Evaporator coil coiler for refrigerator

An evaporative coil and coil machine technology, which is applied to heat exchange equipment and other directions, can solve the problems of labor-consuming and low efficiency of the coil machine, and achieve the effects of saving manpower, improving efficiency, and facilitating disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

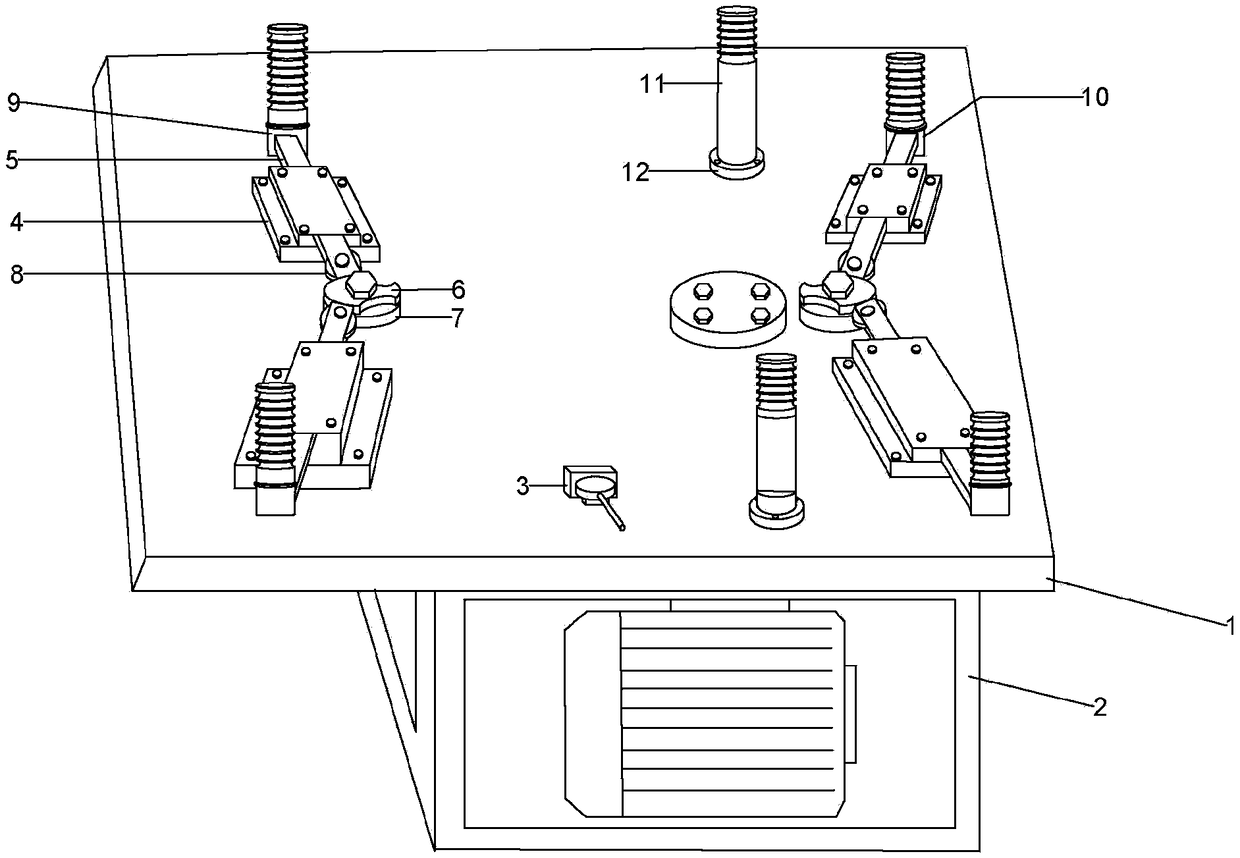

[0020] As shown in the figure, a refrigerator evaporative coil coil machine is composed of a workbench panel 1 and a base 2. It is characterized in that: the workbench panel 1 can be rotated; the workbench panel 1 is provided with a pipe fixture 3 and multiple sets Guide assembly; one or more sets of guide assemblies can slide; each set of guide assemblies includes a mold column; the mold column is provided with a number of ring grooves; the mold column is distributed on the worktable panel 1 in a ring. The guide assembly includes a mold column, a fixed seat 4 and a support rod 5; the fixed seat 4 is fixed on the worktable panel 1; the support rod 5 is slidably placed in the middle of the fixed seat 4; the outer end of the support rod 5 is connected with the mold column, and the inner end Offset wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com