Patents

Literature

1032results about "Using seed in melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

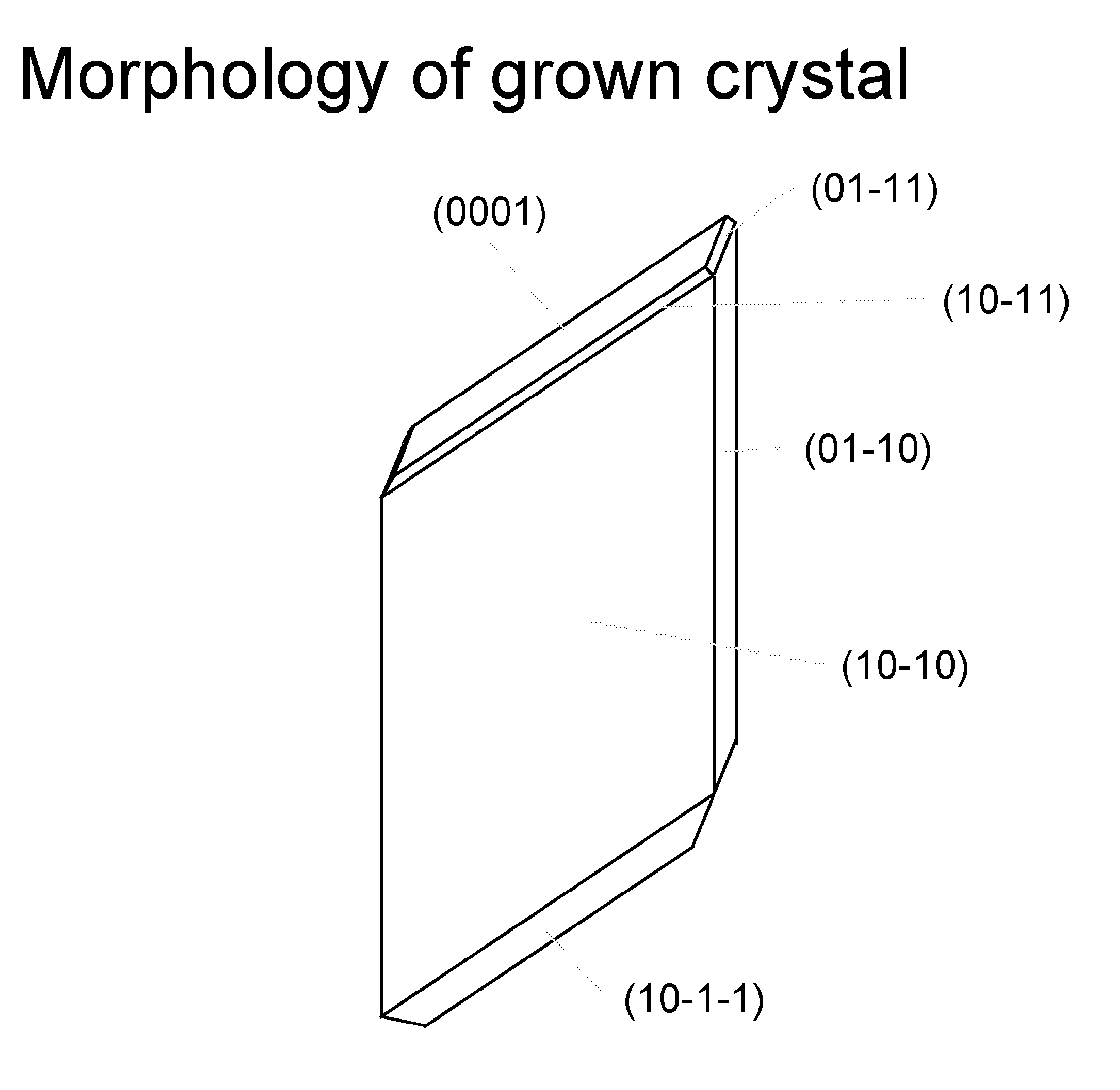

Method for producing nitride semiconductor, crystal growth rate increasing agent, single crystal nitride, wafer and device

InactiveUS20100104495A1Improve performanceIncrease probabilityPolycrystalline material growthFrom normal temperature solutionsNitrogenCrystal structure

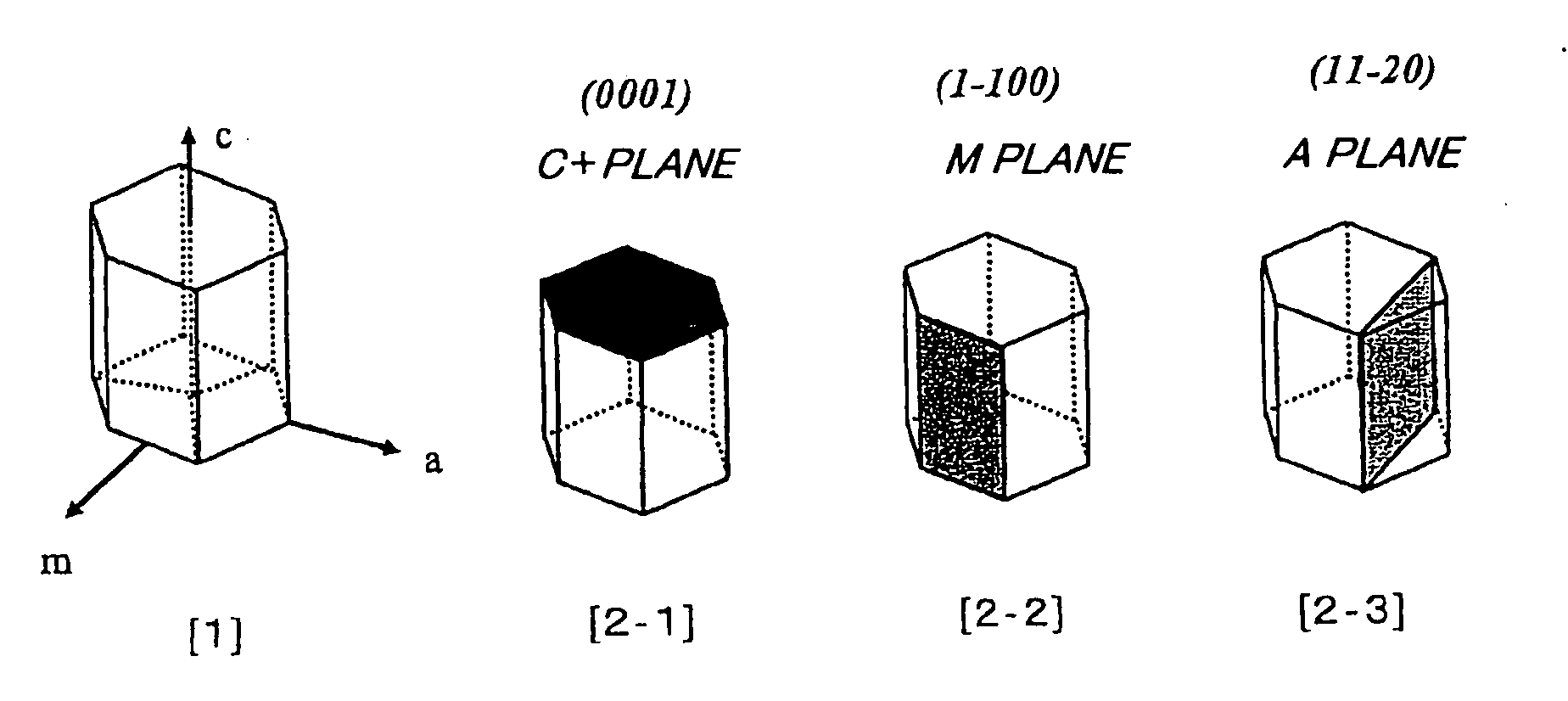

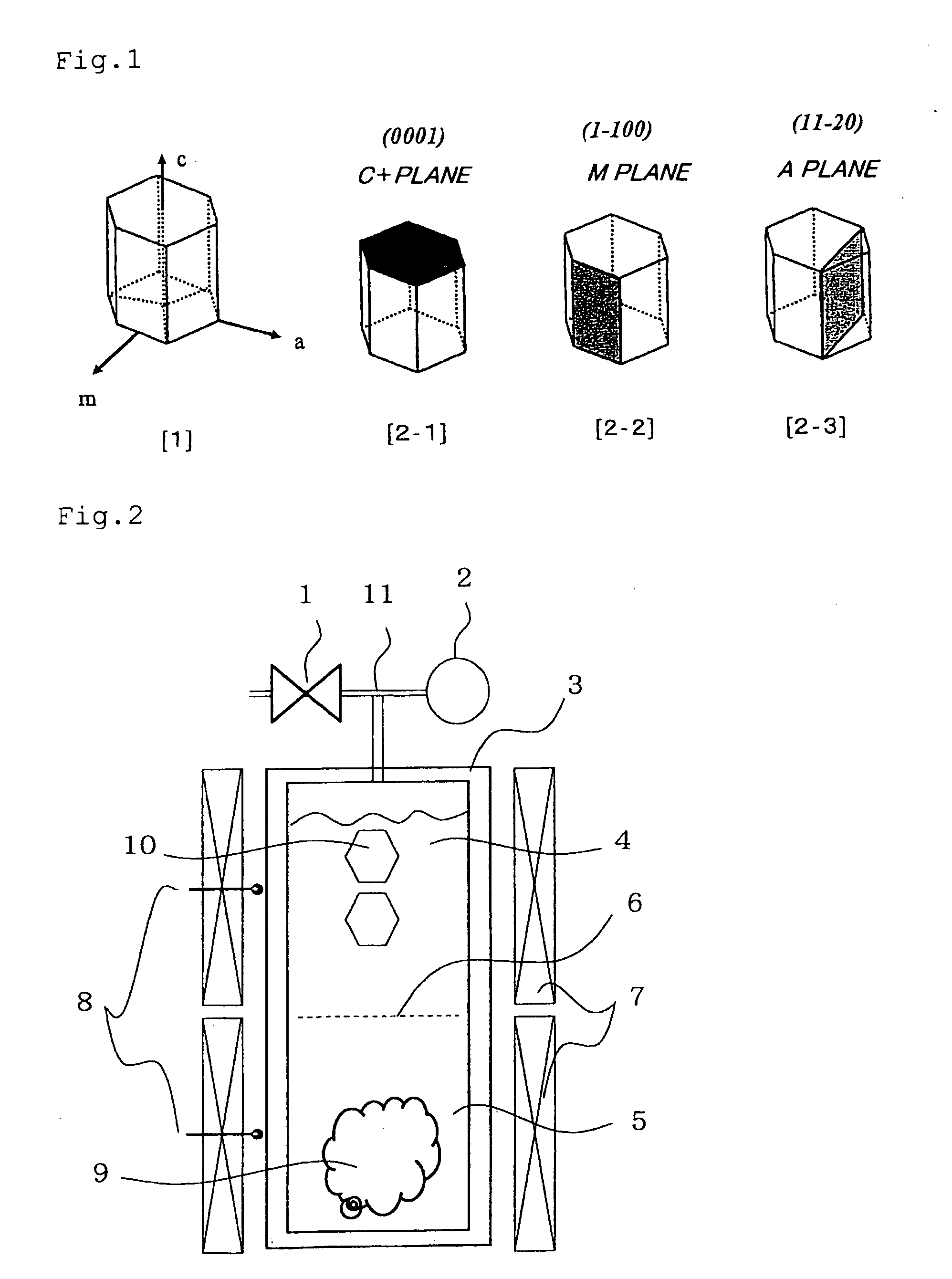

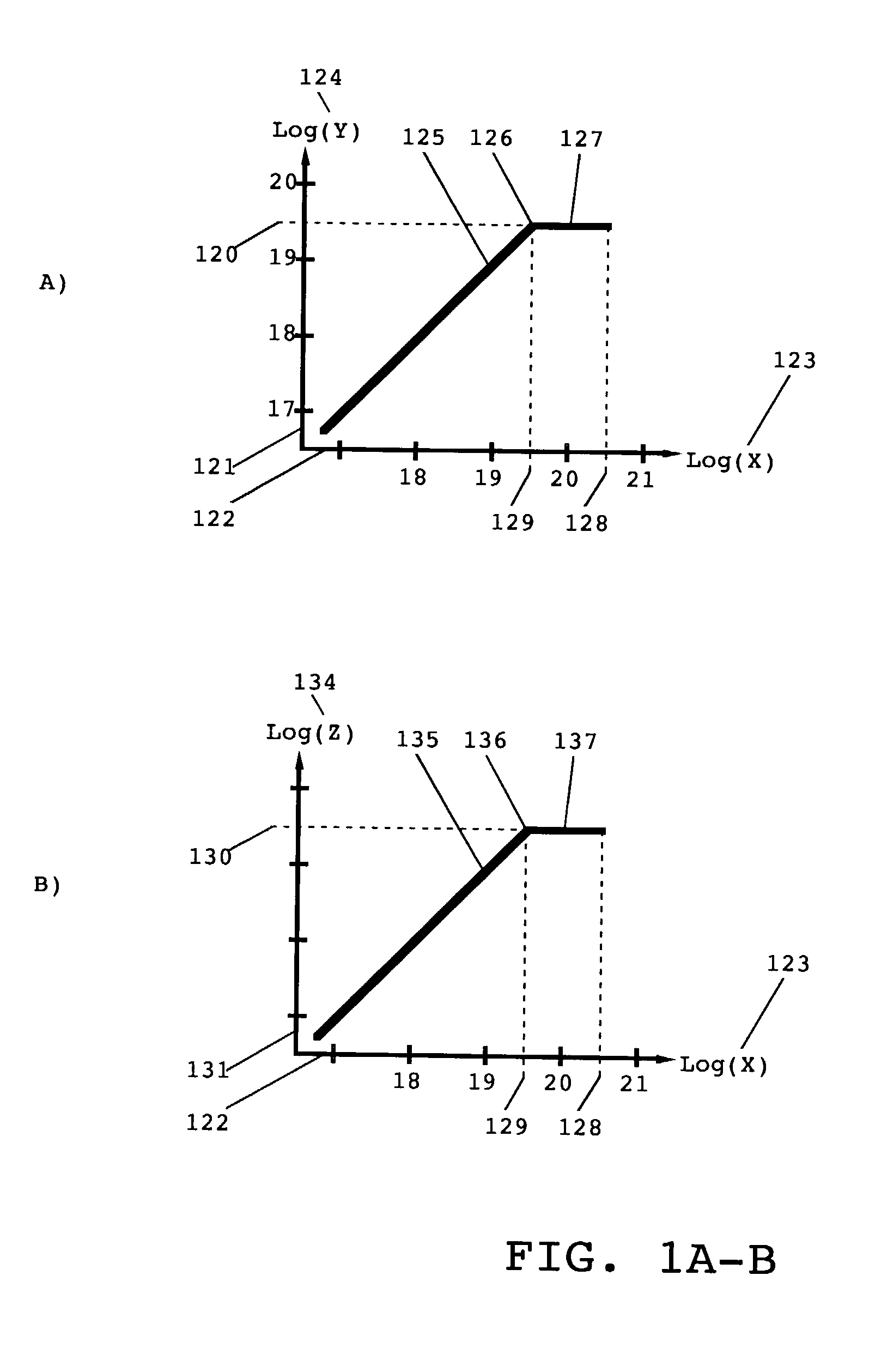

A method for producing a nitride semiconductor, comprising controlling temperature and pressure in a autoclave containing a seed having a hexagonal crystal structure, a nitrogen element-containing solvent, a raw material substance containing a metal element of Group 13 of the Periodic Table, and a mineralizer so as to put said solvent into a supercritical state and / or a subcritical state and thereby ammonothermally grow a nitride semiconductor crystal on the surface of said seed, wherein the crystal growth rate in the m-axis direction on said seed is 1.5 times or more the crystal growth rate in the c-axis direction on said seed. By the method, a nitride semiconductor having a large-diameter C plane or a nitride semiconductor thick in the m-axis direction can be efficiently and simply produced.

