Preparation method of self-adhesive organic pigment microcapsules for pigment printing

An organic pigment and paint printing technology, applied in the directions of organic dyes, dyeing, textiles and papermaking, etc., can solve the problems such as the unpublished problem of organic pigment microcapsules, improve color fastness and hand feel, improve dispersibility and dispersion stability The effect of improving the stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

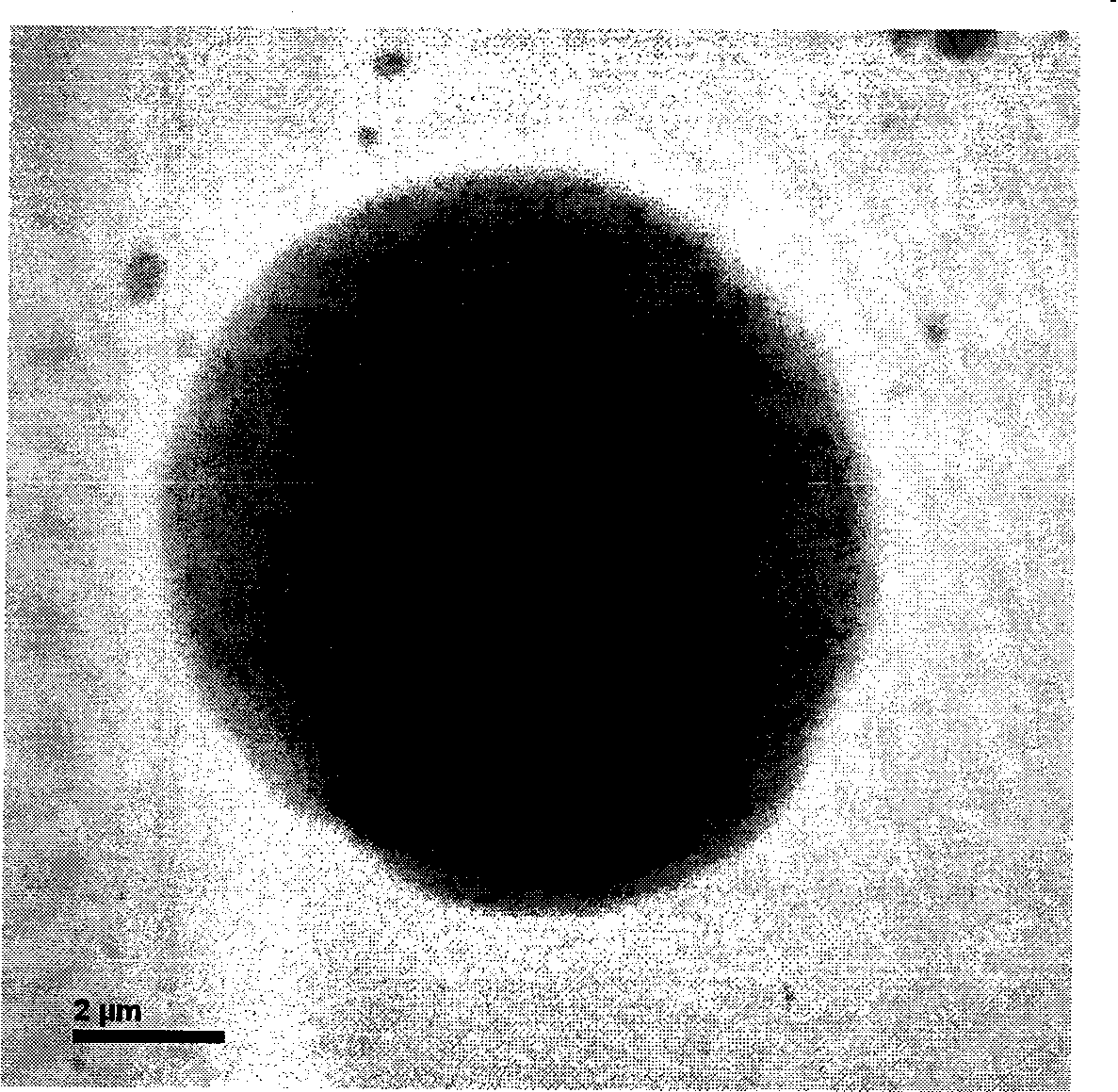

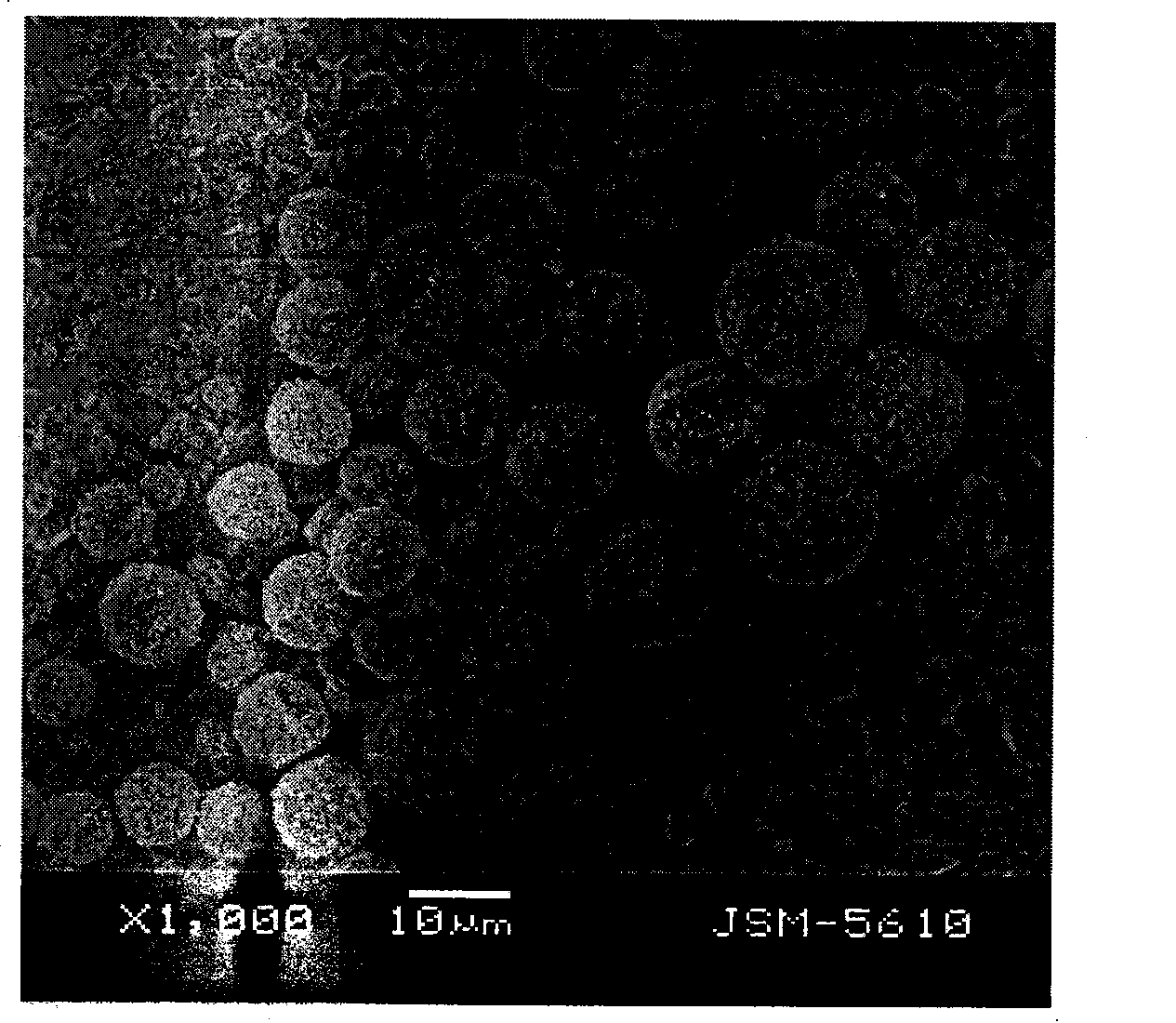

