High-strength plastic-steel composite cable protection pipe

A composite cable and protective tube technology, applied in electrical components, synthetic resin layered products, layered products, etc., can solve the problems of easy handling and installation of workers' hands, easy damage of glass steel pipe, easy rupture of mechanical strength, etc. Achieve the effect of avoiding cable threading failure, high mechanical strength, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

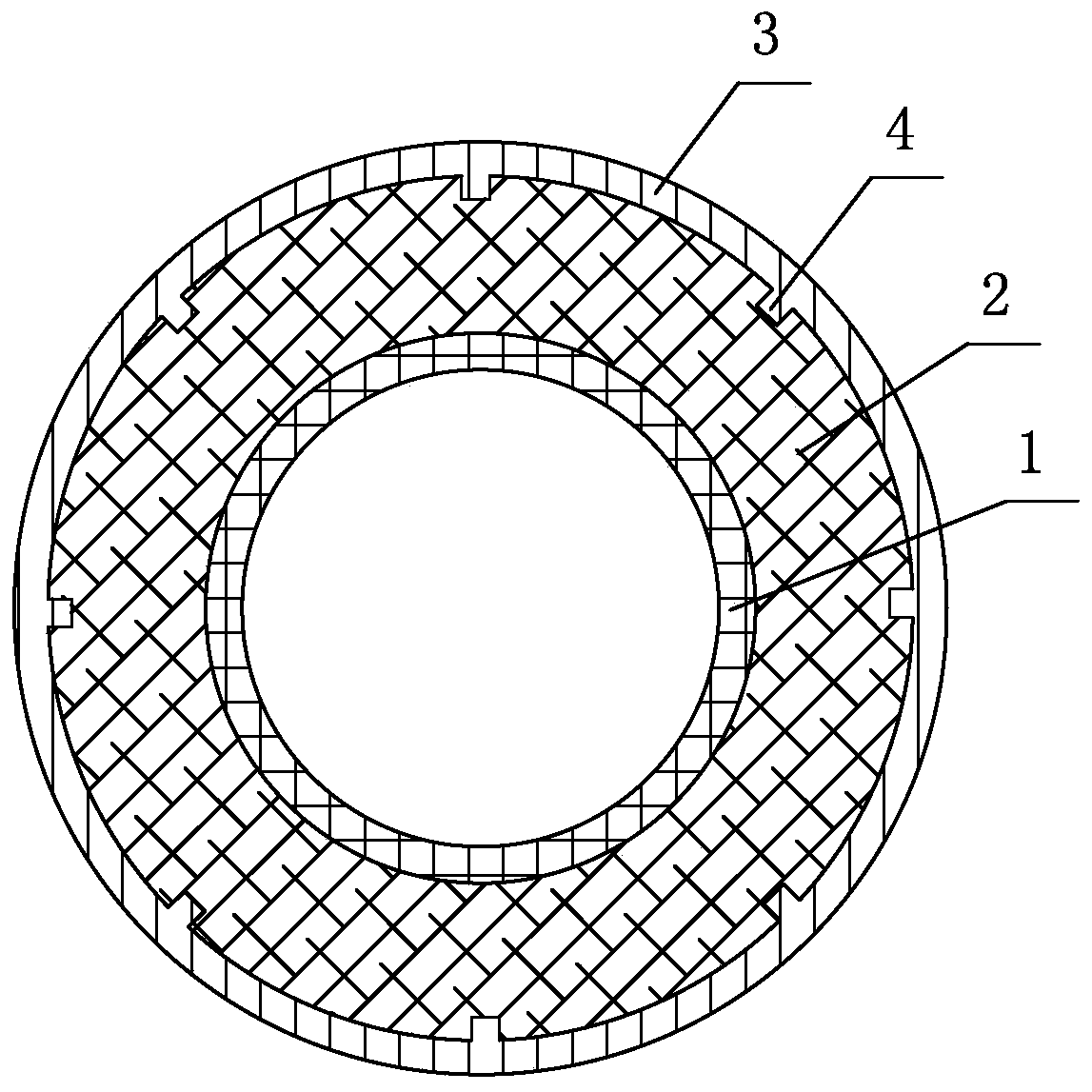

[0026] Such as figure 1 As shown, a high-strength plastic-steel composite cable protection tube includes:

[0027] Inner layer 1, the inner layer is woven by fiber filaments, and its interior is used for laying and easy-wearing cables;

[0028] The intermediate reinforcement layer 2, the intermediate reinforcement layer is formed by weaving and winding multi-layers of fiber filaments, and is fixedly laid and composited on the outer surface of the inner layer, which greatly improves the mechanical strength of the pipe;

[0029] Heat-shrinkable layer 3, said heat-shrinkable layer is shrunk and fixed on the outer surface of the middle reinforcement layer, which completely solves the difficult problem of burrs on the surface of any FRP pipe in the past.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com