Patents

Literature

543results about "Ignifugeants addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ionic Liquid Flame Retardants

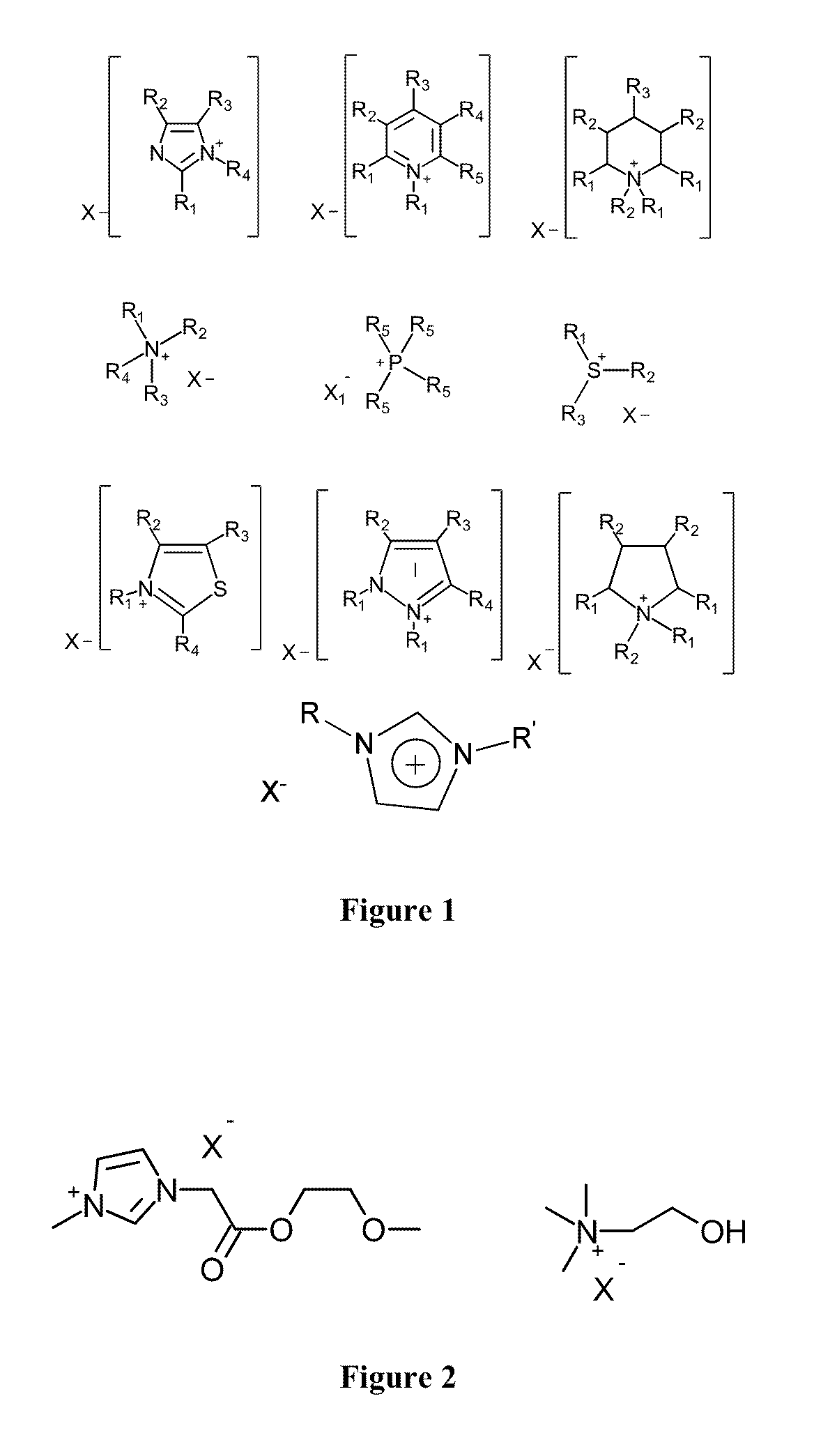

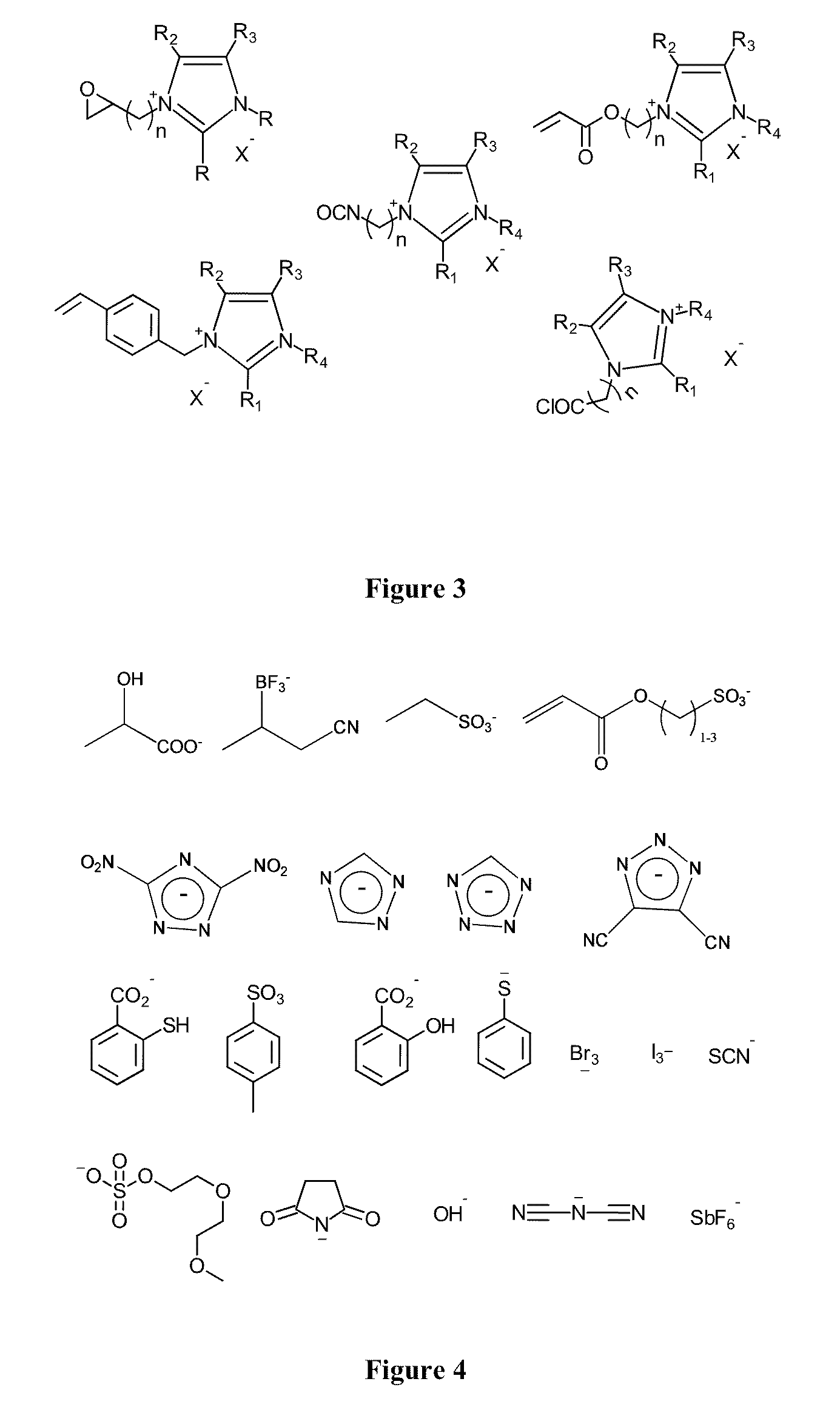

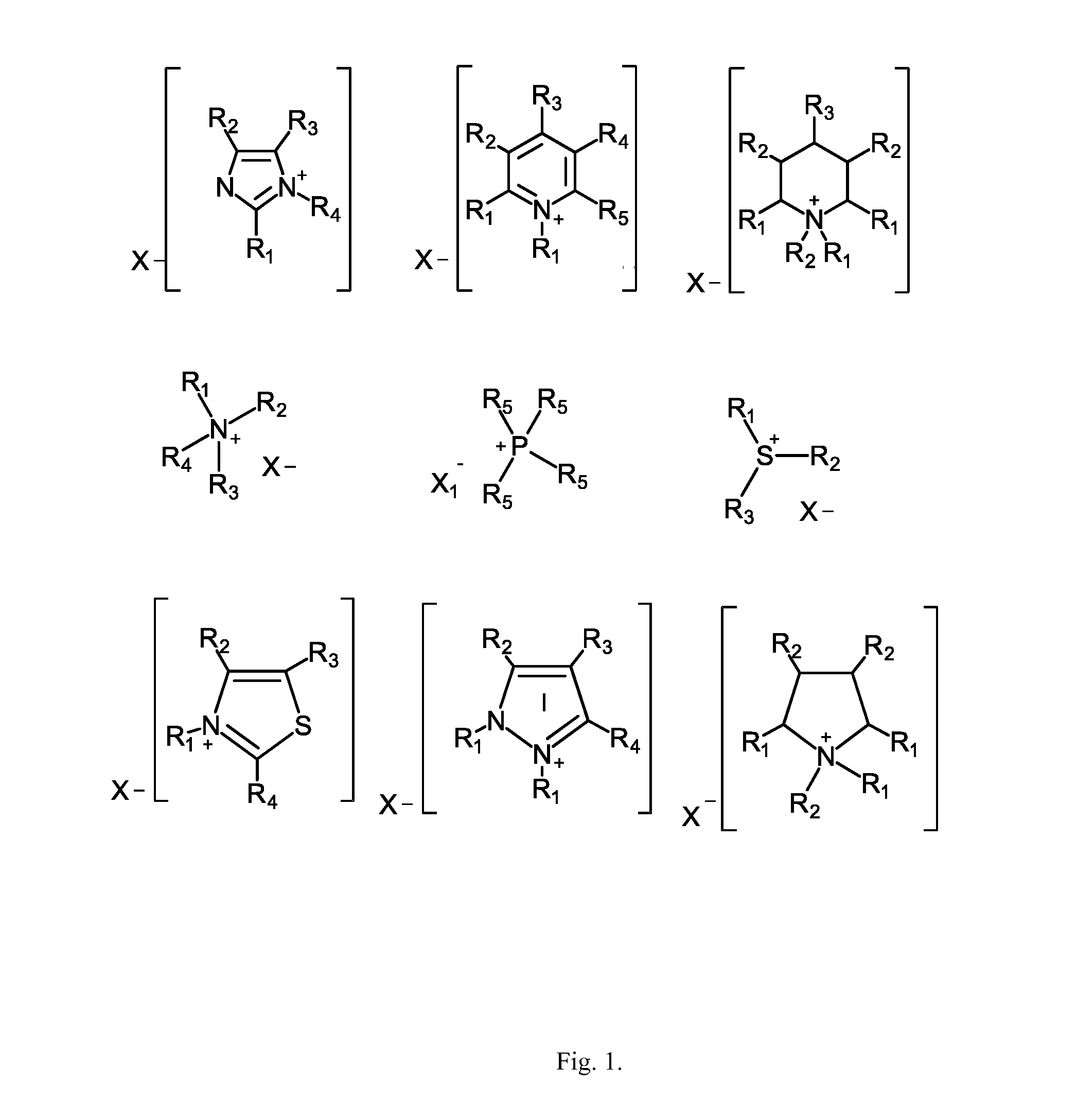

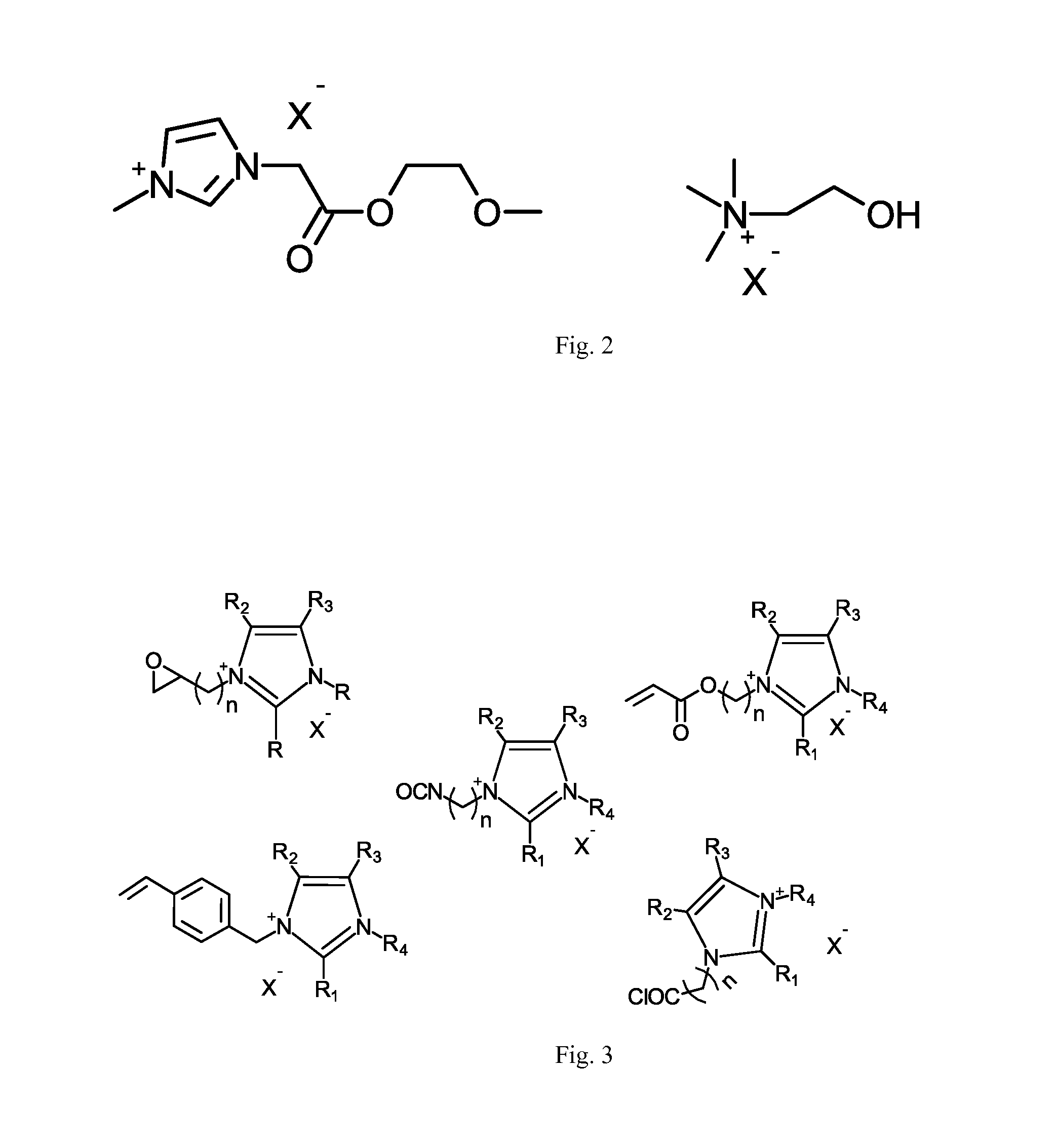

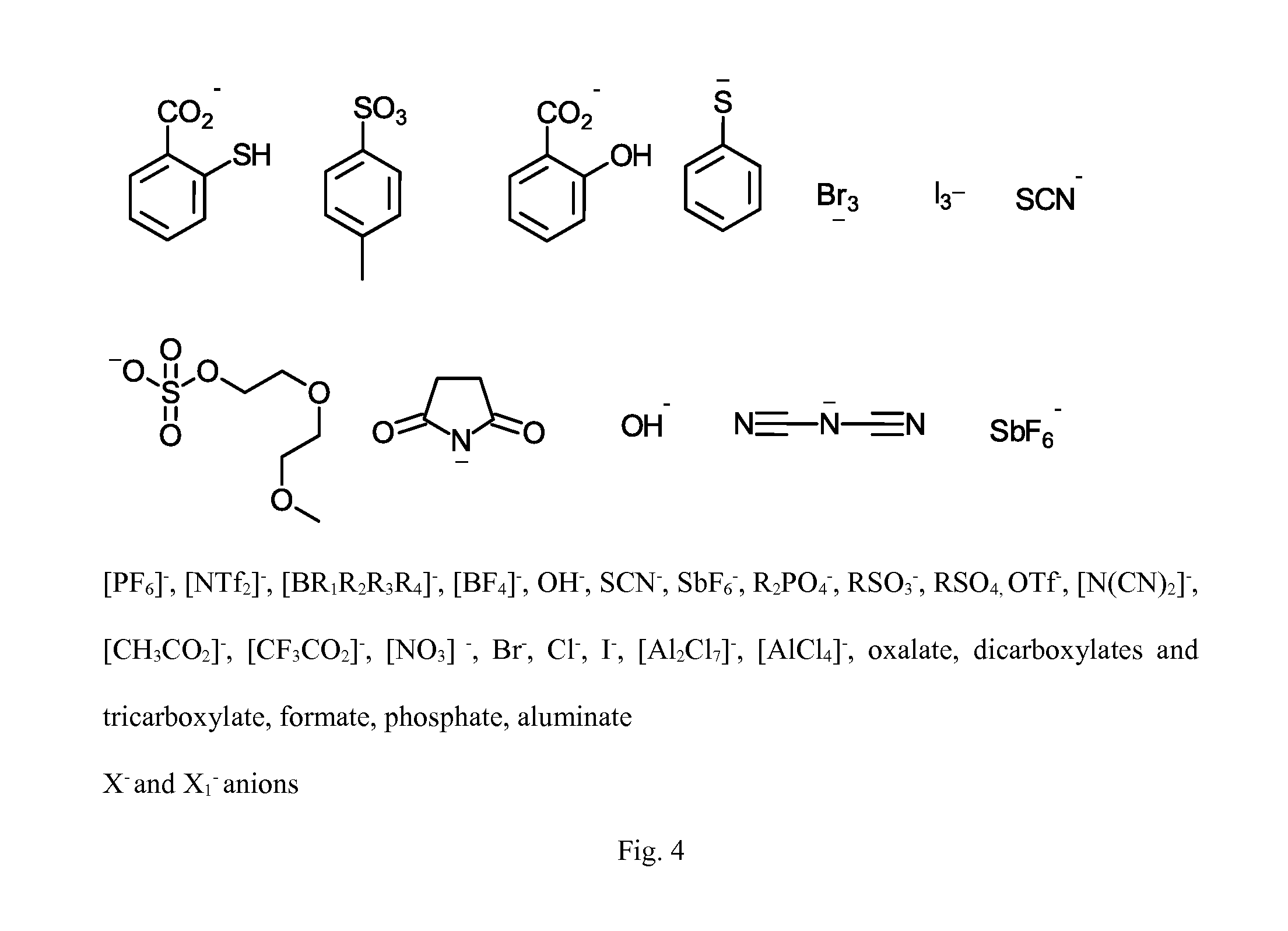

ActiveUS20110073331A1Excellent resistance to migrationPromote leachingPretreated surfacesHeat resistant fibresFire retardantIonic liquid

The present invention relates to the use of ionic liquids as flame retardants. The compounds of the invention may be used as flame retardants in various materials without causing damage to the environment and or health of humans or animals. Ionic liquid flame retardants maybe applied alone or in combination with traditional flame retardants. Ionic liquid flame retardants can be applied to finish textile, plastic, leather, paper, rubber or as wild fire flame retardants.

