High-strength environment-friendly scaffold pedal and preparation method thereof

A scaffolding and high-strength technology, which is applied in the field of building board production, can solve problems such as flammability, unfavorable use, and general load-bearing performance, and achieve the effects of improving thermal stability and weather resistance, enhancing interface bonding strength, and low surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

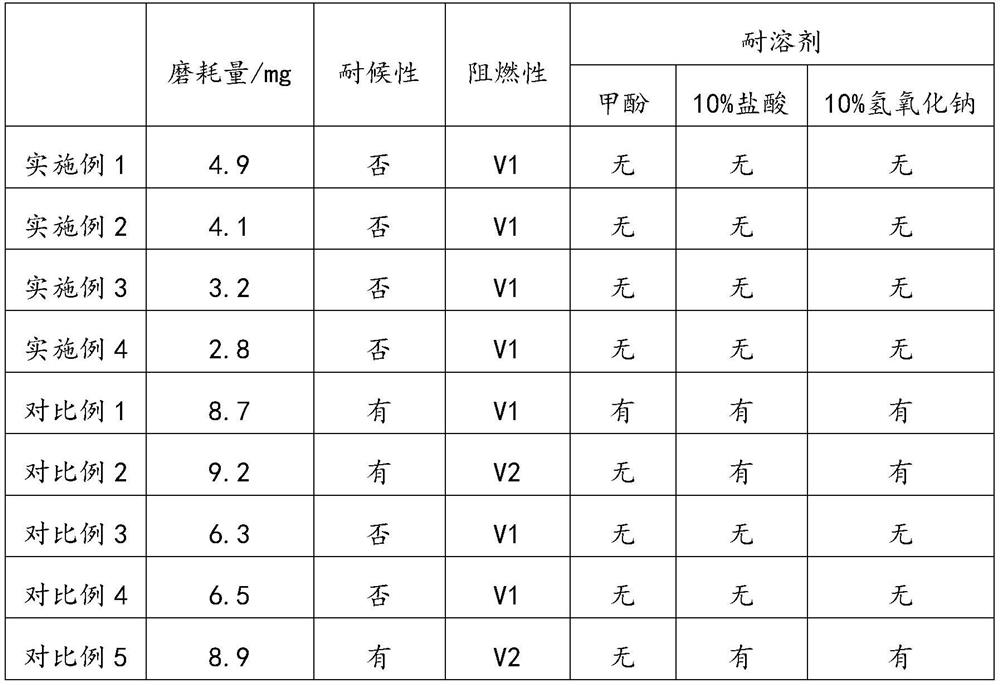

Examples

Embodiment 1

[0031] A high-strength environment-friendly scaffolding pedal, the pedal material is composed of the following raw materials in parts by weight: 30 parts of polyvinyl chloride, 40 parts of modified plant fiber, 10 parts of polyamide resin, 20 parts of butadiene-styrene copolymer emulsion , 5 parts of metakaolin, 10 parts of silica fume, 5 parts of hexamethylphosphoric triamide, 1 part of phenyl o-hydroxybenzoate, 4 parts of heat stabilizer and 1 part of lubricant.

[0032] According to the preparation method of the scaffolding pedal that above-mentioned component is formed, specifically comprise the following steps:

[0033] (1) Preparation of PVC-bs-PA blend: Add polyvinyl chloride to methyl ethyl ketone and place it in a reaction kettle, then add butadiene-styrene copolymer emulsion and mix evenly, heat up to 50-60°C Stir for 1 hour, then add polyamide resin, raise the temperature to 70-90°C, and stir for 2 hours to obtain a PVC-bs-PA blend. Wherein, the ratio of polyvinyl ...

Embodiment 2

[0041] A high-strength environment-friendly scaffolding pedal, the pedal material is composed of the following raw materials in parts by weight: 50 parts of polyvinyl chloride, 20 parts of modified plant fibers, 15 parts of polyamide resin, 15 parts of butadiene-styrene copolymer emulsion, 10 parts metakaolin, 5 parts silica fume, 2 parts hexamethylphosphoric triamide, 3 parts phenyl o-hydroxybenzoate, 2 parts heat stabilizer and 3 parts lubricant. The preparation method of the pedal material composed of this component is the same as in Example 1, specifically refer to Example 1, the difference is that the ratio of polyvinyl chloride to butanone in Example 2 is 8 g / mL.

[0042] The preparation method of the above-mentioned modified plant fiber is the same as that in Example 1, except that the mass ratio of plant fiber to diacetone alcohol solution is 1:1.8, and the mass ratio of plant fiber to silane coupling agent is 1:0.08.

[0043] The above heat stabilizer components and p...

Embodiment 3

[0045] A high-strength environment-friendly scaffolding pedal, the pedal material is composed of the following raw materials in parts by weight: 40 parts of polyvinyl chloride, 30 parts of modified plant fibers, 12 parts of polyamide resin, 18 parts of butadiene-styrene copolymer emulsion, 8 parts metakaolin, 6 parts silica fume, 4 parts hexamethylphosphoric triamide, 2 parts phenyl o-hydroxybenzoate, 4 parts heat stabilizer and 2 parts lubricant. The preparation method of the pedal material composed of this component is the same as in Example 1, specifically refer to Example 1, the difference is that the ratio of polyvinyl chloride to butanone in Example 2 is 5 g / mL.

[0046] The preparation method of the above-mentioned modified plant fiber is the same as that in Example 1, except that the mass ratio of plant fiber to diacetone alcohol solution is 1:2, and the mass ratio of plant fiber to silane coupling agent is 1:0.06.

[0047] The above heat stabilizer components and prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com