Method for peeling anacardium occidentale kernels

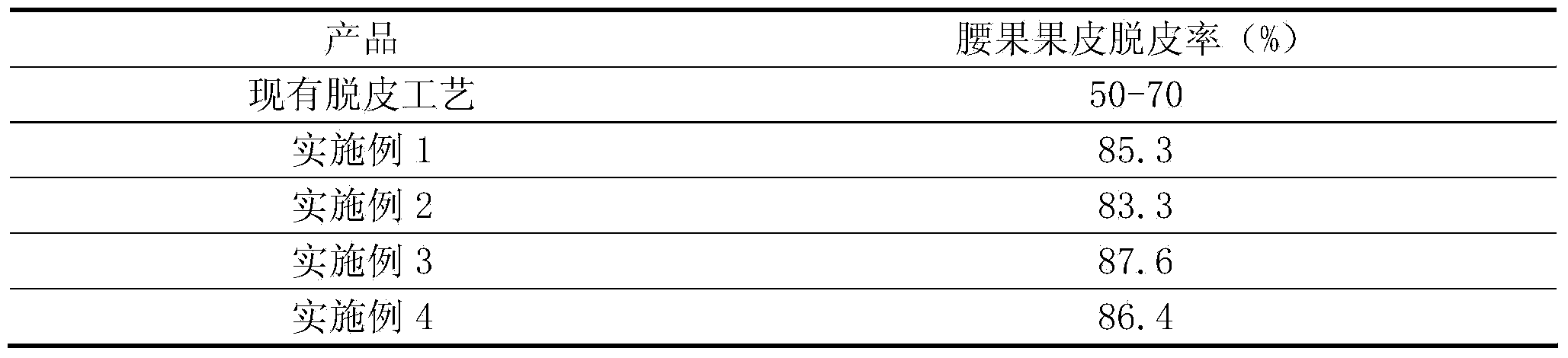

A cashew and nut technology, which is applied in the field of food processing, can solve the problems of difficult removal of the peel of the cashew nut, uneven shape and size of the cashew nut, and difference in the size and shape of the cashew nut, and achieves high peeling rate, good stability and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Put the cracked skinned nuts in a mesh tray for gradient hot air drying. The treatment process is as follows: the first stage: 85°C, drying for 10 minutes, the second stage drying temperature 75°C, drying for 10 minutes, the second stage The third stage is 60°C, and the drying time is 10 minutes. The fourth stage drying temperature is 90°C, and the drying time is 10 minutes.

[0023] 2) Cold treatment is carried out on the cashew kernels after the first drying. The present invention adopts dynamic cold air treatment, and the dynamic cold air treatment conditions: the temperature is 20°C, the treatment is 20 minutes, and the air volume is 5000m 3 / h.

[0024] 3) The cold-treated cashew kernels are subjected to water mist humidification treatment: the treatment conditions are that the humidity is controlled at 100%, the humidification temperature is controlled at 10° C., and the humidification time is controlled at 48 hours.

[0025] 4) After the humidification treatm...

Embodiment 2

[0029] 1) Put the cracked skinned nuts in a mesh tray for gradient hot air drying. The treatment process is as follows: the first stage: 70°C, drying for 40 minutes, the second stage drying temperature 60°C, drying for 40 minutes, the second stage The third stage is 50°C, and the drying time is 40 minutes. The fourth stage drying temperature is 70°C, and the drying time is 40 minutes.

[0030] 2) The cashew kernels after the first drying are subjected to cold treatment. The present invention adopts static refrigeration treatment, and the static refrigeration treatment condition is -15° C. for 5 hours.

[0031] 3) The cold-treated cashew kernels are subjected to water mist humidification treatment: the treatment conditions are that the humidity is controlled at 70%, the humidification temperature is controlled at 40° C., and the humidification time is controlled at 20 hours.

[0032] 4) After the humidification treatment, the cashew kernels are subjected to the second hot air d...

Embodiment 3

[0036] 1)) Place the shelled nuts in a mesh tray for gradient hot air drying. The treatment process is as follows: the first stage: 85°C, drying for 30 minutes, the second stage drying temperature 75°C, drying for 30 minutes, The third stage is 55°C, and the drying time is 30 minutes. The fourth stage is at 80°C, and the drying time is 30 minutes.

[0037] 2) After the first drying, the cashew kernels are subjected to cold treatment, and the dynamic cold air treatment is adopted: dynamic cold air treatment conditions: temperature -15°C, treatment for 10 minutes, and the air volume is 3000m 3 / h.

[0038] 3) The cold-treated cashew kernels are subjected to water mist humidification treatment: the treatment conditions are that the humidity is controlled at 80%, the humidification temperature is controlled at 30° C., and the humidification time is controlled at 40 h.

[0039] 4) After the humidification treatment, the cashew kernels are subjected to the second hot air drying: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com