Owner:INOVIA MATERIALS (HANGZHOU) CO LTD

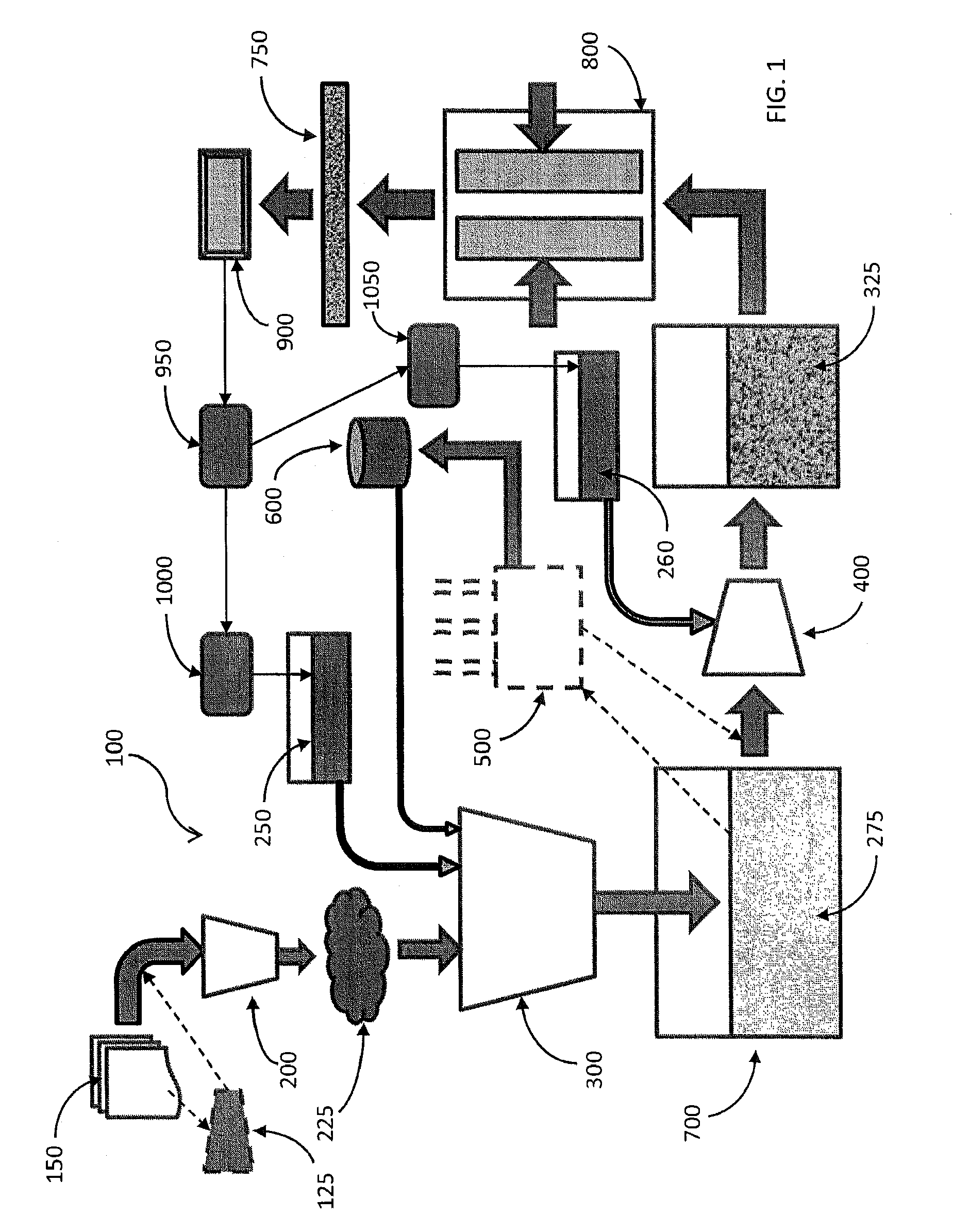

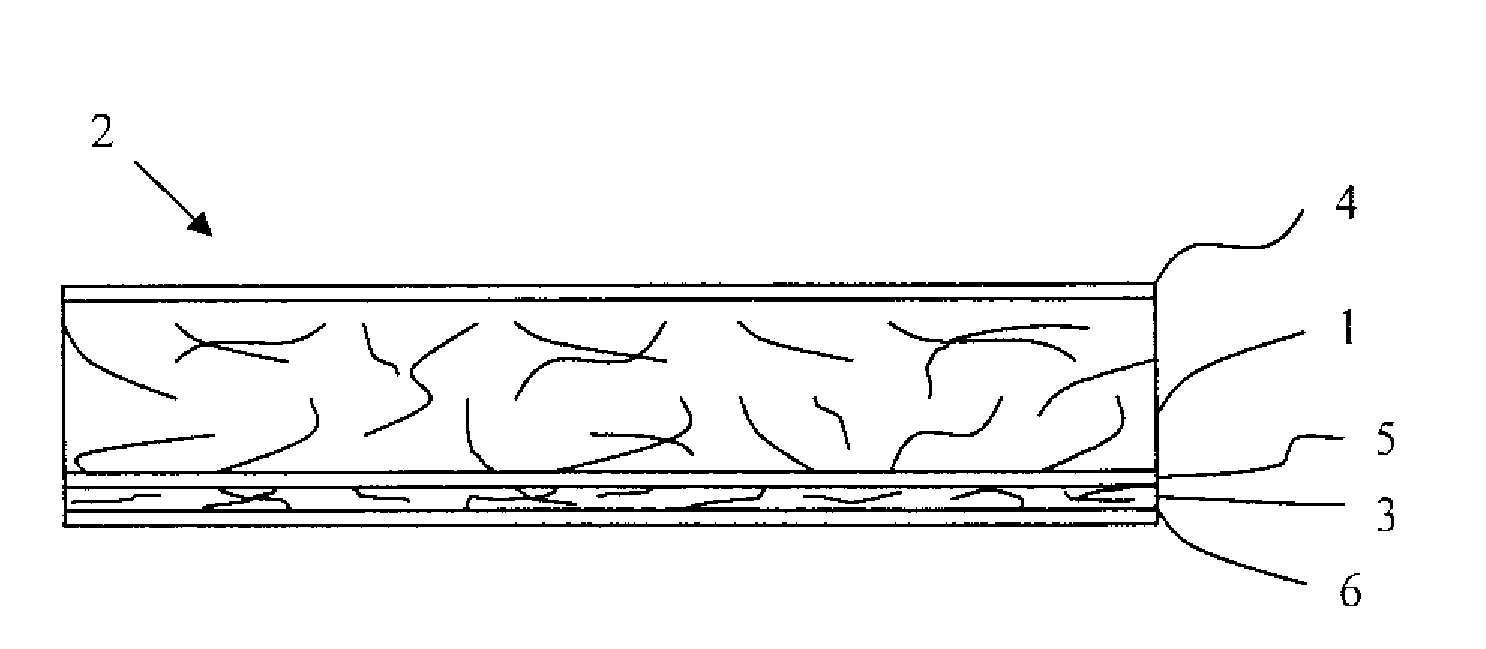

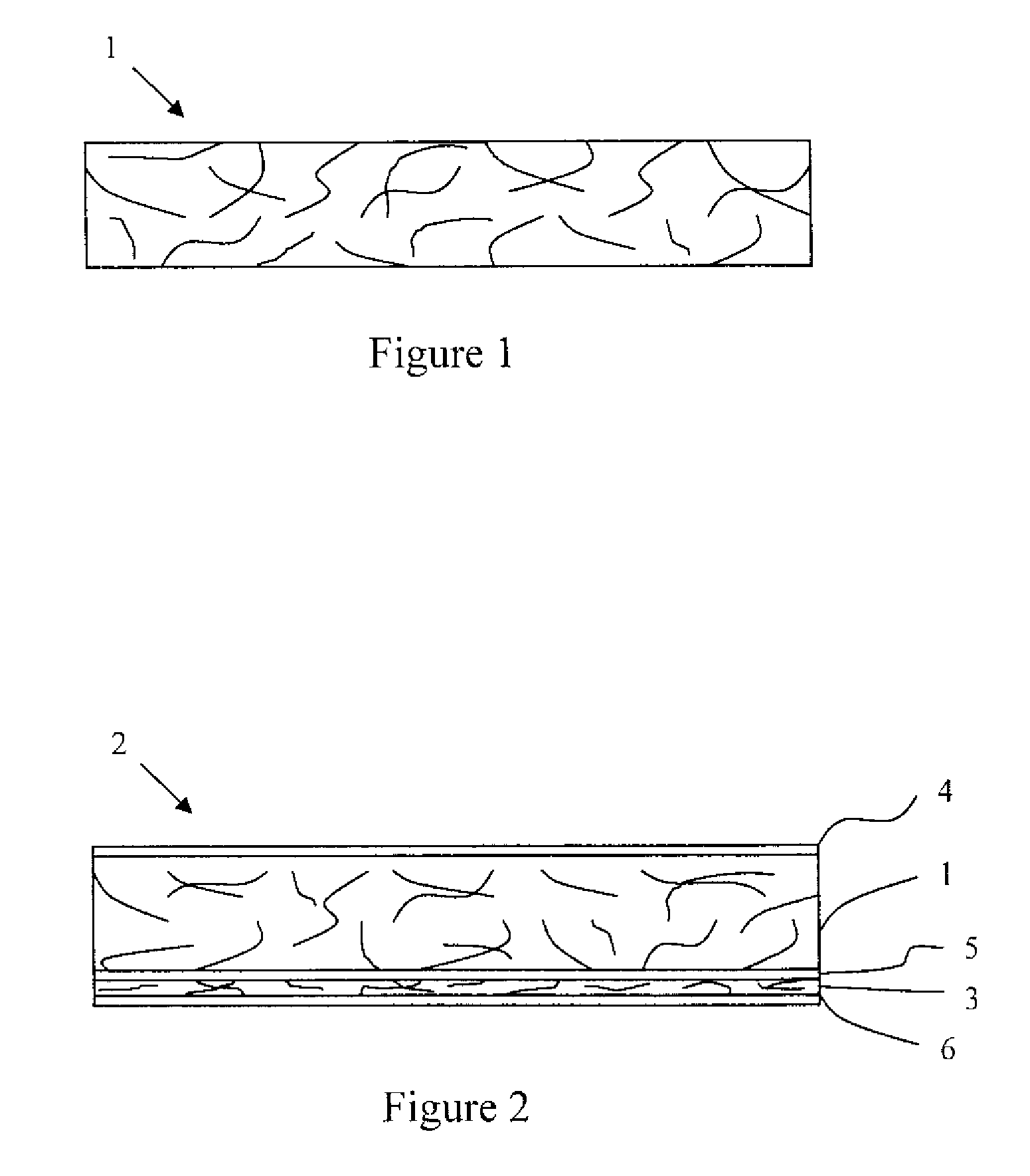

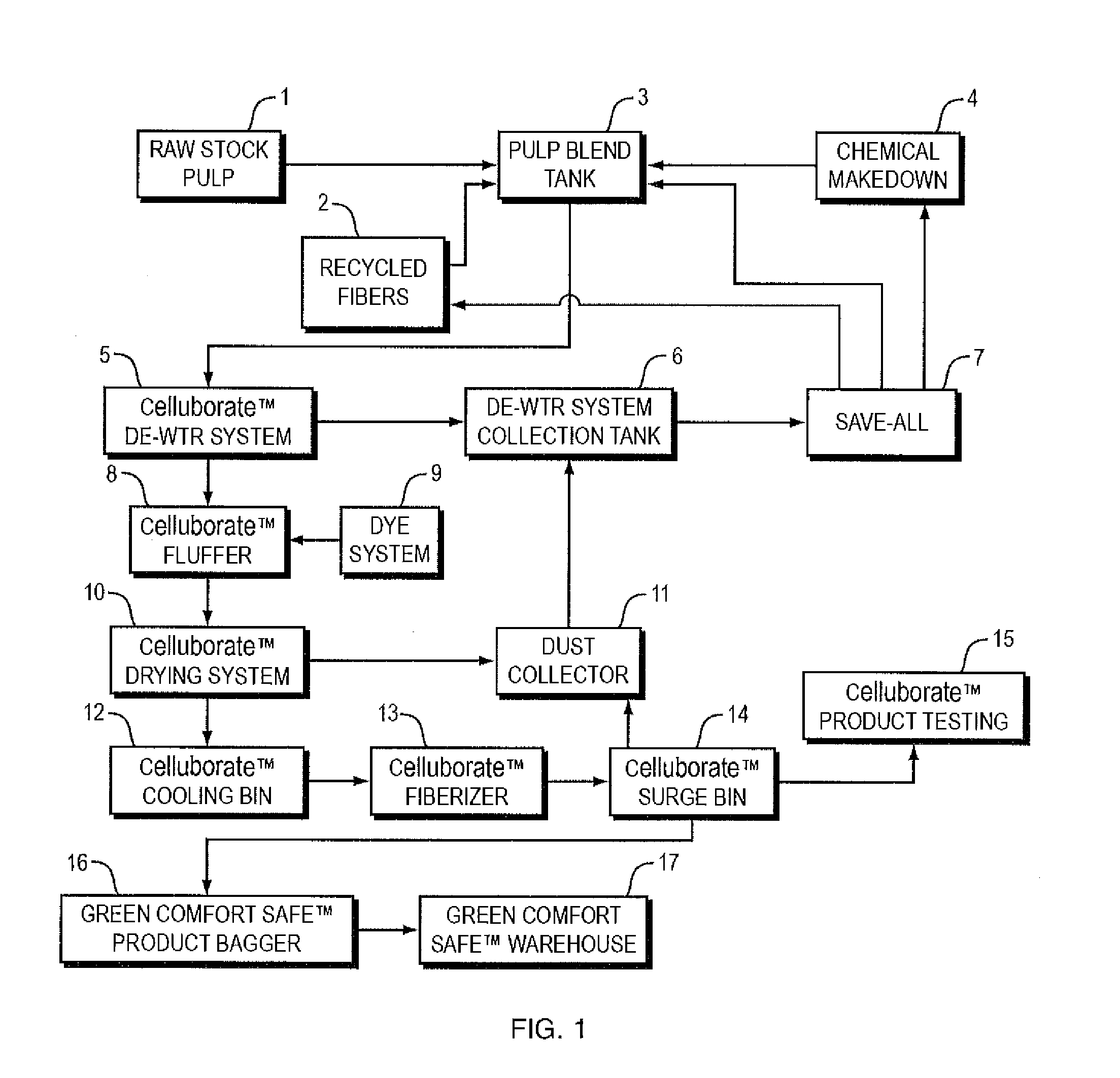

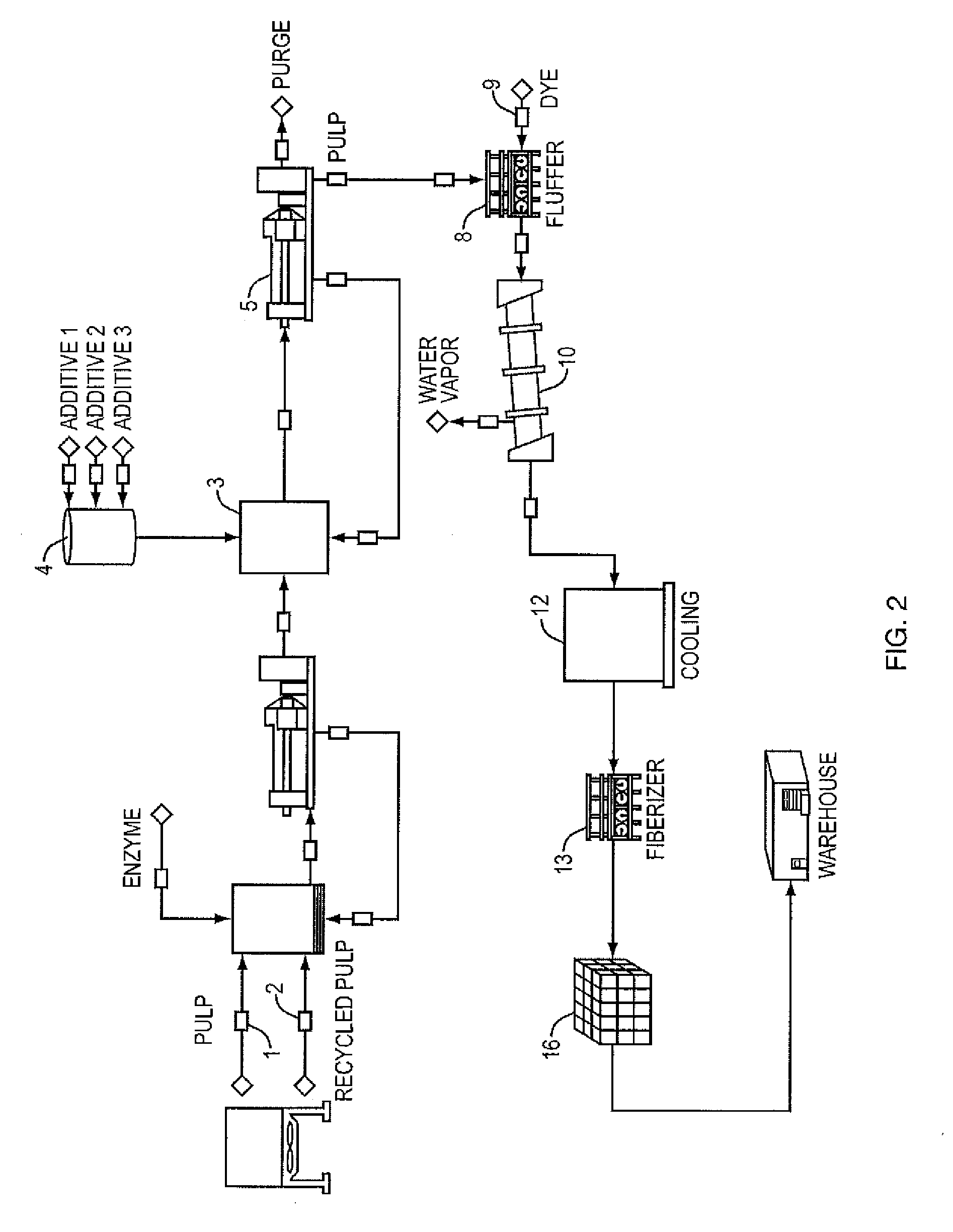

Fire retardant nonwoven material and process for manufacture

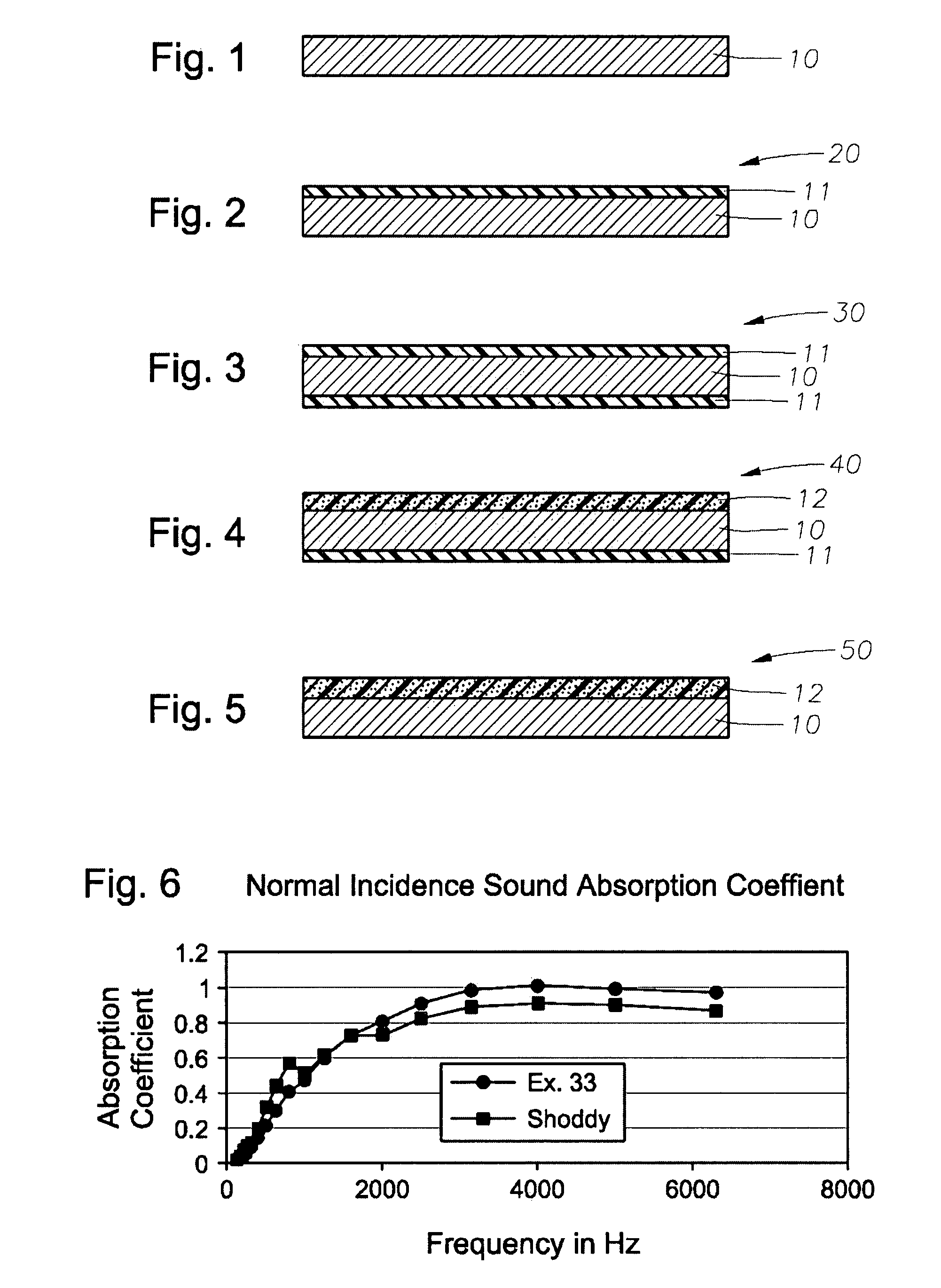

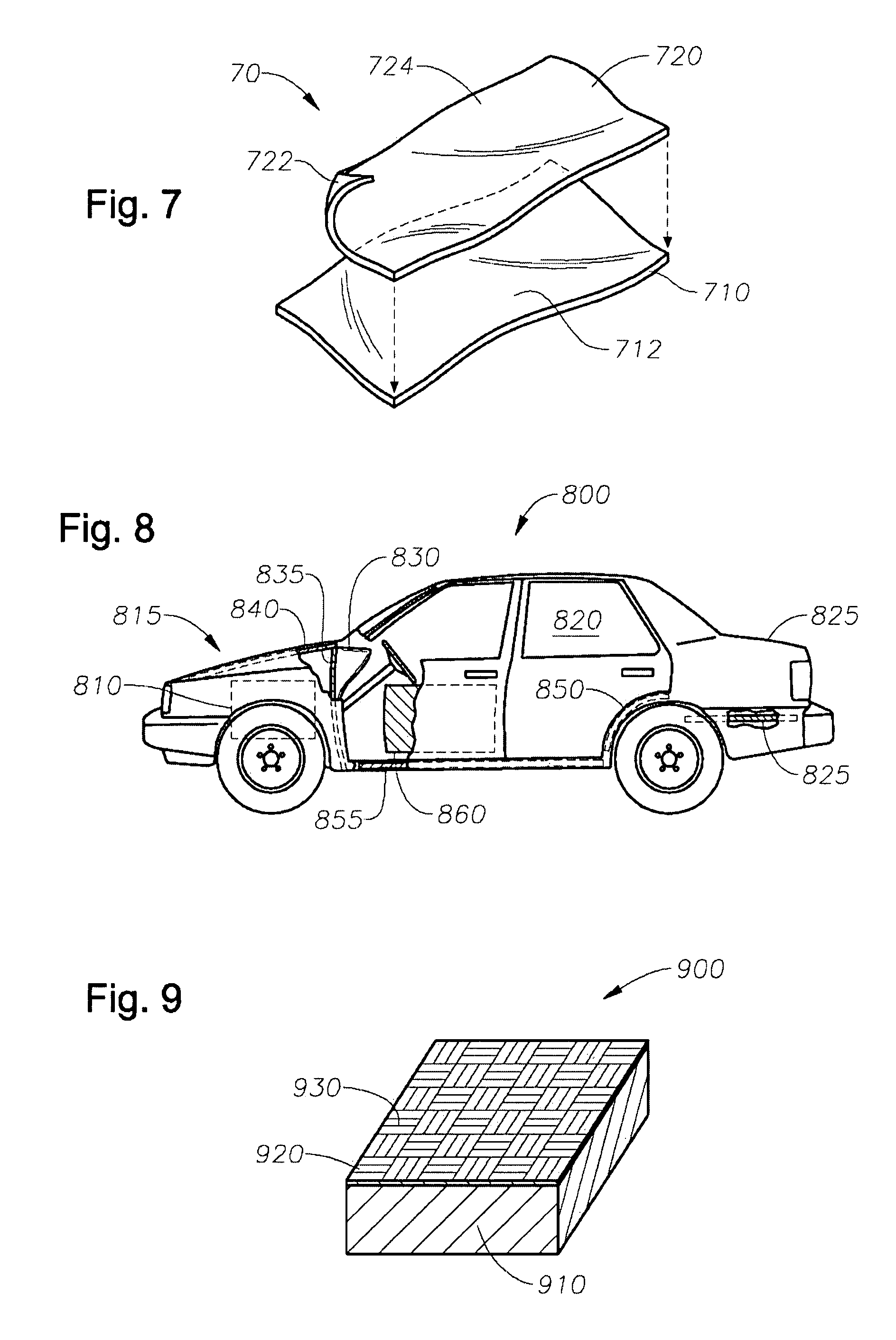

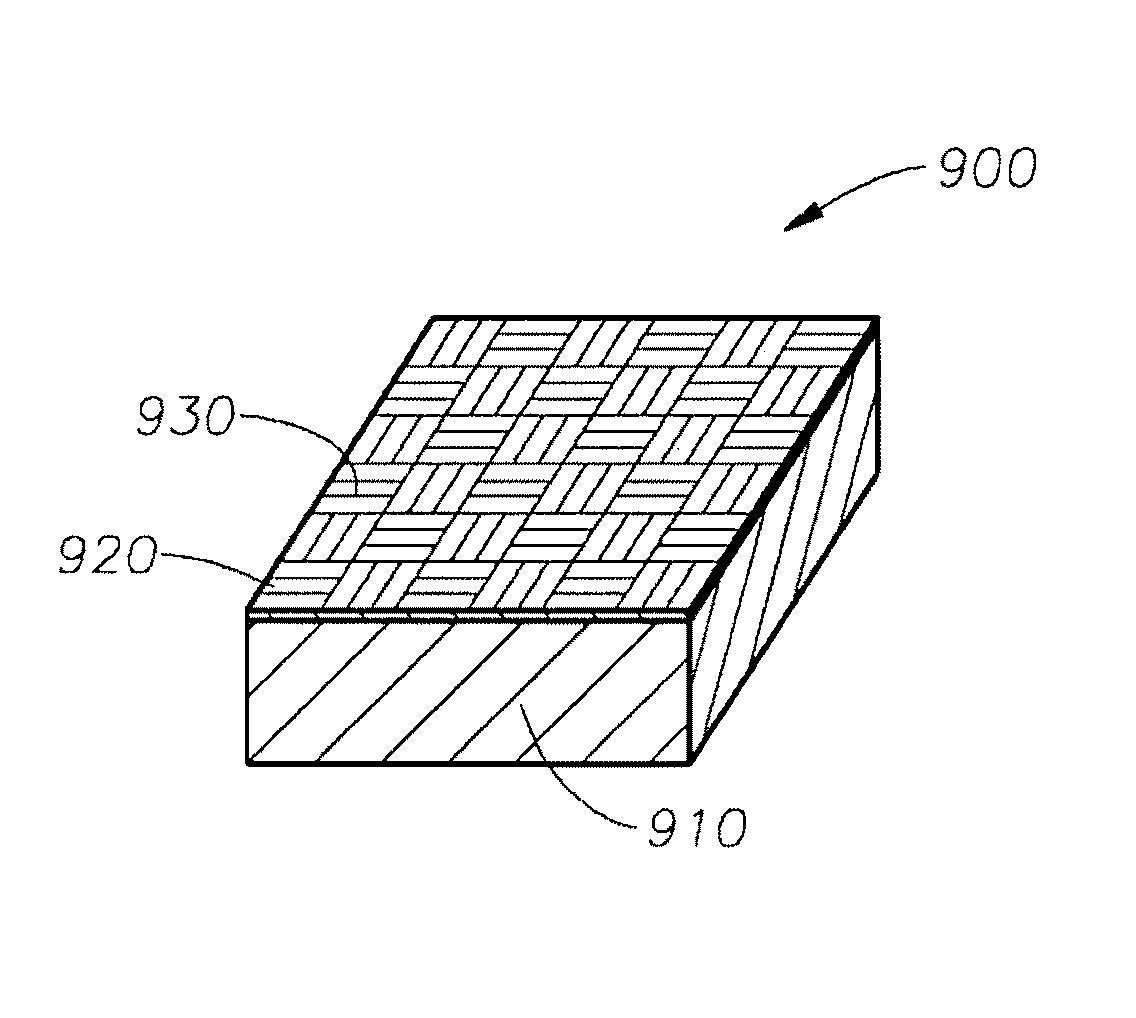

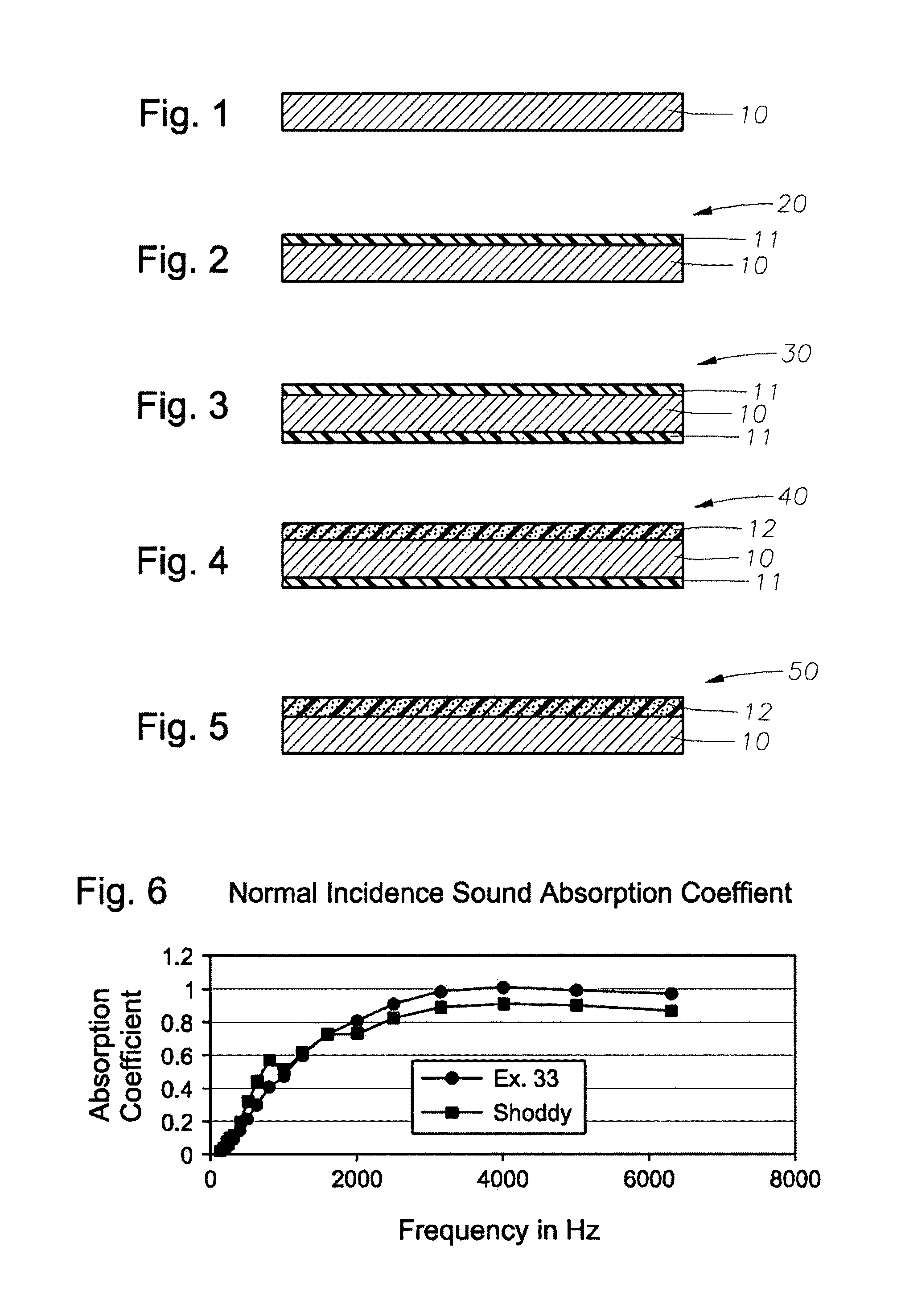

An improved acoustically and thermally insulating fire-retardant composite material suitable for use in structures such as buildings, appliances, and the interior passenger compartments and exterior components of automotive vehicles is provided. The material is comprised of at least one airlaid fibrous layer of controlled density and composition and incorporating suitable binding agents and additives as needed to meet expectations for noise abatement, fire-retardancy, and mildew resistance. Separately, an airlaid structure which provides a reduced, controlled airflow therethrough useful for acoustic insulation is provided, and which includes a woven or nonwoven scrim. A process for the production of the fire retardant nonwoven material is also provided.

Owner:GLATFELTER CORP

Fire retardant nonwoven material and process for manufacture

Owner:GLATFELTER CORP

Fungicidal and parasiticidal fire-retardant powder

InactiveUS20150368560A1Reduce weightReduce the amount requiredFireproof paintsBiocidePhosphateFire retardant

Fire-retardant powder comprising at least 30% by weight of mono ammonium dihydrogen phosphate and / or di-ammonium monohydrogen phosphate, at least 5% by weight of alkaline bicarbonate, at least 3% by weight of silica, and at least 5% by weight of a compound selected from the group consisting of: sodium chloride, potassium chloride, potassium bromide, potassium sulfate, magnesium carbonate hydroxide pentahydrate, magnesium chloride hexahydrate, iron(II) sulfate heptahydrate, zinc (II) chloride, and combinations thereof. The invention also relates to building materials preferably comprising natural fibers and comprising at least 5% by weight, and at most 30% of a powder according to the invention.

