Patents

Literature

142 results about "Hexamethylphosphoric Triamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-content environmental alcohol ether fuel used for compression ignition engine

InactiveCN105505484AEmission reductionLarge latent heat of evaporationLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol fuel

The invention discloses a high-content environmental alcohol ether fuel used for a compression ignition engine, which belongs to the technical field of alcohol ether fuel clean energy. The alcohol ether fuel comprises the following raw materials: methanol or ethanol or a mixture of methanol and ethanol, toluene, stearic acid, hexamethylphosphoric triamide, a nitryl solvent, acetone, fatty acid methyl ester, n-alkane, N-toluidine, plant oil, an alcohol fuel ether stabilizing agent, a catalysis combustion-supporting agent, an anti-knock reinforcing agent, a cetane number regulator, an eduction agent, an alcohol fuel recognition agent, an alcohol fuel rubber / plastic part corrosion and swelling inhibitor, an alcohol fuel metal corrosion inhibitor, an antioxidant anti-gum inhibitor, a metal deactivator, a corrosion inhibitor, an antistatic agent, a purification dispersant, an anti-wear repair agent, and an alcohol fuel sterilizing agent. The high-content environmental alcohol ether fuel has the advantages of stable performance, strong power, full combustion, good anti-knock property, good acceleration speed, easy starting, no air resistance, and low fuel consumption, and is especially suitable for the compression ignition engine.

Owner:SICHUAN ZHENGJIA NEW ENERGY TECH CO LTD

Flame-retardant zinc stearate modified calcium carbonate filler

The invention relates to a calcium carbonate filler, and particularly relates to a flame-retardant zinc stearate modified calcium carbonate filler. The modified calcium carbonate is prepared from the following raw materials in parts by weight: 200 parts of calcium carbonate, 1-2 parts of shell powder, 8-10 parts of aluminium hydroxide, 2-3 parts of zinc stearate, 1-2 parts of sodium borate, 2-3 parts of ammonium molybdate, 3-4 parts of chromium oxide, 1-2 parts of morpholine, 23-25 parts of triethyl citrate, 1-2 parts of hexamethylphosphoric triamide, 1-2 parts of anti-aging agent NBC and 4-5 parts of assistant. Modification treatment is carried out on calcium carbonate by adopting the raw materials such as zinc stearate, morpholine and the like; the performance indexes such as oil absorption value, viscosity, activating rate and the like of the modified calcium carbonate powder are improved, which indicates that the modified calcium carbonate filler is more easily dispersed and compatible in a medium. Compared with the material filled by unmodified calcium carbonate, the mechanical property of a polyvinyl chloride (PVC) material filled by the modified calcium carbonate filler disclosed by the invention is obviously improved, the flame-retardant and fire-resistant grades are also improved, and good toughening and reinforcing effects are achieved.

Owner:安徽雪城超细碳酸钙有限公司

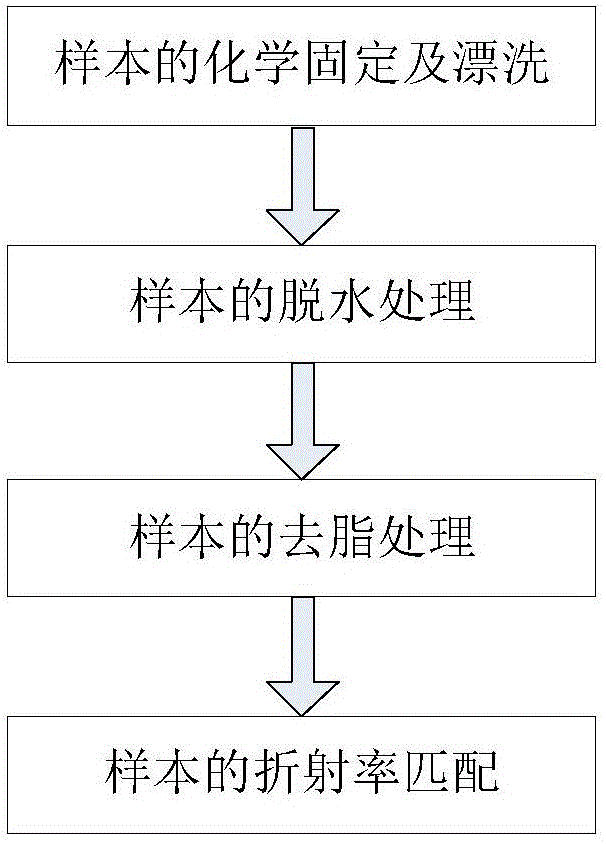

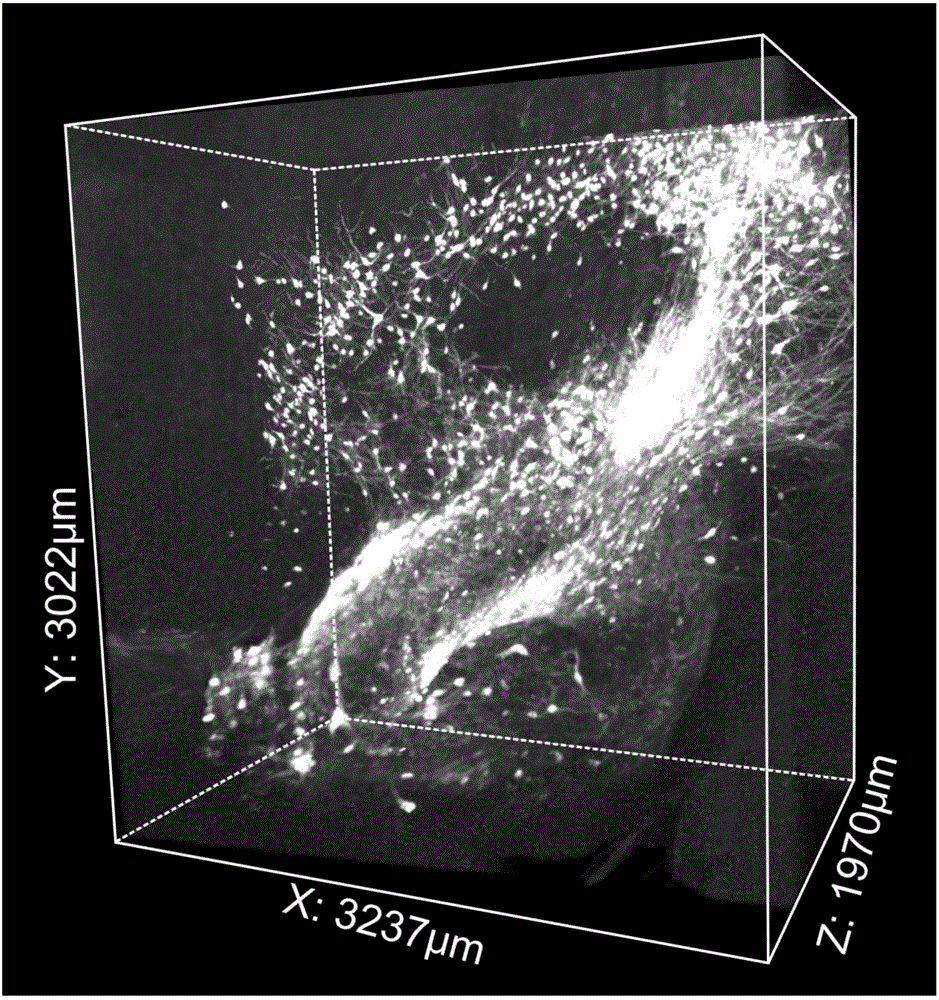

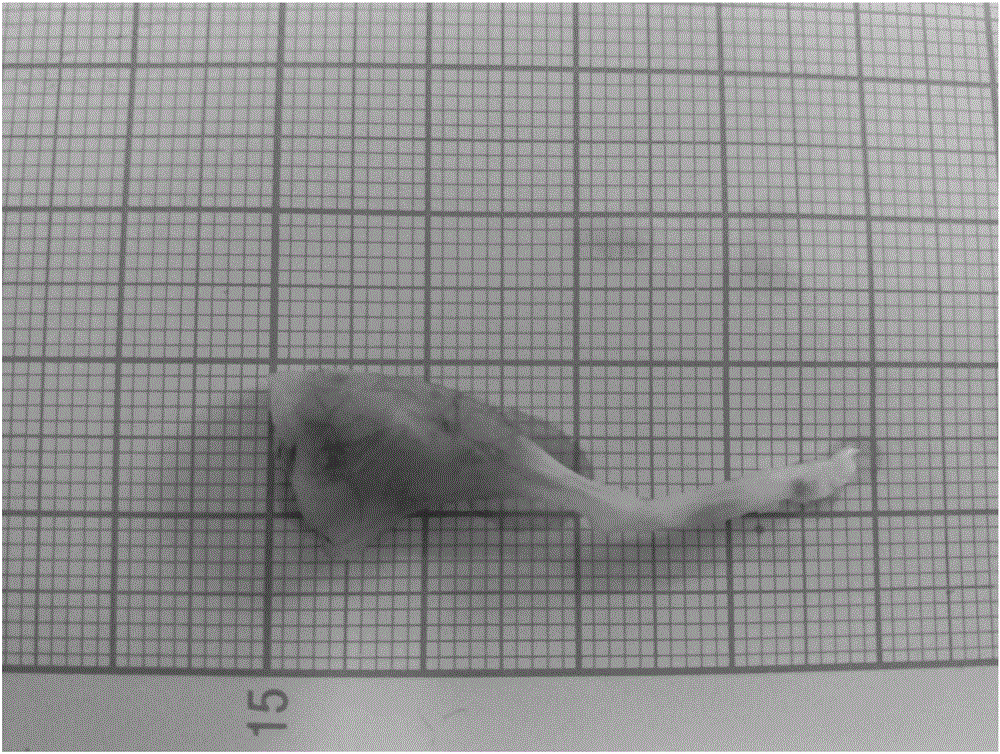

Method for optical clearing of biological tissues

InactiveCN106556582ATransparent and fastKeep the original shapeFluorescence/phosphorescenceOptical clearingFluorescence

The invention discloses a method for rapid optical clearing of biological tissues. The method includes: employs a strong polar aprotic solvent to conduct degreasing, wherein the strong polar aprotic solvent can be methyl methacrylate, hexamethylphosphoric triamide, N-methyl pyrrolidone, 1, 3-dimethyl-2-imidazolidinone, 1, 4-dioxane or 2, 5-dimethylfuran, then selecting a specific refractive index matching reagent with a refractive index of 1.52-1.59 to conduct clearing treatment, thus realizing rapid clearing of biological tissues. The degreasing and clearing treatment totally need only 18h to realize high clearing of mouse brain tissues, the method not only can realize brain tissue clearing, but also can achieve clearing of various organs, can well maintain the original morphology of biological tissues, and has high clearing degree and repeatability, and good fluorescence retaining effect, the soma and nerve fiber have strong fluorescence signal, and the application range is wide.

