Preparation method of cool polyester washed cloth and special device used in method

A special device and cool-feeling technology, applied in the field of preparation of cool-feeling polyester water-washable cloth, can solve the problems of easy to stick to the skin, easy to be stained with dirt, not soft enough to touch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

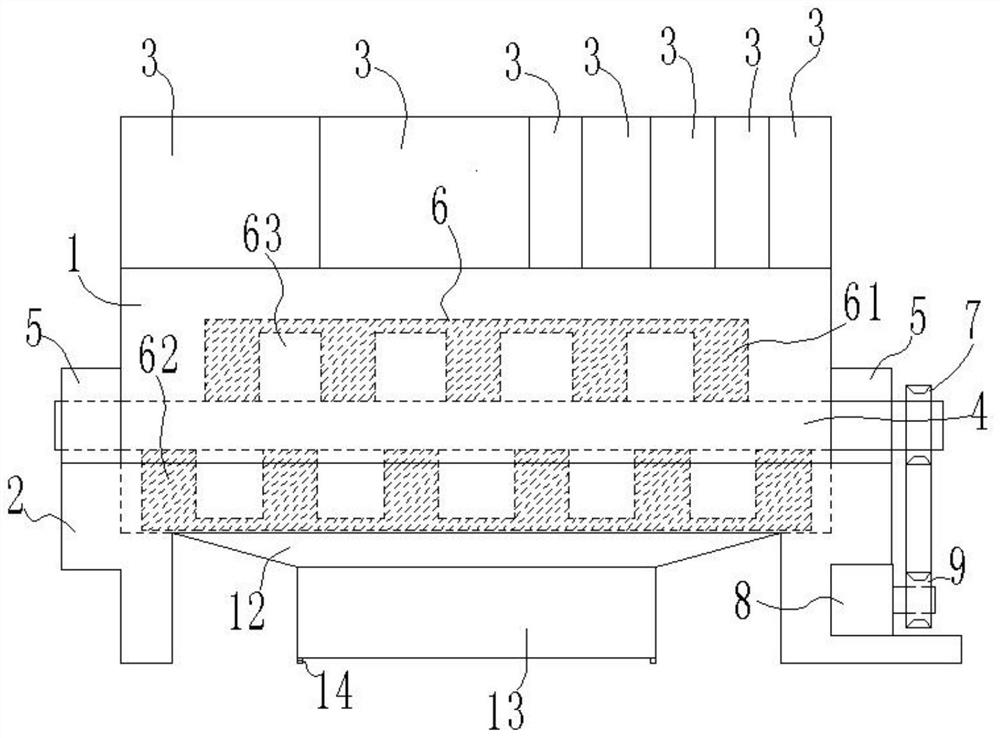

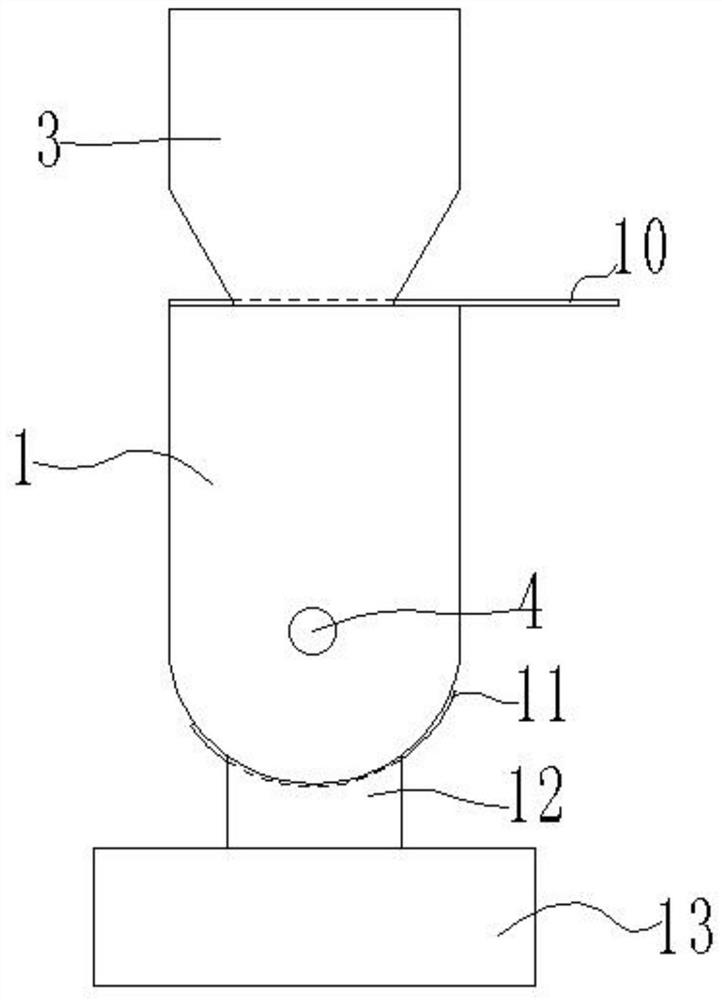

[0037] One cooling sensation preparing polyester fabric washing, comprising the steps of:

[0038] S1: Material mix

[0039] Parts by weight basis, taking coldness jade powder 15 parts, 2 parts nano tourmaline powder, 14 parts of the masterbatch, 30 parts of the polyester powder, 1 part of a dispersant, an antioxidant, 1 part of 1 part of smoothing agent for mixing in a blender to give a mixture;

[0040] S2: silk

[0041] The mix into the extruder, after melt extrusion, ejected from the hole spinneret, the filaments through the air discharge means for cooling the wire after oiling, after completion of oil into the wound wire wound into a roll mill, to give a sense of cool silk; oil containing chemical, oil when the oil temperature is 24 deg.] C, cool feeling after the completion of oil wire relative humidity is 40%;

[0042] S3: Wiring

[0043] Obtained in the step S2 and cool feeling silk cotton nylon twist yarn according to certain after twisting, to give a sense of cool cotton...

Embodiment 2

[0057] One cooling sensation preparing polyester fabric washing, comprising the steps of:

[0058] S1: Material mix

[0059] Parts by weight basis, taking coldness jade powder 18 parts, tourmaline nanometer powder 3 parts, 15 parts of the masterbatch, 35 parts of the polyester powder, 2 parts of a dispersant, 2 parts of antioxidant, 2 parts of leveling agent for mixing in a blender to give a mixture;