Owner:SOLVAY SA

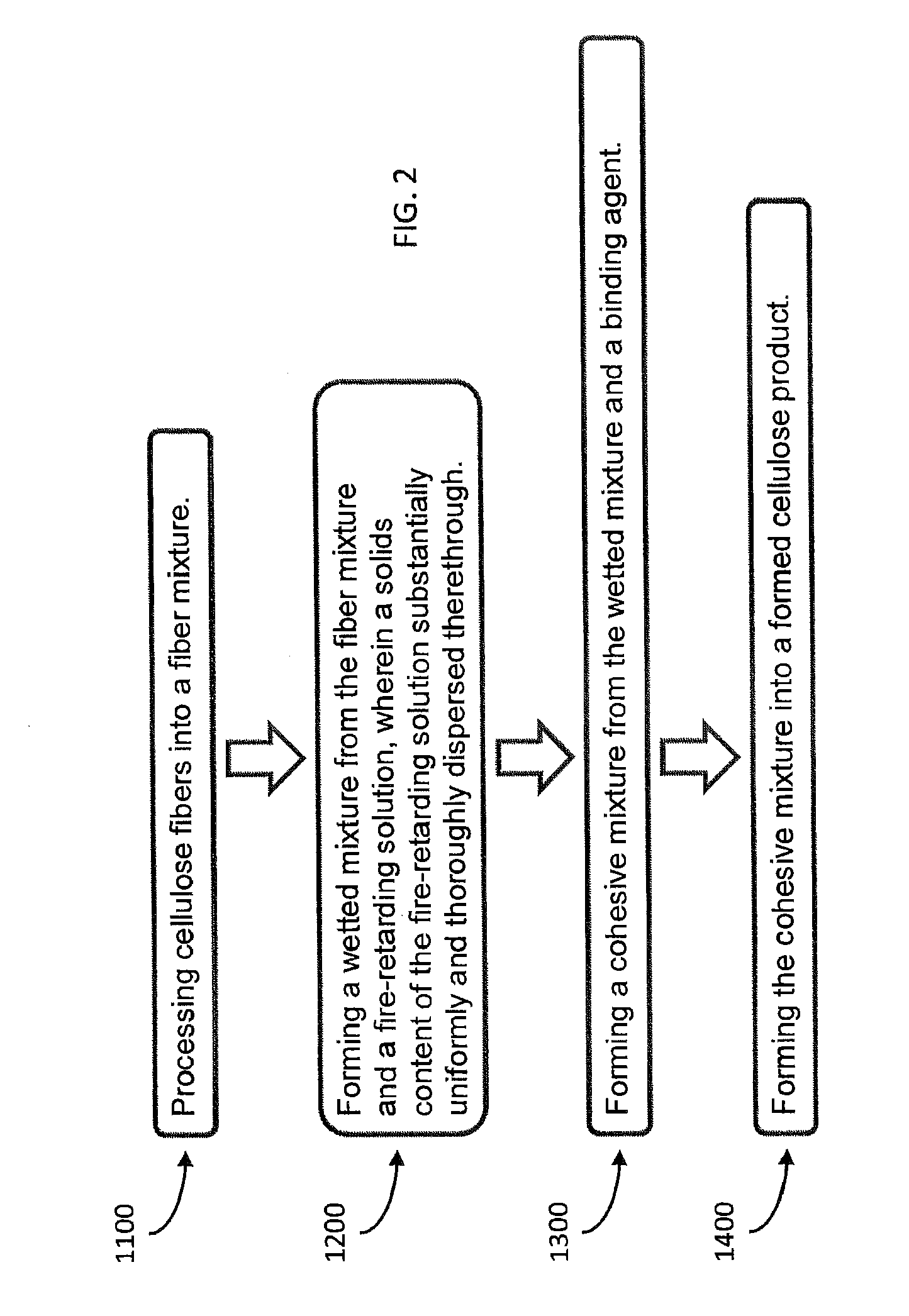

Method for forming a fire resistant cellulose product

A method is provided for forming a fire resistant cellulose material. Such a method comprises processing cellulose fibers into a fiber mixture, and then forming a wetted mixture from the fiber mixture and a fire-retarding solution, wherein the wetted mixture has a solids content of the fire-retarding solution substantially uniformly and thoroughly dispersed therethrough. In some aspects, a cohesive mixture may be formed from the wetted mixture and a binding agent, and the cohesive mixture then formed into a formed cellulose product. An associated apparatus is also provided.

Owner:BLH TECH

Ionic liquid flame retardants

InactiveUS20110039467A1Excellent resistance to migrationPromote leachingNatural cellulose pulp/paperSpecial paperFire retardantIonic liquid

The present invention relates to the use of ionic liquids as flame retardants. The compounds of the invention may be used as flame retardants in various materials without causing damage to the environment and or health of humans or animals. Ionic liquid flame retardants maybe applied alone or in combination with traditional flame retardants. Ionic liquid flame retardants can be applied to finish textile, plastic, leather, paper, rubber, or as wild fire flame retardants.

Owner:H&C CHEM

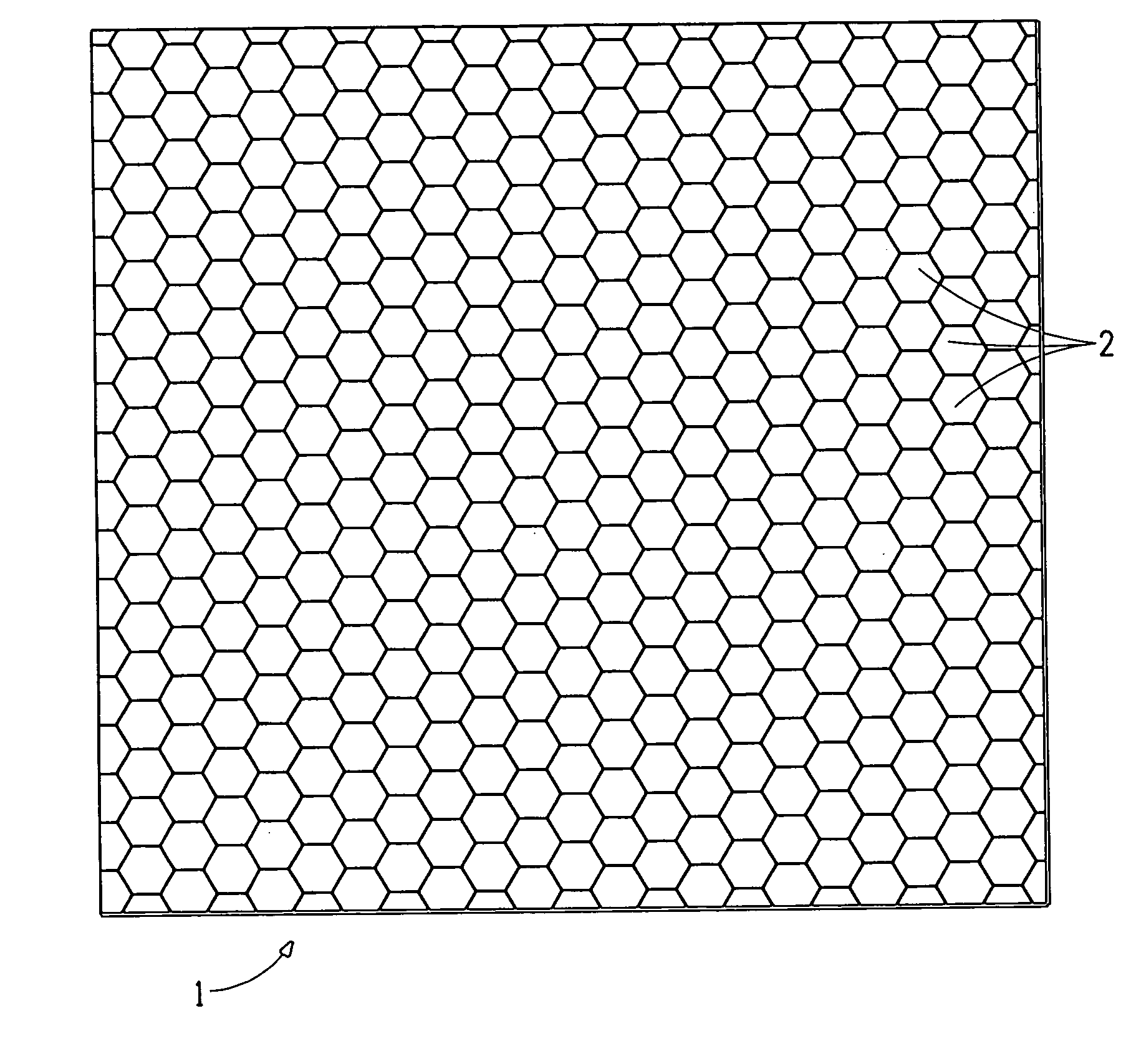

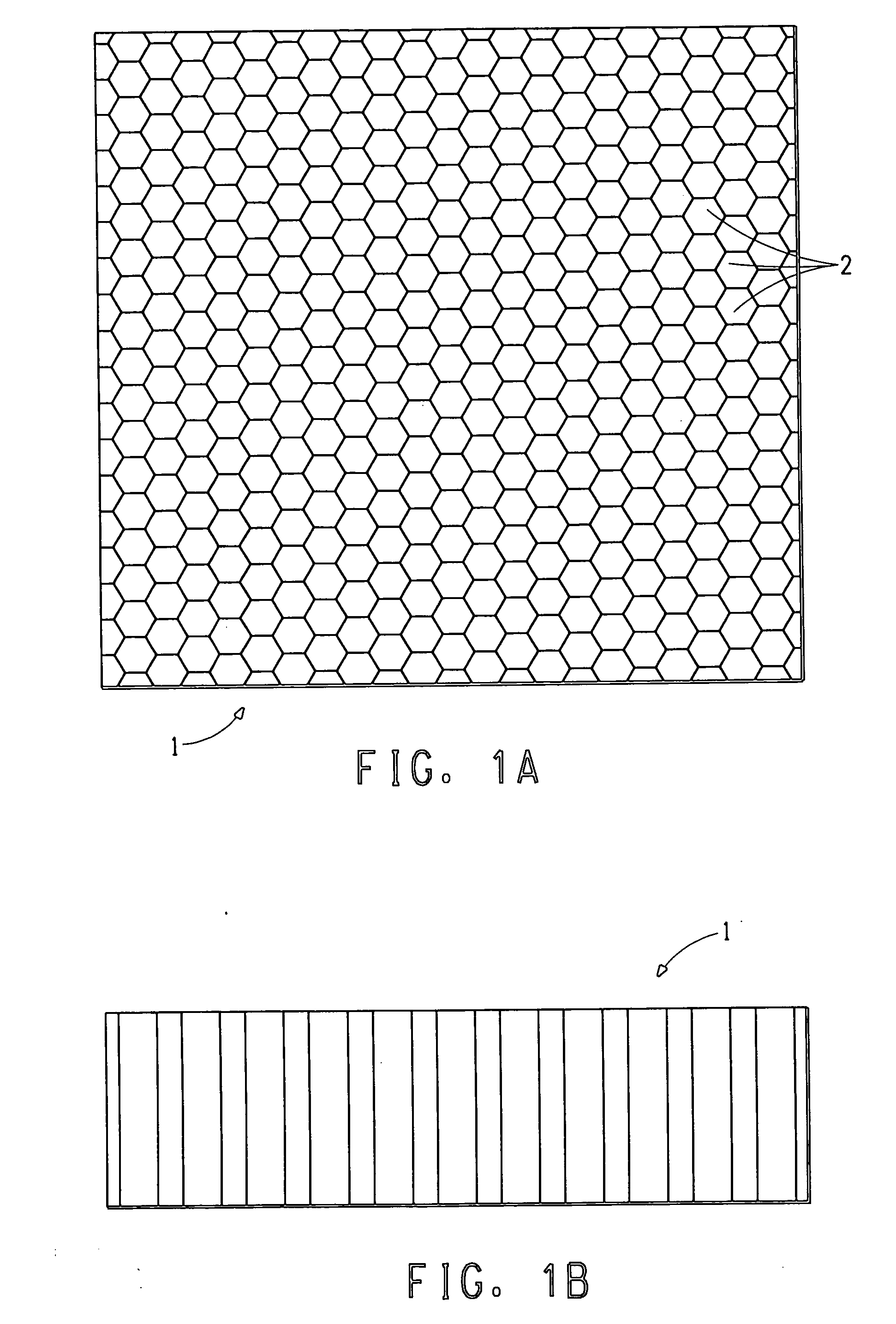

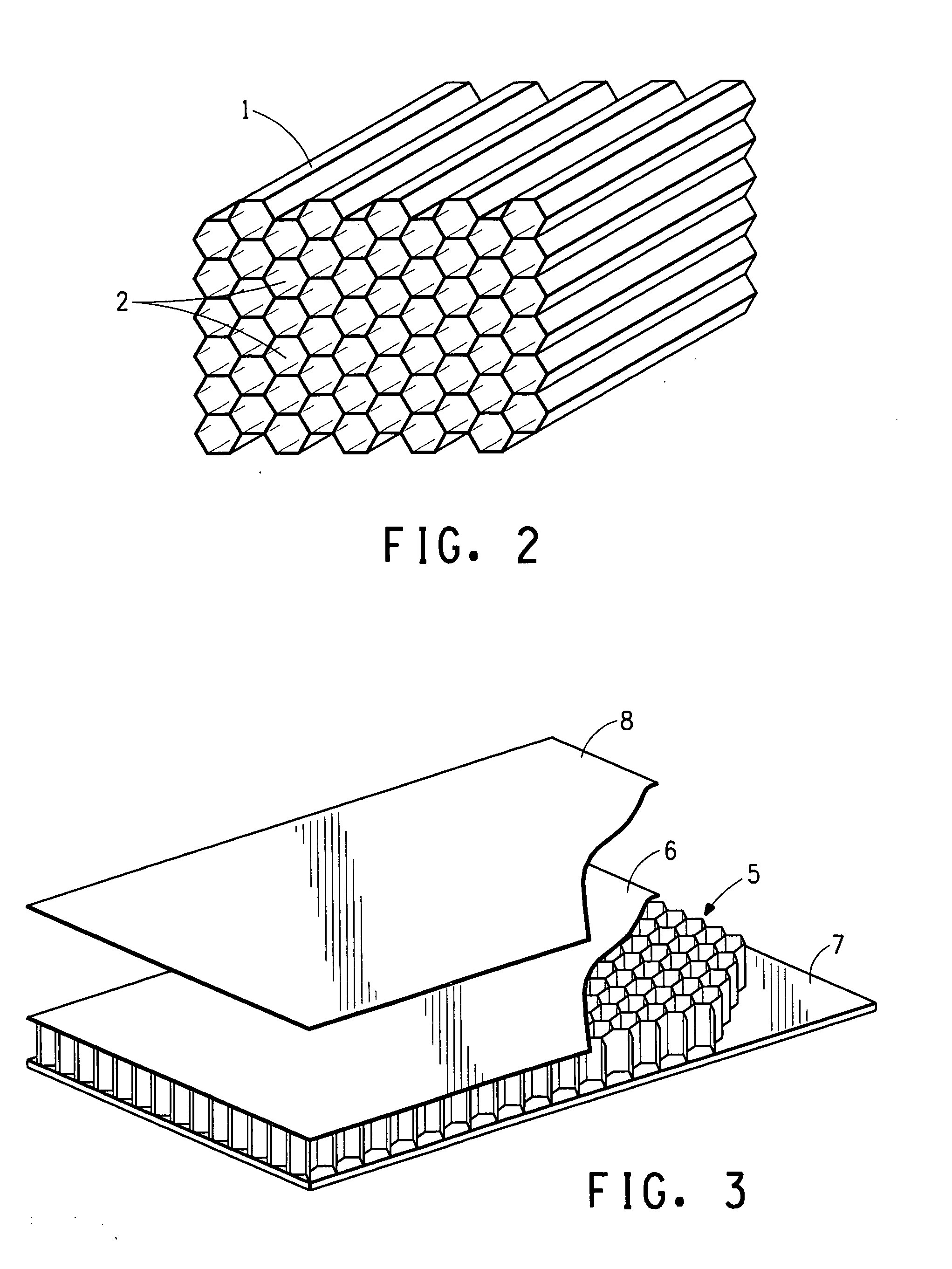

Honeycomb from paper having flame retardant thermoplastic binder

This invention relates to an improved flame retardant honeycomb comprising high modulus fiber and a flame retardant thermoplastic binder having a melt point of from 120° C. to 350° C. and a limiting oxygen index of 26 or greater, methods for making the honeycomb, and articles comprising the honeycomb. In a preferred embodiment the paper in the honeycomb has a flame classification of UL-94 V-0.

