Preparing method of Roma cloth

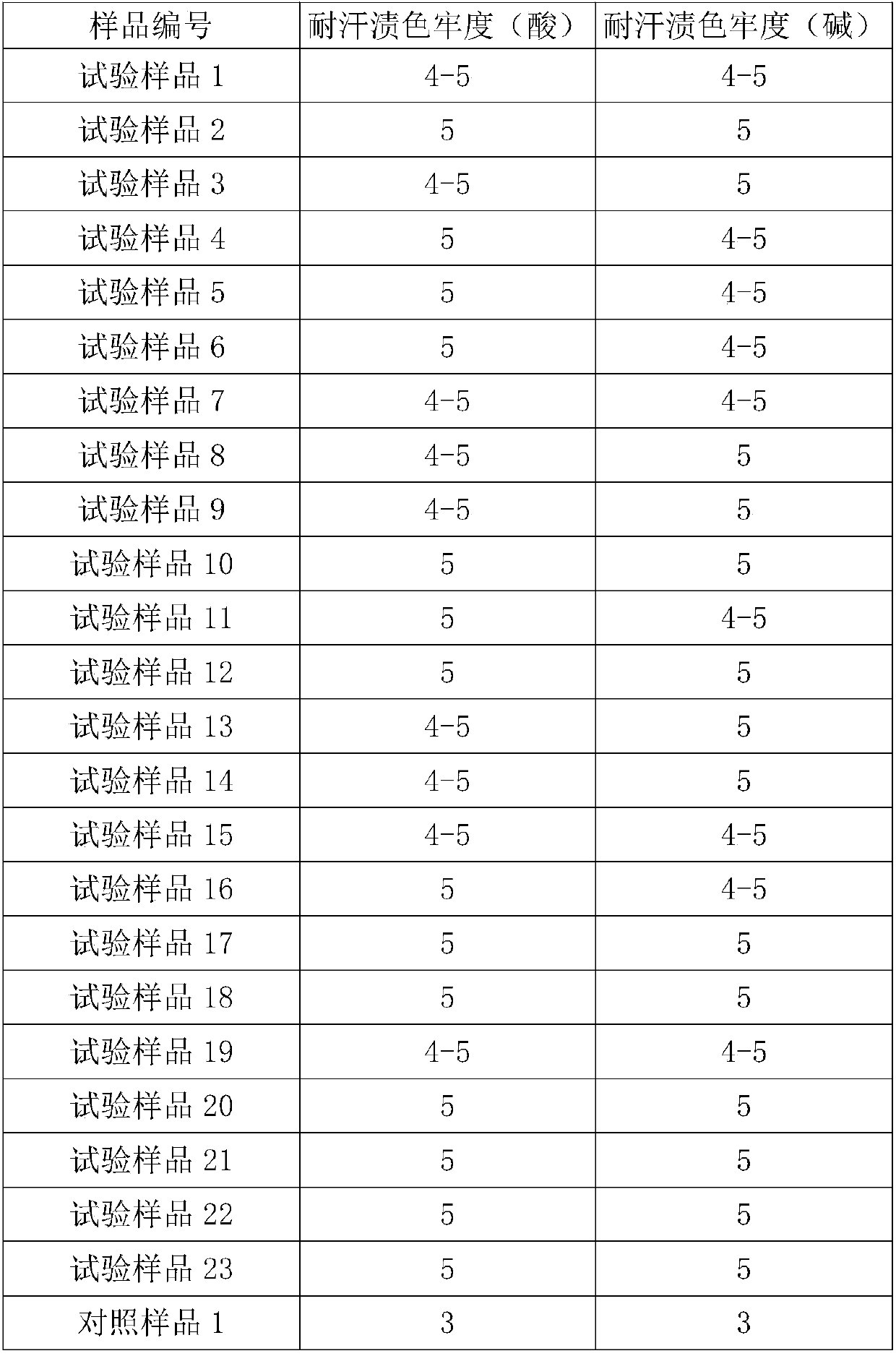

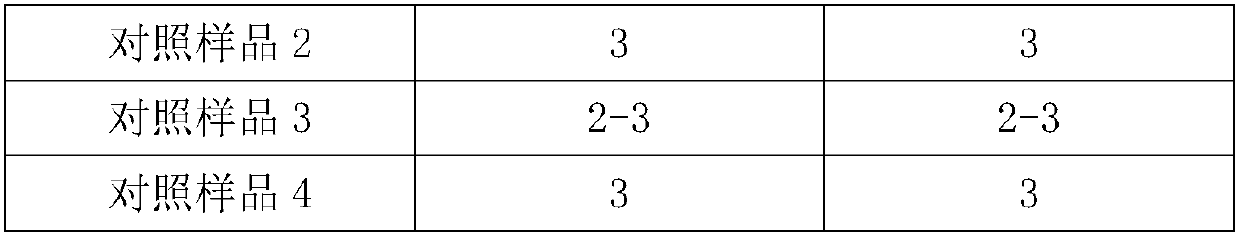

A grey fabric and yarn technology, applied in the field of roman cloth preparation, can solve the problems of easy fading of perspiration stains on roman cloth, and achieve the effects of improving color fastness, increasing gaps, improving color fastness to rubbing and color fastness to perspiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

