Optimal design method for cathode protection system of drilling platform ballast water tank

A cathodic protection, drilling platform technology, applied in the field of marine engineering, to achieve the effect of reducing weight, improving operating capacity, and increasing variable load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

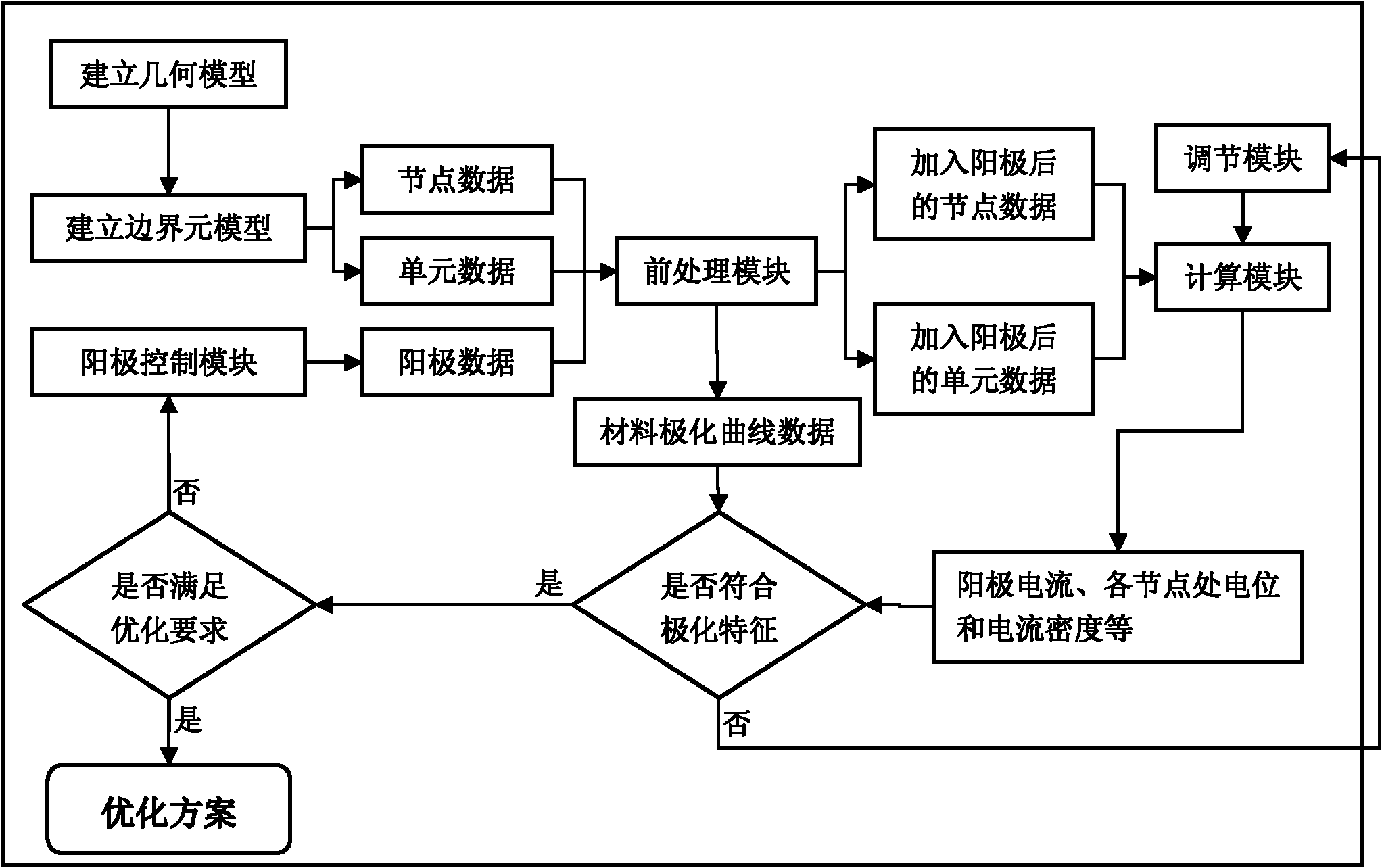

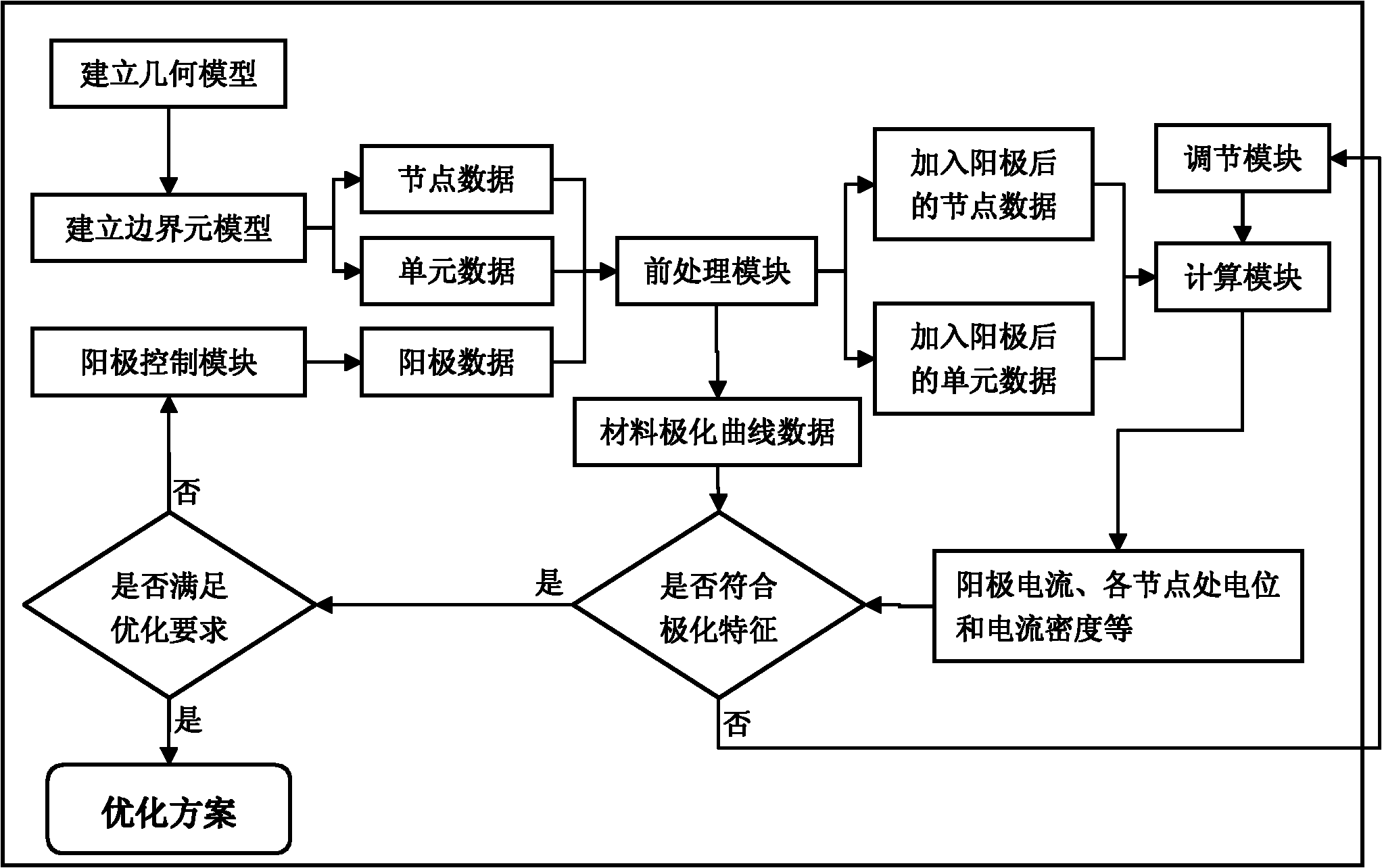

Method used

Image

Examples

Embodiment Construction

[0025] The beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings. The present invention calculates as follows taking the ballast water tank of certain in-service deepwater semi-submersible drilling platform as an example:

[0026] The basic parameters required by the design: the design life is 12 years, the protection area is 59228m2, the service marine environment parameters...etc.

[0027] When adopting the traditional method, referring to the DNV specification and combining the empirical formula provided by it, the anode layout scheme A is obtained:

[0028] Anode position: (omitted);

[0029] Total weight of anode: 36117.1kg;

[0030] Number of anodes: 1184 pieces.

[0031] However, when the method of the present invention is adopted, the setting of scheme A is calculated once, that is, without optimization, and the actual protection life of scheme A is only 10.81 years. The protection lifetime can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com