Owner:DUPONT SAFETY & CONSTR INC

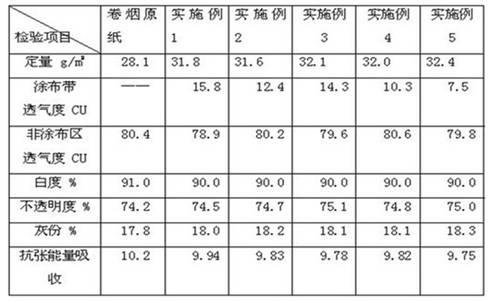

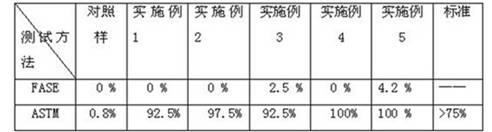

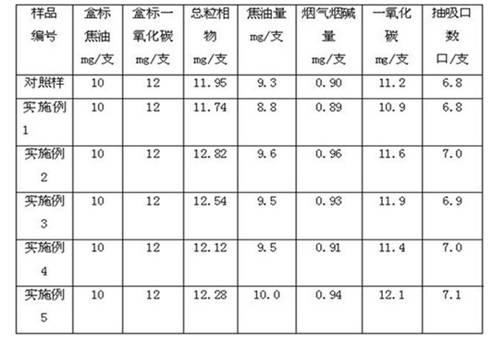

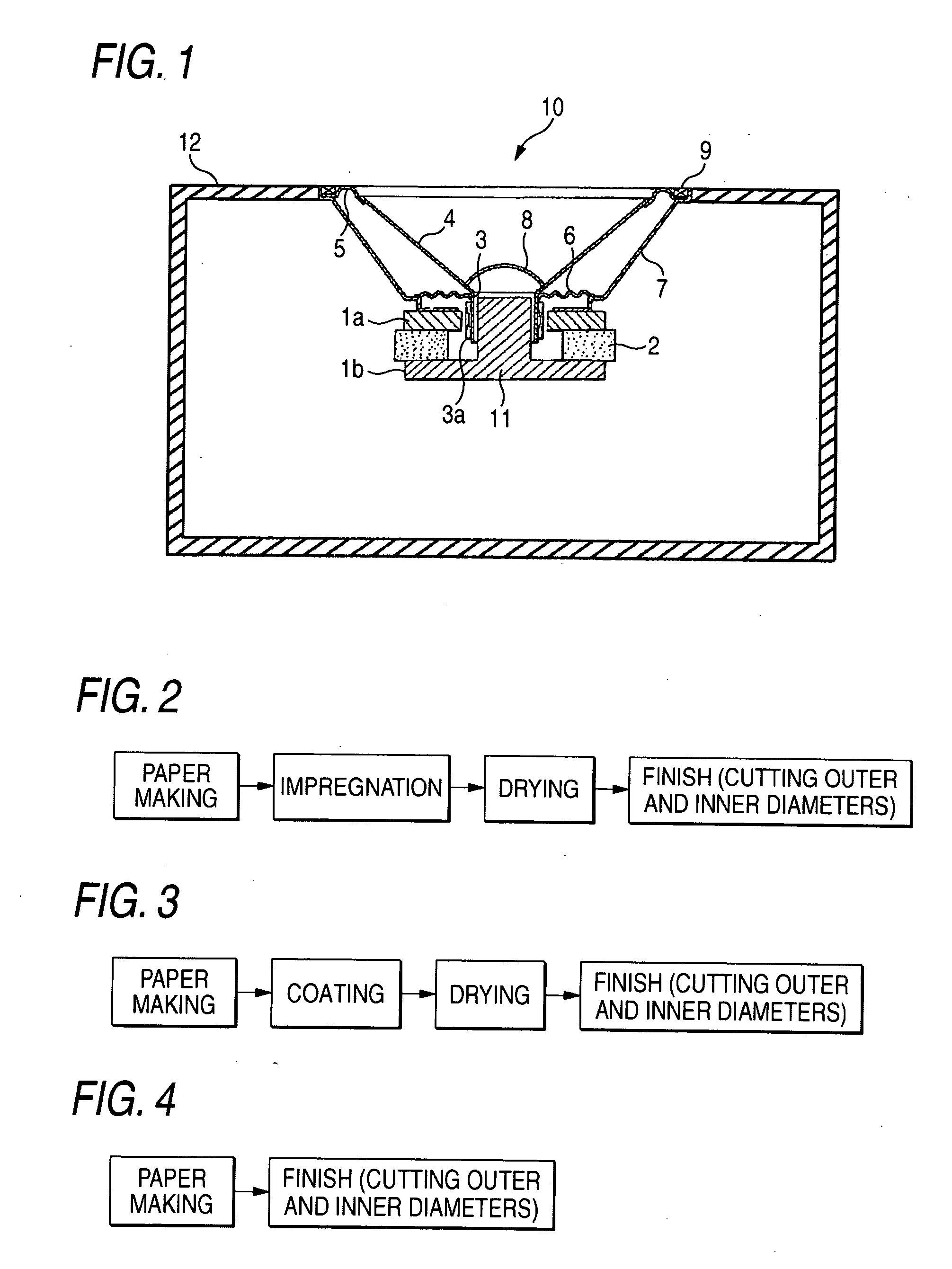

Cigarette paper with low ignition tendency and preparation method

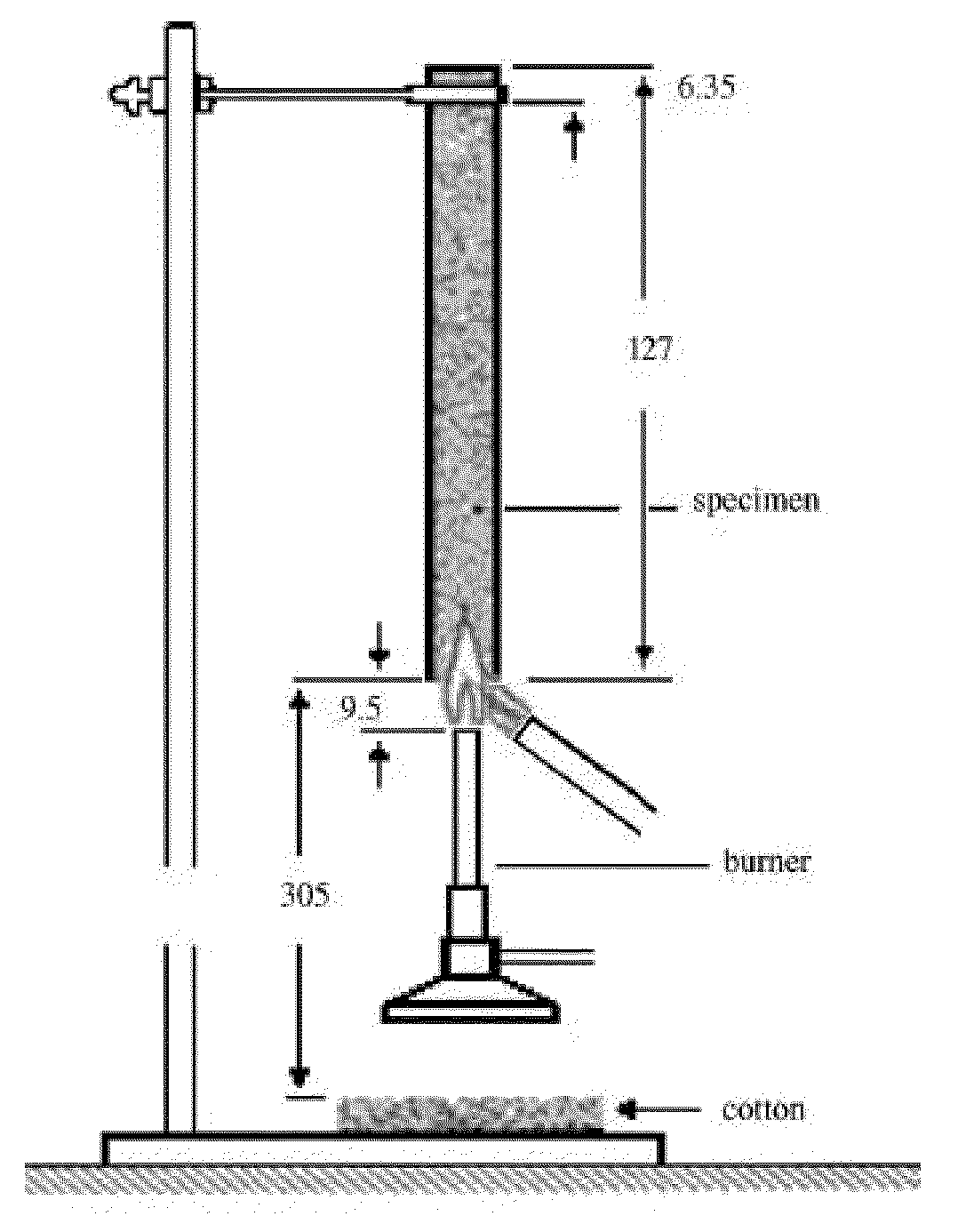

ActiveCN102199902AGuaranteed uniformitySimple and fast operationSpecial paperCigar manufacturePapermakingStandard test condition

The invention discloses cigarette paper with low ignition tendency and a preparation method. The cigarette paper comprises common cigarette paper manufactured by a papermaking process; and a coating liquid film consisting of film forming agent, viscosity regulator and filler is printed on the inner surface of the common cigarette paper. The preparation method comprises the following steps of: (1) preparing the common cigarette paper of certain specification; (2) preparing the filler into 40 to 60 percent suspension, and stirring uniformly; (3) adding the viscosity regulator component into the (2) at normal temperature to prepare 2 to 4 mass percent aqueous solution, and stirring for 10 minutes; (4) adding the film forming agent component into the (3) at normal temperature to prepare 25 to 35 mass percent aqueous solution, and stirring for 20 minutes; and (5) adding the sizing material prepared in the (4) on the surface of the cigarette paper through a silk screen in certain interval by adopting a printing and coating mode. When the cigarette paper is burnt to a coated strip in the atmospheric environment, the cigarette has low extinguishing rate and even is not extinguished; and under the standard test condition, the filter paper of contact matrix has high extinguishing rate, and meanwhile, the cigarette paper has no obvious adverse effects on the cigarette smoke and the smoking quality.

Owner:MINFENG SPECIAL PAPER

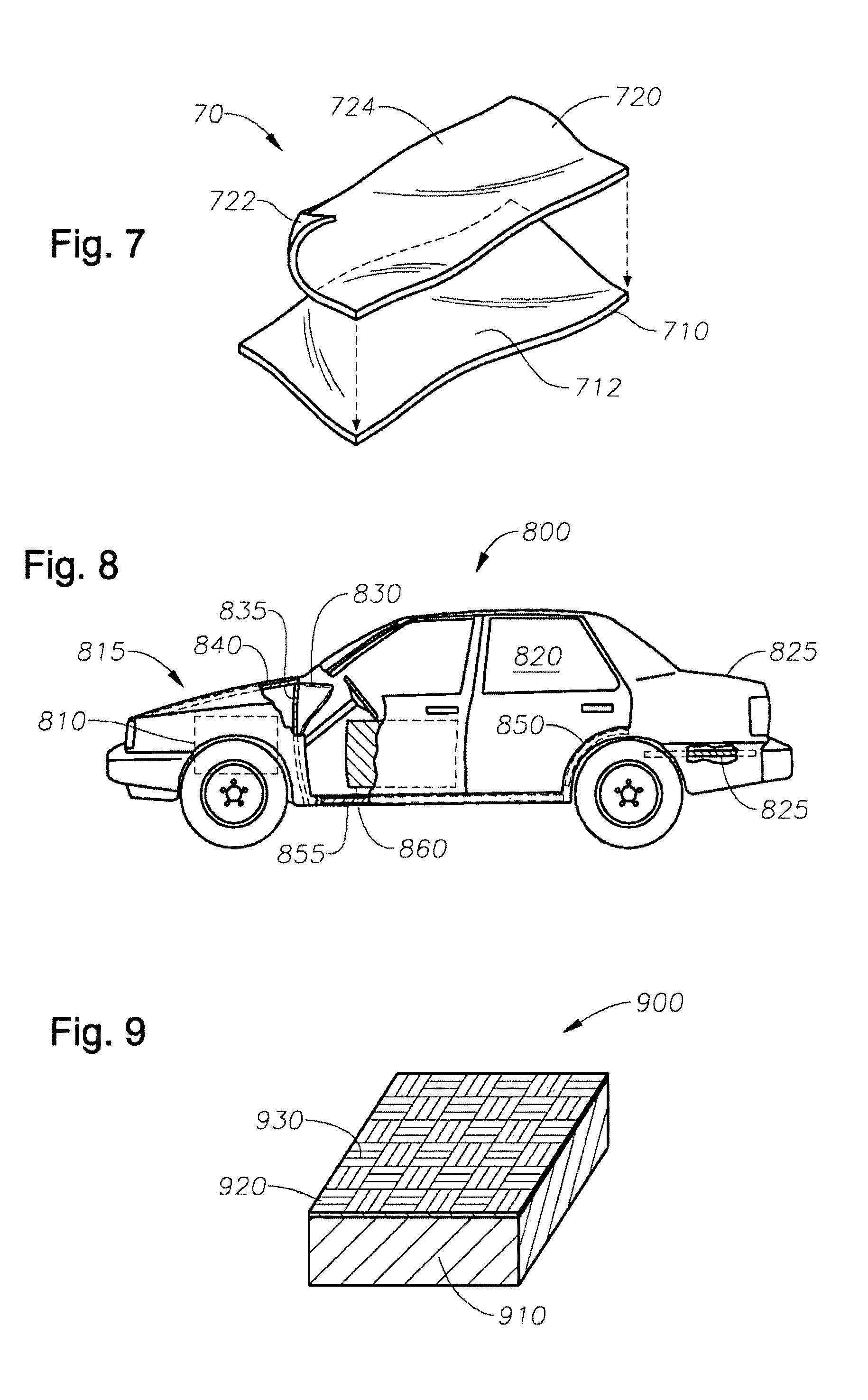

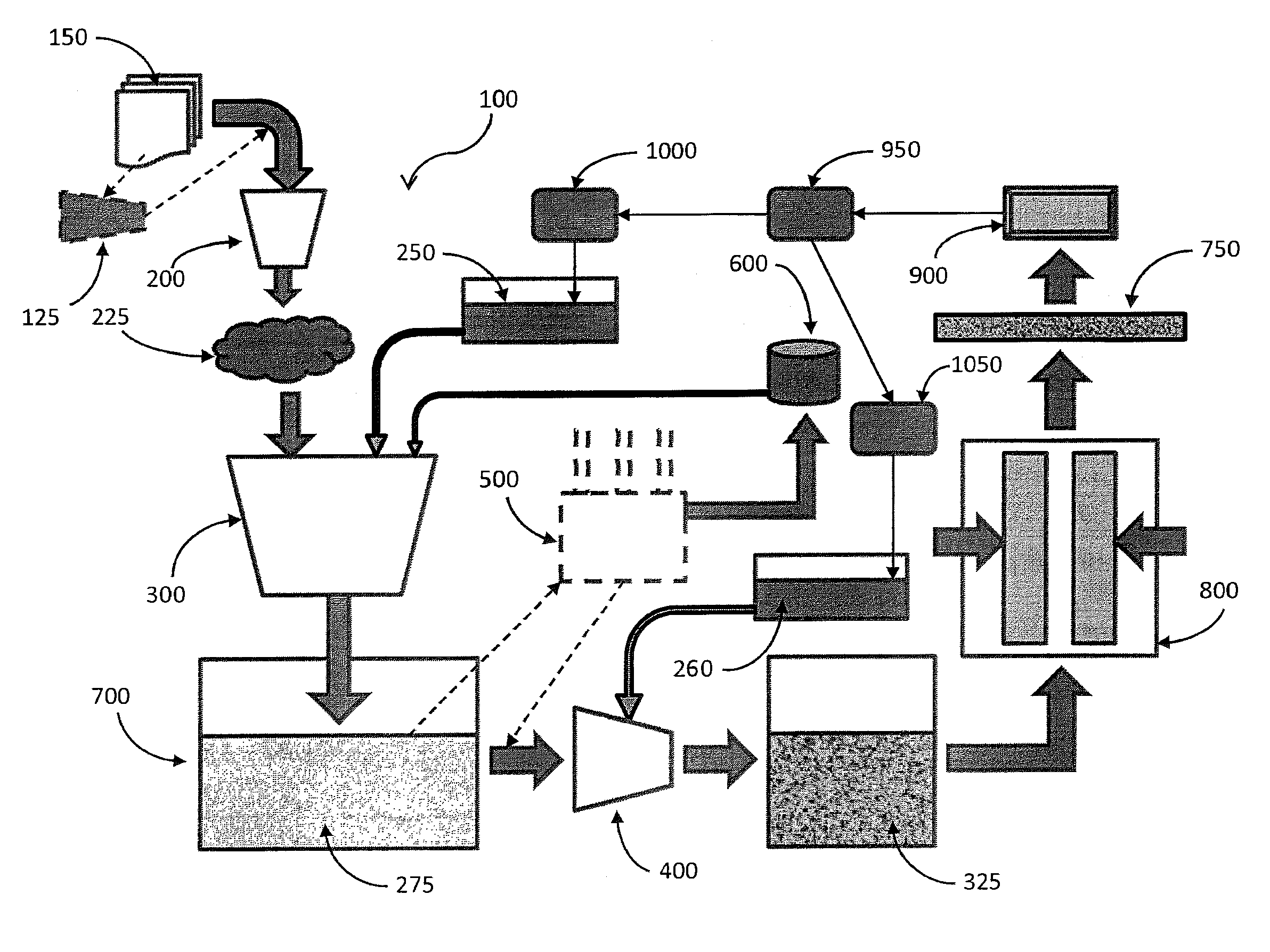

Method for forming a fire resistant cellulose product, and associated apparatus

A method is provided for forming a fire resistant cellulose product. A fire-retarding solution and a bonding agent are combined with refined cellulose fibers to form a fiber mixture, and the fire-retarding solution and bonding agent are substantially uniformly distributed with respect to the cellulose fibers within the fiber mixture. The fiber mixture is exposed to an actuating element, wherein the actuating element is configured to actuate the bonding agent so as to facilitate cohesion of the cellulose fibers and form the fiber mixture into a fiber board member, the fiber board member having opposing major surfaces. A cellulose sheet member is engaged with each major surface of the fiber board member, such that each cellulose sheet member substantially covers the respective major surface. An associated apparatus is also provided.

Owner:BLH TECH

Fire and Sag Resistant Acoustical Panel and Substantially Clear Coating Therefor

A ceiling panel structure which includes a fire retardant mat, a scrim and a substantially clear scrim coating. The fire retardant mat includes a fire retardant fiber component and a binder material which binds the fibers. The fire retardant fiber component includes natural fibers treated with a fire retardant. The scrim being attached to a surface of the mat and the substantially clear coating is applied to the surface of the scrim opposite a surface of the scrim positioned next to the mat. The ceiling panel structure has flame spread index of 25 or less and a smoke generation index of 50 or less, as measured by ASTM E 84 that is uniform throughout the mat.

Owner:ARMSTRONG WORLD INDUSTRIES

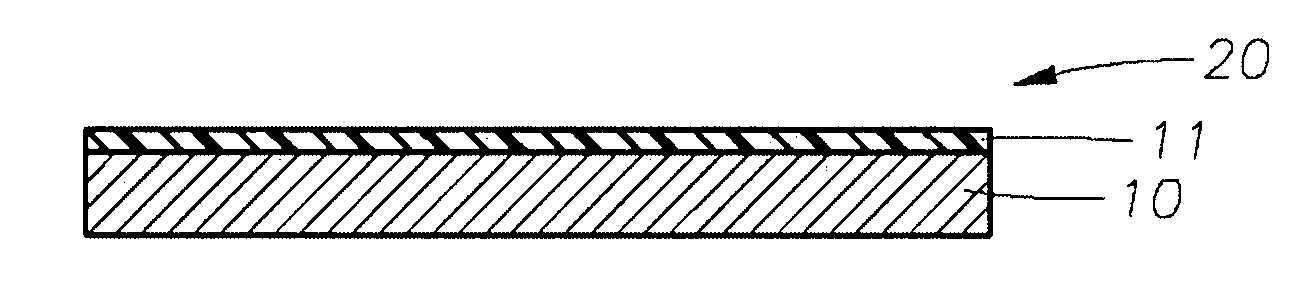

Thermally protective flame retardant fabric

InactiveUS20090061131A1High protection levelLow costChemical protectionHeat protectionFiberEngineering

A thermally protective, flame retardant fabric includes a substrate treated with a combination of a flame retardant agent and an intumescent agent. The substrate includes non-thermoplastic fibers or a blend of non-thermoplastic fibers and thermoplastic fibers having a basis weight ranging from 2.0 to 15.0 ounces per square yard. The fabric has a contact thermal protective performance value of at least 4.5 and a contact thermal protective performance efficiency greater than 1.1. Applications of the fabric include protective garments, articles of furniture, vehicle components, building components, electrical components, decorative components, appliances, and containers.