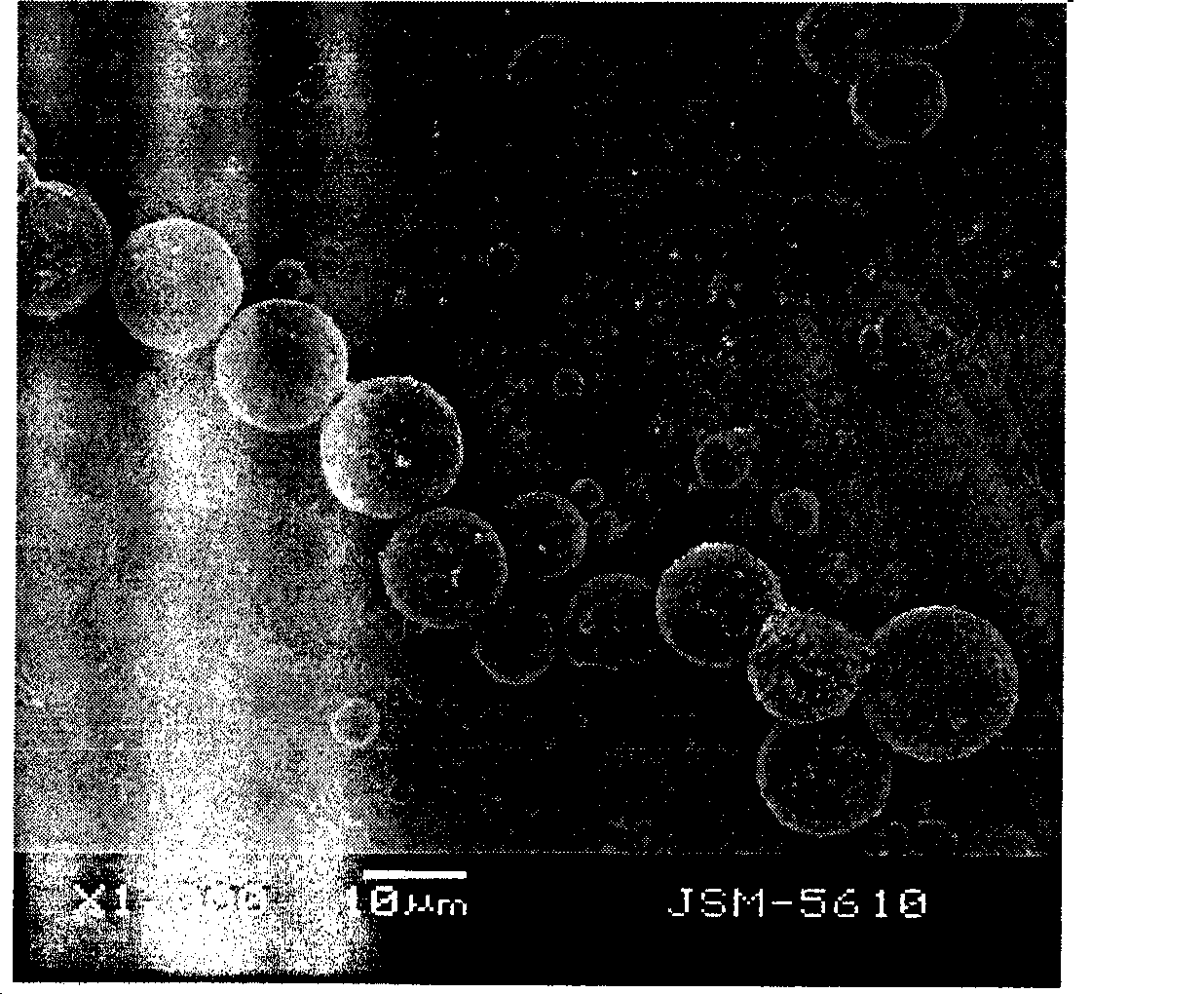

[0030] According to the feeding ratio shown in Table 1, step (1): Add the organic pigment phthalocyanine green to the reaction mixed monomer A in which the oil-soluble initiator dibenzoyl peroxide is dissolved, stir evenly and then transfer it into In the reactor of the aqueous phase of magnesium hydroxide, high-speed stirring forms a suspension dispersion liquid, and in N 2 After polymerizing for a period of time at a certain temperature in the atmosphere, a suspension dispersion of composite microspheres is formed.

[0031] Step (2): add dropwise reaction monomer B in the dispersion liquid of the composite microsphere that step (1) obtains, in N 2 Polymerization reaction at a certain temperature in the atmosphere for a period of time to end the reaction. That is, a suspension dispersion liquid of organic pigment phthalocyanine green microcapsules is obtained.

[0032] The suspension dispersion obtained in step (2) is cooled at room temperature, pickled, washed with water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com