Center driving type water jet bunker cleaning mechanism and cleaning method thereof

A center-driven, water-jet technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of stability and reliability that need to be studied experimentally, and achieve convenient implementation, small overall weight, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

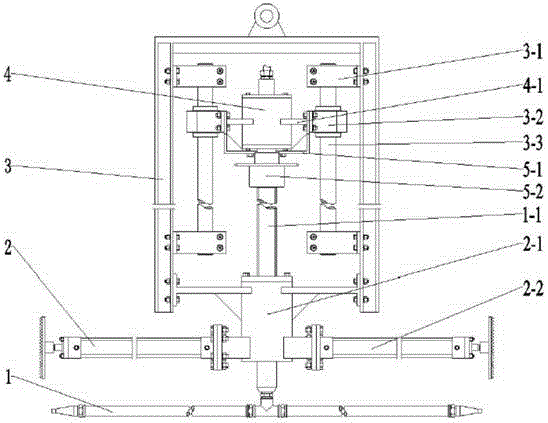

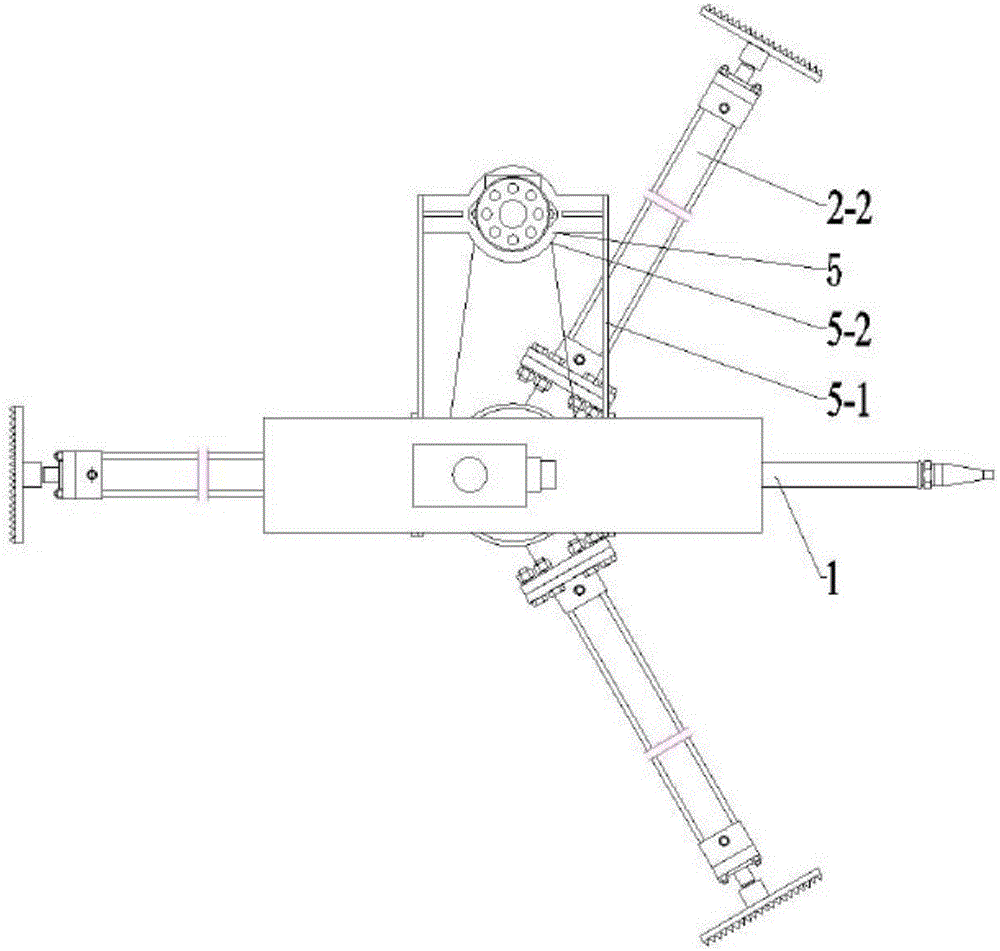

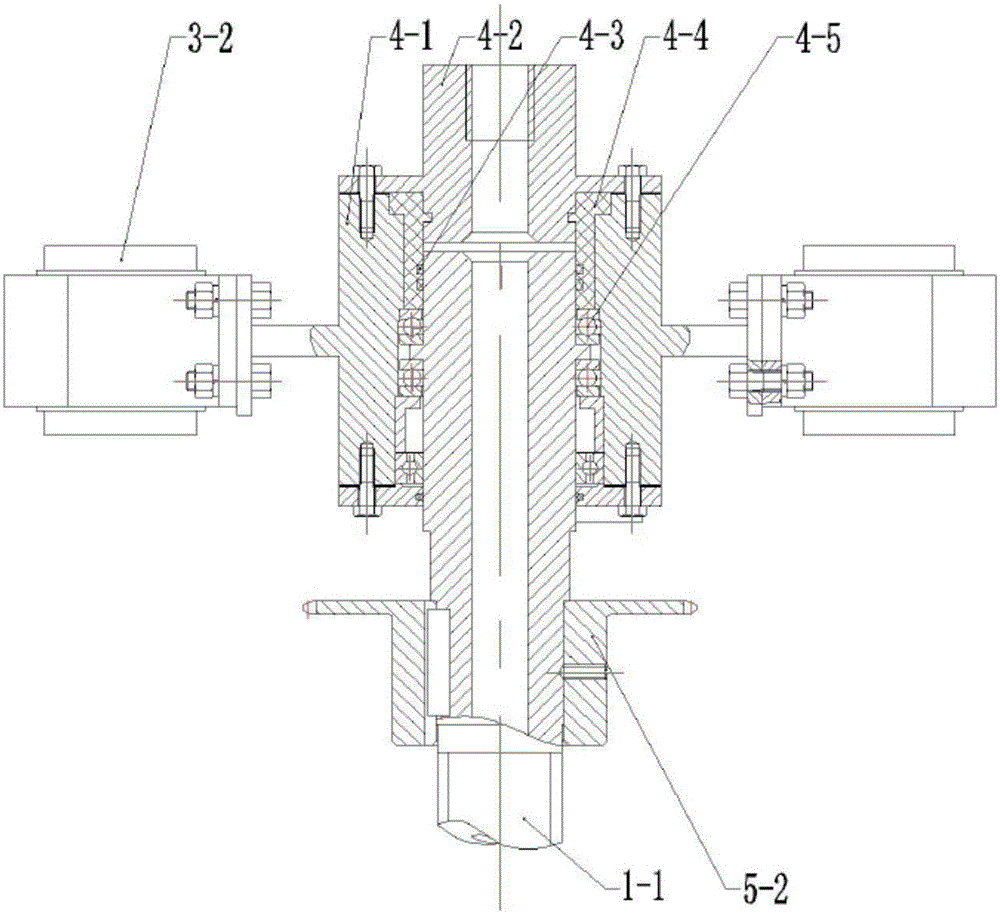

[0025] Such as figure 1 , 2 , 3 and 4 show a center-driven water jet clearance mechanism, including a water jet pipeline 1, a support device 2, a frame 3, a rotary sealing mechanism 4, and a driving rotary mechanism 5, and the support device 2 includes three hydraulic Oil cylinder 2-2, one end of the three hydraulic cylinders 2-2 is uniformly arranged radially on the side wall of the cylinder seat 2-1 around the central axis of the coal bunker, and the other ends of the three hydraulic cylinders 2-2 are supported on The inner wall of the coal bunker. The support device 2 is provided with an oil cylinder seat 2-1, the oil cylinder seat 2-1 is set as a whole with the frame 3, and a hollow rod 1-1 is arranged through the oil cylinder seat 2-1, and the hollow rod 1-1 The middle part of the cylinder base 2-1 is threaded and rotated, and the lower end of the hollow rod 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com