Owner:PRECISION FABRICS GROUP

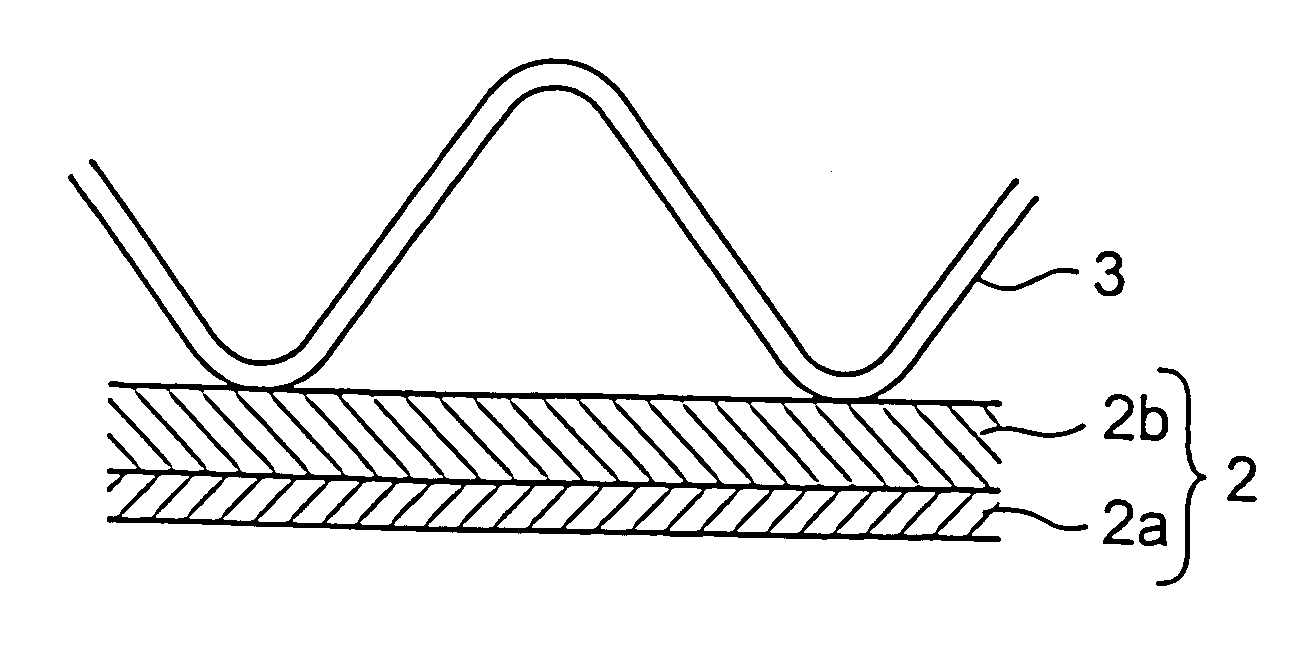

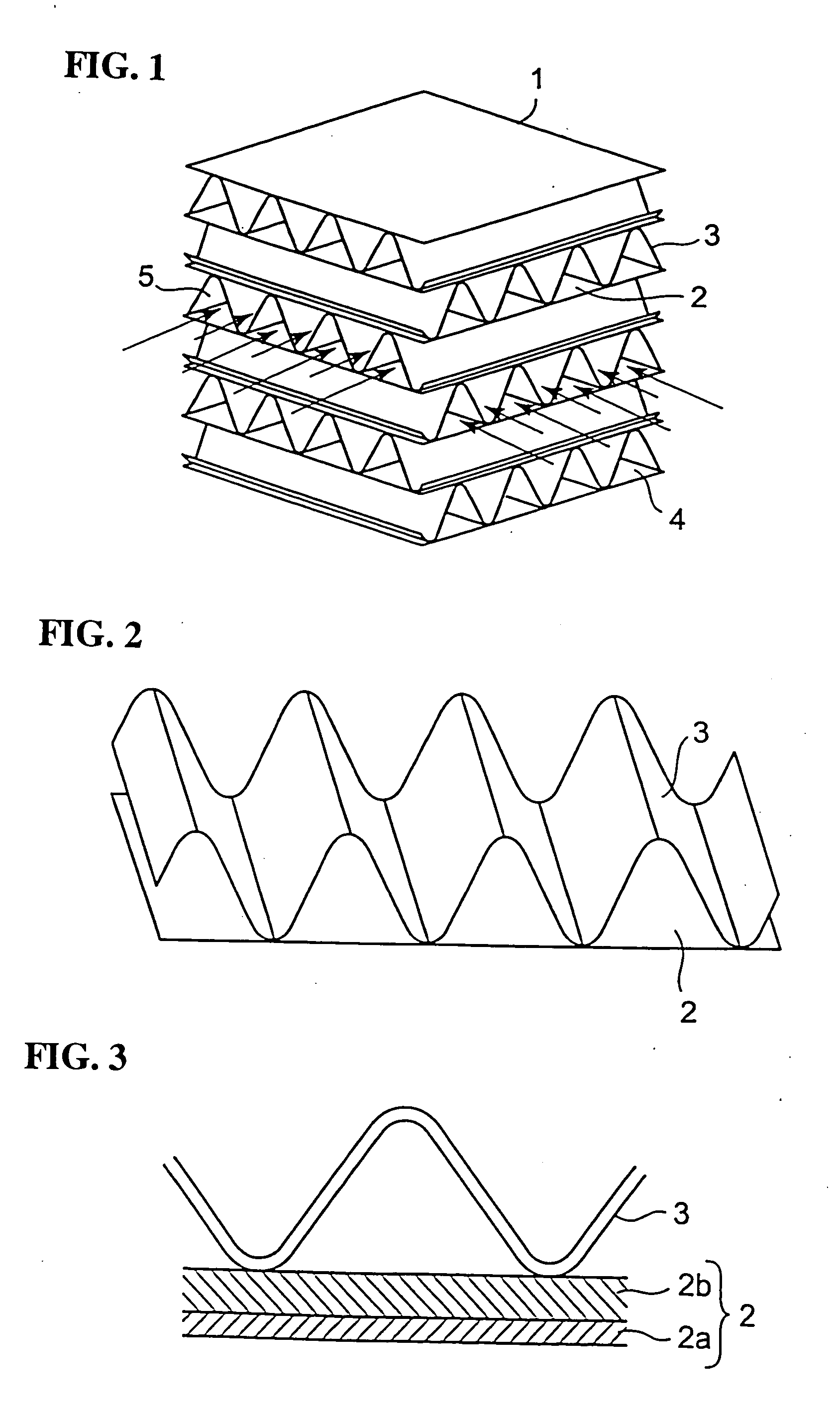

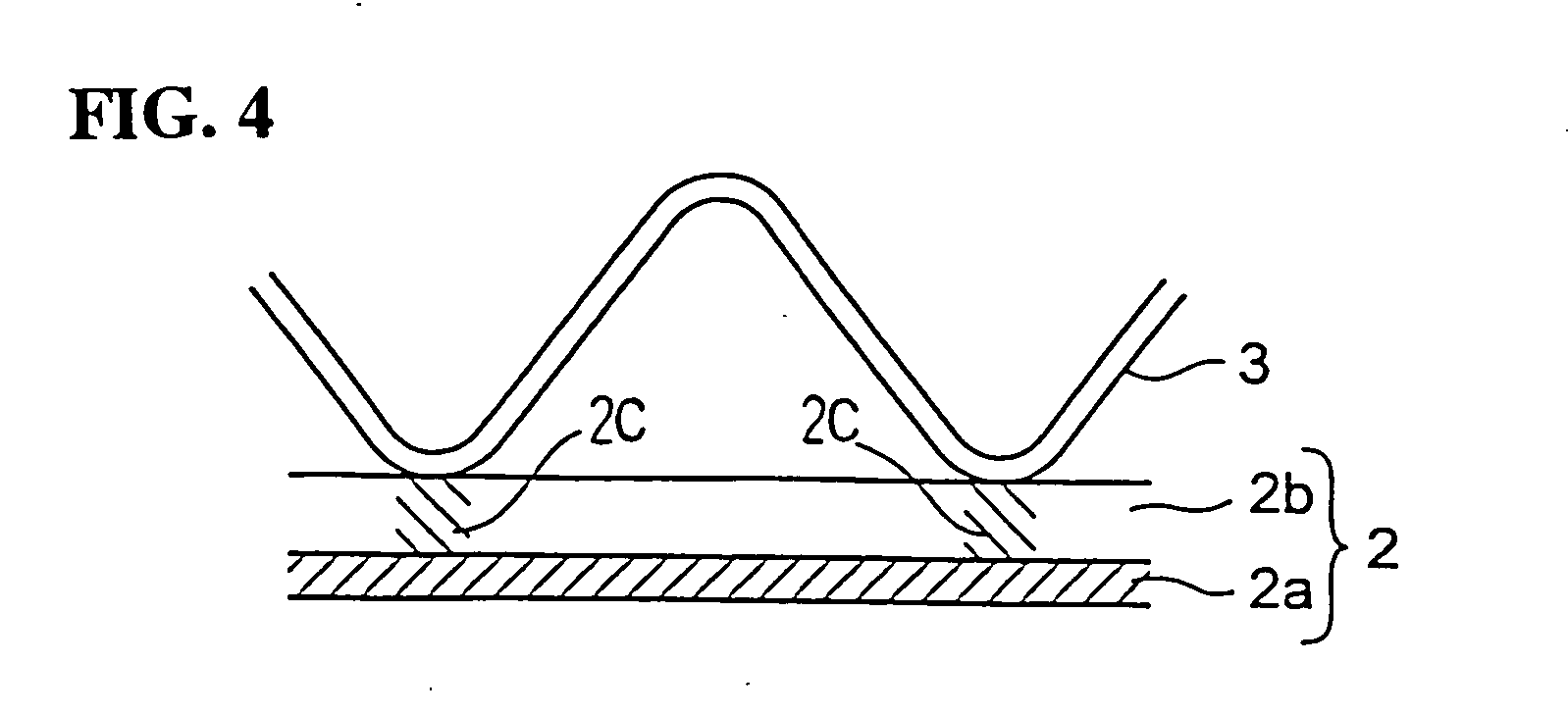

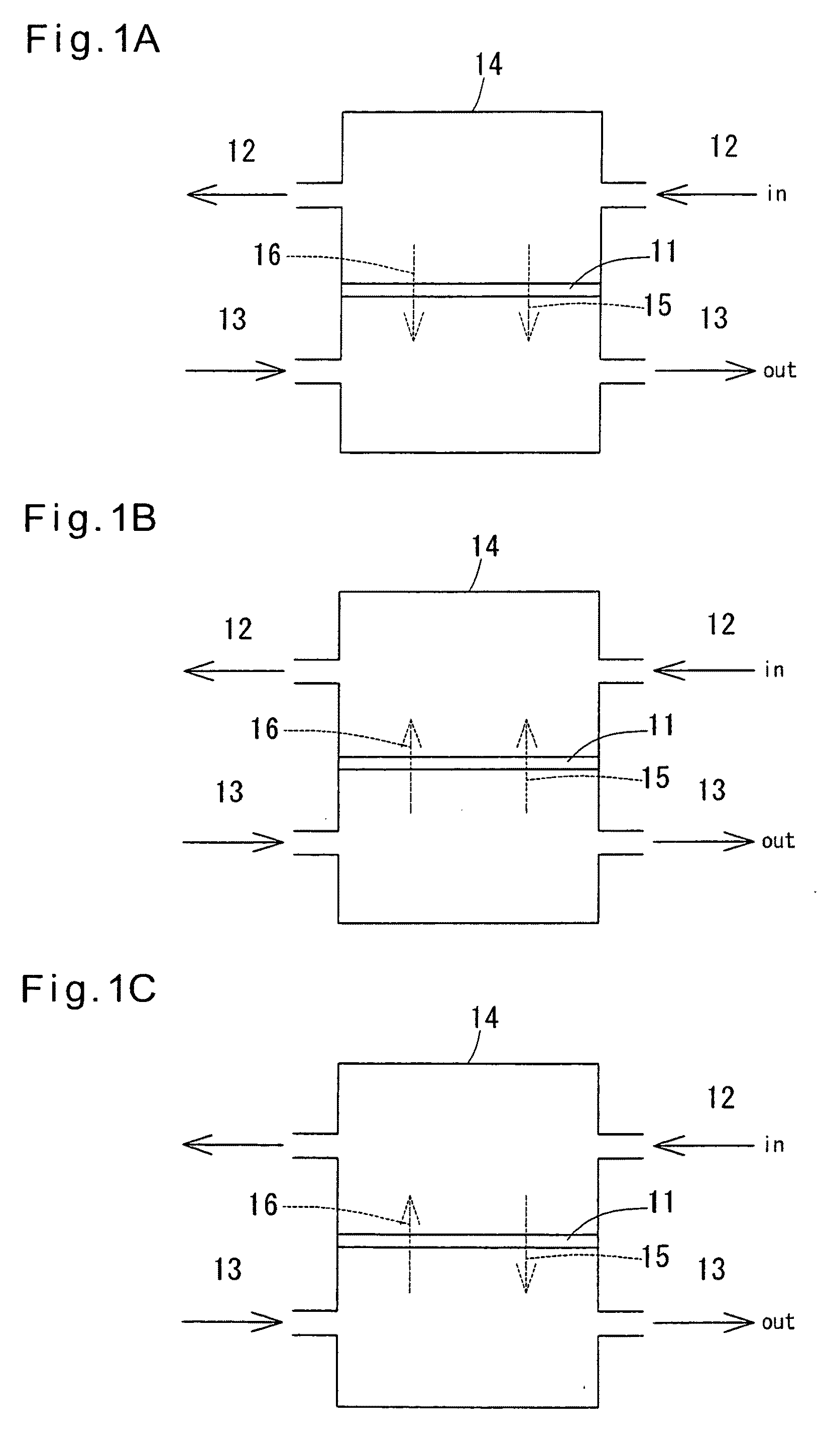

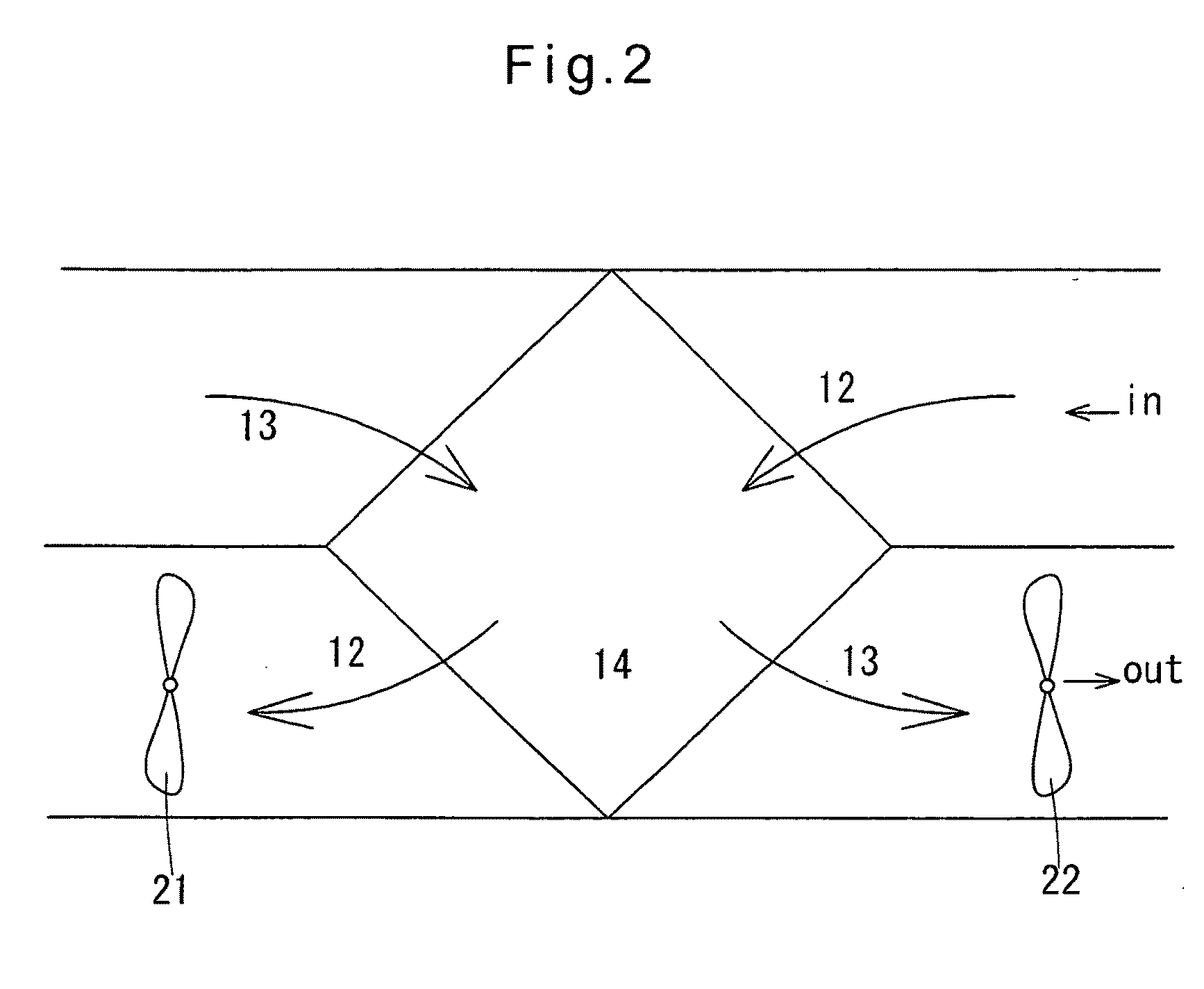

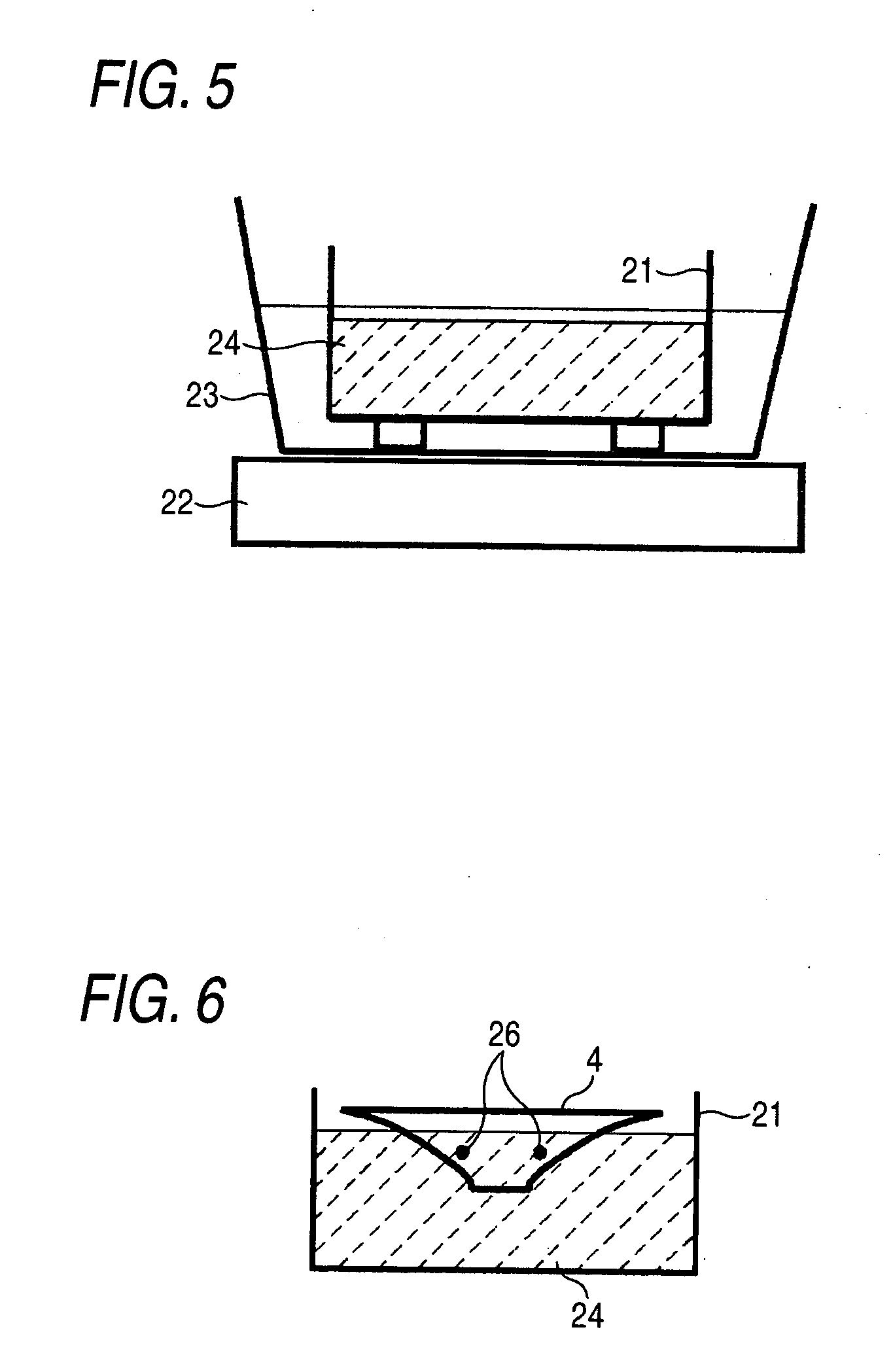

Total heat exchanging element

InactiveUS20050082045A1Good effectImprove flame retardant performanceFibreboardSpecial paperMoisture permeabilityLatent heat

When latent heat is transferred between the two airflows flowing along the respective sides of each partition member, not only a layer of moisture absorbent but also a layer of flame retardant lies in the direction of transfer of the moisture. Thus, even if the moisture is absorbed by the layer of moisture absorbent, the layer of flame retardant resists the moisture transfer so that the amount of transfer of the moisture decreases in that part with a drop in the moisture permeability of the partition member. To solve the problem, there is provided a total heat exchanging element comprising partition members and spacing members having moisture permeable portions provided with moisture permeability and flame resisting portions provided with flame retardancy, the both portions not overlapping with each other within each single member. For example, the partition members have the moisture permeable portions provided with moisture permeability, and the spacing members have the moisture resisting portions provided with flame retardancy.

Owner:MITSUBISHI ELECTRIC CORP +1

Fireblocking/insulating paper

InactiveUS6884321B2Prevent the spread of flamesHigh burnthrough prevention capabilityNatural cellulose pulp/paperSpecial paperSilicon dioxideUltimate tensile strength

A flame and heat resistant paper is disclosed having high burnthrough prevention capability, as required in aircraft applications. The paper is prepared from modified aluminum oxide silica fibers, in addition to other components, and has exceptional tensile strength and flexibility as compared to conventional inorganic papers.

Owner:TEX TECH INDS

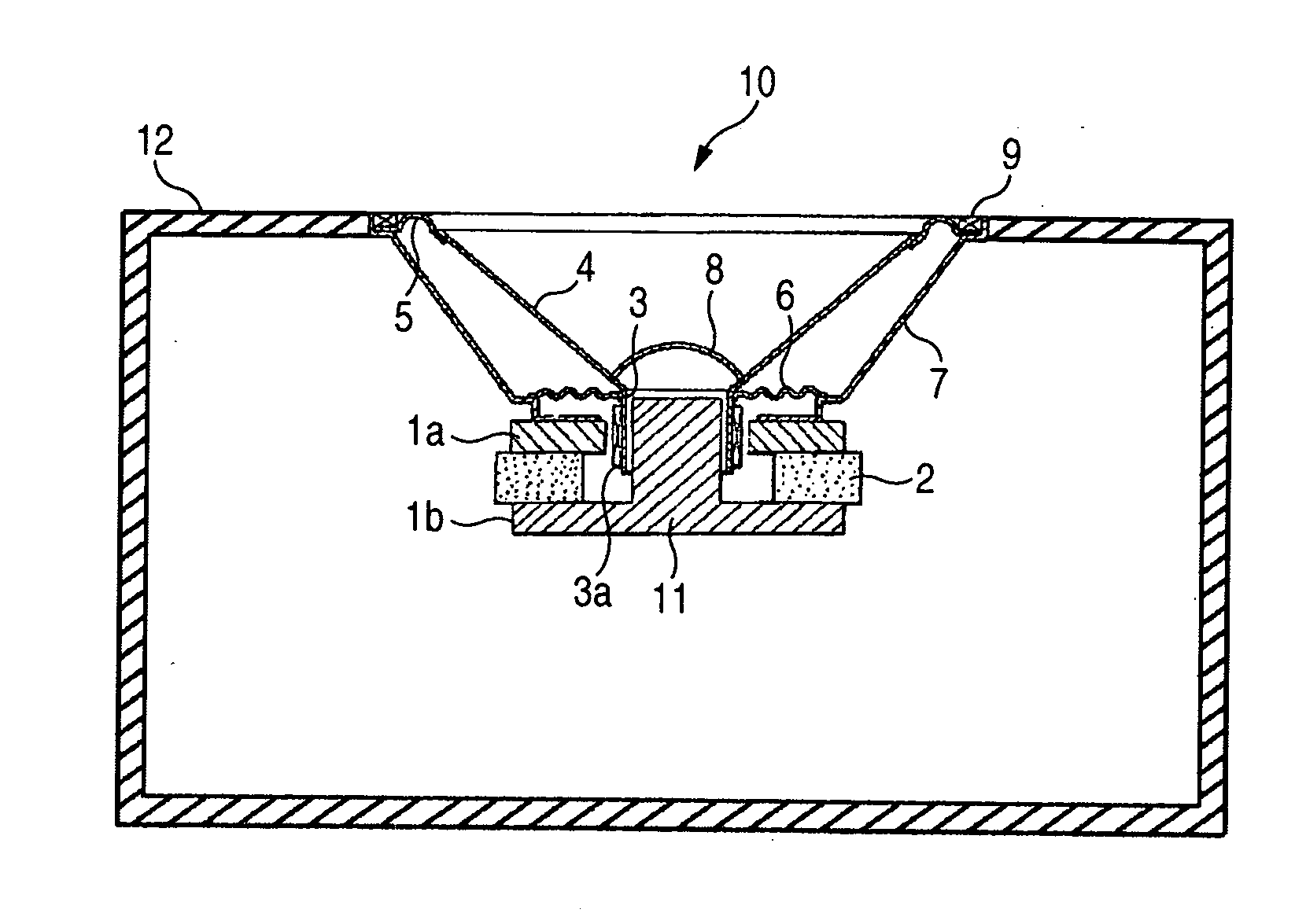

Waterproof and flame-retardant paper cone

ActiveCN106948211AHigh bromine contentImprove thermal stabilityWater-repelling agents additionReinforcing agents additionSodium metasilicateSodium Bentonite

The invention discloses a waterproof and flame-retardant paper cone, belonging to the technical field of electroacoustic products. The slurry of the paper cone is prepared by mixing and sitrring the following main raw materials in parts by weight: wood pulp, sisal hemp, cotton pulp, kapok, bulletproof fiber, wool, glass fiber, a dye, table salt, a hardening agent, a flexibilizer, a regulator, a waterproofing agent and a flame retardant, wherein the waterproofing agent is prepared through the following steps: adding acrylic rubber latex, hydroxyethyl cellulose, bentonite and sodium metasilicate according to a weight ratio of 1: (0.1-0.5): (0.2-0.5): (0.05-0.2) into water, carrying out mixing under stirring so as to form an emulsion, placing the emulsion in a stirring reflux device, and carrying out a reflux reaction for 3 to 4 hours; and the flame retardant is prepared by uniformly mixing kaolin with decabrominated dipheny ethane and antimonous oxide or magnesium hydroxide with a weight ratio of 1: (1-5) under stirring. The waterproof and flame-retardant paper cone provided by the invention has subdued sound effect and good dampproof and waterproof performances, flame retardance and mechanical performance, and is improved in use safety and prolonged in service life.

Owner:广西玉林市禹力音响配件有限公司

Paper for painting and calligraphy and manufacturing process of paper for painting and calligraphy

ActiveCN106283837AWith flame retardant effectImprove waterproof performanceOrganic non-cellulose fibresWater-repelling agents additionHigh volume manufacturingPolyvinyl alcohol

The invention provides paper for painting and calligraphy. The paper for painting and calligraphy is prepared from, by weight, 10-30 parts of bamboo pulp, 50-80 parts of herba junci setchuensis pulp, 5-20 parts of wood pulp, 5-15 parts of water-soluble polyvinyl alcohol fibers, 5-20 parts of silk, 0.01-1 part of starch adhesive and 0.001-0.5 part of a waterproof agent. The starch adhesion is prepared from starch, carbamido resin, sodium bromide, ammonium chloride and water. The invention further discloses a manufacturing process of the paper for painting and calligraphy. By addition of the starch adhesive according to a specific formulation, the paper for painting and calligraphy has flame-retardant and fireproof effects; due to addition of the silk, light weight, thinness and softness of the paper are achieved; by spraying of the waterproof agent, water resistance of the paper is improved. The manufacturing process is suitable for large-batch production, and operation efficiency is improved.

