Rotary shoulder technique for growing sapphire crystal by kyropoulos method

A technology of sapphire crystal and Kyropoulos method, which is applied in the direction of seed crystal remaining in the molten liquid, single crystal growth, and crystal growth during the growth period. It can solve the problems of a large number of bubbles, affecting the quality and utilization of crystals, and reduce the bubbles. Content, the effect of improving crystal quality and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

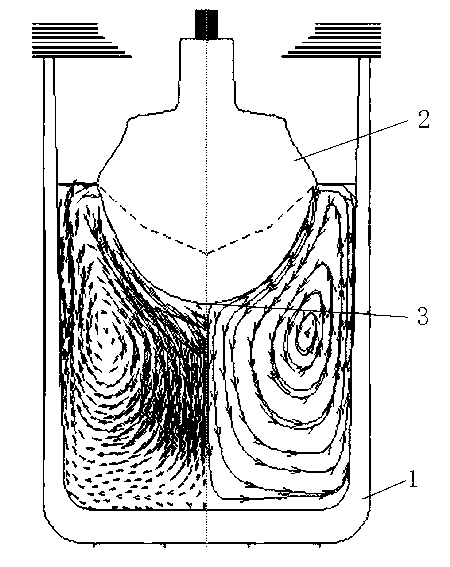

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0018] The Kyropoulos sapphire growth process mainly includes:

[0019] 1. Raw material charging: the prepared Al 2 o 3 Put the powder, crystalline block material or briquette sintered cake into the tungsten crucible, stack it as tightly as possible to increase the feeding amount; then install the thermal field components (crucible cover plate, insulation upper screen, etc.) The final seed crystal is fixed at the lower end of the seed crystal rod, and the position of the seed crystal head is 10-30mm away from the dry material surface;

[0020] 2. Vacuumize, heat up chemical material: two-step vacuumize, first use 9L / S mechanical pump to evacuate, when the pressure in the furnace is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com