[0060] S2: silk

[0061] The mix into the extruder, after melt extrusion, ejected from the hole spinneret, the filaments through the air discharge means for cooling the wire after oiling, after completion of oil into the wound wire wound into a roll mill, to give a sense of cool silk; using chemical oil, the oil temperature at 25 ℃ oil, oil cool feeling after the completion of the wire relative humidity is 50%;

[0062] S3: Wiring

[0063] Obtained in the step S2 and cool feeling silk cotton nylon twist yarn according to certain after twisting, to give a sense of cool cotton and pol...

Embodiment 3

[0077] One cooling sensation preparing polyester fabric washing, comprising the steps of:

[0078] S1: Material mix

[0079] Parts by weight basis, 20 to take jade cool feeling powder, tourmaline nanometer powder 3, 16 parts of the masterbatch, polyester powder 40, Dispersant 2, 2 antioxidant, smoothing agent, 2 parts of the blender for mixing to obtain a mixed material;

[0080] S2: silk

[0081] The mix into the extruder, after melt extrusion, ejected from the hole spinneret, the filaments through the air discharge means for cooling the wire after oiling, after completion of oil into the wound wire wound into a roll mill, to give a sense of cool silk; oil containing chemical, oil when the oil temperature is 28 ℃, cool feeling after the completion of oil relative humidity of 60% yarn;

[0082] S3: Wiring

[0083] Obtained in the step S2 and cool feeling silk cotton nylon twist yarn according to certain after twisting, to give a sense of cool cotton and polyamide thread lines, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com