Owner:ZHEJIANG VOCATIONAL COLLEGE OF COMMERCE

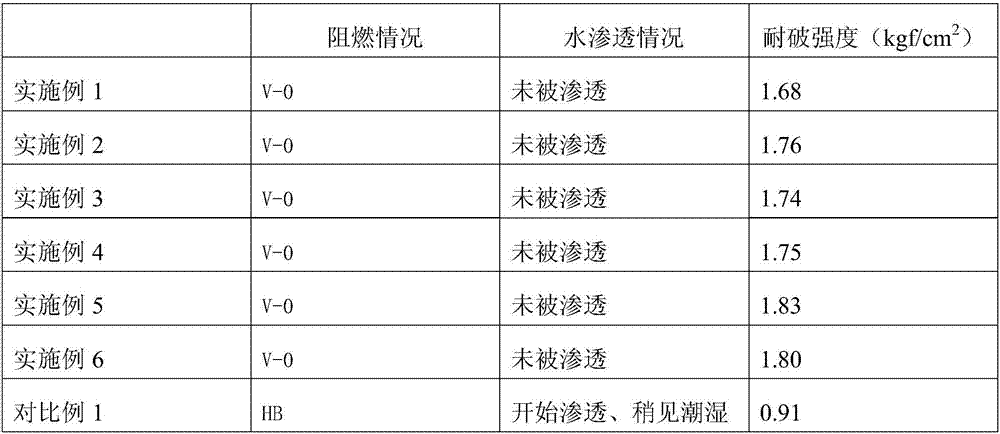

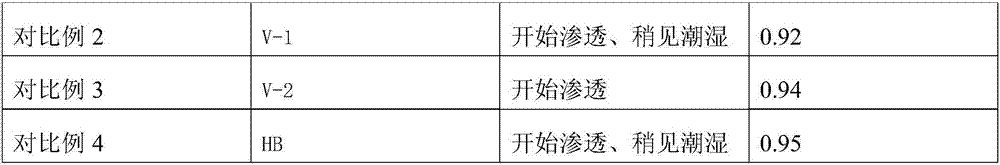

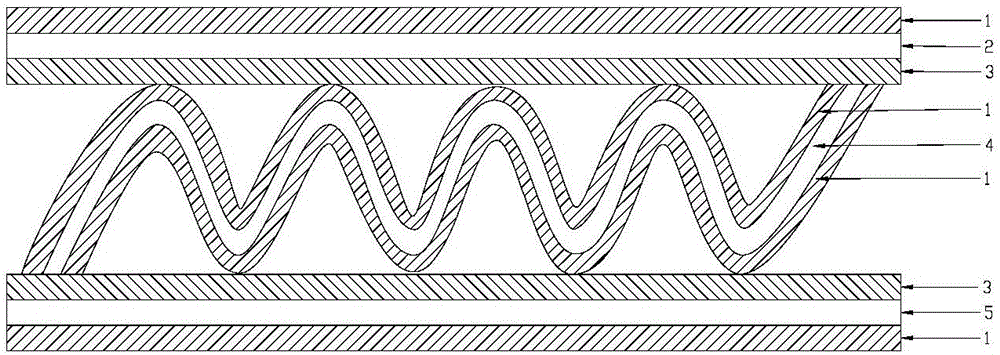

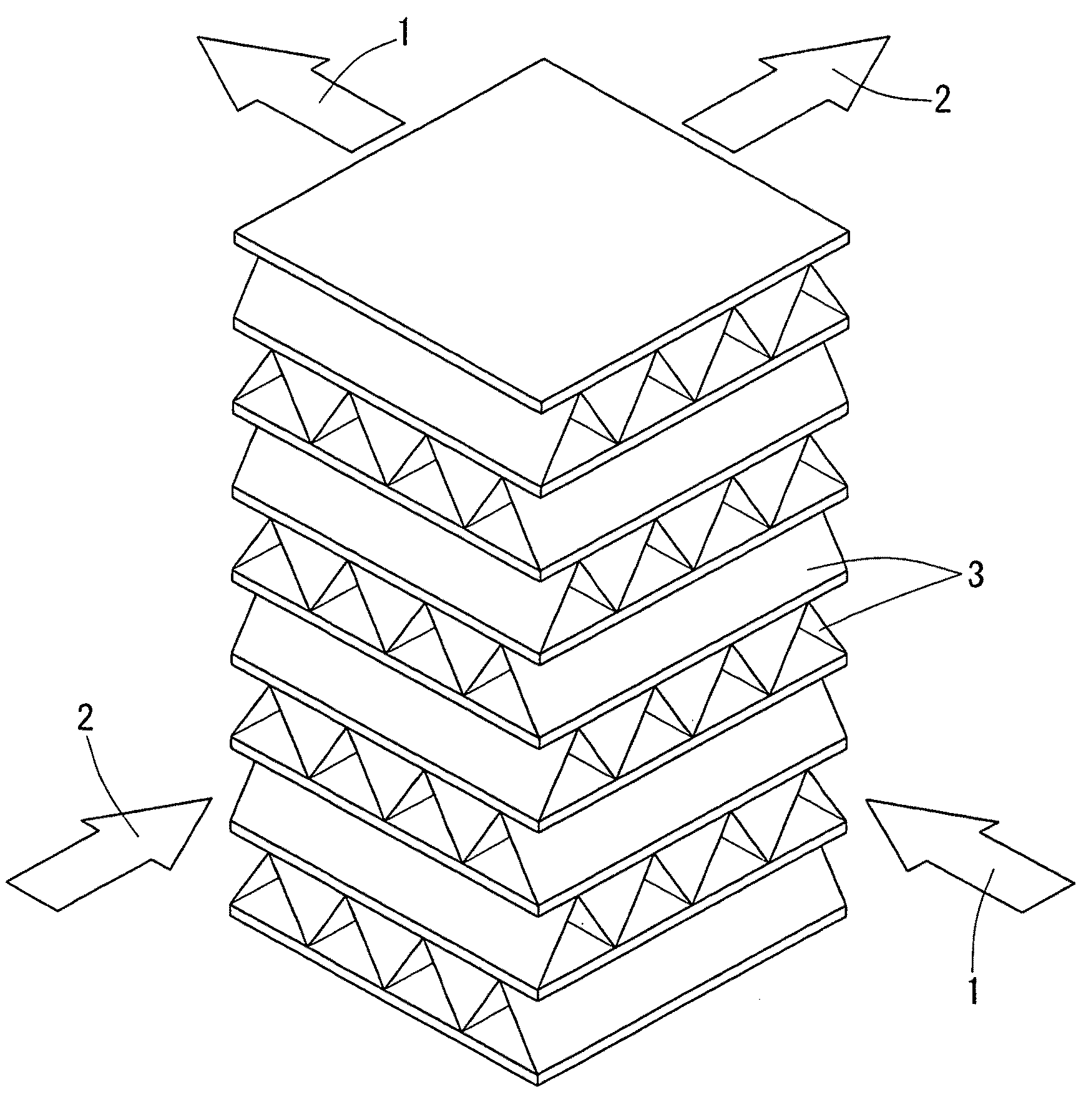

Flame retardant, flame-retardant corrugated board, preparation methods of flame retardant and flame-retardant corrugated board, and preparation equipment of flame-retardant corrugated board

The invention discloses a flame retardant, a flame-retardant corrugated board, preparation methods of the flame retardant and the flame-retardant corrugated board, and preparation equipment of the flame-retardant corrugated board. The flame retardant comprises dissolvent, ammonium polyphosphate, magnesium-aluminum hydrotalcite, aluminum hydroxide, a dispersant, adhesive and fatty alcohol-polyoxyethylene ether with the percentage by weight of 100 : (10-25) : (15-30) : (10-25) : (1-3) : (5-10) : (1-2); the corrugated board comprises a flame retardant layer, a surface paper layer, a ceramic fiber paper layer, a flame retardant layer, a corrugating medium paper layer, a flame retardant layer, a ceramic fiber paper layer, an inner paper layer and a flame retardant layer from the upper part to the lower part in sequence, wherein the flame retardant layer is formed by drying the flame retardant. The flame-retardant corrugated board has the advantage that burning of paper can be effectively prevented, and has good strength and cushioning performance.

Owner:力嘉包装(东莞)有限公司 +2

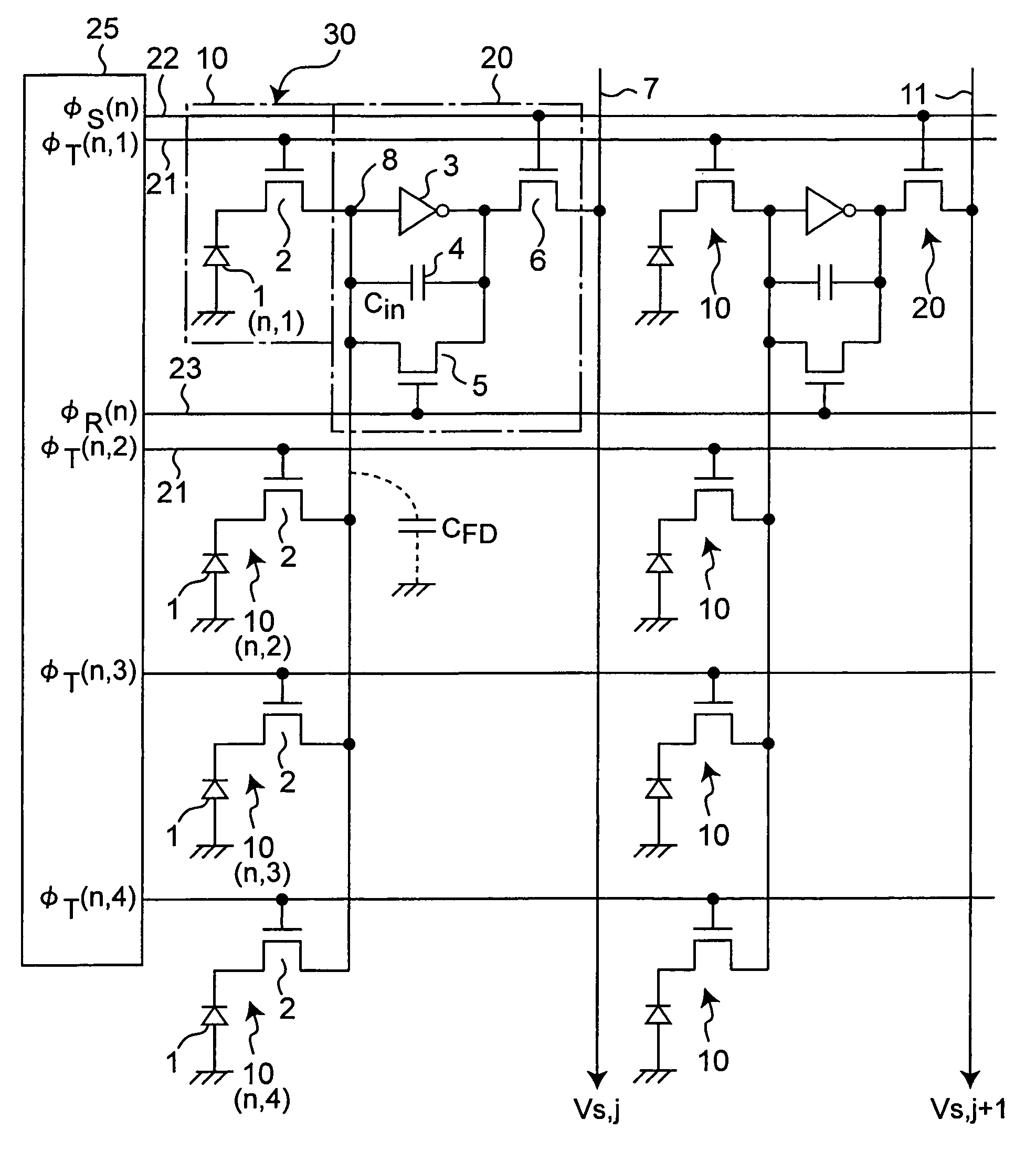

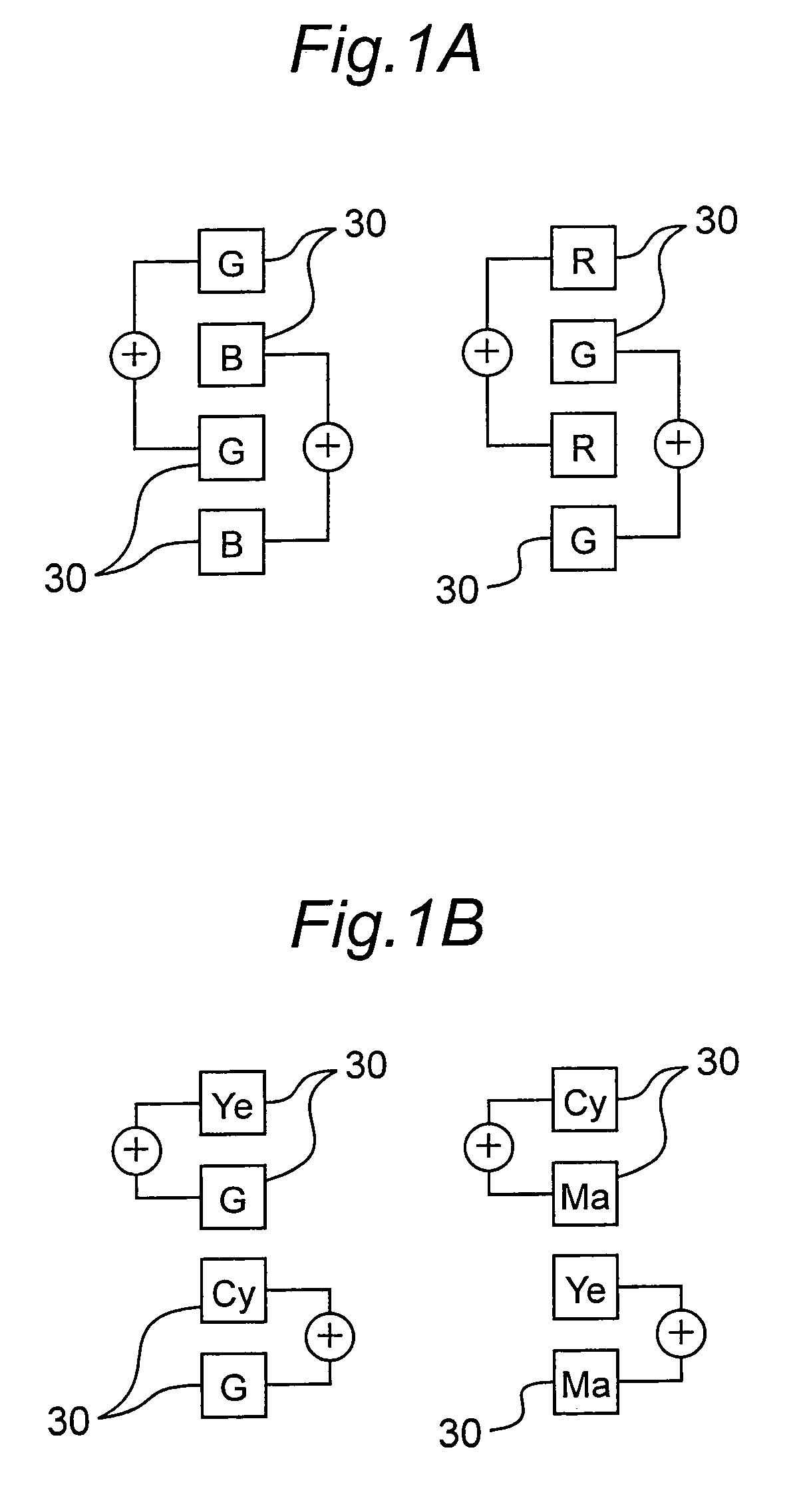

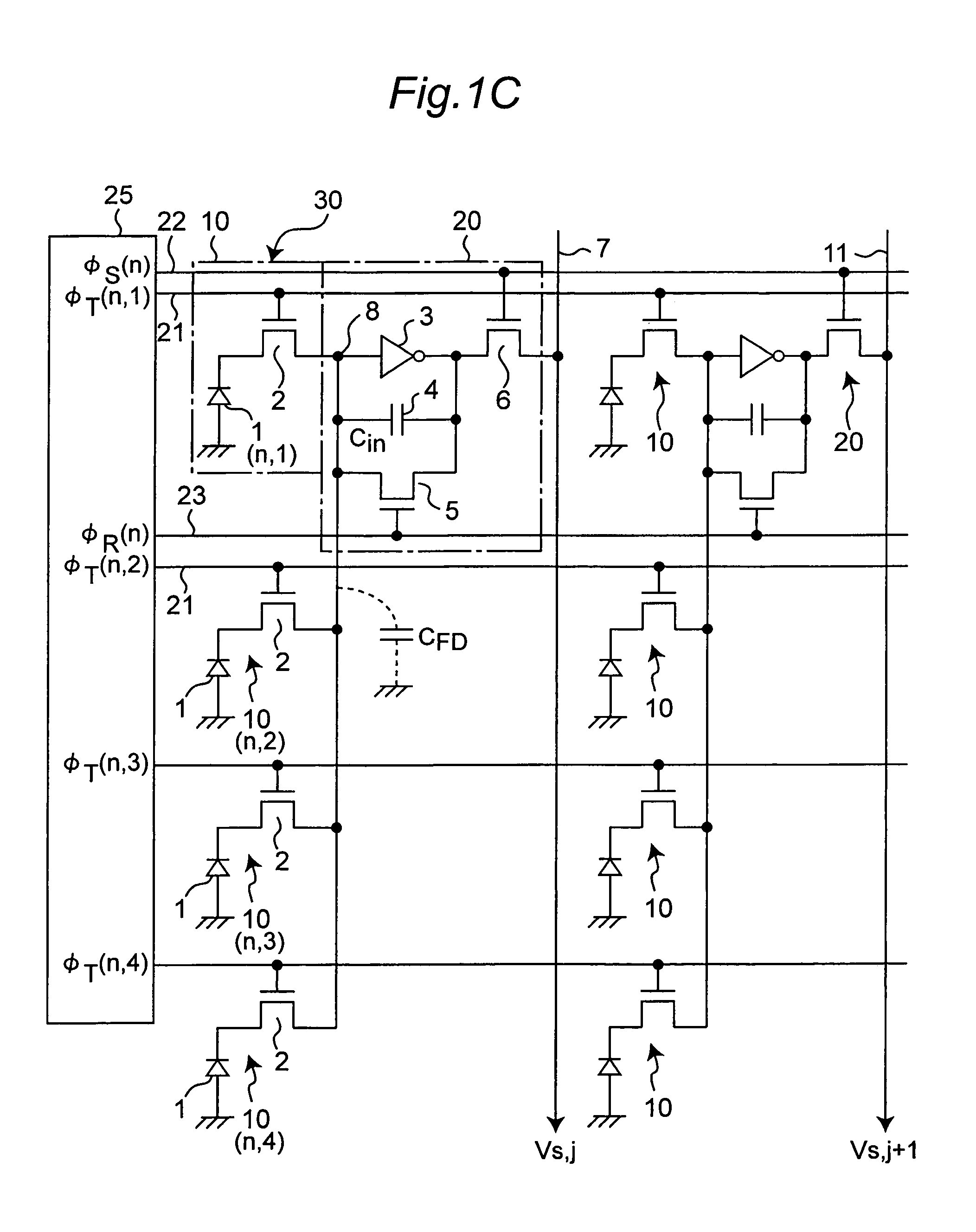

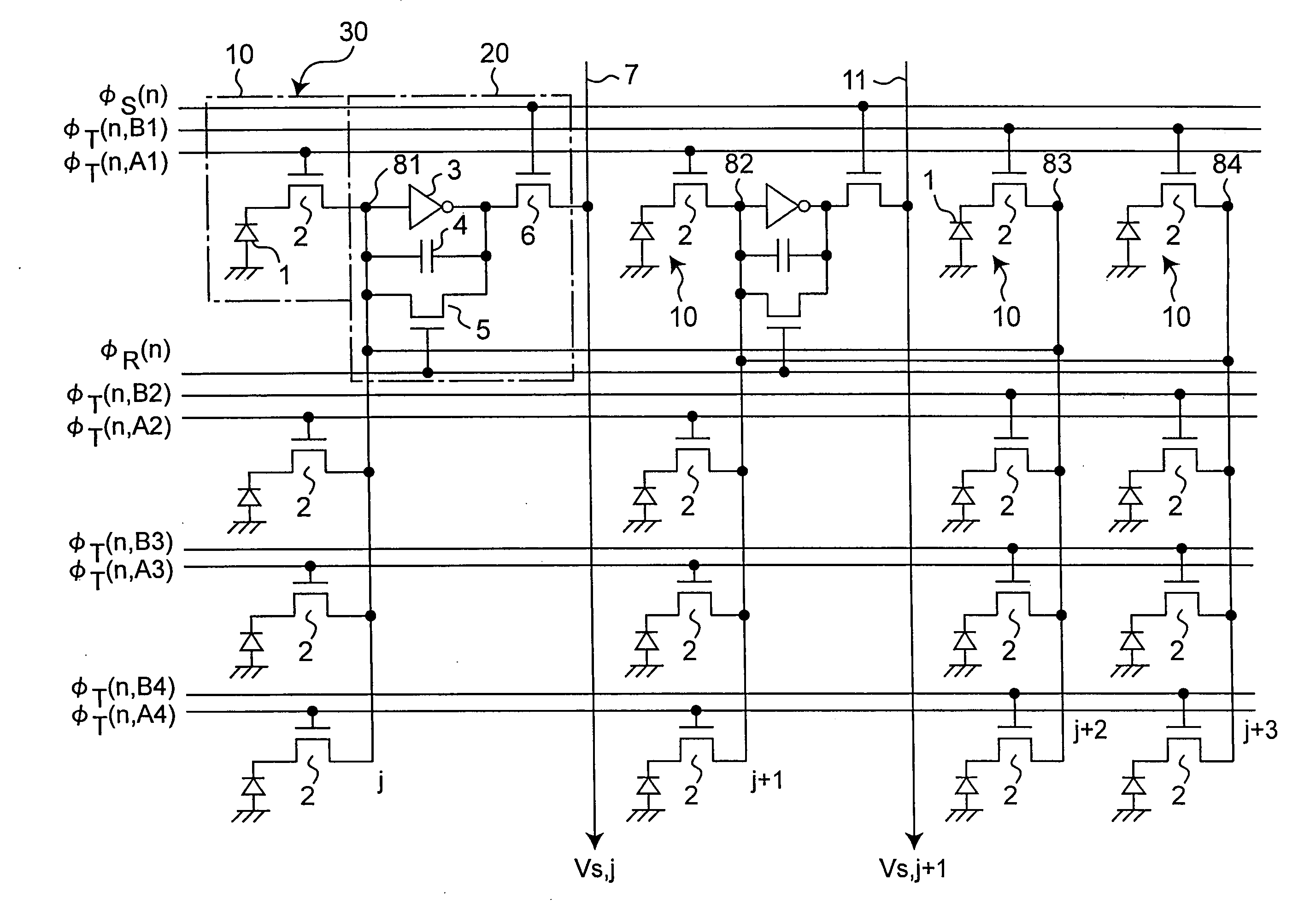

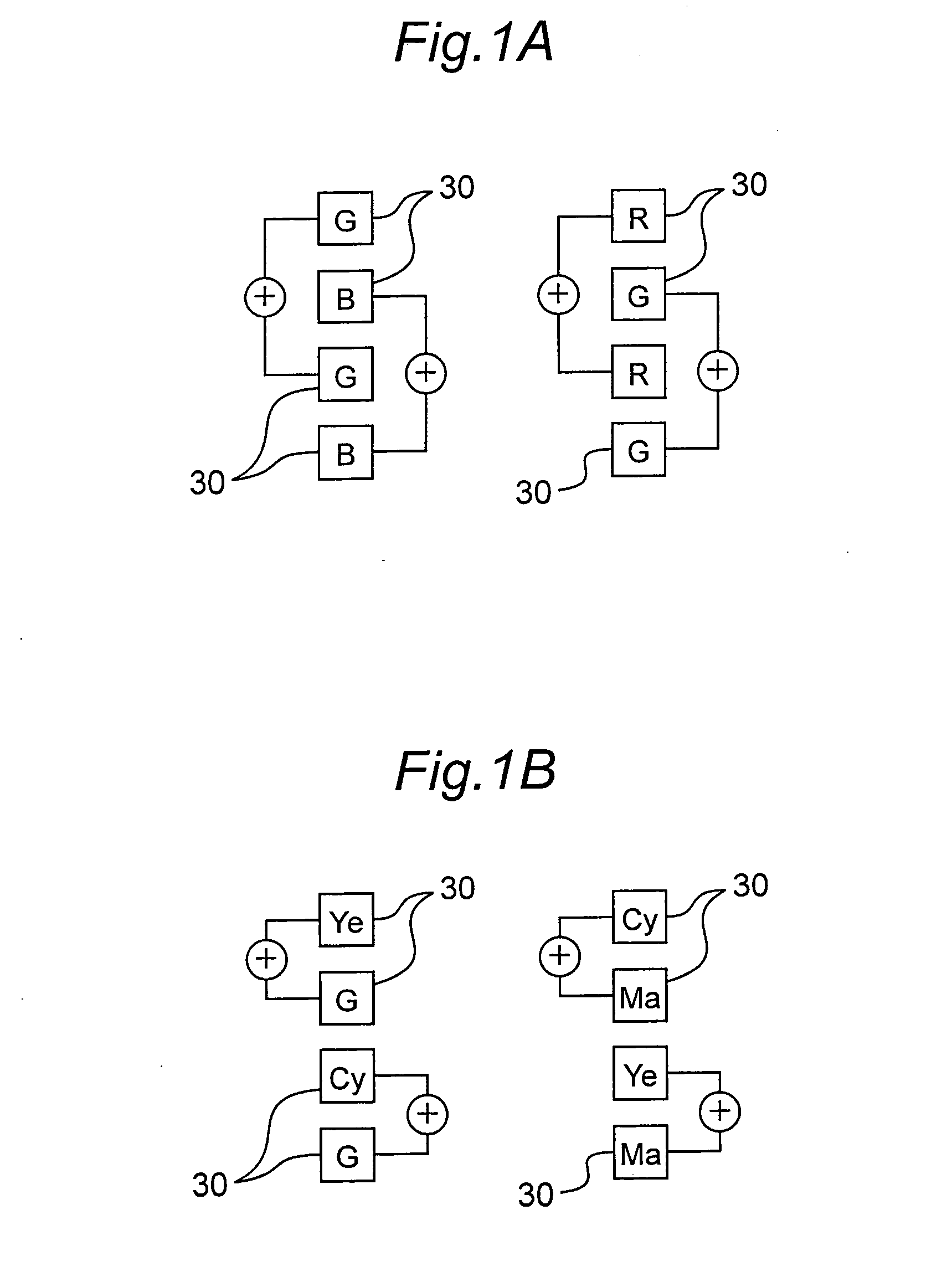

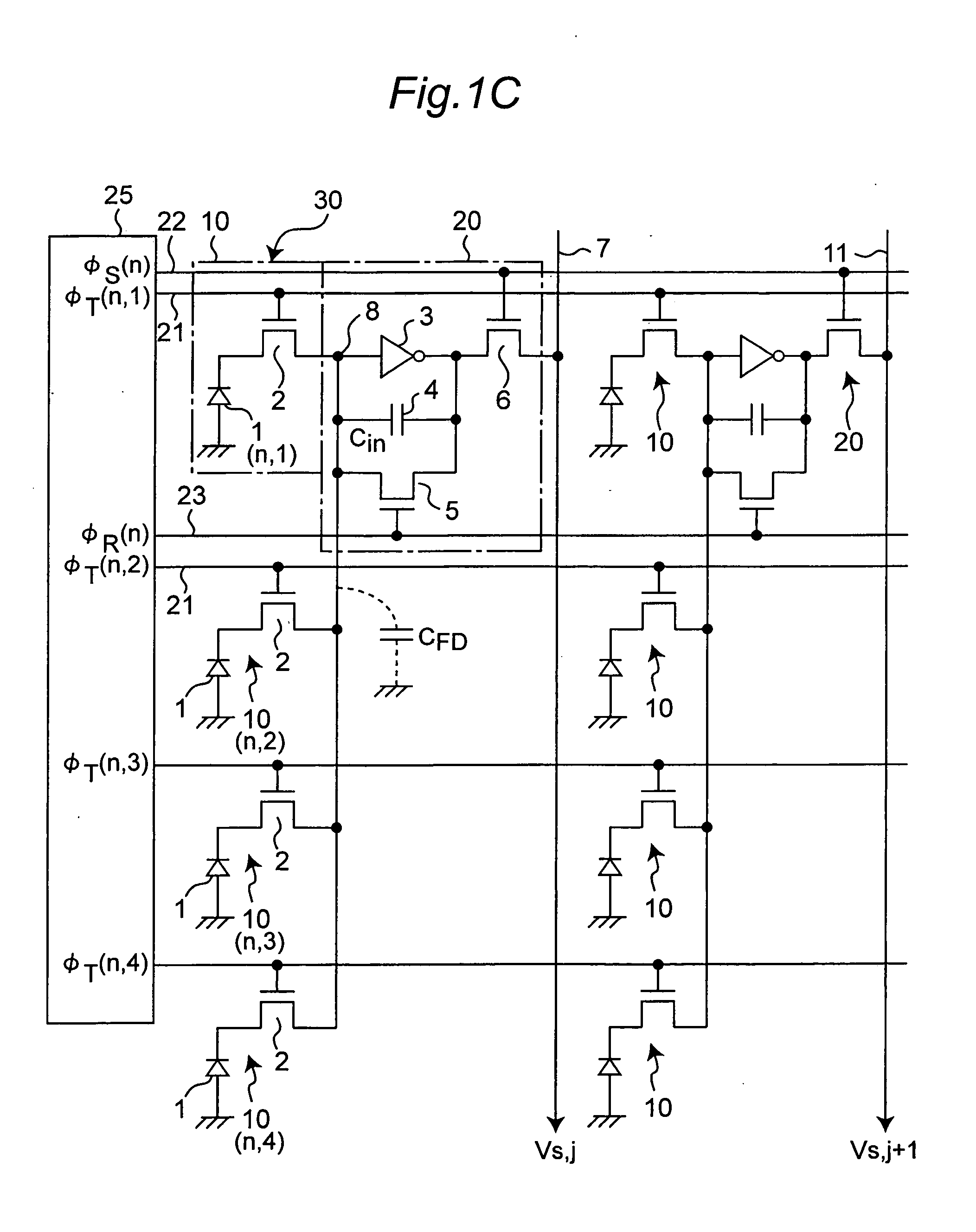

Amplifying solid-state image pickup device

InactiveUS6992341B2Improve convenienceEfficient conversionTelevision system detailsTelevision system scanning detailsPhotodiodeSwitched capacitor