Owner:HUAZHONG UNIV OF SCI & TECH

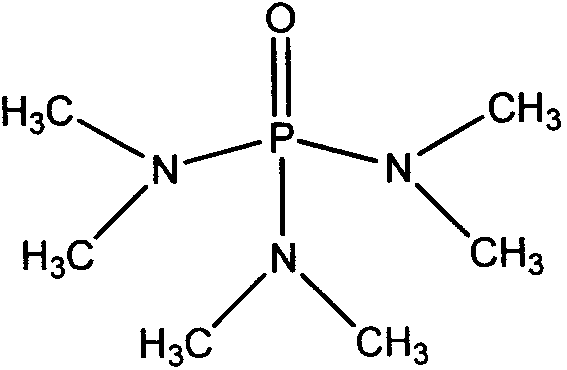

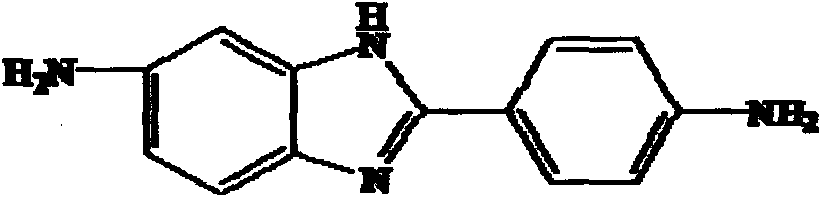

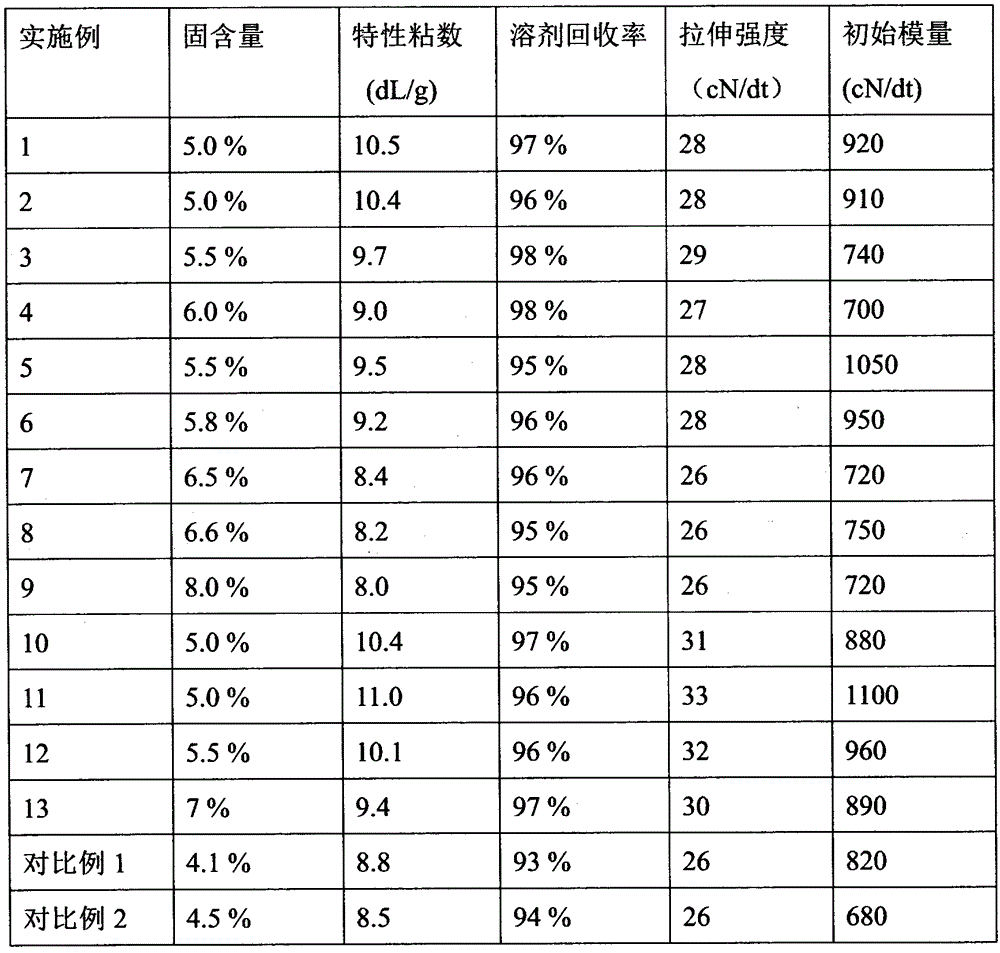

Method for preparing heterocyclic aramid solution

InactiveCN106700065AStrong ability to dissolve heterocyclic aramid fibersHigh solid contentArtificial filament recoveryMonocomponent copolyamides artificial filamentHexamethylphosphoric TriamideChloride

The invention belongs to the technical fields of heterocyclic aramid solution and preparation thereof, and specifically, relates to a method for preparing a heterocyclic aramid solution, wherein the method comprises the steps: a diamine substance and an aromatic dicarbonyl chloride are subjected to a polymerization reaction in an inert gas atmosphere and in a hexamethylphosphoric triamide solution containing no cosolvent, wherein the diamine substance comprises 2-(4-aminophenyl)-5-aminobenzimidazole.

Owner:SICHUAN UNIV

Hydrotalcite-lanthanum cyanurate composite environmental protection stabilizer for PVC, and preparation method thereof

The present invention provides a hydrotalcite-lanthanum cyanurate composite environmental protection stabilizer for PVC, wherein the hydrotalcite-lanthanum cyanurate composite environmental protection stabilizer is prepared from the following raw materials by weight: 20-30 parts of modified magnesium aluminum hydrotalcite, 10-12 parts of dibutyl tin oxide, 6-8 parts of lanthanum cyanurate, 6-9 parts of cerium laurate, 1-3 parts of trimethyl phosphite, 13-15 parts of tri(2-ethylhexyl) acetylcitrate, 3-6 parts of barium stearate, 2-4 parts of diphenyl thiourea, 5-6 parts of zinc stearate, 1-2 parts of hexamethylphosphoric triamide, 1-2 parts of stearic acid, and 10-13 parts of vermiculite powder. According to the present invention, the PVC stabilizer has characteristics of good thermal stability, good processing performance, environmental protection, no toxicity, low cost, good plasticity and balance torque reducing during the PVC processing process, and low cost.

Owner:HWASU

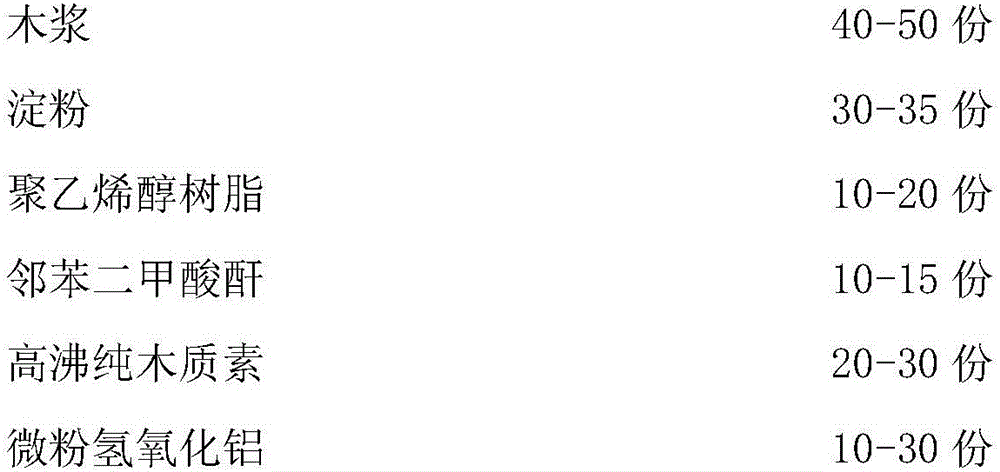

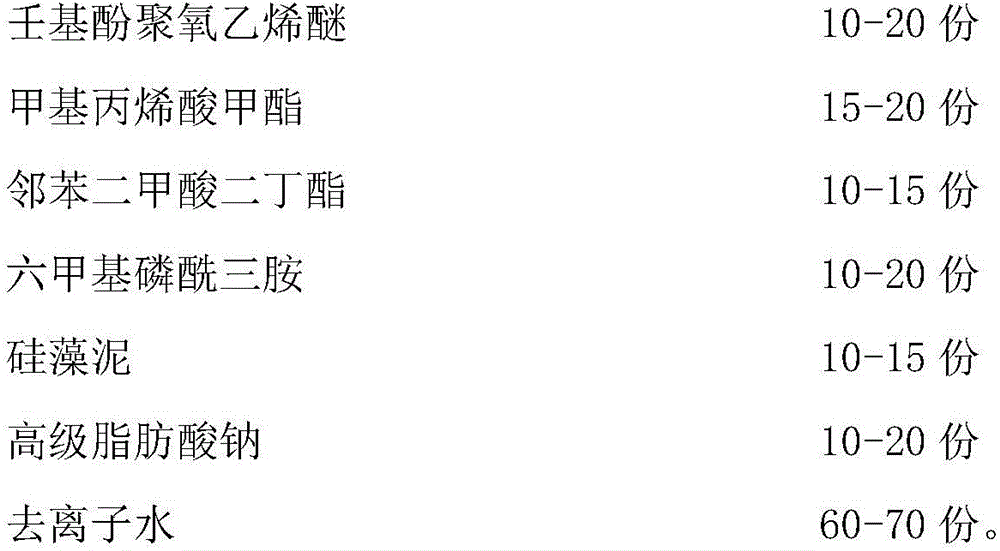

Formula of environment-friendly packaging box

InactiveCN106320055AImprove pressure resistanceImprove flame retardant performanceNatural cellulose pulp/paperPaper/cardboardPolyvinyl alcoholHexamethylphosphoric Triamide

The invention belongs to the technical field of corrugated paper manufacturing, and particularly relates to a formula of an environment-friendly packaging box. The formula comprises wood pulp, starch, polyvinyl alcohol resin, phthalic anhydride, high boiling solvent lignin, fine powder aluminum hydroxide, nonylphenol polyoxyethylene ether, methyl methacrylate, dibutyl phthalate, hexamethylphosphoric triamide, diatom ooze, higher aliphatic acid sodium and deionized water. By the adoption of the formula, the pressure resistance of the packaging box can be improved, the flame retardant property of the packaging box can be improved through fine powder aluminum hydroxide and nonylphenol polyoxyethylene ether, foul gas in the air can be adsorbed through diatom ooze, and the environment can be protected through reaction between higher aliphatic acid sodium and peracid substance in the air.