Owner:MITSUBISHI CHEM CORP +1

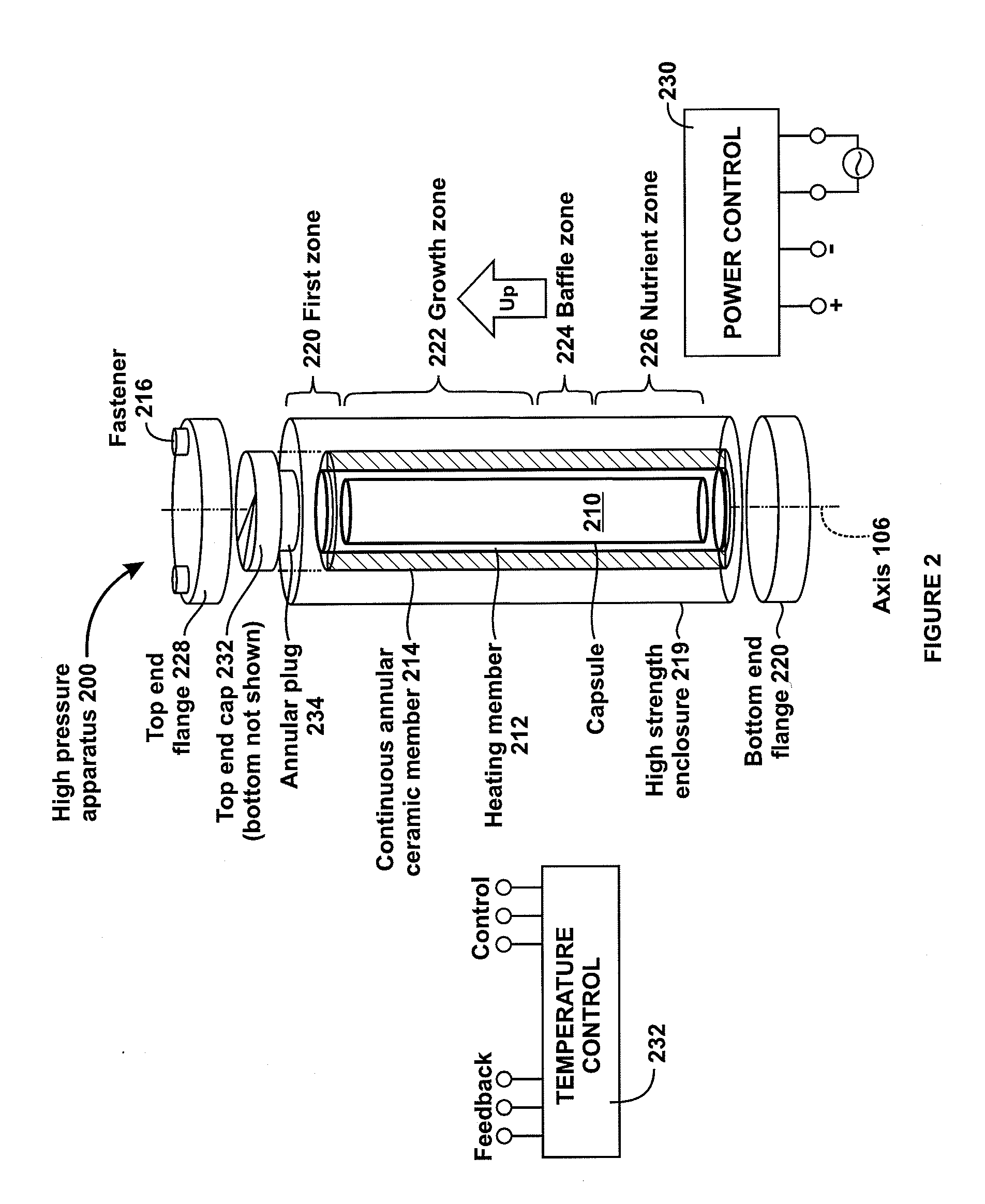

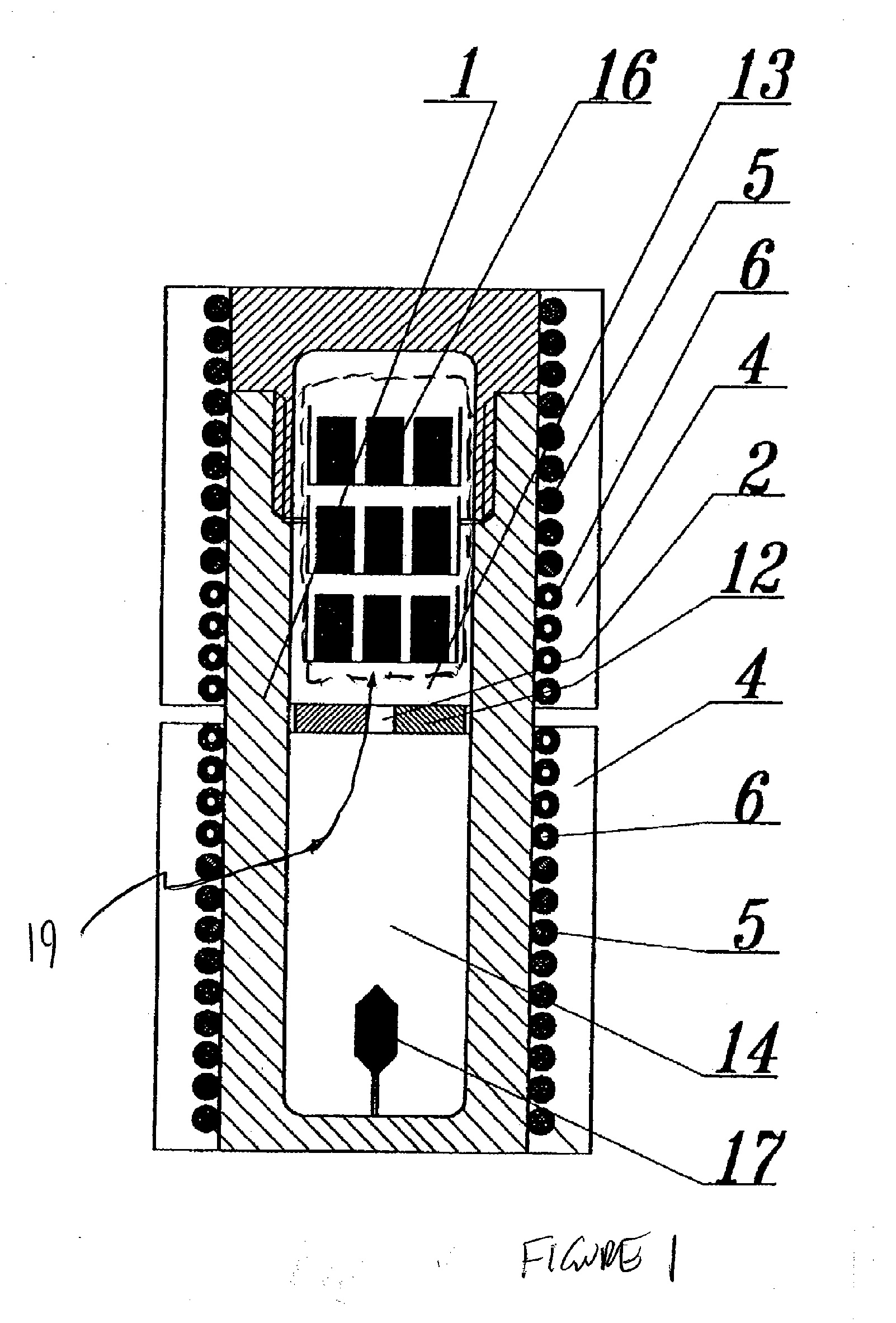

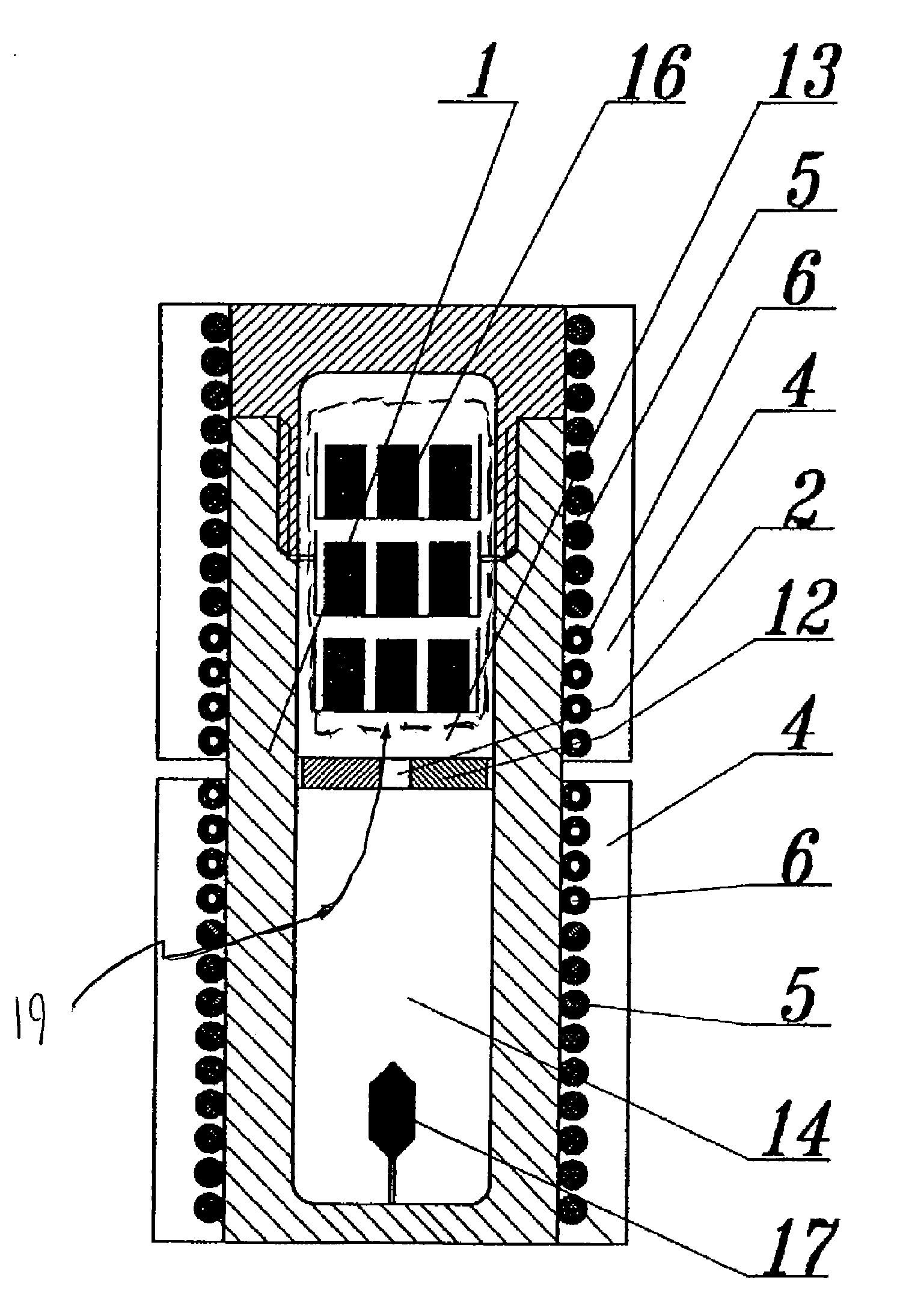

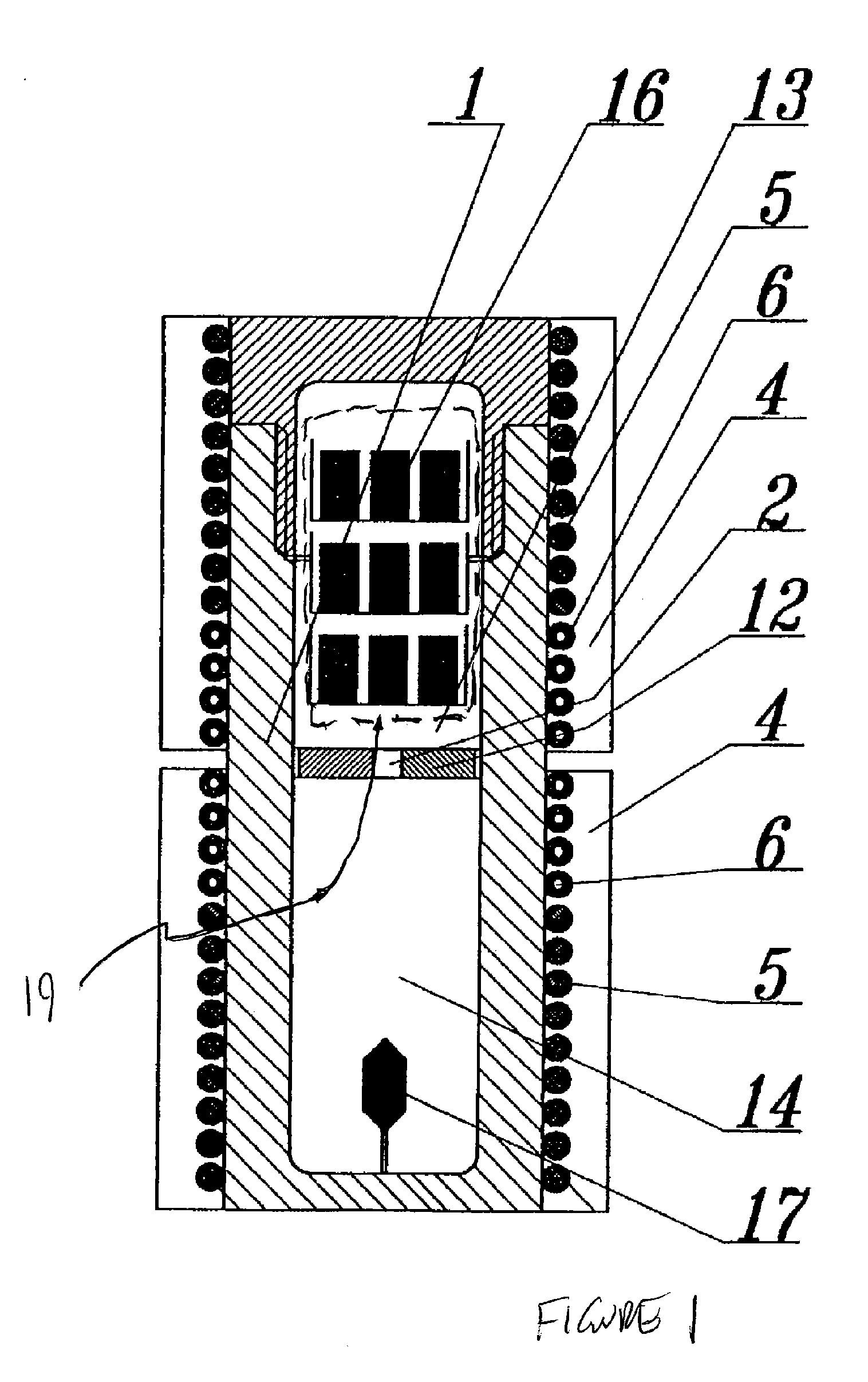

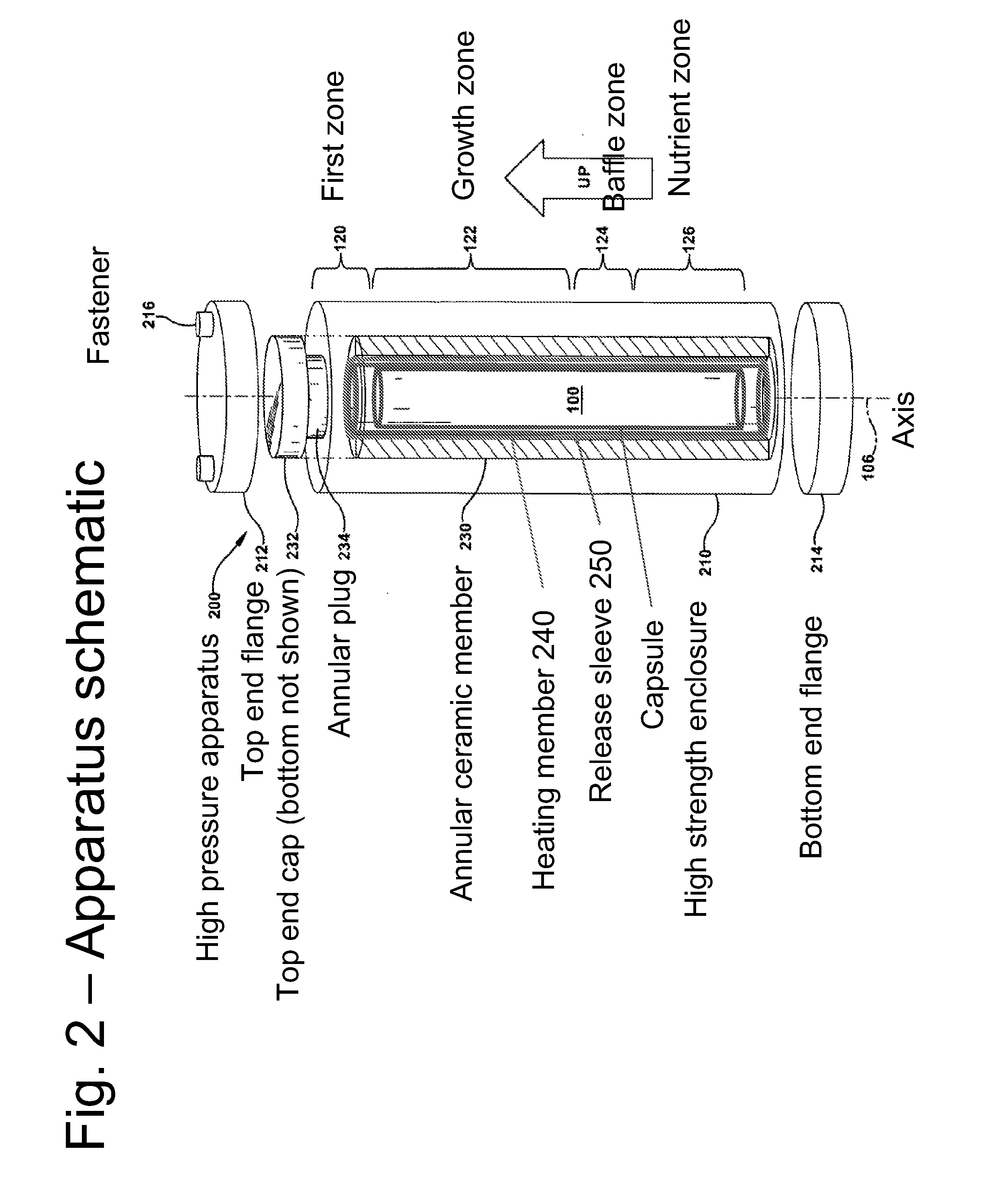

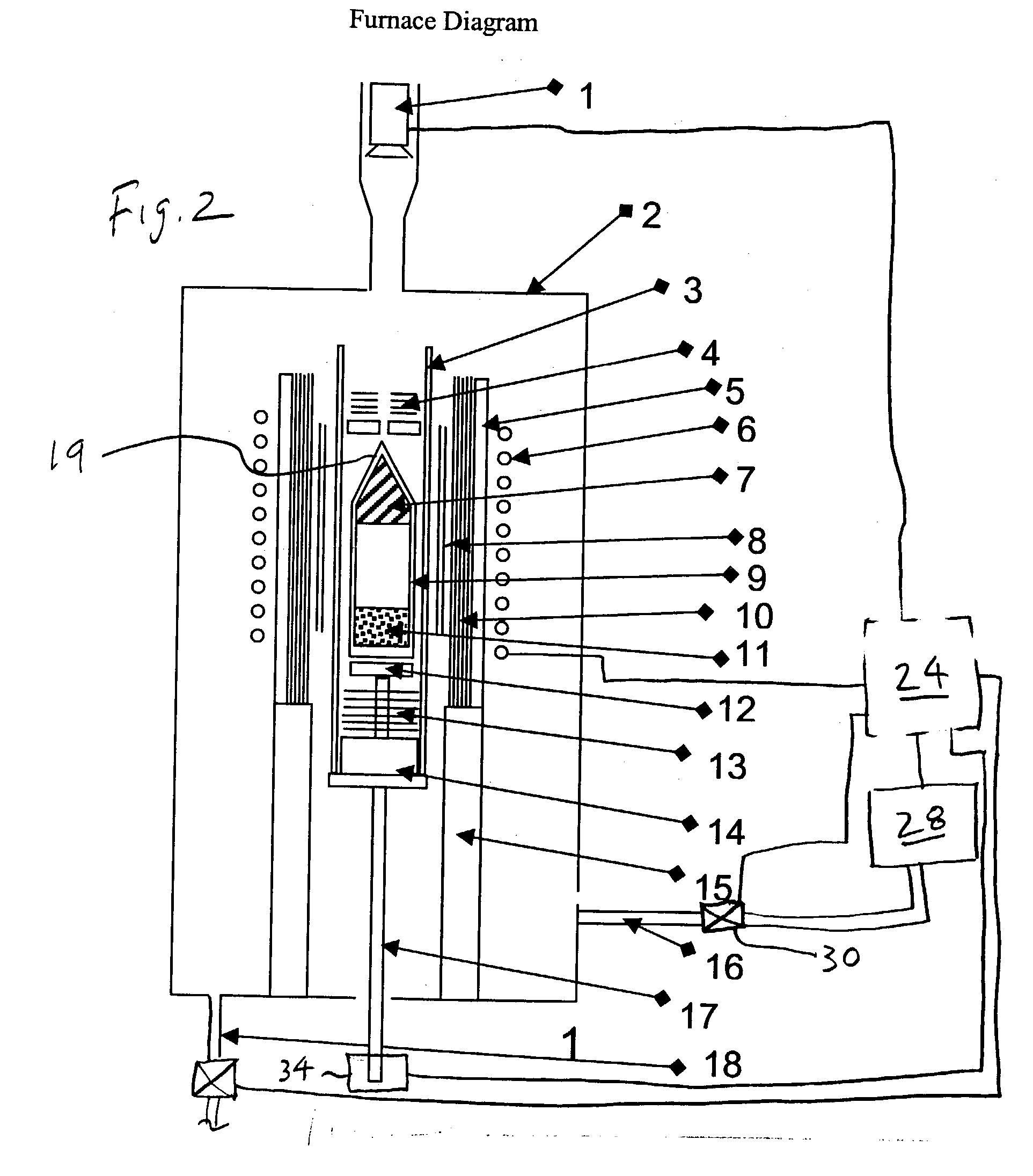

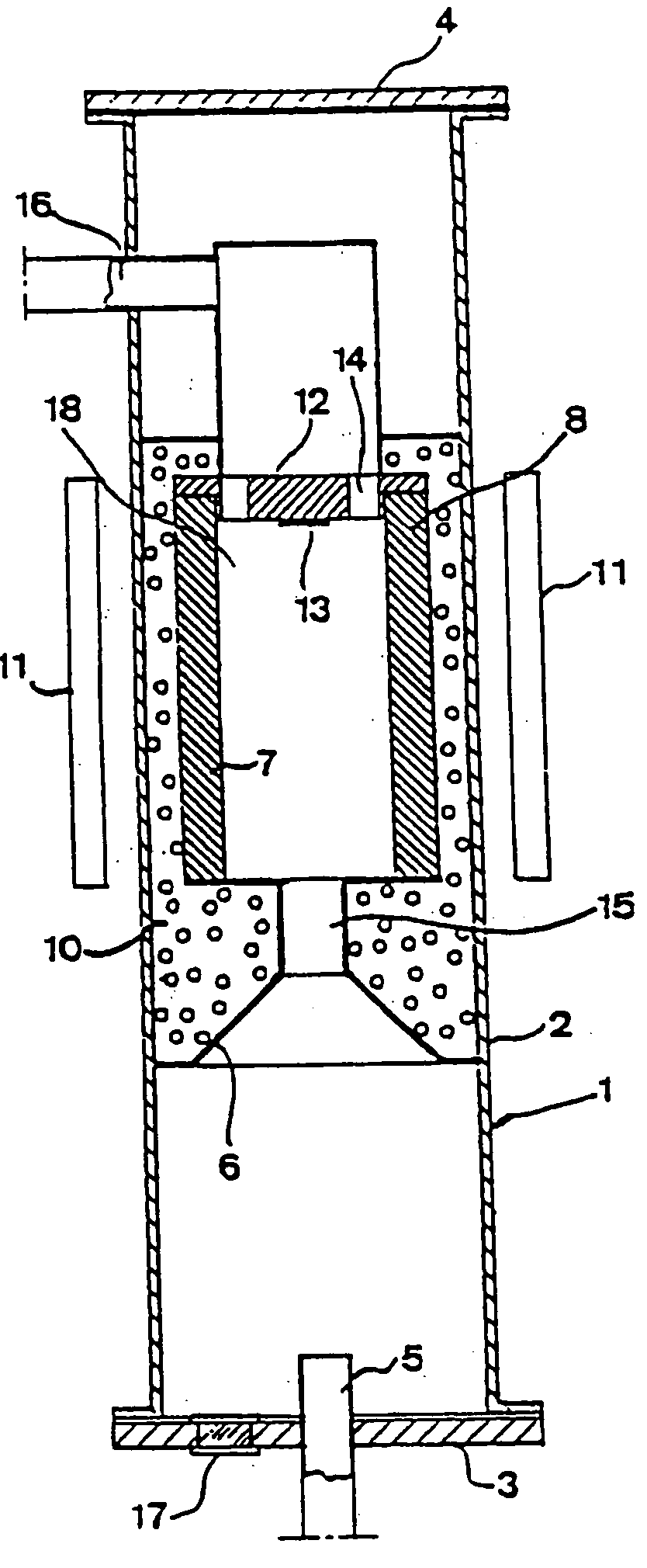

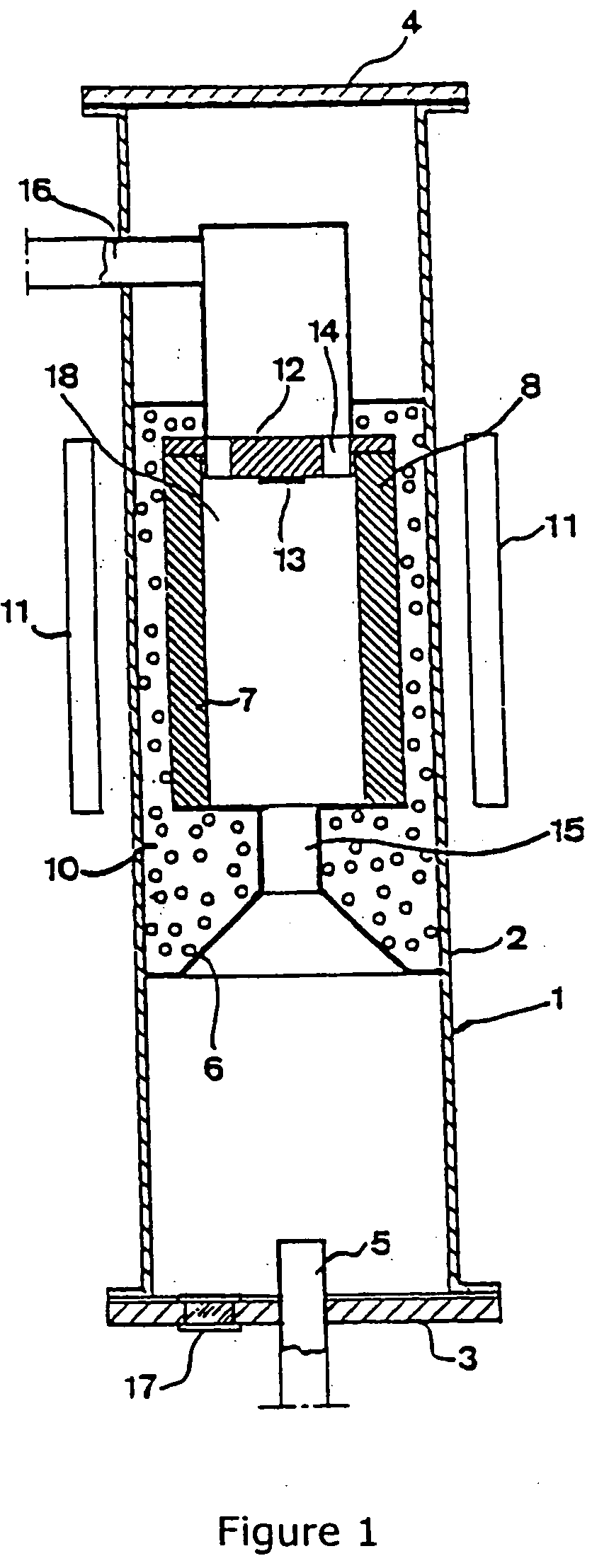

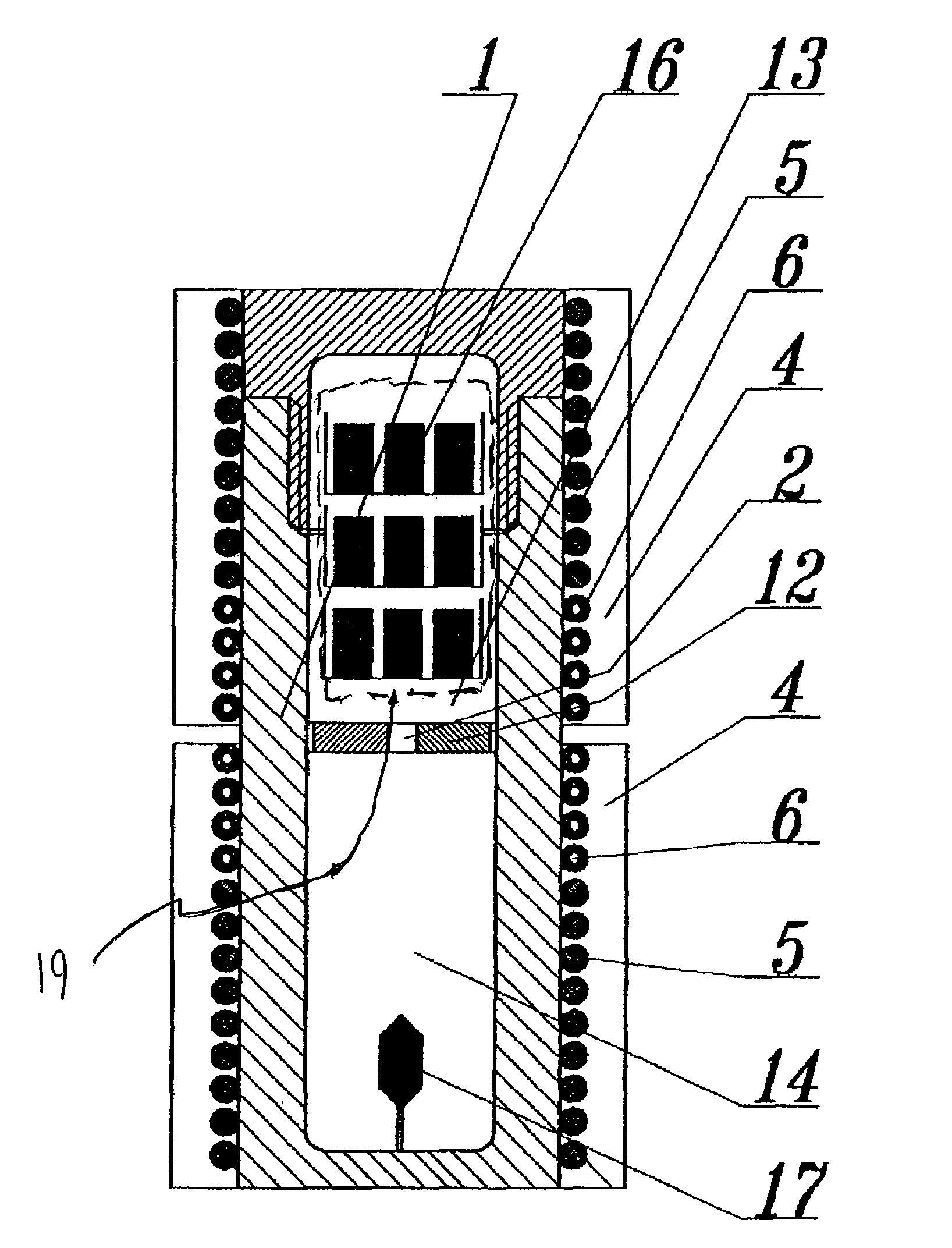

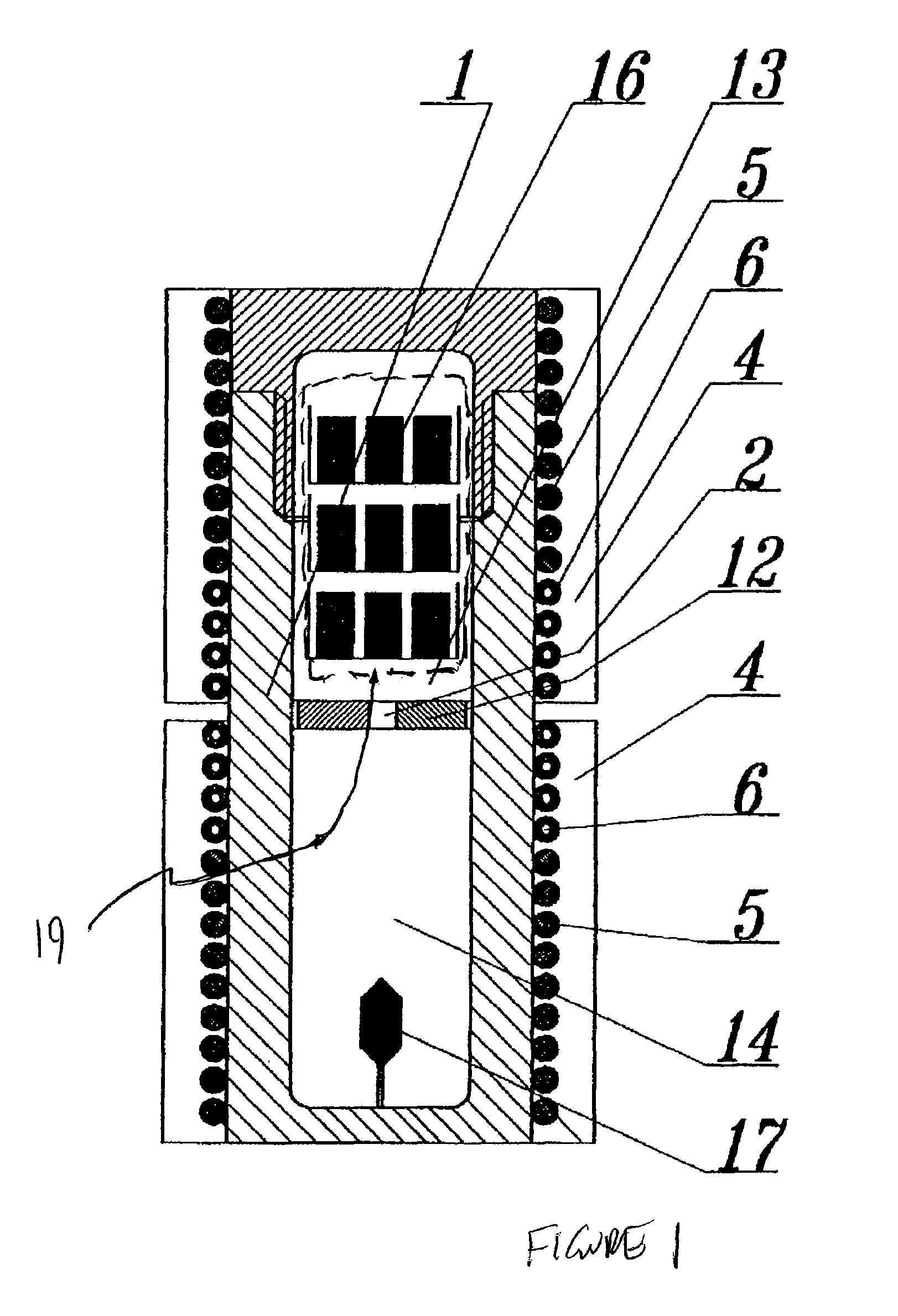

High pressure apparatus and method for nitride crystal growth

ActiveUS20090320744A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

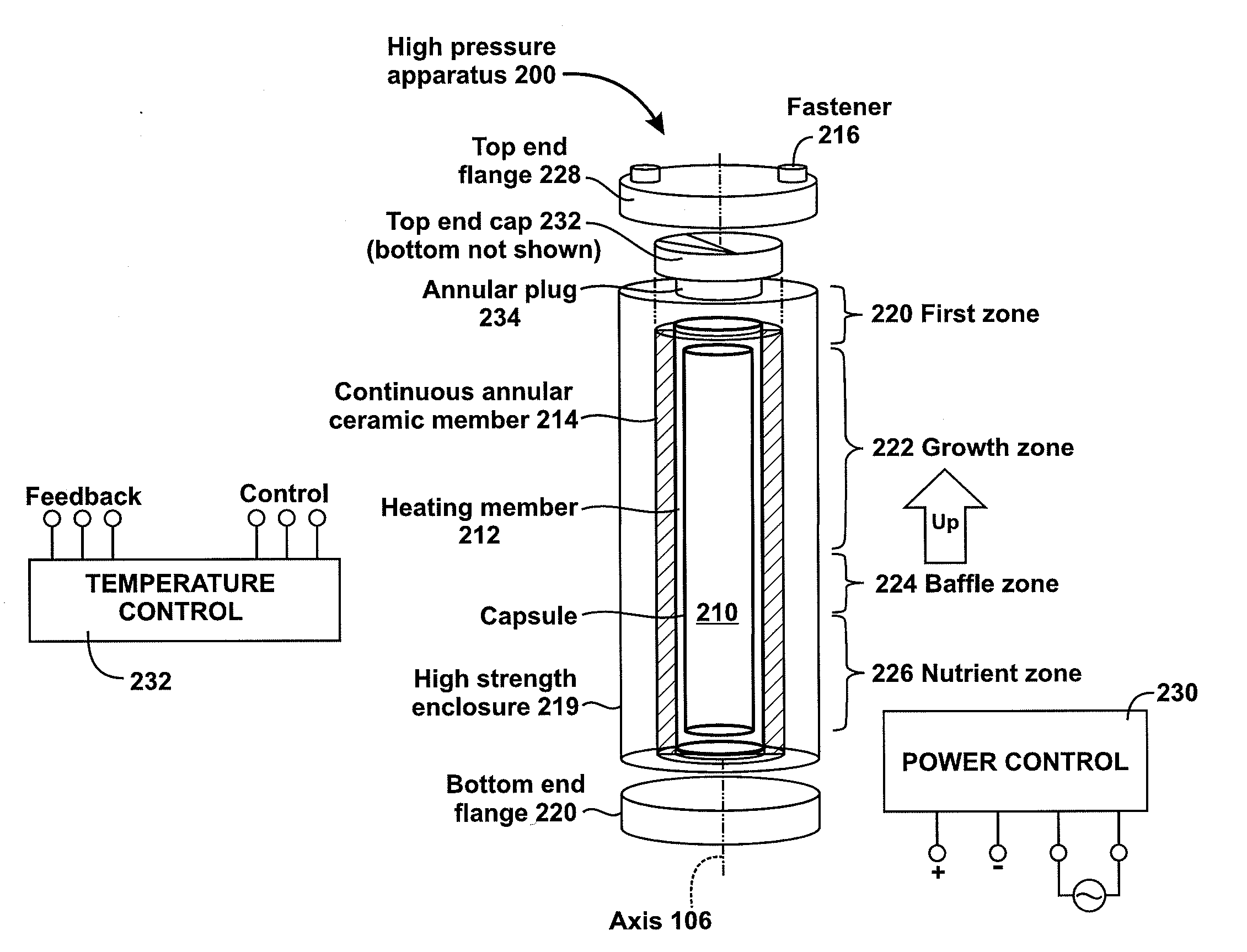

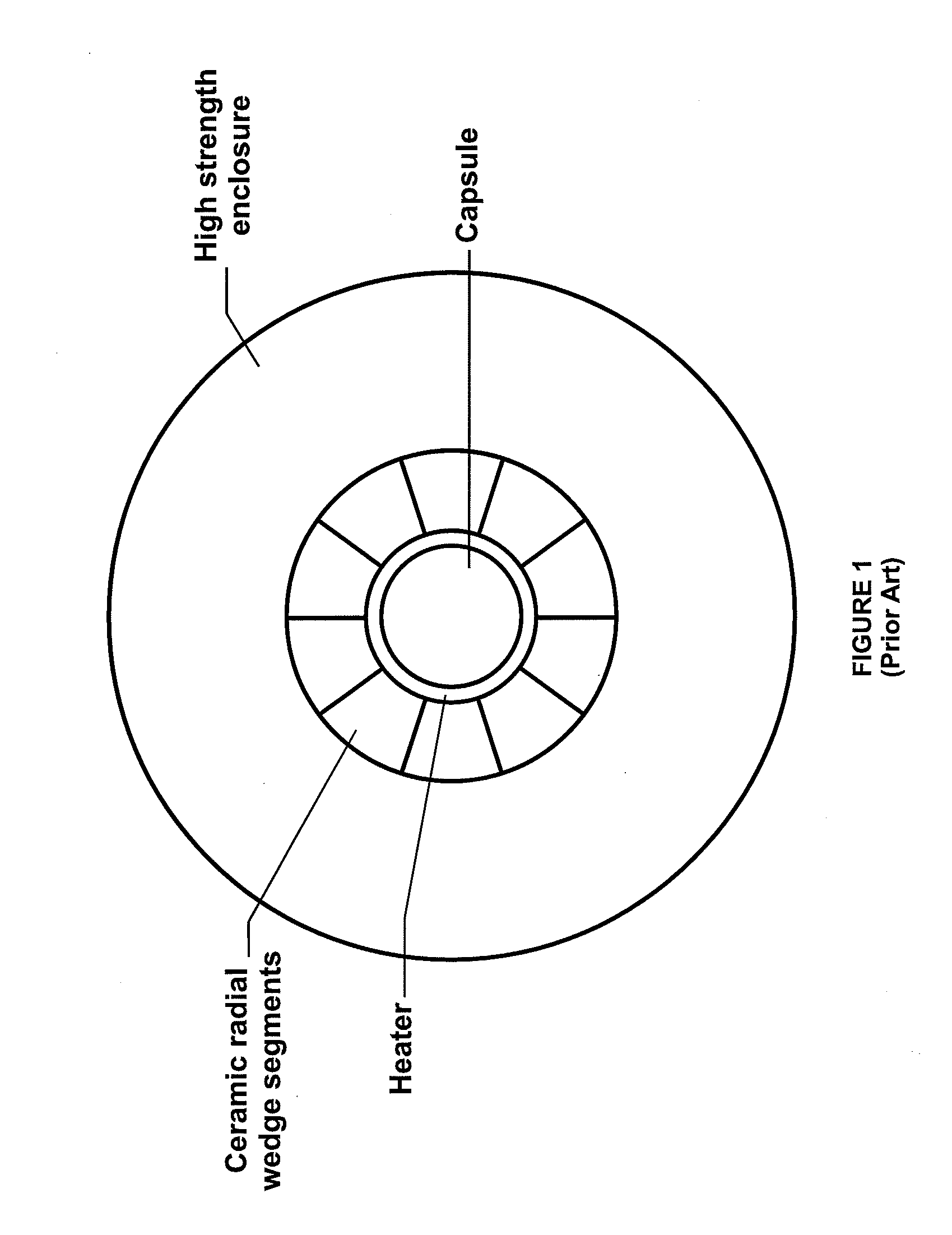

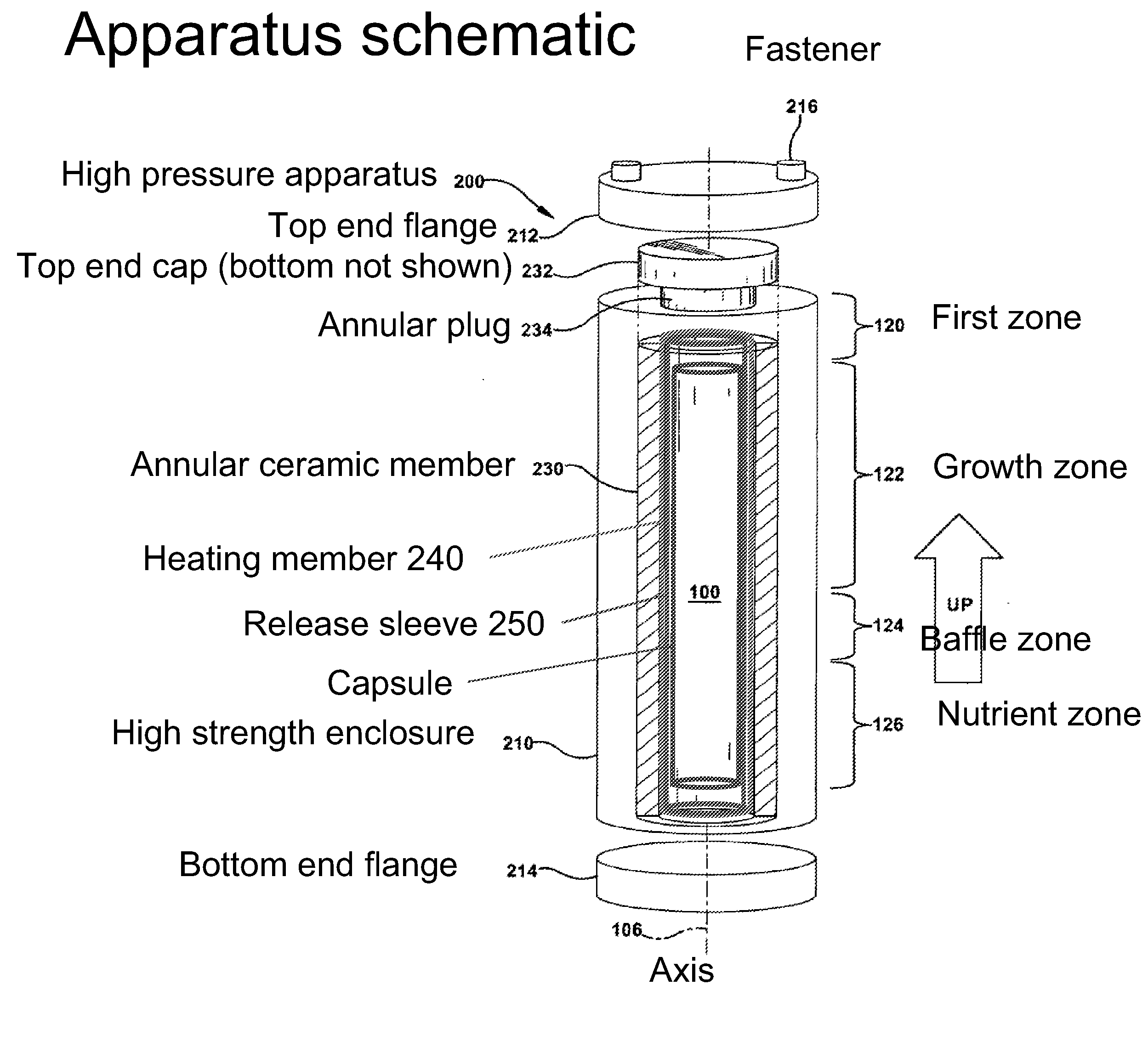

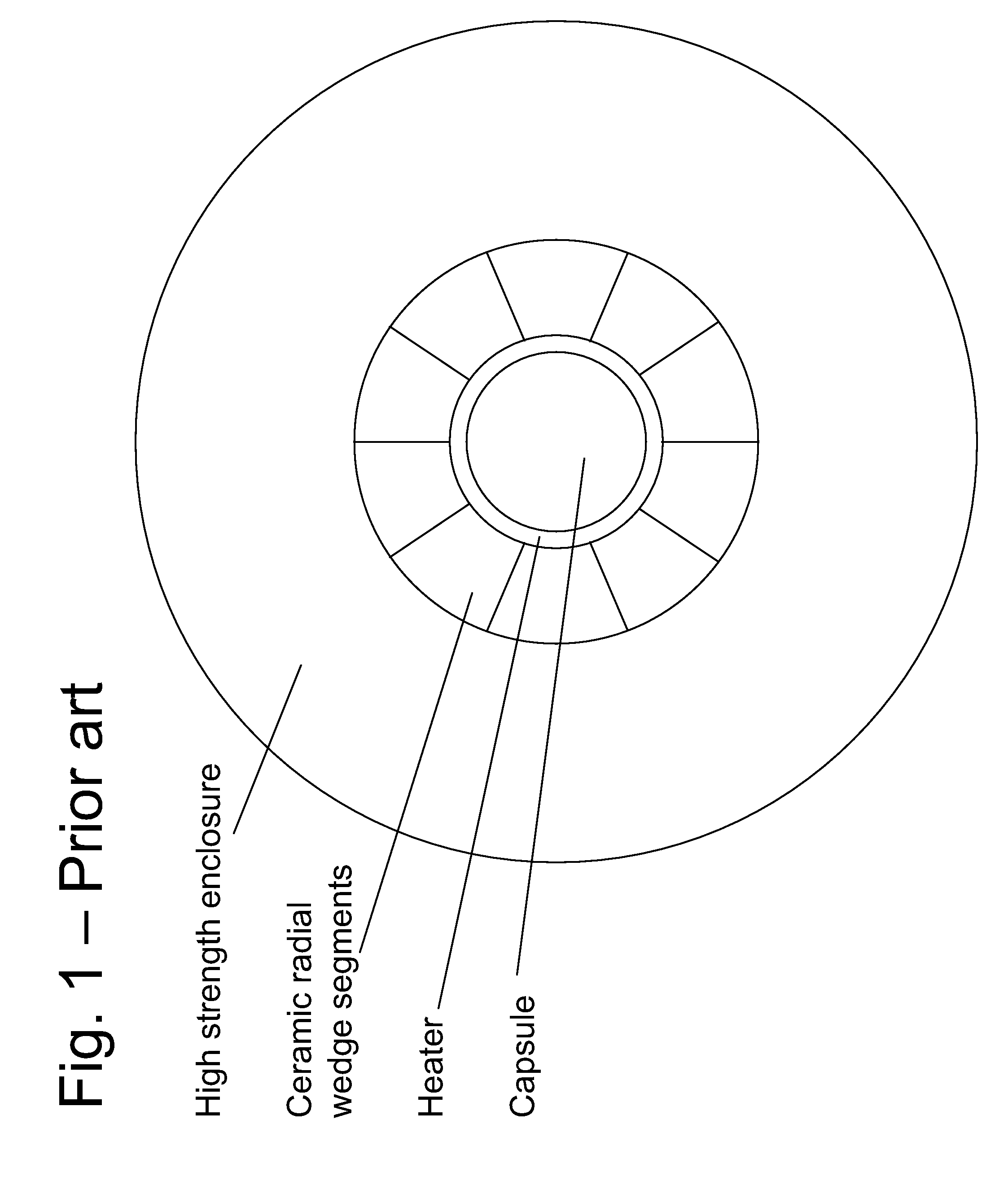

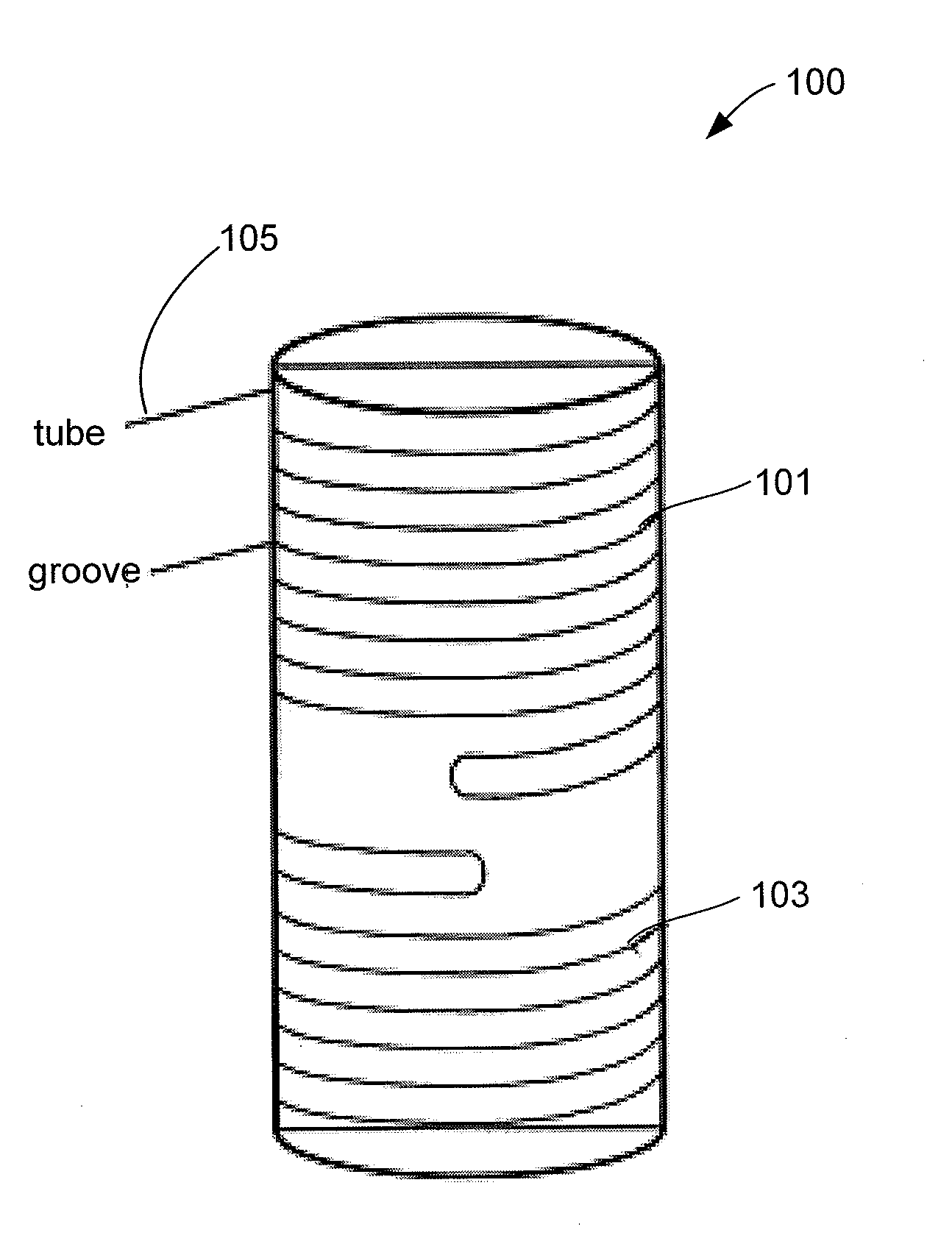

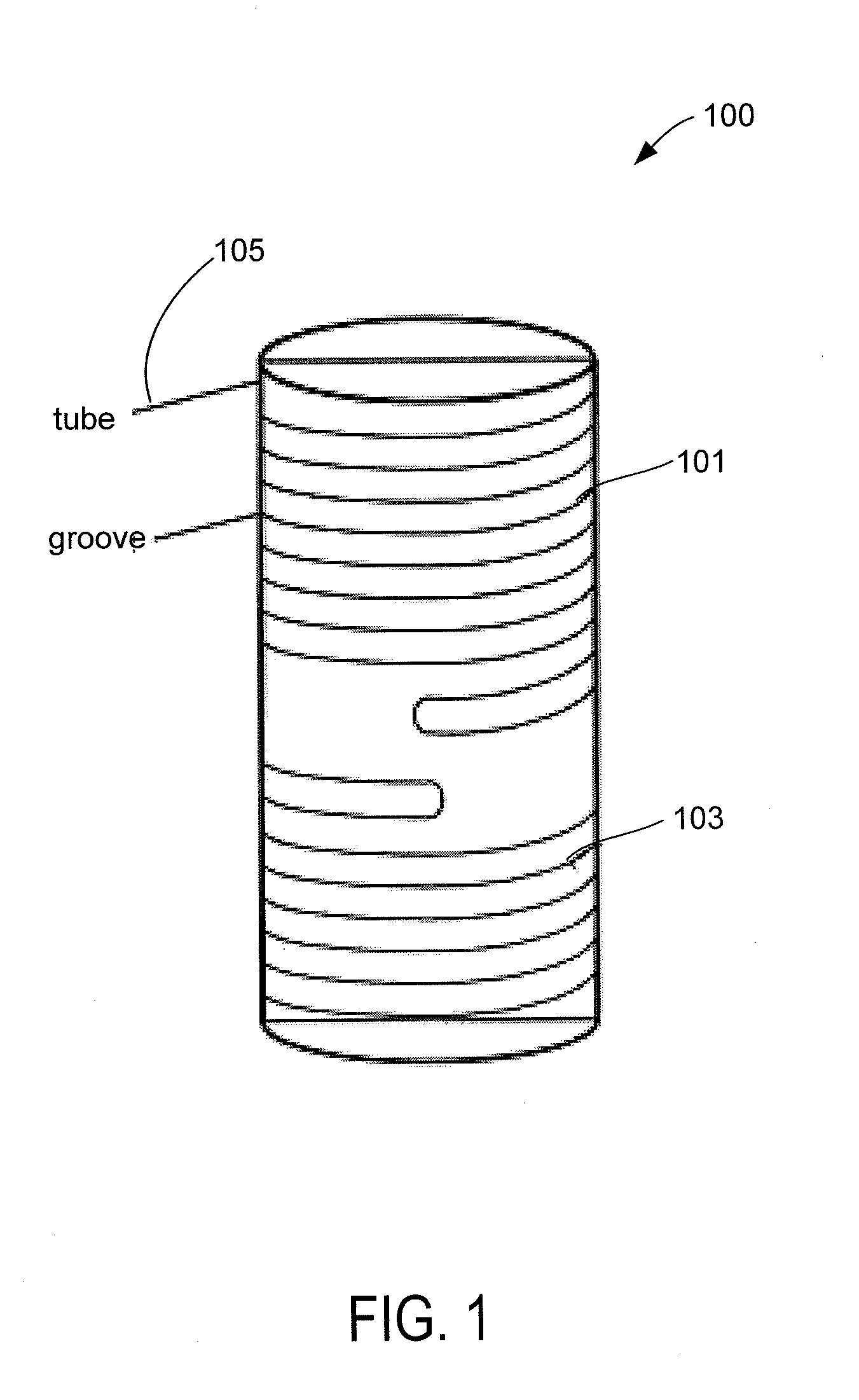

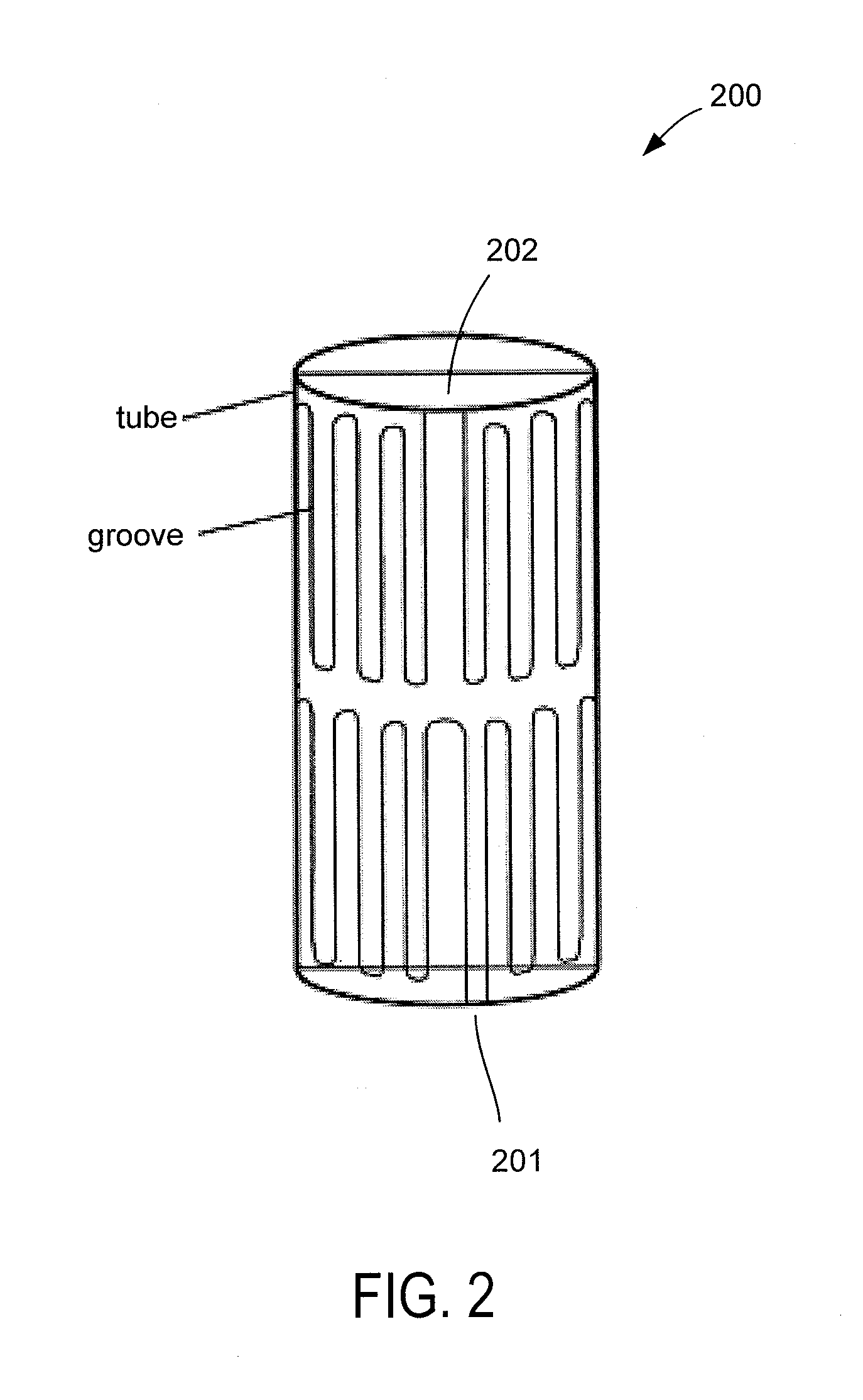

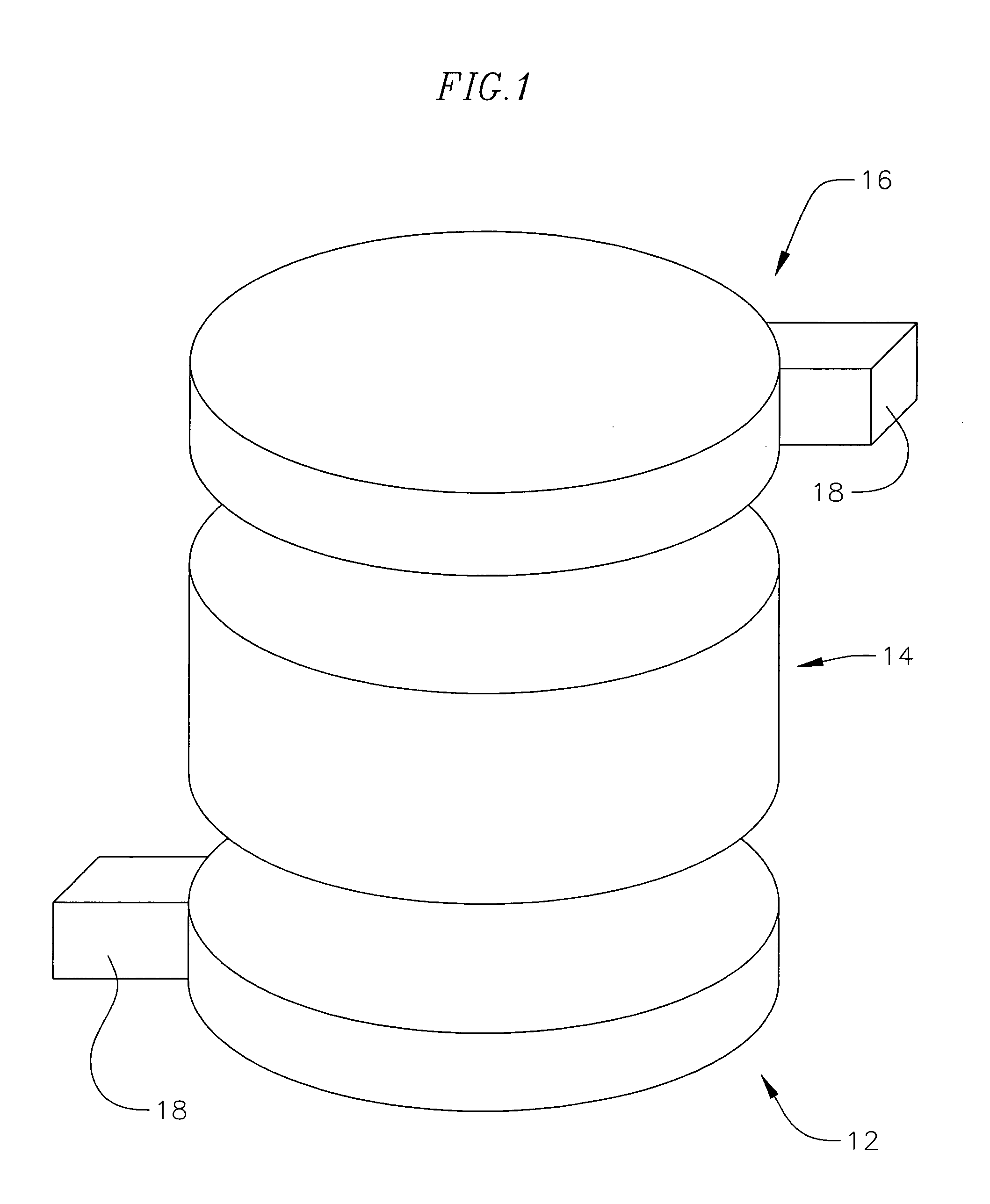

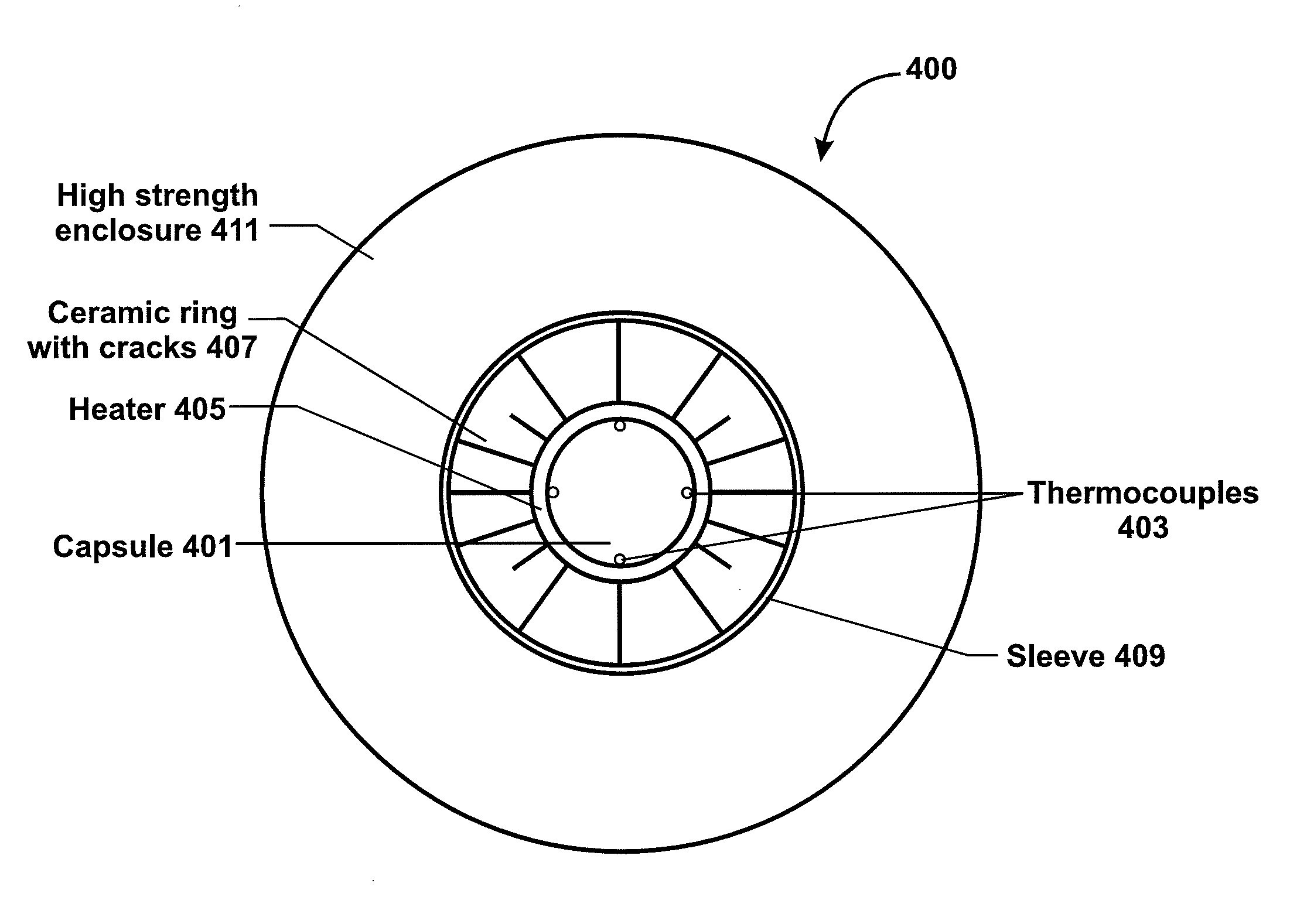

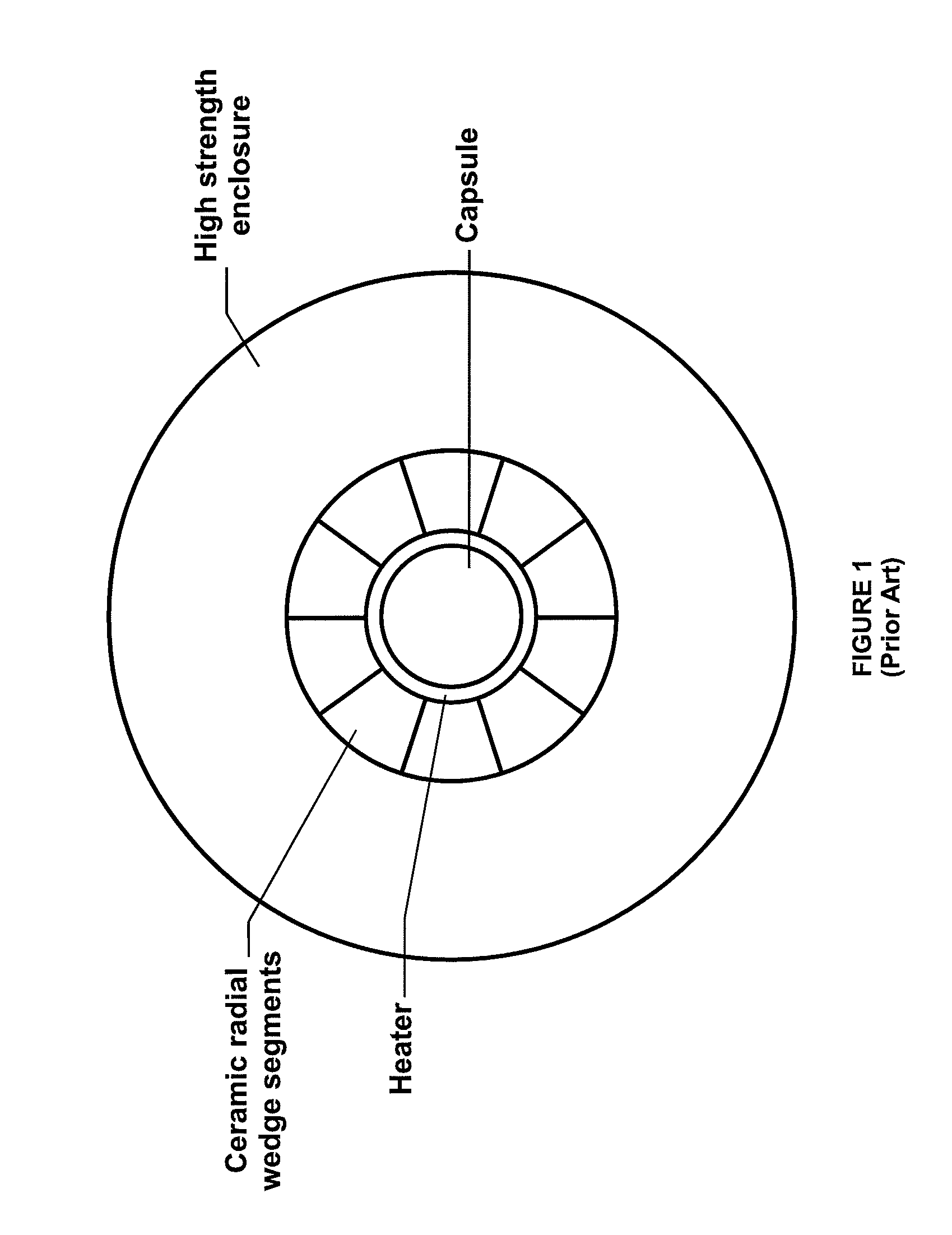

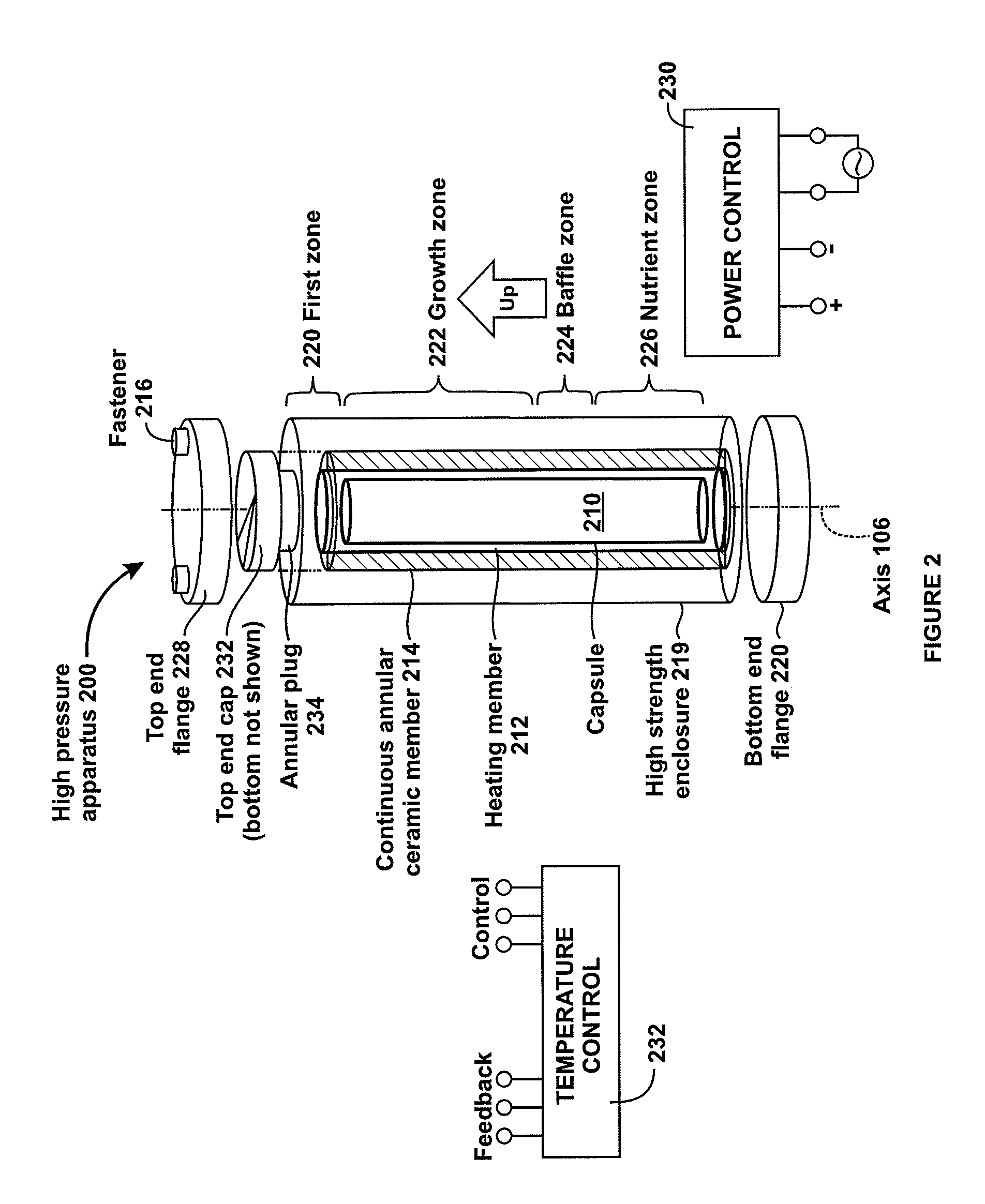

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

