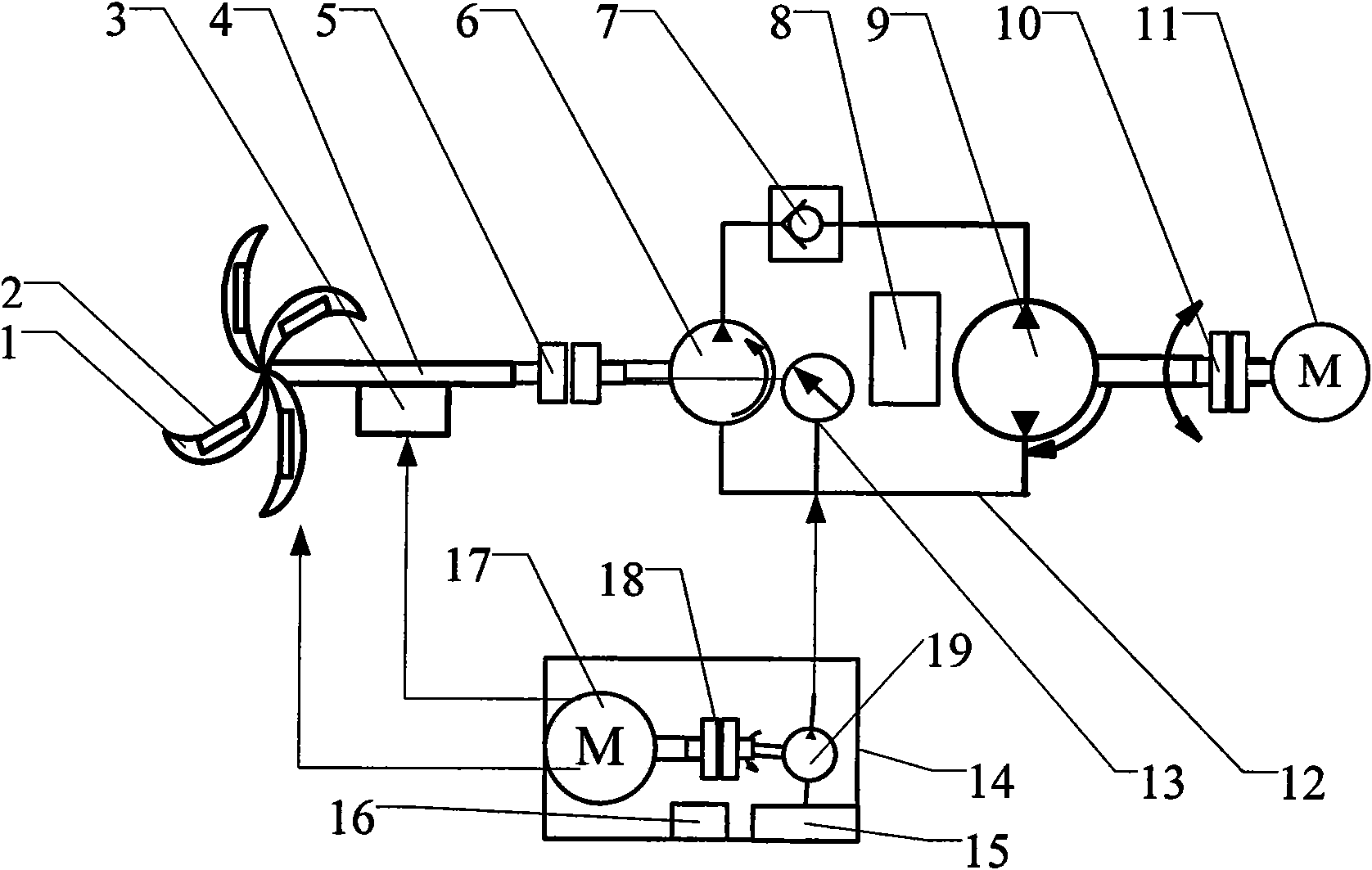

Hydraulic transduction device for wind power generation

InactiveCN101586530ALess investmentReduce overall weightEnergy industryMachines/enginesAutomotive engineeringWind force

The invention discloses a hydraulic transduction device for wind power generation. The front end of a hydraulic pump is connected with a wind-power rotating main shaft through a first coupling; the back end of a hydraulic motor is connected with a first generator through a second coupling; the hydraulic pump converts pulse-type kinetic energy generated by the wind-power rotating main shaft into hydraulic energy; the hydraulic energy is transmitted to the hydraulic motor through a hydraulic oil outlet pipeline; the hydraulic motor converts the hydraulic energy into constant kinetic energy output to the first generator; a hydraulic pressure protection device is connected with the hydraulic oil outlet pipeline and maintains the pressure constancy of hydraulic oil in the hydraulic oil outlet pipeline; and a hydraulic auxiliary unit is arranged on the hydraulic transduction device. The invention reduces the overall weight of wind power generation devices, greatly saves metal materials and investment in wind power generation equipment, and provides a transduction device which is more convenient, effective and friendly to environment.

