Metal rear cover of mobile electronic product and manufacturing technology thereof

A product metal and mobile electronics technology, applied in the direction of telephone communication, electrical components, telephone structure, etc., can solve the problems of high processing cost, poor mass production, low hardness, etc., achieve fewer machining steps, increase hardness, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0039] The invention provides a metal back cover manufacturing process for mobile electronic products, such as Figures 5a-5e shown, including the following steps:

[0040] (a), the strip 300 is first etched and then cut to a required length;

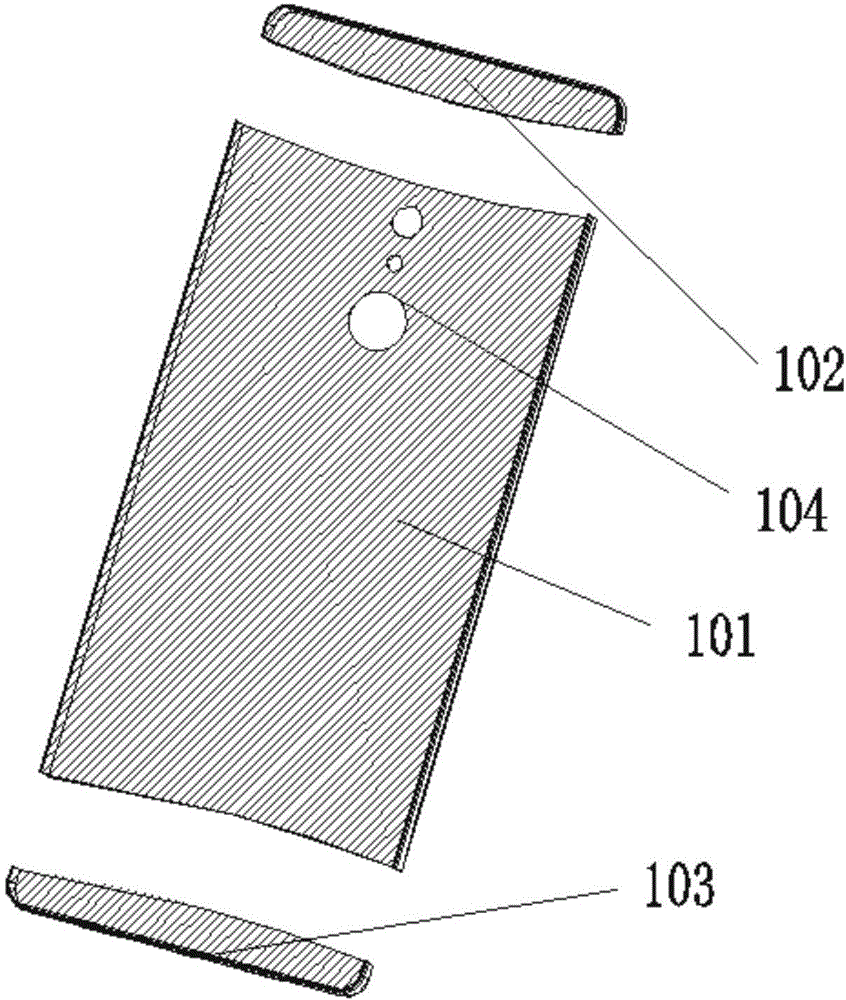

[0041] (b), punching and forming the trimmed strip 300 into a rear cover 101, an upper frame 102, and a lower frame 103, and then performing CNC rough machining on the rear cover 101, the upper frame 102, and the lower frame 103;

[0042] (c), the rear cover 101 is overlapped with the upper frame 102 and the lower frame 103 respectively to form the rear cover shell 100;

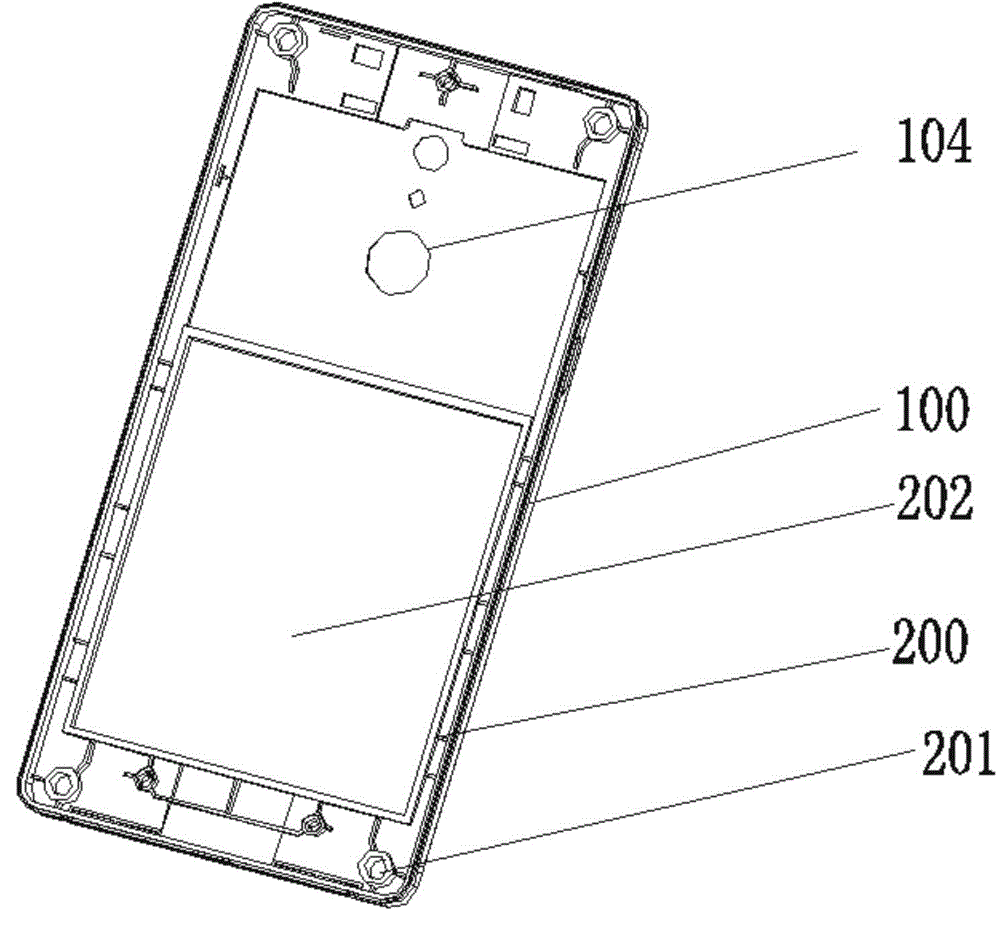

[0043] (d) forming the metal back cover of the mobile electronic product through secondary fixing by injection molding, and forming the inner panel 200 of the back cover through injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com