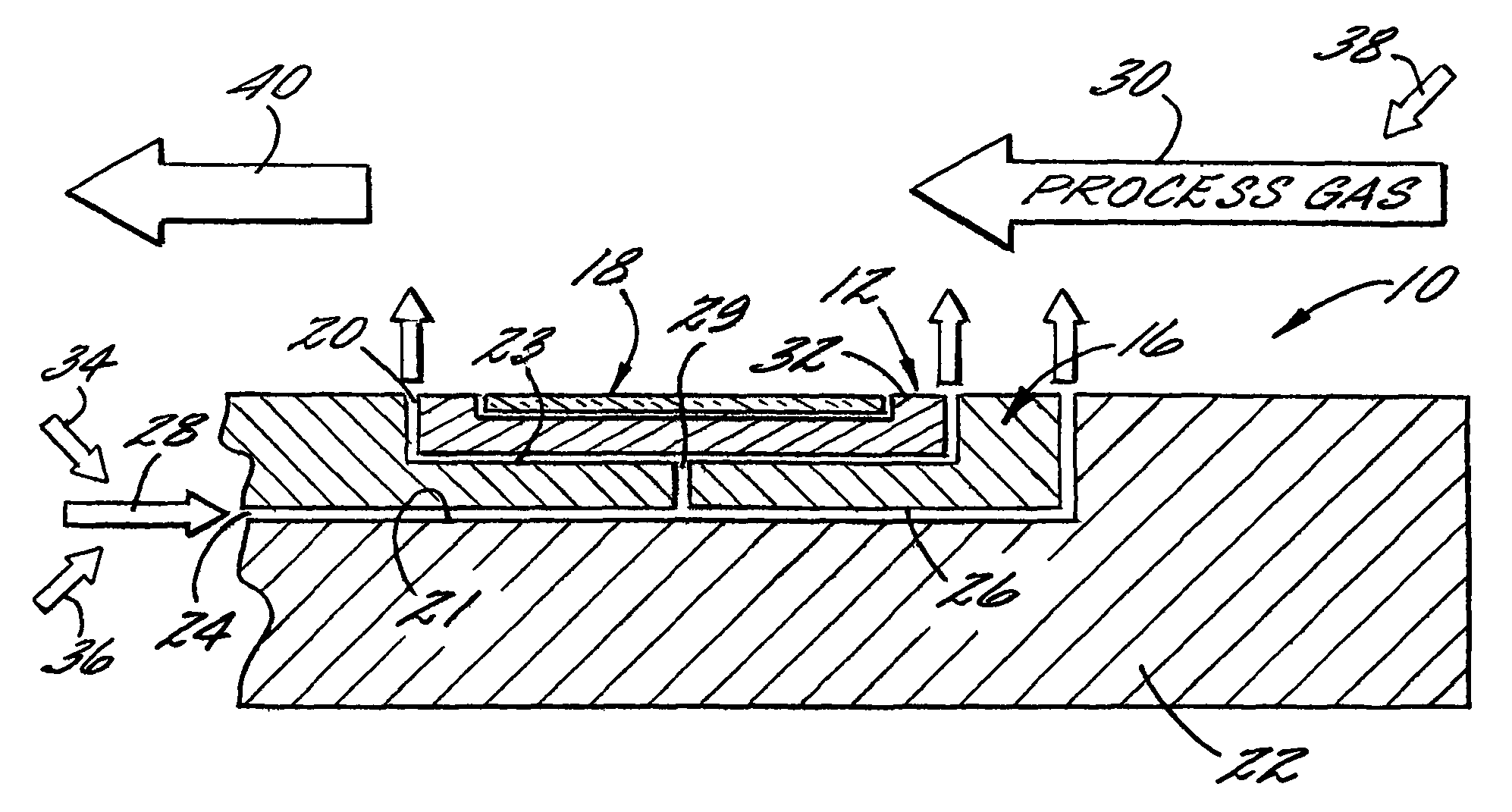

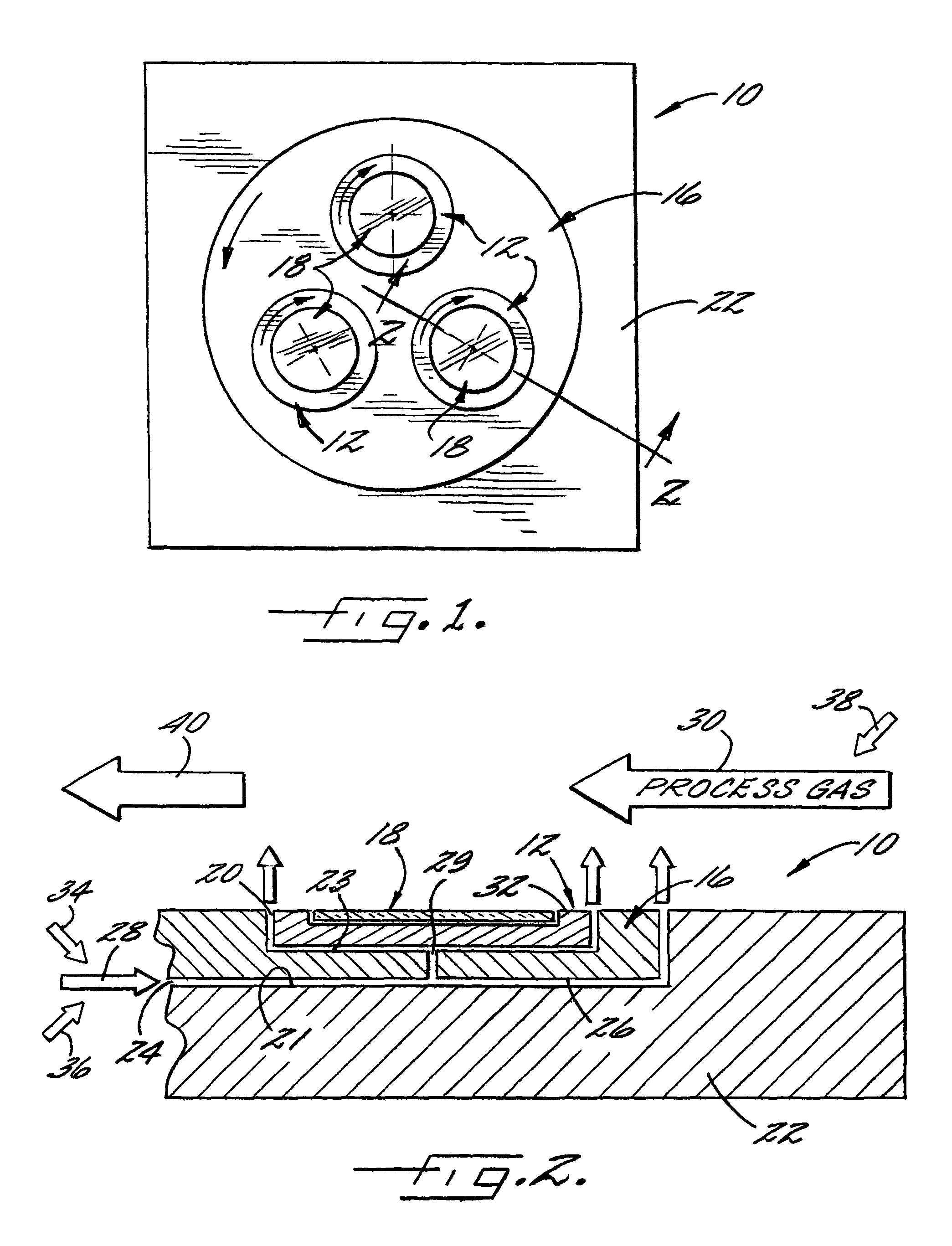

Directed reagents to improve material uniformity

A method for locally controlling the stoichiometry of an epitaxially deposited layer on a semiconductor substrate is provided. The method includes directing a first reactant gas and a doping gas across a top surface of a semiconductor substrate and directing a drive gas and a second reactant gas against the substrate separately from the first reactant gas in a manner that rotates the substrate while introducing the second reactant gas at an edge of the substrate to control each reactant separately, thereby compensating and controlling depletion effects and improving doping uniformity in resulting epitaxial layers on the substrate.

Owner:CREE INC

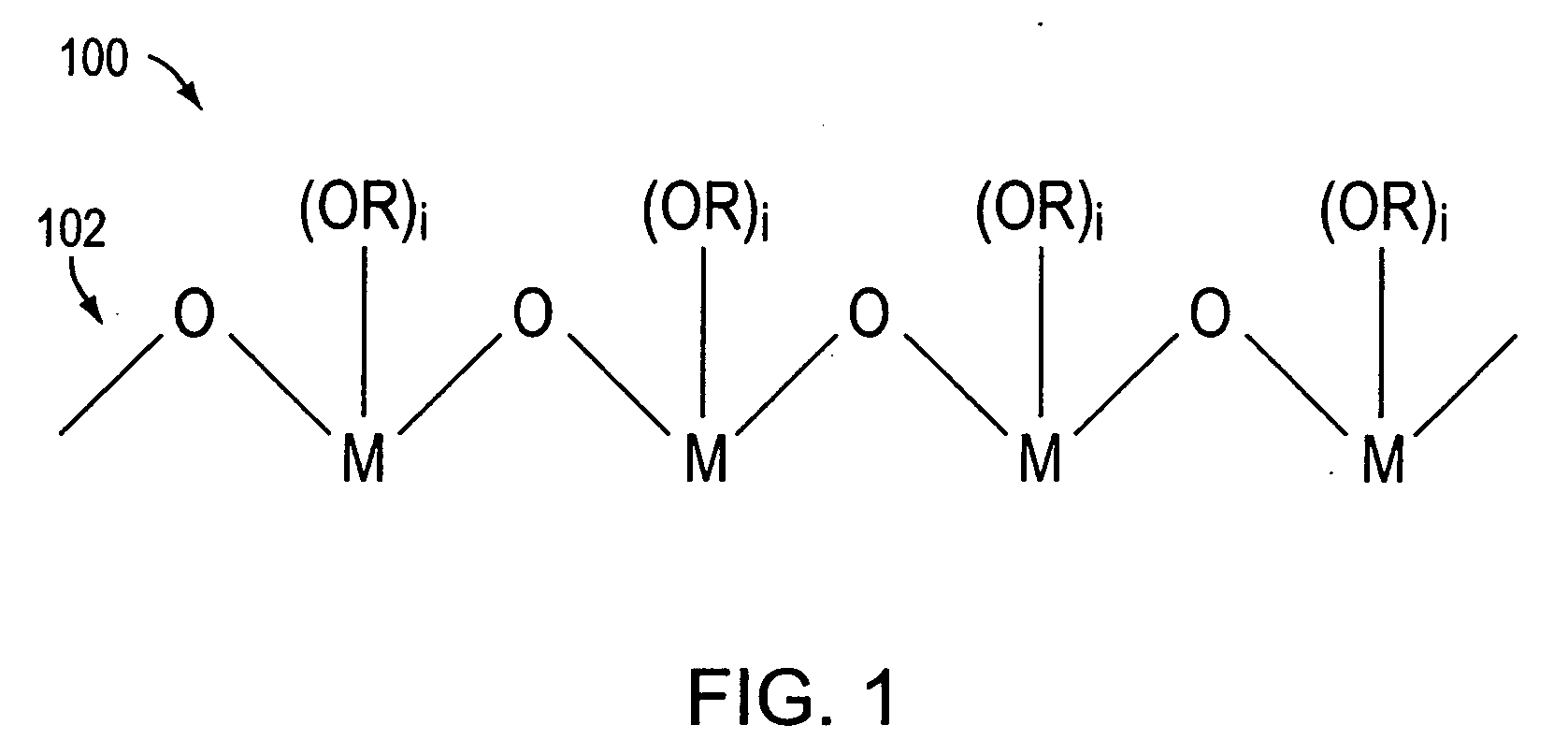

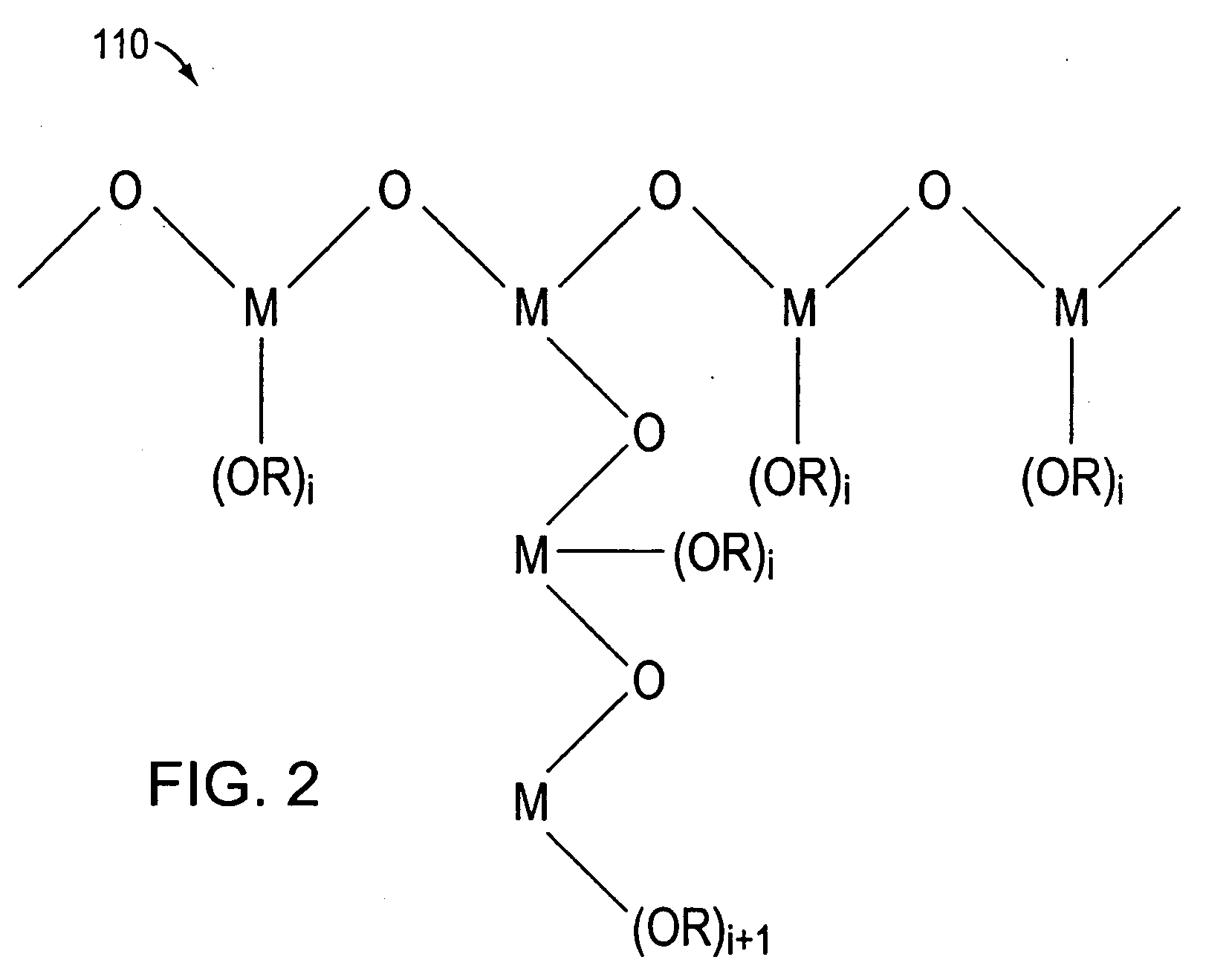

Low temperature interconnection of nanoparticles

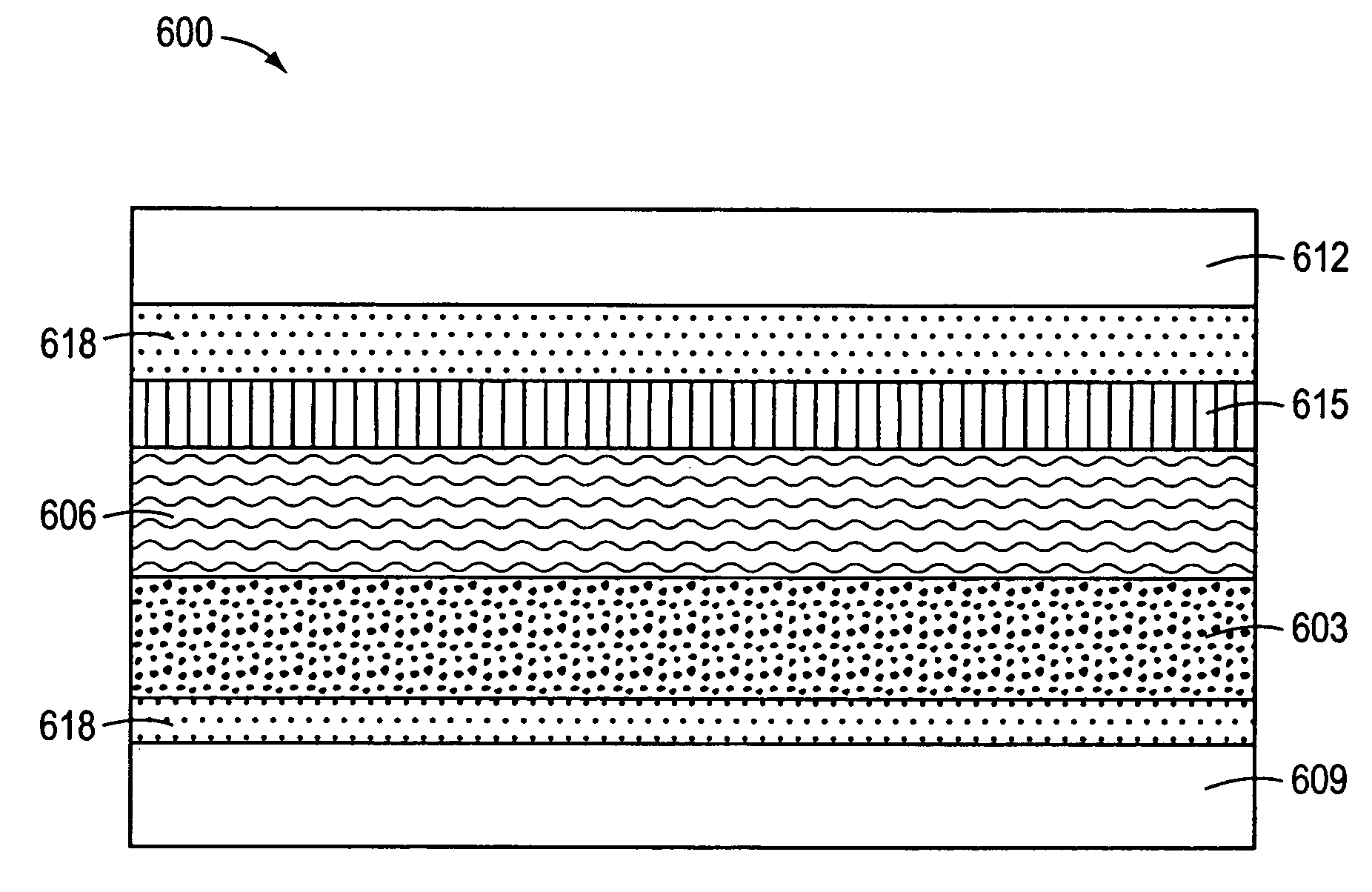

InactiveUS20050011550A1From normal temperature solutionsLight-sensitive devicesNanoparticleEngineering