Owner:XI AN JIAOTONG UNIV

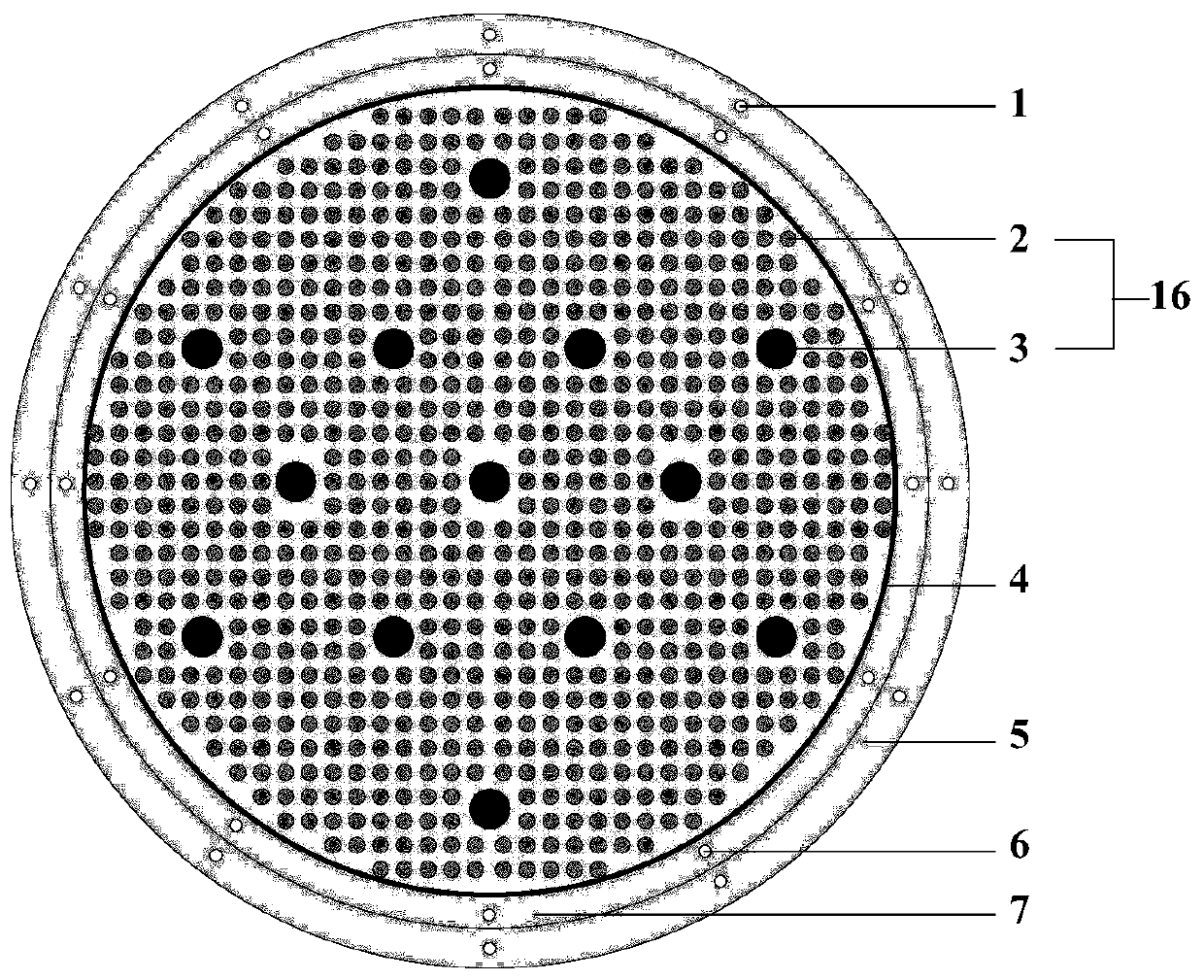

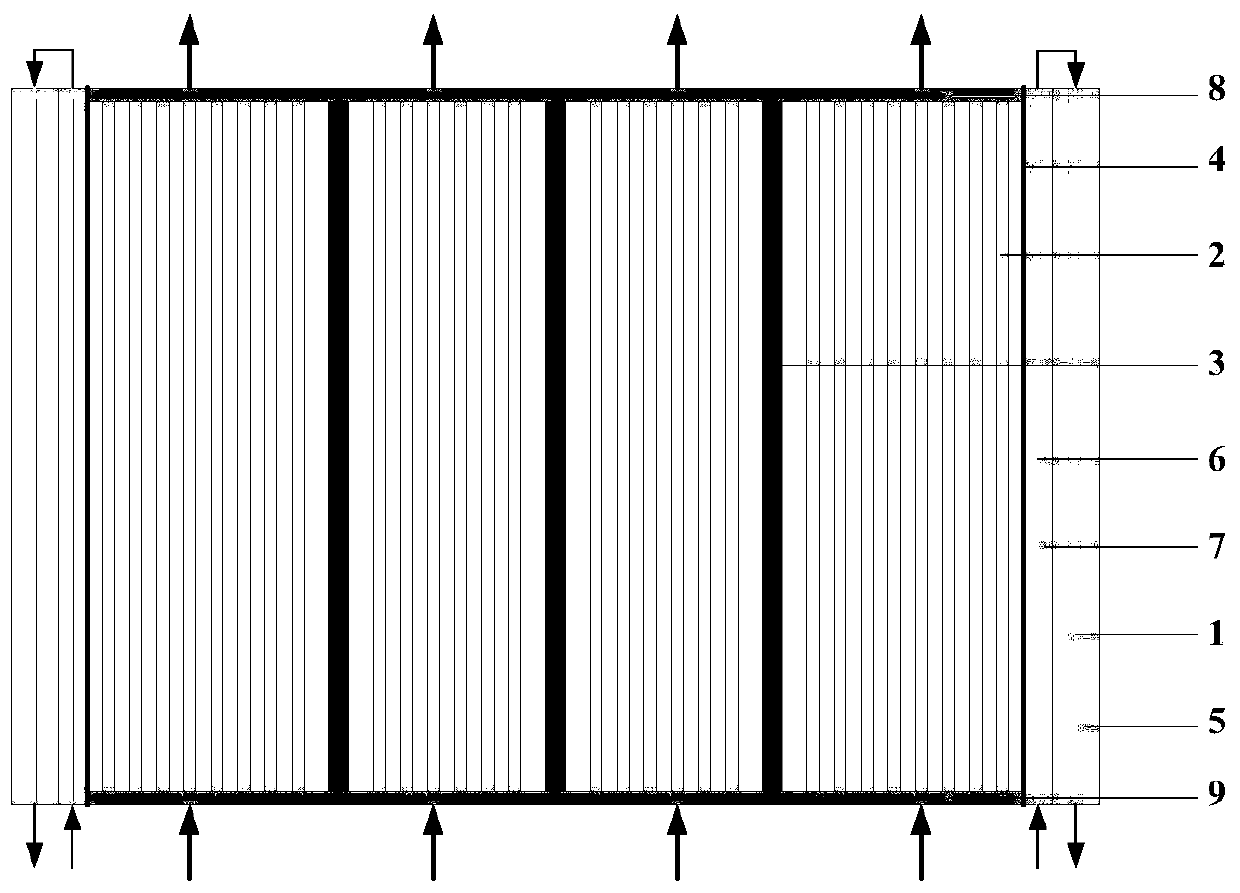

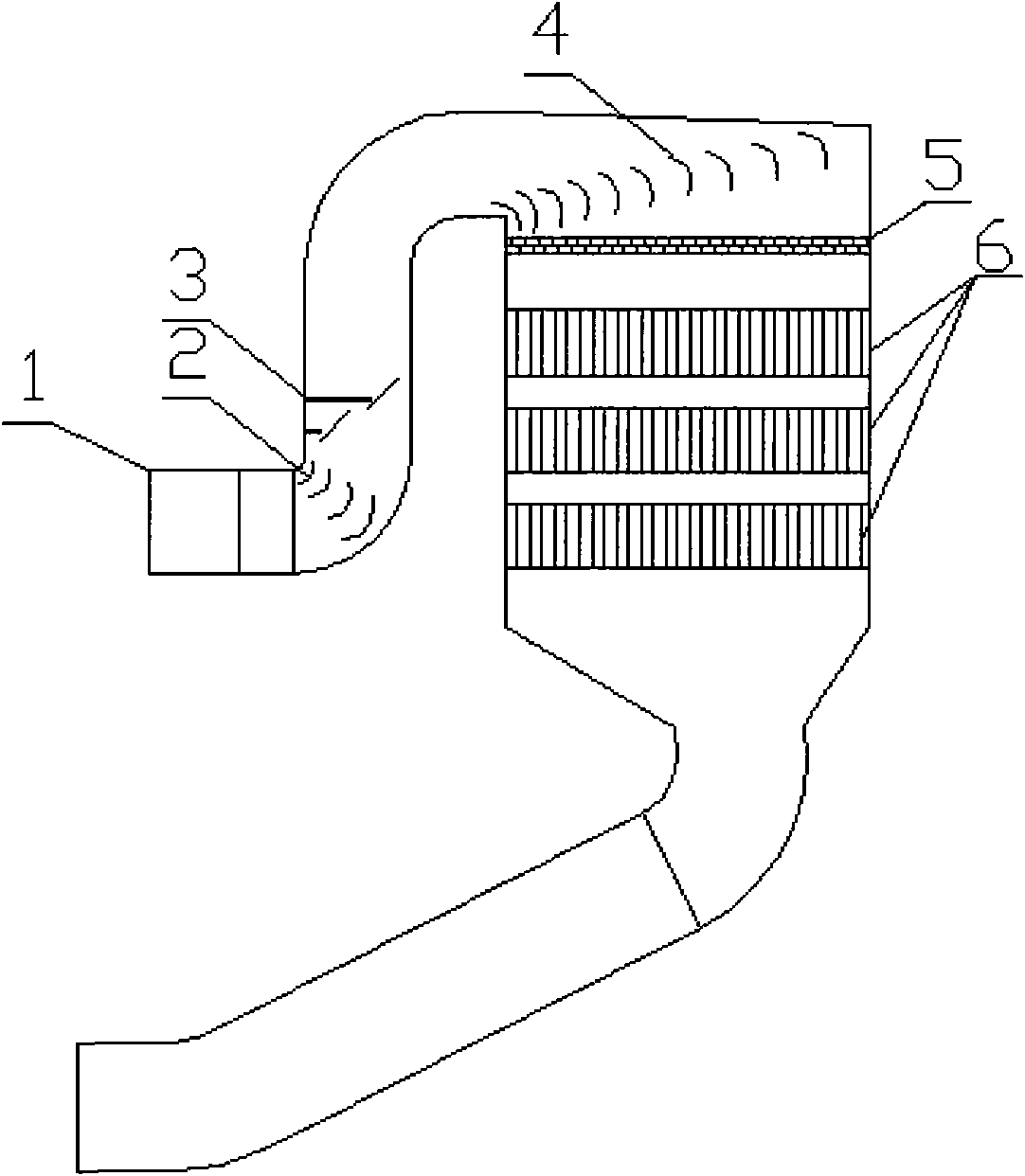

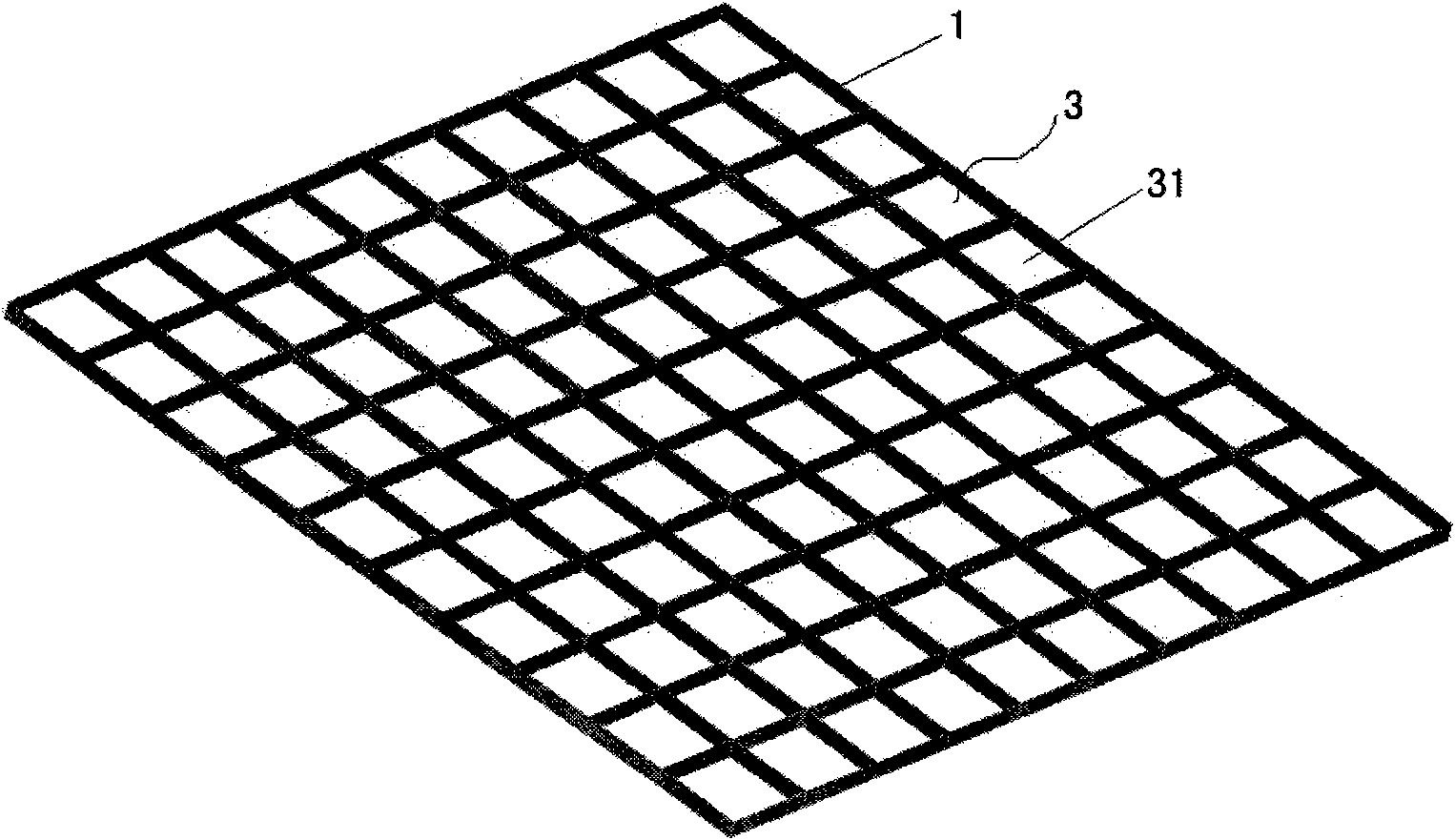

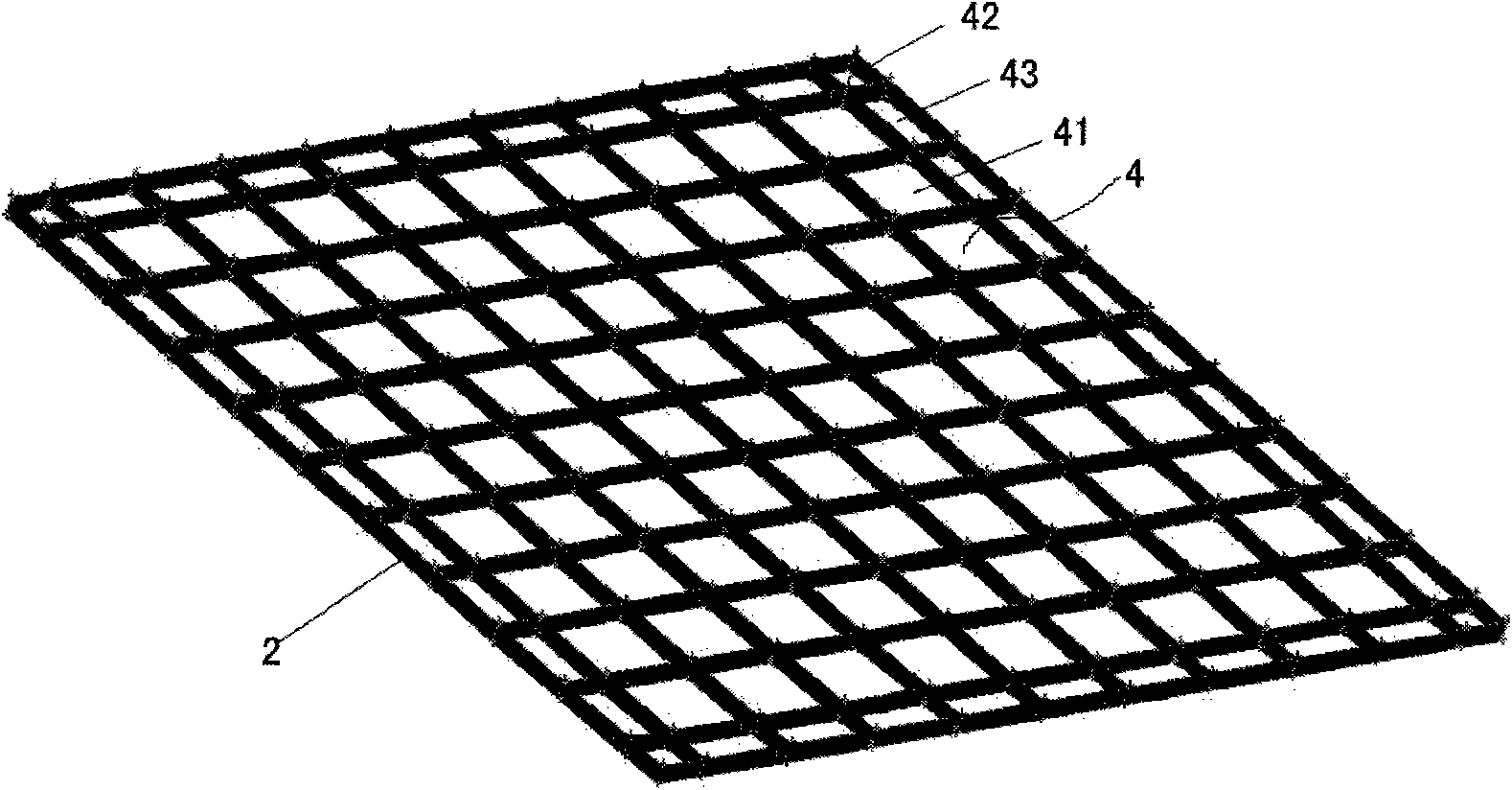

Cascading type rectifier used for SCR denitration device

ActiveCN101642678ASave materialReduce overall weightDispersed particle separationSmokeMechanical engineering

The invention discloses a cascading type rectifier used for SCR denitration device, comprising an upper rectifying plate and a lower rectifying plate that are laminated together; wherein the upper rectifying plate is provided with a plurality of regular spread rectifying holes I penetrating the upper rectifying plate body, the lower rectifying plate is provided with rectifying holes II which correspond to the rectifying holes I and penetrates the lower rectifying plate body, the rectifying holes I and the rectifying holes II are partially laminated in vertical direction, and the laminated partforms a plurality of rectifying channels vertically penetrating the rectifier body. The rectifier is formed by adopting the upper and lower rectifying plates, and a plurality of rectifying channels are formed through overlap of the rectifying holes opened on the upper and lower rectifying plates in different directions, thus not only the effect of uniform smoke movement is achieved but also manufacturing cost can be saved.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

