Method for producing e-commerce special craft paper with low gram weight and high strength by using domestic waste paper

A low-gram weight, high-strength technology, applied in the field of papermaking, can solve the problems of poor water resistance, product damage, and poor water resistance of e-commerce cartons, so as to improve water insolubility and flame retardant effects, improve product strength, and improve resistance to water. water-based effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

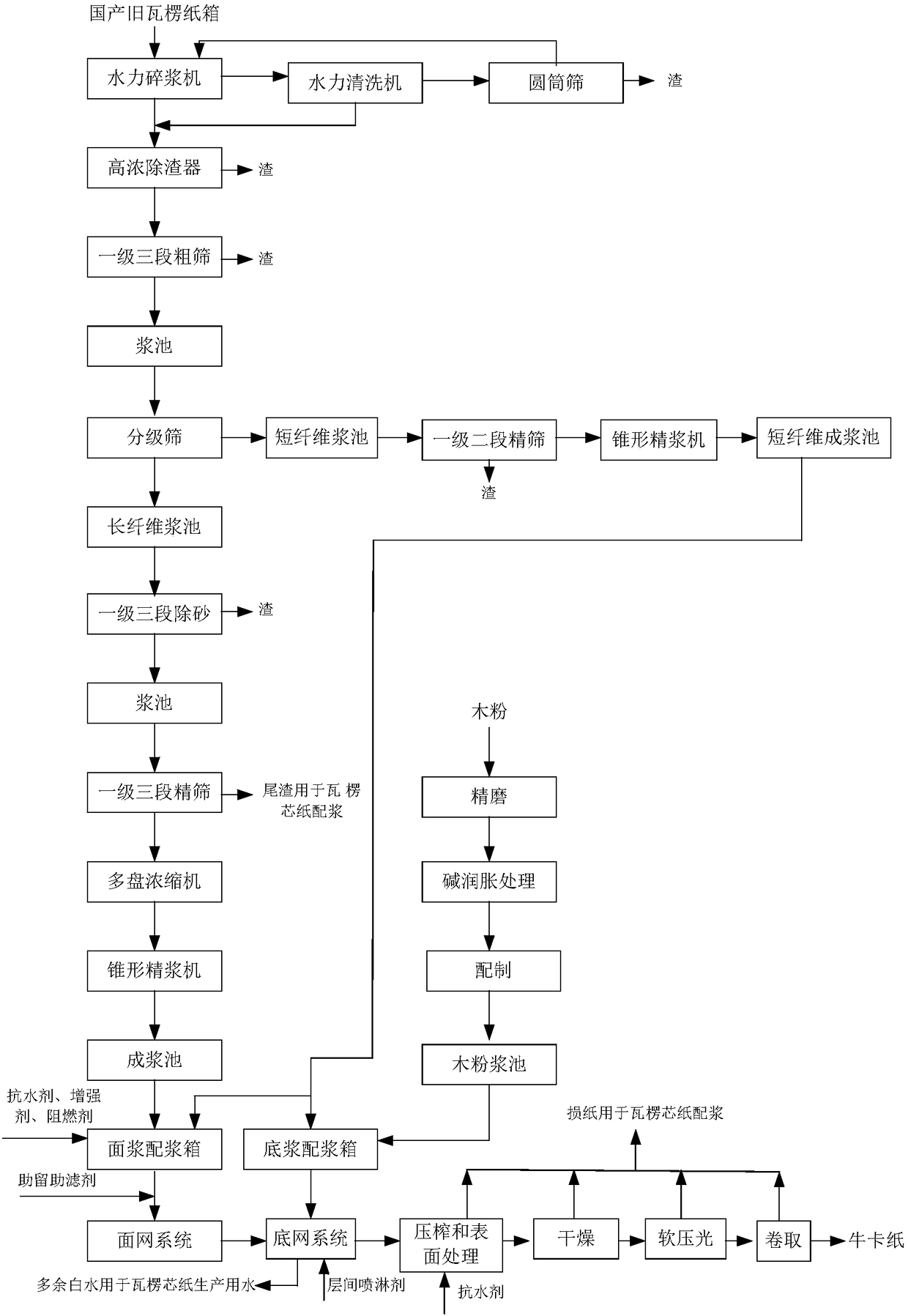

[0036] A method of utilizing domestic waste paper to produce low-grammage and high-strength e-commerce special kraftboard of the present embodiment, the method mainly includes the following steps:

[0037] (1) Pulping step: disintegrate domestic old corrugated cardboard boxes with a hydropulper, then carry out high-concentration slag removal, then pass through a first-level three-stage coarse sieve, and then classify and sieve long fibers and short fibers. The fibers are firstly treated with one-stage and three-stage slag removal, and the slag is discharged. The long fibers after deslagging are then successively processed through one-stage three-stage fine screening, multi-disc recovery machine concentration treatment, and conical refiner fine grinding treatment. Dilute the beating with white water to obtain long-fiber fine pulp, store the long-fiber fine pulp in the pulping tank for later use, and the tailings after the first-level and three-stage fine sieves are decomposed an...

Embodiment 2

[0048] A method of utilizing domestic waste paper to produce low-grammage and high-strength e-commerce special kraftboard of the present embodiment, the method mainly includes the following steps:

[0049] (1) Pulping step: disintegrate domestic old corrugated cardboard boxes with a hydropulper, then carry out high-concentration slag removal, then pass through a first-level three-stage coarse sieve, and then classify and sieve long fibers and short fibers. The fibers are firstly treated with one-stage and three-stage slag removal, and the slag is discharged. The long fibers after deslagging are then successively processed through one-stage three-stage fine screening, multi-disc recovery machine concentration treatment, and conical refiner fine grinding treatment. Dilute the beating with white water to obtain long-fiber fine pulp, store the long-fiber fine pulp in the pulping tank for later use, and the tailings after the first-level and three-stage fine sieves are decomposed an...

Embodiment 3

[0060] A method of utilizing domestic waste paper to produce low-grammage and high-strength e-commerce special kraftboard of the present embodiment, the method mainly includes the following steps:

[0061] (1) Pulping step: disintegrate domestic old corrugated cardboard boxes with a hydropulper, then carry out high-concentration slag removal, then pass through a first-level three-stage coarse sieve, and then classify and sieve long fibers and short fibers. The fibers are firstly treated with one-stage and three-stage slag removal, and the slag is discharged. The long fibers after deslagging are then successively processed through one-stage three-stage fine screening, multi-disc recovery machine concentration treatment, and conical refiner fine grinding treatment. Dilute the beating with white water to obtain long-fiber fine pulp, store the long-fiber fine pulp in the pulping tank for later use, and the tailings after the first-level and three-stage fine sieves are decomposed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com