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

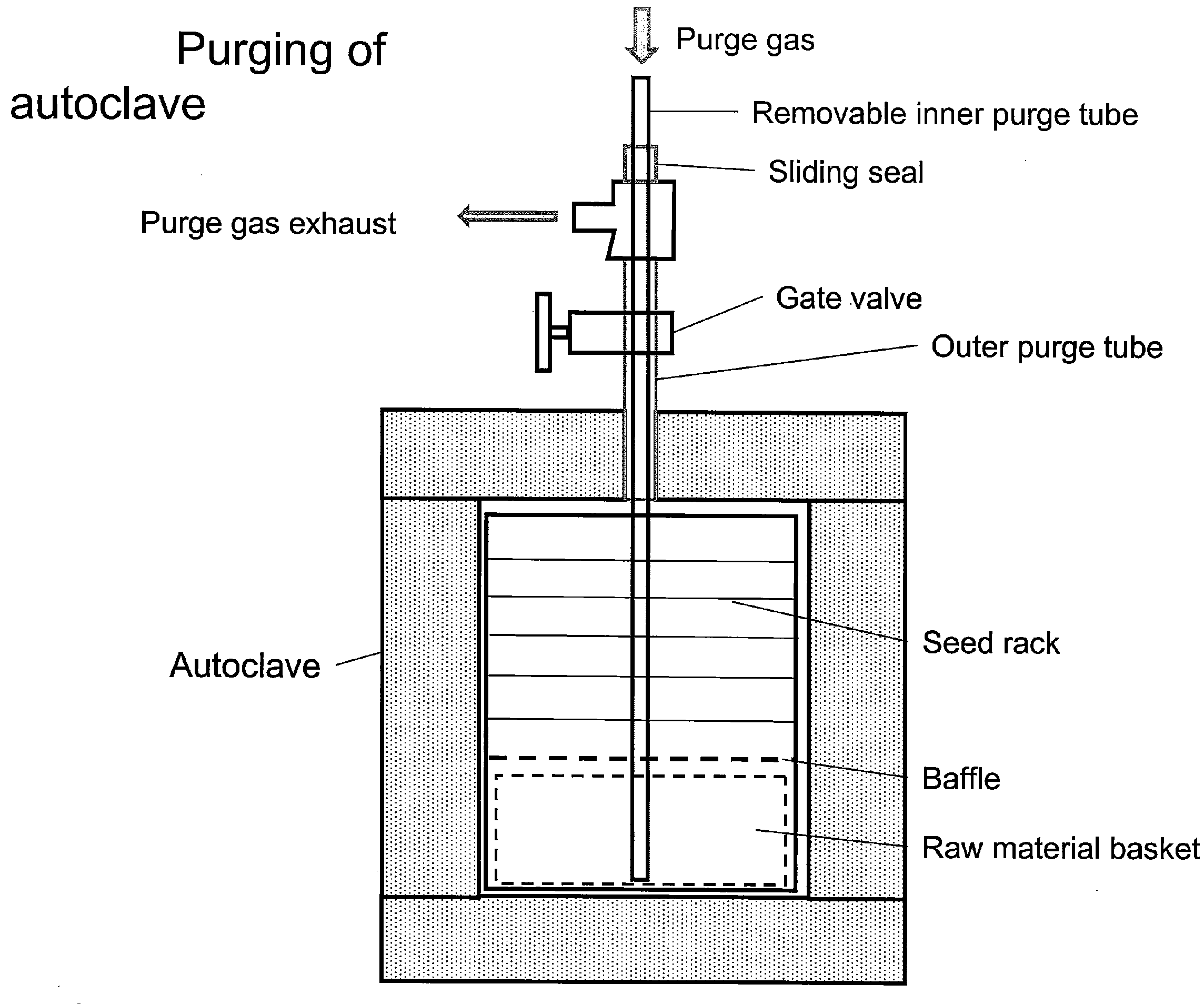

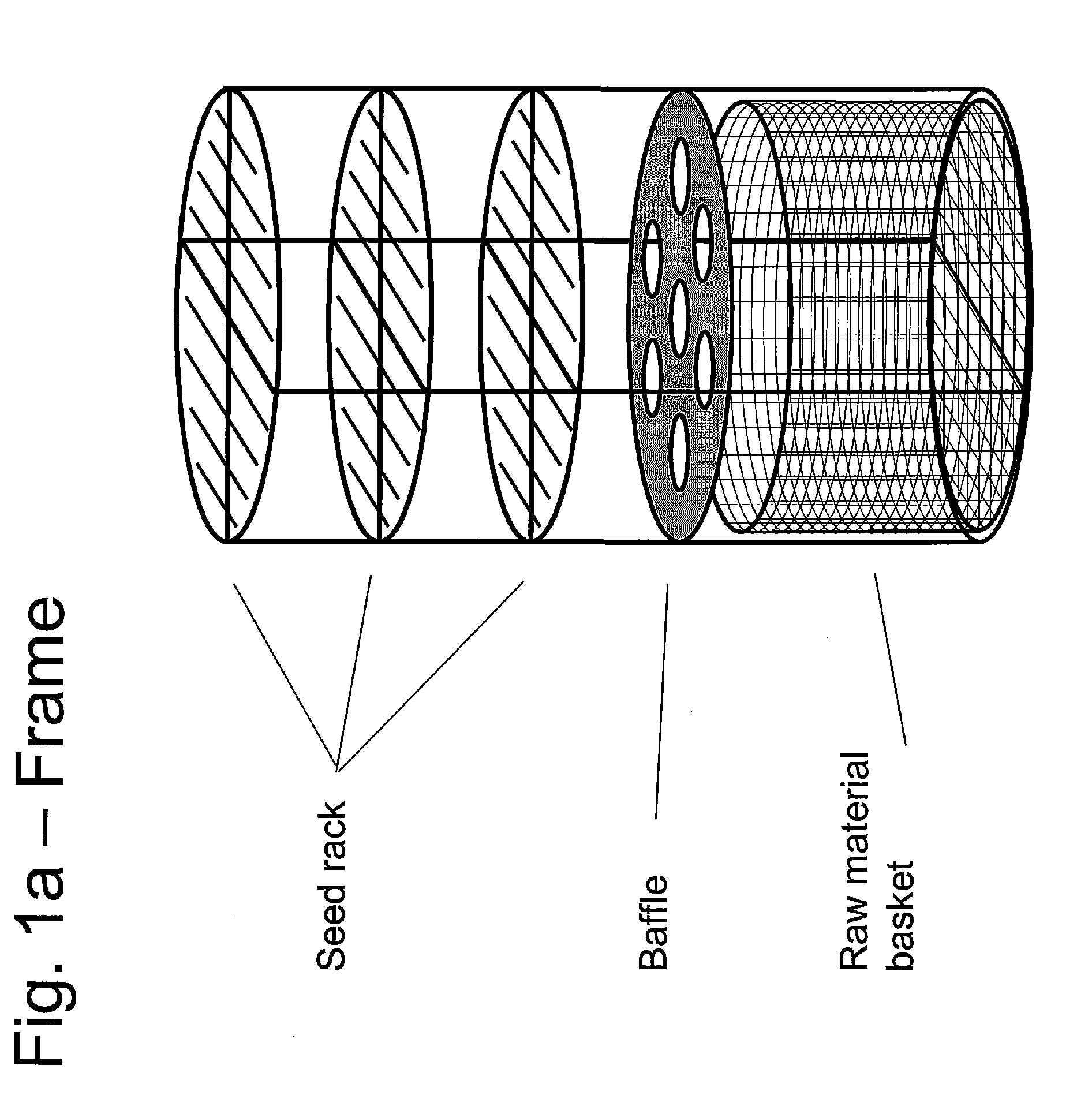

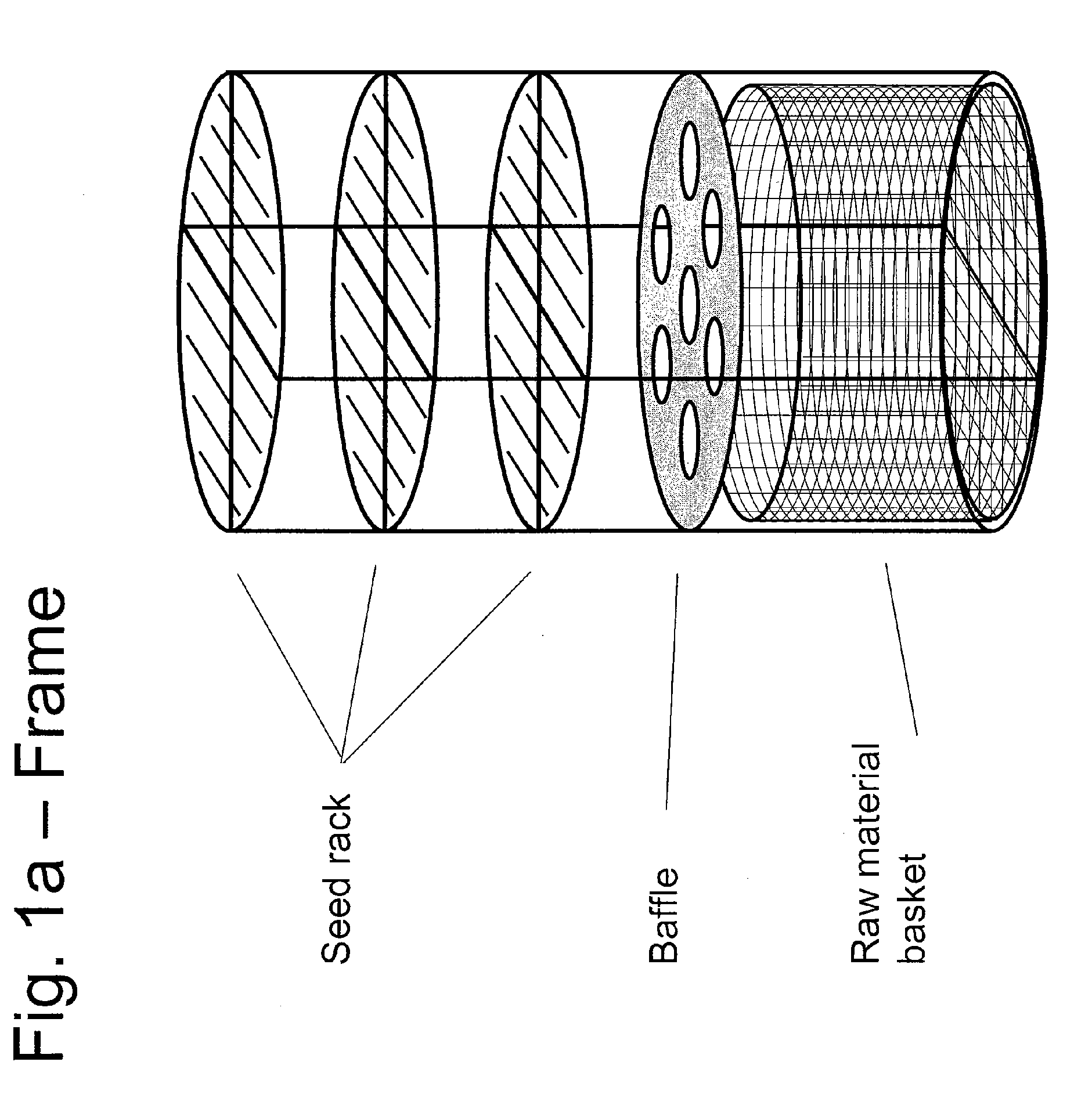

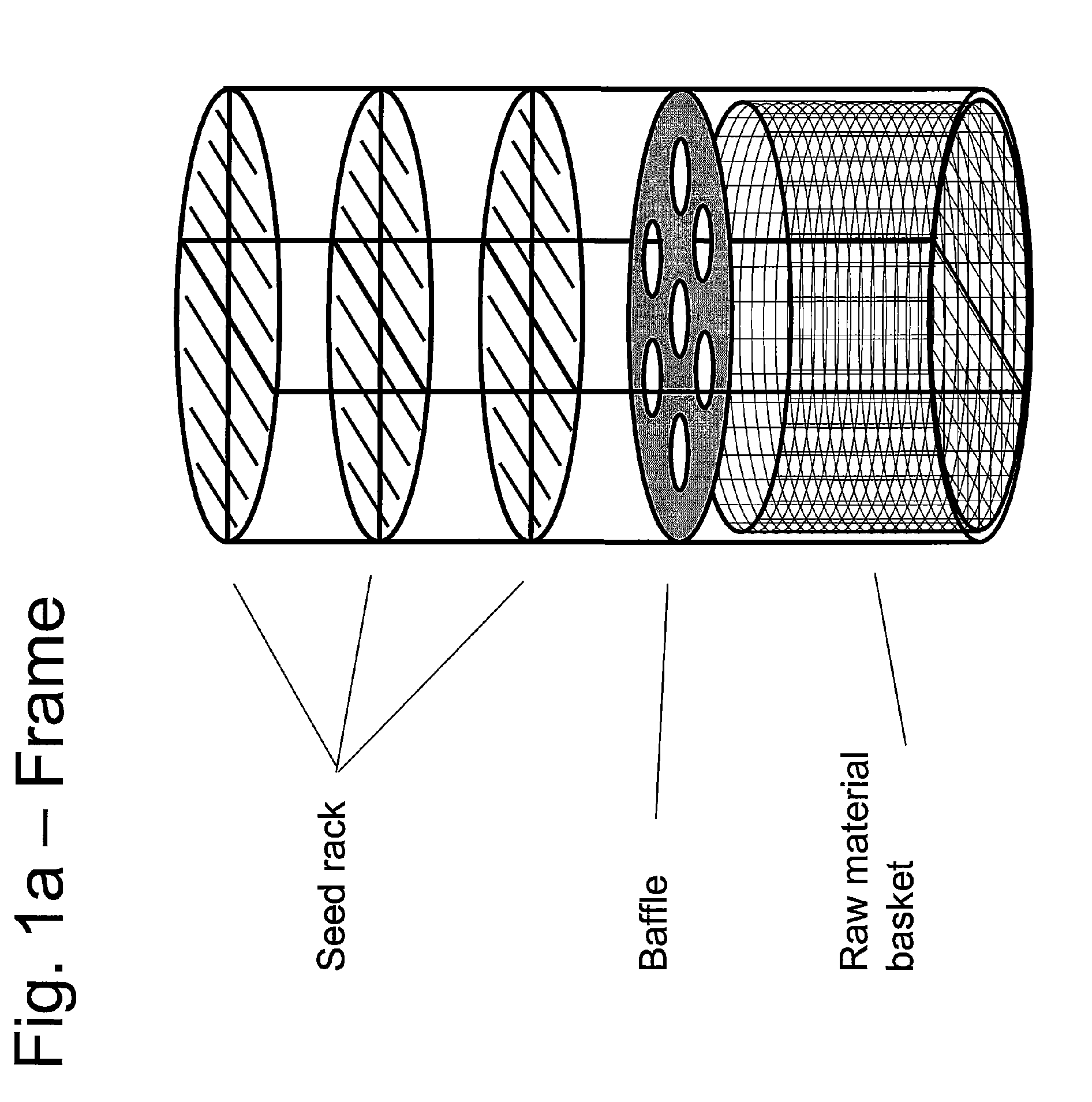

Process and apparatus for large-scale manufacturing of bulk monocrystalline gallium-containing nitride

ActiveUS20100031876A1Cost-effectiveSimple and cost-effective to manufacturePolycrystalline material growthFrom normal temperature solutionsCost effectivenessSingle crystal

A method for large-scale manufacturing of gallium nitride includes a process for reducing and / or minimizing contamination in the crystals, for solvent addition to an autoclave, for improving or optimizing the solvent atmosphere composition, for removal of the solvent from the autoclave, and for recycling of the solvent. The method is scalable up to large volumes and is cost effective.

Owner:SLT TECH

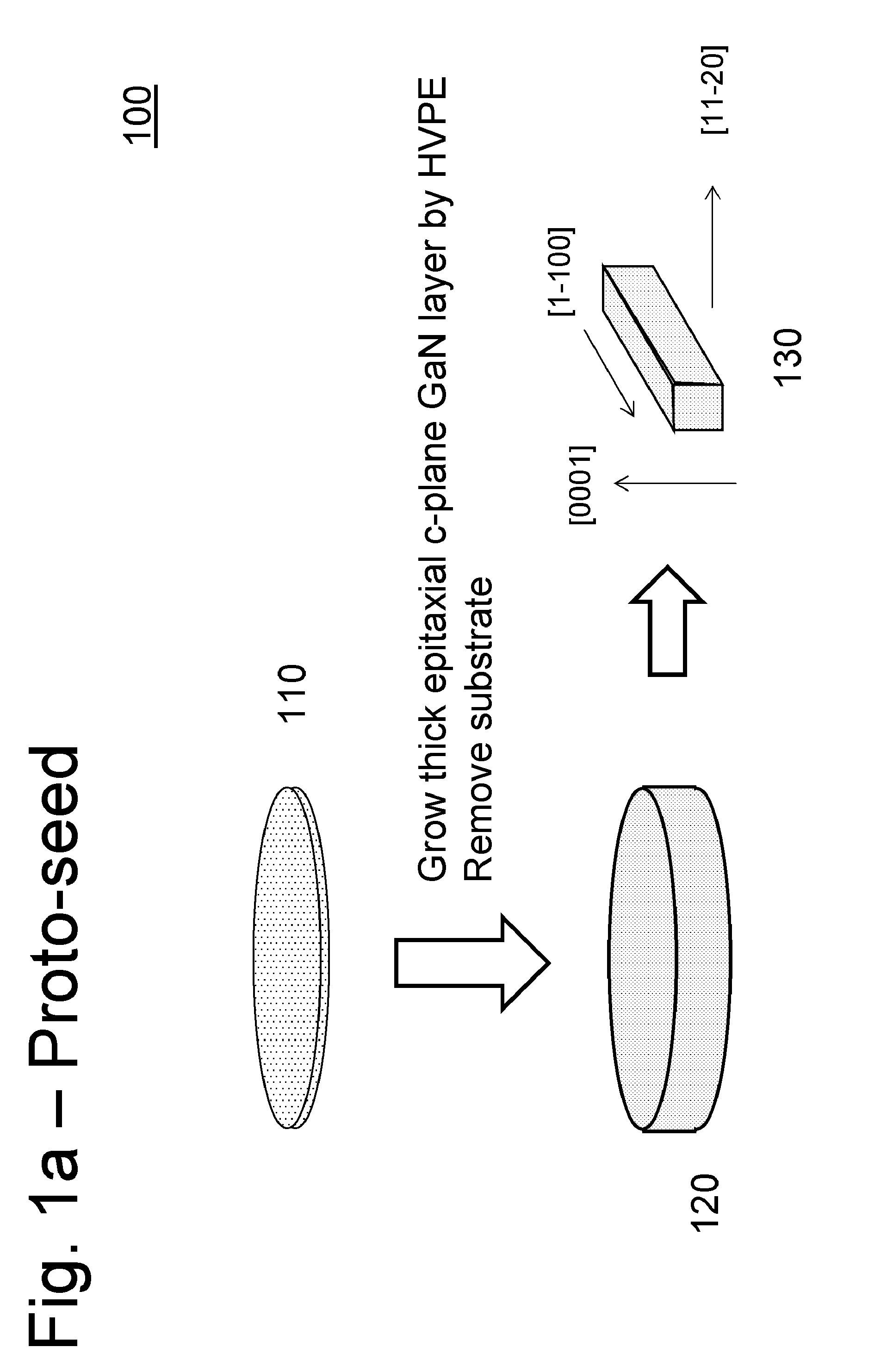

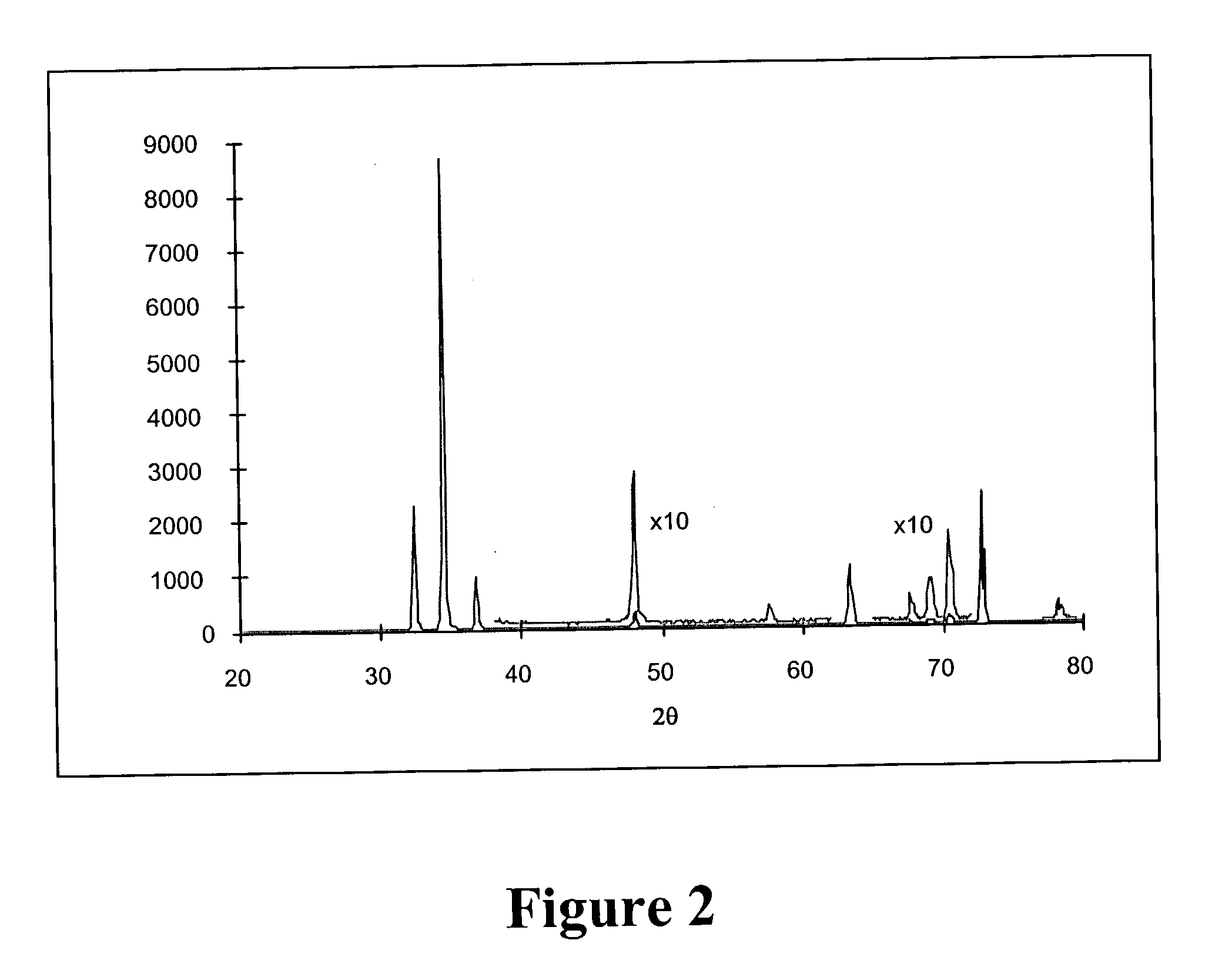

Method for Synthesis of High Quality Large Area Bulk Gallium Based Crystals

ActiveUS20110256693A1Improve crystal qualityPolycrystalline material growthFrom normal temperature solutionsPhotodetectorSolar cell

A large area nitride crystal, comprising gallium and nitrogen, with a non-polar or semi-polar large-area face, is disclosed, along with a method of manufacture. The crystal is useful as a substrate for a light emitting diode, a laser diode, a transistor, a photodetector, a solar cell, or for photoelectrochemical water splitting for hydrogen generation.

Owner:SLT TECH

Process and apparatus for growing a crystalline gallium-containing nitride using an azide mineralizer

ActiveUS20100031874A1Increase in sizeCost effectivePolycrystalline material growthFrom normal temperature solutionsDopantCost effectiveness