Owner:苏州炫之彩新材料股份有限公司

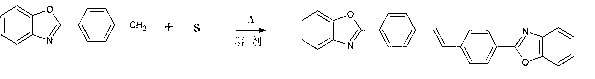

Preparation method of 2,2'-(4,4'-distylyl) dibenzoxazole by adopting new sulphur method

The invention relates to a preparation method of 2,2'-(4,4'-distylyl) dibenzoxazole by adopting a new sulphur method. The preparation method is characterized in that methyl benzoic acid and ortho-aminophenol are dissolved in solvent oil, and boric acid is taken as a catalyst, so as to generate 4-methyl benzoxazole taken as a raw material; in an oxidation condensation reaction process of 4-methyl benzoxazole, an aprotic organic solvent is adopted for replacing sulphur as a reaction medium, wherein the aprotic organic solvent is diphenyl ether, hexamethylphosphoric triamide or formamide, a reaction temperature is 190-230 DEG C, reaction time is controlled to be 3-4 hours, energy consumption is reduced, and reaction yield and product quality are improved as the salvation effect and using amount of sulphur are reduced; and besides, equipment investment is reduced, and solid waste is greatly reduced, so that the preparation method is a clean production technology. A fluorescent brightener OB-1 provided by the invention can be used in ingredients of plastics, chemical fibers and the like for whitening and brightening.

Owner:HUBEI HONGXIN CHEM CO LTD

PVC (polyvinyl chloride) formula

InactiveCN104844964AImprove impact resistanceHigh strengthHexamethylphosphoric TriamidePolyvinyl chloride

The invention provides a PVC (polyvinyl chloride) formula, which is prepared from the following raw materials in parts by weight: 70 to 90 parts of PVC resin, 3 to 6 parts of calcium stearate, 4 to 7 parts of zinc oxide, 6 to 8 parts of hexamethylphosphoric triamide, 1 to 2 parts of impact modifier, 2 to 3 parts of chlorcosane, and 0.5 to 1.3 parts of auxiliaries. PVC pipes produced by using the formula have the advantages that the impact resistance property and the strength can be enhanced, through adding the hexamethylphosphoric triamide, the oxidation resistance of the PCV pipes can be greatly improved, and the cost is relatively low. The PVC formula is suitable for popularization and application.

Owner:钱万标

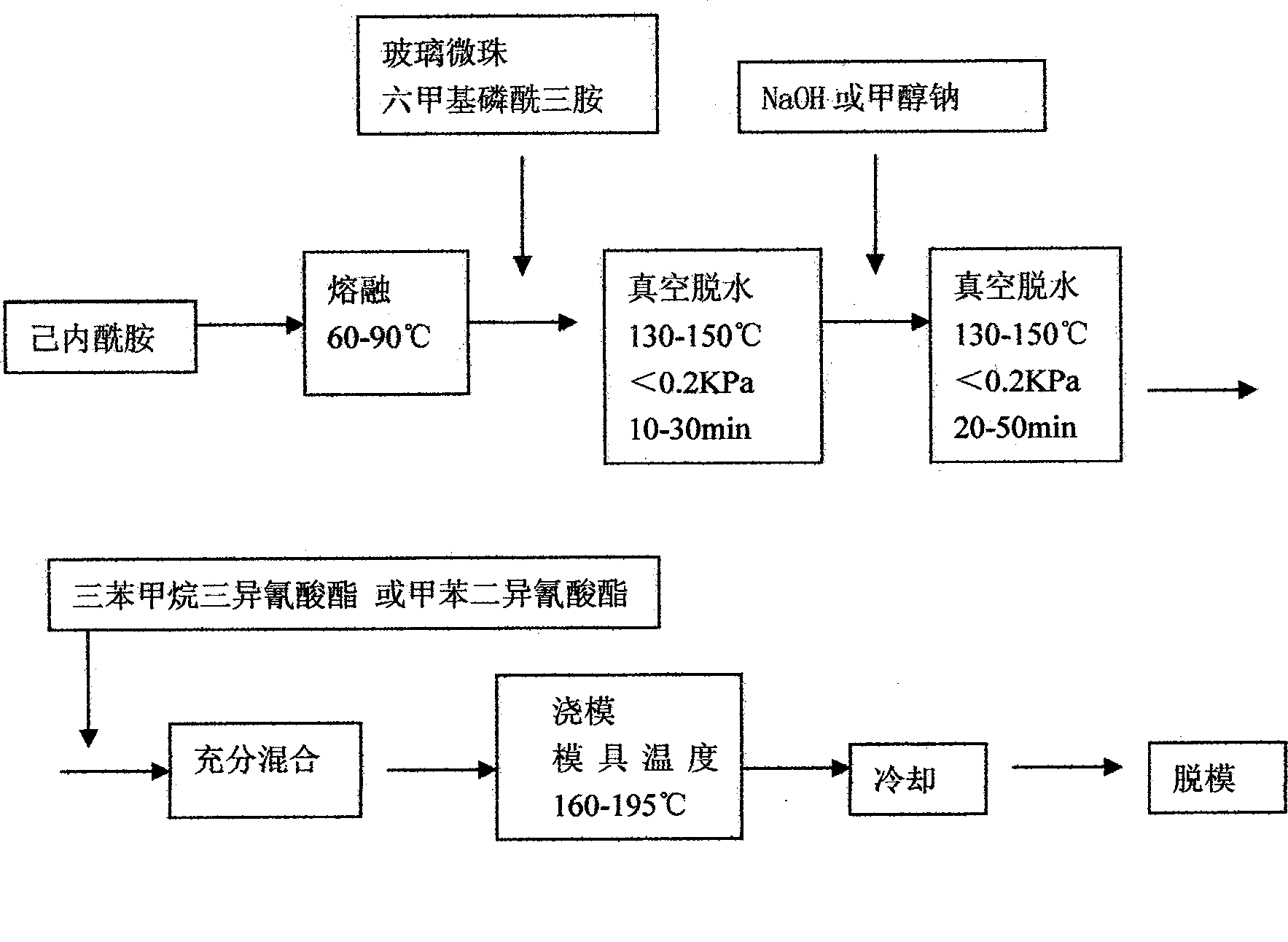

Cold-proof, impactive and high toughness casting nylon and method for producing the same

The invention discloses monomer cast nylon with cold-resistance, impact-resistance and high-tenacity and a preparation method thereof. The components and the weight percentage are as follows: 65.4 percent to 96 percent of caprolactam, 0.1 percent to 0.65 percent of NaOH or sodium methoxide, 0.1 percent to 1.3 percent of isocyanate activator, 1.9 percent to 13 percent of hexamethylphosphoric triamide (HPT) and 1.9 percent to 19.6 percent of glass beads. The process flow is as follows: (1) the caprolactam is melted at 60 DEG C to 90 DEG C; (2) the glass beads and the flexibilizer HPT are added and dehydrated under vacuum with pressure smaller than 0.2KPa; (3) the catalyzer NaOH or sodium methoxide is added and dehydrated under vacuum again or methanol is added; (4) the isocyanate activator is added, fully and evenly mixed and then poured into a mould quickly; and the fashioned nylon product is obtained after natural cooling and demoulding. The monomer cast nylon prepared by the method is characterized by excellent cold resistance, impact resistance and high tenacity.

Owner:邱玉佩

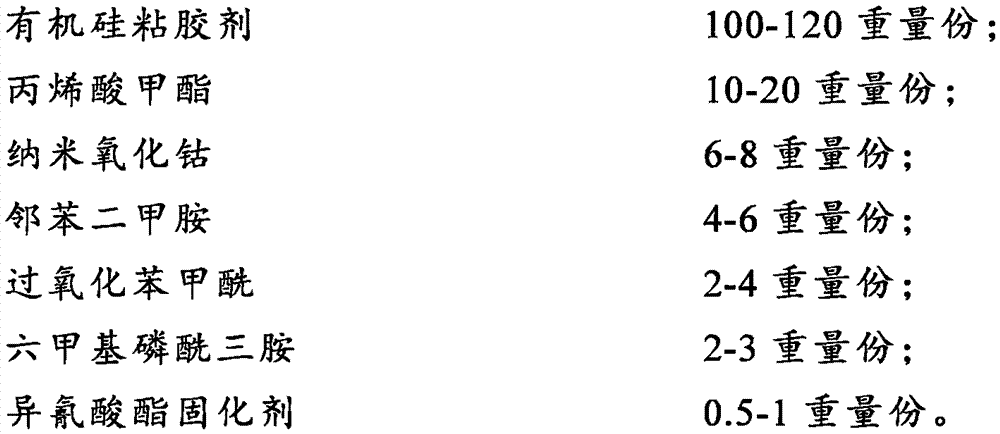

Eye-protective automobile adhesive film and preparation method thereof

ActiveCN105061794AImprove insulation performancePromote absorptionPolyurea/polyurethane coatingsPolyester coatingsTectorial membraneBenzoyl peroxide

