A light crawler lateral positioning structure

A technology of lateral positioning and track, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc. It can solve the problems of insufficient lateral rigidity of light crawler, achieve the effect of improving overall walking performance, increasing lateral rigidity, and not easy to take off the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

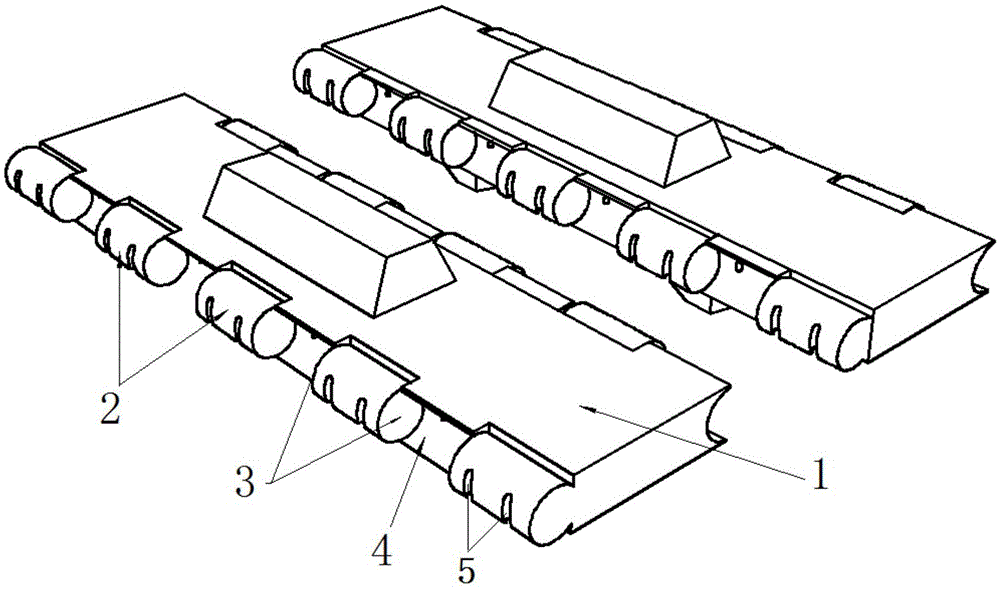

[0009] Below in conjunction with accompanying drawing, the present invention is described in detail: as figure 1 As shown, in the embodiment of the light-duty track lateral positioning structure, it includes nine positioning protrusions 2 arranged in dislocation on both sides of the track joint 1, the positioning protrusions are cylindrical, and the positioning protrusions formed between two adjacent positioning protrusions 2 Groove 4, the two end faces of positioning convex body 2 are positioning surfaces 3, and radially are provided with the cable hole 5 that passes for drag cable, and positioning convex body 2 also can be circular tube shape, not shown in the figure.

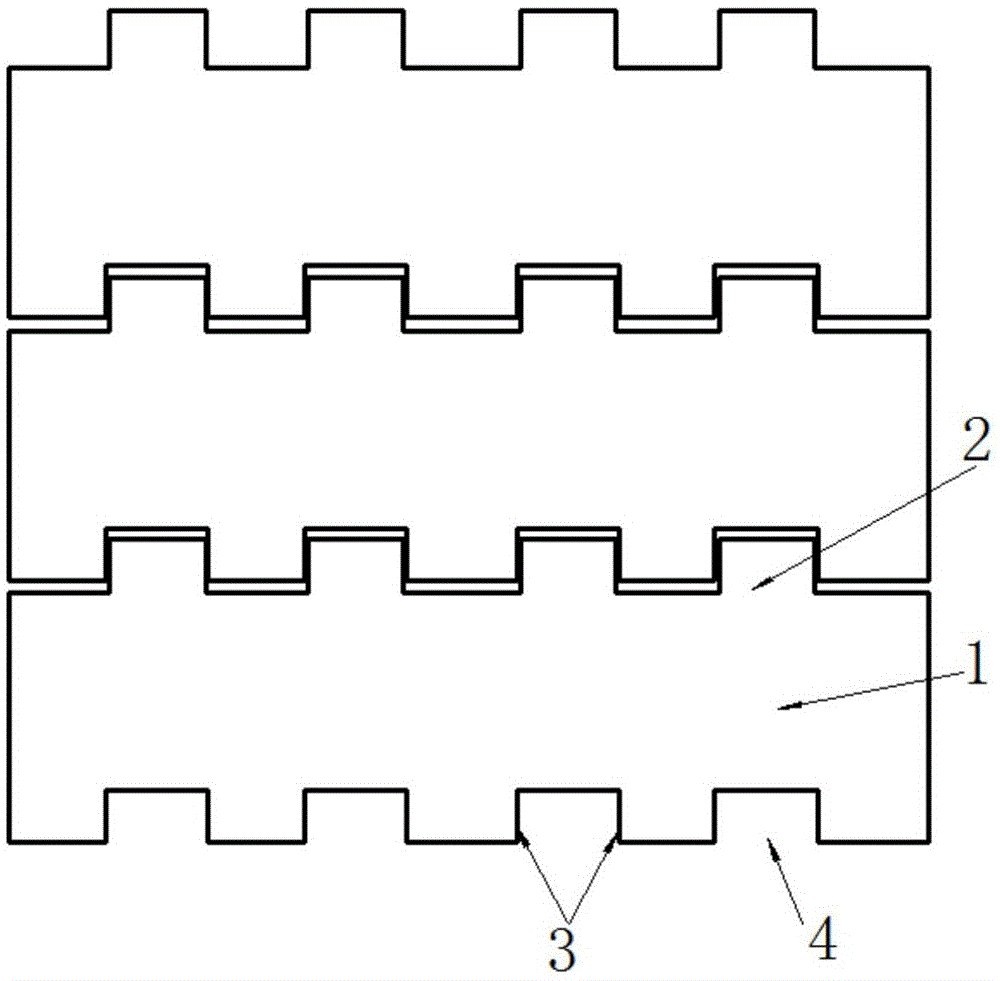

[0010] Such as figure 2 As shown, after two track joints 1 are combined, the positioning protrusion 2 of one track joint 1 is embedded in the positioning groove 4 of the other track joint 1 to form a complementary shape. The positioning surface 3 of one track joint 1 is in contact with the positioning surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com