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

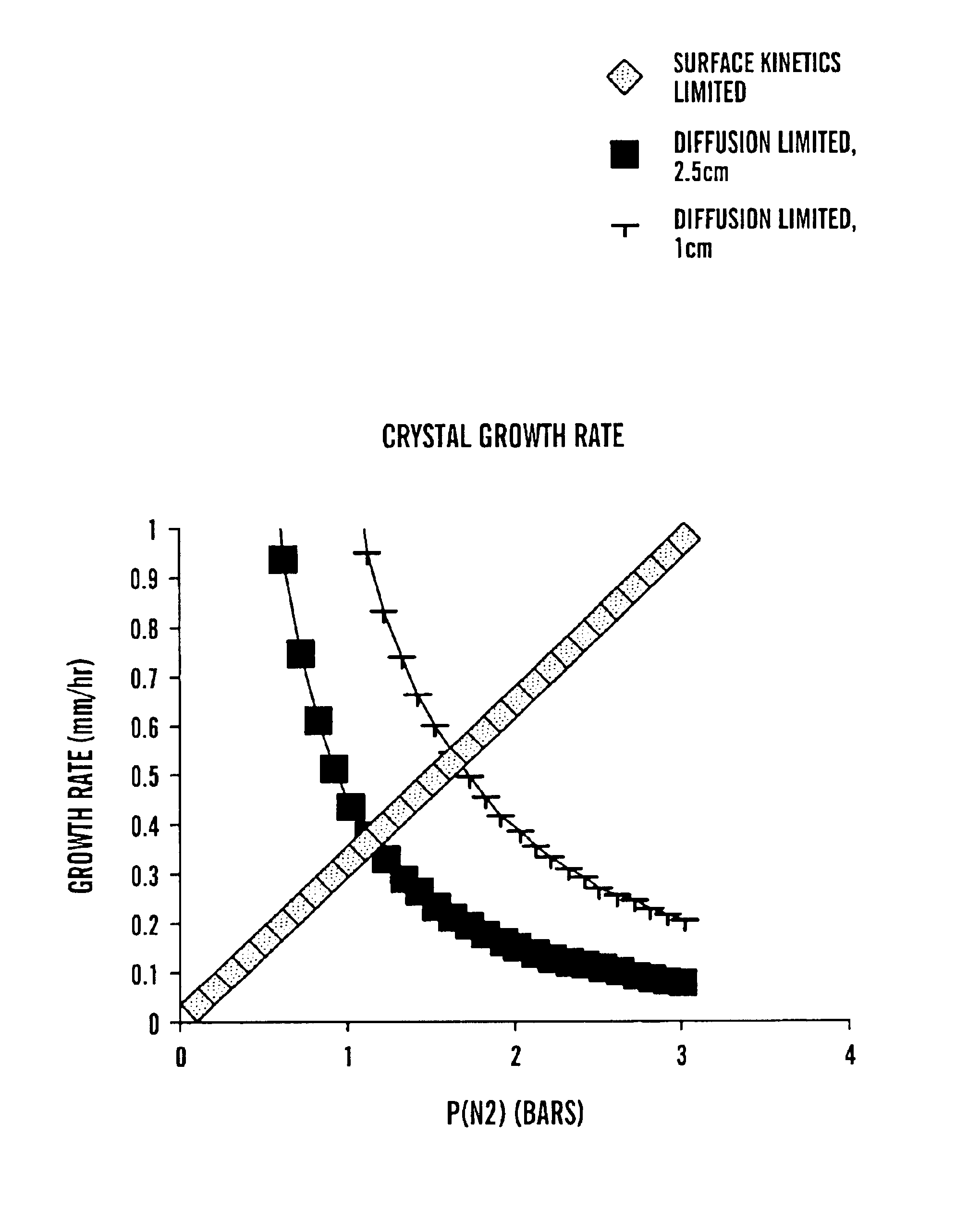

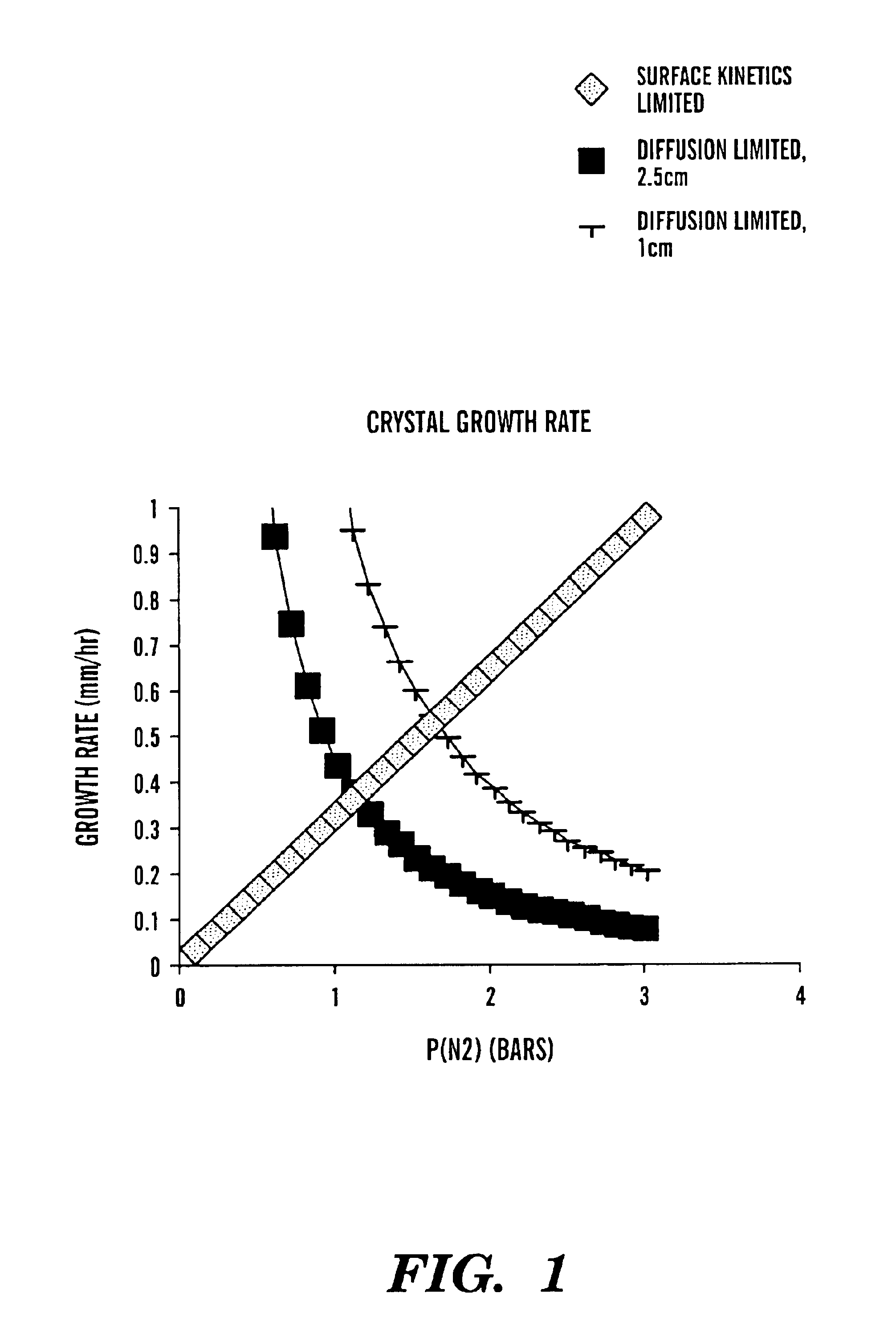

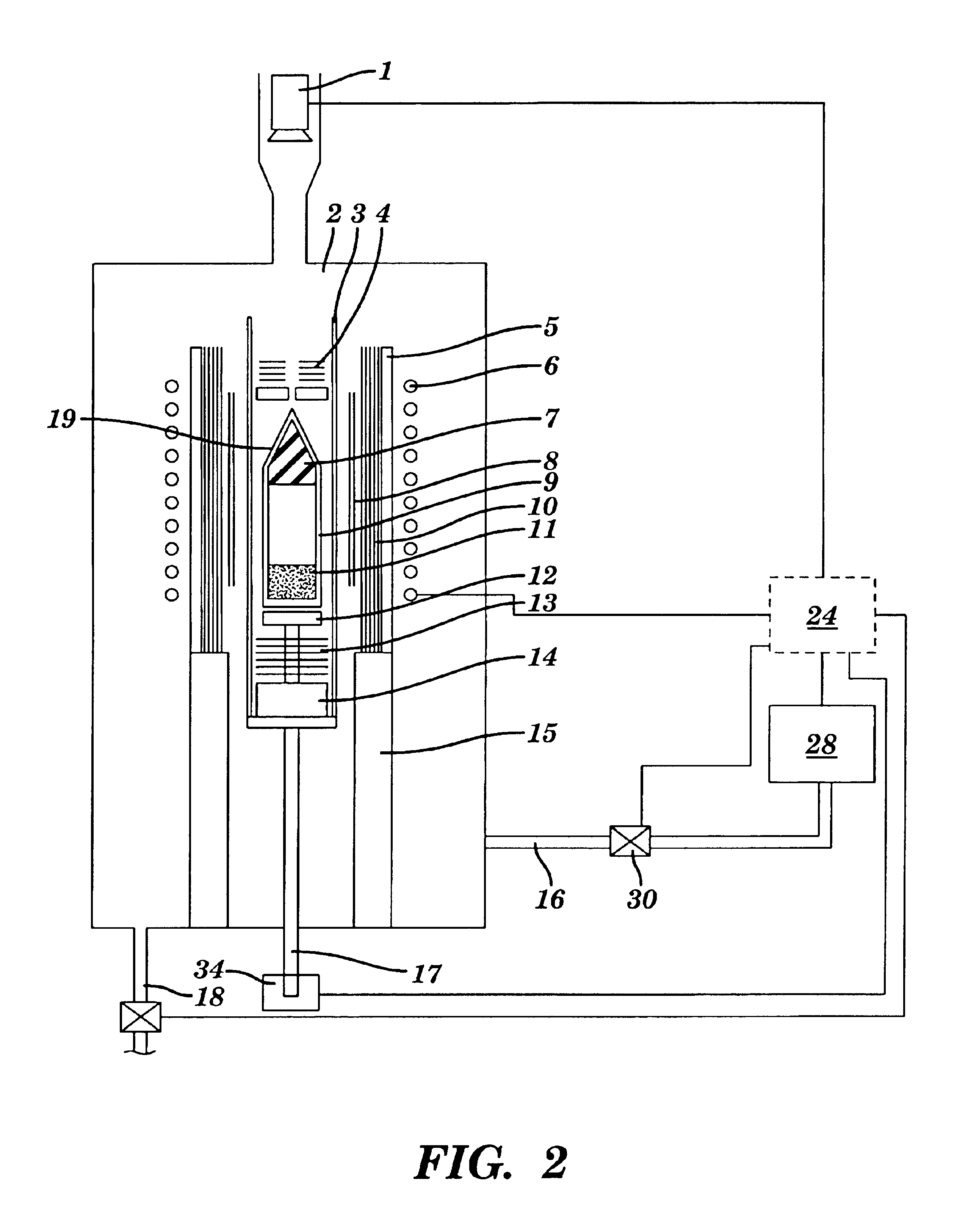

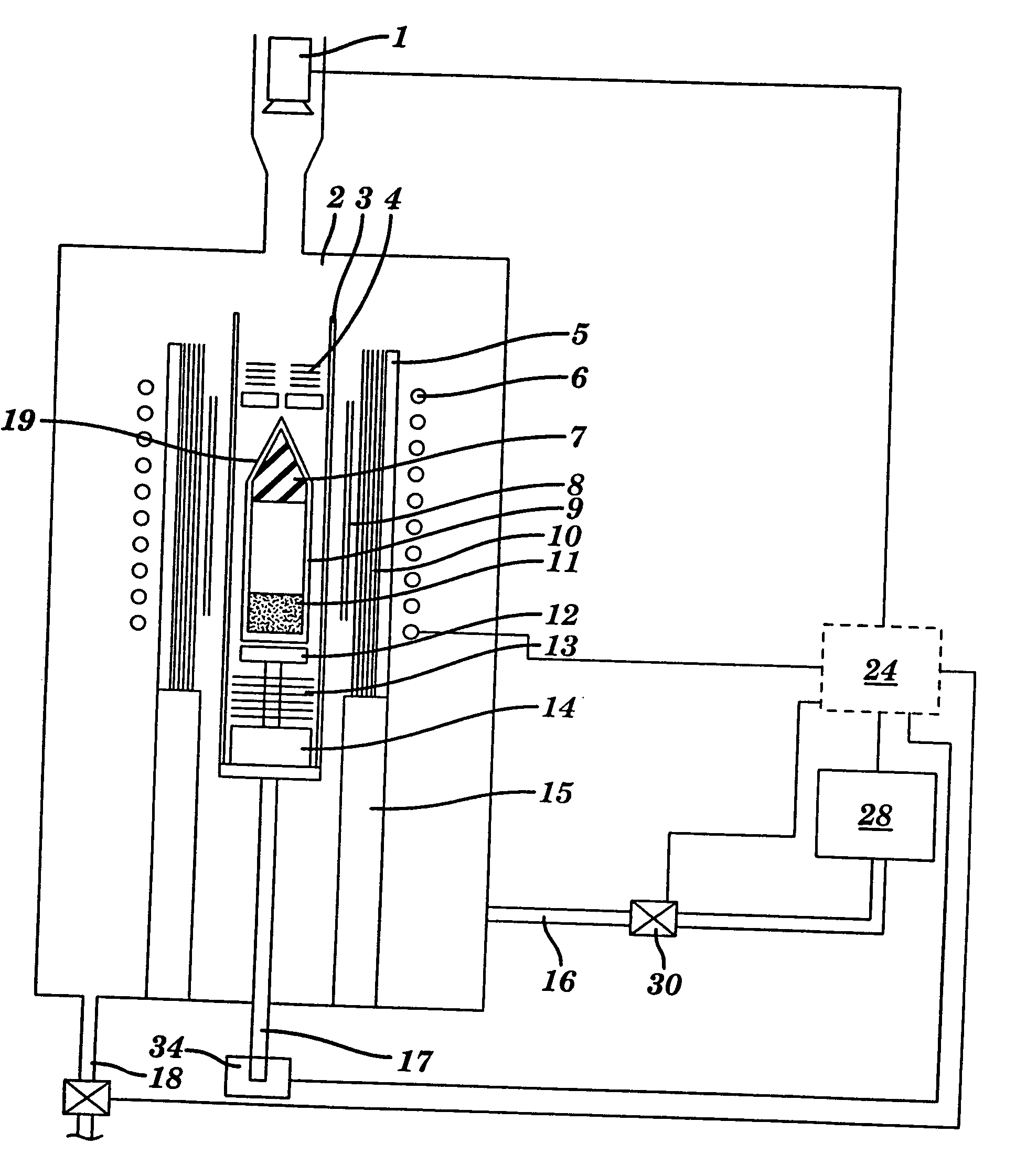

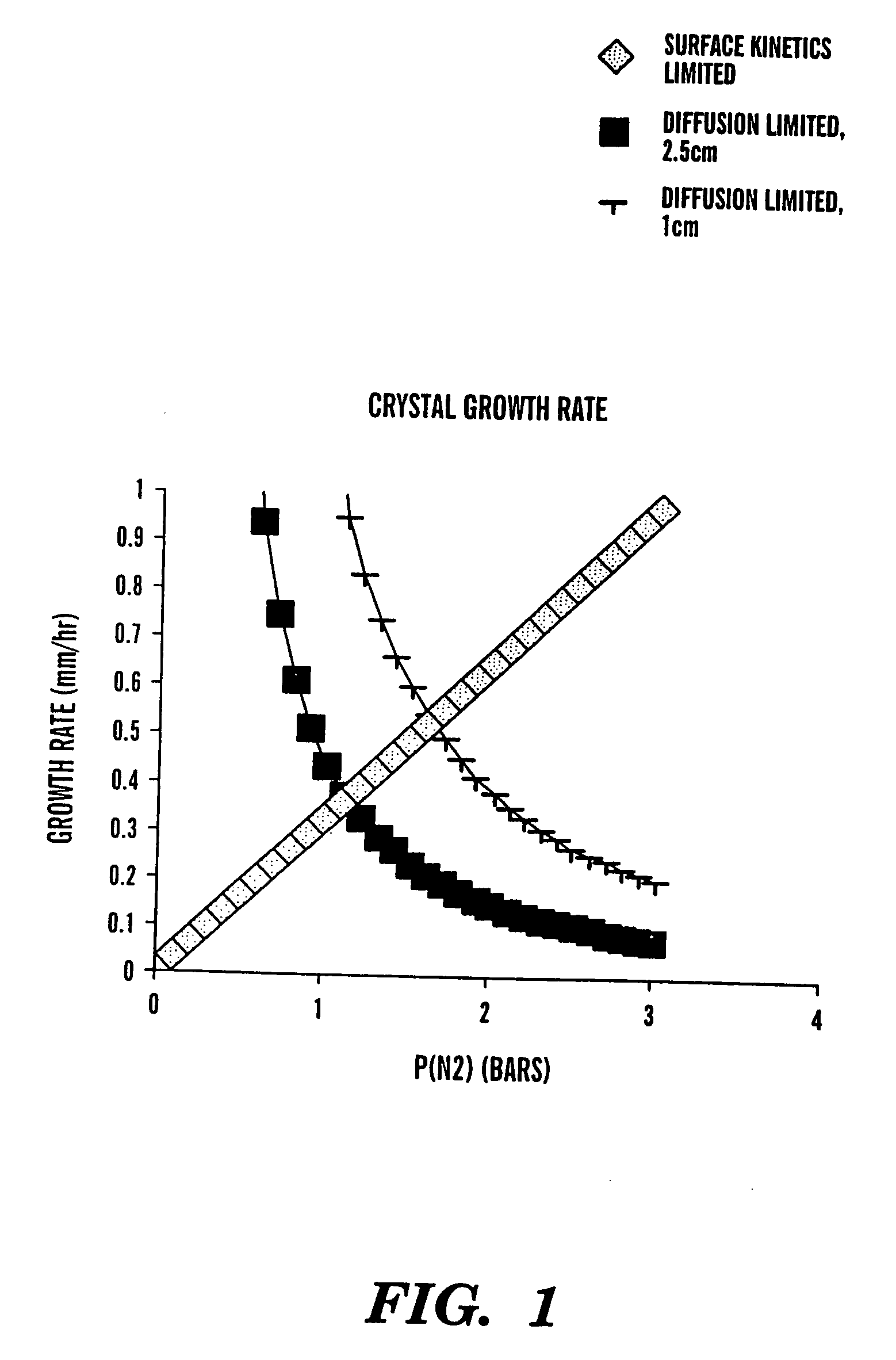

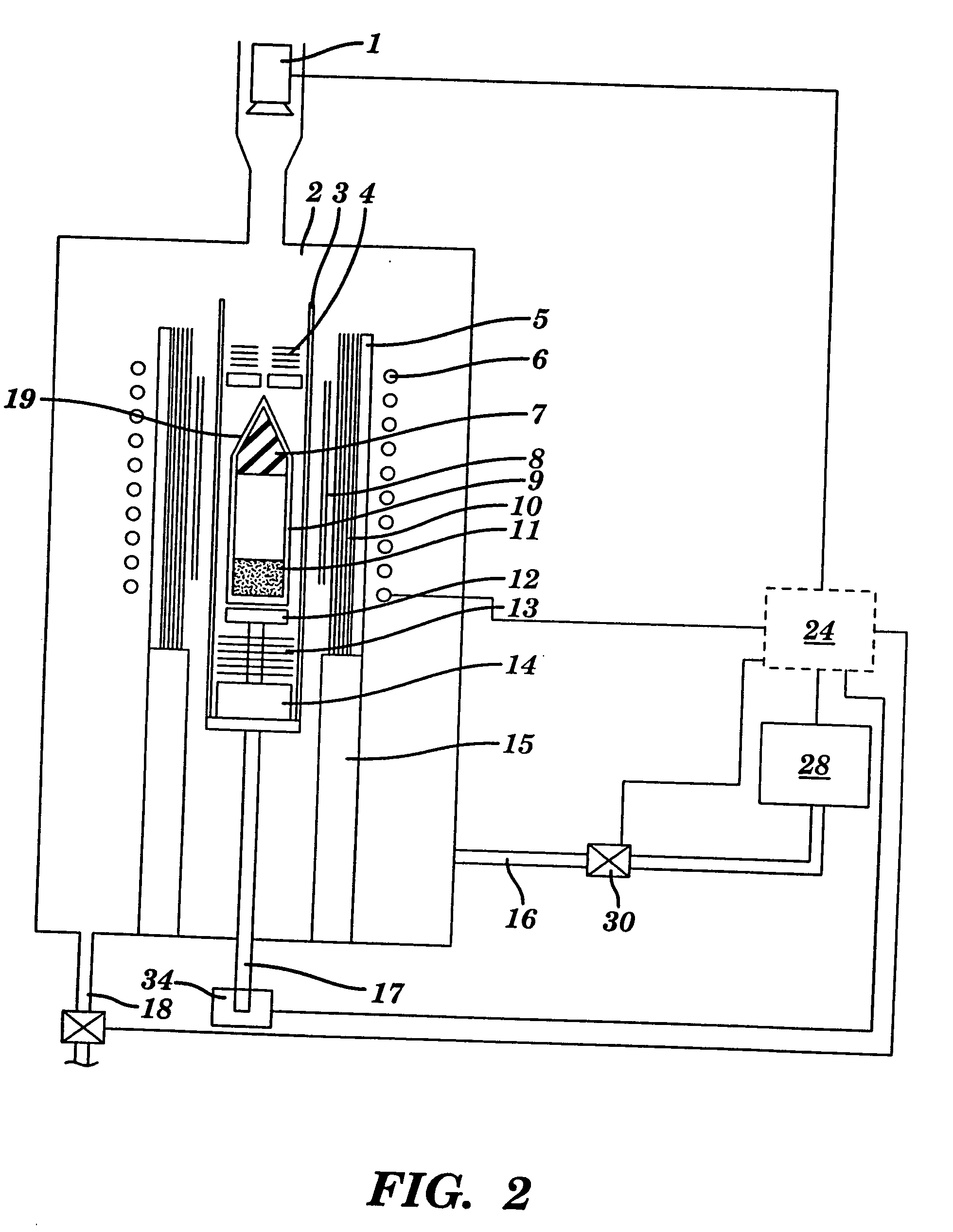

Method and apparatus for producing large, single-crystals of aluminum nitride

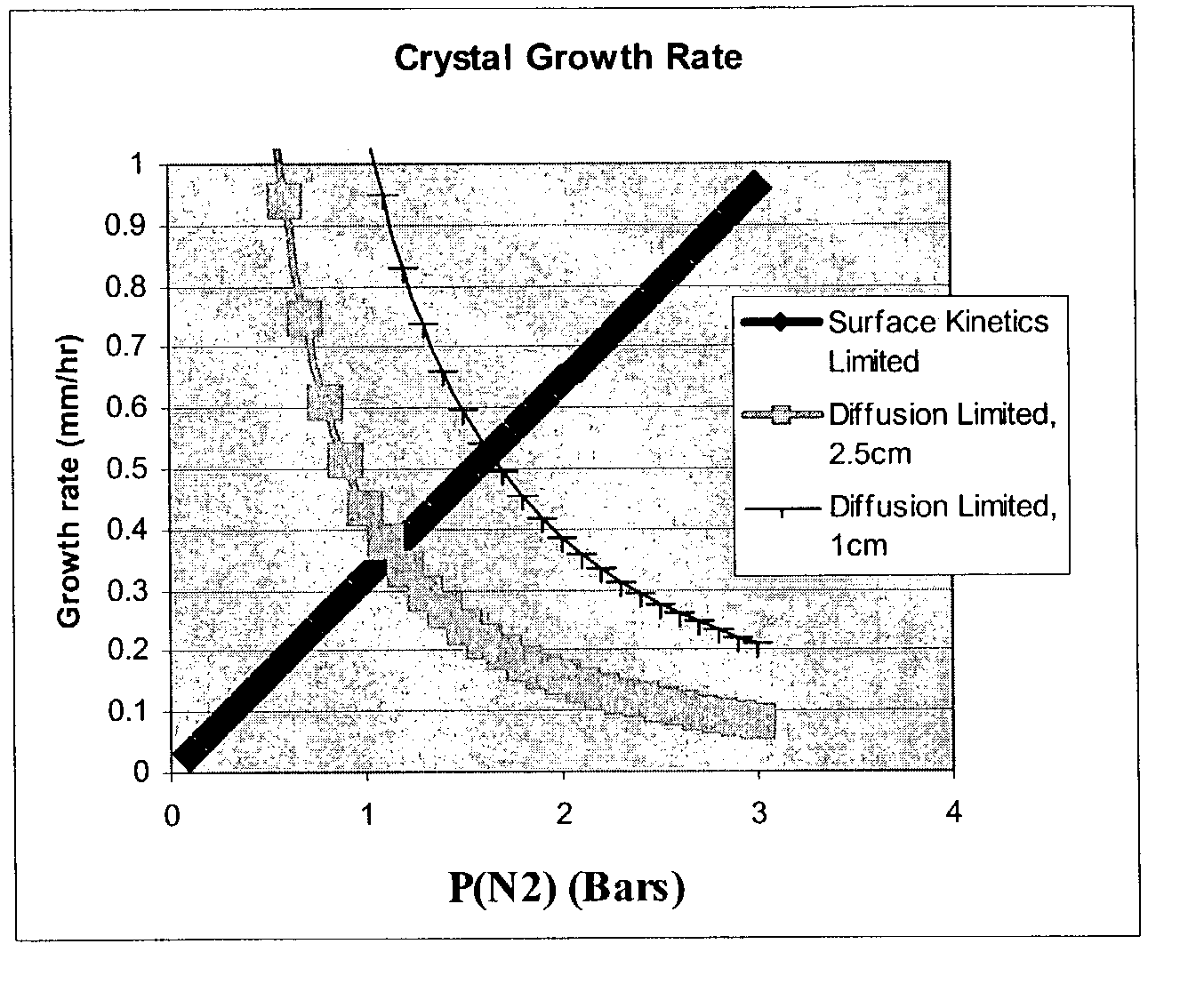

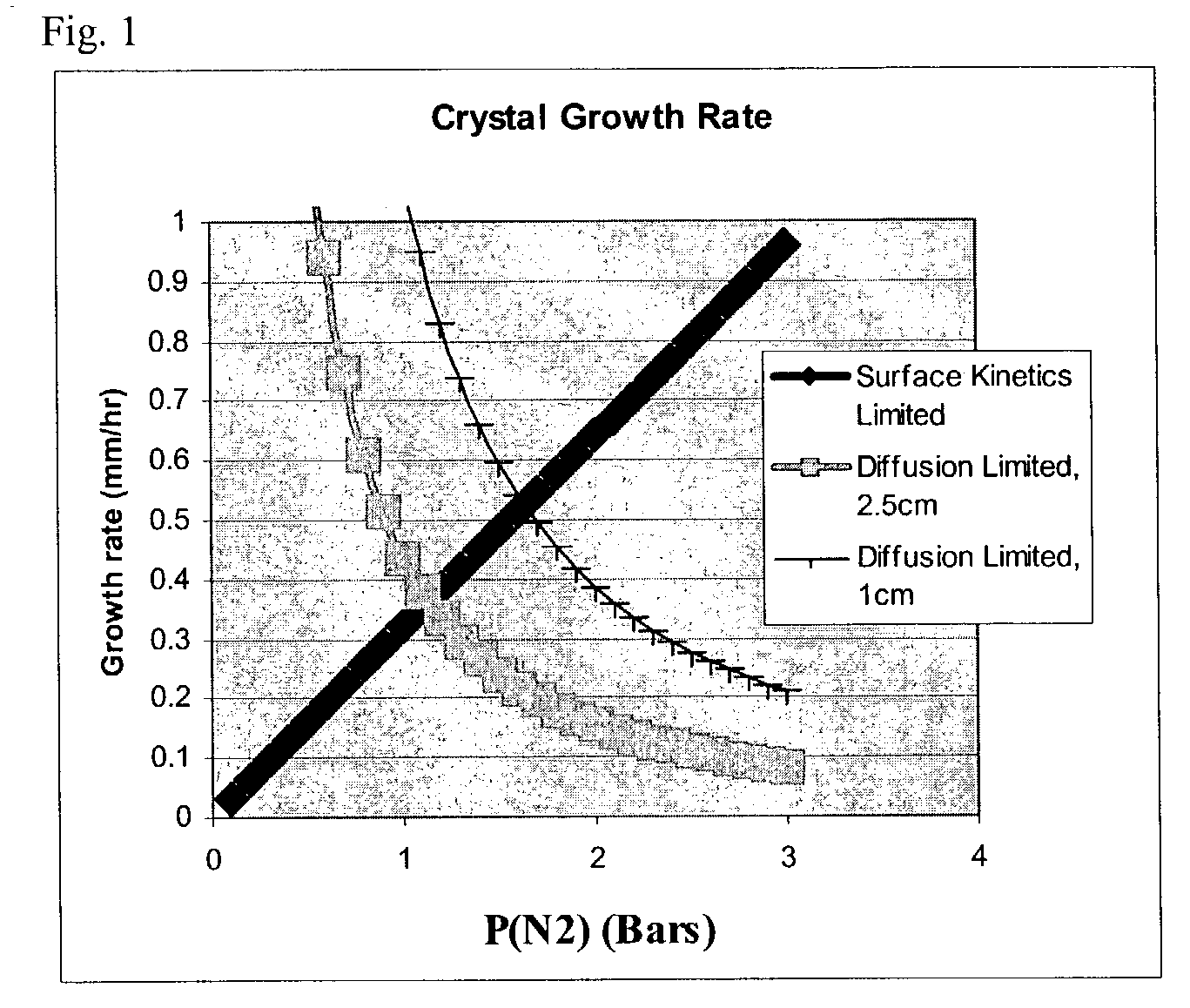

InactiveUS6770135B2After-treatment apparatusPolycrystalline material growthBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

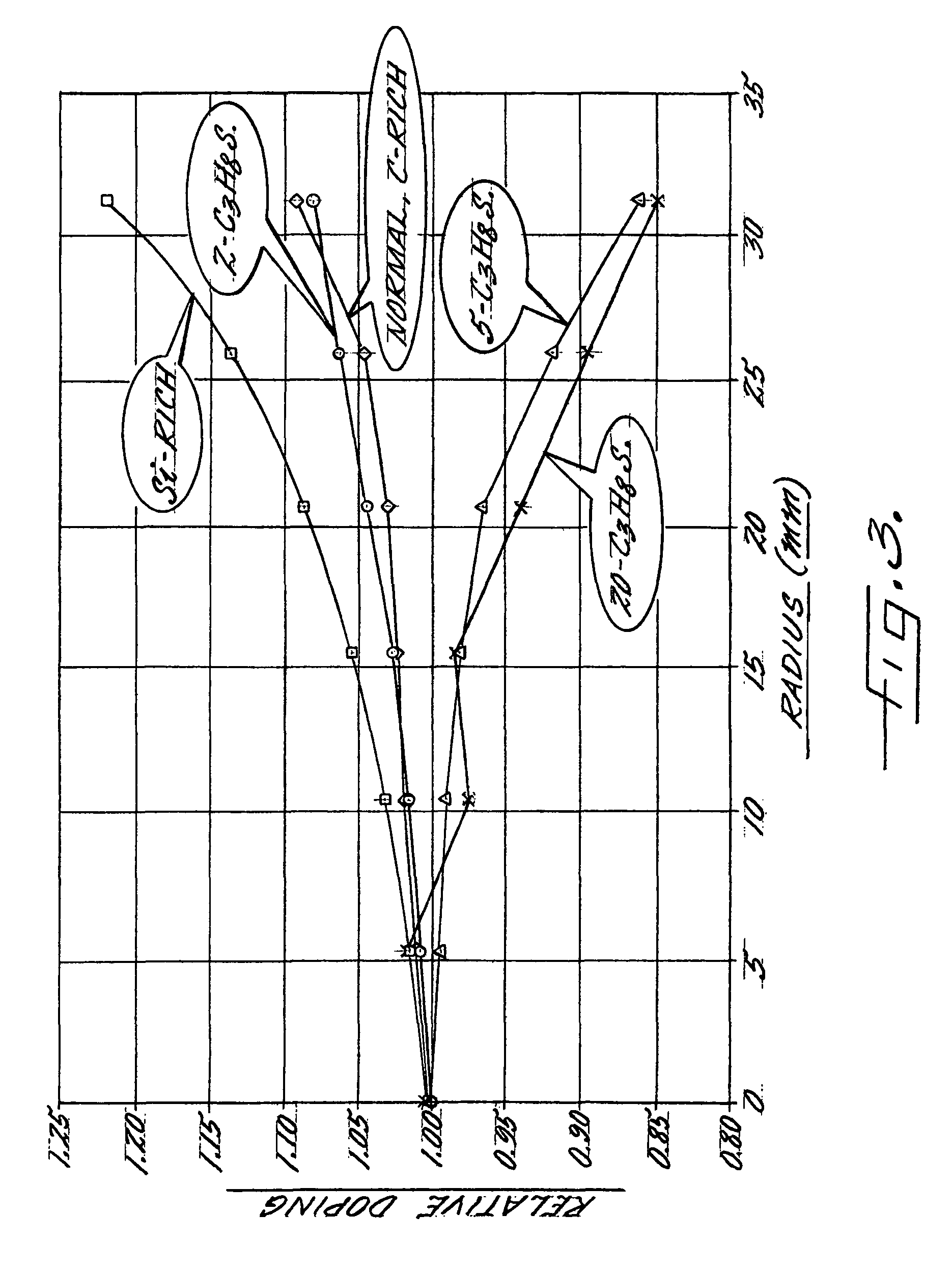

Methods of hyperdoping semiconductor materials and hyperdoped semiconductor materials and devices

InactiveUS20030121468A1Avoiding and mitigating formationEasy to operateTransistorPolycrystalline material growthSide effectSemiconductor materials

Methods are disclosed for producing highly doped semiconductor materials. Using the invention, one can achieve doping densities that exceed traditional, established carrier saturation limits without deleterious side effects. Additionally, highly doped semiconductor materials are disclosed, as well as improved electronic and optoelectronic devices / components using said materials. The innovative materials and processes enabled by the invention yield significant performance improvements and / or cost reductions for a wide variety of semiconductor-based microelectronic and optoelectronic devices / systems. Materials are grown in an anion-rich environment, which, in the preferred embodiment, are produced by moderate substrate temperatures during growth in an oxygen-poor environment. The materials exhibit fewer non-radiative recombination centers at higher doping concentrations than prior art materials, and the highly doped state of matter can exhibit a minority carrier lifetime dominated by radiative recombination at higher doping levels and higher majority carrier concentrations than achieved in prior art materials. Important applications enabled by these novel materials include high performance electronic or optoelectronic devices, which can be smaller and faster, yet still capture or emit light efficiently, and high performance electronics, such as transistors, which can be smaller and faster, yet cooler.

Owner:YALE UNIV

High pressure apparatus and method for nitride crystal growth

InactiveUS20100147210A1Simple and cost-effective to manufactureEasy to disassemblePolycrystalline material growthFrom normal temperature solutionsControl systemPower control system

An improved high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a release sleeve, a heater, at least one ceramic segment or ring but can be multiple segments or rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively. Following a run, the release sleeve may be at least partially dissolved or etched to facilitate removal of the capsule from the apparatus.

Owner:SORAA

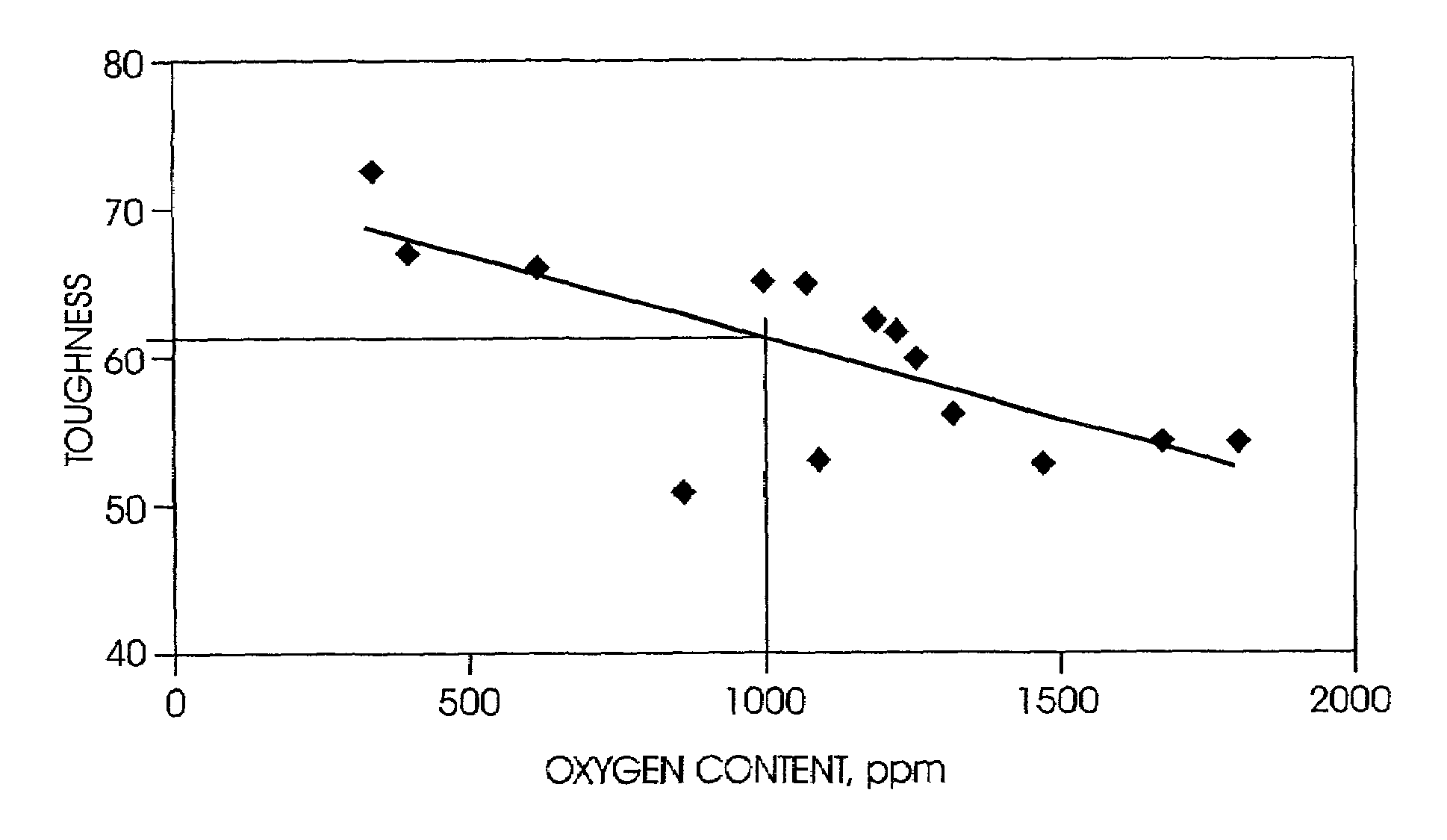

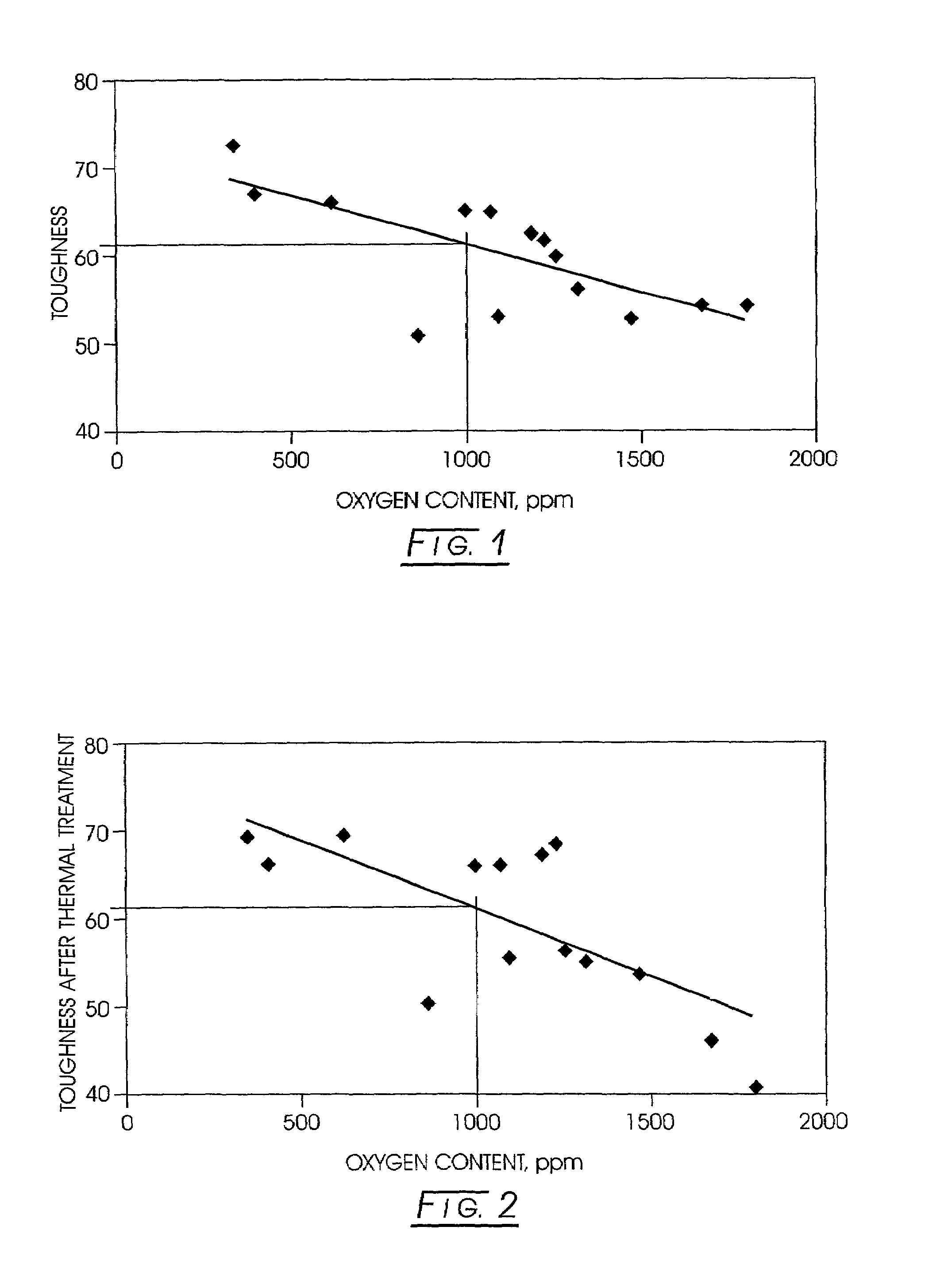

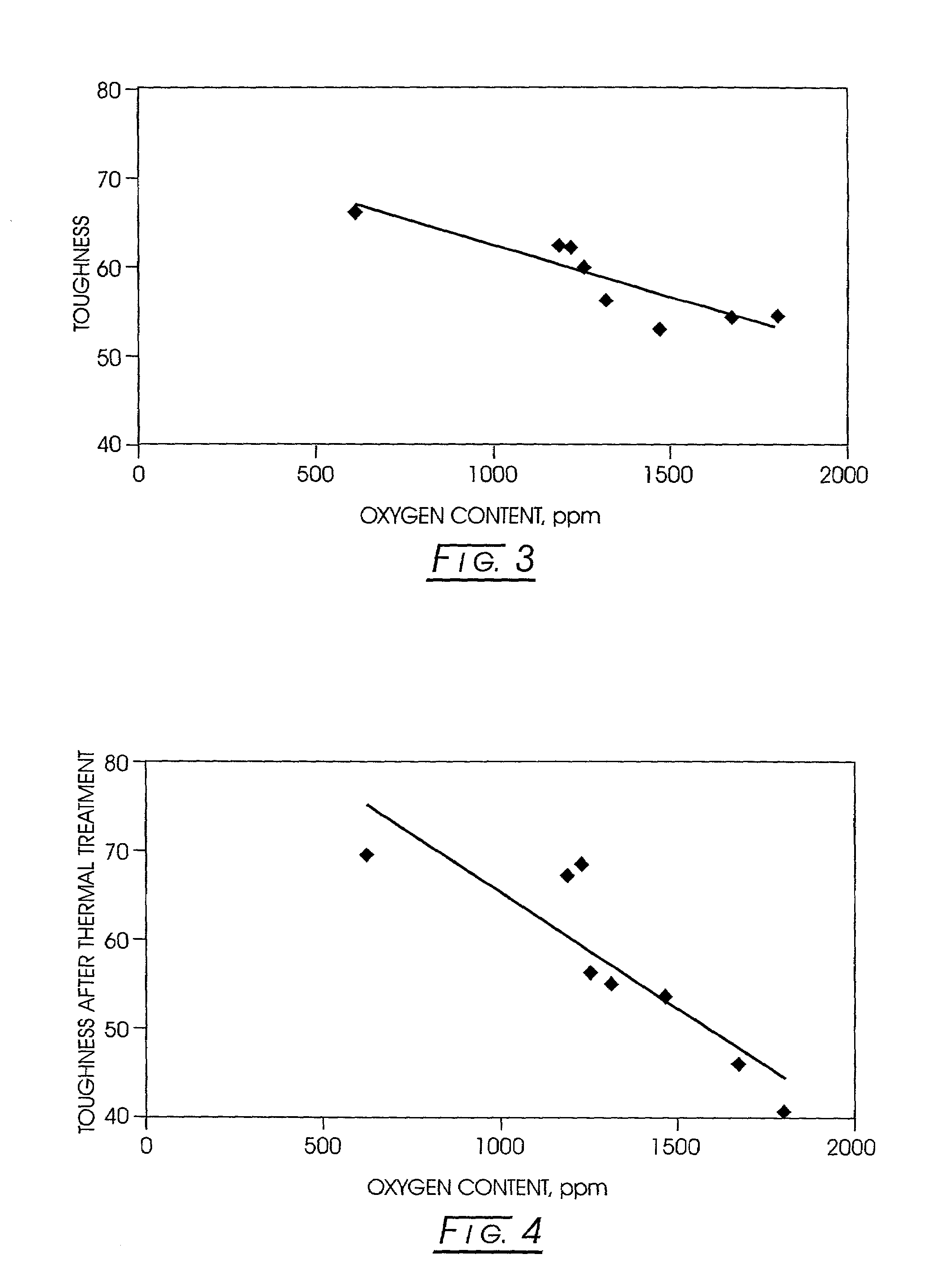

Low oxygen cubic boron nitride and its production

InactiveUS7001577B2Increased toughness indexImprove toughnessFrom gel statePolycrystalline material growthBoron nitrideHigh pressure

A method for improving the toughness of a CBN product made by a high temperature / high pressure (HP / HT) process commences by forming a blend of an oxygen getter and CBN product-forming feedstock. The blend is subjected to a CBN high temperature / high pressure (HP / HT) process for forming a CBN product. The amount of oxygen getter in the blend is sufficient to improve the toughness of the CBN product. The resulting CBN product desirably has an oxygen content of less than about 300 ppm. Oxygen getters include Al, Si, and Ti. The HP / HT process is conducted in the absence or presence of catalytic materials.

Owner:DIAMOND INNOVATIONS INC

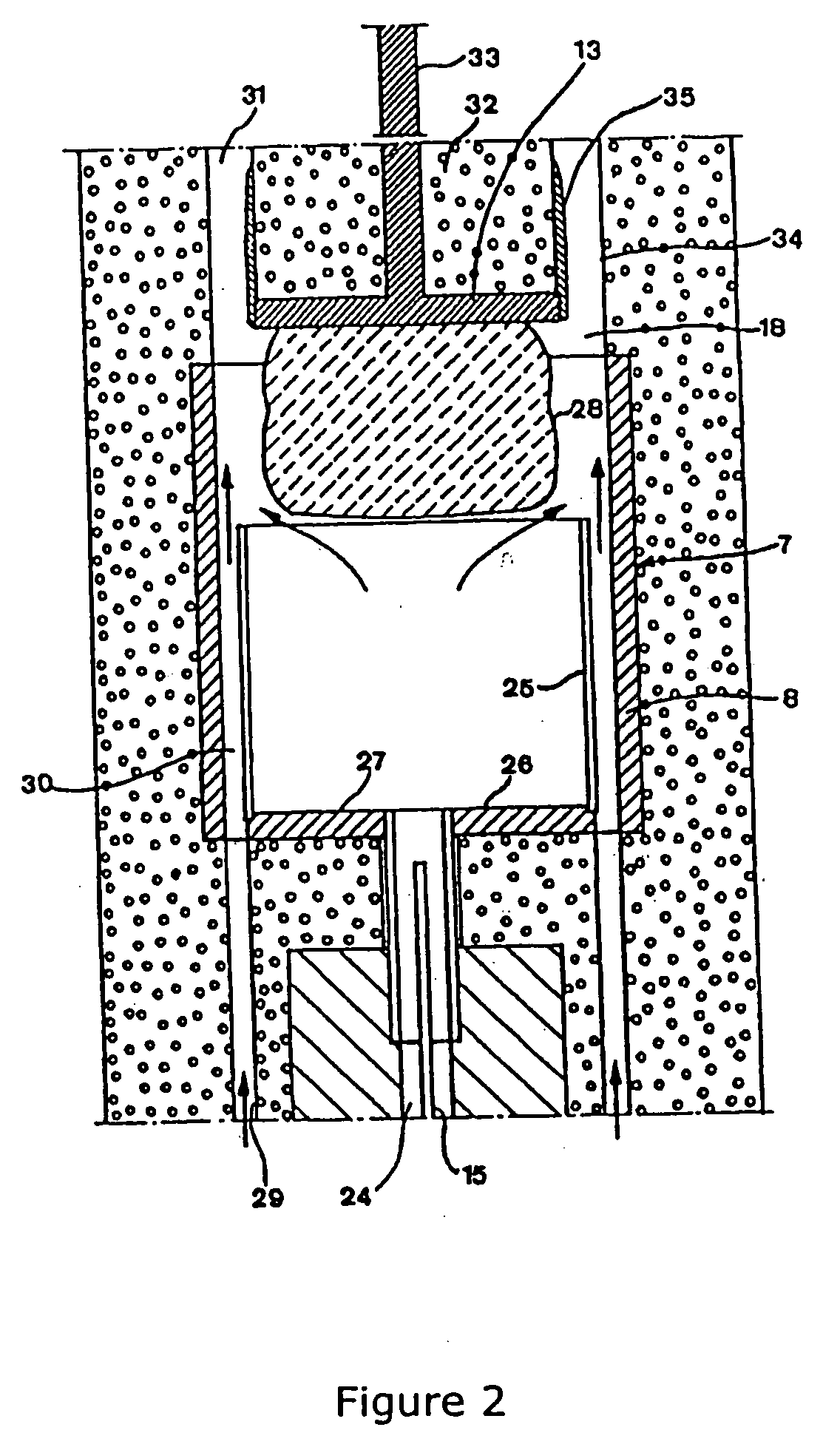

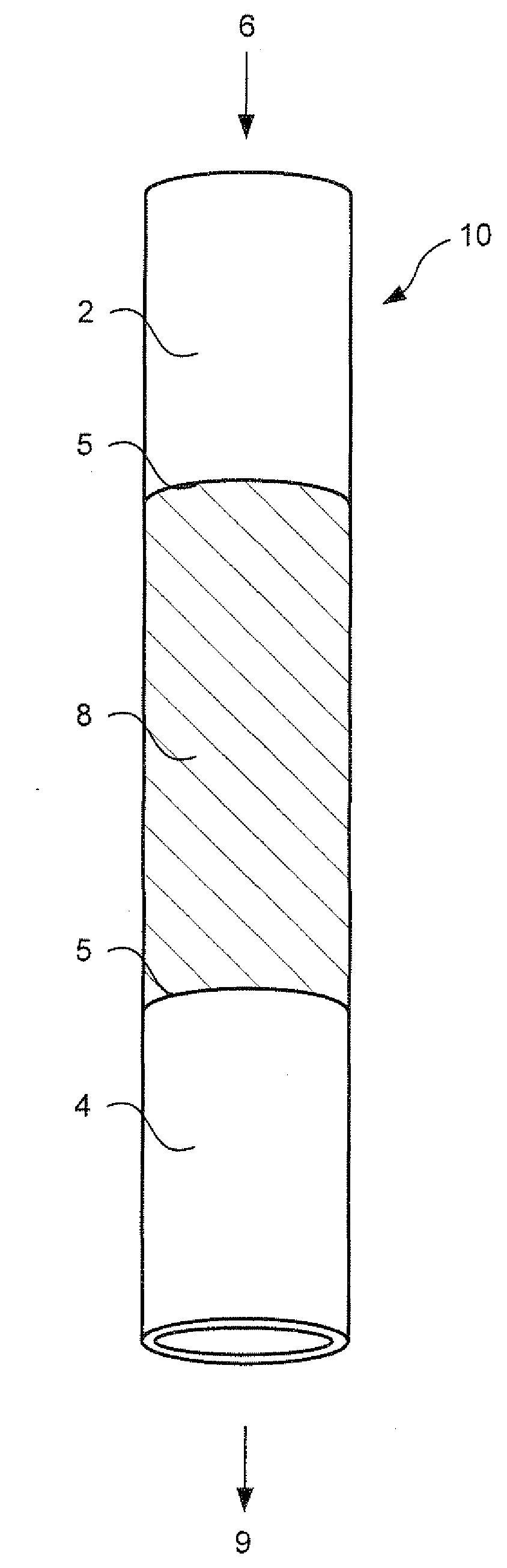

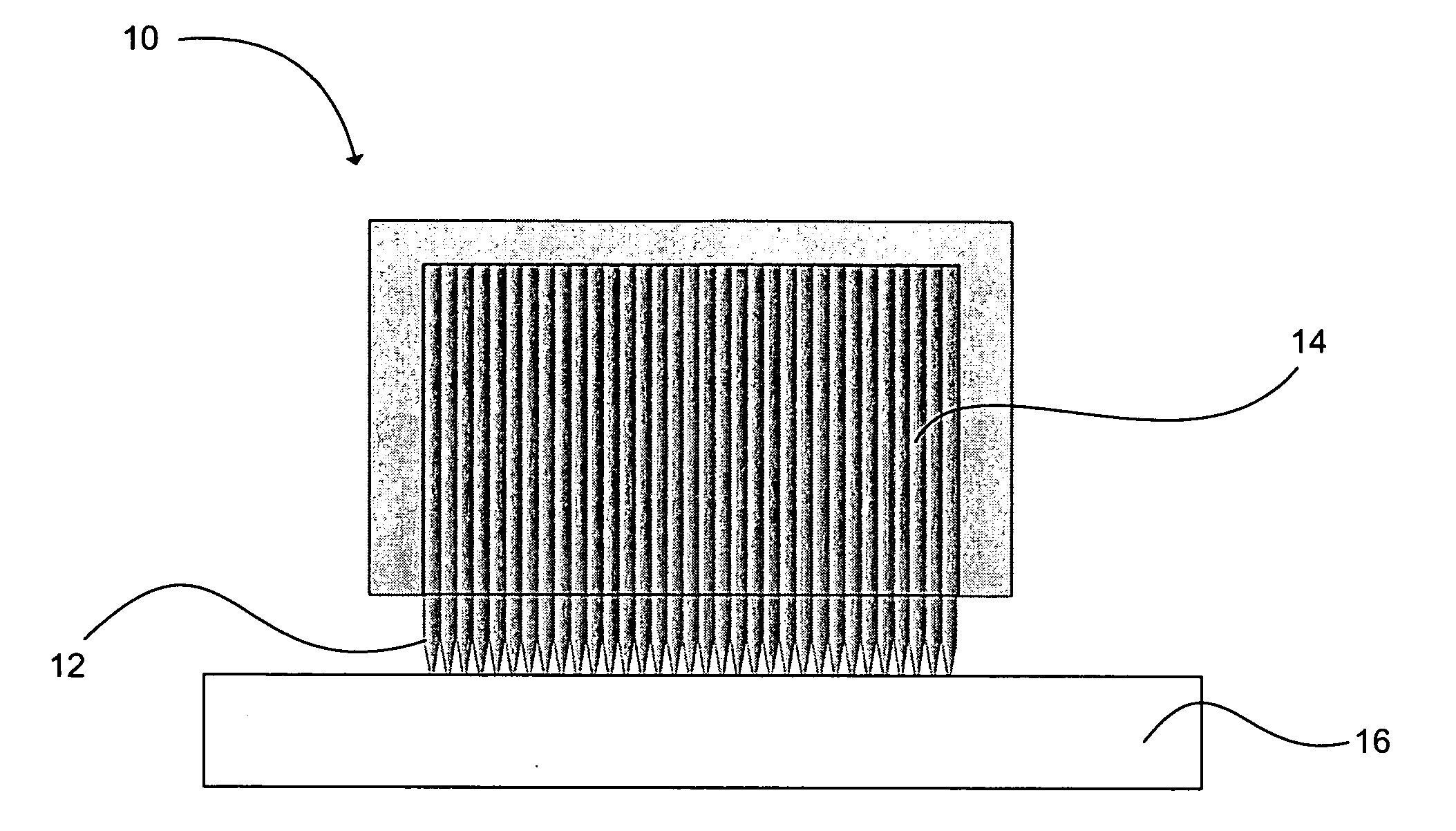

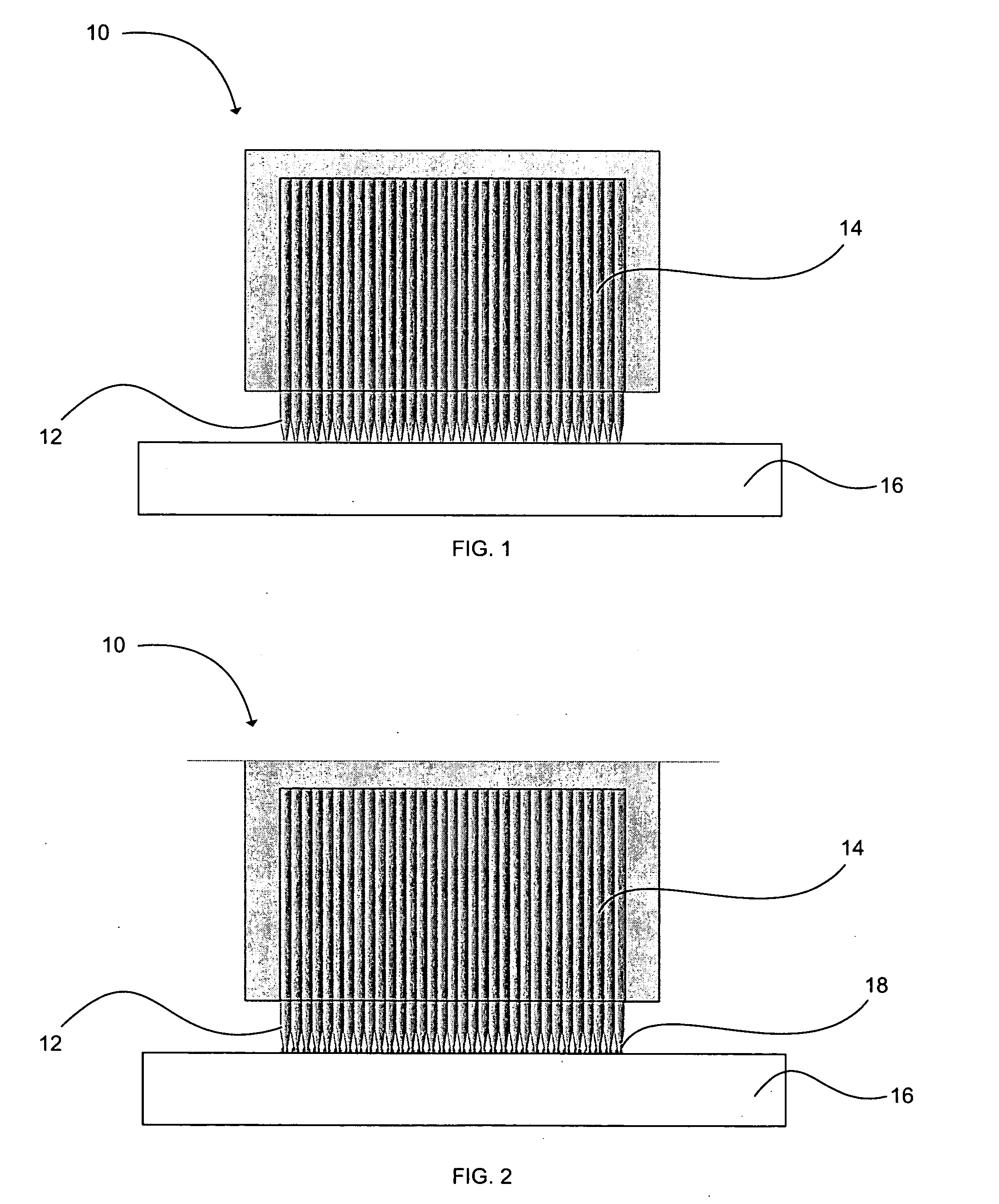

Heater device and method for high pressure processing of crystalline materials

InactiveUS20090320745A1ThinnerEasy to usePolycrystalline material growthFrom melt solutionsCost effectivenessMetallurgy

An improved heater for processing materials or growing crystals in supercritical fluids is provided. In a specific embodiment, the heater is scalable up to very large volumes and is cost effective. In conjunction with suitable high pressure apparatus, the heater is capable of processing materials at pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SORAA

Three dimensional array films

The present invention provides nanoparticle film and methods of making such films. The nanoparticle film comprises a three dimensional cross-linked array of nanoparticles and linker molecules. The nanoparticle film is coherent, robust and self supporting. The film may be produced by adding linker molecules to a suspension of nanoparticles. The linker molecules form cross-links between the nanoparticles. Prior to completion of the cross-linking reaction the cross-linked nanoparticles are separated from the suspension.