Owner:宁波申山新材料科技有限公司

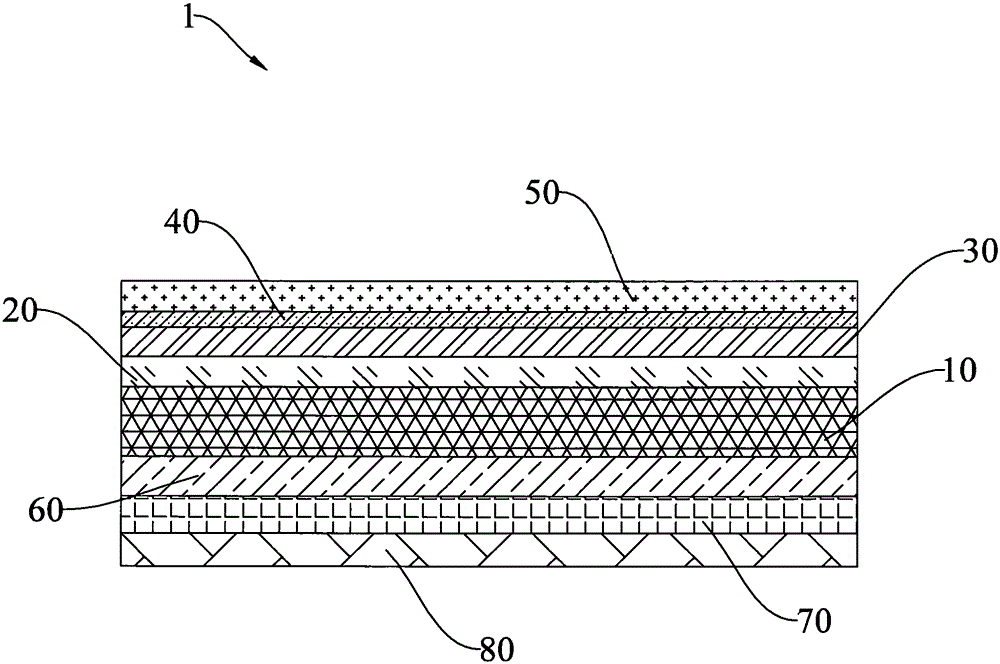

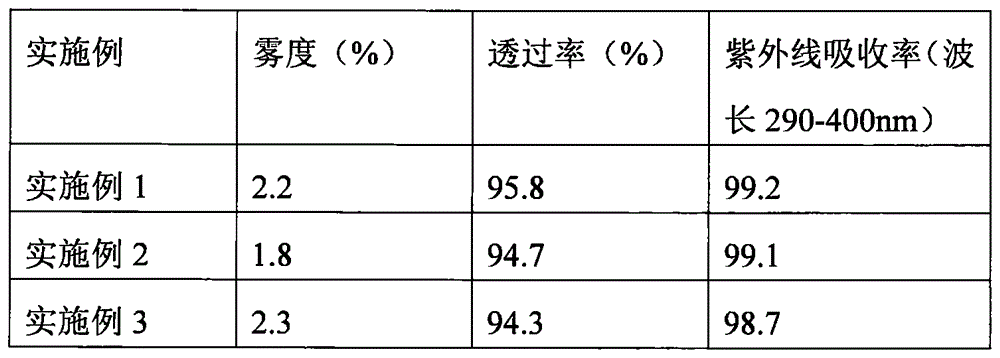

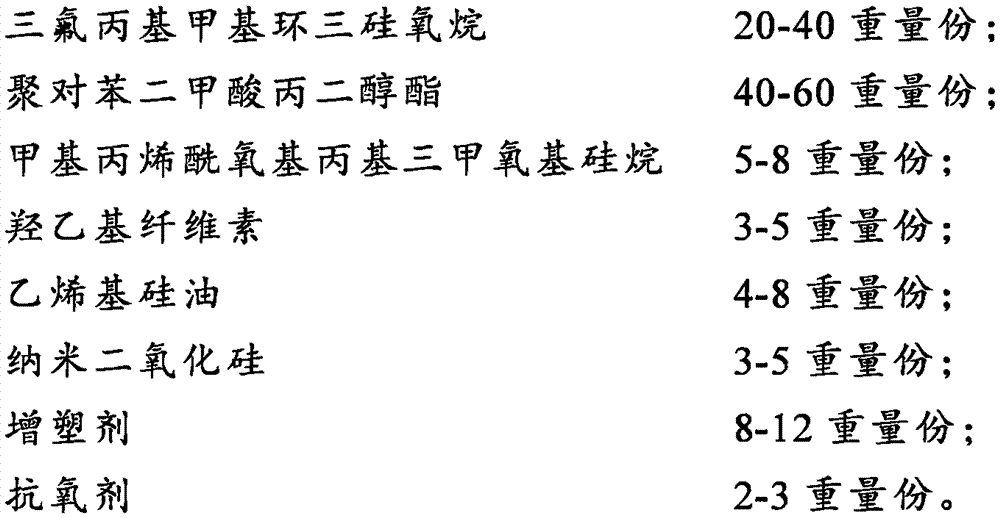

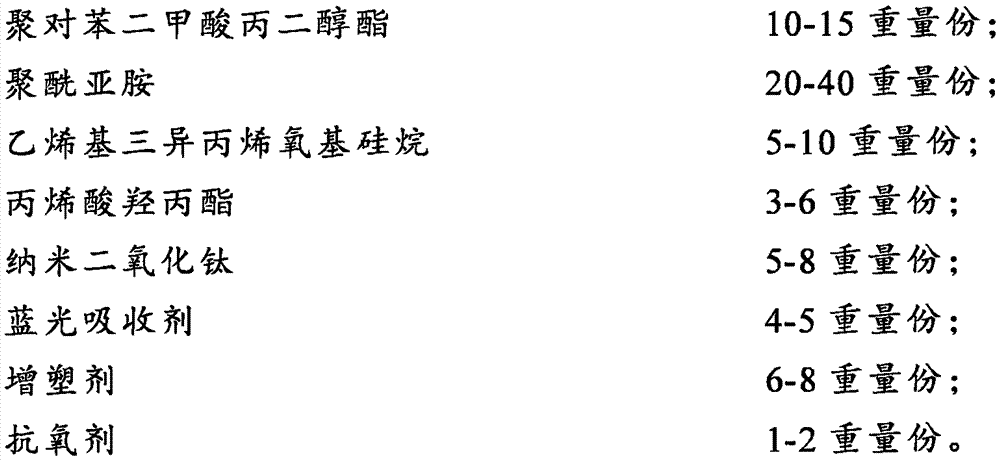

Blue-light-proof film

InactiveCN105445837APromote absorptionImprove the effect of absorbing blue lightNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveBenzoyl peroxideAdhesive

The invention provides a blue-light-proof film. The blue-light-proof film includes a release protection film, a mounting adhesive, a PET layer, a blue-light-proof adhesive sticky layer, a blue light absorbing layer and a wear resistant layer which are arranged sequentially; the blue-light-proof adhesive sticky layer is made of raw materials of an organosilicone adhesive, methyl acrylate, nanometer cobalt oxide, phthalic dimethylamine, benzoyl peroxide, hexamethylphosphoric triamide and isocyanate curing agent. Compared with the prior art, the nanometer cobalt oxide in the blue-light-proof adhesive sticky layer of the blue-light-proof film of the invention can well absorb blue light, and the phthalic dimethylamine and the hexamethylphosphoric triamide act cooperatively so as to further improve a blue light absorbing effect, and thus, the blue-light-proof film can assuredly have an excellent blue light filtering effect. As indicated by experiment results, the blue-light-proof film can filter out about 90% of blue light, and the light transmittance of the blue-light-proof film is more than 90%.

Owner:NINGBO XIAYUAN TECH

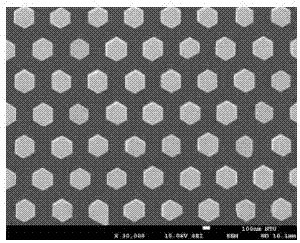

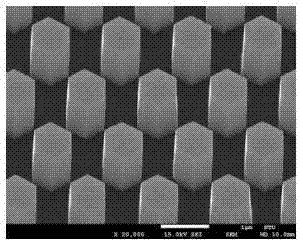

Method for preparing zinc oxide nanopillar array

InactiveCN107344730AReduce manufacturing costHigh degree of orderZinc oxides/hydroxidesHexamethylphosphoramideHexamethylphosphoric Triamide

The invention provides a method for preparing a zinc oxide nanopillar array. According to the method, the current micro-electronic processing technology with technical maturity is utilized. The method comprises the following steps: by taking an aqueous solution of Zn(NO3)2 and hexamethylphosphoramide as a precursor solution for growth of a ZnO nanopillar array on a GaN template with nano-array patterns, preparing the ZnO nanopillar array with ordered height and uniform size through gravity-assisted inverted growth by adopting a hydrothermal method. The nano-array templates of different patterns are manufactured to grow different ZnO nanopillar arrays; and the nanopillar size is regulated by adjusting the concentration of the Zn(NO3)2 and hexamethylphosphoramide and the growth temperature of the nanopillar array. According to the method disclosed by the invention, various ZnO nanopillar arrays with ordered heights and uniform sizes can be prepared by adjusting different process parameters.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

High-pressure PVC (polyvinyl chloride) hose

InactiveCN103554782AImprove antioxidant capacityImprove corrosion resistanceFlexible pipesGlycolurilPolyvinyl chloride

The invention discloses a high-pressure PVC (polyvinyl chloride) hose. The high-pressure PVC hose is characterized by comprising the following raw materials in parts by weight: 70-76 parts of polyvinyl chloride, 1-2 parts of 4, 4'- diphenylmethane diisocyanate, 6-8 parts of stearate, 2-3 parts of powdered butyronitrile, 2-3 parts of hexamethylphosphoric triamide, 2-4 parts of epoxy soybean oil, 2-3 parts of trimethylolpropane, 1-2 parts of aluminium oxide, 3-5 parts of fast extruding carbon black, 3-4 parts of polytetrafluoroethylene, 0.8-2 parts of zirconium silicate, 1-2 parts of tetramethoxy methyl glycoluril and 6-10 parts of composite filler. The high-pressure PVC hose has very high oxidation resistance and corrosion resistance; the added zirconium silicate and powdered butyronitrile are capable of greatly improving the physical properties of the high-pressure PVC hose, and the pressure-resistant property of the high-pressure PVC hose; the high-pressure PVC hose is low in cost.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Anti-fatigue PVC (polyvinyl chloride) cable jacket material and preparation method thereof

