Floater component and water tank and dehumidifier comprising same

A dehumidifier and float technology, applied in the field of dehumidifiers, can solve the problems of wire drawing, toxic substances, pungent odor, etc., and achieve the effect of convenient disassembly and assembly, firm locking, and solving the problem of wire drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

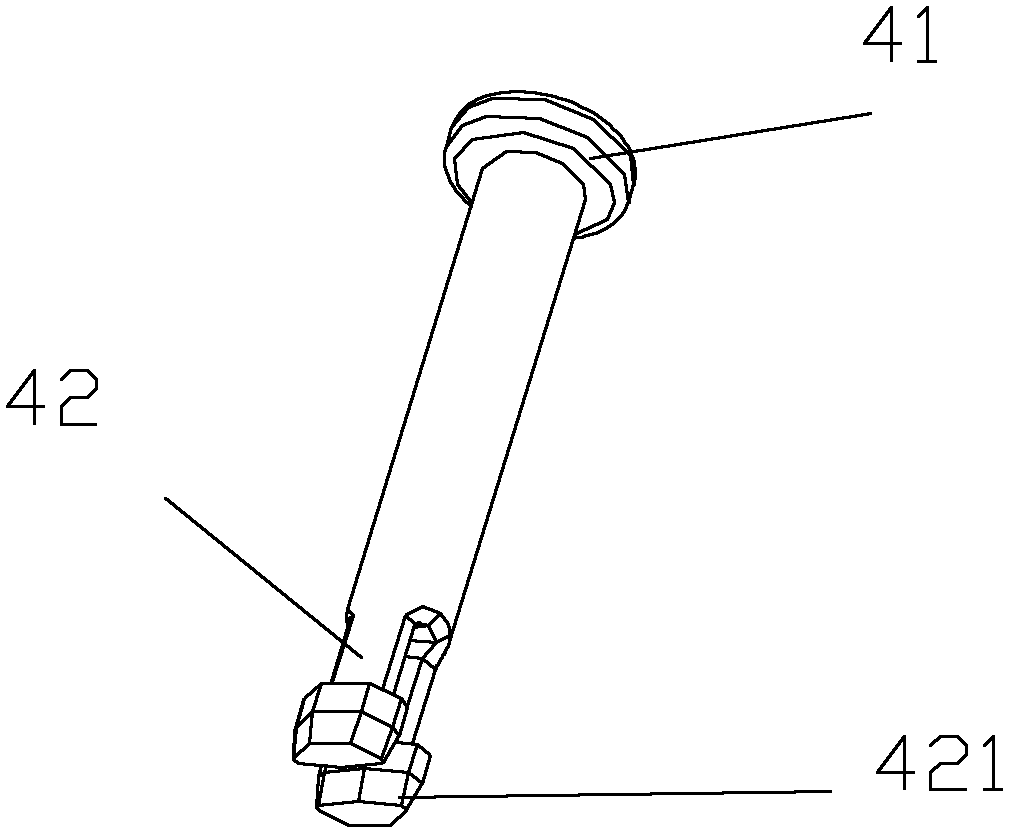

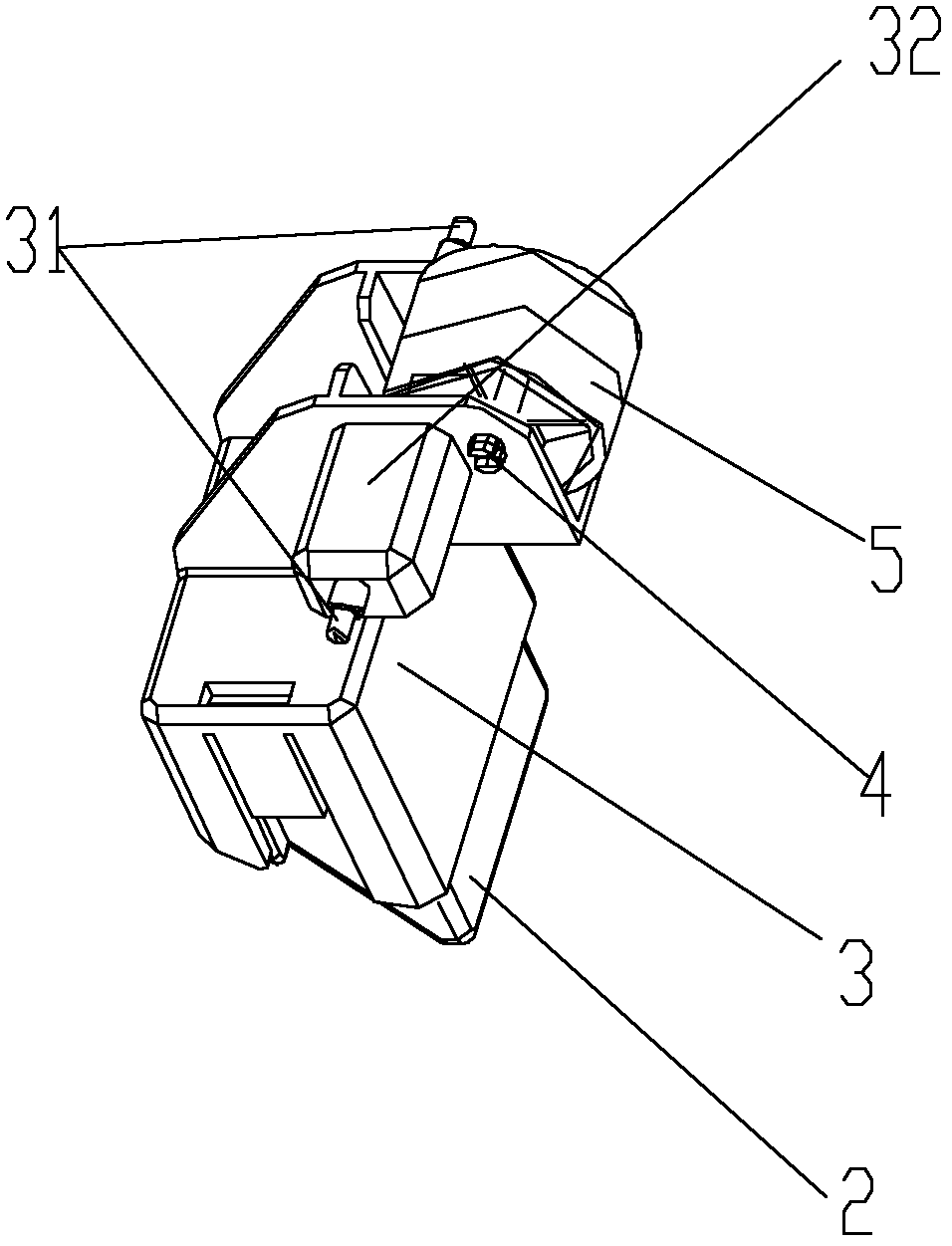

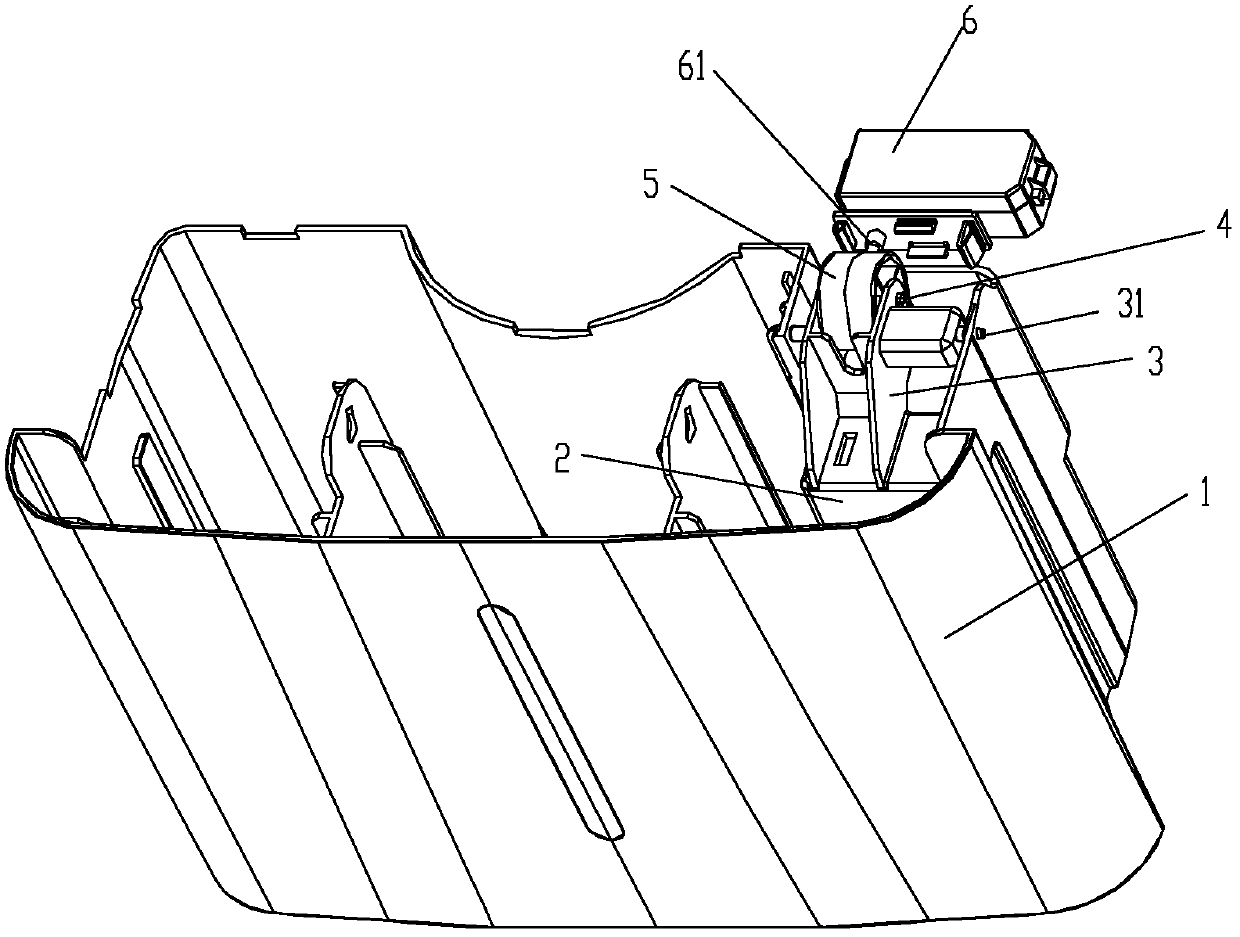

[0027] Such as figure 1 with figure 2 As shown, the present invention provides a buoy assembly, comprising: a buoy 3, a float 2, a roller 5 and a connecting rod 4, wherein, one side of the buoy 3 is provided with a float installation part, and the other side is provided with a roller installation part, and the roller A first connecting rod installation hole is respectively arranged on the two side walls of the installation part, and a pivot shaft 31 is respectively arranged on the two outer side walls of the roller installation part; The buoy 3 also includes a reinforcement block 32, the reinforcement block 32 can be sleeved on the outer surface of the pivot shaft 31 or can be directly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com