Concrete prefabricated wall body and vertical pouring hole remaining method thereof

A prefabricated wall and concrete technology, applied in the direction of walls, buildings, building components, etc., to achieve the effect of reducing the total weight and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

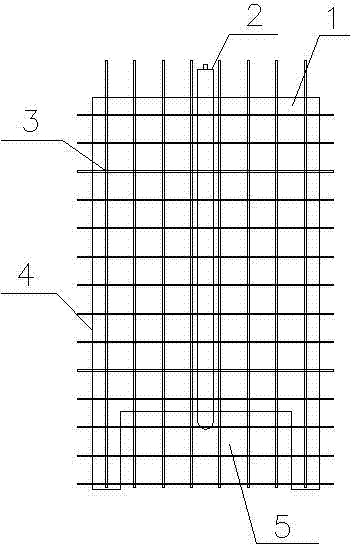

[0022] see figure 1 , the width of the wall body 1 of the prefabricated concrete shear wall is 1600mm, the outriggers are removed, and the cast-in-place section width L=1200mm is reserved for the overlapping parts of the steel bars at the bottom, and a rubber mandrel 2 is placed in the middle part of the wall reinforcement cage 3, Reserve a vertical pouring hole that corresponds to the cast-in-place section 5 and penetrates up and down.

Embodiment 2

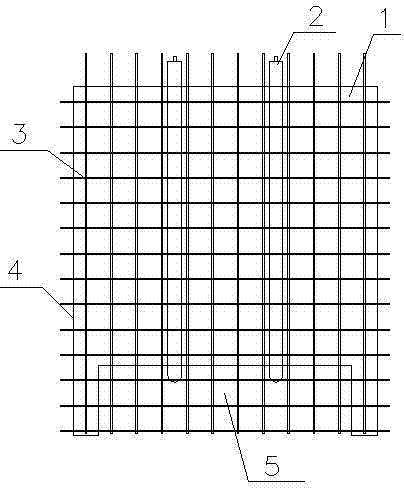

[0024] see figure 2 , the width of the wall body 1 of the concrete prefabricated shear wall is 2400mm, the outriggers are removed, and the cast-in-place section width L=2000mm is reserved for the overlapping parts of the steel bars at the bottom, and the middle part of the wall reinforcement cage 3 is placed by placing two The rubber mandrel 2 reserves two vertical pouring holes corresponding to the cast-in-place section 5 and passing through from top to bottom.

Embodiment 3

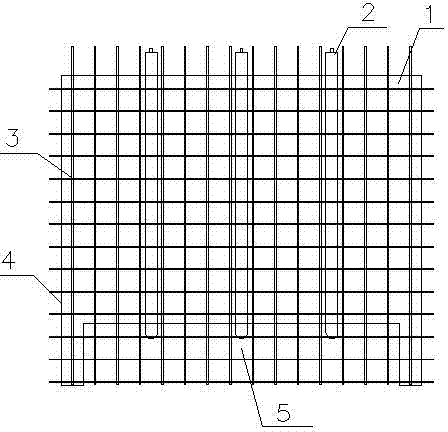

[0026] see image 3 , the width of the wall body 1 of the prefabricated concrete shear wall is 3200mm, the outriggers are removed, and the cast-in-place section width L=2800mm is reserved for the overlapping parts of the steel bars at the bottom, and the middle part of the wall reinforcement cage 3 is placed at intervals. The rubber mandrel 2 reserves three vertical pouring holes corresponding to the cast-in-place section 5 and passing through from top to bottom.

[0027] The concrete prefabricated body of wall described in embodiment 1-3 is poured and molded according to the following steps:

[0028] (1) Molding: Bind the wall reinforcement cage 3 in the prefabricated wall mold 4, and prefabricate the rubber core mold 2 matching the diameter of the vertical pouring hole in the wall body 1 and having a suitable length; The mold 2 penetrates into the wall reinforcement cage 3 that has been bound, and the inflation nozzle is placed outside to avoid sharp hard objects from pierc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com