InactiveCN104371217AImprove fatigue resistanceNo crackingPlastic/resin/waxes insulatorsCarbon fibersAcrylic rubber

The invention discloses an anti-fatigue PVC (polyvinyl chloride) cable jacket material and a preparation method thereof. The anti-fatigue PVC cable jacket material is prepared from the following raw materials in parts by weight: 42-56 parts of SG-4 type polyvinyl chloride, 24-38 parts of polyhydroxyethyl methylacrylate, 16-24 parts of acrylic rubber, 11-17 parts of vulcanic ash, 10-15 parts of polypropylene glycol adipate, 2-3 parts of calcium stearate, 2-3 parts of barium stearate, 3-5 parts of pentaerythritol ester monooleate, 2.5-4.5 parts of hexadecyl palmitate, 10-15 parts of magnesia, 5-10 parts of carbon nanofiber, 13-19 parts of diethylene glycol dibenzoate, 10-15 parts of calcium hypophosphite, 2-4 parts of hydrogenated terphenyl, 3-5 parts of dimethylpropane carboxylic ether, 6-12 parts of hexamethylphosphoric triamide, 1.5-2.5 parts of 1,1-di(4-hydroxyphenyl)cyclohexane and 15-20 parts of a flame retardant. The cable jacket material disclosed by the invention is good in fatigue resistance, cannot generate cracks and ruptures after 50-100 thousands of times of repeated bending, has characteristics of excellent heat resistance, ageing resistance, chemical corrosion resistance, wear resistance and the like, and is long in service life and wide in application range.

Owner:安徽电信器材贸易工业有限责任公司

Preparation method of film capable of resisting blue rays and protecting eyes

InactiveCN104210196AReduce reflectivityDoes not increase hazeSynthetic resin layered productsLaminationBenzoyl peroxideHexamethylphosphoric Triamide

The invention discloses a preparation method of a film capable of resisting blue rays and protecting eyes. The preparation method comprises the following steps: firstly preparing a base film, compounding a blue ray resisting coating on one surface of the base film and compounding an antireflection anti-scratch coating on the other surface of the base film, wherein the blue ray resisting coating comprises the following components: organosilicon pressure sensitive adhesive, hexamethylphosphoric triamide, butanone, benzoyl peroxide and an organosilicon leveling agent; the antireflection anti-scratch coating comprises the following components: polyurethane acrylate oligomer, dipentaerythritol pentaacrylate, a photoinitiator 184, an organosilicon leveling agent, butanone and silicon oxide water suspension with mass percent of 30%. By virtue of the components of the blue ray resisting coating, the blue ray resisting coating is capable of resisting the blue rays, and haze caused by reduction of the blue rays can not be increased; the antireflection anti-scratch coating is capable of effectively reducing the reflectivity of the protecting film and has the anti-scratch protection function.

Owner:宁波雅歌新材料科技有限公司

Silicon oil for packaging LED (light-emitting diode) and preparation method thereof

InactiveCN103145993AReduce aggregationHigh refractive indexSemiconductor devicesNitrobenzeneRefractive index

The invention provides silicon oil for packaging an LED (light-emitting diode) and a preparation method of the silicon oil. The preparation method comprises the following steps of: mixing methyl cyclosiloxane, phenyl cyclosiloxane, a catalyst, a blocking agent and a promoter to obtain a mixed solution, and performing ring-opening polymerization reaction and purification to obtain the silicon oil for packaging the LED, wherein the promoter is one or more of dimethyl sulfoxide, N,N-dimethylfomamide, hexamethylphosphoric triamide, acetonitrile, nitrobenzene and butanone. According to the preparation method, when the promoter reacts with the raw materials, the promoter can be subjected to solvation with the catalyst to ensure that the aggregation of the catalyst is reduced, the catalytic efficiency is improved, the uniform rearrangement of polymers is favored, and a ring-opening polymerization is balanced, so that the product has uniform composition, and the refractivity and light transmittance of the silicon oil for packaging the LED are effectively improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

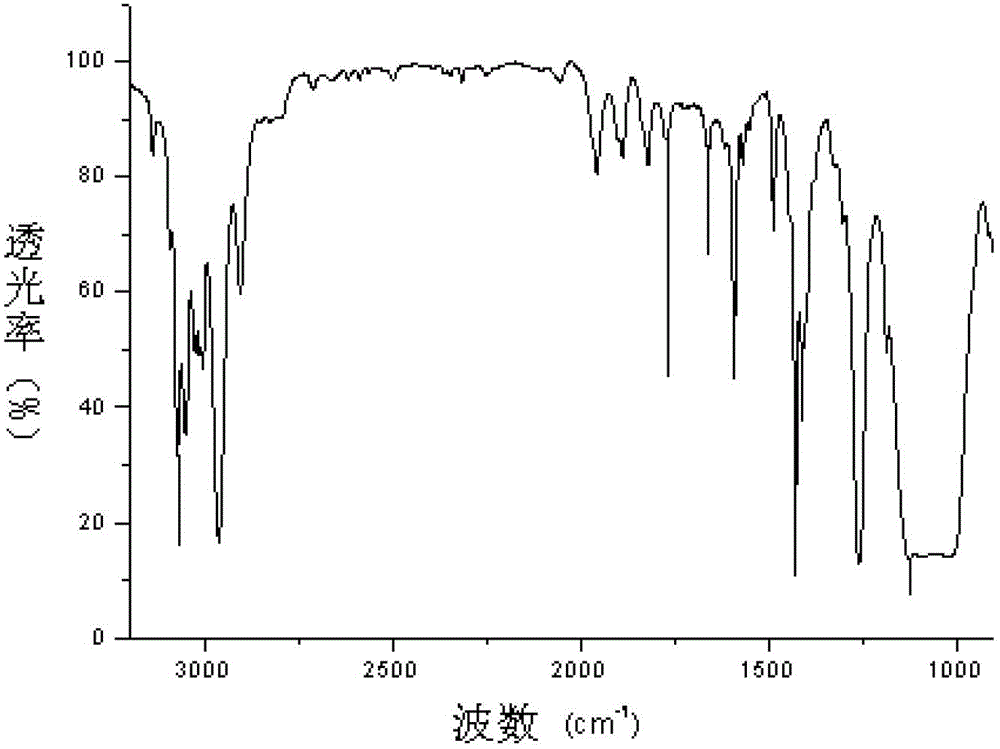

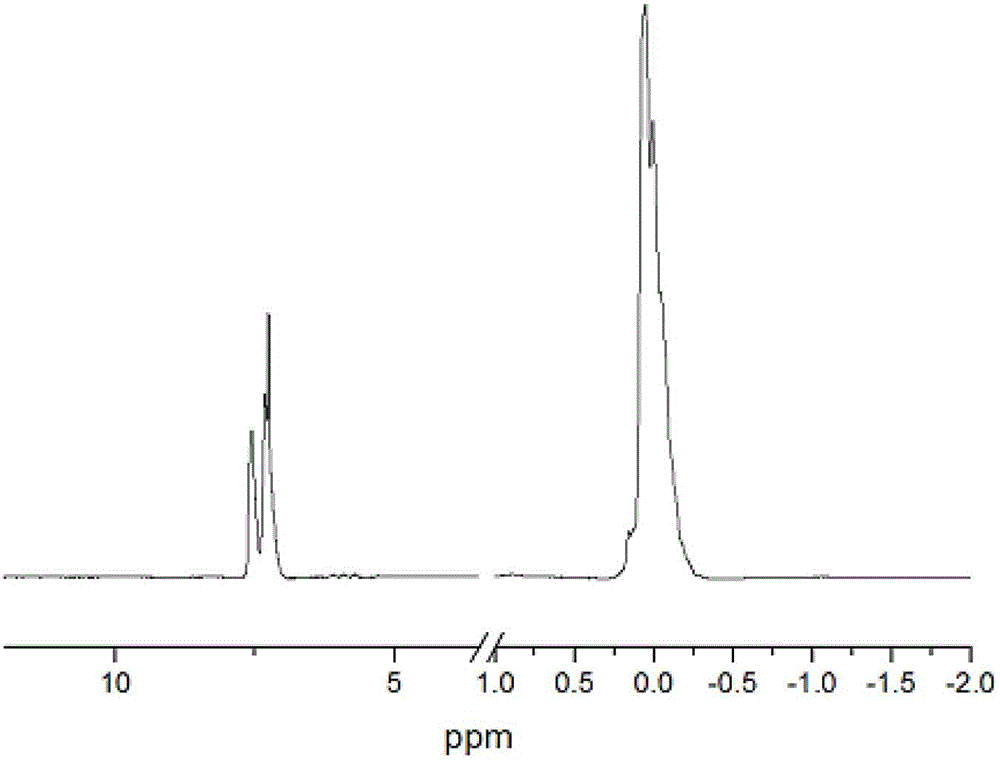

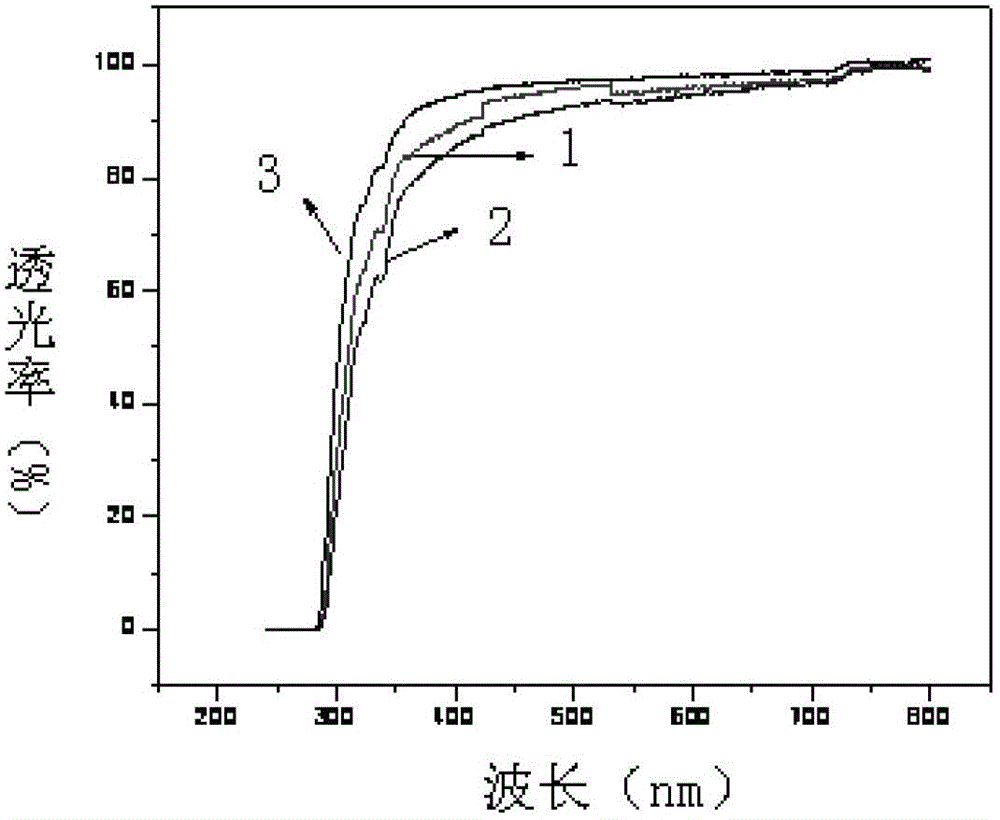

Method for preparing light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n with picric acid detecting function