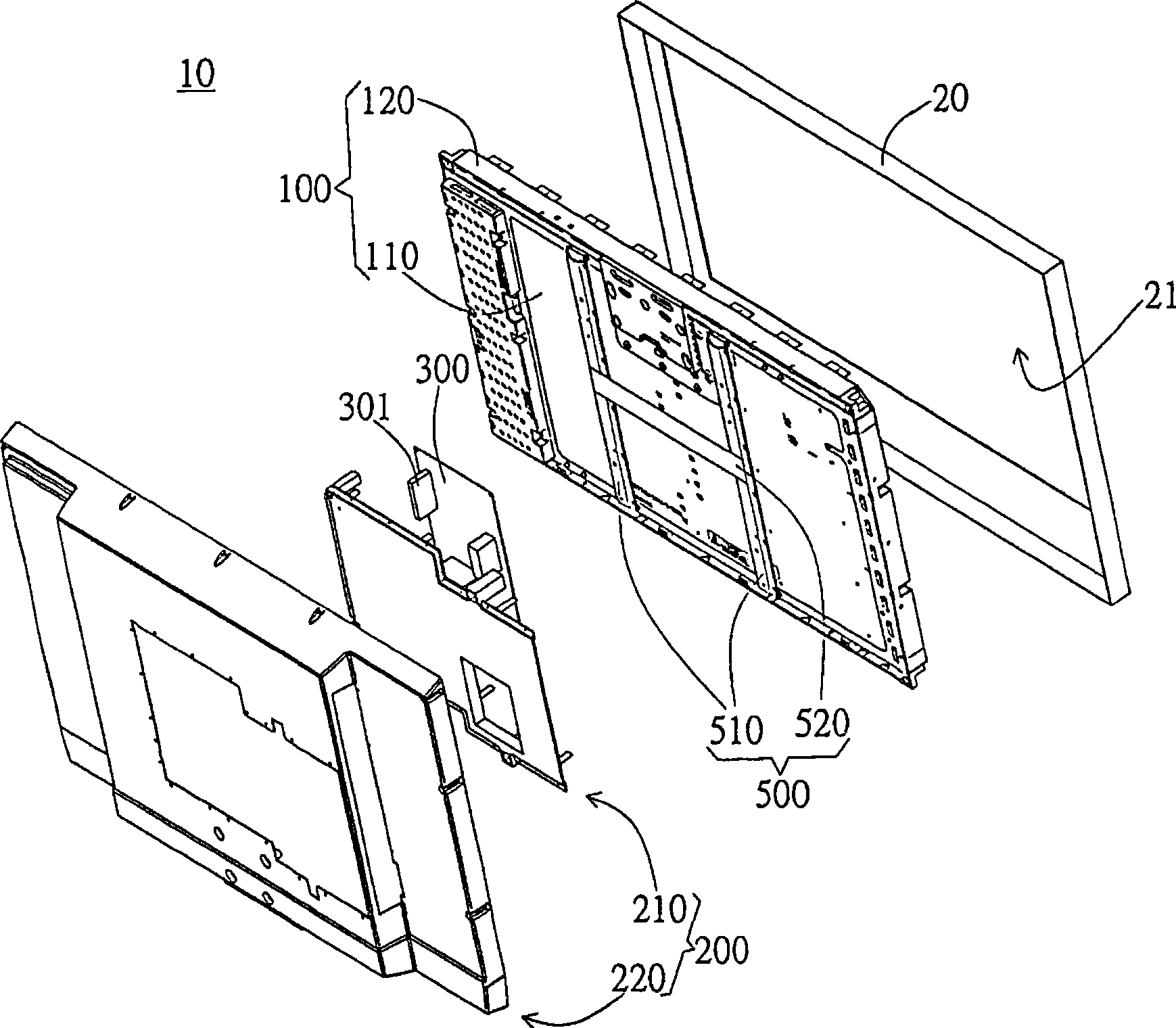

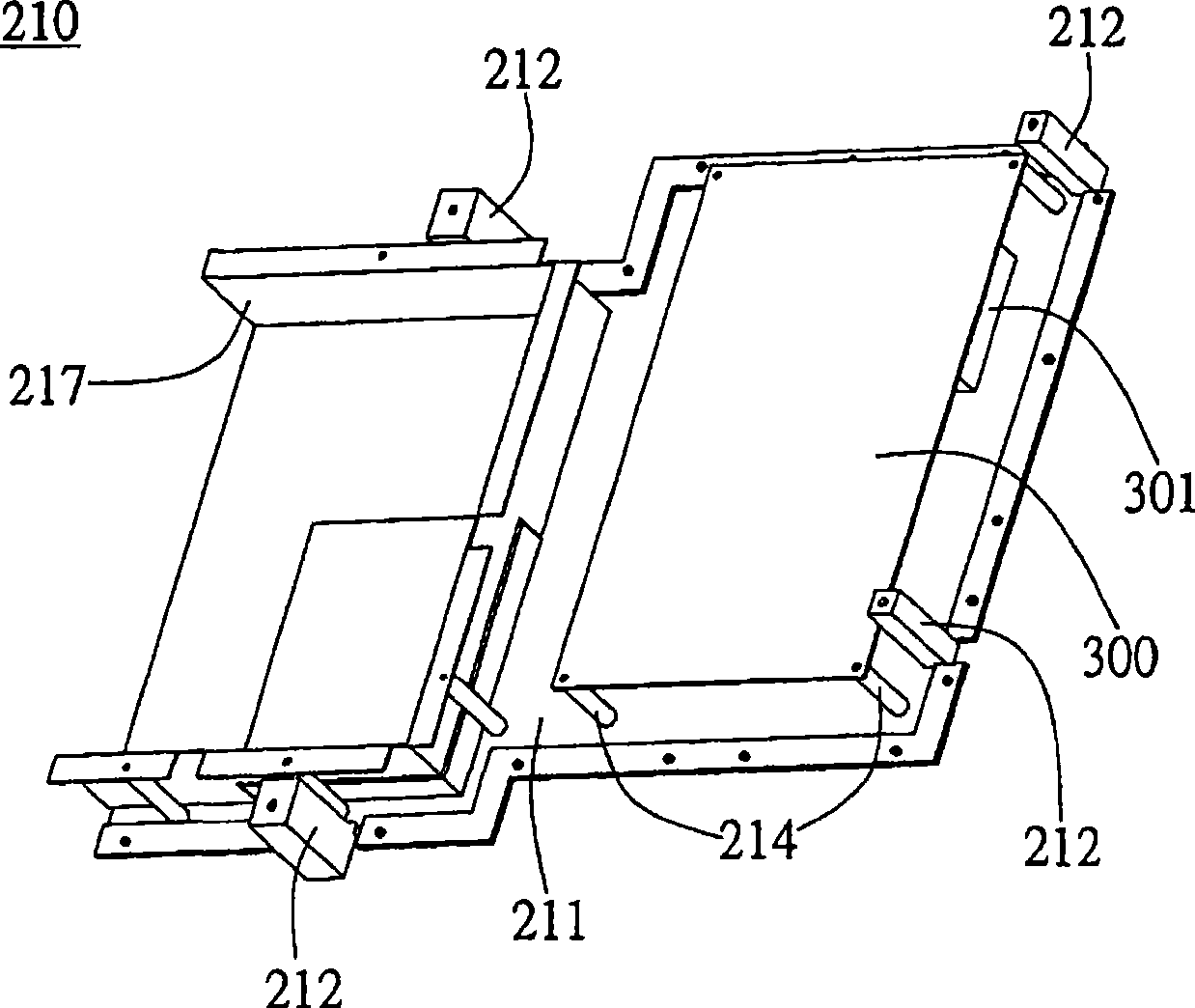

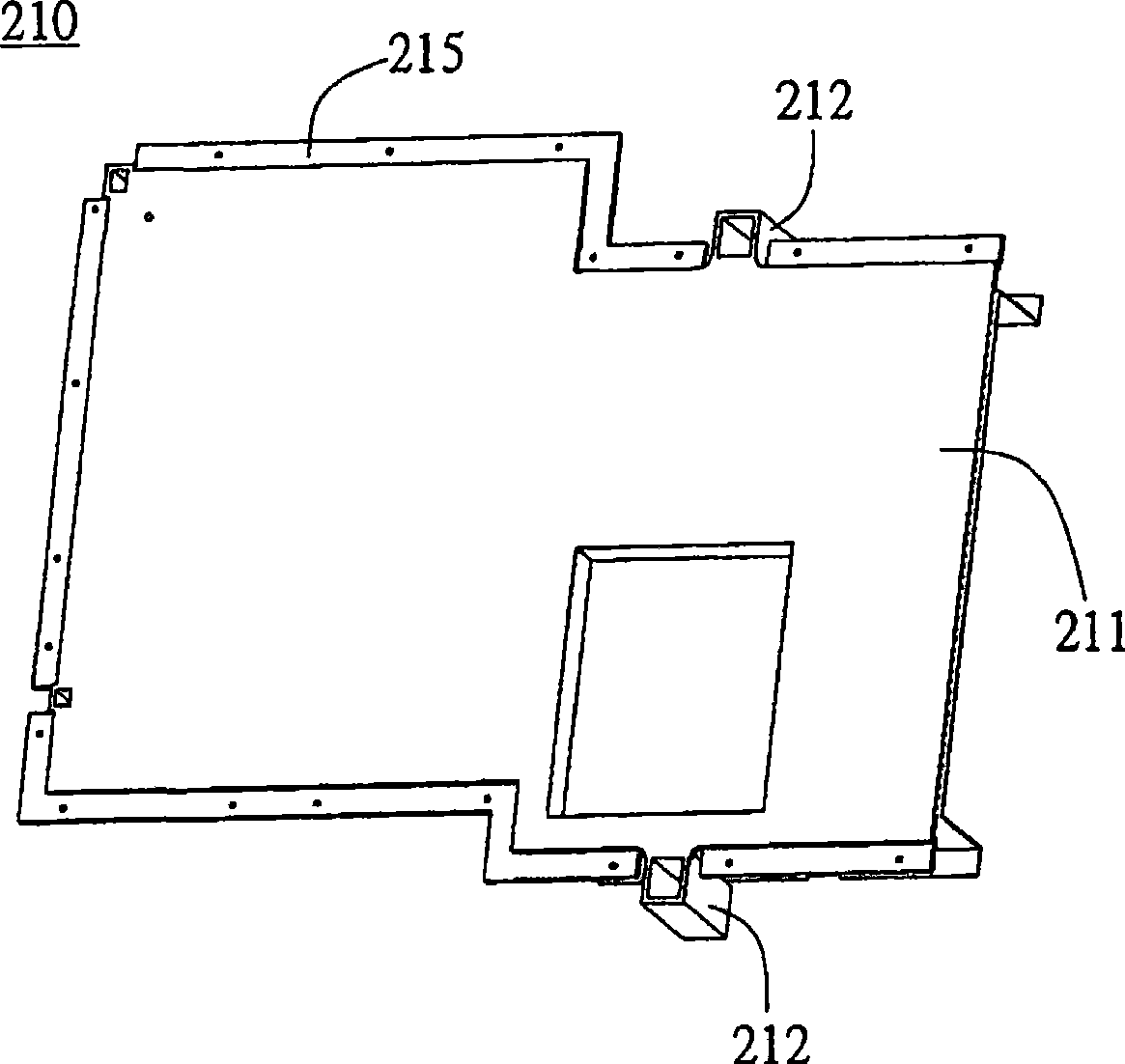

Flat panel display device and manufacturing method thereof

ActiveCN101446698AReduce overall weightSimplify sorting and linking proceduresNon-linear opticsFlat panel displayFront cover

The invention discloses a flat panel display device and a manufacturing method for the flat panel display device. The flat panel display device comprises a flat panel display module, a front cover, an auxiliary support, a back cover group and a circuit board, wherein, the back cover group comprises an auxiliary back cover and a main back cover, the circuit board is correspondingly arranged on the inner surface of the auxiliary back cover, the front cover is provided with a display opening, so that the display surface of the flat panel display module is exposed outside the display opening to display the image by the display opening, and the main back cover comprises an opening so that the partial auxiliary back cover can penetrates through the opening and is exposed outside the opening.

Owner:AU OPTRONICS CORP

Fire-fighting robot capable of carrying out fire-fighting operation inside fire attack

The invention relates to the field of fire-fighting equipment, in particular to a fire-fighting robot capable of carrying out fire-fighting operation inside fire attack. The fire-fighting robot comprises a rotary base and a car body; the rotary base is arranged on the car body; a water-spraying gun barrel is arranged at the front side of the rotary base; a camera is arranged at the upper side of the water-spraying gun barrel; a waterproof division water curtain belt and a sprinkler head used for forming a protective water curtain are arranged at the upper side of the rotary base; a water separating system used for controlling the water-spraying gun barrel, the waterproof division water curtain belt and the sprinkler head to spray is arranged in the rotary base; the water separating system is connected to a fire-fighting truck through a fire-fighting water tube; a control module unit is arranged in the car body; the control module unit is connected to a control system outside a fire scene through a circuit assembly; a refractory layer is arranged at the inner side of each of the rotary base and the car body; and a towing car used for towing the fire-fighting water tube and the circuit assembly in an assisted manner is arranged at the rear side of the car body. The fire-fighting robot can remotely carry out operations such as a fire behavior investigation, fire extinguishment and the like in a manner of entering the fire scene, so that the fire behaviors are effectively controlled.

