Formula of environment-friendly packaging box

An environmentally friendly, carton technology, applied in the field of corrugated paper manufacturing, can solve the problems of white pollution, poor impact resistance, serious problems, etc., and achieve the effects of protecting the environment, improving flame retardancy, and improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A formula for environmentally friendly packaging cartons, the formula of the environmentally friendly packaging cartons includes wood pulp, starch, polyvinyl alcohol resin, phthalic anhydride, high boiling pure lignin, micronized aluminum hydroxide, nonylphenol polyoxyethylene Ether, methyl methacrylate, dibutyl phthalate, hexamethylphosphoric triamide, diatom mud, sodium higher fatty acid, deionized water.

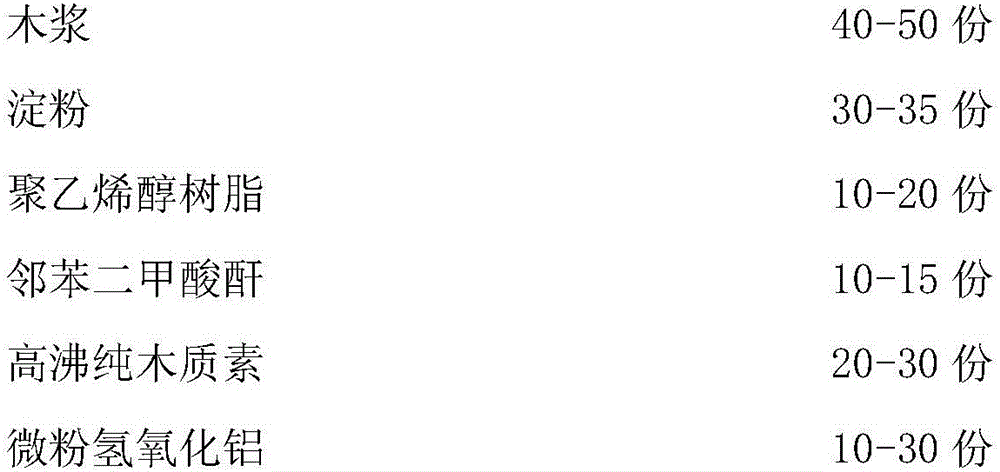

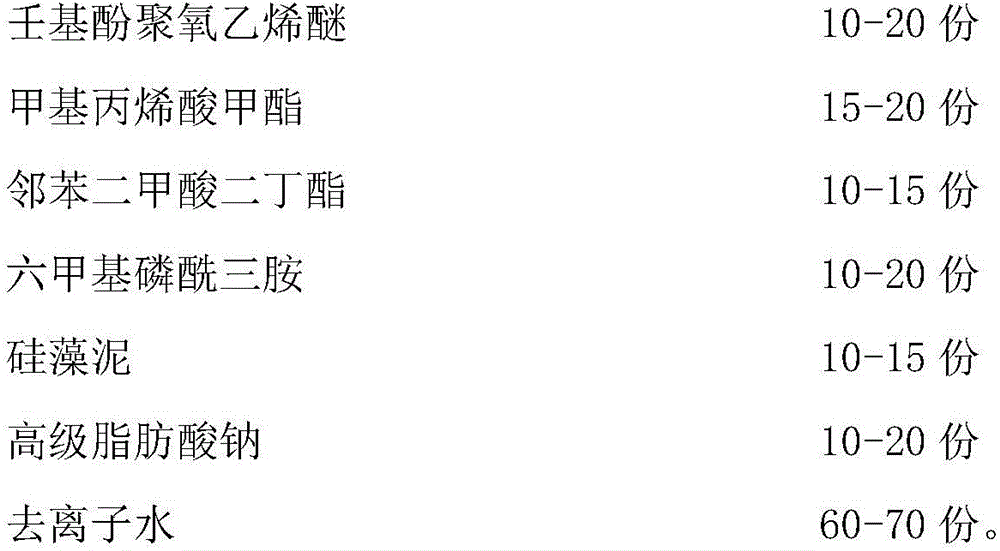

[0014] The consumption (mass parts) of each raw material is:

[0015]

Embodiment 2

[0017] A formula for environmentally friendly packaging cartons, the formula of the environmentally friendly packaging cartons includes wood pulp, starch, polyvinyl alcohol resin, phthalic anhydride, high boiling pure lignin, micronized aluminum hydroxide, nonylphenol polyoxyethylene Ether, methyl methacrylate, dibutyl phthalate, hexamethylphosphoric triamide, diatom mud, sodium higher fatty acid, deionized water.