InactiveCN105622956AGood picric acid detection performanceGood optical stabilityLuminescent compositionsFiltrationHexamethylphosphoric Triamide

The invention discloses a method for preparing a light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n with a picric acid detecting function. Hydrogen sulfide is introduced into an ammonia water solution of tungstic acid to react, and ammonium tetrathiotungstate is prepared through suction filtration and drying; ammonium tetrathiotungstate and cuprous thiocyanate are added into a hexamethylphosphoric triamide solvent to prepare a solution, isonicotinic acid is added into the prepared solution to be stirred and dissolved, and after a red clear solution is prepared, the pH of the solution is adjusted to range from 8 to 10; a solution of terbium trinitrate is added into the red clear solution, and the light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n is obtained through crystallization, filtration, washing and drying. The method has the advantage that the light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n capable of efficiently detecting picric acid is obtained.

Owner:JIANGNAN UNIV

Novel polyvinyl chloride (PVC) noise-reduction drainage pipe

The invention discloses a novel polyvinyl chloride (PVC) noise-reduction drainage pipe which is prepared from the following components in parts by weight: 50-70 parts of PVC resin, 1-3 parts of plasticizer, 5-10 parts of hexamethylphosphoric triamide, 15-50 parts of barium sulfate, 5-10 parts of thermoplastic polyurethane elastomer, 10-20 parts of plastic resin, 1-2 parts of chlorinated paraffin wax and 10-12 parts of flame retardant. The drainage pipe has the following advantages: excellent noise-reduction effect: the high-density special molecular structure material is utilized to absorb the energy of sound waves, so the noise-reduction effect is better than that of any other pipeline, and the noise value of conventional drainage can be down to 45db below; and favorable shock resistance: the polypropylene material has excellent toughness, can not crack when being subjected to superhigh impact, and can not break even if the pipe is flattened, thereby ensuring the pipe to have favorable shock resistance.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

Synthetic gasoline and preparation method thereof

InactiveCN102994174AImprove operational safetyImprove securityLiquid carbonaceous fuelsDibenzoyl PeroxideP-Cresol

The invention relates to synthetic gasoline. The synthetic gasoline is characterized by being formed by adding 99.5% alcohol, naphtha, acetone, toluene, methyl tertiary butyl ether, octane, ferrocene, 2,6-ditertiary butyl p-cresol, polyisobutene, polyvinyl pyrrolidone, Span 85, middle-base-value synthetic calcium sulfonate, isopropyl ether, cerous nitrate, hexamethylphosphoric triamide and benzoyl peroxide into a stainless steel pot according to certain weight parts to be agitated and mixed. The synthetic gasoline disclosed by the invention takes industrial alcohols as main raw materials and is low in cost; a preparation method is simple; the boiling point of the synthetic gasoline is high, the heat stability is good and the sufficient combustion efficiency is high; the synthetic gasoline has smoke elimination and combustion supporting effects, reduces the carbon-depositing and anti-explosion effect of a nozzle, prolongs the service life of an engine, reduces the environmental pollution and has good safety; and the synthetic gasoline has no corrosion on a fuel oil pipeline and can be directly used on Santana sedan cars and Dongfeng 5-tonnage trucks, the equal effect of 93# gasoline is achieved, the oil price is reduced by more than 20% and the economical efficiency is good.

Owner:刘伟

Novel multi-layer composite polyvinyl chloride antibacterial pipeline

InactiveCN110154476AImprove toughnessImprove anti-aging propertiesSynthetic resin layered productsRigid pipesHexamethylphosphoric TriamidePolyvinyl chloride

The invention relates to a novel multi-layer composite polyvinyl chloride antibacterial pipeline. The novel multi-layer composite polyvinyl chloride antibacterial pipeline comprises an outer layer, anintermediate layer and an inner layer which are successively arranged from outside to inside, wherein the intermediate layer comprises the following components by weight: 60 to 80 parts of PVC resin,10 to 30 parts of an impact modifier, 10 to 30 parts of a toughening modifier, 3 to 6 parts of a stabilizer, 1 to 3 parts of a lubricant, 2 to 5 parts of a coupling agent, 0 to 15 parts of a fillingagent and 1 to 4 parts of hexamethylphosphoric triamide. The novel multi-layer composite polyvinyl chloride antibacterial pipeline provided by the invention increases the toughness of a PVC pipe, endows an antibacterial effect to the PVC pipe at the same time, improves the anti-aging ability of the PVC pipe, and enables the PVC pipe to obtain strong comprehensive performance.

Owner:福建亚通新材料科技股份有限公司

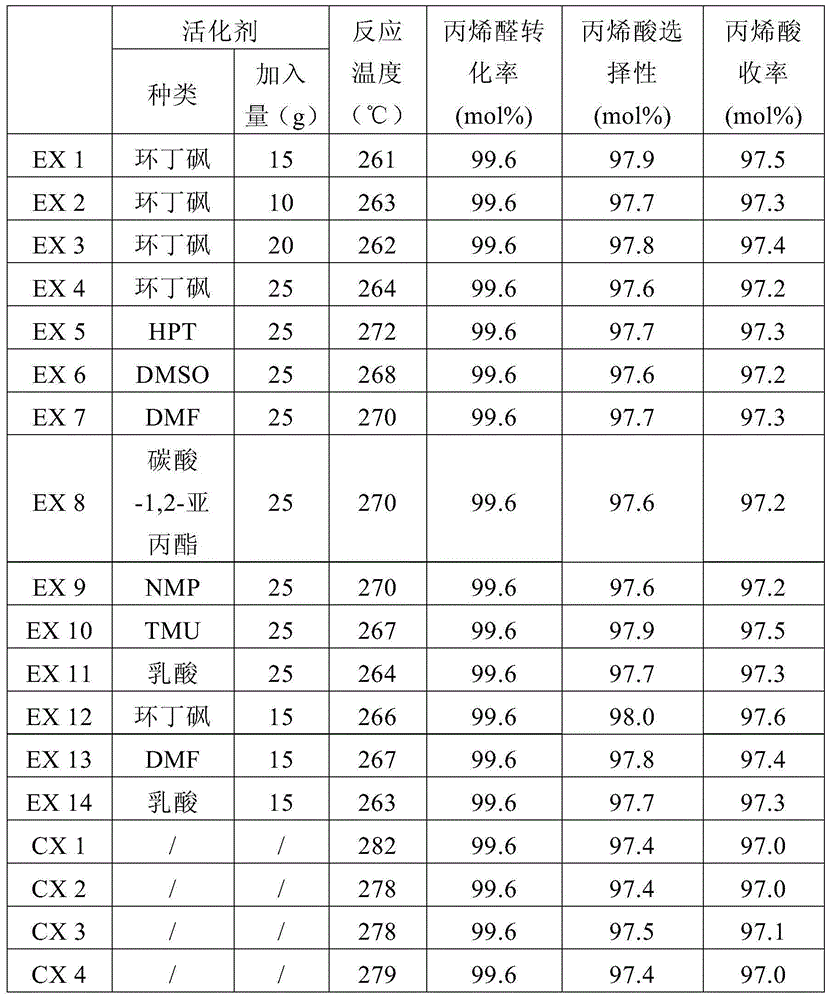

Modified composite oxide catalyst and modification method

ActiveCN104646014AHigh activityOrganic compound preparationCarboxylic compound preparationSulfolaneHexamethylphosphoric Triamide

The invention discloses a modified composite oxide catalyst and a modification method. The catalyst comprises a catalyst precursor shown in a following general formula, wherein X is at least one of Nb, Sb, Te, Ce, La, Nd, Sm, Cs and Ge; Y is at least one of Mg, Ca, Sr and Ba; a is 1-10; b is 0-6; c is 0-7; d is 0-4; e is 0-5; f is a value determined by n oxidation state of the composition elements; Z is simple substance silicon; wherein the catalyst precursor is activated by the following steps: 1)according to weight of the catalyst precursor, adding 5-100wt% of hexamethyl phosphoric triamide, dimethyl sulfoxide, N,N-dimethyl formamide, carbonic acid-1,2-propylene, sulfolane, N-methyl 2 pyrrolidone, 1,1,3,3-tetramethylurea and lactic acid; 2)drying for 2-28 hours at 60-250 DEG C in oxygen containing gas; 3)forming; and 4)calcinating for 1-24 hours under 350-410 DEG C in oxygen containing gas. Mo12VaCubWcXdYeOf / Z (1).