Owner:李苗 +1

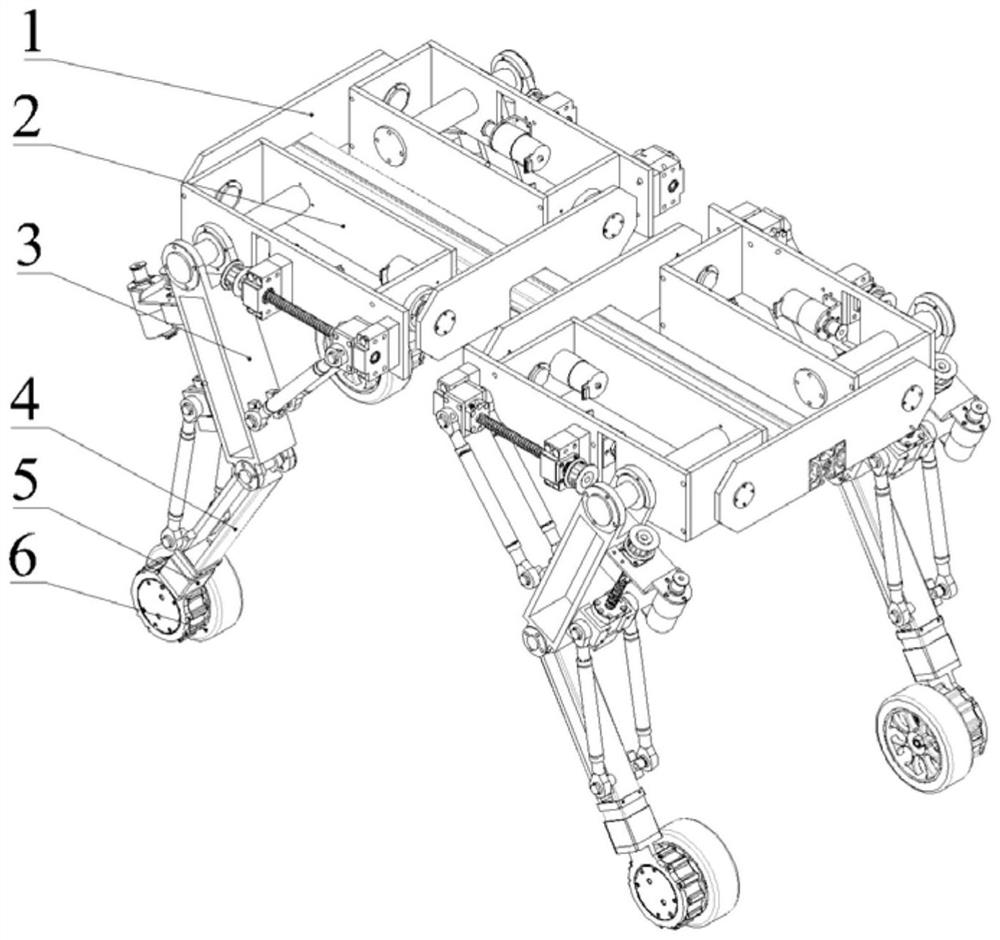

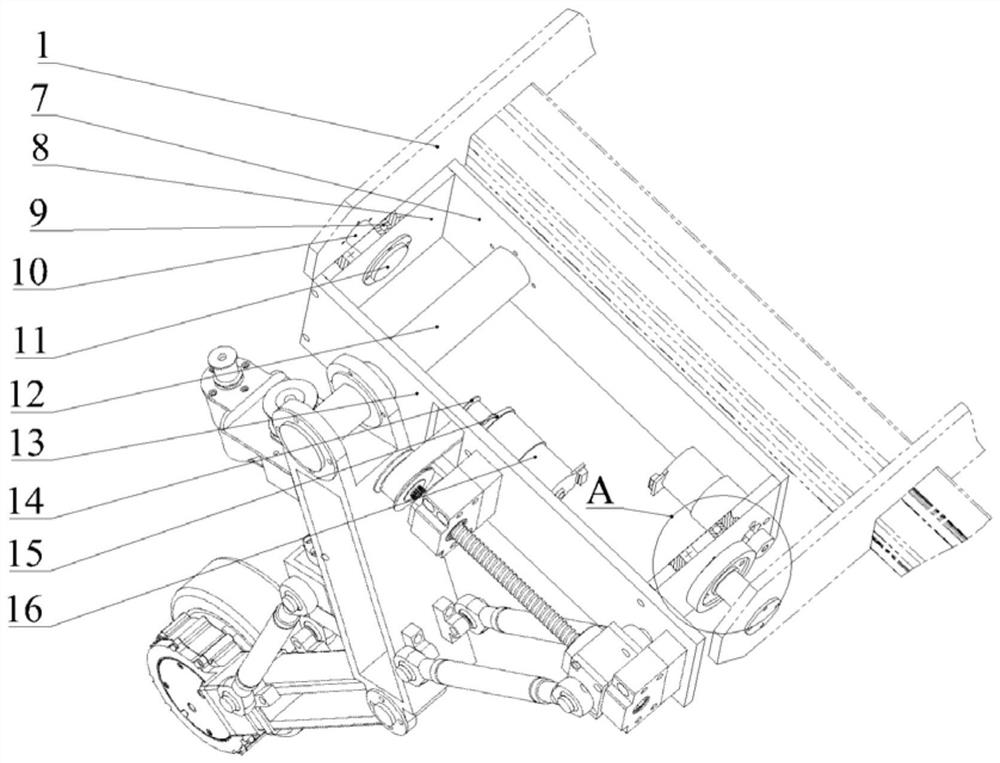

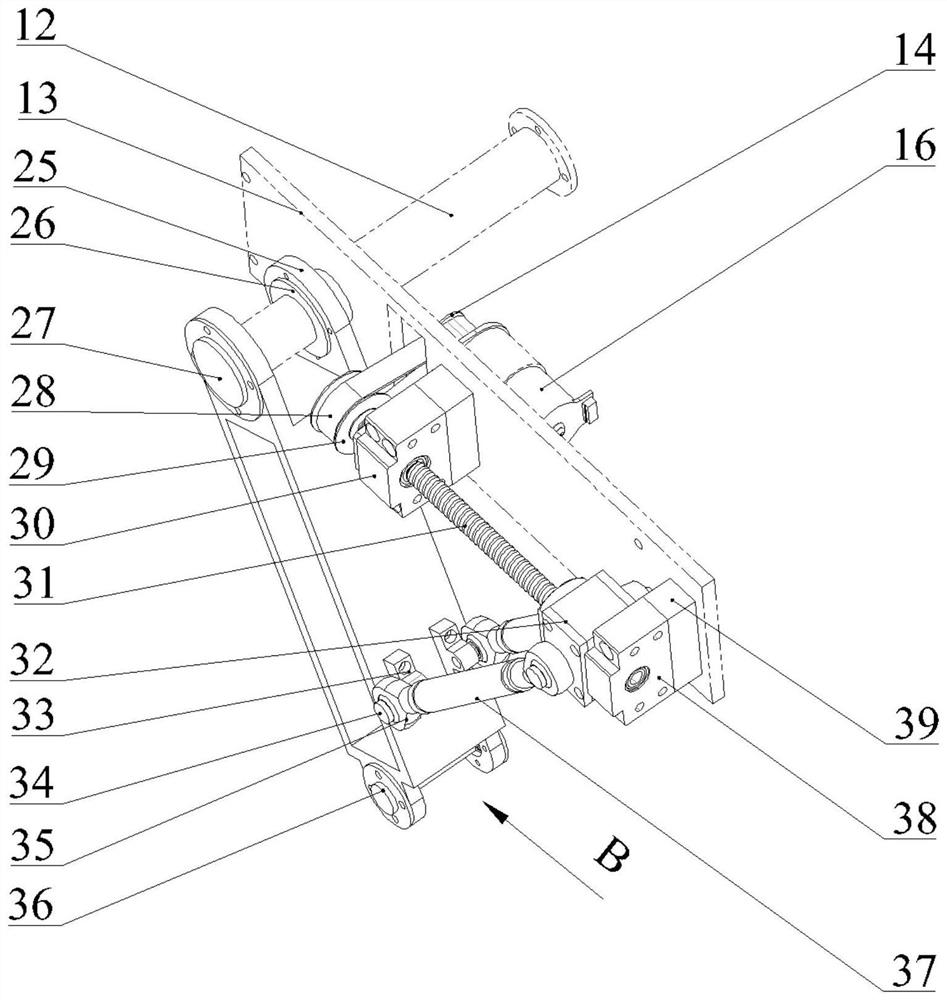

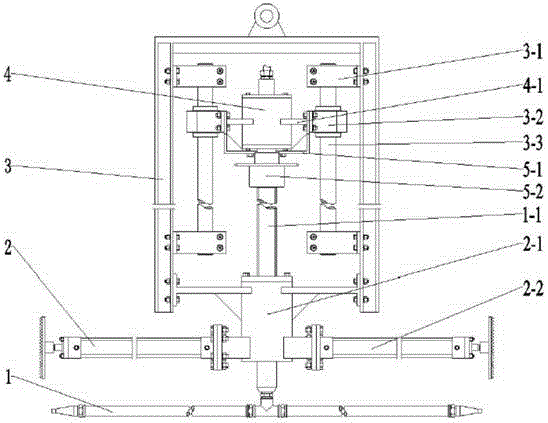

Wheel-foot type robot leg system with damping function

The invention discloses a wheel-foot type robot leg system with a damping function. The wheel-foot type robot leg system comprises a hip joint mechanism, a thigh mechanism, a shank mechanism, a springdamping system and a wheel-foot mechanism; the hip joint mechanism is used for rotating relative to a robot main body structure; the thigh mechanism is used for rotating relative to the hip joint mechanism; the shank mechanism is used for rotating relative to the thigh mechanism; the spring damping system is used for damping; and the wheel-foot mechanism is used for driving the robot main body structure, the hip joint mechanism, the thigh mechanism, the shank mechanism and the spring damping system to do wheel-type movement along with the wheel-foot mechanism. According to the wheel-foot typerobot leg system, wheel type movement and foot type movement can be achieved, compared with a traditional wheel-foot combined type robot, the robot is simpler in structure, the wheel type movement and the foot type movement can be achieved only by adding the wheel-foot mechanism to the foot end of a foot type movement robot, a wheel type movement mechanism does not need to be independently designed at other positions of the robot, and the overall weight of the robot is effectively reduced.

Owner:KUNMING UNIV OF SCI & TECH

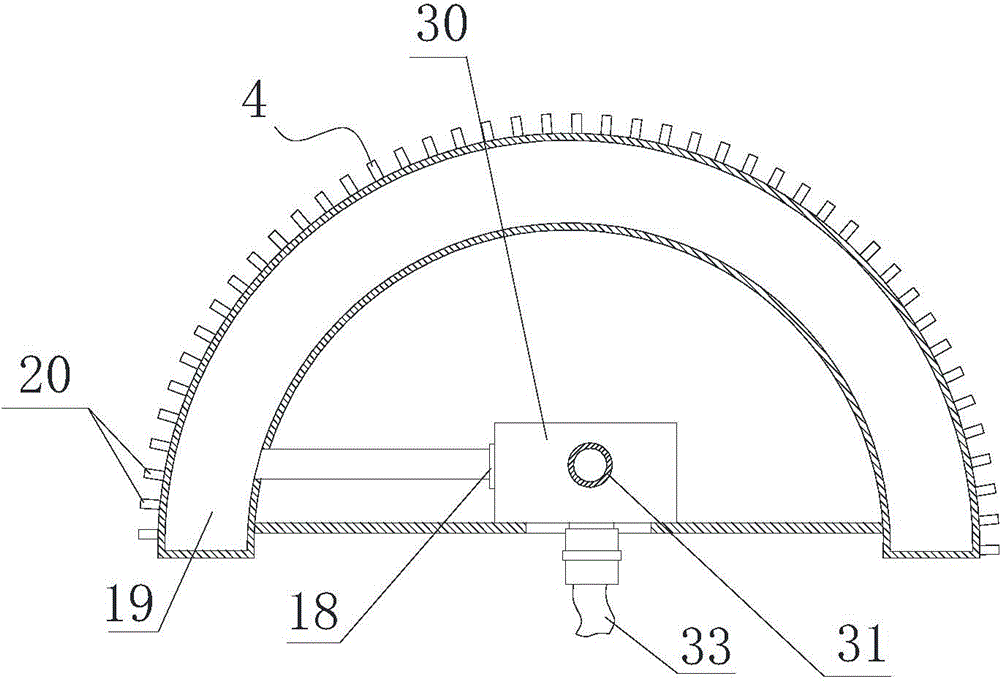

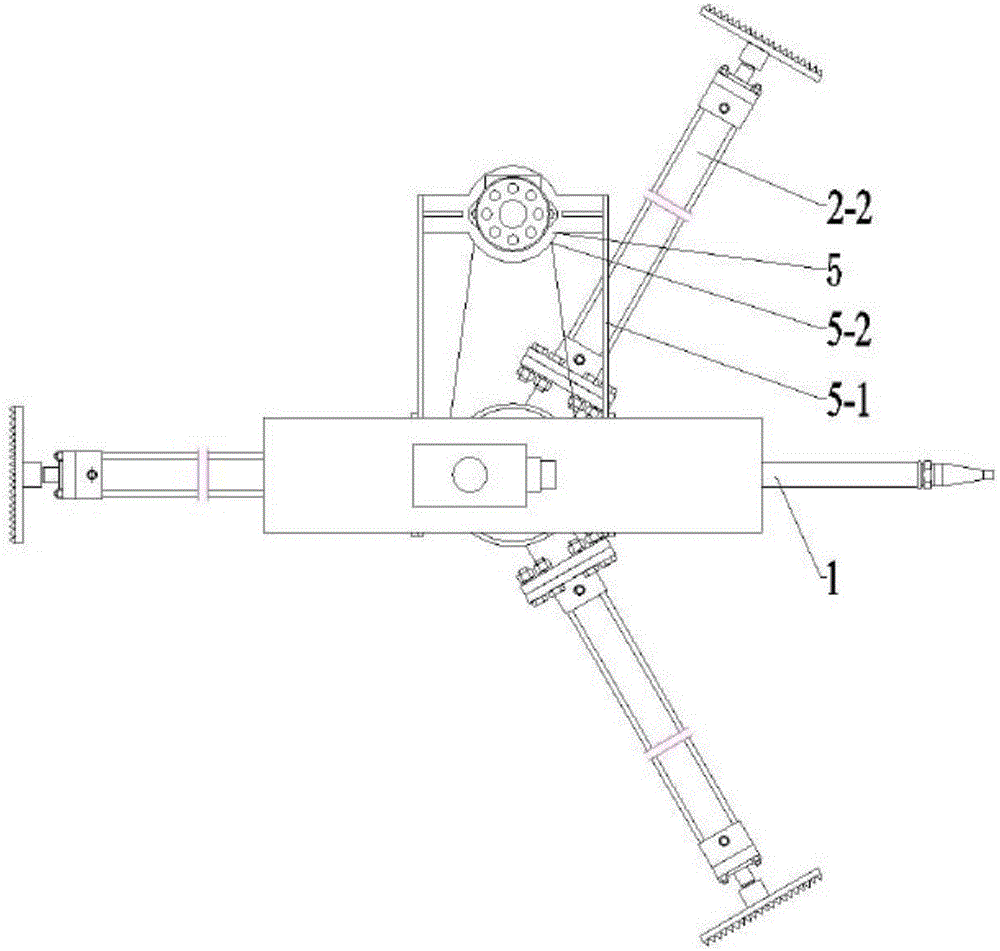

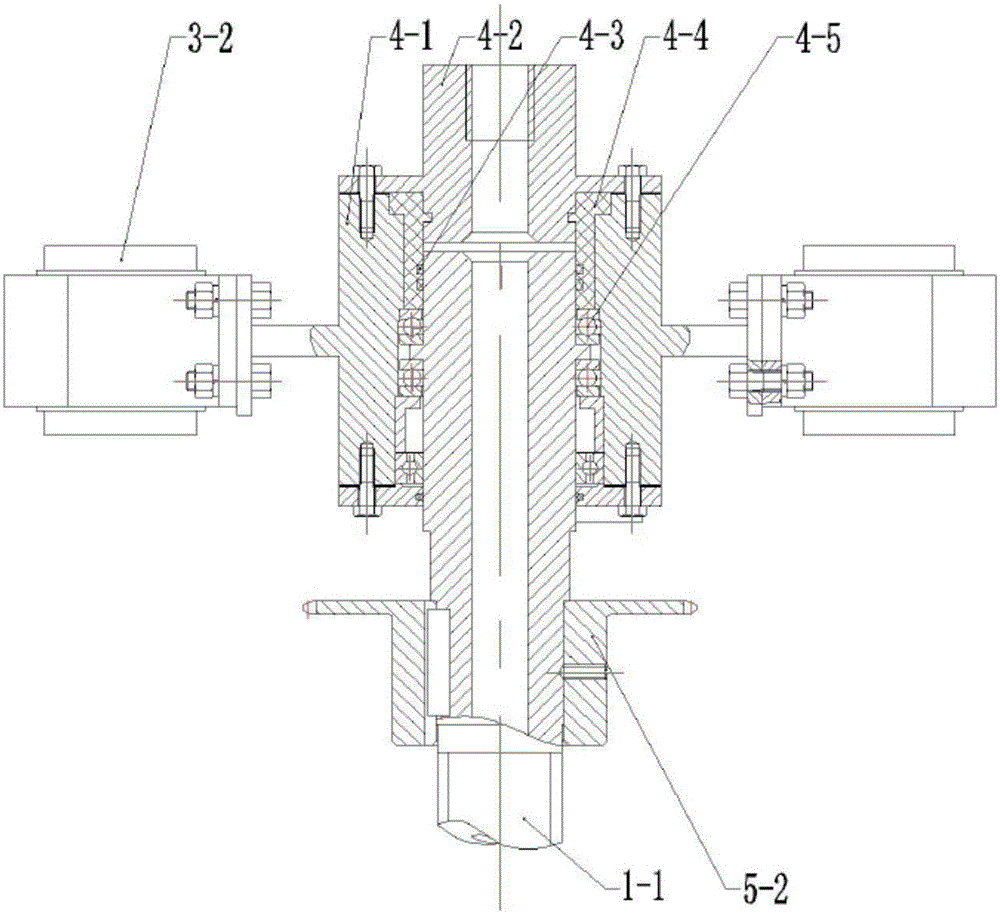

Center driving type water jet bunker cleaning mechanism and cleaning method thereof

The invention discloses a center driving type water jet bunker cleaning mechanism. The center driving type water jet bunker cleaning mechanism comprises a water jet pipeline, a supporting device, a machine frame, a rotary sealing mechanism and a swing driving mechanism. The supporting device is supported on the inner wall of a bunker. An oil cylinder base is arranged on the supporting device and integrated with the machine frame. A hollow rod penetrating through the oil cylinder base is arranged. The middle portion of the hollow rod and the penetrating portion of the oil cylinder base are arranged in a threaded and rotary mode. The lower end of the hollow rod is connected with the water jet pipeline. The water jet pipeline is perpendicular to the hollow rod. The upper end of the hollow rod is sleeved with the rotary sealing mechanism. The rotary sealing mechanism is arranged on the machine frame through a limiting guide rail in the vertical direction. The swing driving mechanism drives the hollow rod to rotate. The hollow rod drives the water jet pipeline to make rotary movement in the vertical direction relative to the oil cylinder base and the machine frame which are integrated. The center driving type water jet bunker cleaning mechanism is reliable in structure, simple in way and high in working efficiency.