Owner:COMMONWEALTH SCI & IND RES ORG

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20030168003A1After-treatment apparatusPolycrystalline material growthBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

Device and method for producing single crystals by vapor deposition

ActiveUS20050000406A1Down and eliminate formationPreventing structural defect generationFrom gel statePolycrystalline material growthGas phaseSingle crystal

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL

Method for producing monocrystalline metal or semi-metal bodies

InactiveUS20090047203A1Cheap methodCost effective productionPolycrystalline material growthSiliconVertical gradientCrucible

Owner:SCHOTT AG

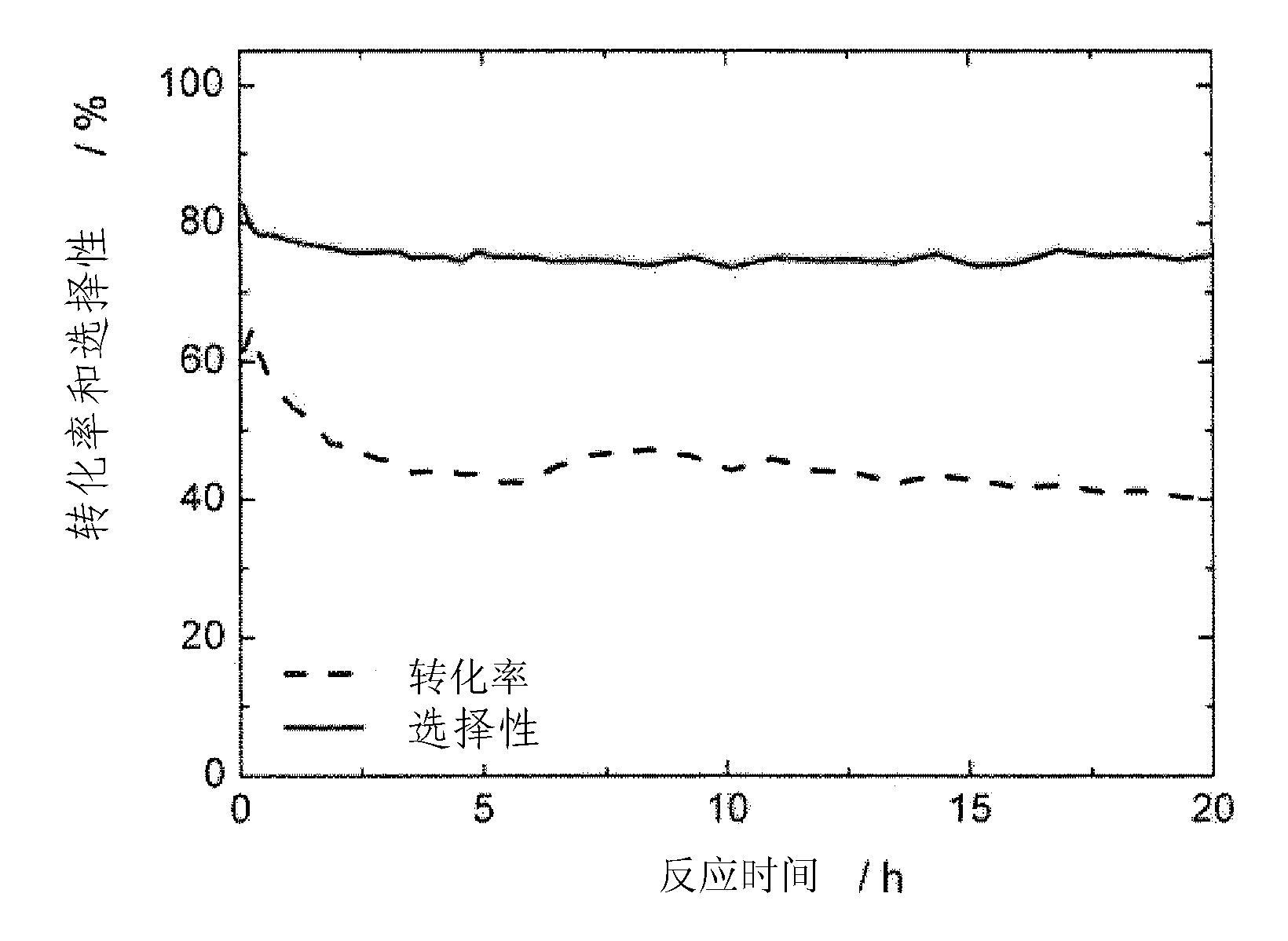

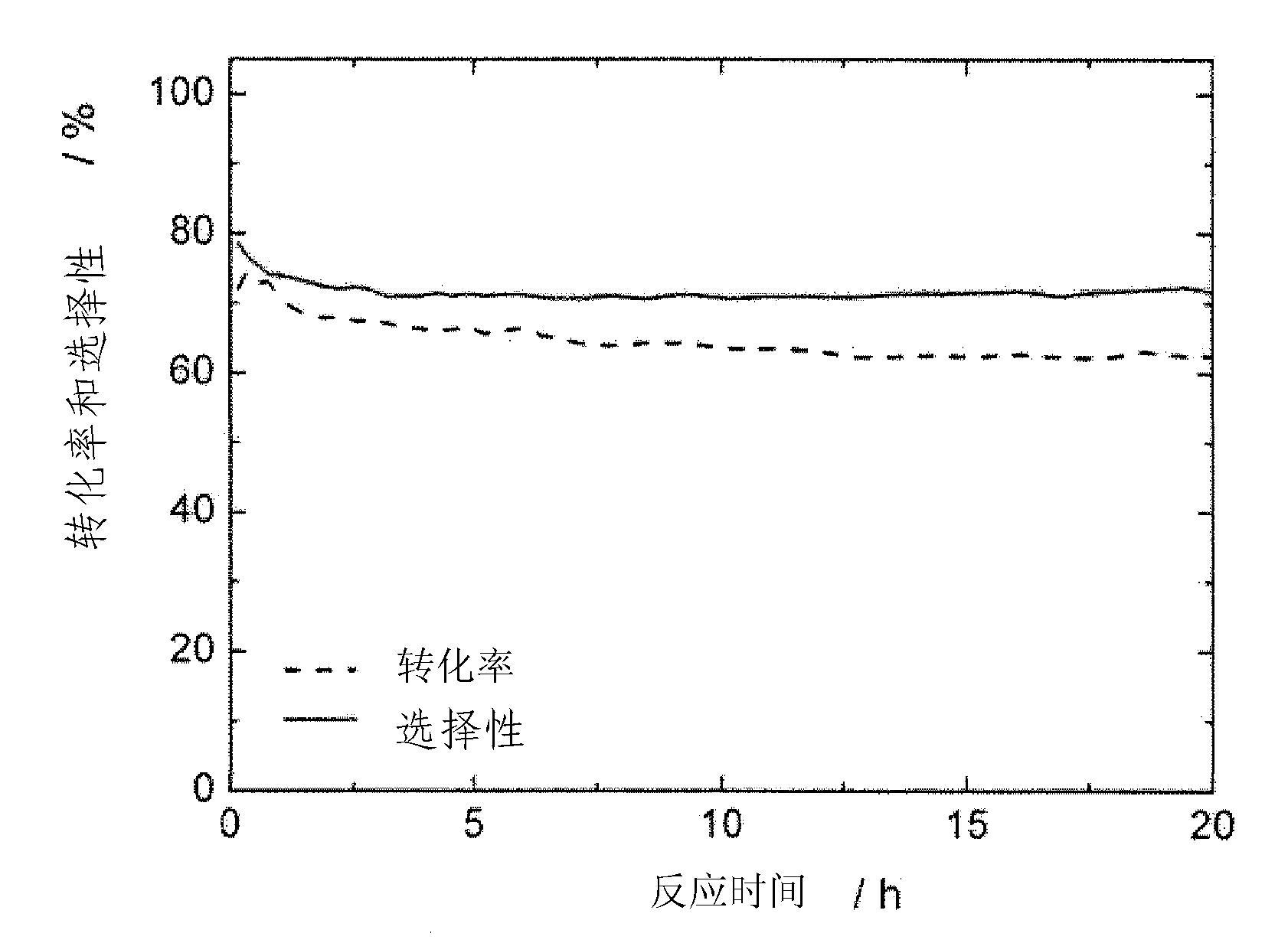

Ordered cobalt-aluminum and iron-aluminum intermetallic compounds as hydrogenation catalysts

InactiveCN102369074ALow costHigh selectivityPolycrystalline material growthHydrocarbon by hydrogenationPtru catalystUnsaturated hydrocarbon

The present invention relates to a process for the hydrogenation, in particular the selective hydrogenation of unsaturated hydrocarbon compounds, such as the selective hydrogenation of acetylene to ethylene, using a hydrogenation catalyst comprising an ordered intermetallic compound, namely an ordered cobalt- aluminum or iron- aluminum intermetallic compound. According to another aspect, the present invention relates to a catalyst comprising a support and at least one specific ordered cobalt -aluminum and / or iron-aluminum intermetallic compound supported thereon, as well as to the use of specific ordered intermetallic cobalt-aluminum and iron -aluminum intermetallic compounds as catalysts. The ordered cobalt-aluminum and iron-aluminum intermetallic compounds proved to be highly selective and long-term stable catalysts, e.g. in the selective hydrogenation of acetylene to ethylene in a large excess of ethylene.

Owner:MAX PLANCK SOCIETY FOR THE ADVANCEMENT OF SCI +1

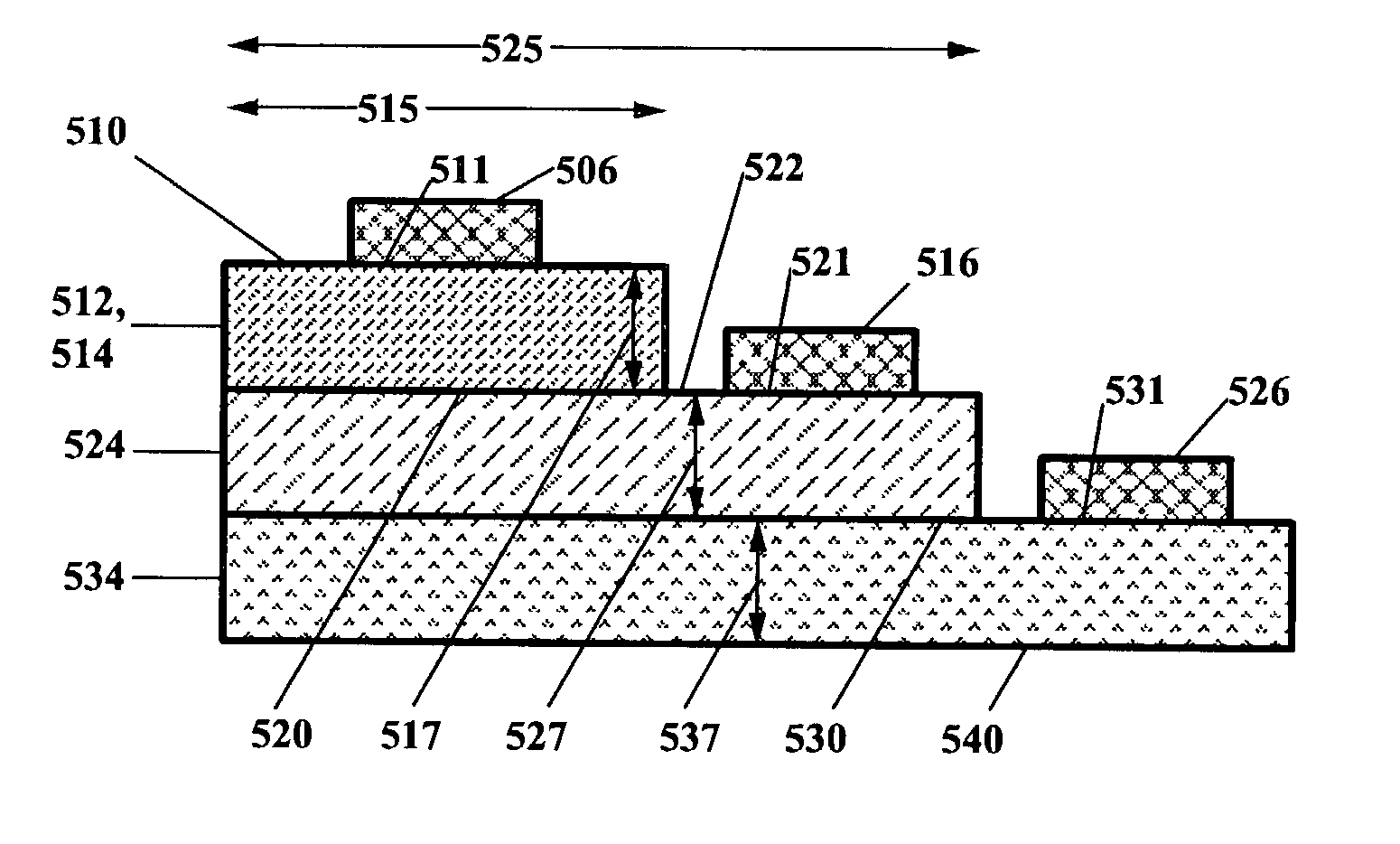

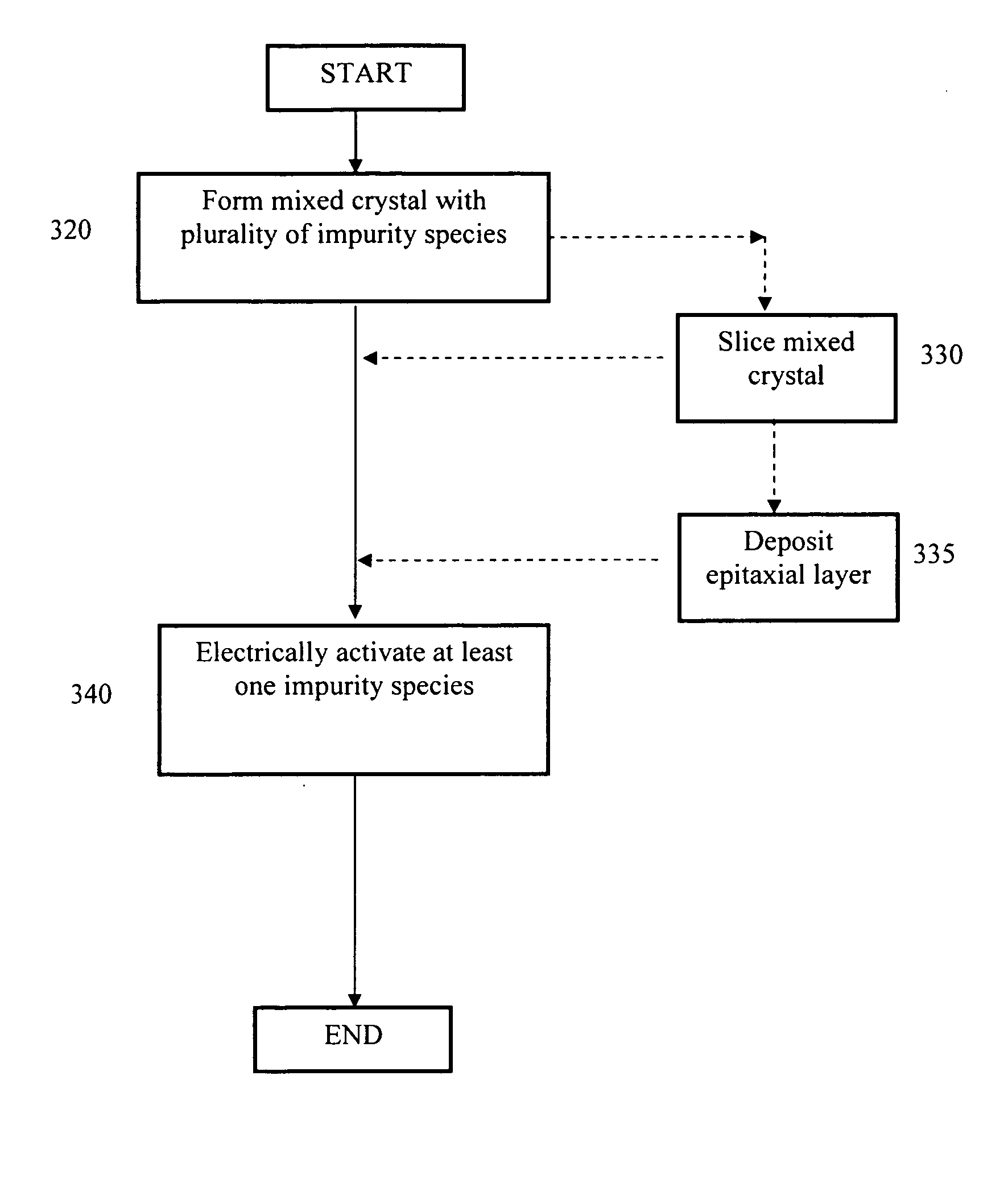

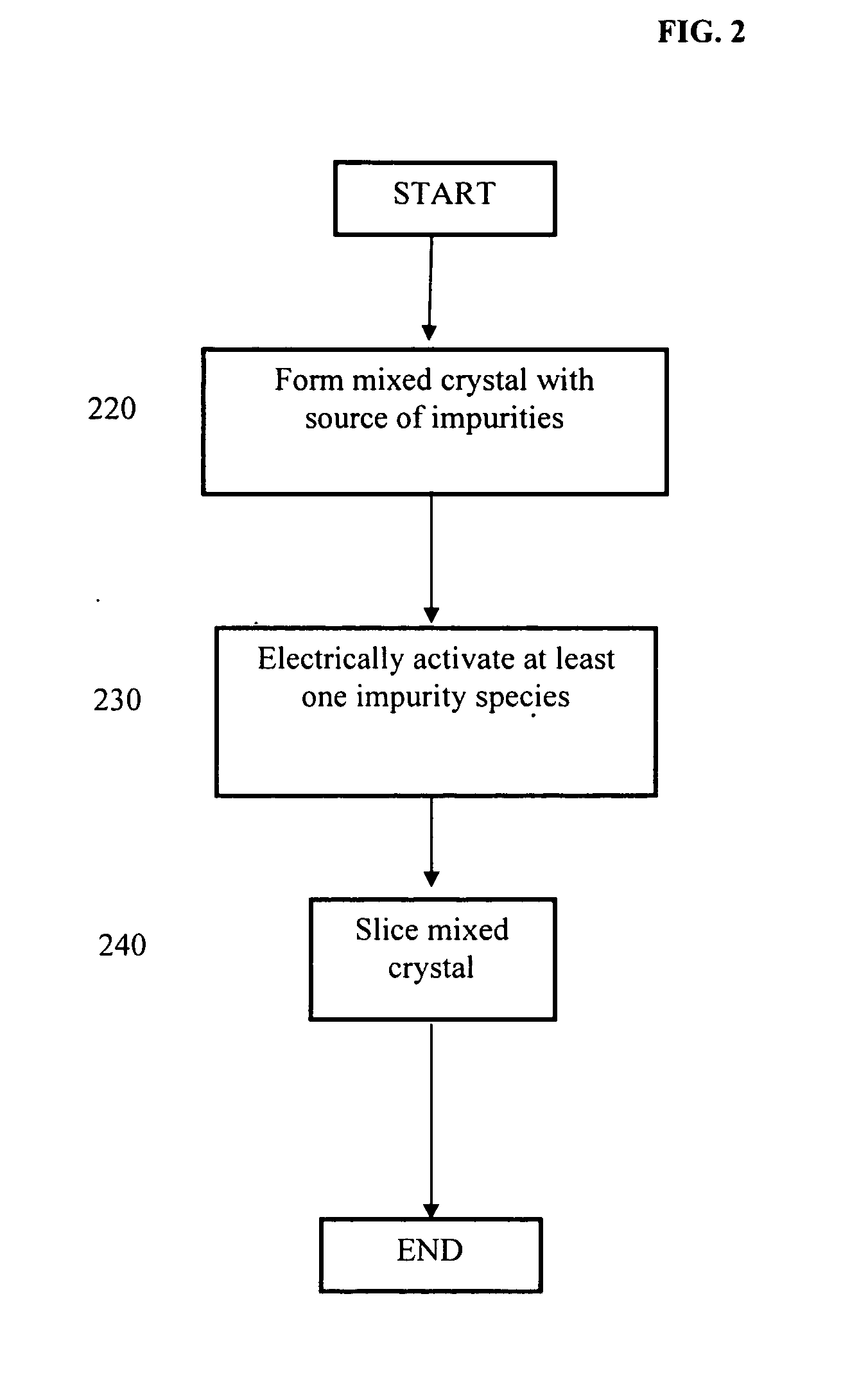

Doped aluminum nitride crystals and methods of making them

ActiveUS20070131160A1Promote formationSufficient conductivity and mobility characteristicPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrideImpurity

Fabrication of doped AlN crystals and / or AlGaN epitaxial layers with high conductivity and mobility is accomplished by, for example, forming mixed crystals including a plurality of impurity species and electrically activating at least a portion of the crystal.

Owner:CRYSTAL

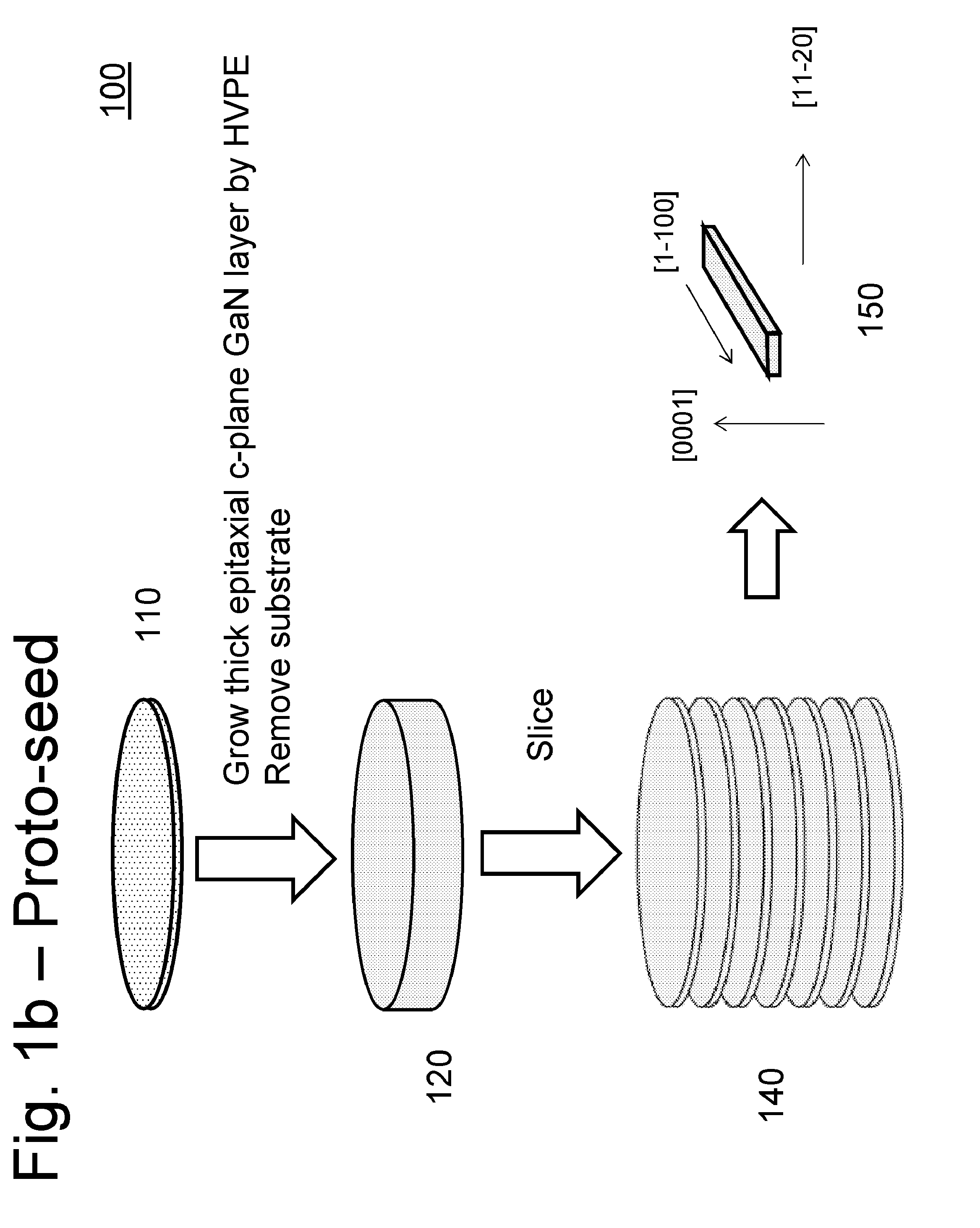

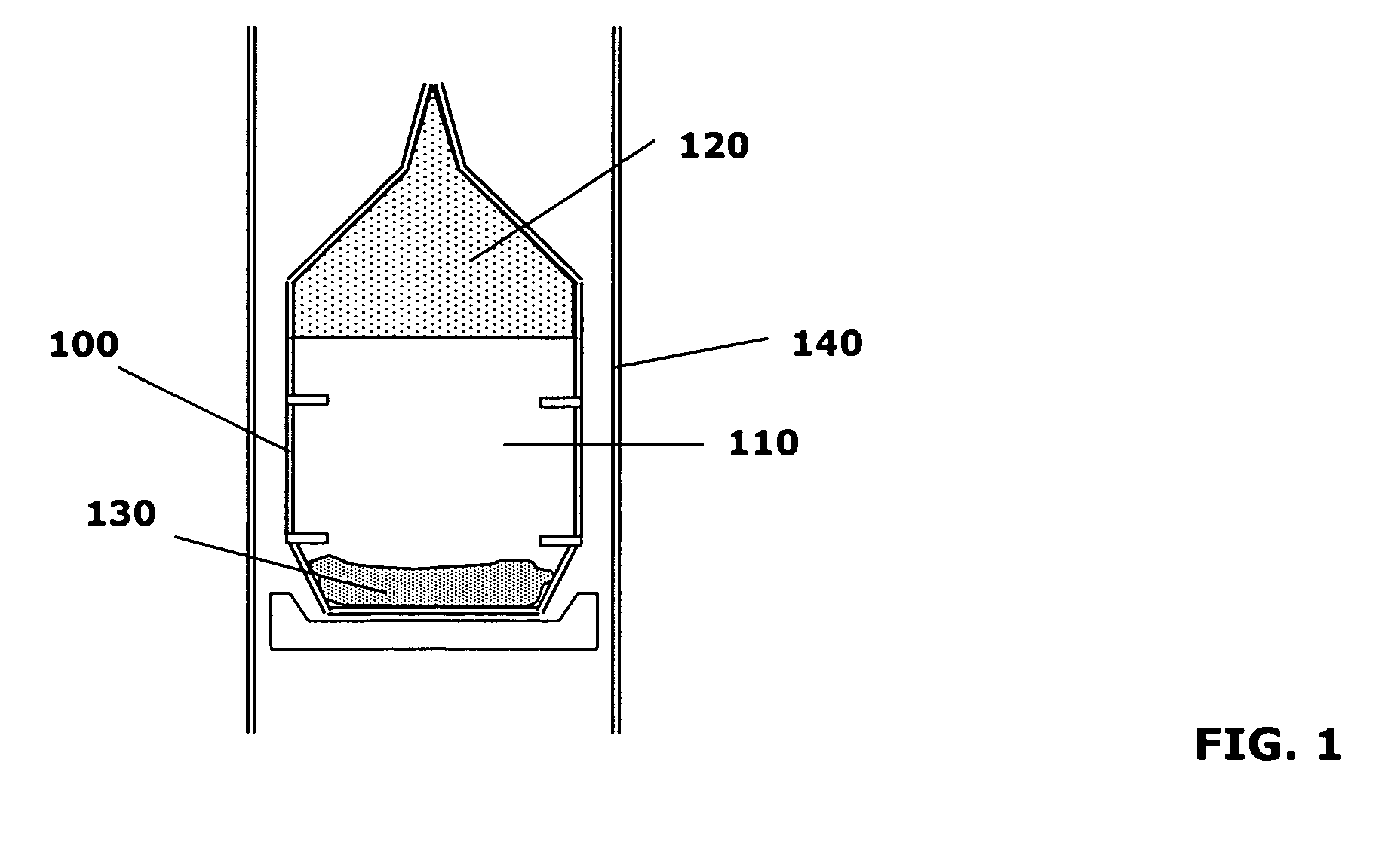

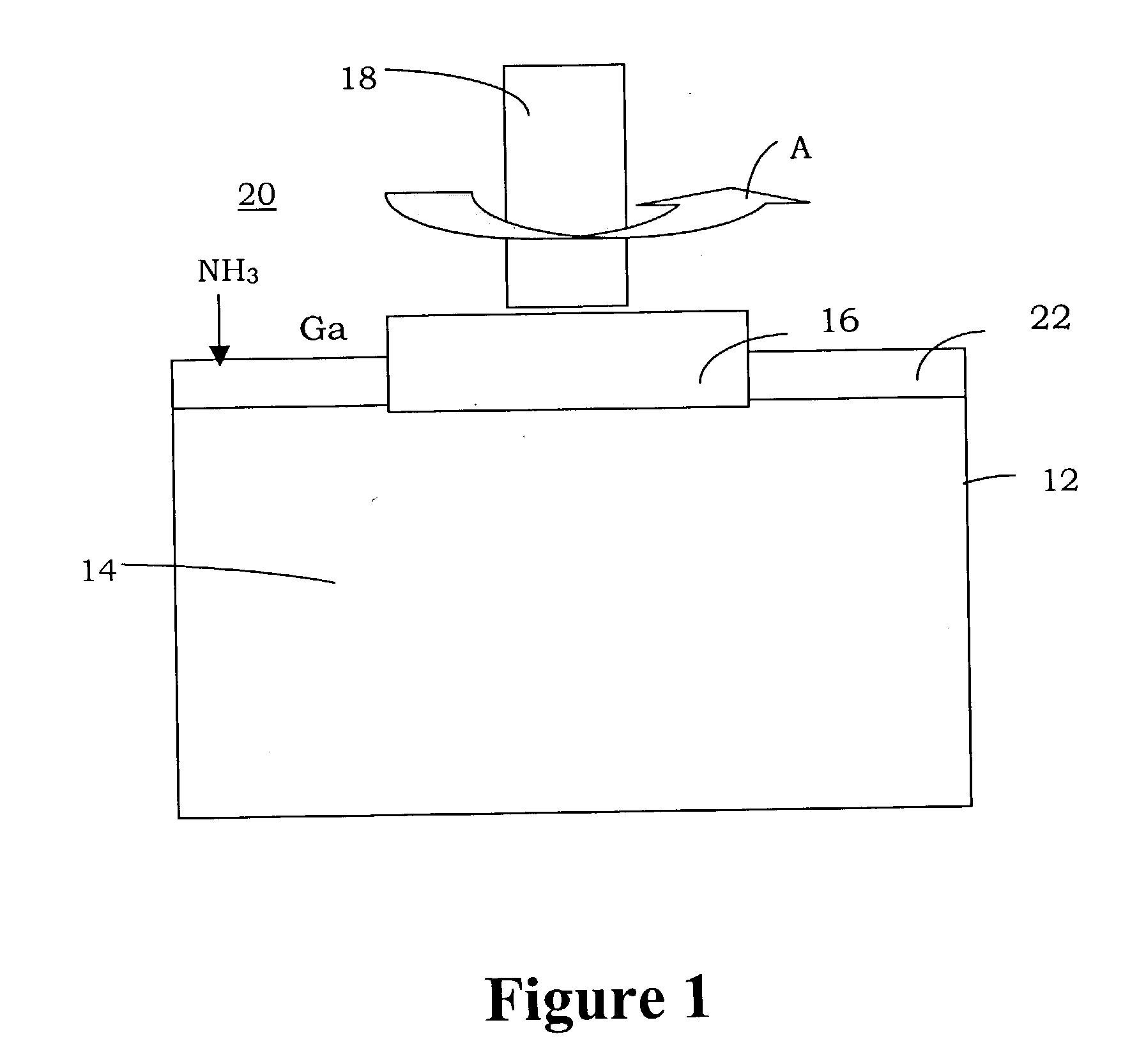

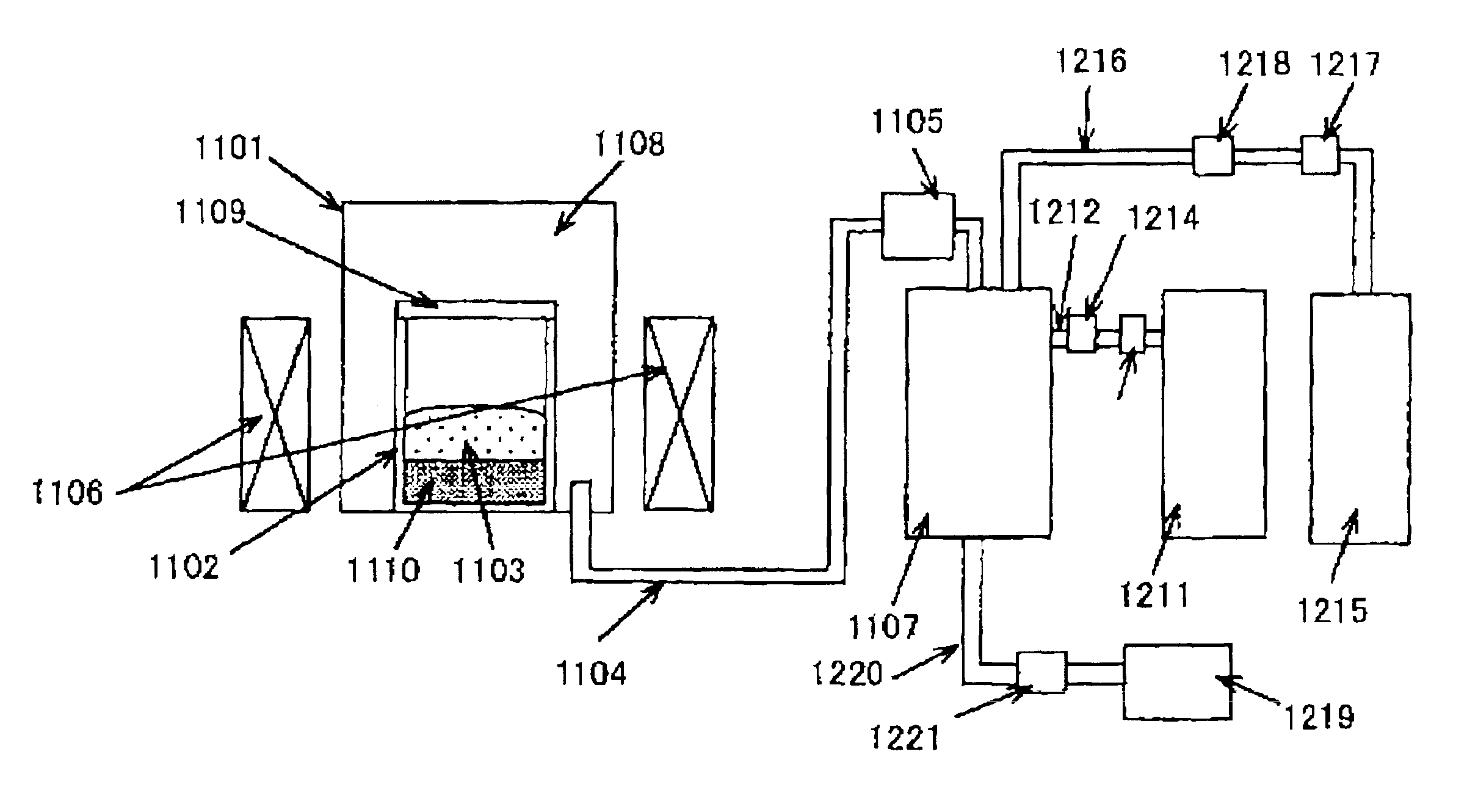

GaN boule grown from liquid melt using GaN seed wafers

ActiveUS20040003495A1Semiconductor/solid-state device manufacturingBy pulling from meltWaferingMetallurgy

A method of making a single crystal GaN boule, comprising contacting a GaN seed wafer with a GaN source environment under process conditions including a thermal gradient in the GaN source environment producing growth of gallium nitride on the GaN seed wafer, thereby forming the GaN boule. The GaN source environment in various implementations includes gallium melt in an ambient atmosphere of nitrogen or ammonia, or alternatively, supercritical ammonia containing solubilized GaN. The method produces single crystal GaN boules >10 millimeters in diameter, of device quality suitable for production of GaN wafers useful in the fabrication of microelectronic, optoelectronic and microelectromechanical devices and device precursor structures therefor.