Owner:SHANGHAI HUAYI NEW MATERIAL

Salt spray resistant metal surface silane treatment agent and preparation method thereof

InactiveCN103254778AImprove adhesionExtended service lifeAnti-corrosive paintsEnvironmental resistanceSilanes

The invention discloses a salt spray resistant metal surface silane treatment agent, which is a mixed solution prepared from the following components. Per liter of the mixed solution comprises the following components by weight (g): 25-30 of propyltrimethoxy silane, 15-25 of vinyltrimethoxy silane, 4-5 of sodium hexametaphosphate, 1-2 of tetrahydrofuran, 5-7 of hexamethylphosphoric triamide, 3-4 of citric acid, 6-7 of sorbitol, 2-4 of a film-forming agent, and the balance water. The treatment process of the salt spray resistant metal surface silane treatment agent produced in the invention generates no dreg, the treatment time is short, and the control is simple and convenient. Being free of harmful heavy metal ions, the salt spray resistant metal surface silane treatment agent is safe and environment-friendly, and can form a silane coating having excellent corrosion resistance with a metal surface, thus prolonging the service life of metals.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

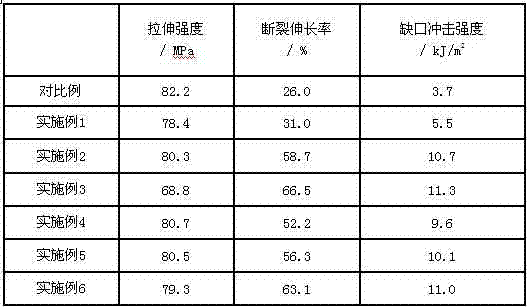

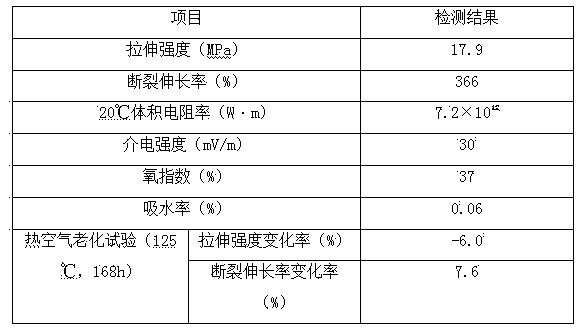

Preparation method for composite material of cast nylon/attapulgite clay

The invention discloses a preparation method for a composite material of cast nylon / attapulgite clay. The preparation method includes the steps as follows: firstly, preparing suspension colloid by hexamethylphosphoric triamide, attapulgite clay and toluene diisocynate in given proportion; adding the suspension colloid as a function modifier of the cast nylon in caprolactam polymerization monomer;and taking sodium hydroxide-toluene diisocynate as a catalyzing-activating system and triggering caprolactam anionic ring-opening polymerization, and finishing polymerization in a mould at normal pressure and simultaneously moulding. The preparation technology is simple and high efficient and has an industrial practical value; and for the prepared composite material of cast nylon / attapulgite clay, on the basis that the high stretching strength of the common cast nylon is kept, the toughness and the impact resistance are effectively reinforced, and the prepared composite material can meet the using requirements of substituting for non-ferrous metal and alloy steel to manufacture mechanical parts in multiple industrial fields.

Owner:黄秋环

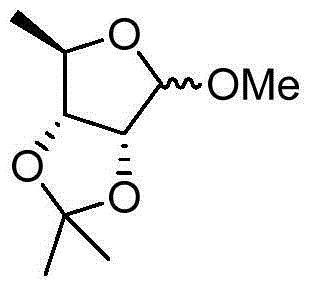

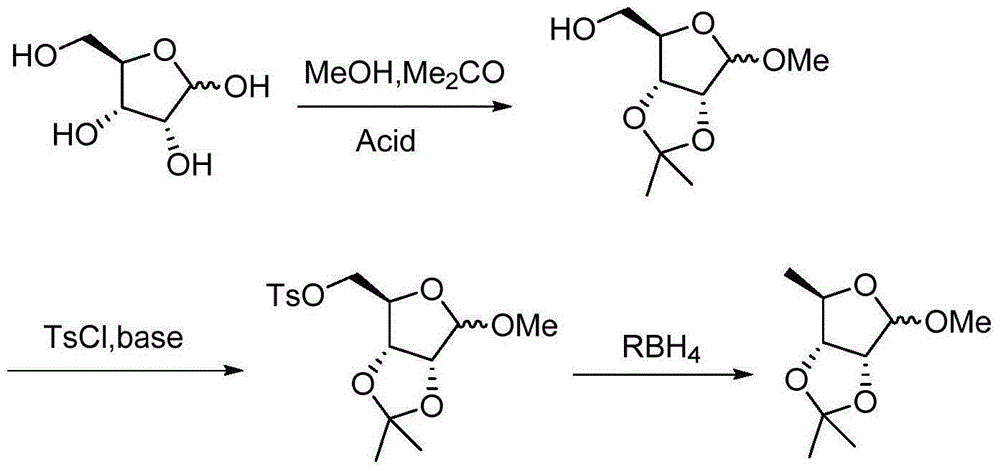

Preparation method of methyl-2,3-O-isopropylidene-5-deoxy-D-ribofuranoside

InactiveCN105037453ANo purification requiredMild conditionsSugar derivativesSugar derivatives preparationProper treatmentReaction intermediate

The invention discloses a preparation method of methyl-2,3-O-isopropylidene-5-deoxy-D-ribofuranoside. The method comprises: taking D-ribose as an initial material to obtain methyl-2,3-O-isopropylidene-D-ribofuranoside under the protection of methanol / acetone; reacting methyl-2,3-O-isopropylidene-D-ribofuranoside with paratoluensulfonyl chloride to obtain methyl-2,3-O-isopropylidene-5-O-paratoluenesulfonyl-D-ribofuranoside in alkaline condition, wherein the reaction is subjected to proper treatment and needs no purification; taking hexamethylphosphoric triamide or N,N-dimethyl-2-imidazolidinone as a reducing solvent; and using hydroboron for reduction to obtain methyl-2,3-O-isopropylidene-5-deoxy-D-ribofuranoside. The reducing reaction agent can be recycled; the reaction intermediates are subjected to proper treatment and need no purification; and the preparation method is simple to operate, wild in condition, and low in production cost.

Owner:启东东岳药业有限公司

High-adhesive force interior wall coating material and preparation method thereof

The invention discloses a high-adhesive force interior wall coating material. The high-adhesive force interior wall coating material is prepared from the following raw materials in parts by weight: 40-50 parts of styrene acrylic emulsion, 20-26 parts of modified adhesive, 20-25 parts of mica powder, 20-25 parts of nanometer calcium carbonate, 2-3 parts of hydroxyethyl cellulose, 2-3 parts of allyl alcohol, 3-4 parts of ethylene glycol, 3-4 parts of sodium tripolyphosphate, 1-2 parts of hexamethylphosphoric triamide, 2-3 parts of 2,2,4-trimethyl-1,3-pentanediol mono(2-methylpropanoate), 3-4 parts of sodium ethylenediamine tetramethylene phosphonate, 0.2-0.3 part of calcium-zinc stabilizer, 0.8-1 part of gamma-3-aminopropyl triethoxysilane and 20-40 parts of deionized water. The formula components of the high-adhesive force interior wall coating material have good compatibility, dispersibility and temperature property; a coating formed by the prepared coating material product is firm, safe and environmentally-friendly and has smooth surfaces, strong adhesive force, washing resistance, acid-base resistance and strong contamination resistance; the cohesiveness of the coating is further enhanced due to the addition of the modified adhesive, so that the coating is unlikely to fall off, and the property of the coating material is improved.

Owner:ANHUI ZHENXIN PAINT

Preparation method of acidic cross-linking agent

ActiveCN105061486AOvercome many deficiencies in the preparation processSuitable for industrial mass productionGroup 4/14 element organic compoundsCross-linkChemical reaction

The invention relates to a preparation method of an acidic cross-linking agent, which belongs to the technical field of organic chemistry. According to the invention, propyl trimethoxy silane and glacial acetic acid are taken as raw materials; hexamethylphosphoric triamide is taken as a catalyst, the acidic cross-linking agent product can be synthesized through a group exchange reaction, in the reaction process, by-product methanol is steamed out of the reaction system, and chemical reaction moves to the direction of generation of the acidic cross-linking agent. The method is a substitution method of the acidic cross-linking agent, the method technology is simple and is suitable for industrial scale production, compared with the current preparation method of the acidic cross-linking agent, the by-product with strong corrosivity and difficult treatment can not be generated; no side reaction for influencing the product quality of the acidic cross-linking agent is generated; especially the product content. In addition, the raw materials do not contain chlorine, so that the prepared acidic cross-linking agent product has low free chlorine.

Owner:JINGZHOU JIANGHAN FINE CHEM

Novel synthetic fuel and preparation method thereof

InactiveCN108315066ASave resourcesSolve the dwindling problemLiquid carbonaceous fuelsFuel additivesZinc peroxideParaffin wax

The invention provides novel synthetic fuel and a preparation method thereof. The novel synthetic fuel is prepared from the following components in parts by weight: 40 to 60 parts of methanol, 15 to 30 parts of crude benzene, 5 to 10 parts of xylol, 4 to 8 parts of tert-butyl alcohol, 2 to 4 parts of trimethyl butane, 0.3 to 0.5 part of n-hexane, 15 to 25 parts of methyl tert-butyl ether, 15 to 20parts of water, 4 to 6 parts of paraffin wax, 3 to 6 parts of magnesium oxide, 15 to 25 parts of acetone, 2 to 4 parts of hydrogen peroxide, 0.8 to 1.2 parts of dicyclopentadieny iron, 0.5 to 1 partof cyclopentadienyl tricarbonyl manganese, 4 to 6 parts of dimethylaniline, 2 to 4 parts of zinc butyl octyl dithiophosphate, 0.3 to 0.8 part of zinc peroxide, 2 to 4 parts of hexamethylphosphoric triamide, 15 to 25 parts of trimethyl phosphate and 6 to 8 parts of lubricant. The novel synthetic fuel can replace gasoline to be applied to automobiles and has good anti-detonation performance, stability, safety, corrosion resistance and low cost; petroleum resources are greatly saved and the problem that the petroleum resources are exhausted day by day is effectively solved.