Owner:CHINA UNIV OF MINING & TECH

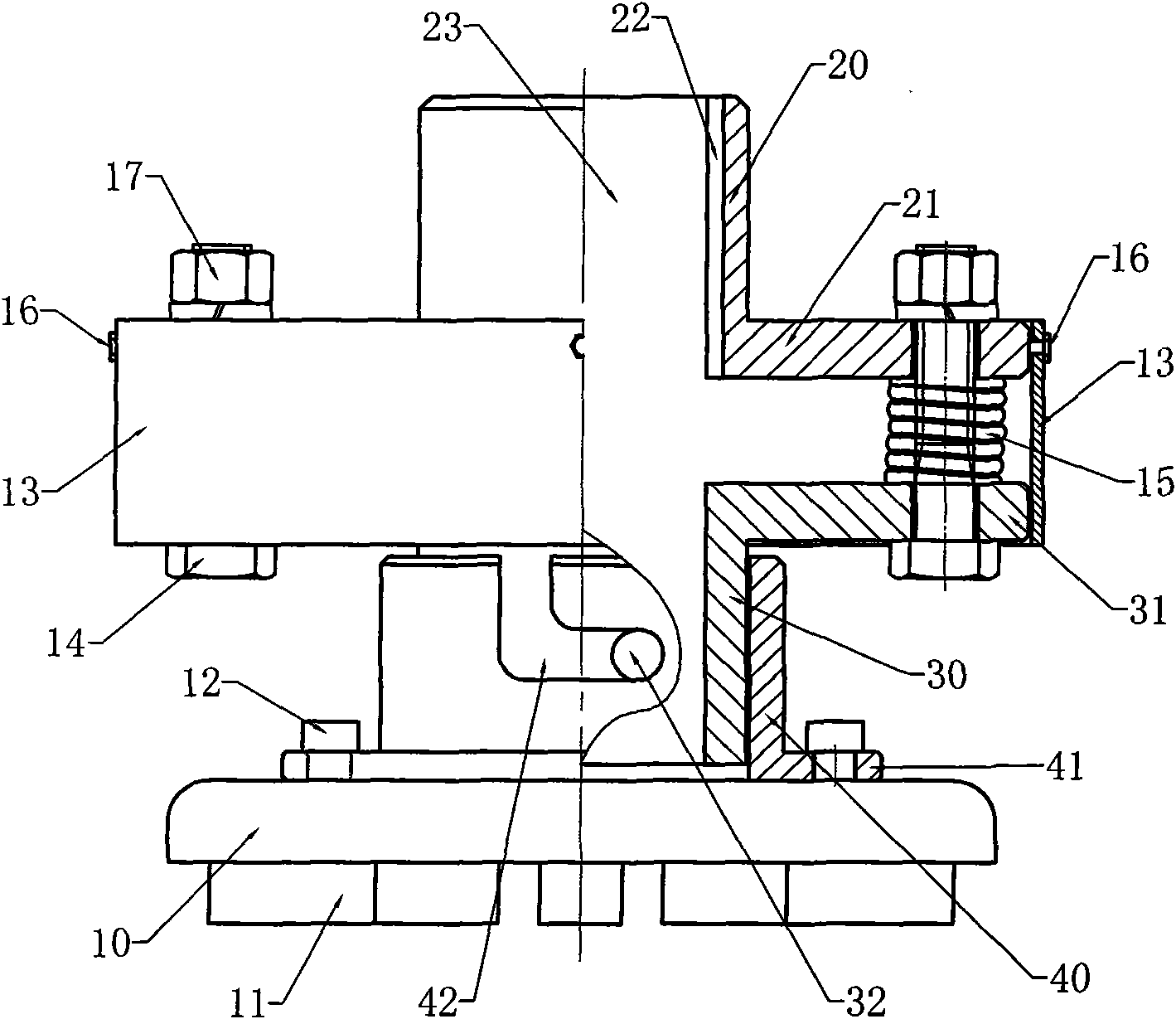

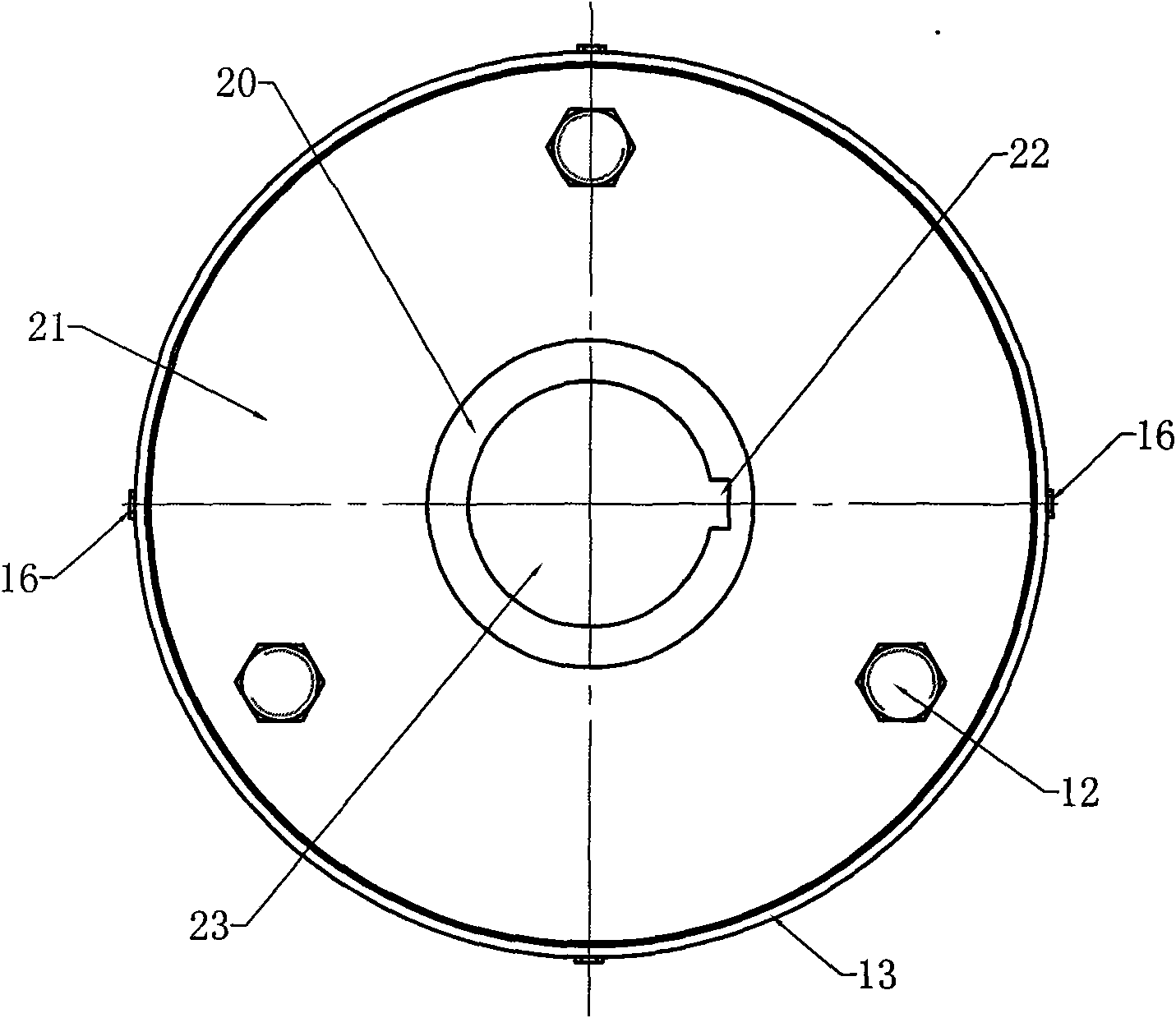

Polishing grinding head

The invention relates to a polishing grinding head, comprising a grinding disc and a grinding head installation structure, wherein a cylindric lower grinding seat, a cylindric middle grinding seat and a cylindric upper grinding seat are successively arranged on the upper part of the grinding disc; the lower end of the lower grinding seat, the upper end of the middle grinding seat and the lower end of the upper grinding seat are respectively provided with a flange plate, the grinding disc is connected with the flange plate of the lower grinding seat by bolts, the cylindric lower grinding seat is externally nested on the cylindric middle grinding seat and is in transmission connection by a fastening device, and an elastic connecting device is arranged between the flange plate of the cylindric middle grinding seat and the flange plate of the cylindric upper grinding seat. The elastic connecting device is arranged between the flange plate of the upper grinding seat and the flange plate of the middle grinding seat, so that the flange plates can automatically change the inclined angles of the grinding disc along with the shapes of processed workpieces so as to adapt to the processing of the cambered workpieces with uneven surfaces; and the grinding head can reduce the processing noise and increase the percent of pass of products.

Owner:JIEYANG HESHENG MACHINERY STONE

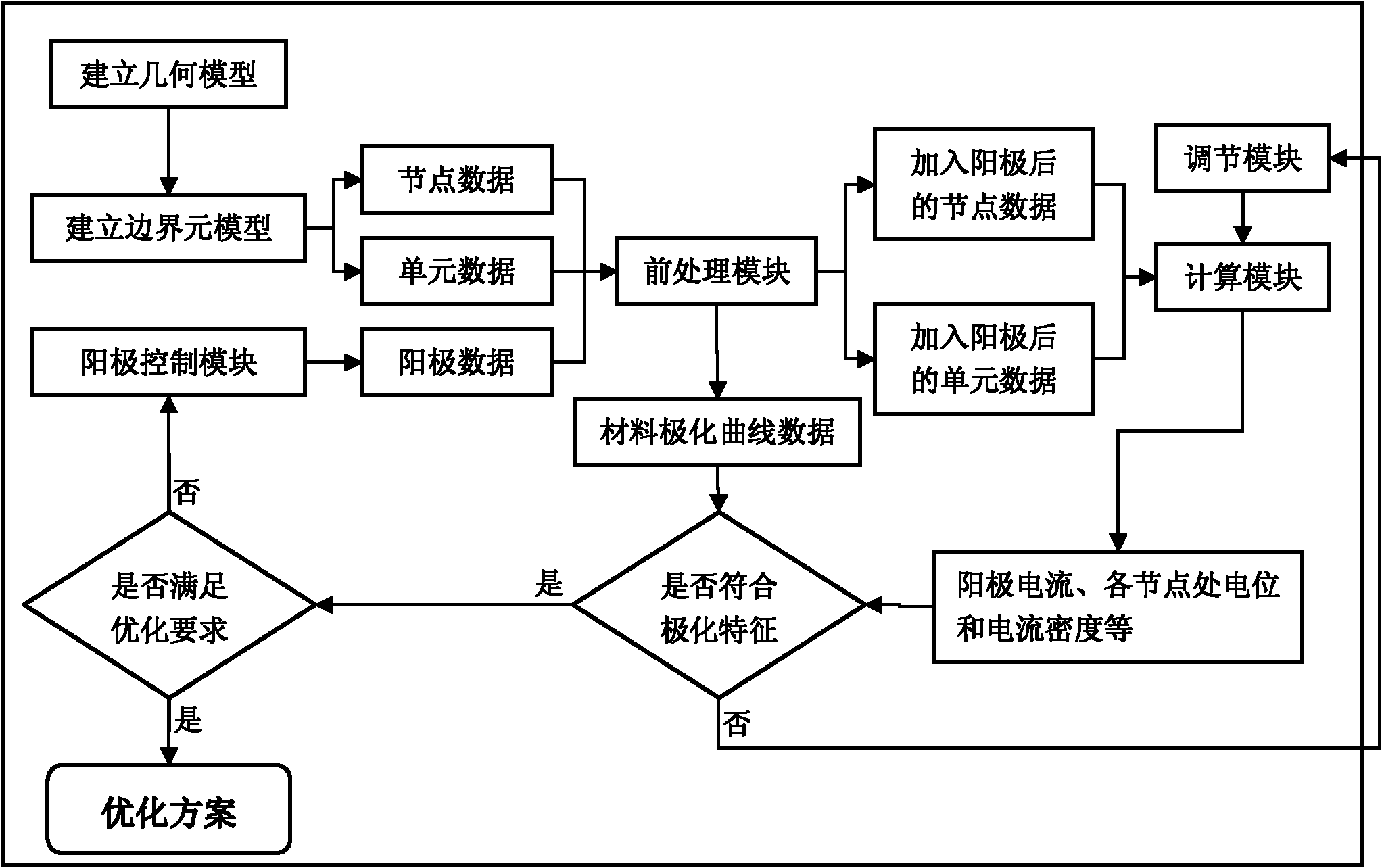

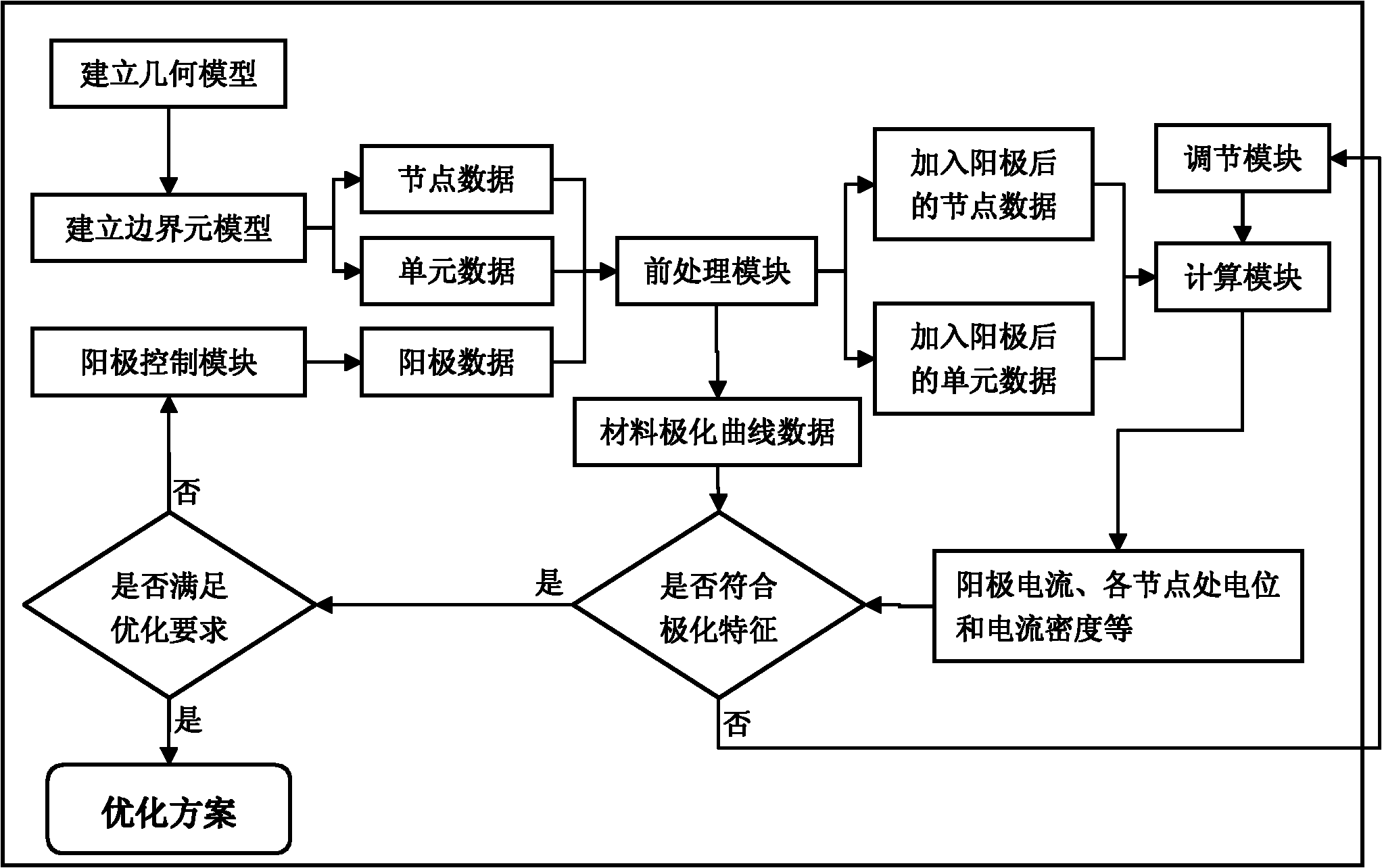

Optimal design method for cathode protection system of drilling platform ballast water tank

InactiveCN102043888AReduce overall weightReduce weightSpecial data processing applicationsOptimal designWater tanks

The invention discloses an optimal design method for a cathode protection system of a drilling platform ballast water tank. Based on boundary element numerical value analog simulation calculation, the optimal design method comprises the following steps: carrying out geometric modeling to a target platform by computer modeling software, and determining numbering information, space coordinate information and other information of each unit and each node in a boundary element model; loading an anode control module to generate digitalized sacrificial anode information; carrying out numerical value simulation calculation by a boundary element algorithm; judging whether the calculation result conforms to polarization characteristics; and judging whether optimized conditions are satisfied nor not. In the method, numerical value calculation is carried out on the basis of the boundary element algorithm, continuous potential information of the structure surface can be obtained, and when the protection potential of any local structure can not satisfy the requirement, the anode is adjusted and calculated again until all protection potential at any position satisfies the requirement. Thus, the problems of 'adsorption-type shielding effect' and 'dodging-type shielding effect' are perfectly solved, and the service life of the platform is prolonged.