Owner:CREE INC

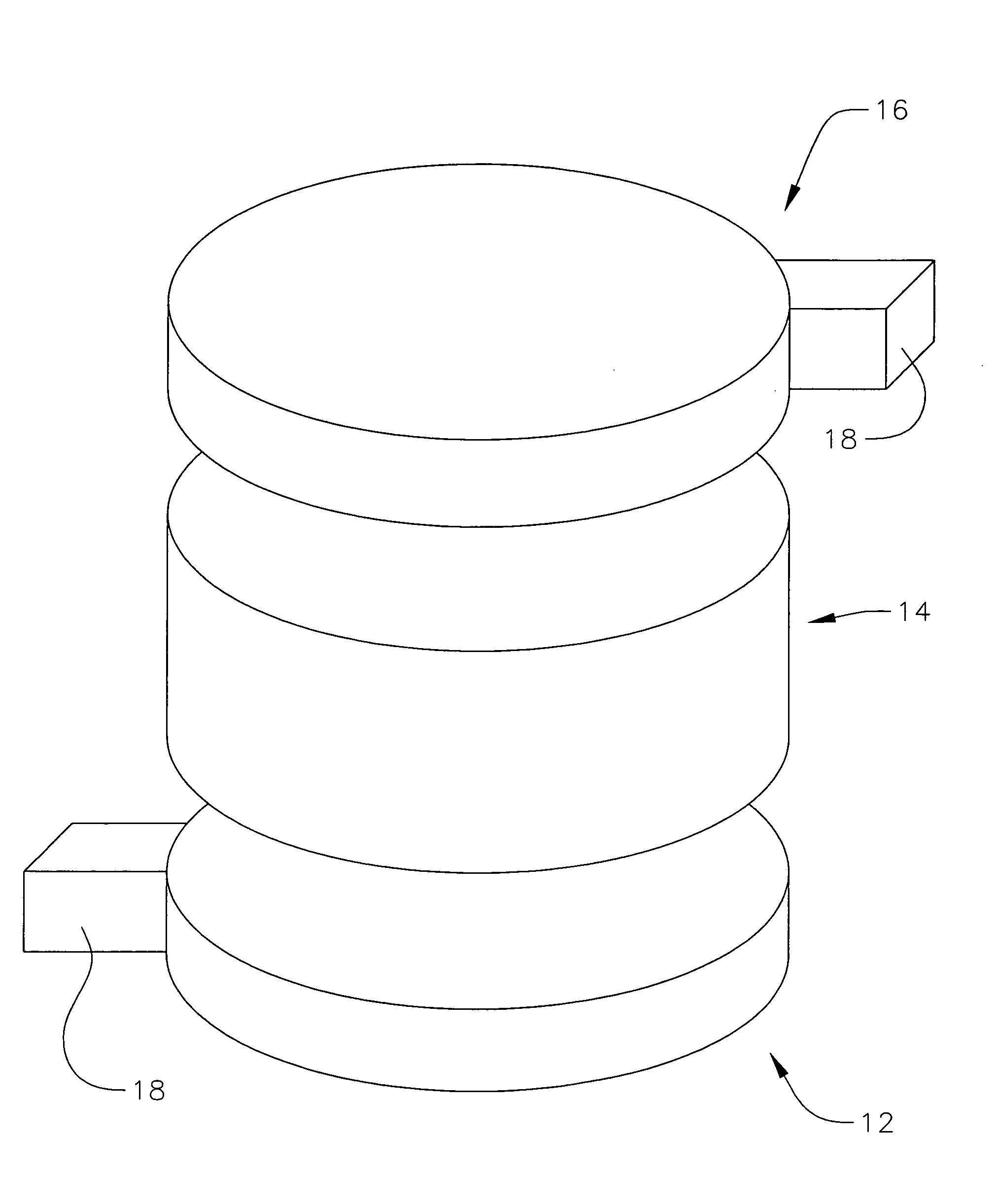

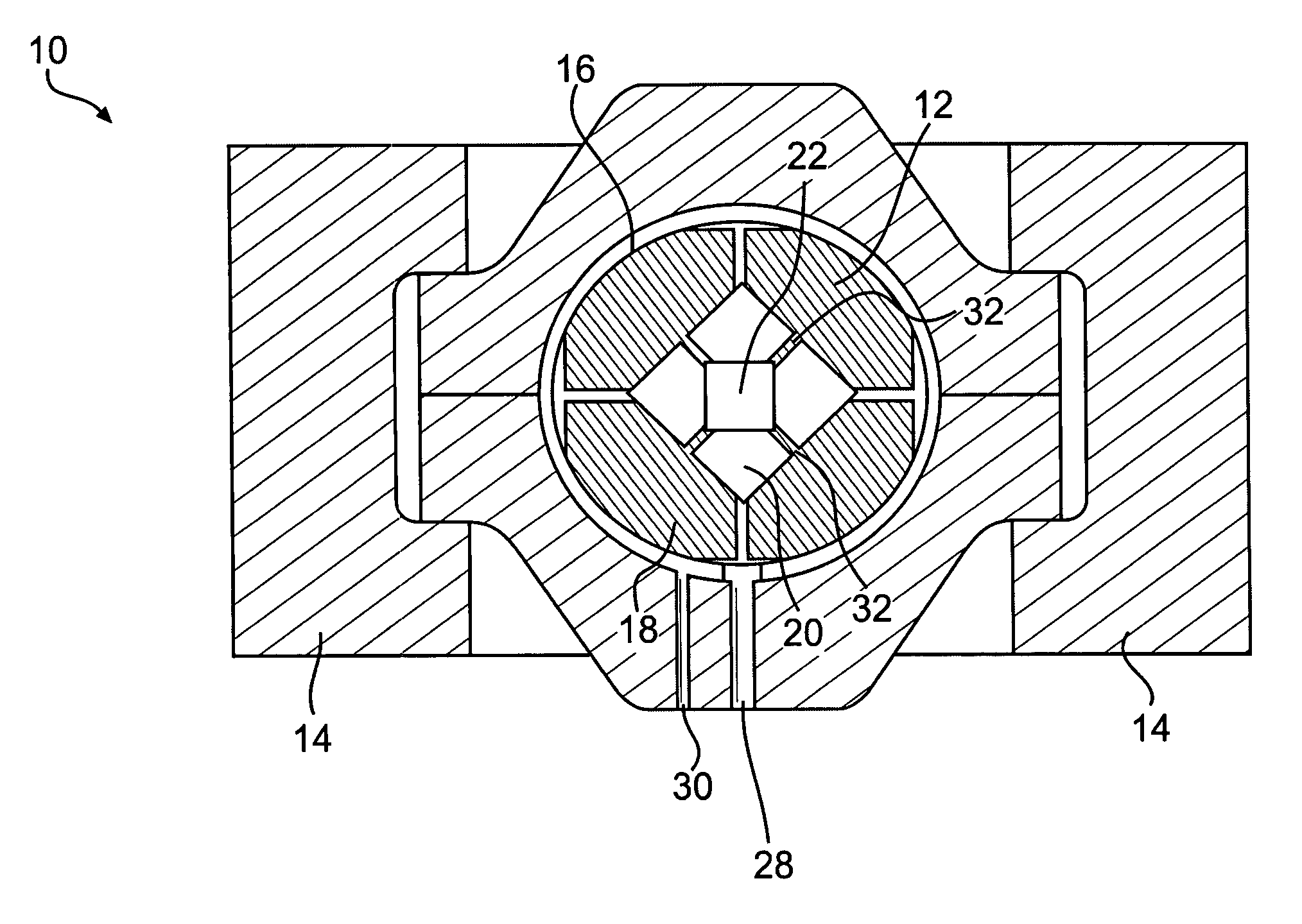

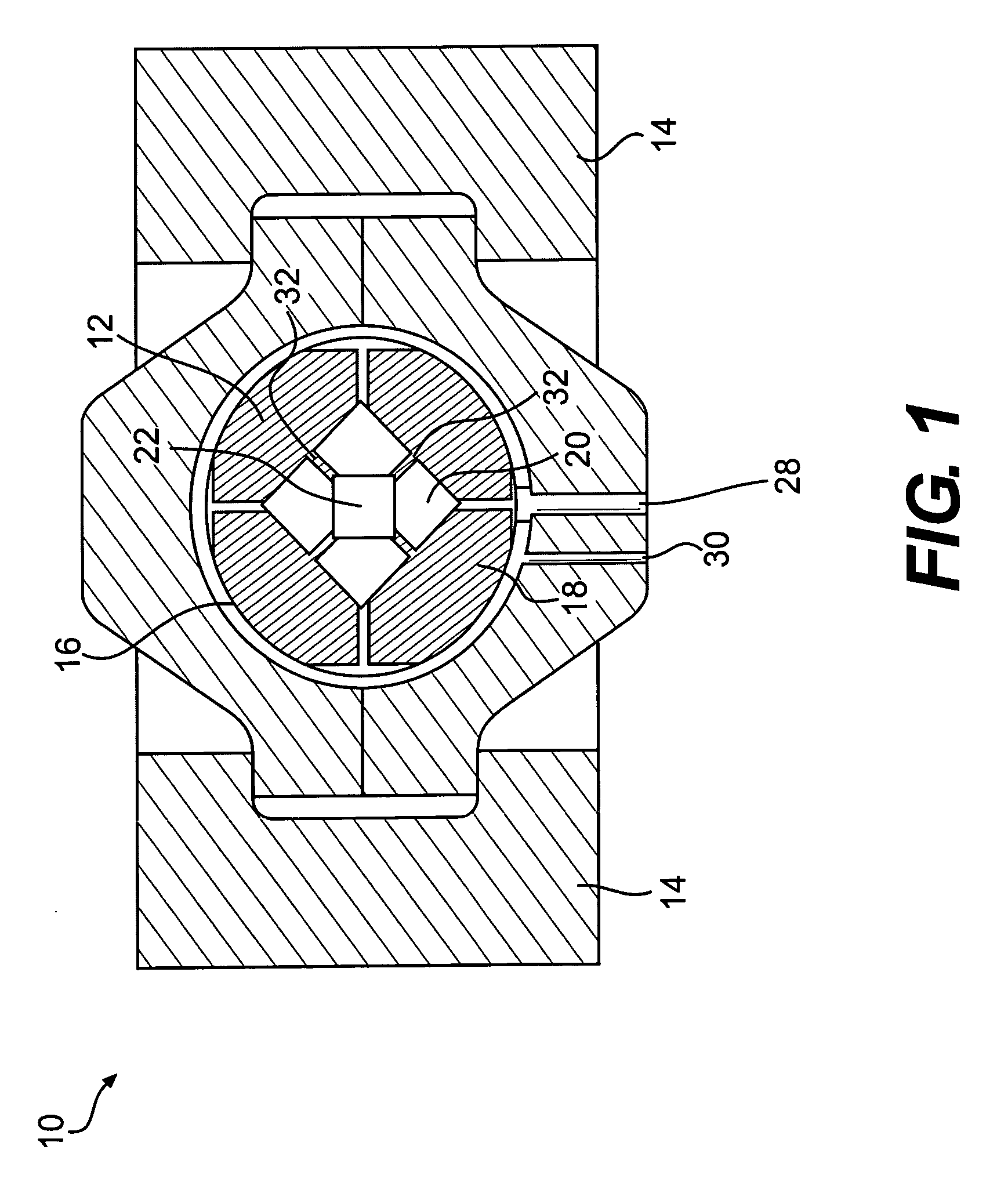

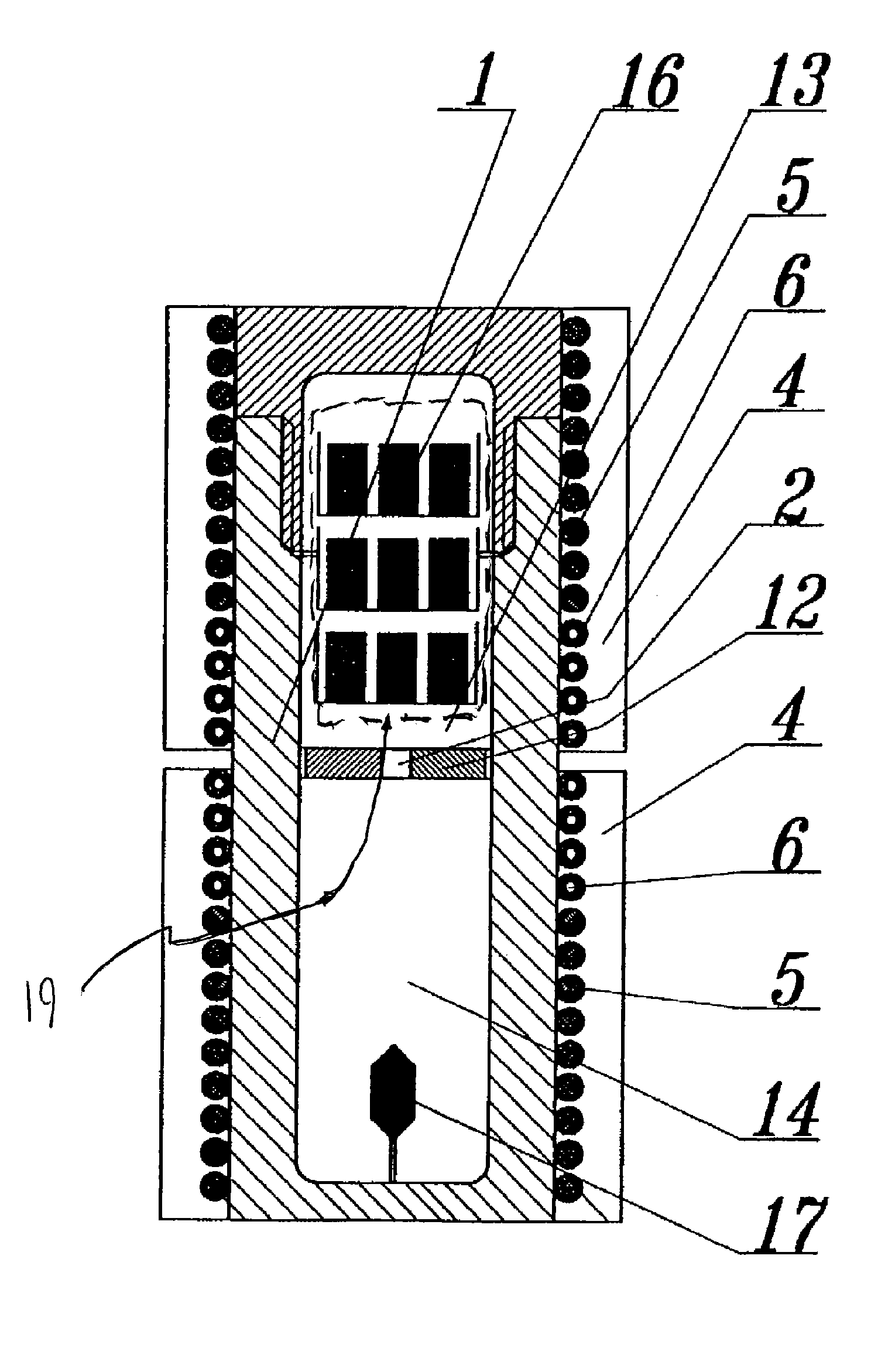

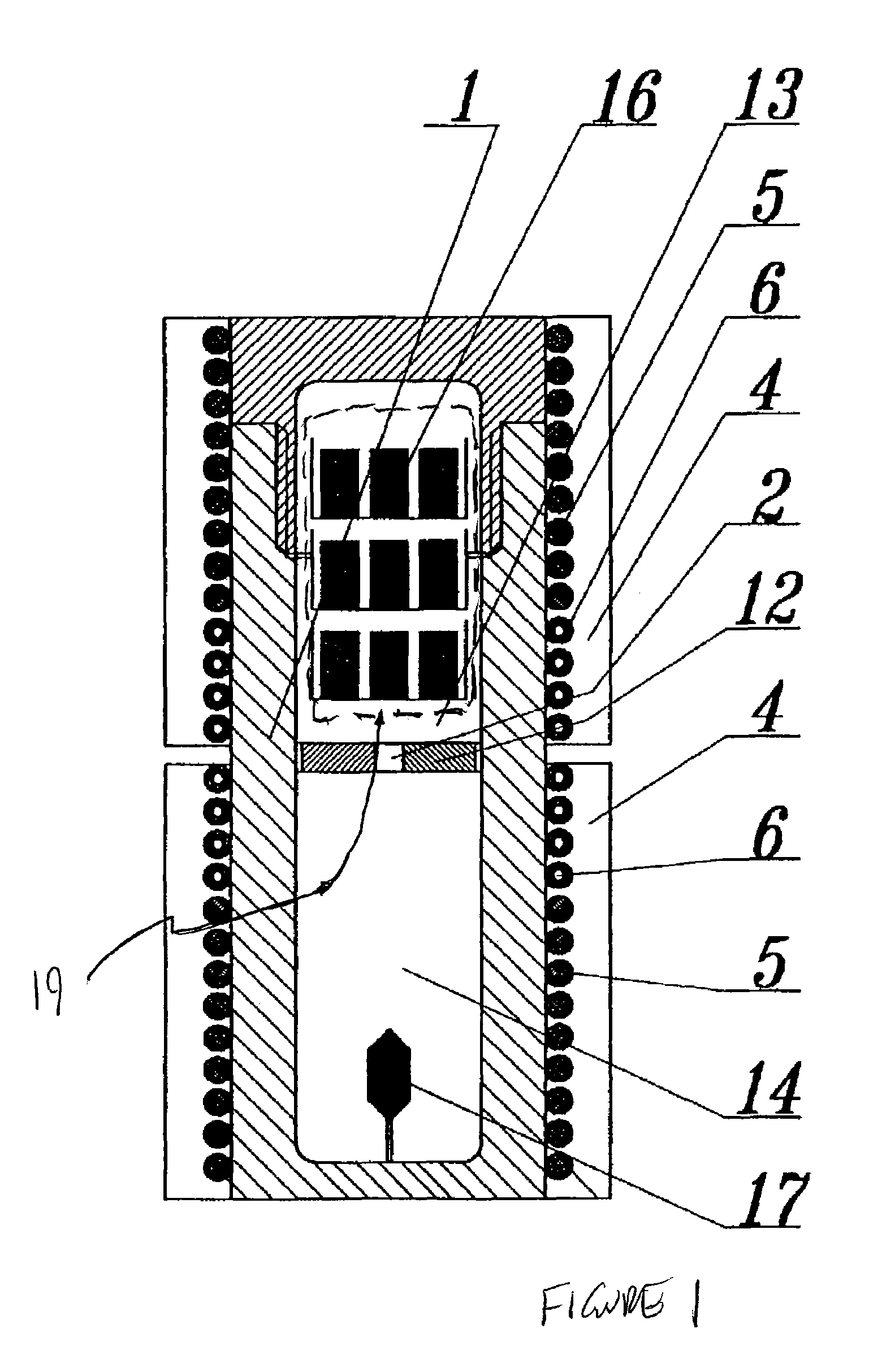

System and high pressure, high temperature apparatus for producing synthetic diamonds

An apparatus for growing a synthetic diamond comprises a growth chamber, at least one manifold allowing access to the growth chamber, and a plurality of safety clamps positioned on opposite sides of the growth chamber; wherein the growth chamber and the plurality of safety clamps are comprised of a material having a tensile strength of about 120,000-200,000 psi, a yield strength of about 100,000-160,000 psi, an elongation of about 10-20%, an area reduction of about 40-50%, an impact strength of about 30-40 ft-lbs, and a hardness greater than 320 BHN.

Owner:THE GEMESIS CORP

High pressure apparatus and method for nitride crystal growth

ActiveUS8303710B2Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

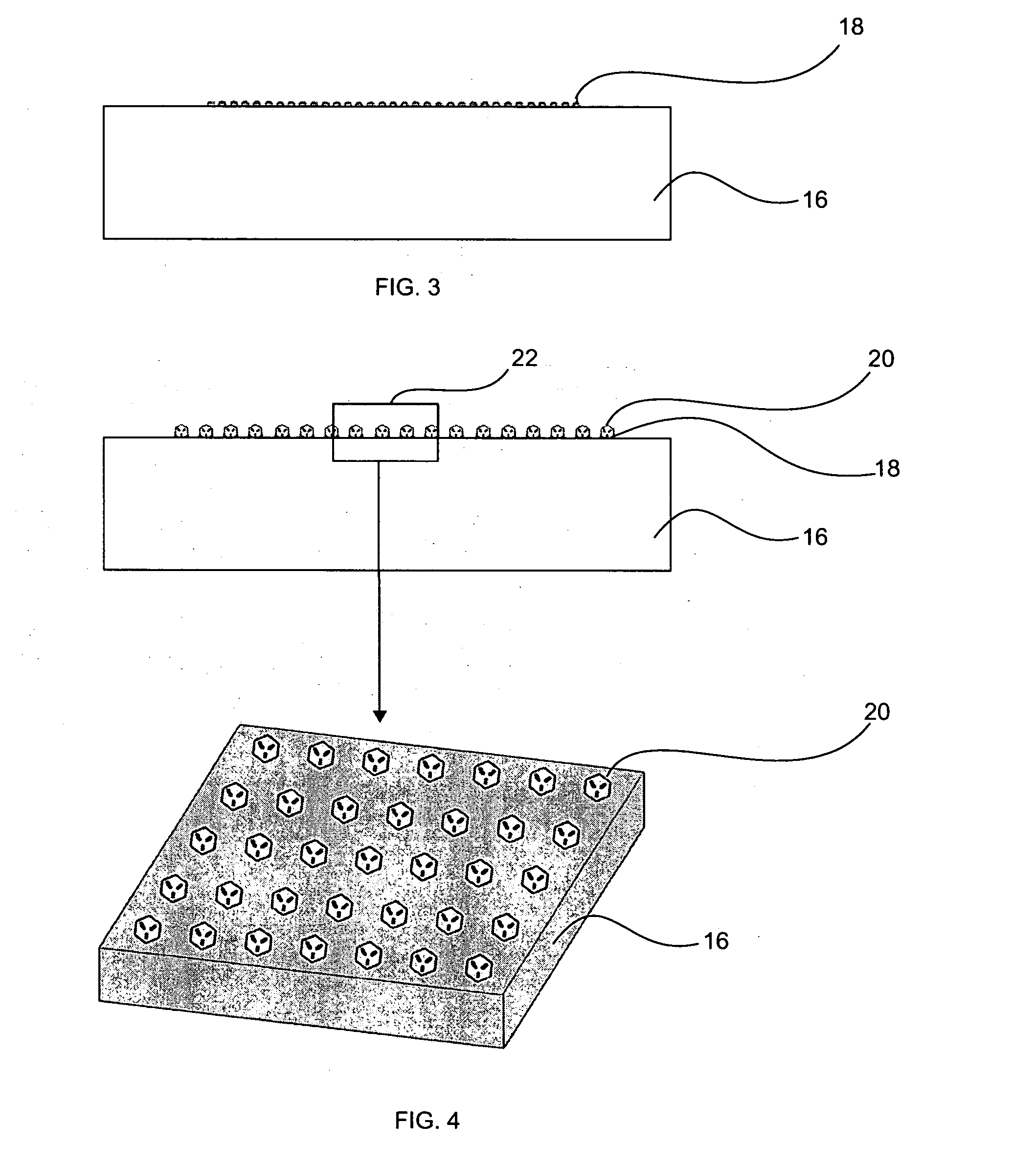

Methods for securing individual abrasive particles to a substrate in a predetermined pattern

InactiveUS20080098659A1Pigmenting treatmentPolycrystalline material growthEngineeringParticle growth

A method for temporarily securing superabrasive particles to a substrate such as a tool substrate or a growth precursor and articles formed therefrom are provided. The method can include applying an array of adhesive droplets onto at least a portion of a substrate in accordance with a predetermined pattern. The pattern may be uniform grid equally spacing each adhesive droplet. The adhesive droplets can be suitable to each secure only a single superabrasive particle. The method may further include adhering a single superabrasive particle to each adhesive droplet. As a result of the method can yield a tool substrate and grow precursor having enhance particle growth and wear properties.

Owner:SUNG CHIEN MIN

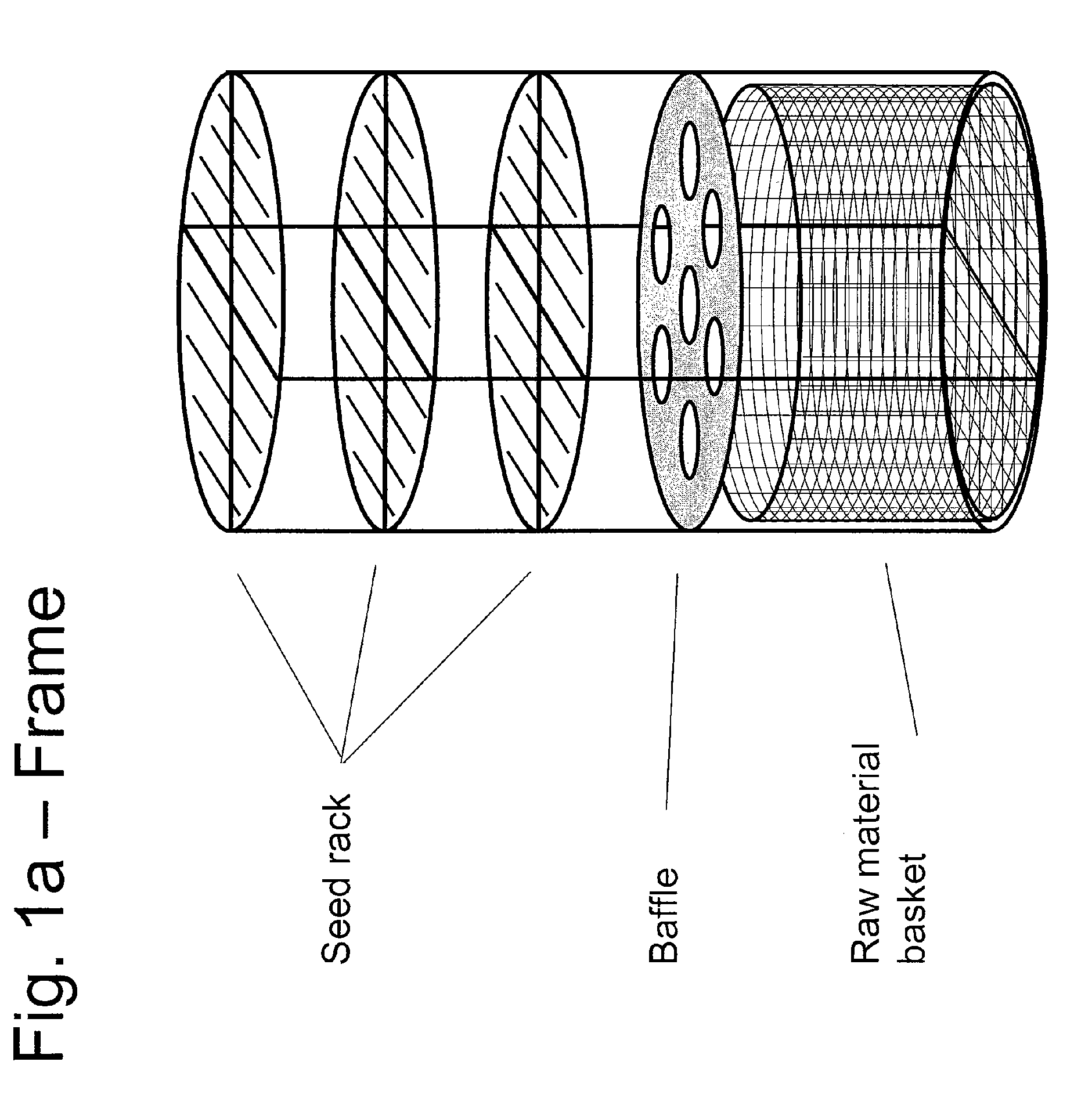

Process and apparatus for growing a crystalline gallium-containing nitride using an azide mineralizer

ActiveUS8323405B2Increase in sizeCost effectivePolycrystalline material growthFrom normal temperature solutionsDopantGallium nitride

An apparatus and associated method for large-scale manufacturing of gallium nitride is provided. The apparatus comprises a large diameter autoclave and a raw material basket. Methods include metered addition of dopants in the raw material and control of the atmosphere during crystal growth. The apparatus and methods are scalable up to very large volumes and are cost effective.