There is provided an amplifying solid-state image pickup device capable of improving S / N and maintaining a charge-voltage conversion efficiency high. In the amplifying solid-state image pickup device, signal charges of a plurality of photodiodes 1 are added up on an input side of a switched capacitor amplification part 20 via the transfer transistors 2.

Owner:SHARP KK

Environment-friendly type flame retardant paper and preparation method thereof

InactiveCN105862490AImprove flame retardant performanceEasy to produceWater-repelling agents additionPaper coatingFiberPentaerythritol

The invention belongs to the technical field of papermaking, and discloses an environment-friendly flame-retardant paper and a preparation method thereof. The preparation method is as follows: the plant fiber raw material is placed in a pulper for disintegration, the pulp concentration is controlled between 4% and 9% of the mass concentration, and the disintegration time is 10 to 15 minutes; the disintegrated pulp is beaten to The degree of beating is 40-50°SR, and then the flame retardant pentaerythritol polyphosphate melamine salt (MPP), reinforcing agent, retention aid and water repellent are added for mixing and forming; then use sizing on the surface of the formed paper agent for sizing, hot pressing and drying to obtain the environment-friendly flame-retardant paper. The invention adopts the addition of MPP in the slurry, and can further add MPP in the sizing process, which can greatly improve the flame-retardant performance of the paper, thereby increasing the application range of the paper.

Owner:SOUTH CHINA UNIV OF TECH

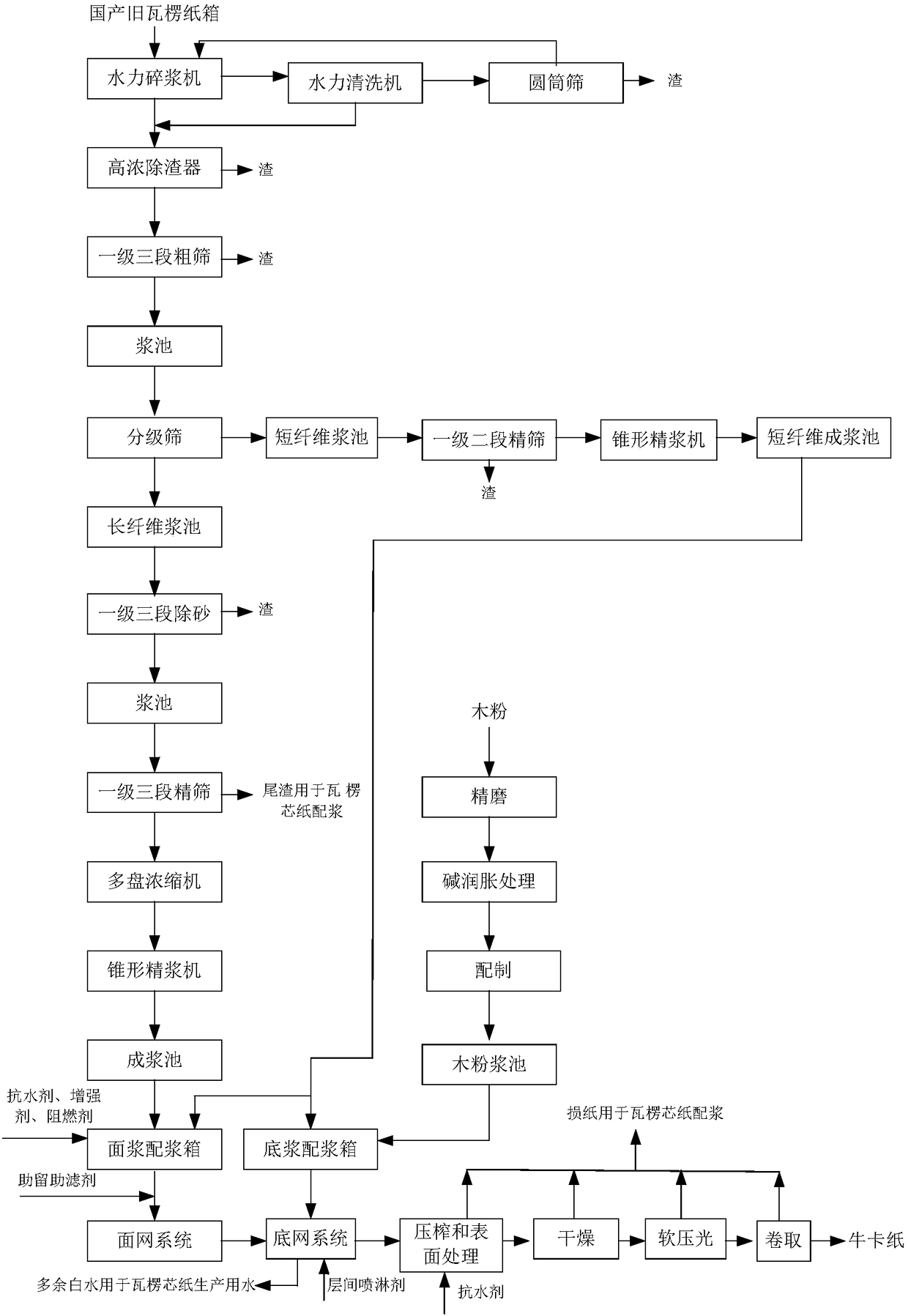

Method for producing e-commerce special craft paper with low gram weight and high strength by using domestic waste paper

ActiveCN108505372ACut offImprove stiffnessWater-repelling agents additionPaper recyclingFiberPapermaking

The invention relates to a method for producing e-commerce special craft paper with low gram weight and high strength by using domestic waste paper, and belongs to the technical field of papermaking.The method comprises a pulping step and a papermaking step. The domestic waste paper is classified by using a classifying screen, and then long fibers are used for surface layers and short fibers areused for bottom layers. According to the invention, a small amount of fine wood powder is added into bottom pulp, so that the stiffness of the craft paper is improved. Starch and a carboxymethylcellulose (CMC) compounding system are sprayed between the two layers, so that the interlayer bonding force of the craft paper is improved. A dual-element reinforcing agent including starch and polyacrylamide is added in pulp, so that the product strength is improved. In addition, the inner-pulp water resistance is combined with the surface water resistance, and simultaneously an inner-pulp flame retardance technology is combined with an interlayer flame retardance technology, so that the water resistance of craft paper products is improved, and simultaneously the flame retardancy of the products isachieved. Therefore, the method provided by the invention saves energy and is environmentally friendly, and the prepared craft paper products are low in weight, high in stiffness, excellent in waterproof performance and good in flame retardance, and are very suitable for e-commerce special paper boxes.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

Sheet for Total Heat Exchanger

ActiveUS20090068437A1Reduce the possibilityReduces possibility of deteriorationSynthetic resin layered productsPaper coatingPolymer sciencePorous sheet

A liquid containing a hydrophilic polymer is applied by spreading or impregnation to a porous sheet comprising paper or a nonwoven fabric containing not less than 30% by weight and not more than 100% by weight of hydrophilic fiber to provide a hydrophilic polymer-processed sheet of which the surface and / or the interior of the porous sheet is filled with the hydrophilic polymer, which is made insoluble to water. This sheet is used as a sheet for a total heat exchanger which has higher conductivity of sensible heat and latent heat than conventional sheet for a total heat exchanger that uses a moisture permeable membrane.

Owner:RENGO CO LTD +1

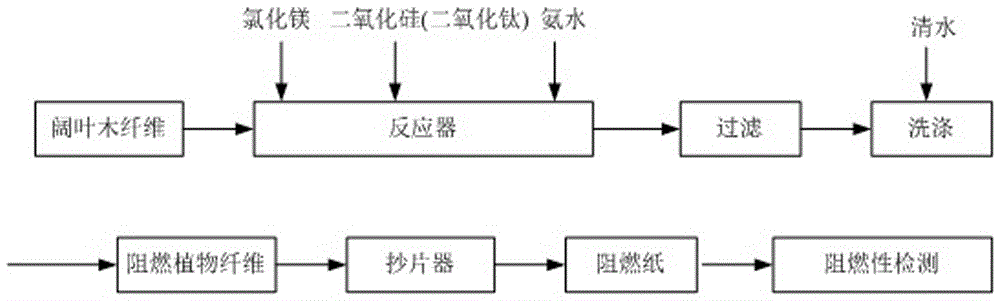

Flame-retardant plant fiber and flame-retardant paper

The invention relates to the field of a flame-retardant material, and especially relates to flame-retardant plant fiber and a piece of flame-retardant paper. The flame-retardant plant fiber comprises plant fiber slurry and a fire retardant; a preparation method of the flame-retardant plant fiber comprises the following steps: a magnesium chloride solution whose concentration is 0.8-1.4mol / L is added into a reactor with heating and stirring, the temperature is controlled at 50-70 DEG C, the plant fiber pulp and an ultrafine filling material are added, stirring is carried out for 20-40 minutes, ammoniacal liquor whose mass fraction is 2.0-2.5% is added, stirring is carried out for 10-30 minutes, the plant fiber pulp is filtered and washed with clear water, and the flame-retardant plant fiber is obtained. The flame-retardant paper which is made from the flame-retardant plant fiber has the advantages of good flame retardation effects, low influence on physical strength of paper, low production cost, and environment protection.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

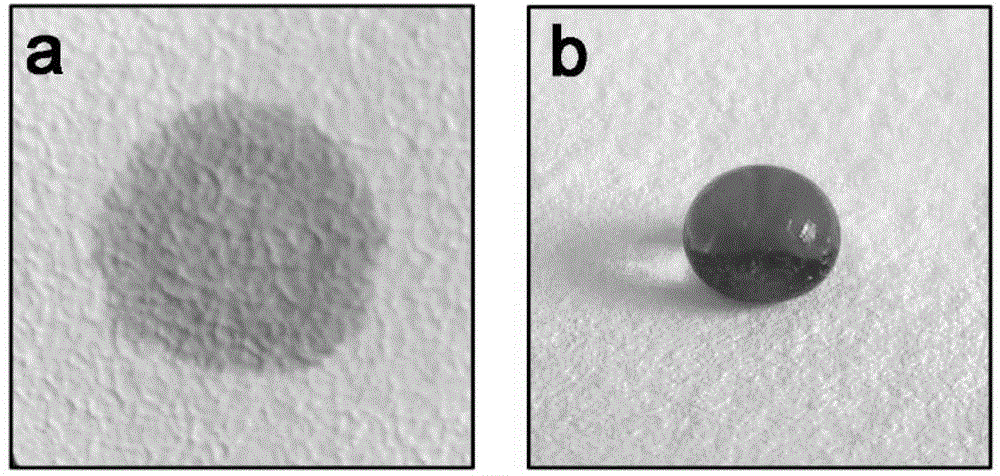

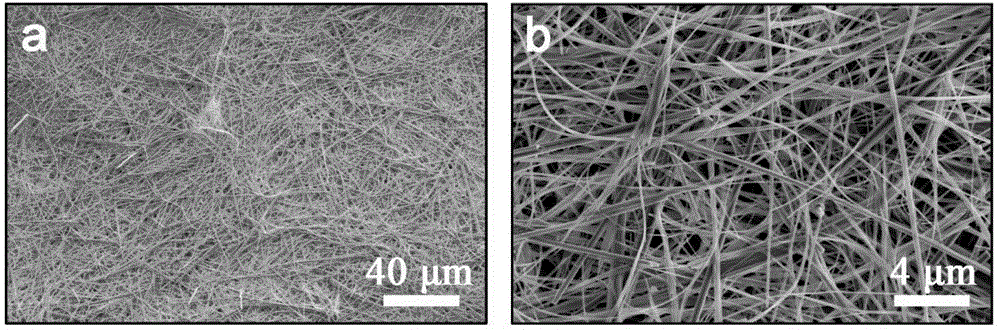

Hydroxyapatite overlength nanowire flameproof paper with waterproof function

ActiveCN106522015AWaterproofWith waterproof functionWater-repelling agents additionPaper/cardboardNanowireApatite

The invention relates to hydroxyapatite overlength nanowire flameproof paper with a waterproof function. The hydroxyapatite overlength nanowire flameproof paper with the waterproof function has super-hydrophobicity and fireproof and flame-retardant functions. The main component of the flameproof paper is hydroxyapatite overlength nanowire. The product also contains fatty acid salt or a perfluorinated compound modified on the hydroxyapatite overlength nanowire. The fatty acid salt or the perfluorinated compound carries out surface modification on the hydroxyapatite overlength nanowire. As hydroxyapatite overlength nanowire has rich surface reactive groups, the hydroxyapatite overlength nanowire is easy to undergo surface modification. Thus, the hydroxyapatite overlength nanowire is easy to combine with the fatty acid salt or the perfluorinated compound such that the hydroxyapatite overlength nanowire flameproof paper is endowed with an excellent waterproof function.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

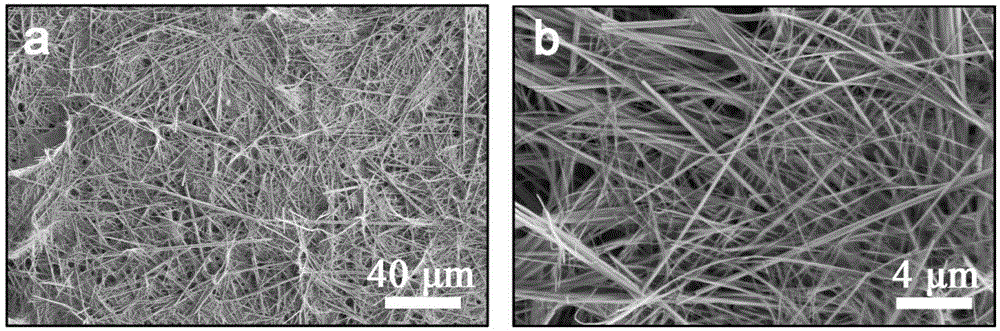

Aramid nanofiber-based insulation paper and preparation method thereof

ActiveCN110485195AEasy to prepareEasy to operateInorganic fibres/flakesPlastic/resin/waxes insulatorsNetwork structureNanofiber

Owner:HUNAN UNIV

Waterproof flame-retardant paper cone, speaker and preparation method of paper cone

ActiveCN110219206AGuaranteed acoustic performanceGuaranteed soundInorganic fibres/flakesElectrical transducersPulp and paper industryFire retardant

The invention provides a waterproof flame-retardant paper cone, a speaker and a preparation method of the paper cone. The waterproof flame-retardant paper cone is composed of pulp, the front surface of the waterproof flame-retardant paper cone contains a waterproof agent, and the back surface of the paper cone contains a flame retardant. According to the waterproof flame-retardant paper cone provided by the invention, the suitable pulp is selected, so that acoustic performance and tone of the paper cone are ensured; at the same time, the paper cone is subjected to waterproof treatment and flame-retardant treatment, the front surface of the paper cone is coated with the waterproof agent, the back surface is coated with the flame retardant, so that the usage amount of the flame retardant andthe waterproof agent can be reduced, the weight increment of the paper cone can be effectively controlled within 5% without affecting the paper pulp composition of the paper cone, the problem that effects are affected because a mutual reaction exists when the flame retardant and the waterproof agent are mixed for use is avoided, the flame retardant grade can reach V-0, the waterproof grade can reach IPX-7, and the flame-retardant waterproof effects are excellent; and the paper cone has good effects when used in the speaker, and has wide market prospects.

