Poking-proof knitted socks and production process of poking-proof knitted socks

A production process and hosiery-knitting technology, which is applied in the field of textile manufacturing, can solve the problems of low connection strength, poor connection fastness, and low bonding degree, and achieve the effects of not easy to take off silk, enhance bonding fastness, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

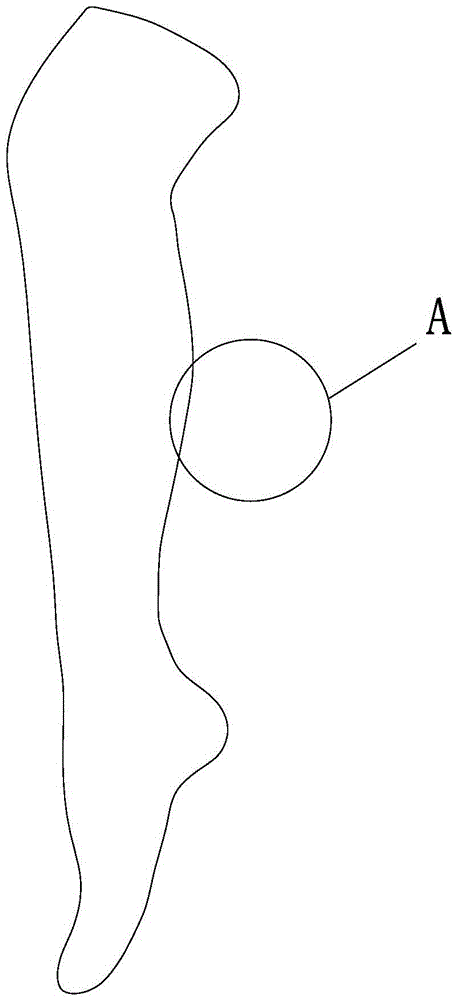

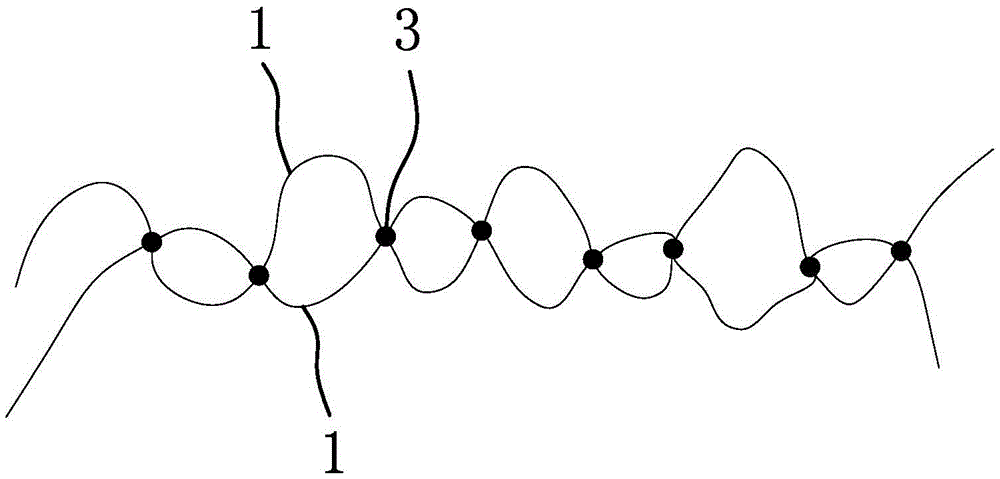

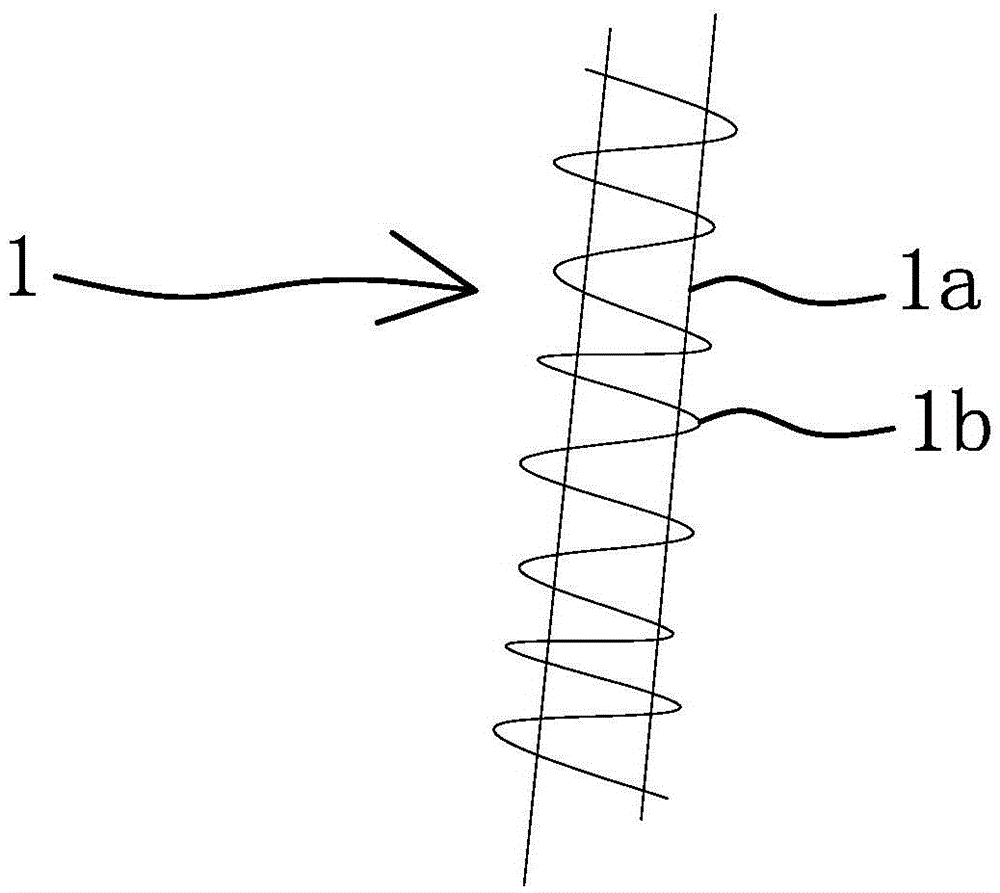

[0024] Such as Figures 1 to 3 As shown, the anti-stab hosiery production process includes the following steps: A, knitting the sock body: knitting the sock body 2 on the sock knitting machine with a cored thread 1 containing meltable spandex; B, pretreatment: knitting the sock body 2. Carry out pre-shrinking and soft treatment for the first time; C. Shaping: put the sock body 2 in a heated and pressurized state so that the meltable spandex in the cored wire 1 of the sock body 2 intersects with each other Precipitation, so that the intersecting parts of the cored wires 1 are fused to form mesh nodes 3, and the sock body 2 is stretched in the heated and pressurized state to make the cored wires 1 at the intersected p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com