Owner:DALIAN UNIV OF TECH

Car controller fixing structure

ActiveCN104386005AReduce overall weightEasy to install and removeElectric/fluid circuitControl theoryRivet

The invention discloses a car controller fixing structure, comprising an upper bracket, a controller box and a lower bracket, wherein the upper bracket is connected with the controller box in a clamping manner; the upper bracket is connected with the lower bracket in an inserting manner; a clamping point and an inserting sheet are arranged on the upper bracket; a limiting hole is also formed in the upper bracket; a clamping spring sheet and a limiting lug boss are arranged on the controller box; an inserting groove is formed in the lower bracket. According to the car controller fixing structure disclosed by the invention, on the basis that the overall strength of an installation structure of the controller is ensured, an original connection mode of screwing by virtue of a plurality of bolts or riveting by virtue of rivets is replaced with a clamping connection mode through coordination of the clamping spring sheet which is arranged on the controller box and the clamping point which is arranged on the upper bracket; the overall weight of the controller fixing structure is greatly reduced; installing and dissembling of the controller are relatively convenient and fast through the clamping and inserting modes; the installation and maintenance efficiencies of the controller fixing structure are improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

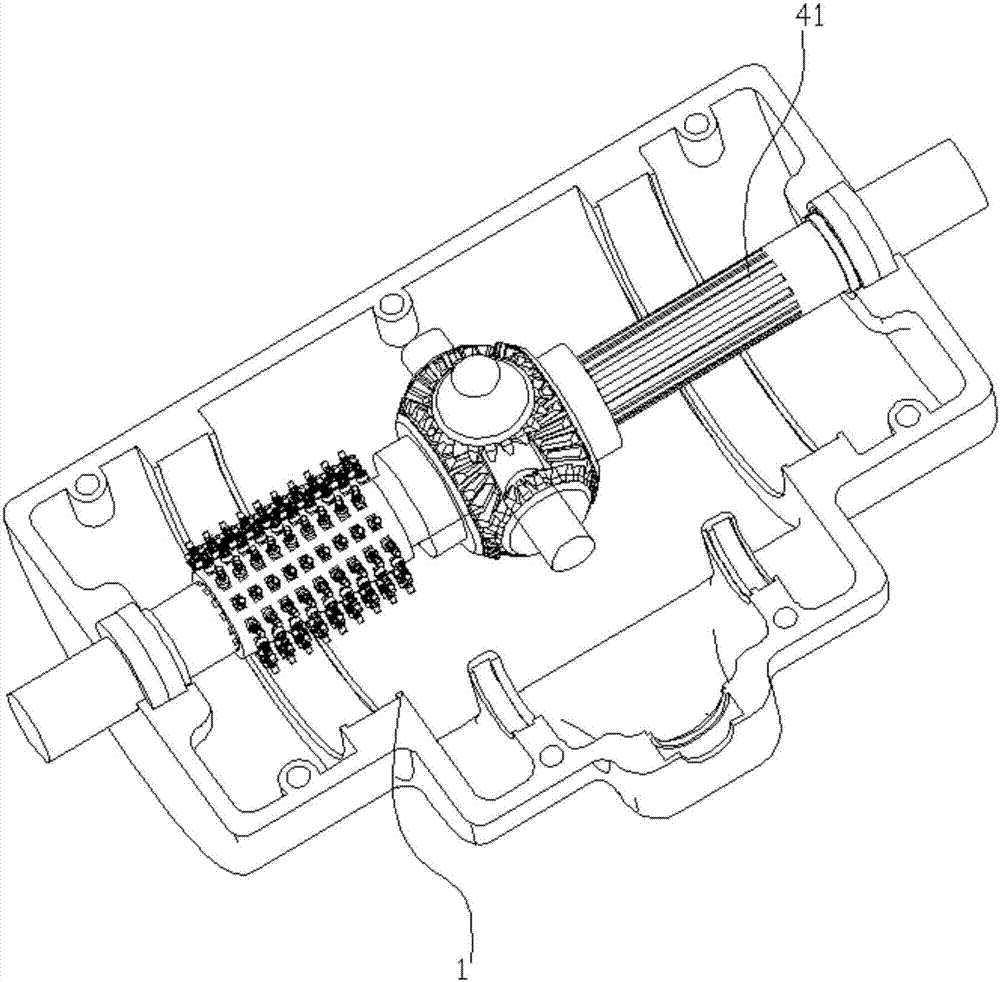

Differential with full-automatic mechanical differential lock

InactiveCN106895128AIncreased size and weightReduce overall weightDifferential gearingsControl devicesEngineeringPlanet

A differential with a fully automatic mechanical differential lock provided by the present invention includes a differential case, a differential cover, a differential lock, an output shaft, a driven gear, a transmission mechanism, and a planetary gear. The differential cover , the driven gear and the transmission mechanism are installed in the differential case; the differential cover and the transmission mechanism are meshed through gears, the differential lock and the output shaft are installed in the differential cover, and the differential lock is installed on the output shaft , the output shaft includes a right half shaft and a left half shaft symmetrically installed in the differential cover. The right half shaft and the left half shaft are meshed through planetary gears. When the vehicle slips, the slider slides The block is in contact with the inner wall of the round hole of the outer ring body. At this time, the axle gear and the differential case rotate at the same speed, and the differential is in a locked state; The inner wall surface of the circular hole enables the differential gear to be released from the locked state. As a result, the differential can be automatically locked and unlocked according to the running state of the vehicle, which solves the inconvenience of manually locking the differential and improves the passability of the vehicle.

Owner:张道勤

Rope-driven mechanical finger and manipulator with same

InactiveCN109262603ASimplify the structure of the manipulatorReduce overall weightProgramme-controlled manipulatorGripping headsDrive motorManipulator

The invention relates to a rope-driven mechanical finger, comprising a base, a rope driving device, a first finger segment, a second finger segment and a third finger segment. The base, the first finger segment, the second finger segment and the third finger segment are coaxially and serially connected in sequence. Each finger segment includes an upper platform, a lower platform, a center supportmechanism and a plurality of springs, two ends of the center support mechanism are fixed to the center of the upper platform and the center of the lower platform respectively, the center support mechanism can bend and rotate, and the springs are distributed evenly between the upper platform and the lower platform outside the center support mechanism. The rope driving device includes a traction rope, a winding wheel and a driving motor, the driving motor and the winding wheel are fixed to the base, the winding wheel is coaxially connected with an output shaft of the driving motor, the tractionrope is passed through the springs of the first, second and third finger segments, the first end of the traction rope is fixed to the upper platform of the third finger segment, and the second end ofthe traction rope is connected with the winding wheel. The rope-driven mechanical finger has small rotational inertia and high transmission precision and can bend continuously.

Owner:YANSHAN UNIV

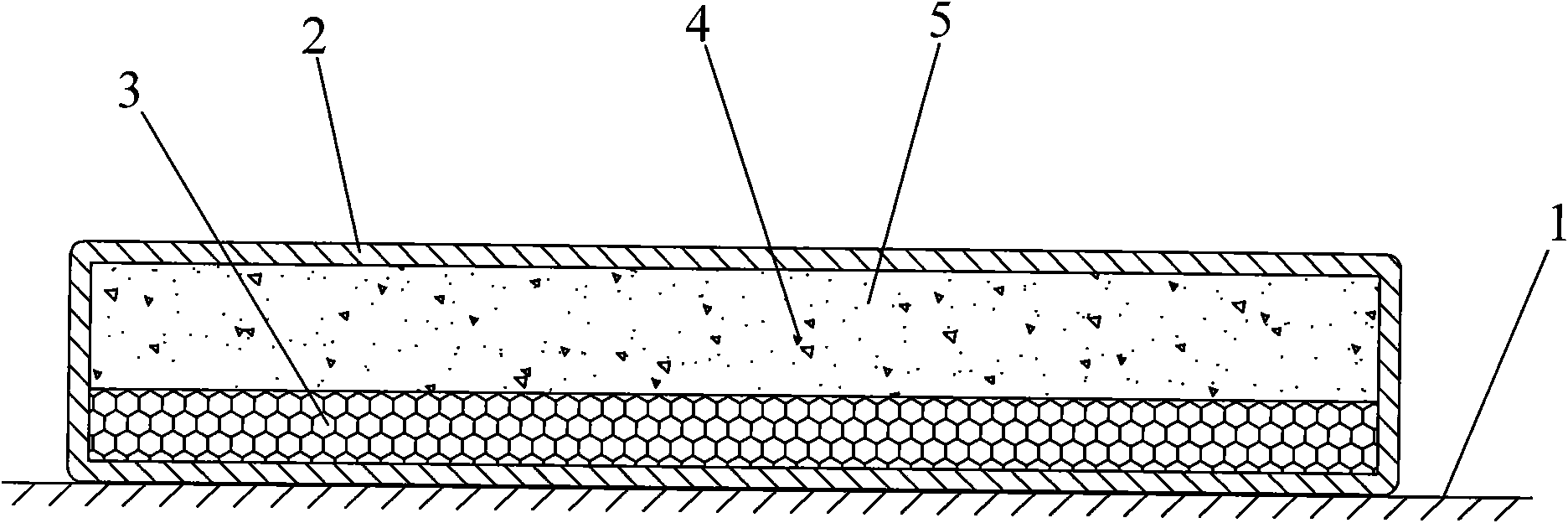

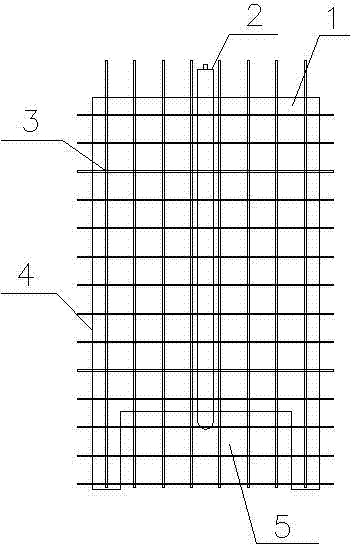

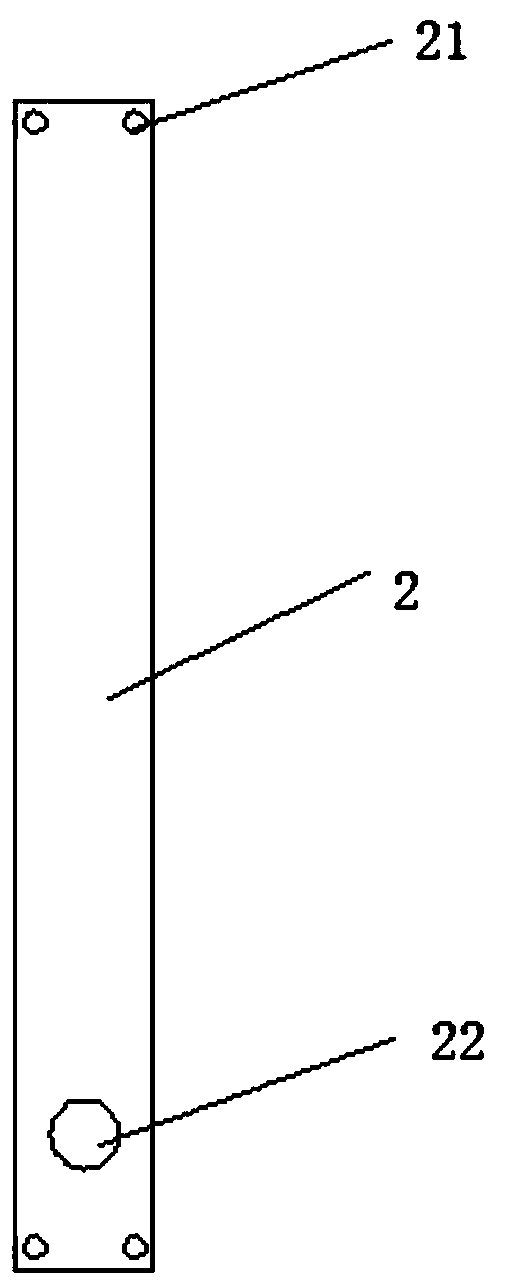

Concrete prefabricated wall body and vertical pouring hole remaining method thereof

InactiveCN104260198AReduce overall weightEasy to operateWallsCeramic shaping apparatusRebarPneumatic pressure

The invention relates to a concrete prefabricated wall body and a vertical pouring hole remaining method thereof. A through vertical pouring hole is formed in the concrete prefabricated wall body corresponding to a cast-in-site section. The vertical pouring hole remaining method comprises producing an inflatable rubber core mold which is matched with the vertical pouring hole in diameter and length, drawing the rubber core mold to penetrate a tied wall body reinforced cage through a rope and enabling an inflatable nozzle to be placed externally; inflating the rubber core mold through an air pump, controlling the monitoring air pressure trough a pressure gauge during inflation and inflating to the specified pressure; fixing the upper side, the lower side, the left side and the right side of the rubber core mold when wall body concrete is poured; performing vibration from the bilateral sides of the rubber core mold simultaneously during concrete vibration to prevent the rubber core mold from moving laterally; deflating the rubber core mold and pulling out the rubber core mold after the concrete is finally set. According to the concrete prefabricated wall body, the design requirements can be met, the total weight of the wall body can be reduced, the wall body vertical pouring hole is reserved in the rubber core mold, the operation is simple, and the labor, the time and materials are saved.

Owner:CHINA 22MCC GROUP CORP

Modularized wooden door with good sound insulation effect and using method thereof

ActiveCN110080659AReduce overall weightEasy to carryFireproof doorsVentilation arrangementEngineeringMechanical engineering

The invention discloses a modularized wooden door with a good sound insulation effect and a using method thereof. The door comprises a door frame body and a door frame edge sealing plate, wherein thedoor frame main body is of a cuboid cavity structure without a cover on one side; a step groove is formed in the inner edge of the uncovered side of the door frame body. The door frame edge sealing plate is embedded in the step groove of the door frame main body; threaded holes are formed in the door frame edge sealing plate and the groove edge of the step groove in the horizontal direction. The door frame edge sealing plate is locked and fixed on the door frame main body through countersunk head screws; a partition plate is fixedly arranged in the cavity of the door frame body and divides thecavity of the door frame body into a sound-insulation flame-retardant cavity and a ventilation cavity, and the wooden door is divided into the sound-insulation flame-retardant cavity and the ventilation cavity, so that the practicability of the wooden door is higher, flame retardance and sound insulation can be achieved, and intelligent ventilation can be achieved.