Owner:GUOGUANG ELECTRIC

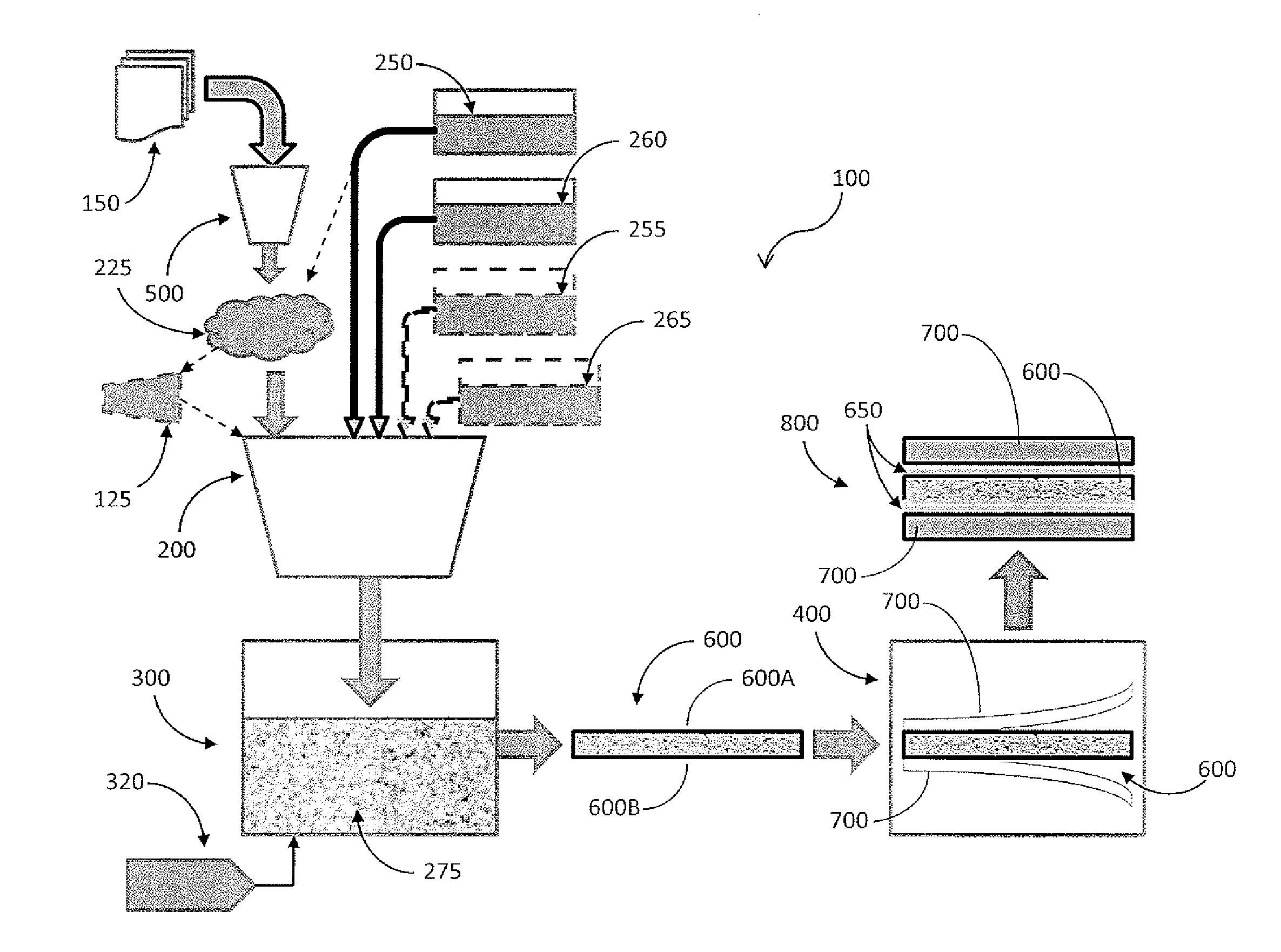

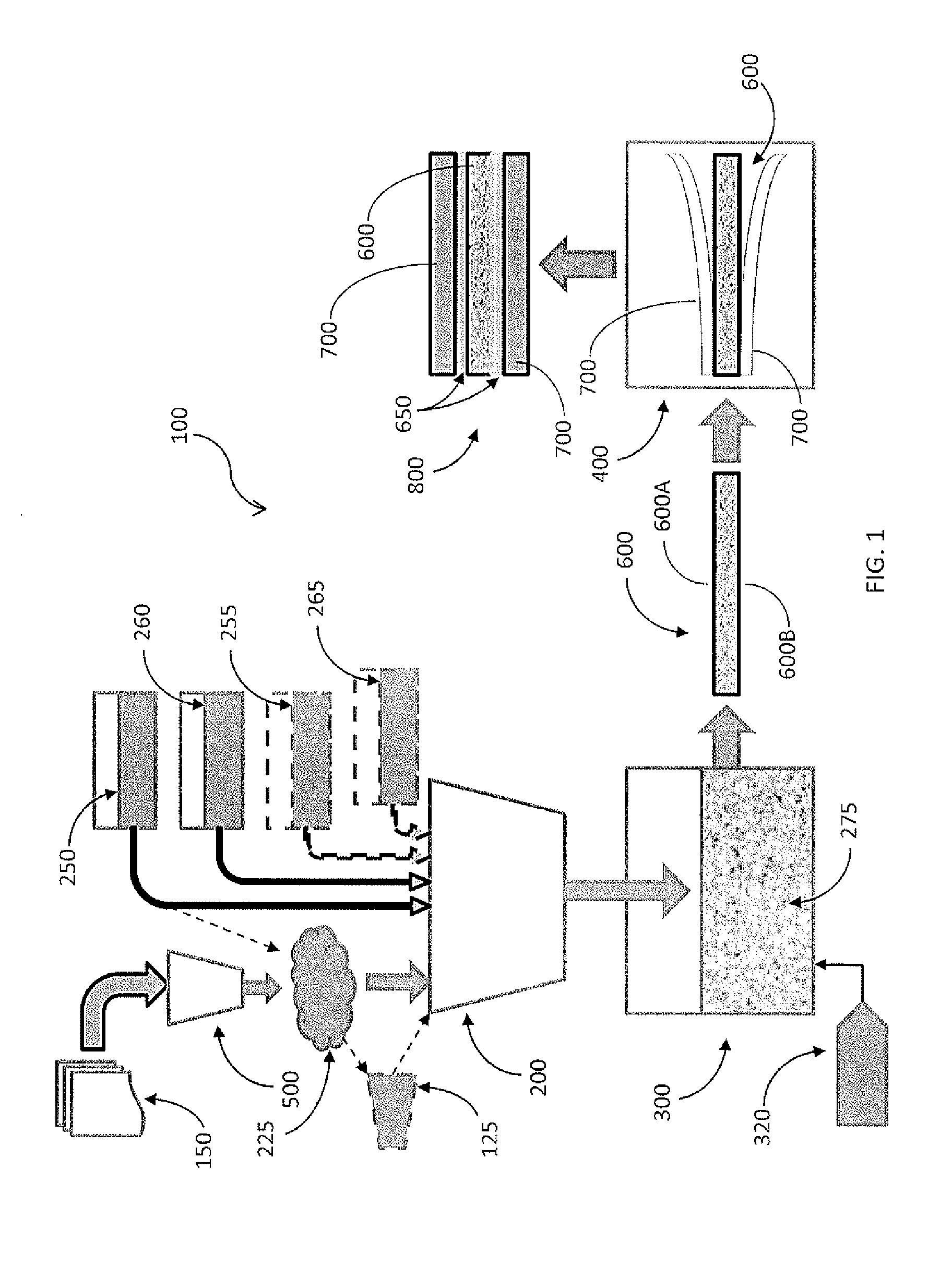

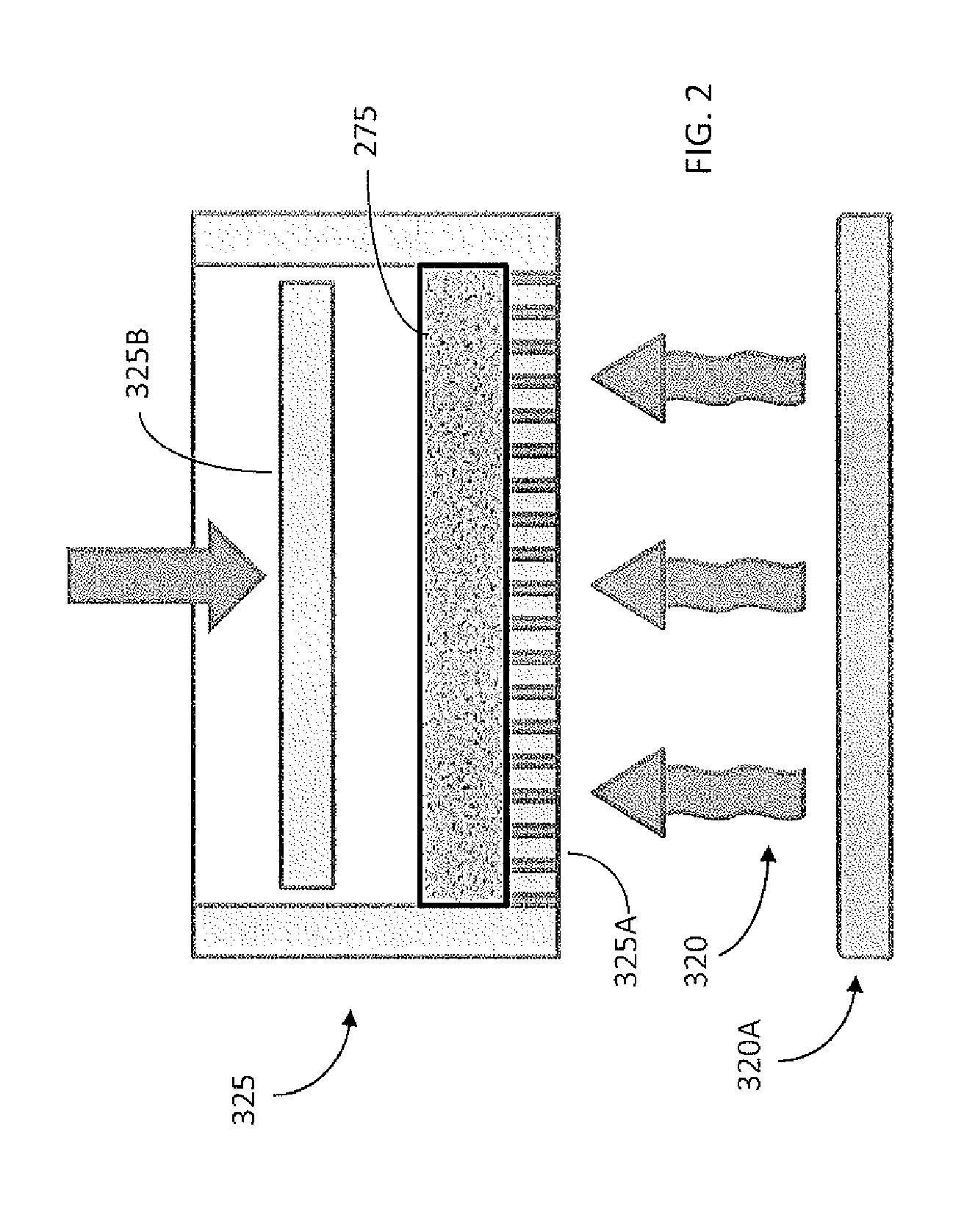

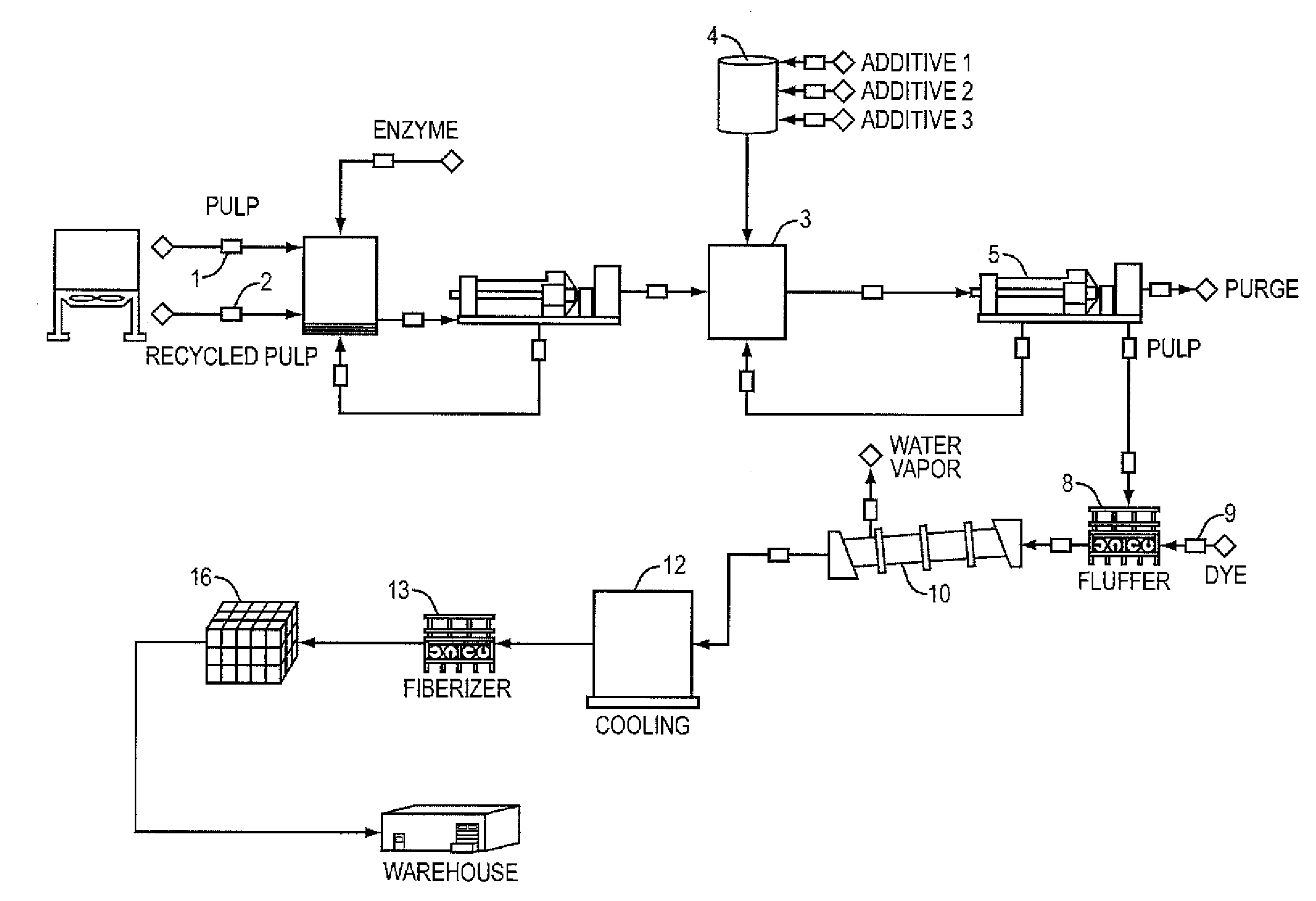

Method for Making Fire Retardant Materials and Related Products

InactiveUS20110095245A1Improves fire retardant application methodWide rangePaper recyclingIgnifugeants additionFiberChemical compound

A method for making fire retardant material including fire retardant cellulosic insulation. The method includes an arrangement for adding one or more feedstocks and a fire retardancy chemical compound to a common blend tank prior to feedstock drying. The one or more feedstocks may include at least one virgin pulp stock feed and at least one recycled material stock feed. The amount and type of both the virgin feedstock and the recycled material feedstock is selectable. Old newsprint (ONP) may be one type of recycled material feedstock. Another suitable type of recycled material feedstock is old corrugated containers (OCC). The method further includes retaining the fiber feedstock and the chemical compound together for enough time to ensure adherence or impregnations of enough of the chemical to the fibers after the drying process. Fluffing or fiberizing of the treated fibers may be accomplished under less severe conditions than ordinarily employed when making conventional cellulose insulation.

Owner:ULTRACELL INSULATION LLC +1

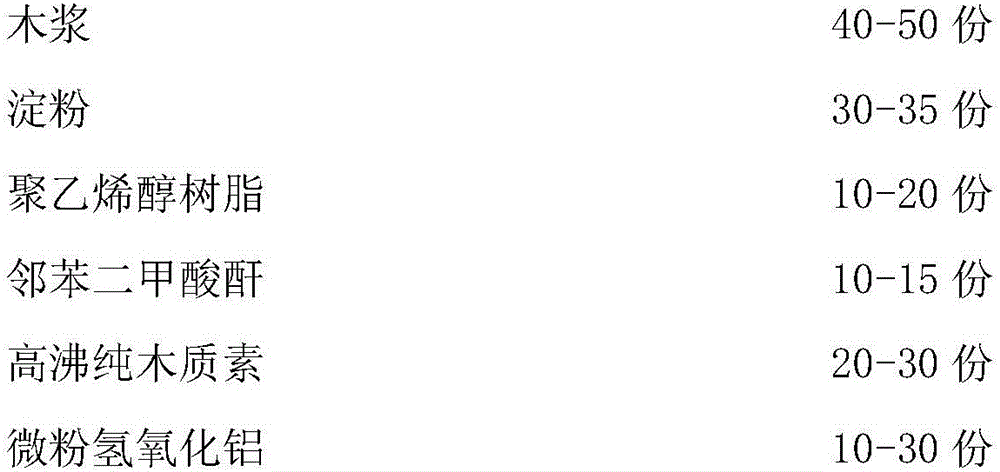

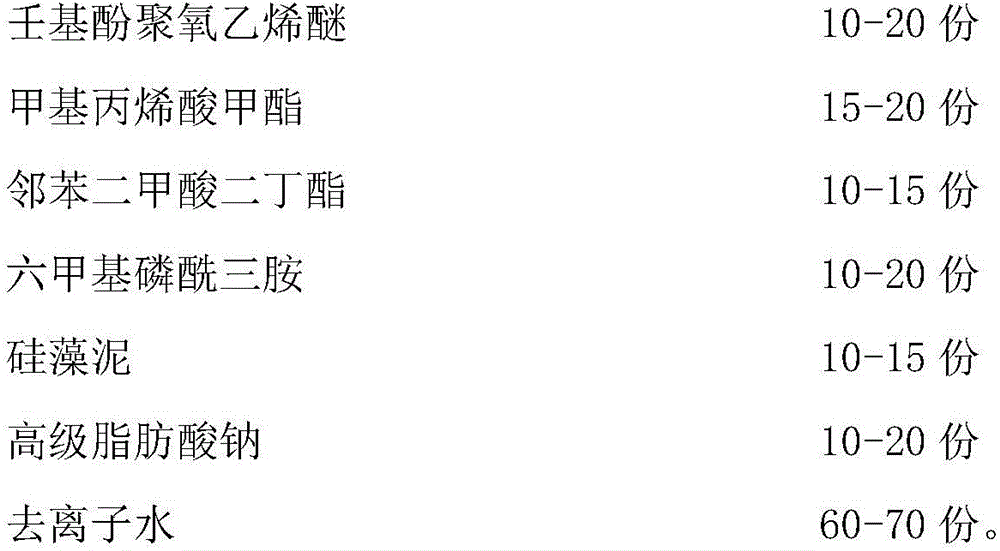

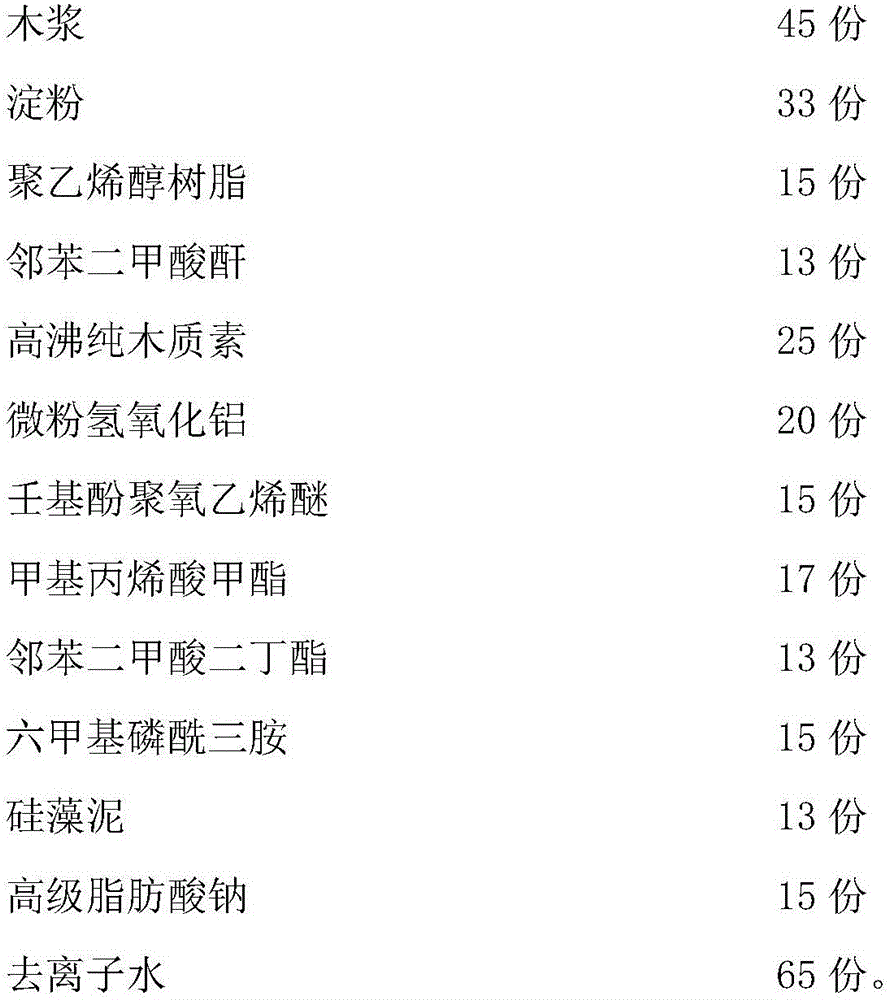

Formula of environment-friendly packaging box

InactiveCN106320055AImprove pressure resistanceImprove flame retardant performanceNatural cellulose pulp/paperPaper/cardboardPolyvinyl alcoholHexamethylphosphoric Triamide

The invention belongs to the technical field of corrugated paper manufacturing, and particularly relates to a formula of an environment-friendly packaging box. The formula comprises wood pulp, starch, polyvinyl alcohol resin, phthalic anhydride, high boiling solvent lignin, fine powder aluminum hydroxide, nonylphenol polyoxyethylene ether, methyl methacrylate, dibutyl phthalate, hexamethylphosphoric triamide, diatom ooze, higher aliphatic acid sodium and deionized water. By the adoption of the formula, the pressure resistance of the packaging box can be improved, the flame retardant property of the packaging box can be improved through fine powder aluminum hydroxide and nonylphenol polyoxyethylene ether, foul gas in the air can be adsorbed through diatom ooze, and the environment can be protected through reaction between higher aliphatic acid sodium and peracid substance in the air.

Owner:苏州炫之彩新材料股份有限公司

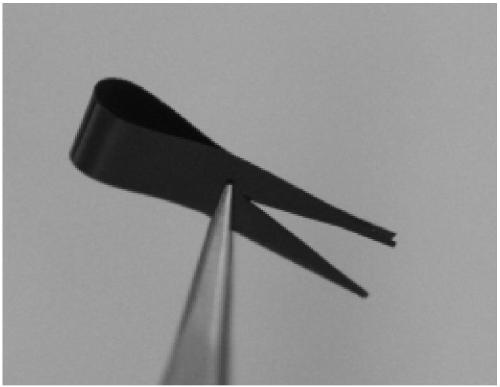

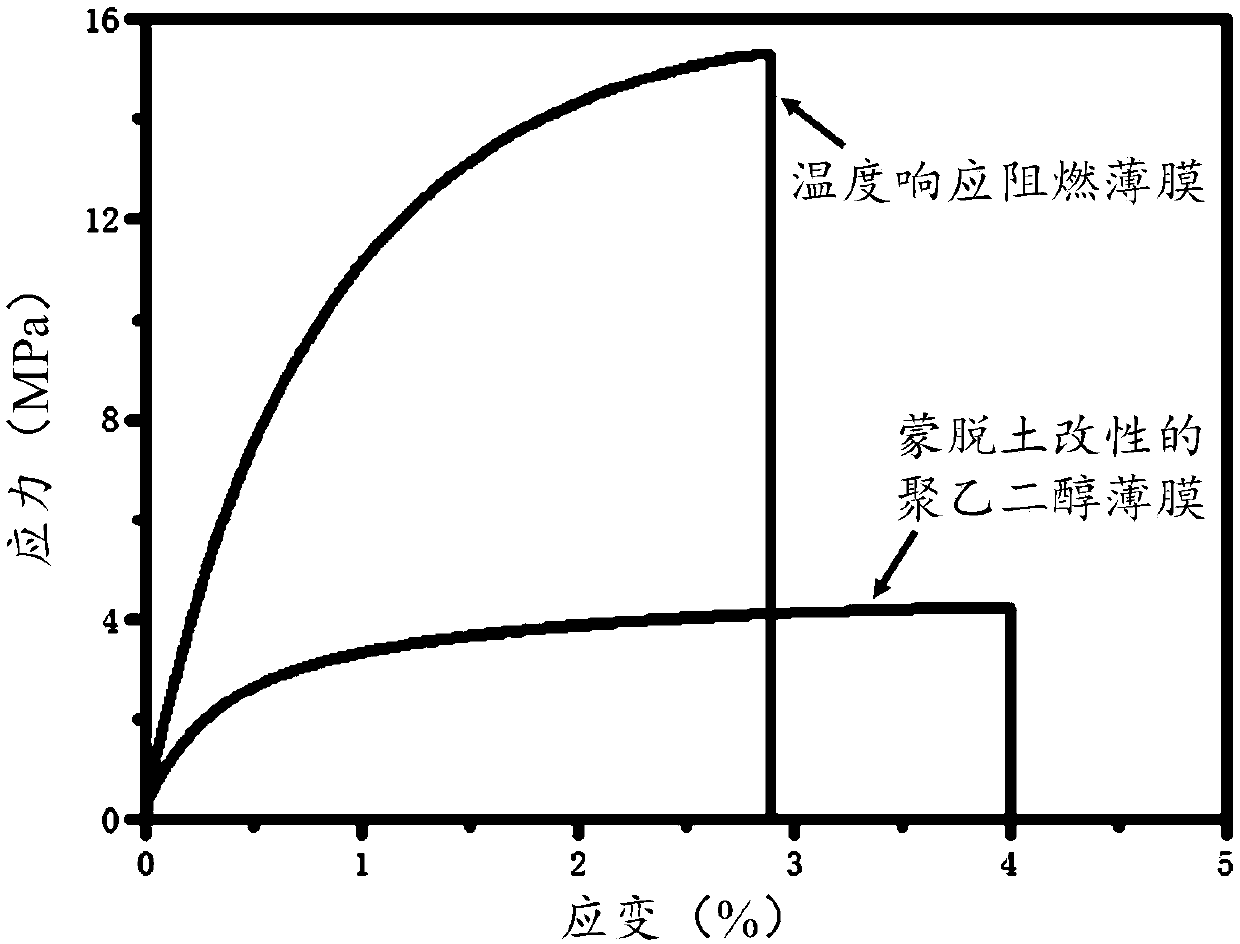

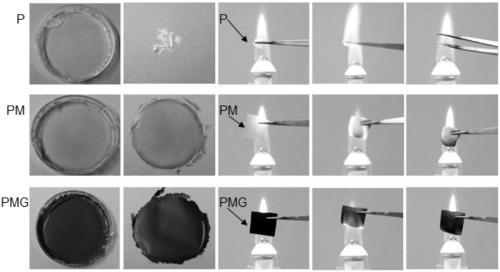

Temperature response flame-retardant film as well as preparation method and applications of temperature response flame-retardant film

ActiveCN109593343ARealize synergistic modificationOvercome the defect of extremely poor mechanical propertiesFireproof paintsThermometers using electric/magnetic elementsTemperature responsePolyethylene glycol

The invention discloses a temperature response flame-retardant film which is formed by adding montmorillonoid into a polyethylene glycol solution, then, adding graphene oxide and carrying out crosslinking by using a crosslinking agent. The invention further discloses a preparation method of the temperature response flame-retardant film. The preparation method comprises the steps: adding polyethylene glycol into deionized water to obtain the polyethylene glycol solution; then adding montmorillonoid, carrying out ultrasonic treatment, then, adding graphene oxide, carrying out stirring, and then,adding tannic acid; and finally, vacuumizing the obtained flame-retardant coating mixed solution to remove air bubbles, and then, carrying out drying to obtain the temperature response flame-retardant film. The invention further discloses an application of the temperature response flame-retardant film to the aspect of fire detection / prewarning. The invention further discloses an application of the temperature response flame-retardant film to the aspect of a flame-retardant coating. The temperature response flame-retardant film obtained by the invention has excellent mechanical properties andflame retardance, and the resistance of the temperature response flame-retardant film has sensitive temperature response property. The preparation method disclosed by the invention is simple in operation, low in cost and suitable for large-scale industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY

High intensity flame resistant composites

InactiveUS20070004307A1Special paperSynthetic cellulose/non-cellulose material pulp/paperHigh intensityMaterials science

Heat and flame resistant composites are provided, suitable for use as construction and furnishing panels and as covers for construction and furnishing panels.

Owner:EI DU PONT DE NEMOURS & CO

Amplifying solid-state image pickup device

InactiveUS20050185073A1Enhancing S/N improvement effectKeeping charge-voltage conversion efficiencyTelevision system detailsTelevision system scanning detailsEngineeringPhotodiode

There is provided an amplifying solid-state image pickup device capable of improving S / N and maintaining a charge-voltage conversion efficiency high. In the amplifying solid-state image pickup device, signal charges of a plurality of photodiodes 1 are added up on an input side of a switched capacitor amplification part 20 via the transfer transistors 2.

Owner:SHARP KK

Speaker component, method of manufacturing the same and speaker apparatus including the same

InactiveUS20050178516A1Good hygroscopicityReduced strengthNatural cellulose pulp/paperSpecial paperEngineeringLoudspeaker

To give solution to a problem that a fire-retarded speaker component has a high hygroscopicity and thus exhibits deteriorated acoustic properties, the speaker component undergoes strength drop, elastic modulus drop and internal loss due to fire retardant and the increase of the number of treatment steps adds to manufacturing cost. A speaker component formed by a paper product including a triphenyl phosphate fire retardant is used.

Owner:PIONEER CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com