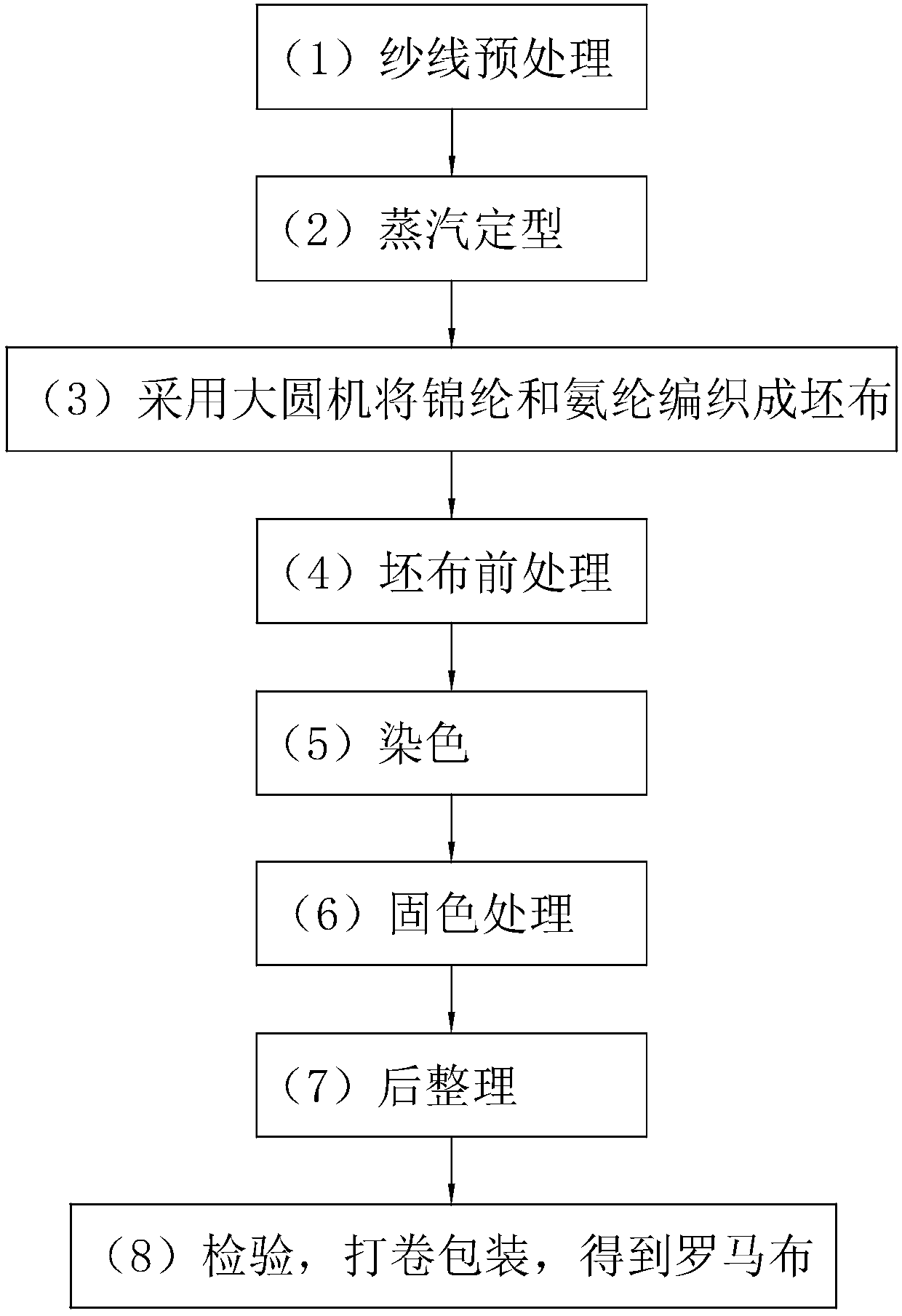

[0043] Embodiment 1: as figure 1 Shown, a kind of preparation method of Roman cloth comprises the following steps:

[0044] (1) Yarn pretreatment: Soak nylon and spandex yarns in caustic soda solution, the concentration of lye solution is 220-250g / L, the initial temperature is controlled at 40°C, and then the temperature is slowly raised to 80°C at 2°C / min, and kept warm After 50 minutes, take it out, wash and dry;

[0045] (2) Steam setting: put nylon and spandex yarns in a steam tank, fill the steam tank with steam after vacuuming, and keep the temperature of the vacuum tank at 100°C for 80 minutes;

[0046] (3) Weaving nylon and spandex into gray cloth by large circular knitting machine;

[0047] (4) Pre-treatment of gray cloth: pad the gray cloth with lye, the water temperature is controlled at 40°C, the lye includes 100g / L degreasing agent, 50g / L penetrating agent and 220g / L caustic soda, and then slow down at 2°C / min Raise the temperature to 80°C, keep it warm for 50 ...

Embodiment 2

[0055] Embodiment 2: a kind of preparation method of roman cloth, differs from embodiment 1 in that the concentration of lye in step (1) is 235g / L.

Embodiment 3

[0056] Embodiment 3: a kind of preparation method of roman cloth, differs from embodiment 1 in that, the concentration of lye in step (1) is 250g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com