Owner:宿州闼闼晨瑞木业有限公司

Plastic cushion featured by coexistence of pipe network and filaments, its production technology and rotary type molding handpiece

ActiveCN102217867AHigh strengthReduce overall weightStuffed mattressesSpring mattressesCushionEngineering

A plastic cushion featured by a coexistence of pipe networks and filaments provided by the invention comprises plastic filaments with a disordered arrangement and connections with each other, and a pipe network in the cushion. The production technology comprises the following steps that: raw materials are sent into an extruder to heat for plasticizing to form a melt; the melt is extruded from a rotary type molding handpiece, the plastic filaments extruded from a fixed mold discharging opening move downward to form disordered filaments through a shaping roller and form connections at the points of contact with each other; the plastic filaments extruded from the second grooves around a rotating mold arranged at the inner side of the fixed mold form a pipe network, and are provided with cavities inside the pipe network; the extruded formed plastic cushion with the pipe network in the center and filaments on the periphery is cooled for shaping; and the shaped plastic cushion is pulled out from a cooling device for cutting according to specifications. The rotary type molding handpiece is characterized by that: the fixing mole is provided with the rotating mold and the second grooves, the rotating mold is connected with a rotating mechanism. The plastic cushion has the advantages of moderate density, adequate connections of filaments, without spraying glue for enhancement, high fastness and no pollution, and the cushion can be provided with temperature regulation members inside.

Owner:DALIAN PLASTICS RES INST CO LTD

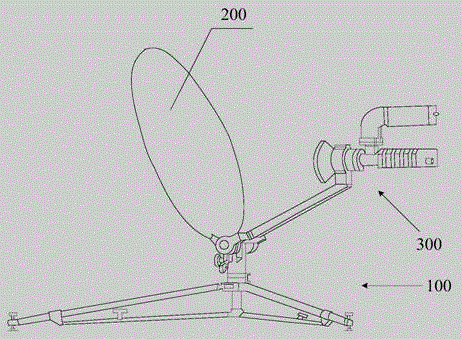

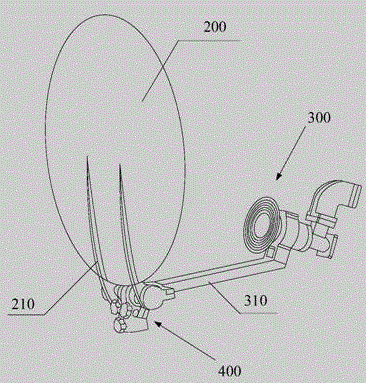

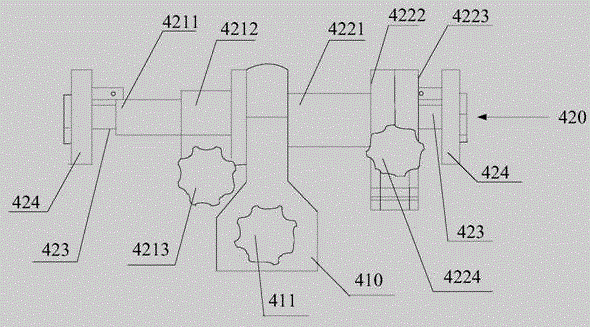

Portable satellite antenna

InactiveCN106602203AReduce overall weightReflection orientation is easy to adjustPivotable antennasAntenna supports/mountingsPhysicsSatellite

The invention relates to a portable satellite antenna. The portable satellite antenna includes a base, a reflecting plate detachably connected with the base, and a feed source device detachably connected with the base, the included angle between the reflecting plate and the base is adjustable, the reflecting plate is made of carbon fiber materials, the included angle between the feed source device and the base is adjustable, and the relative position between the feed source device and the reflecting plate can be adjusted through the included angle between the feed source device and the base. The portable satellite antenna is portable and meets the needs for outdoor portable use while guaranteeing the easy adjustment of satellite antenna reflection position through the angle adjustable design and the detachable design between the reflecting plate and the base and the feed source device and the base.

Owner:SPACE STAR TECH CO LTD

Manufacturing process of high-power short-circuit protection reactor

ActiveCN103700479AReduce overall weightLow manufacturing process costCoils manufactureShort circuit protectionHigher Power

The invention discloses a manufacturing process of a high-power short-circuit protection reactor. The manufacturing process includes the following steps: selecting materials; winding a coil; manufacturing a leading-out copper pipe and a leading-out copper row; welding the leading-out copper pipe with the leading-out copper row; testing pressure and flow; processing and shaping the surface of the coil; preparing before pouring a resistor body; pouring the resistor body; testing a finished product. The manufacturing process is low in cost and high in working efficiency; by the manufacturing process, position deviation or deformation during forming of the coil can be effectively prevented, shape and size of the reactor in large-scale production is ensured to realize standardization, and overall weight of the reactor can be reduced.