Owner:河南世源新能源科技有限公司

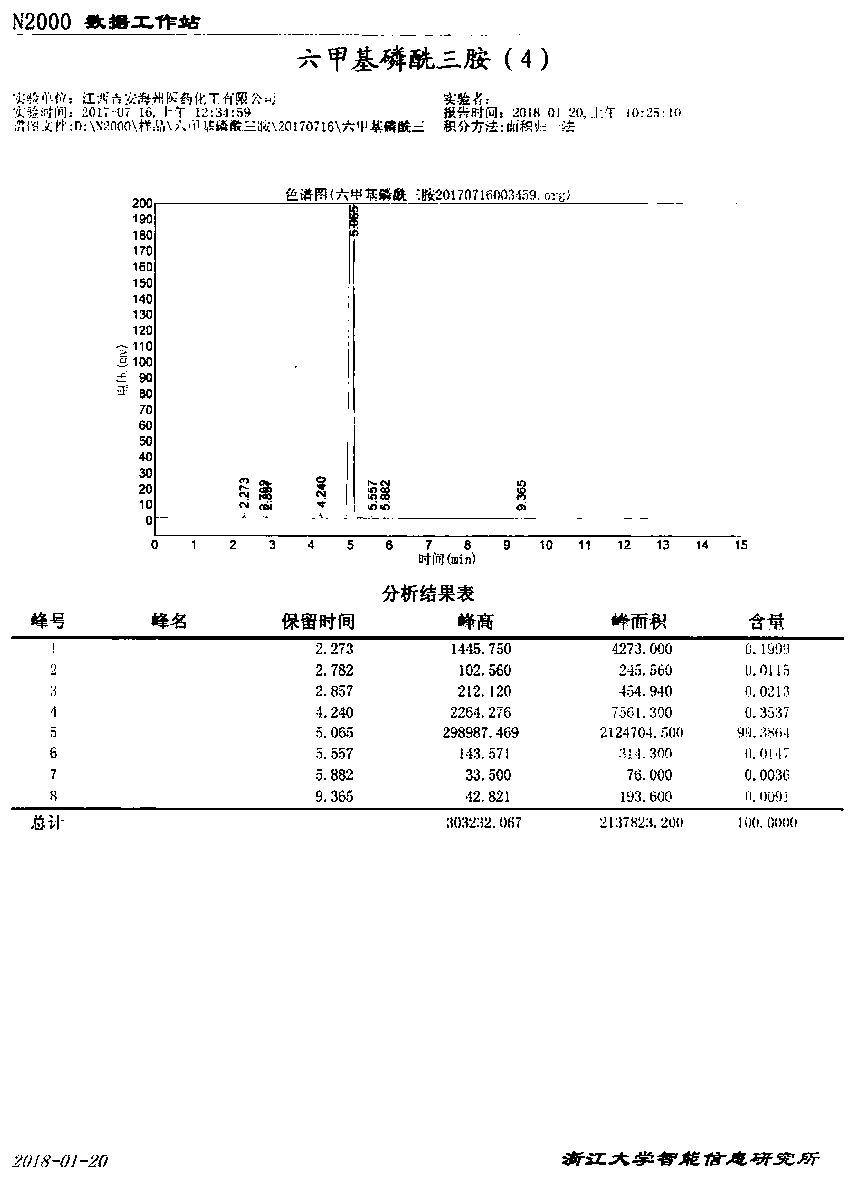

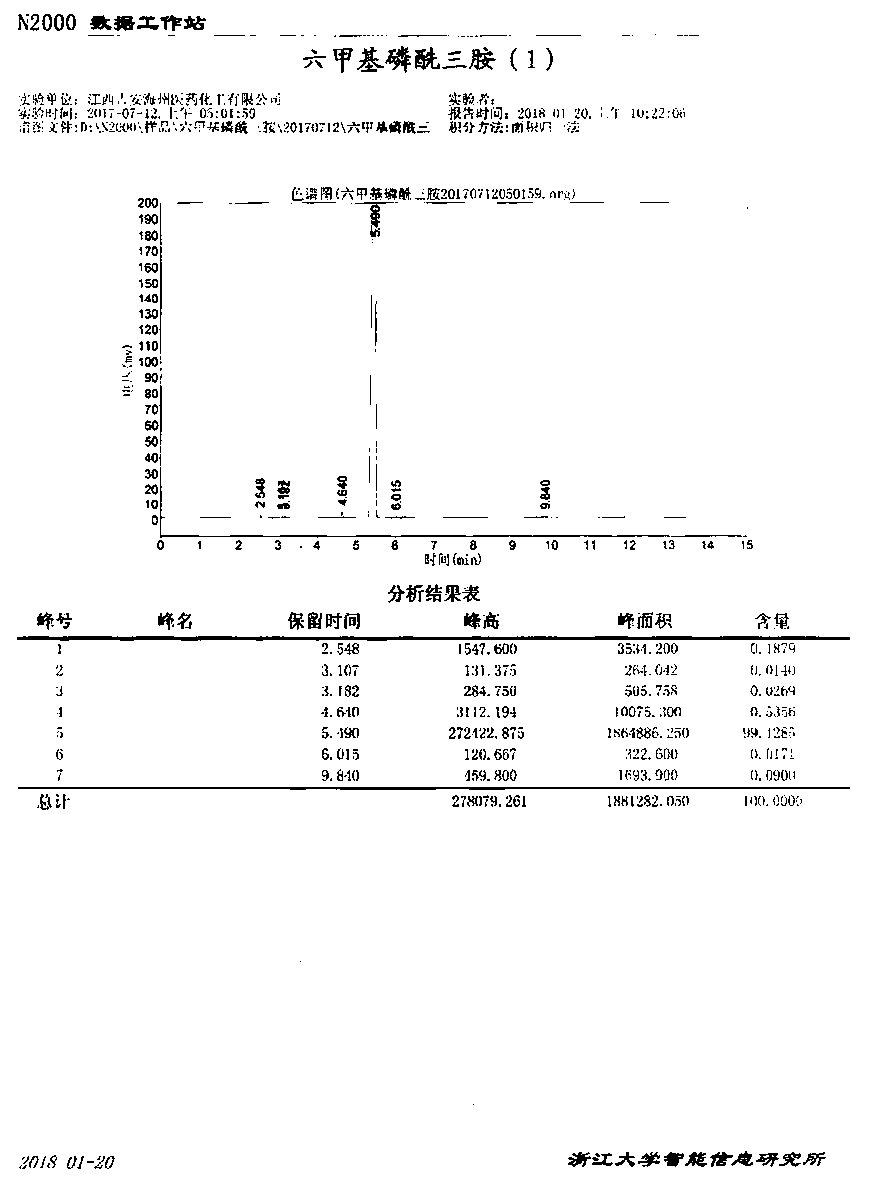

Method for simultaneously preparing hexamethylphosphoric triamide and dimethylamine hydrochloride

InactiveCN108892687AOrganic compound preparationGroup 5/15 element organic compoundsOrganic solventHexamethylphosphoric Triamide

The invention discloses a method for simultaneously preparing hexamethylphosphoric triamide and dimethylamine hydrochloride. The method comprises the following steps: (1) substitution reaction: takingphosphorus oxychloride and dimethylamine as main raw materials, taking low-polarity organic solvents capable of mutually solving with hexamethylphosphoric triamide, such as industrial xylene, methylbenzene, cyclohexane and methyl cyclohexane, as solvents, controlling the initial temperature of reaction at 25-60 DEG C and controlling the temperature in later stage at 50-70 DEG C; (2) aftertreatment: performing solid-liquid separation on the reaction liquid after the ending of the substitution reaction, thereby acquiring the solid, namely, dimethylamine hydrochloride, and then performing liquidrectification on recovered solvent, thereby acquiring hexamethylphosphoric triamide with the content above 99%. The method for simultaneously preparing hexamethylphosphoric triamide and dimethylaminehydrochloride, provided by the invention, has the advantages of small side effect, high yield, high content, simplicity in subsequent treatment and capability of turning the waste, namely side products, into wealth.

Owner:JIAN HAIZHOU CHEM CO LTD

Modified organic glass with excellent toughness and preparing method thereof

The invention discloses modified organic glass with excellent toughness. The modified organic glass is prepared from methyl methacrylate, modified polybutyl acrylate, blocked type polyether F-68, benzoyl peroxide, triethylene glycol, hydroxyethyl methylacrylate, dibutyltin dilaurate, toluene diisocyanate, hexamethylene diisocyanate, azodiisobutyronitrile, ethylene propylene terpolymer, polyvinylbutyral, mercaptopropionic acid, hydroxypropyl methyl cellulose, trioctyl citrate, hexamethylphosphoric triamide, polyaspartic acid, isopropylxanthic disulfide, calcined kaolin, a silane coupling agent KH-570 and nanosilicon dioxide. The invention further provides a preparing method of the modified organic glass with the excellent toughness. The prepared modified organic glass has excellent toughness.

Owner:安徽亚克力实业有限公司

Formula of multi-walled PVC for communication pipe

InactiveCN106987070APlay a protective effectExtended service lifeHexamethylphosphoric TriamideRare earth

The invention discloses a formula of multi-walled PVC for a communication pipe. The multi-walled PVC is prepared from 60 to 100 parts by weight of PVC resin, 4 to 7 parts by weight of calcium stearate, 2 to 7 parts by weight of dioctyl picaprate, 1 to 3 parts by weight of styrene-butadiene rubber, 2 to 8 parts by weight of a lubricant, 0.5 to 3 parts by weight of PE wax, 6 to 8 parts by weight of hexamethylphosphoric triamide, 1 to 2 parts by weight of a rare earth stabilizer, 2 to 3 parts by weight of polyethylene wax and 0.5 to 1.3 parts by weight of an auxiliary agent. The multi-walled PVC is prepared from the PVC resin as the main raw material. Through high temperature and high pressure extrusion molding, the impact resistance, the high temperature resistance, the cold resistance and the long service life are obtained. The multi-walled PVC is used for laying an underground communication pipe, can protect a communication optical cable and cable, realizes a low cost and is suitable for promotion and application.

Owner:东台市荣达塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n with picric acid detecting function Method for preparing light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n with picric acid detecting function](https://images-eureka.patsnap.com/patent_img/c284ea16-9f27-4b74-864e-5798cfbcc2bc/HDA0000943377730000011.PNG)

![Method for preparing light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n with picric acid detecting function Method for preparing light-emitting crystal material [WS4Cu4(SCN)4Tb2(INA)4(HMPA)8]n with picric acid detecting function](https://images-eureka.patsnap.com/patent_img/c284ea16-9f27-4b74-864e-5798cfbcc2bc/HDA0000943377730000012.PNG)