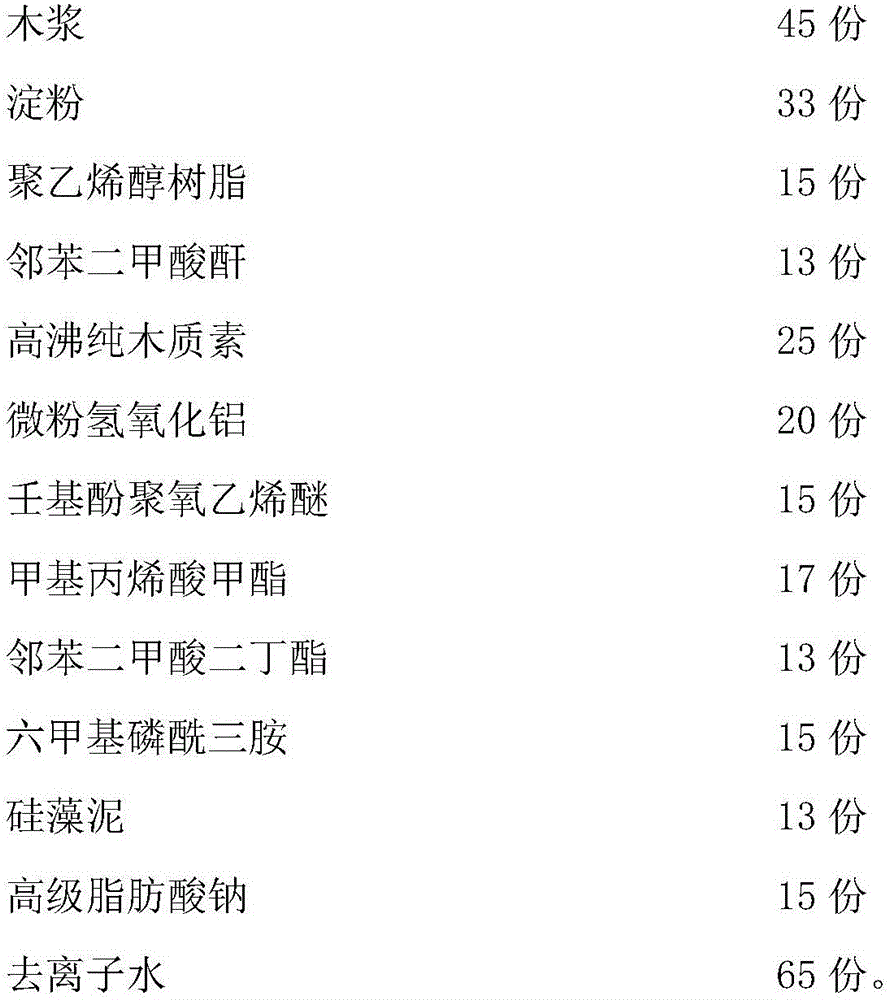

[0018] The consumption (mass parts) of each raw material is:

[0019]

[0020]

Embodiment 3

[0022] A formula for environmentally friendly packaging cartons, the formula of the environmentally friendly packaging cartons includes wood pulp, starch, polyvinyl alcohol resin, phthalic anhydride, high boiling pure lignin, micronized aluminum hydroxide, nonylphenol polyoxyethylene Ether, methyl methacrylate, dibutyl phthalate, hexamethylphosphoric triamide, diatom mud, sodium higher fatty acid, deionized water.

[0023] The consumption (mass parts) of each raw material is:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com