Owner:INDUCTOTHERM GROUP CHINA +1

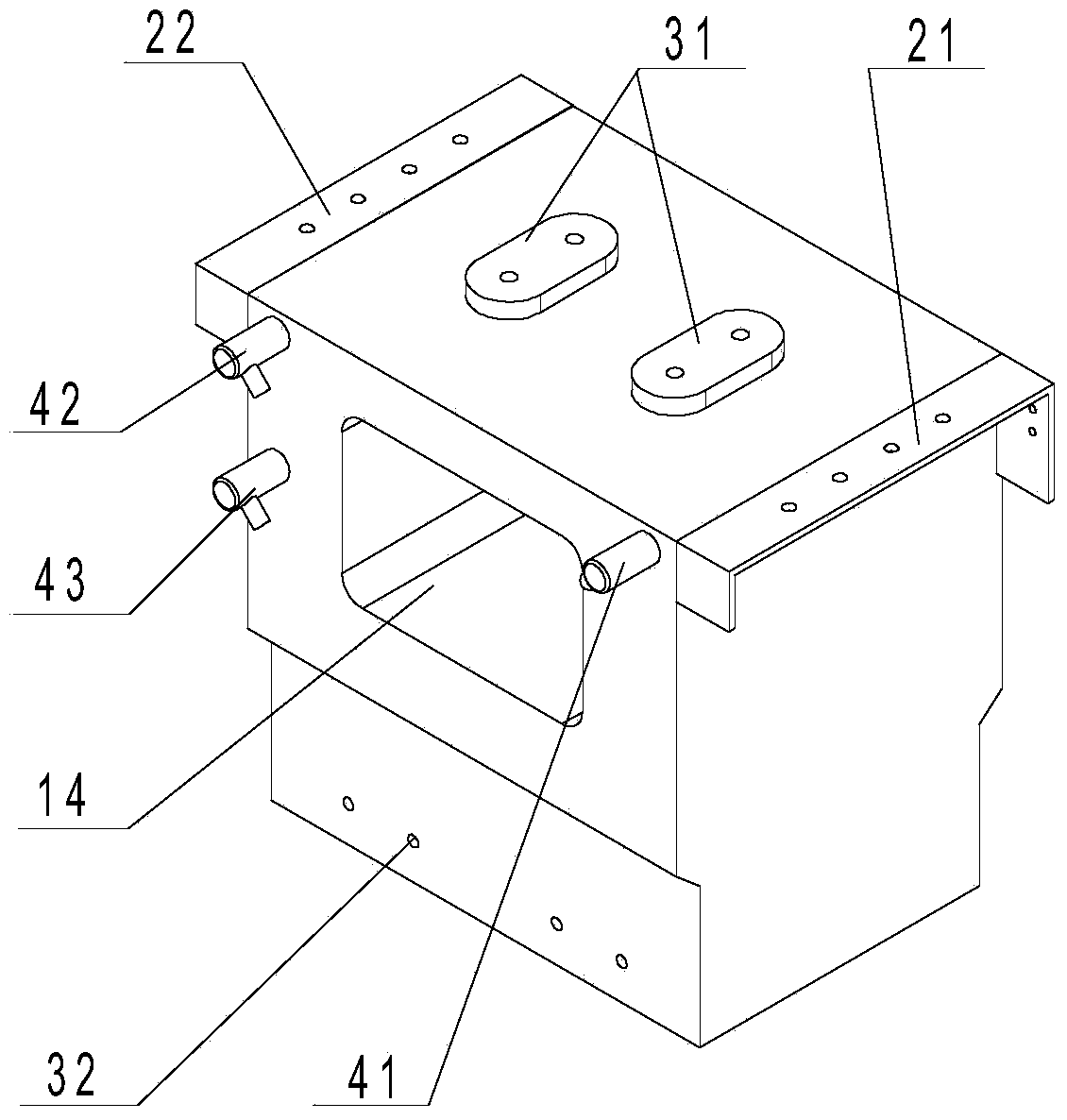

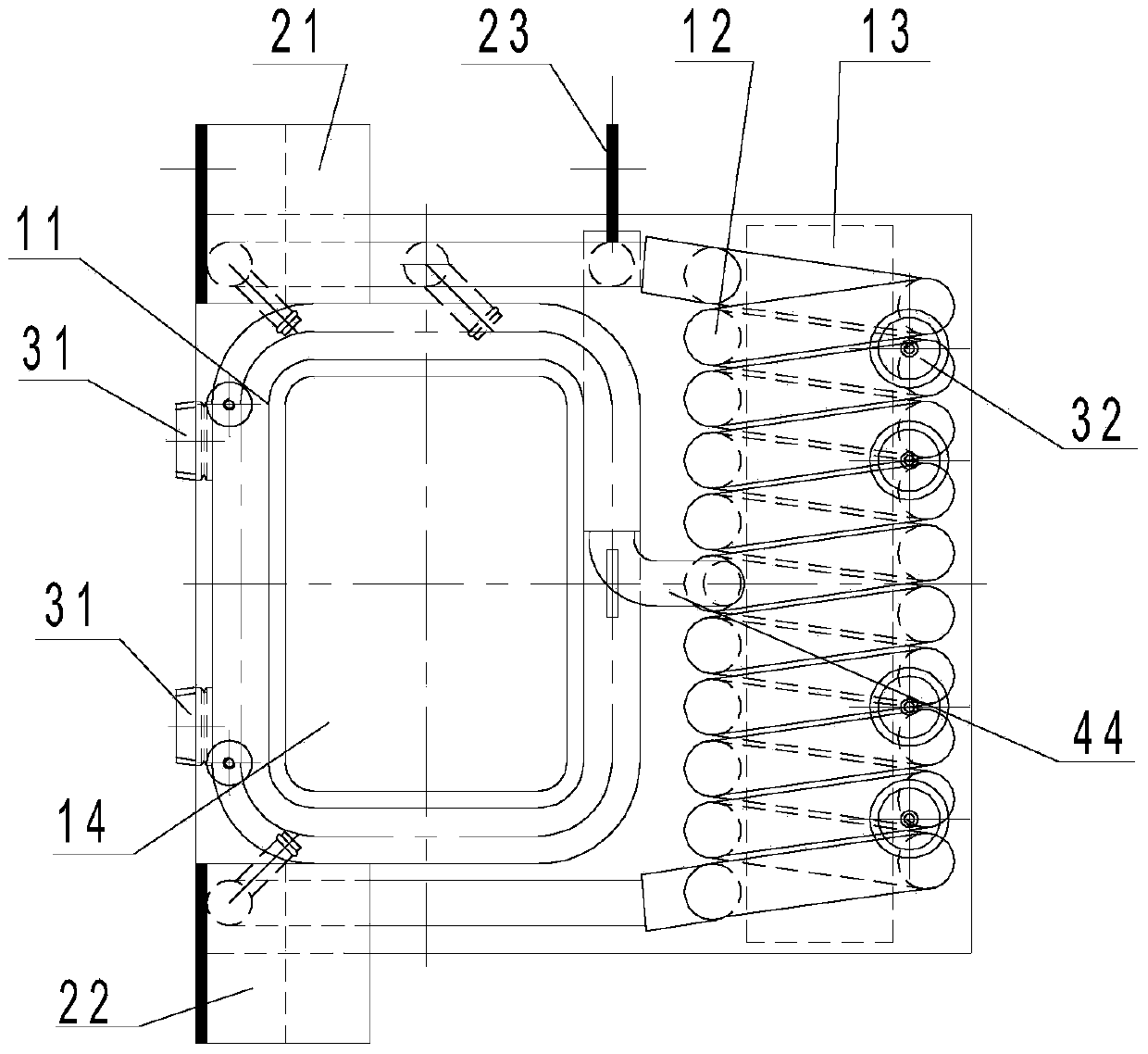

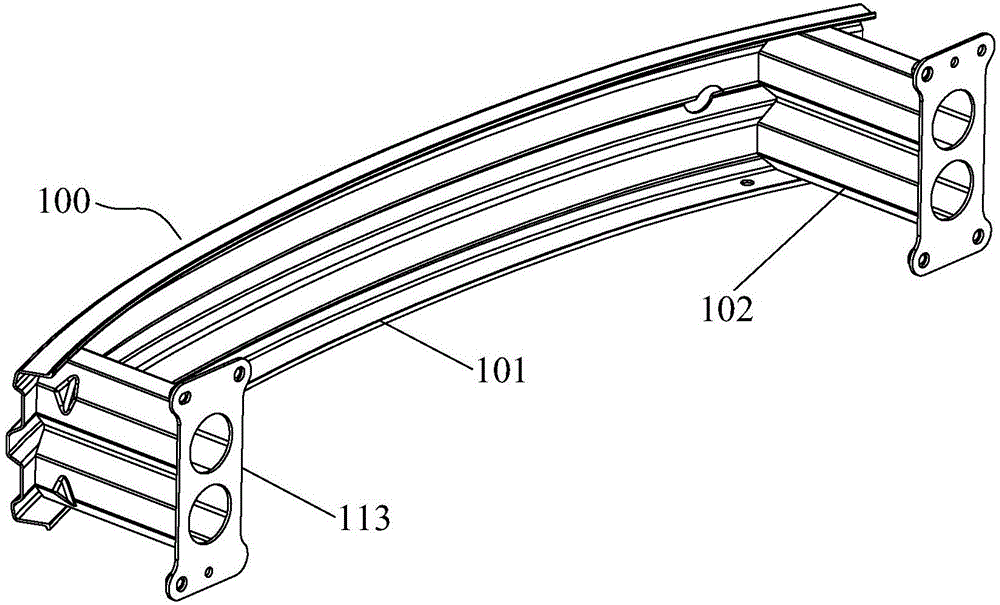

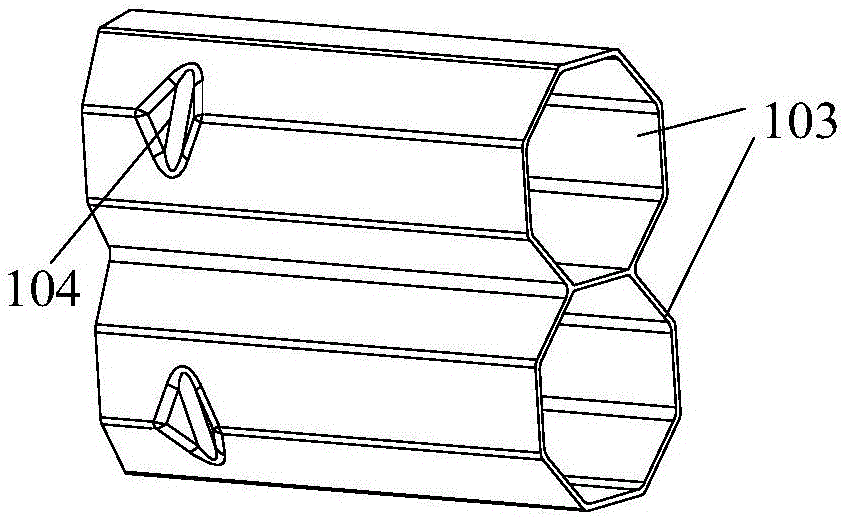

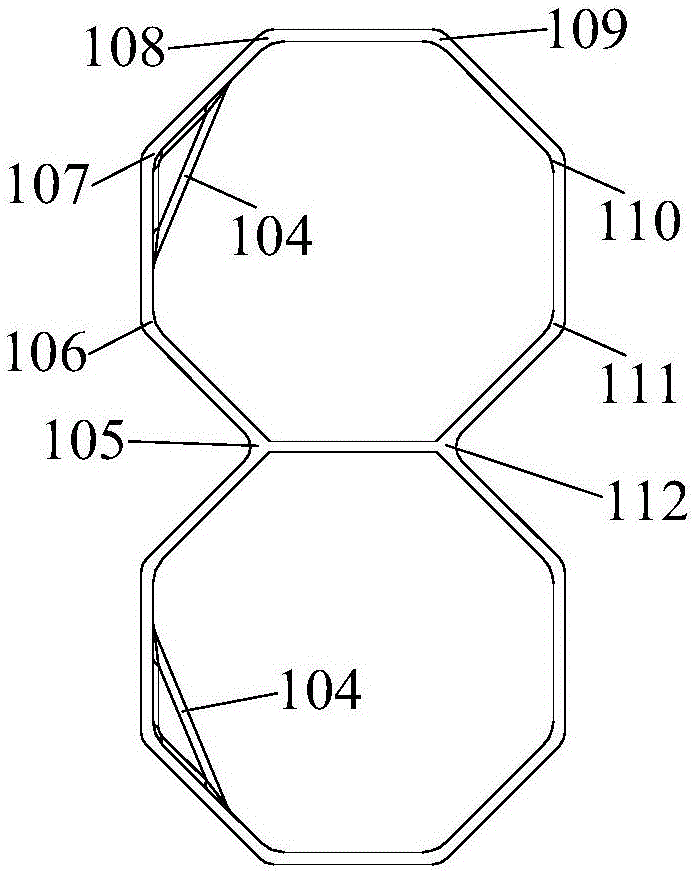

Vehicle front anticollision beam assembly

The invention discloses an automobile front anti-collision beam assembly, comprising an anti-collision beam body and an energy-absorbing box, the energy-absorbing box is made of aluminum profiles and has a cavity inside, and the cross-section of the energy-absorbing box is "8" glyph. The automobile front anti-collision beam assembly of the present invention is made of hollow aluminum profiles, and has low overall weight and high strength, which is beneficial to the lightweight of electric vehicles and can effectively extend the cruising range of electric vehicles; and uses an "8"-shaped energy-absorbing box. , to improve the energy absorption effect of the anti-collision beam assembly, which can minimize the damage to the human body caused by the impact.

Owner:奇瑞新能源汽车股份有限公司

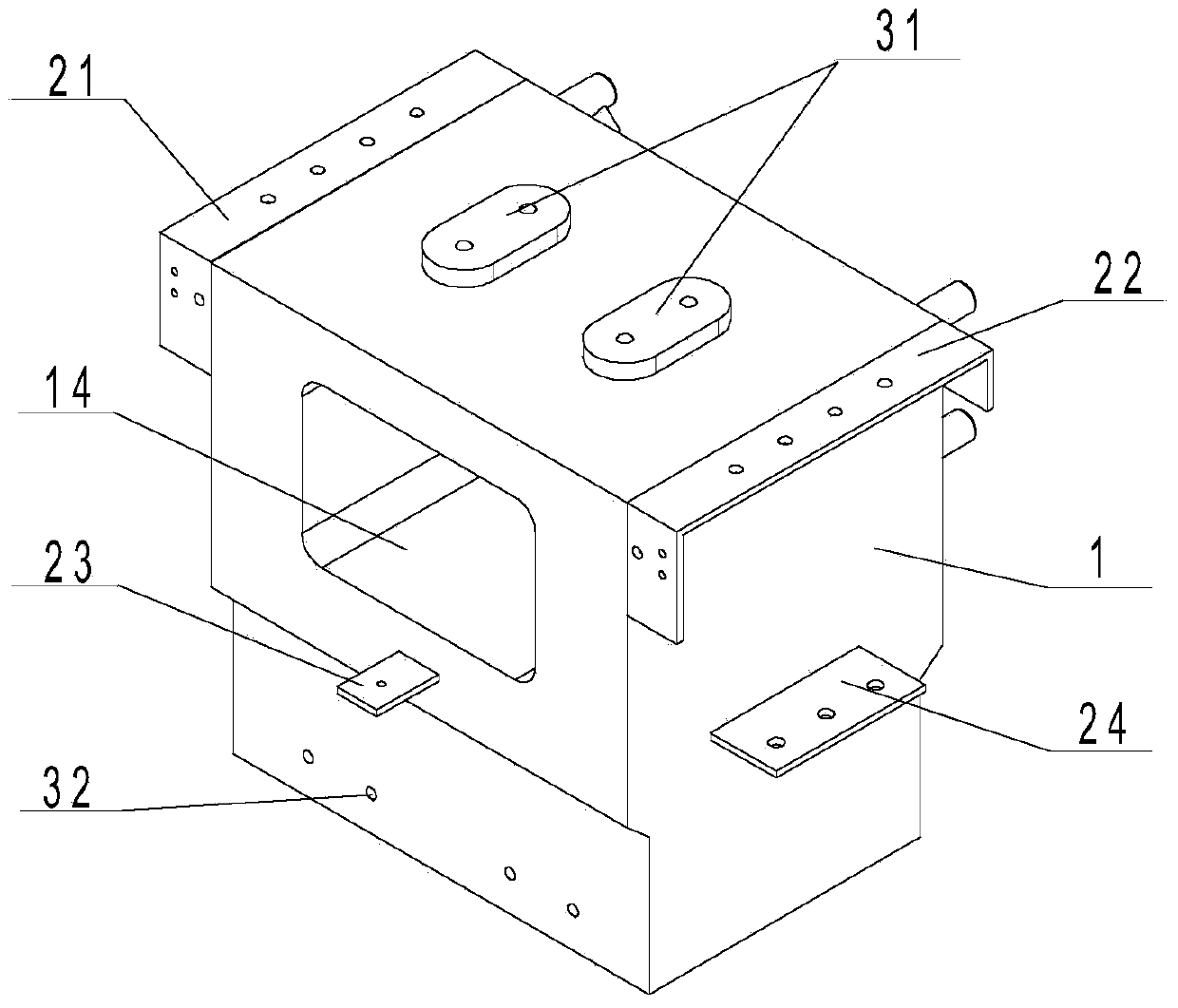

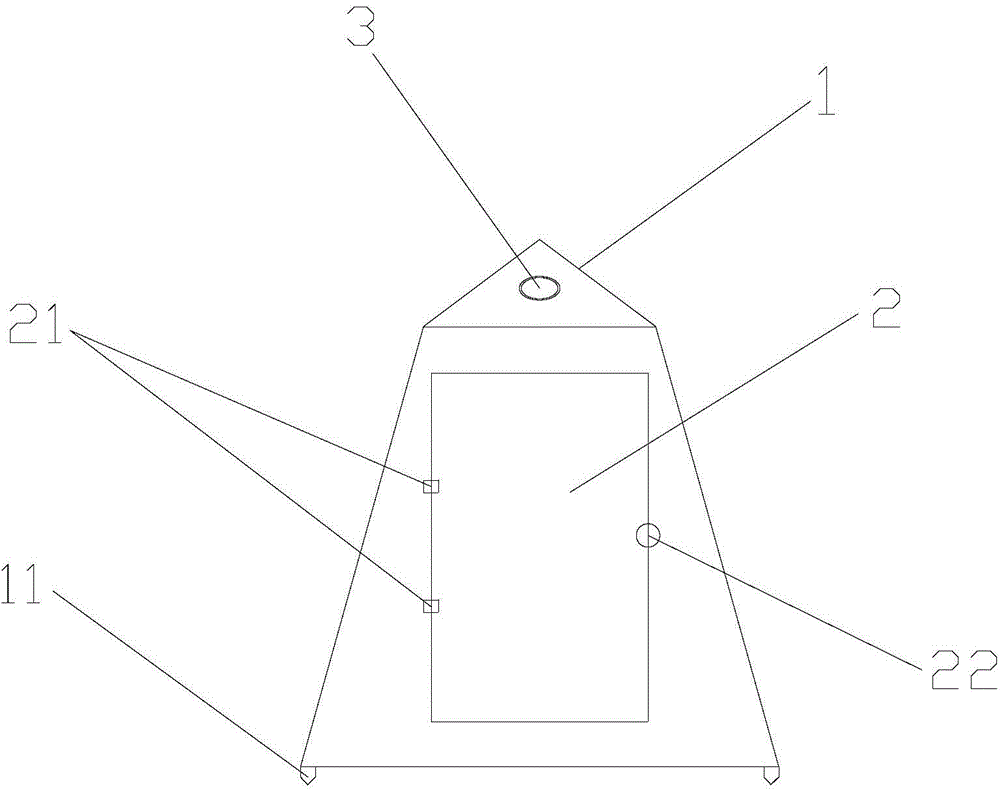

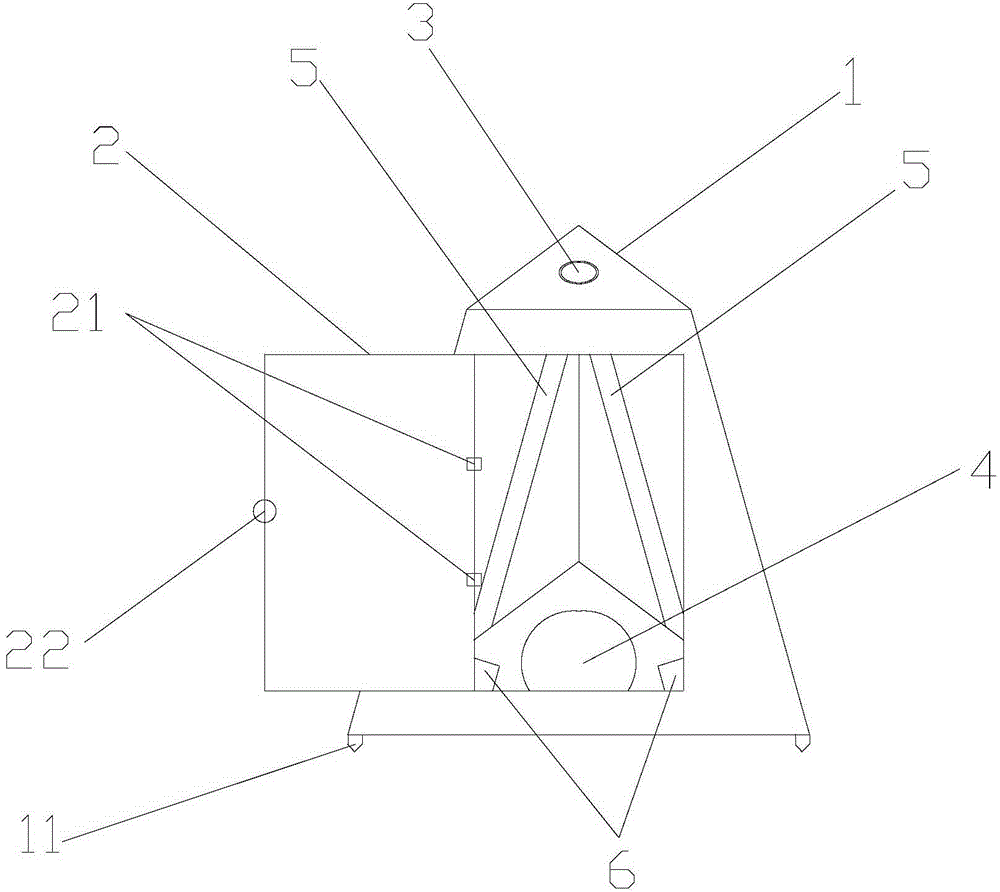

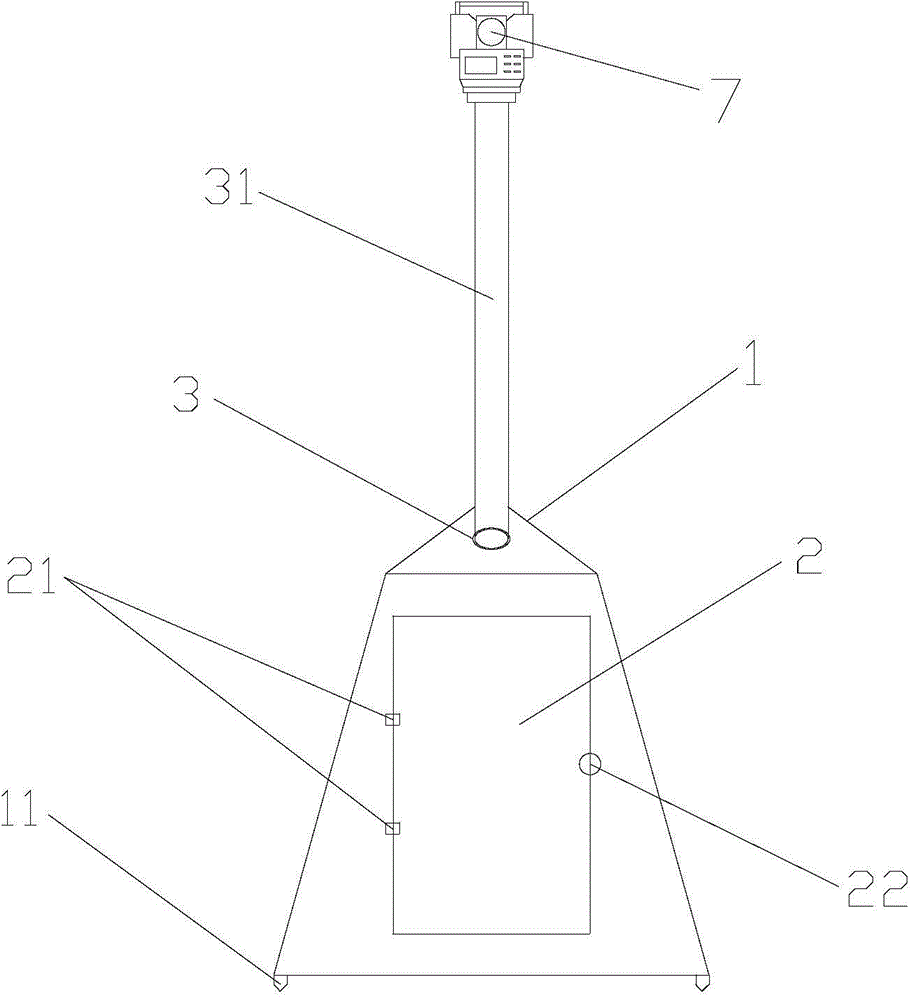

Surveying instrument adaption box

Owner:SUZHOU HUALAI PHOTOELECTRIC INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com