Owner:SLT TECH

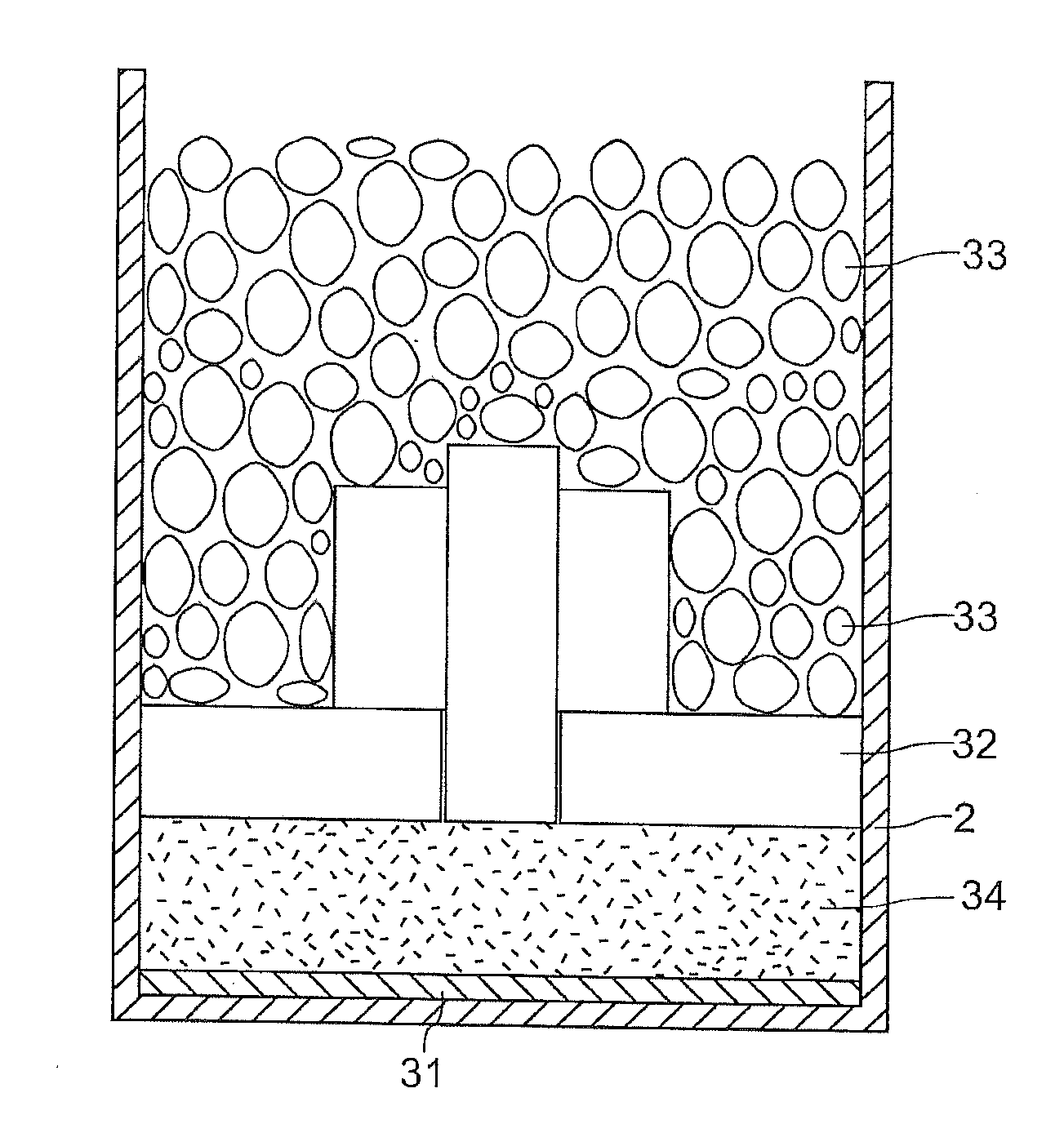

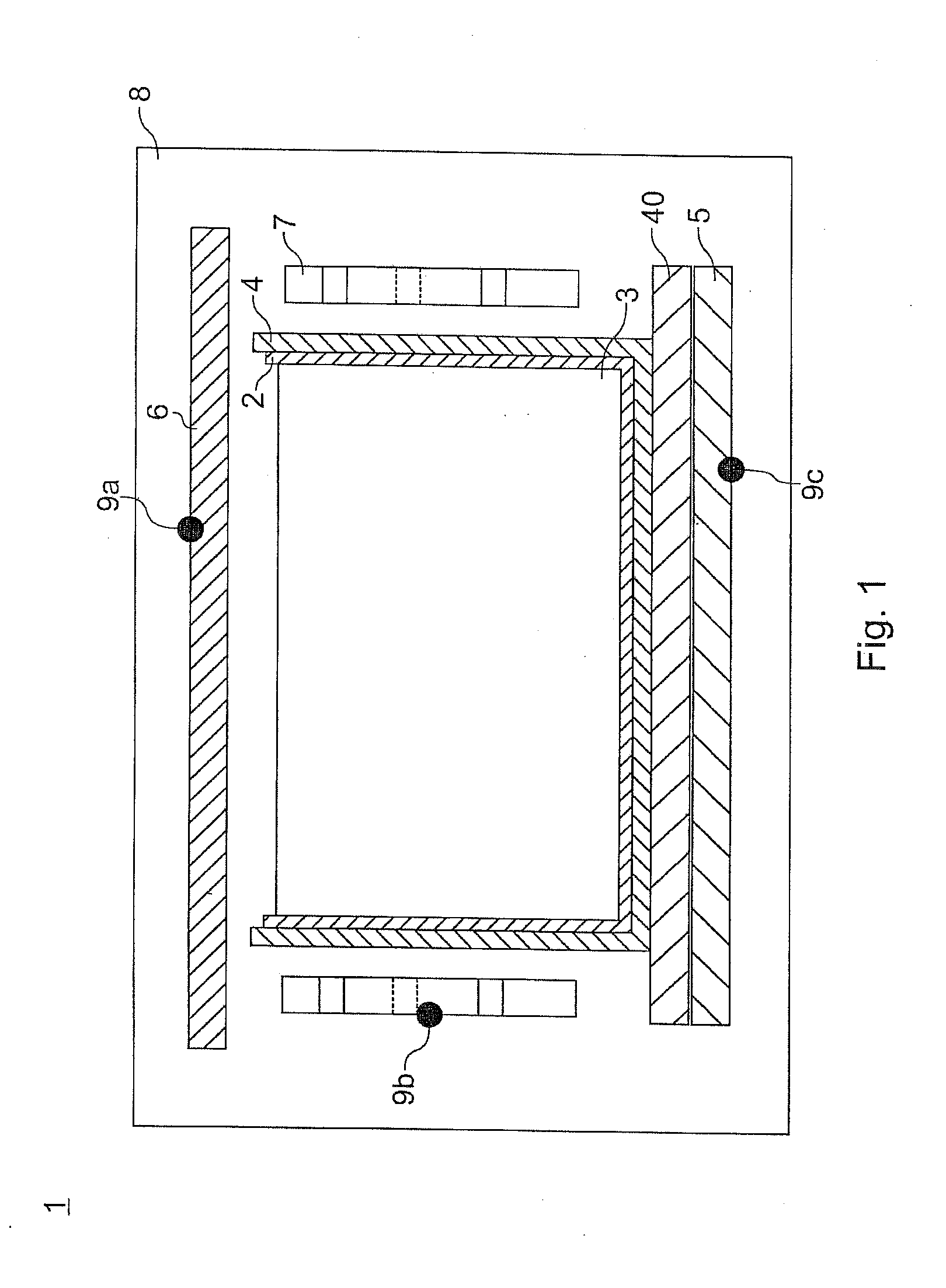

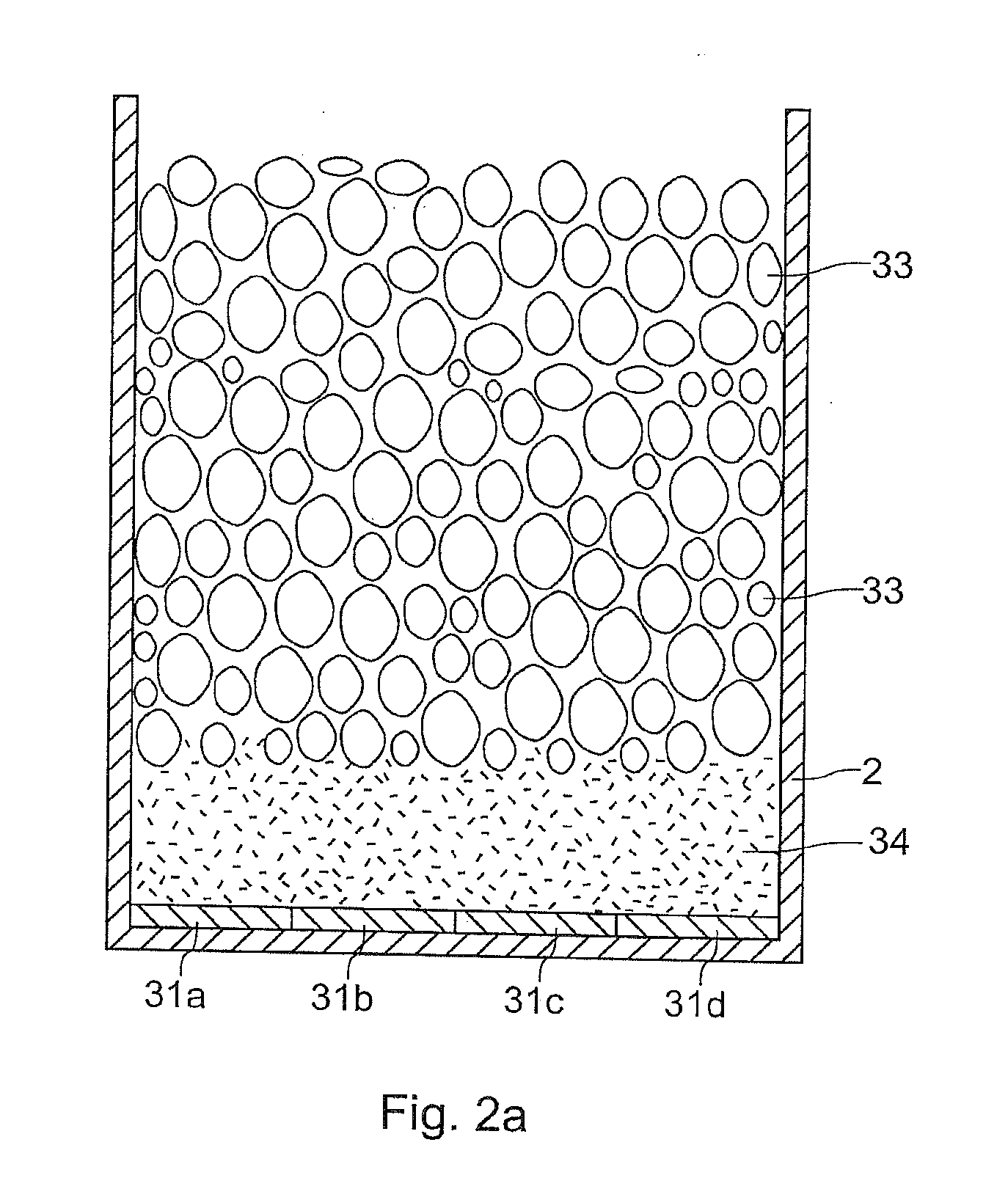

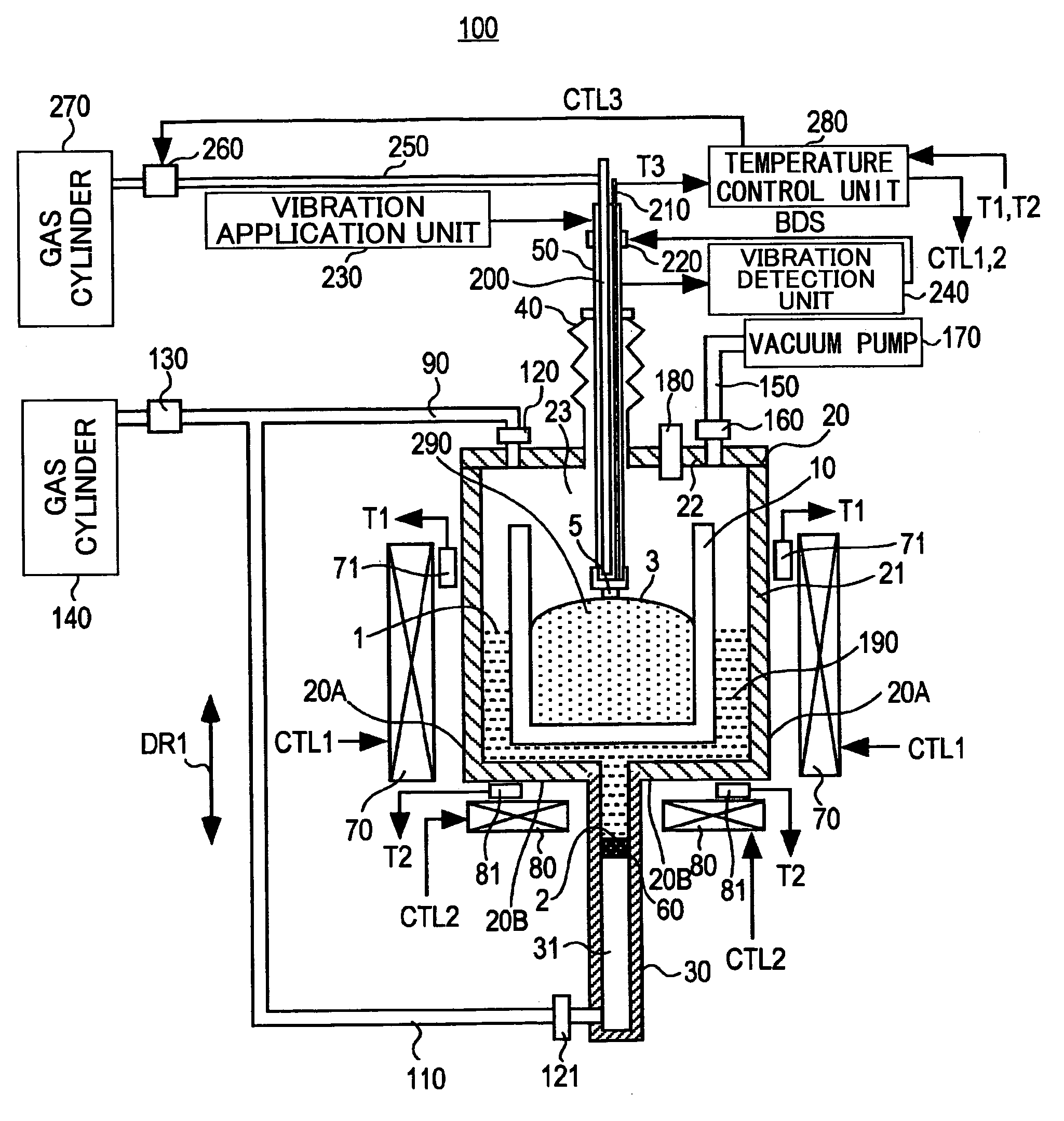

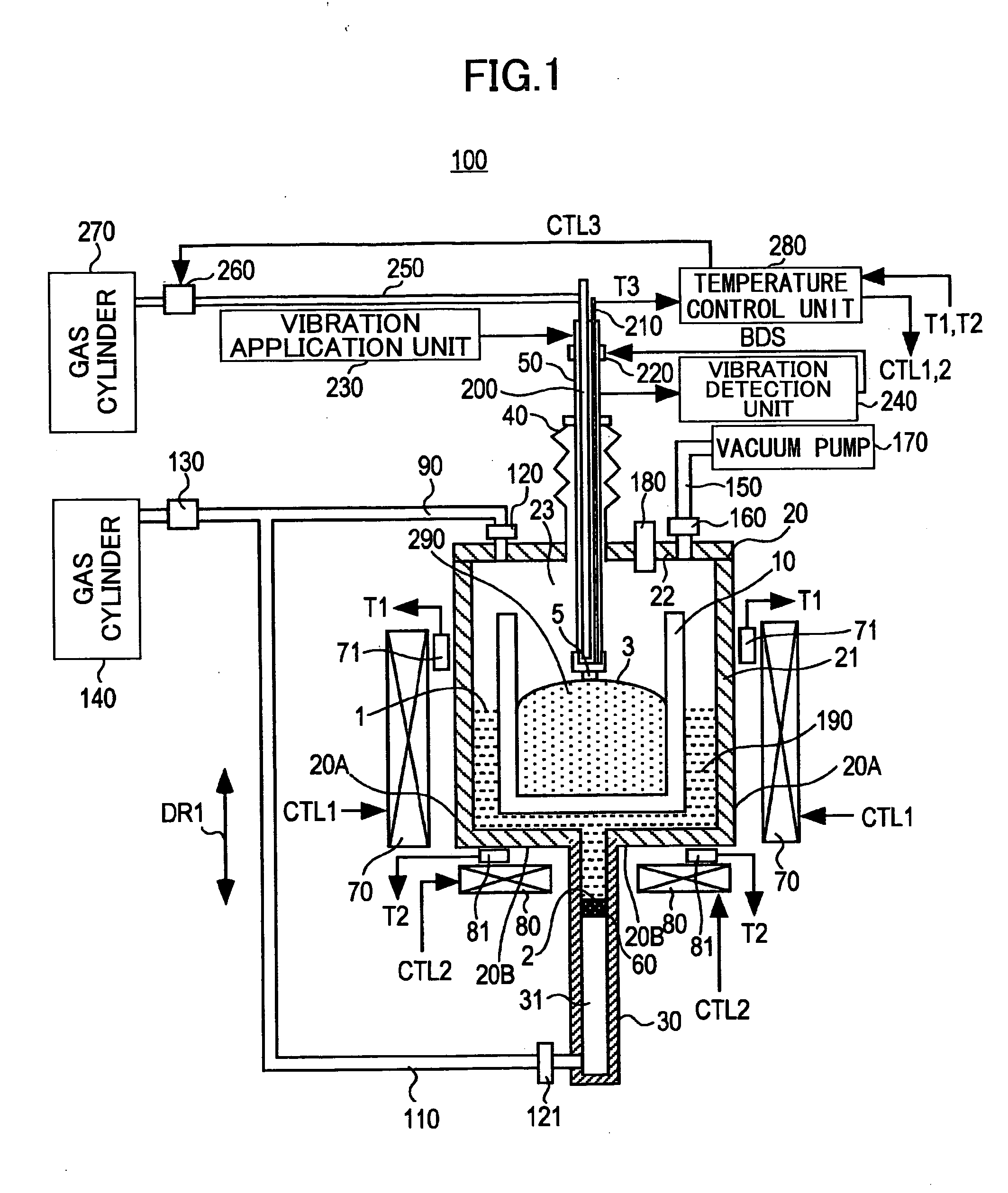

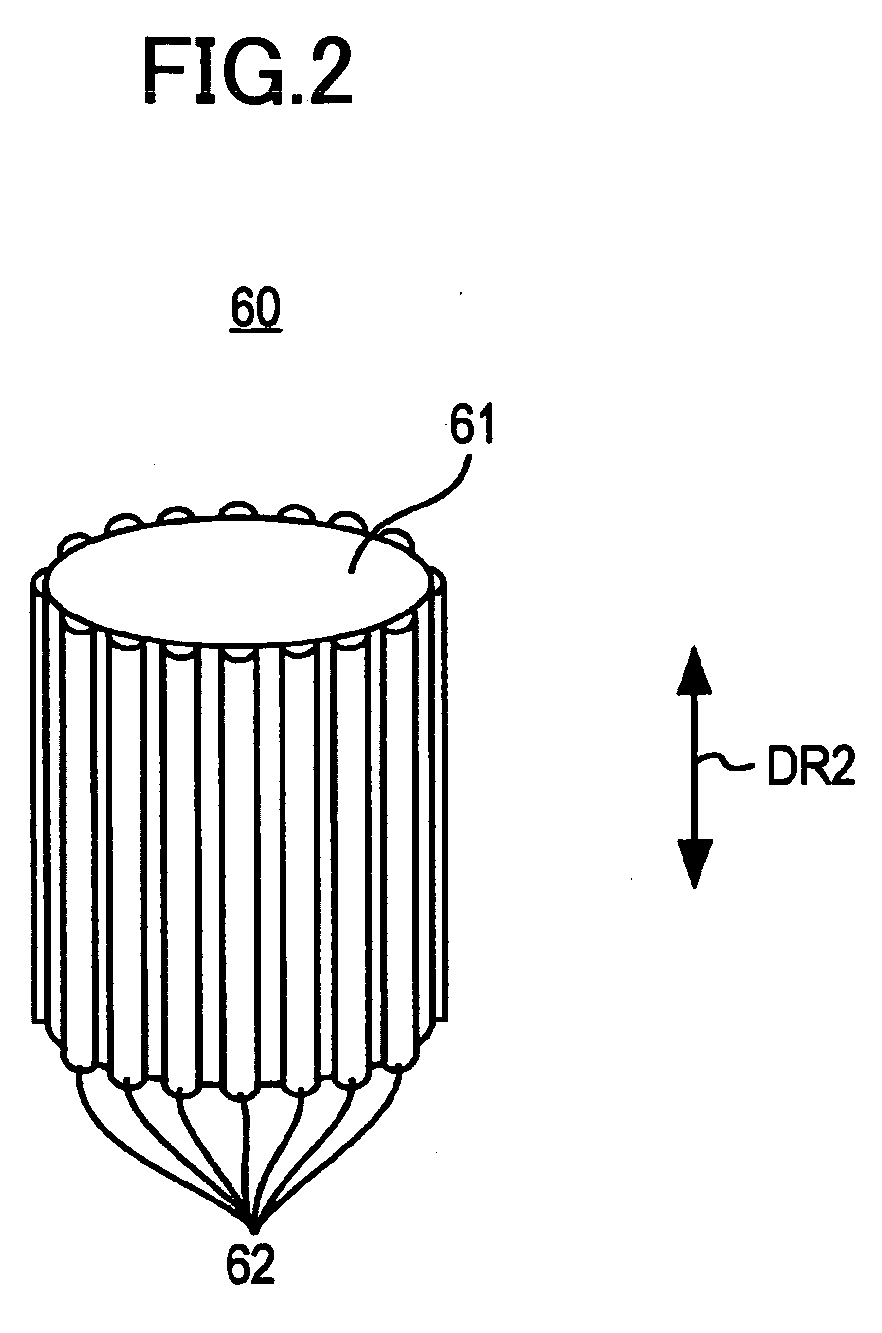

Crystal growth apparatus and manufacturing method of group III nitride crystal

ActiveUS20070084399A1Degree of supersaturation is increasedPromotes crystal growthPolycrystalline material growthLiquid-phase epitaxial-layer growthNitrogen sourceNitride

A crystal growth apparatus comprises a reaction vessel holding a melt mixture containing an alkali metal and a group III metal, a gas supplying apparatus supplying a nitrogen source gas to a vessel space exposed to the melt mixture inside the reaction vessel, a heating unit heating the melt mixture to a crystal growth temperature, and a support unit supporting a seed crystal of a group III nitride crystal inside the melt mixture.

Owner:SUMITOMO CHEM CO LTD +1

Crystal growth method, crystal growth apparatus, group-III nitride crystal and group-III nitride semiconductor device

ActiveUS6949140B2Reduce evaporationIncrease pressurePolycrystalline material growthFrom melt solutionsNitrogenCrystal growth

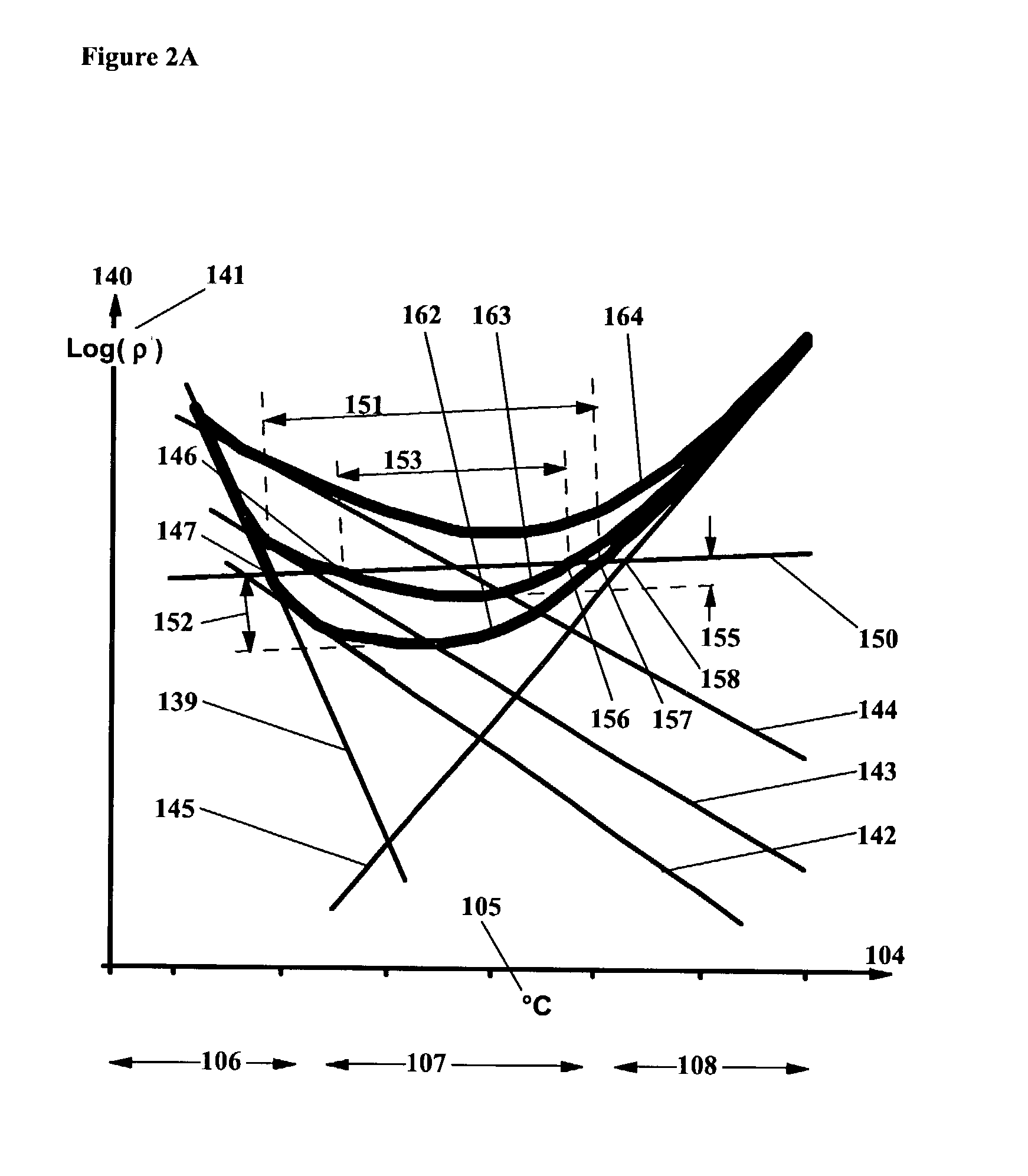

A group-III nitride crystal growth method, comprising the steps of: a) preparing a mixed molten liquid of an alkaline metal and a material at least comprising a group-III metal; b) growing a group-III nitride crystal of the group-III metal and nitrogen from the mixed molten liquid and a material at least comprising nitrogen; and c) setting a predetermined crystal growth condition according to a zone defined by a pressure and a temperature in said step b).

Owner:RICOH KK

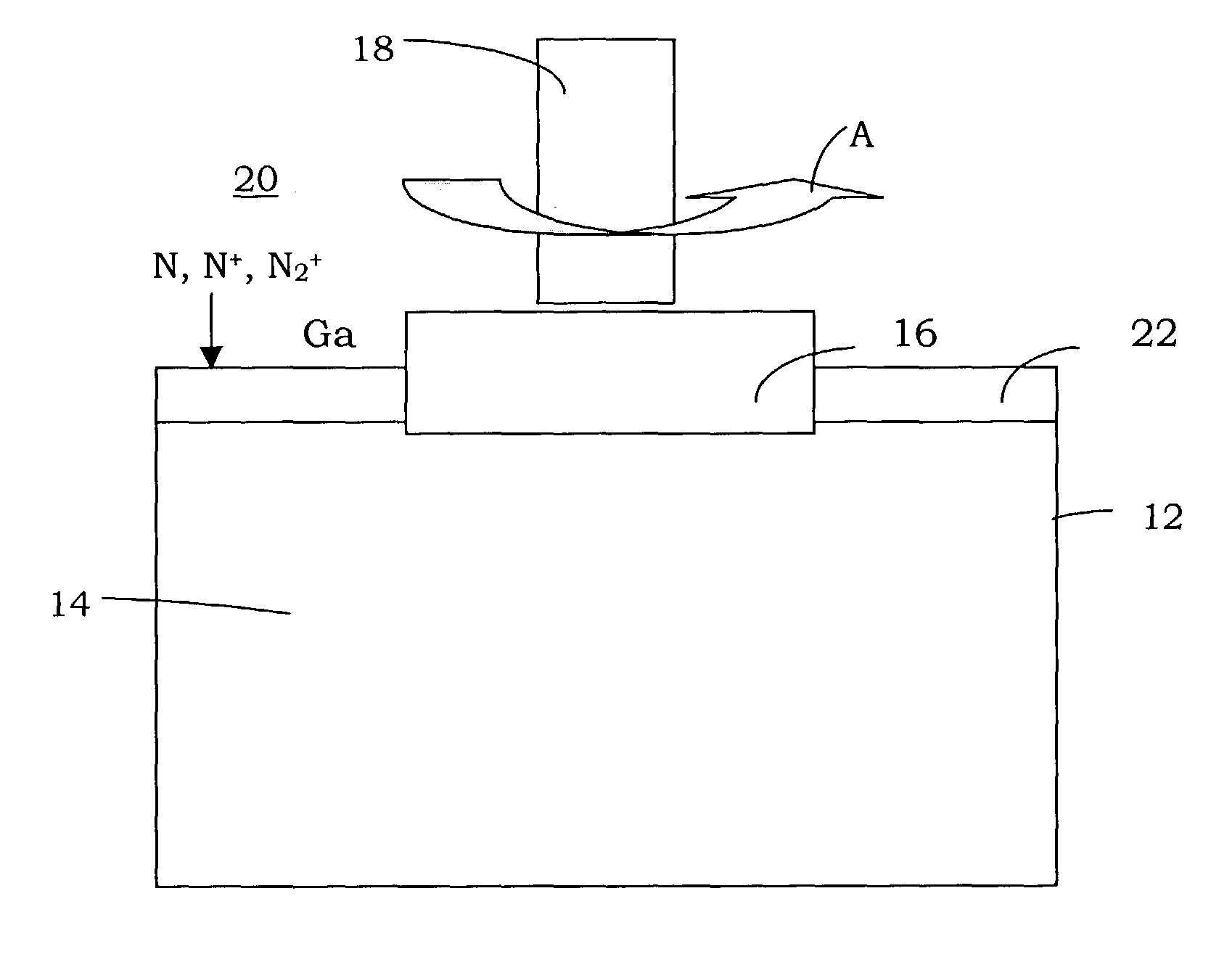

Method of manufacturing GaN ingots

InactiveUS6562124B1Low costSimple growth processSemiconductor/solid-state device manufacturingBy pulling from meltSemiconductor materialsIngot

A novel method for growing semiconductor material including GaN is disclosed. The method involves placing a first substance into a growth reactor, supplying a second gaseous substance into the grouth reactor, and applying electrical field to the second gaseous substance to produce the cry stalline compound material.

Owner:OSTENDO TECH INC

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20060005763A1Polycrystalline material growthSolid-state devicesBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN having low dislocation densities of about 10,000 cm−2 or less includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in the crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline low dislocation density AlN at the nucleation site. High efficiency ultraviolet light emitting diodes and ultraviolet laser diodes are fabricated on low defect density AlN substrates, which are cut from the low dislocation density AlN crystals. Bulk crystals of ZnO may also be produced using the method.

Owner:CRYSTAL

Process and apparatus for large-scale manufacturing of bulk monocrystalline gallium-containing nitride

ActiveUS8021481B2Simple and cost-effective to manufactureIncrease pressurePolycrystalline material growthFrom normal temperature solutionsGallium nitrideMaterials science

A method for large-scale manufacturing of gallium nitride includes a process for reducing and / or minimizing contamination in the crystals, for solvent addition to an autoclave, for improving or optimizing the solvent atmosphere composition, for removal of the solvent from the autoclave, and for recycling of the solvent. The method is scalable up to large volumes and is cost effective.

Owner:SLT TECH

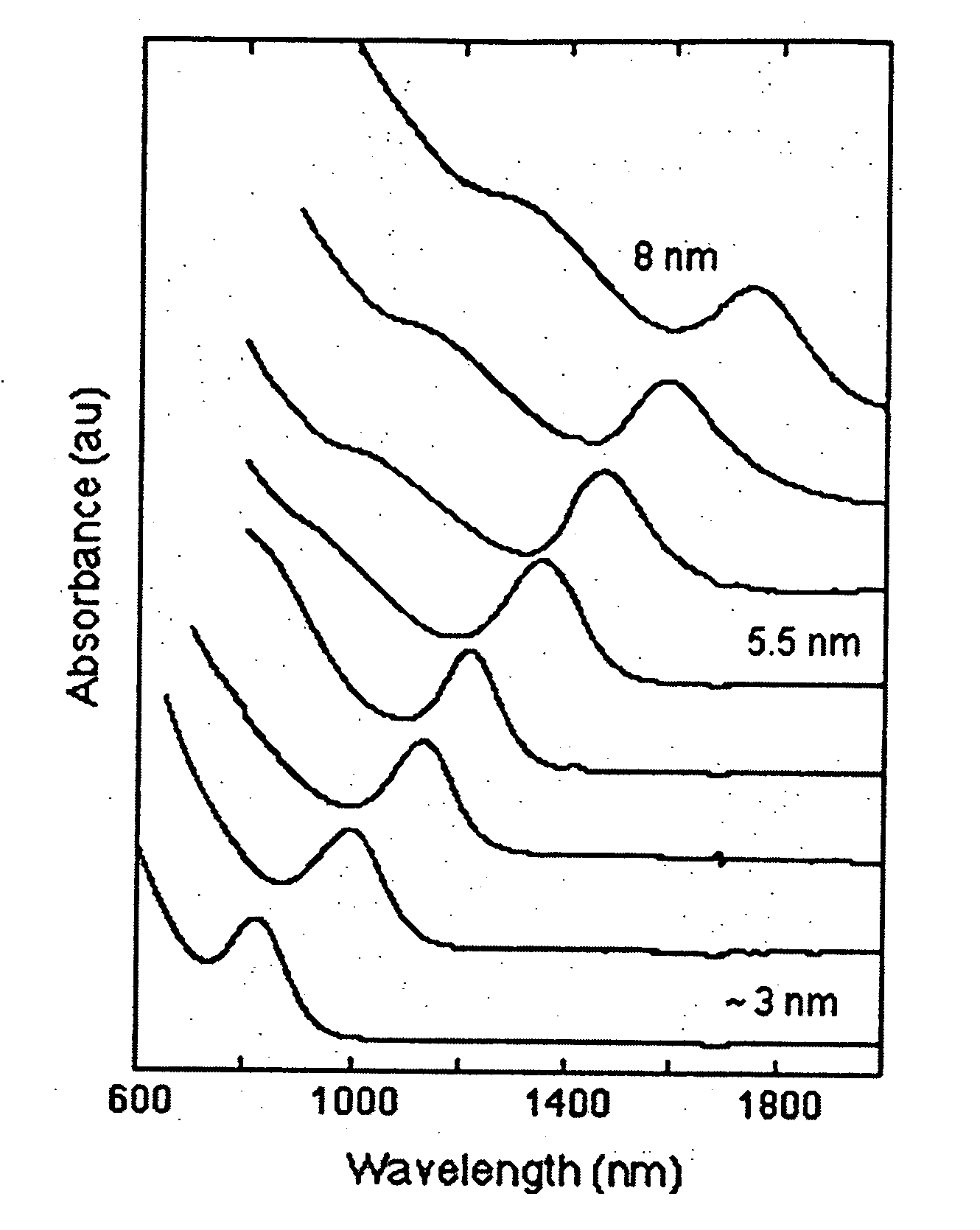

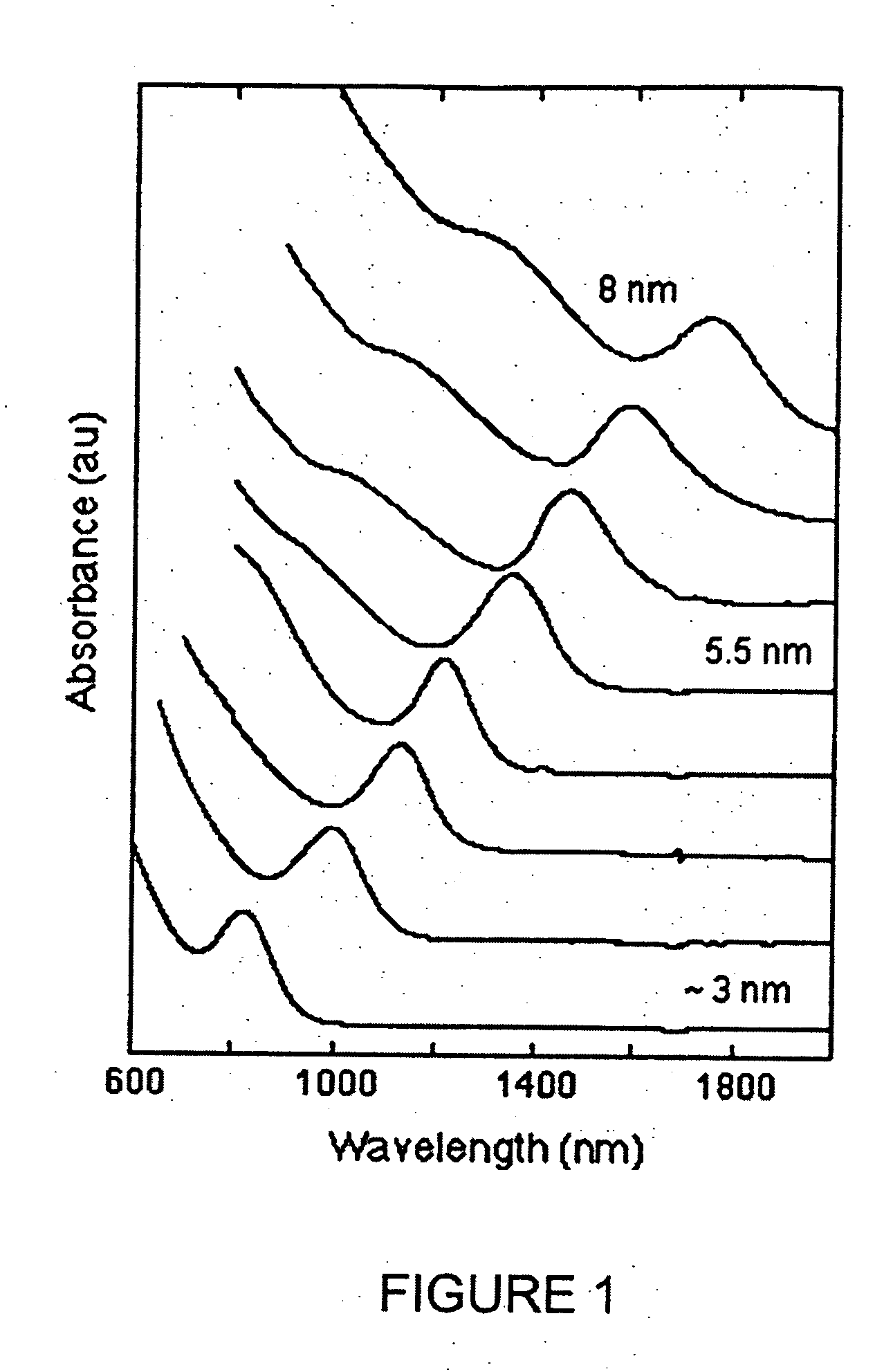

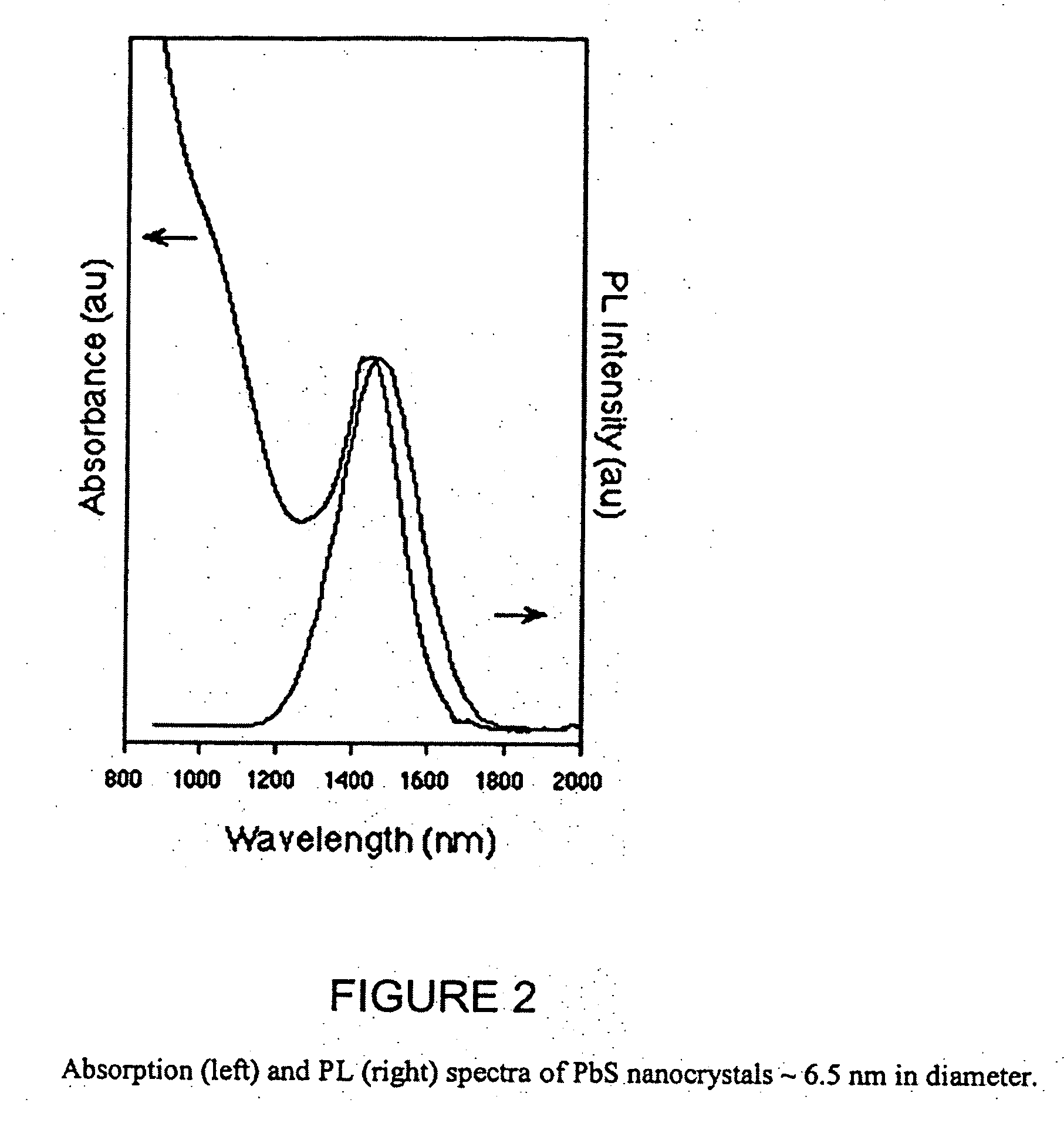

Synthesis of colloidal PbS nanocrystals with size tunable NIR emission

InactiveUS20050120946A1Tunability is providedMaterial nanotechnologyPolycrystalline material growthQuantum dotNanocrystal

The present invention discloses a method for synthesis of narrowly dipsersed colloidal PbS nanocrystals that offer size-tunable near-infrared emission. The stability and processibility of these near-infrared emitting quantum dots makes them ideal materials for device applications. The use of cost-effective and non-pyrophoric precursors as well as the success of larger scale reactions means the present invention provides a method for the industrial scale production of PbS nanocrystals.

Owner:EVIDENT TECH

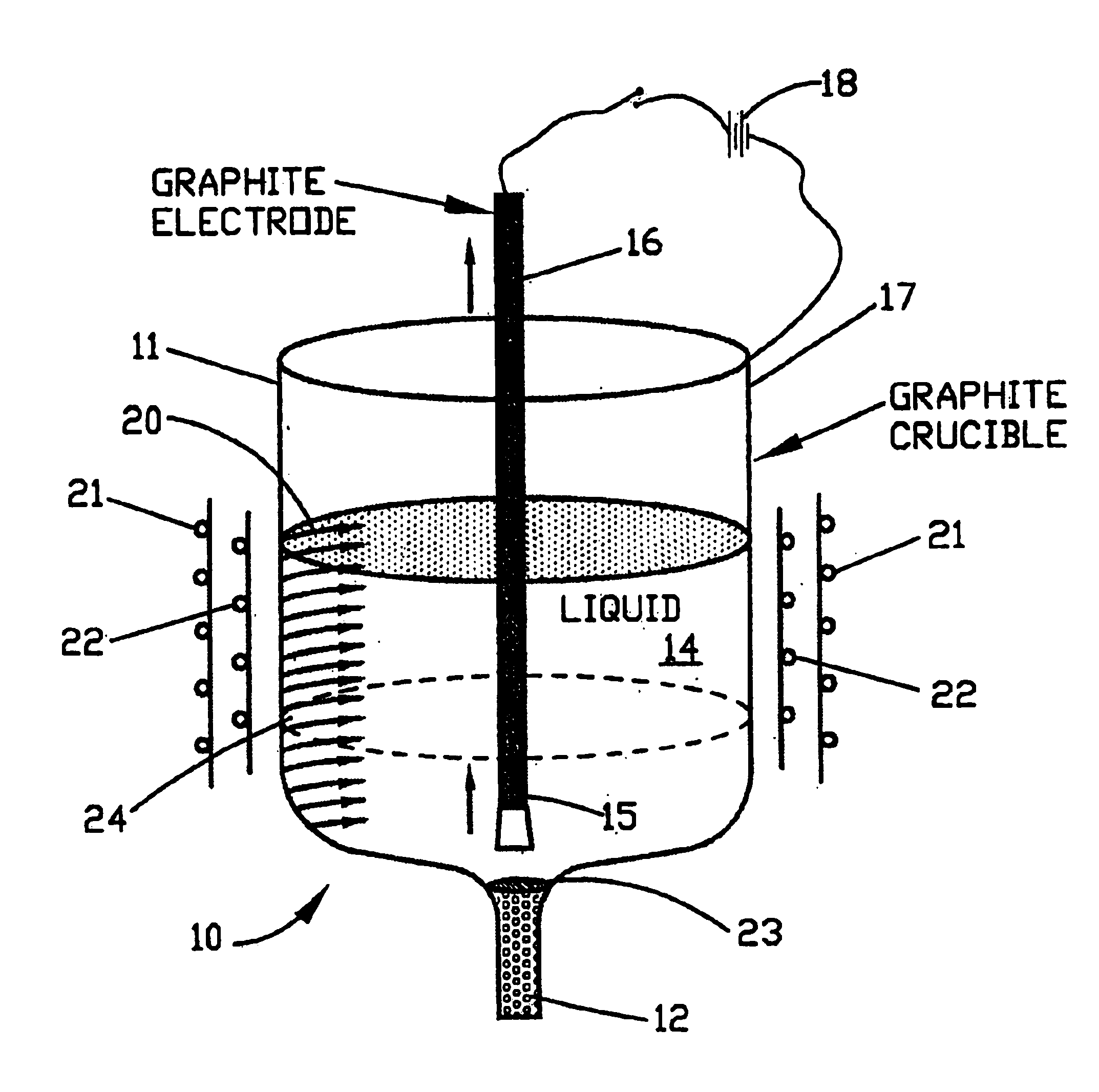

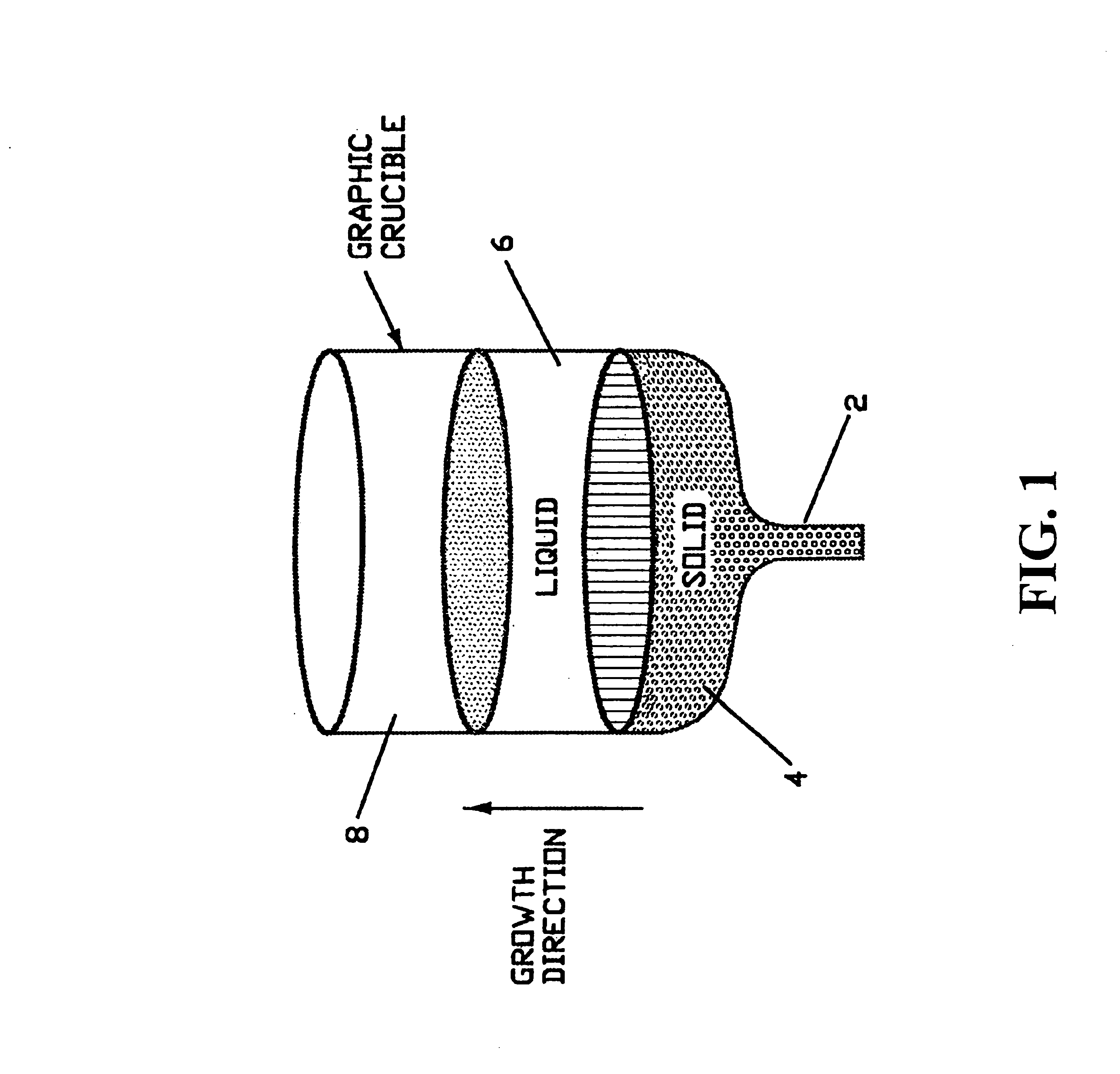

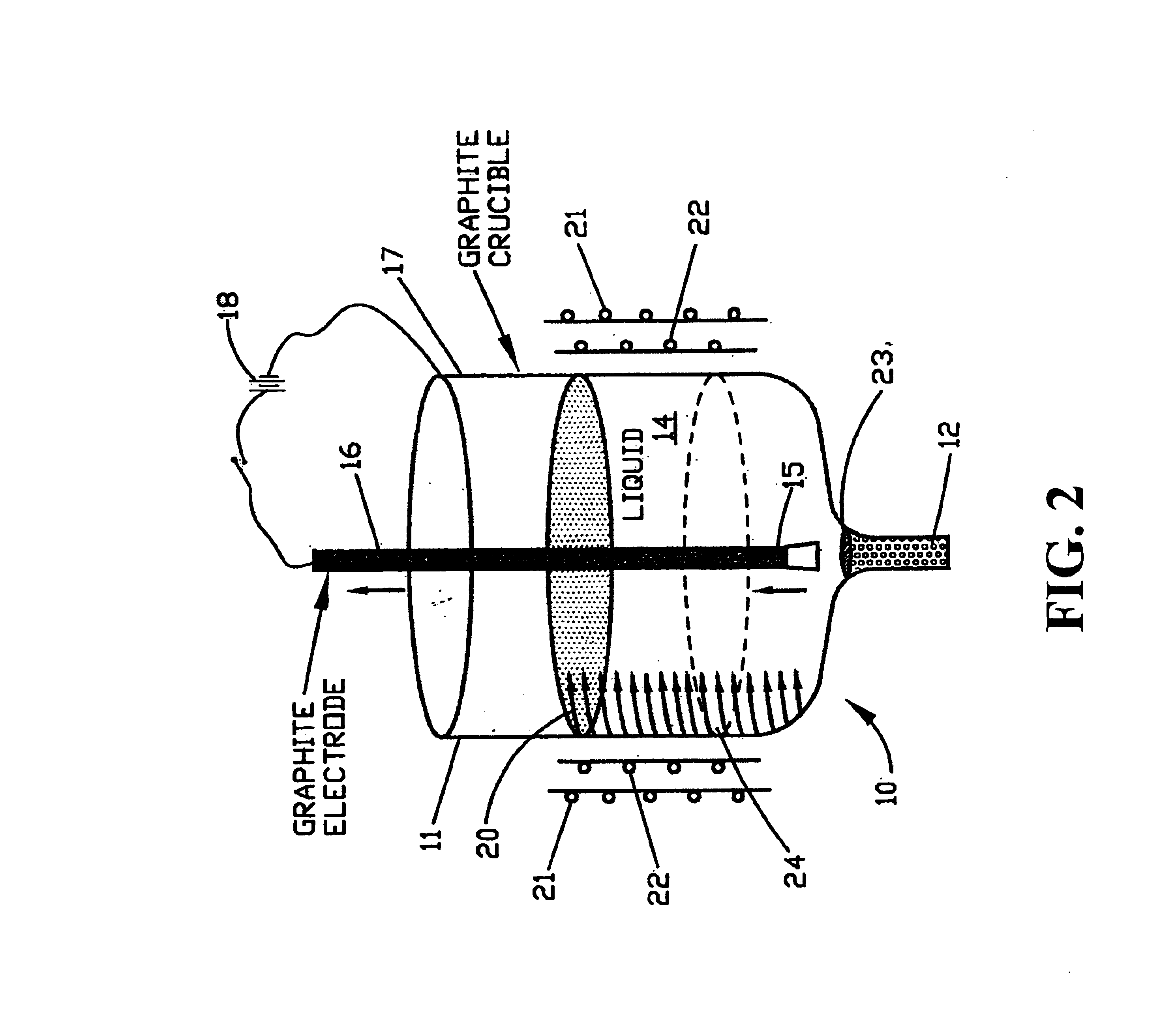

Growth of uniform crystals

InactiveUS6849121B1Easy to unifyLower melting temperaturePolycrystalline material growthFrom melt solutionsMolten stateSeed crystal

The invention provides for growing semiconductor and other crystals by loading a vessel in its lower portion with a seed crystal, loading a charge thereon in the vessel, heating the charge to a molten state and electromagnetically stirring the melt using magnetic and electric fields to obtain a more uniform composition of melt and slowly reducing the temperature of the melt over the crystal to grow a more uniform crystal from such stirred melt.

Owner:AIR FORCE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com